1. Introduction

Selective laser melting (SLM) is a progressive method of additive manufacturing, mainly used for the rapid production of prototypes and lightweight components with complex geometry. For the latter, alloys with a good strength-to-weight ratio, like high strength aluminum (series 2000 and 7000) are best suited [

1]. These alloys are usually considered difficult to weld. Due to its ability to maintain mechanical properties under temperatures of up to 300 °C the aluminum alloy EN AW 2618 is typically used in the automotive and aerospace industry, for pistons, turbochargers and rotary components of aircraft engines [

2].

Nowadays, of all aluminum alloys, those with Al-Si base are predominantly used for the SLM process. These alloys, originally used for casting, are mainly used because they are relatively easy to work due to the small difference between the melting and solidification temperature. From these alloys, AlSi10Mg and AlSi12 were intensively studied [

3,

4,

5,

6,

7,

8]. The mechanical properties of these materials in the SLM state were investigated [

9,

10,

11,

12] and high cycle fatigue behavior was observed [

13,

14,

15,

16]. Compared to the cast material, these alloys in the SLM state reached higher mechanical properties, but lower fatigue properties.

On the other hand, the processing of Al-Cu alloys by SLM technology is difficult, as is shown by initial studies of these alloys [

17,

18,

19,

20]. Karg et al. [

17] studied the processing of EN AW 2022 and EN AW 2024. The approach for finding optimal processing parameters went from single-track welds through wall tests to cube sample testing. A SLM 50 machine from Realizer GmbH with maximum laser power (LP) of 100 W was used for these experiments. The layer thickness was kept at a constant value of 30 µm. A relative density above 99.5% was achieved with LP 100 W and laser speeds (LS) between 150–300 mm/s for alloy EN AW 2024. Alloy EN AW 2022 showed a narrower processing window with LS between 265–295 mm/s.

Ahuja et al. [

18] described the processing of alloys EN AW 2219 and EN AW 2618. They used the same approach and SLM machine as Karg et al. [

17]. The best achieved relative density was 99.96%. Authors from both studies observed an increase in relative density using support structures for the fabrication of small cube samples. According to the author, this is mainly due to the reduction of heat transfer between samples and the building platform when the cross-section area of support is rather small compared to the face of the cube samples. They also observed that relative density is not in direct correlation with volumetric energy density.

The authors Zhang et al. [

19] arrived at other results with alloy EN AW 2024, as they observed a critical volumetric energy density (ED) of 340 J/mm

3. All samples with an energy density higher than this value showed a relative density above 99.5%. To achieve such high energy input, the laser speed had to be lowered to values of around 80 mm/s, while a laser power of 200 W was used. A tensile test and hardness measurement was performed on SLM samples in their as-built state. Results showed an increase in yield strength (YS) from 75 MPa (as-cast state), to 276 MPa (SLM state). Ultimate tensile strength (UTS) increased from 185 MPa to 402 MPa and hardness form 80 HV0.2 to 111 HV0.2.

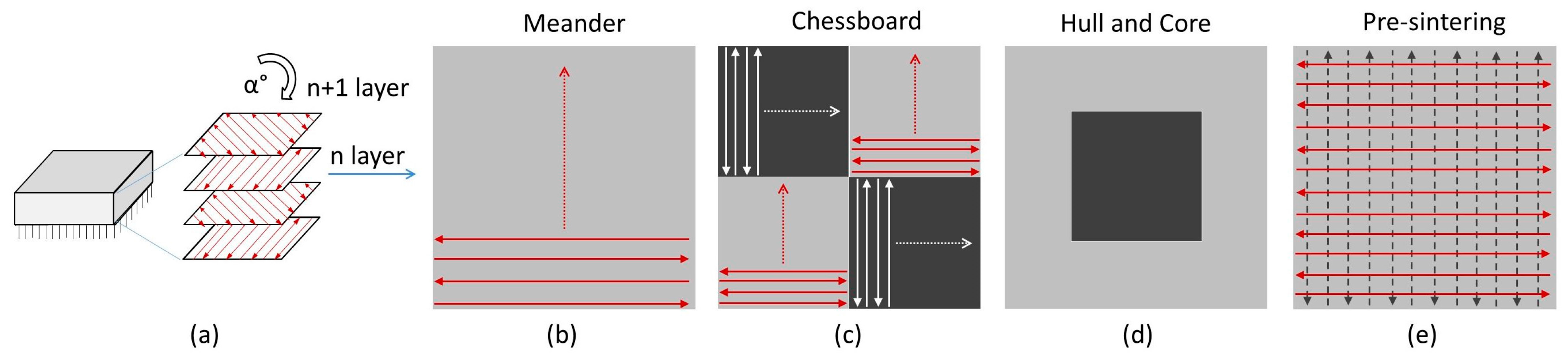

Several studies have focused on the influence of scanning strategies during the processing of different materials. Thijs et al. [

8] found a relation between the crystallographic texture of AlSi10Mg alloy and a applied scanning strategy as a consequence of directional solidification due to the moving heat source, while Read et al. [

