A Review of Selective Laser Melted NiTi Shape Memory Alloy

Abstract

1. Introduction

2. SLM of NiTi SMA

2.1. Effects of Energy Density

2.2. Effects of Process Parameters

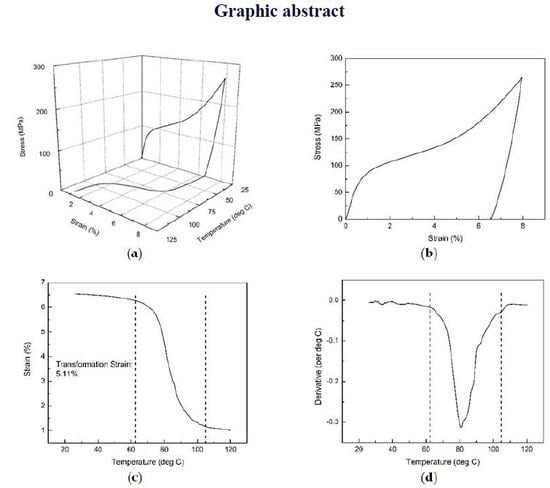

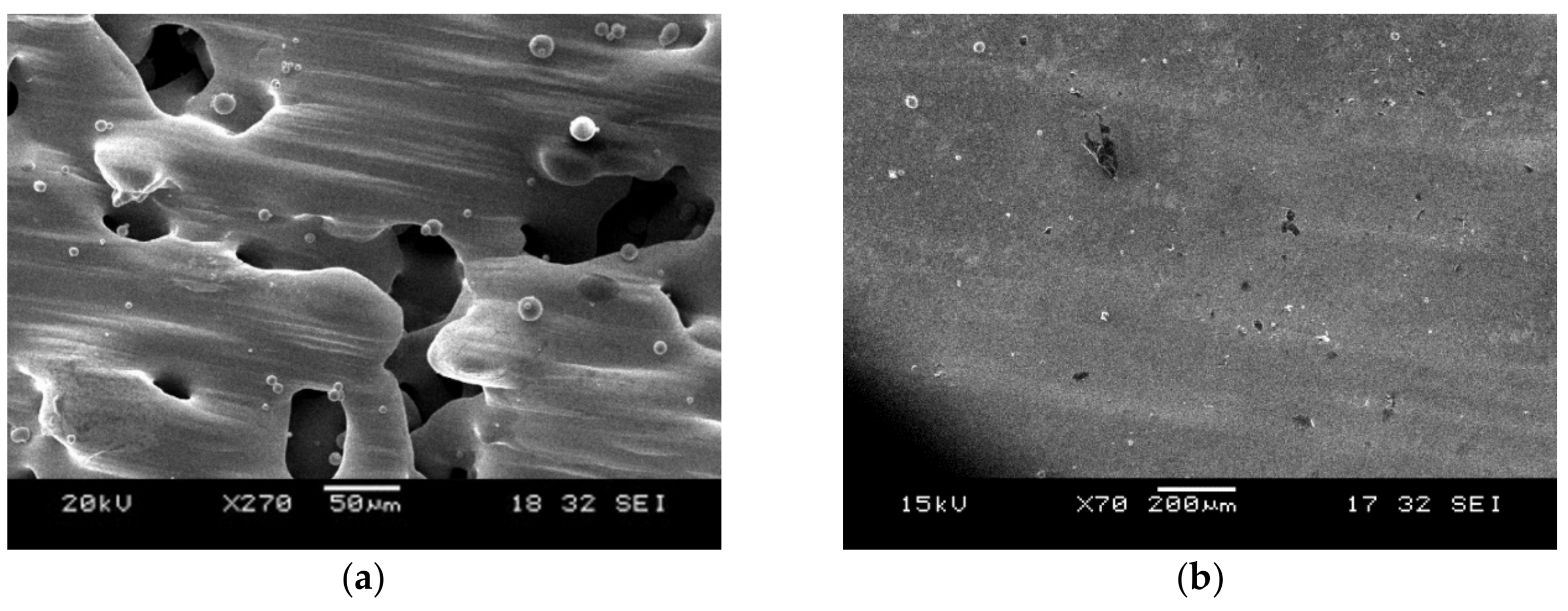

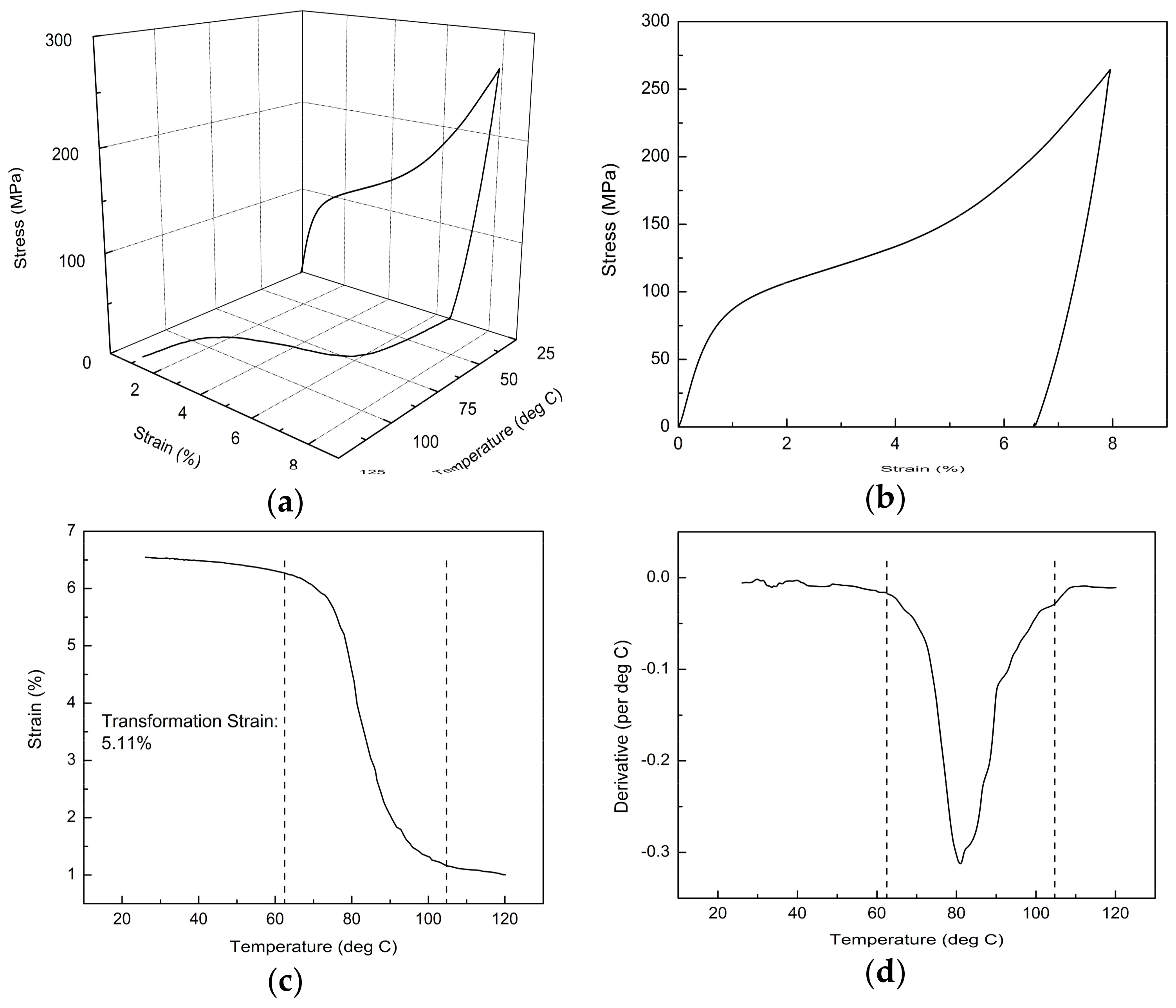

2.3. Shape Memory Responses of SLM NiTi

2.4. Applications of SLM NiTi

3. Summary

- Three adverse effects were observed when energy density directed to the powder bed exceeded the optimal amount; the increase in porosity, transformation temperatures, and impurities of SLM NiTi.

- SLM process parameters have a strong influence on the transformation characteristics, mechanical properties, porosity, and geometrical characteristics of SLM NiTi. Optimization of the parameters is required to obtain a SLM NiTi with controllable transformation characteristics, desired mechanical properties, minimal porosity, low impurity, and optimal shape memory responses.

- SLM NiTi can demonstrate comparable SME and superelasticity as the conventionally-produced NiTi. However, its shape memory responses differ according to the loading direction. Furthermore, it is possible to produce a SLM NiTi that exhibits a much gradual phase transformation than the conventional NiTi.

- The potential applications of SLM NiTi include being carriers for human mesenchymal stem cells, biomedical implants, and MEMS; it is not limited to this review only.

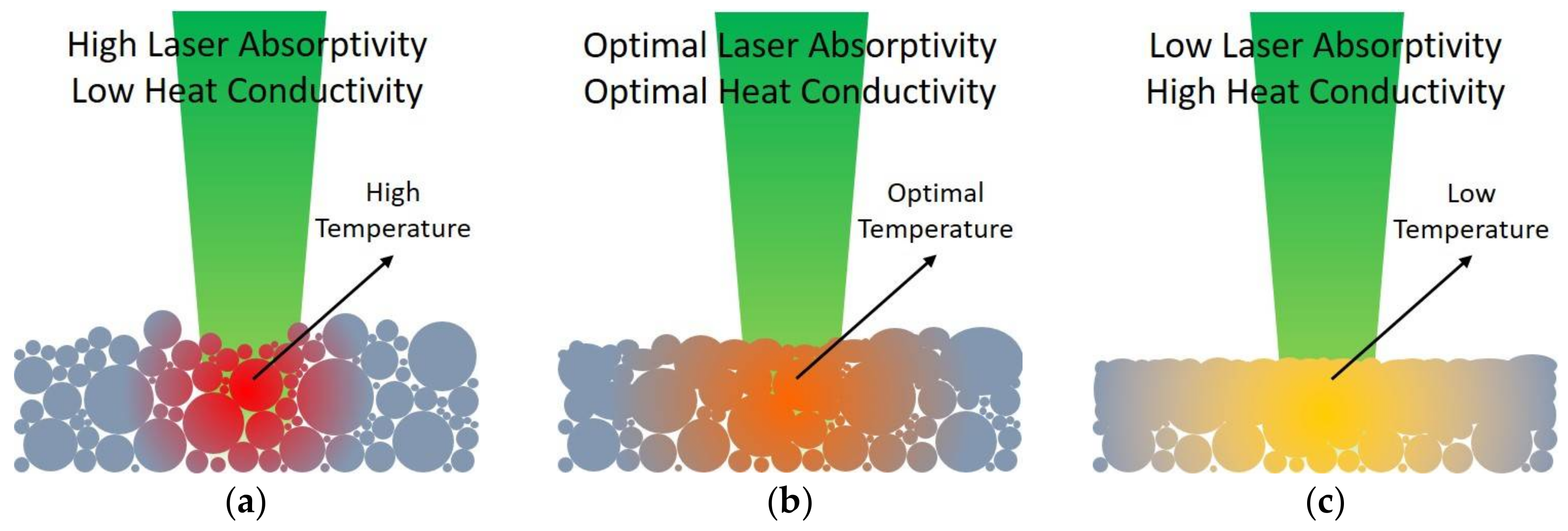

- Repetitive scanning assisted in producing SLM NiTi samples with high-quality. However, the properties of the fabricated parts are dependent on the laser absorptivity and heat conductivity of the materials before and after the first scan. The energy density inputted must be carefully controlled to achieve the desired mechanical and functional properties.

Acknowledgments

Conflicts of Interest

References

- Leo, D.J. Engineering Analysis of Smart Material Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Fremond, M.; Miyazaki, S. Shape Memory Alloys; Springer-Verlag Wien GmbH: New York, NY, USA, 1996. [Google Scholar]

- Kumar, P.K.; Lagoudas, D.C. Introduction to shape memory alloys. In Shape Memory Alloys: Modeling and Engineering Applications; Lagoudas, D.C., Ed.; Springer Science+Business Media, LLC: New York, NY, USA, 2008; pp. 1–51. [Google Scholar]

- Meier, H.; Haberland, C.; Frenzel, J. Structural and functional properties of NiTi shape memory alloys produced by Selective Laser Melting. In Proceedings of the 5th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 28 September–1 October 2011; pp. 291–296. [Google Scholar]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Schrooten, J.; Luyten, J.; van Humbeeck, J. Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts. Adv. Eng. Mater. 2014, 16, 1140–1146. [Google Scholar] [CrossRef]

- Humbeeck, J.V. Shape memory alloys. In Smart Materials; Schwartz, M., Ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Sharma, N.; Raj, T.; Jangra, K.K. Applications of nickel-titanium alloy. J. Eng. Technol. 2015, 5, 1–7. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.-X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Non-medical applications of shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 134–148. [Google Scholar] [CrossRef]

- Bhagyaraj, J.; Ramaiah, K.V.; Saikrishna, C.N.; Bhaumik, S.K. Gouthama Behaviour and effect of Ti2Ni phase during processing of NiTi shape memory alloy wire from cast ingot. J. Alloys Compd. 2013, 581, 344–351. [Google Scholar] [CrossRef]

- Bormann, T.; Schumacher, R.; Muller, B.; Mertmann, M.; Wild, M.D. Tailoring Selective Laser Melting process parameters for NiTi implants. J. Mater. Eng. Perform. 2012, 21, 2519–2524. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Yadroitsev, I.; Smurov, I. Direct Selective Laser Melting of nitinol powder. Phys. Procedia 2012, 39, 447–454. [Google Scholar] [CrossRef]

- Habijan, T.; Haberland, C.; Meier, H.; Frenzel, J.; Wittsiepe, J.; Wuwer, C.; Greulich, C.; Schildhauer, T.A.; Köller, M. The biocompatibility of dense and porous nickel–titanium produced by Selective Laser Melting. Mater. Sci. Eng. C 2013, 33, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; van Humbeeck, J. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann. Manuf. Technol. 2015, 64, 209–212. [Google Scholar] [CrossRef]

- Bormann, T.; Müller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; Wild, M.D. Microstructure of selective laser melted nickel–titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stockel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273–275, 149–160. [Google Scholar] [CrossRef]

- Clare, A.T.; Chalker, P.R.; Davies, S.; Sutcliffe, C.J.; Tsopanos, S. Selective Laser Melting of high aspect ratio 3D nickel-titanium structures two way trained for MEMS applications. Int. J. Mech. Mater. Des. 2008, 4, 181–187. [Google Scholar] [CrossRef]

- Sanusi, K.O.; Ayodele, O.L.; Khan, M.T.E. A concise review of the applications of NiTi shape-memory alloys in composite materials. S. Afr. J. Sci. 2014, 110, 1–5. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Meier, H.; Haberland, C.; Frenzel, J.; Zarnetta, R. Selective Laser Melting of NiTi shape memory components. Presented at the Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 6–10 October 2009. [Google Scholar]

- Hartl, D.J.; Lagoundas, D.C. Thermomechanical characterization of shape memory alloy materials. In Shape Memory Alloys: Modeling and Engineering Applications; Lagoundas, D.C., Ed.; Springer Science + Business Media, LLC: New York, NY, USA, 2008; pp. 53–119. [Google Scholar]

- Weinert, K.; Petzoldt, V. Machining of NiTi based shape memory alloys. Mater. Sci. Eng. A 2004, 378, 180–184. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, J.; Coddet, C. Microstructure and transformation behavior of in-situ shape memory alloys by Selective Laser Melting Ti-Ni mixed powder. J. Mater. Sci. Technol. 2013, 29, 863–867. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Yadroitsev, I.A.; Smurov, I.Y. Manufacturing three-dimensional nickel titanium articles using layer-by-layer laser-melting technology. Tech. Phys. Lett. 2013, 39, 1081–1084. [Google Scholar] [CrossRef]

- Speirs, M.; Wang, X.; Baelen, S.V.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.-P.; Van Humbeeck, J. On the transformation behavior of NiTi shape-memory alloy produced by SLM. Shape Mem. Superelast. 2016, 2, 310–316. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Vrancken, B.; Kruth, J.-P.; Luyten, J.; van Humbeeck, J. Texture and anisotropy in Selective Laser Melting of NiTi alloy. Mater. Sci. Eng. A 2016, 650, 225–232. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Ong, C.; Liu, Y.; Chua, C.K.; Leong, K.F.; Yang, S.F. Selective Laser Melting of nickel titanium shape memory alloy. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Nanyang Executive Centre, Nanyang Technological University, Singapore, 16–19 May 2016; pp. 451–456. [Google Scholar]

- Khoo, Z.X.; Lim, Y.L.; Liu, Y.; Chua, C.K. Effect of hatch distance on Selective Laser Melting of nickel titanium shape memory alloy. In Proceedings of the 2nd International Conference in Sports Science & Technology, Nanyang Executive Centre, Nanyang Technological University, Singapore, 12–13 December 2016; pp. 98–101. [Google Scholar]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; Low, Z.H.; An, J.; Chua, C.K.; Leong, K.F. Fabrication of SLM NiTi shape memory alloy via repetitive laser scanning. Shape Mem. Superelast. 2018, 1–9. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Haberland, C.; Karaca, H.; Elahinia, M. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloys Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Leist, S.K.; Zhou, J. Current status of 4D printing technology and the potential of light-reactive smart materials as 4D printable materials. Virtual Phys. Prototyp. 2016, 11, 249–262. [Google Scholar] [CrossRef]

- Zarek, M.; Layani, M.; Eliazar, S.; Mansour, N.; Cooperstein, I.; Shukrun, E.; Szlar, A.; Cohn, D.; Magdassi, S. 4D printing shape memory polymers for dynamic jewellery and fashionwear. Virtual Phys. Prototyp. 2016, 11, 263–270. [Google Scholar] [CrossRef]

- Teoh, J.E.M.; An, J.; Chua, C.K.; Lv, M.; Krishnasamy, V.; Liu, Y. Hierarchically self-morphing structure through 4D printing. Virtual Phys. Prototyp. 2017, 12, 61–68. [Google Scholar] [CrossRef]

- Leist, S.K.; Gao, D.; Chiou, R.; Zhou, J. Investigating the shape memory properties of 4D printed polylactic acid (PLA) and the concept of 4D printing onto nylon fabrics for the creation of smart textiles. Virtual Phys. Prototyp. 2017, 12, 290–300. [Google Scholar] [CrossRef]

- Lee, A.Y.; An, J.; Chua, C.K. Two-way 4D printing: A review on the reversibility of 3D-printed shape memory materials. Engineering 2017, 3, 663–674. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications, 5th ed.; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2017. [Google Scholar]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective Laser Melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the Selective Laser Melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on Selective Laser Sintering/Melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. Densification mechanism and microstructural evolution in Selective Laser Sintering of Al–12Si powders. J. Mater. Process. Technol. 2011, 211, 113–121. [Google Scholar] [CrossRef]

- Simchi, A.; Pohl, H. Effects of laser sintering processing parameters on the microstructure and densification of iron powder. Mater. Sci. Eng. A 2003, 359, 119–128. [Google Scholar] [CrossRef]

- Wang, X.J.; Zhang, L.C.; Fang, M.H.; Sercombe, T.B. The effect of atmosphere on the structure and properties of a selective laser melted Al–12Si alloy. Mater. Sci. Eng. A 2014, 597, 370–375. [Google Scholar] [CrossRef]

- Yaws, C.L. Ni-Nickel. In Yaws Handbook of Properties of the Chemical Elements; Konvel: Norwich, NY, USA, 2011; Chapter 66; pp. 271–274. [Google Scholar]

- Yaws, C.L. Ti-Titanium. In Yaws Handbook of Properties of the Chemical Elements; Knovel: Norwich, NY, USA, 2011; Chapter 103; pp. 420–424. [Google Scholar]

- Tolochko, N.K.; Laoui, T.; Khlopkov, Y.V.; Mozzharov, S.E.; Titov, V.I.; Ignatiev, M.B. Absorptance of powder materials suitable for laser sintering. Rapid Prototyp. J. 2000, 6, 155–160. [Google Scholar] [CrossRef]

- Morgan, R.; Sutcliffe, C.J.; O’Neill, W. Density analysis of direct metal laser re-melted 316L stainless steel cubic primitives. J. Mater. Sci. 2004, 39, 1195–1205. [Google Scholar] [CrossRef]

- Pohl, H.; Simchi, A.; Issa, M.; Dias, H.C. Thermal stresses in direct metal laser sintering. In Solid Freeform Fabrication Symposium; University of Texas: Austin, TX, USA, 2001; pp. 366–372. [Google Scholar]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

| Maximum Strain (%) | Residual Strain (%) | Transformation Strain (%) | Permanent Strain (%) |

|---|---|---|---|

| 7.95 | 6.55 | 5.11 | 1.17 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A Review of Selective Laser Melted NiTi Shape Memory Alloy. Materials 2018, 11, 519. https://doi.org/10.3390/ma11040519

Khoo ZX, Liu Y, An J, Chua CK, Shen YF, Kuo CN. A Review of Selective Laser Melted NiTi Shape Memory Alloy. Materials. 2018; 11(4):519. https://doi.org/10.3390/ma11040519

Chicago/Turabian StyleKhoo, Zhong Xun, Yong Liu, Jia An, Chee Kai Chua, Yu Fang Shen, and Che Nan Kuo. 2018. "A Review of Selective Laser Melted NiTi Shape Memory Alloy" Materials 11, no. 4: 519. https://doi.org/10.3390/ma11040519

APA StyleKhoo, Z. X., Liu, Y., An, J., Chua, C. K., Shen, Y. F., & Kuo, C. N. (2018). A Review of Selective Laser Melted NiTi Shape Memory Alloy. Materials, 11(4), 519. https://doi.org/10.3390/ma11040519