11] found the island size to have the least influence on porosity formation in comparison to laser speed and laser power when processing AlSi10Mg alloy using the island scanning strategy. In addition, Lu et al. [

21] studied the mechanical properties and residual stress induced in the Inconel 718 alloy while using a different size of island scanning strategy. They found that the 5 × 5 mm island size is promising for lowering the residual stress. They observed the cracks on the border of the islands, thus the enlargement of island size (lowering the number of borders) produced material with lower porosity and higher elongation. On the contrary, the smaller island produced material with slightly higher UTS and lower residual stress. Carter et al. [

22] also investigated the island scanning strategy. They found the influence on the grain structure of nickel superalloy CM247LC by the localization of cracks in the border zones of the islands. They estimated that the higher crack occurrence is present at the high-angle grain boundaries. Popovich et al. [

23] showed that the different process parameters together with the scanning strategy strongly affects grain orientation and the resulting mechanical properties of Inconel 718, thus functionally graded materials can be produced with this approach.

This paper builds mainly on the findings of the initial study of high power processing of EN AW 2618 proposed in two articles, Koutny et al. [

24] and Koukal et al. [

25]. In these studies, a SLM 280

HL machine from SLM Solutions with a maximum laser power of 400 W was used. Experiments comprised of single-track welds and volume samples (cubes 5 × 5 × 5 mm), all with a layer thickness of 50 µm. A wide range of processing parameters (laser power, laser speed, and hatch distance) was studied. For cube tests, a relative density above 99% was achieved with LP 200 W, LS 200 mm/s and a hatch distance (HD) of 110 µm. These results correspond with the other studies of Al-Cu alloy mentioned above. However, low surface roughness was observed with parameters LP 400 W and LS 1400 mm/s. In all of the above mentioned articles focused on aluminum alloy EN AW 2618 [

17,

18,

20], the authors describe the presence of a large number of cracks in the samples.

The aim of this study is a detailed examination of the process parameter window found in previous studies [

24,

25]. Larger cube samples which have been built and evaluated to explore the influence of different scanning strategies and other SLM process parameters on relative density and mechanical properties, have not yet been investigated.

3. Results and Discussion

3.1. Single Track Welds

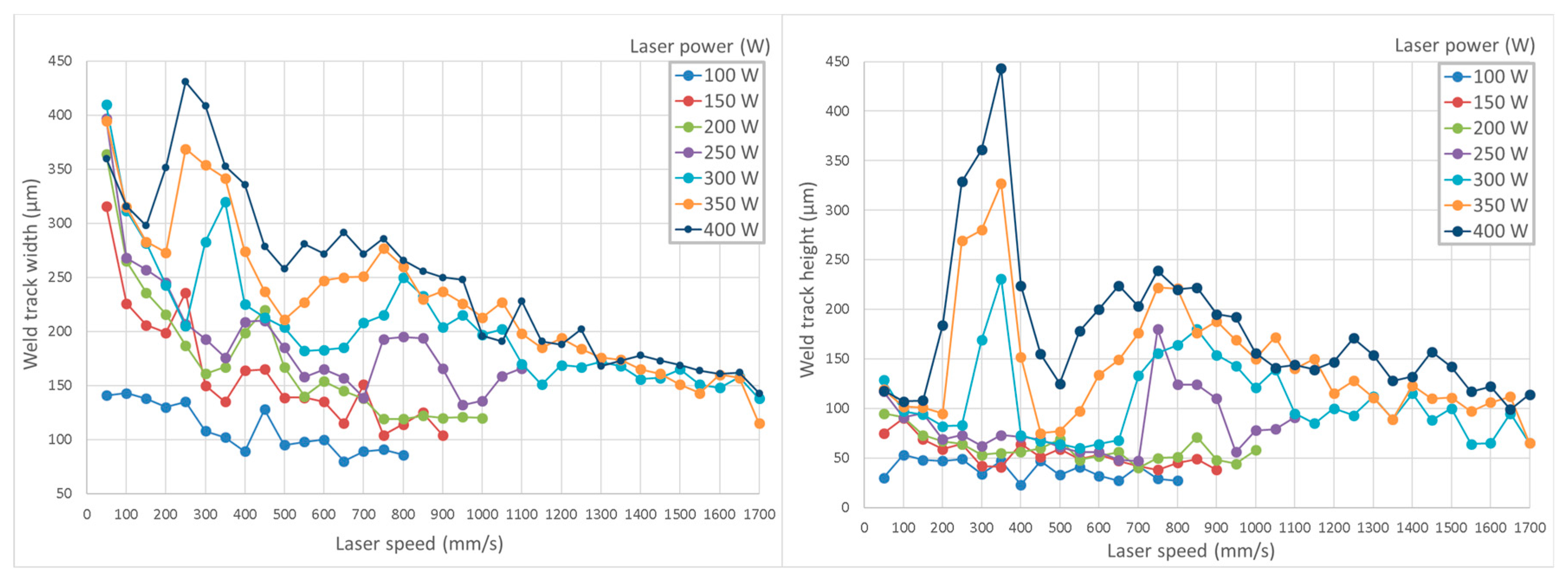

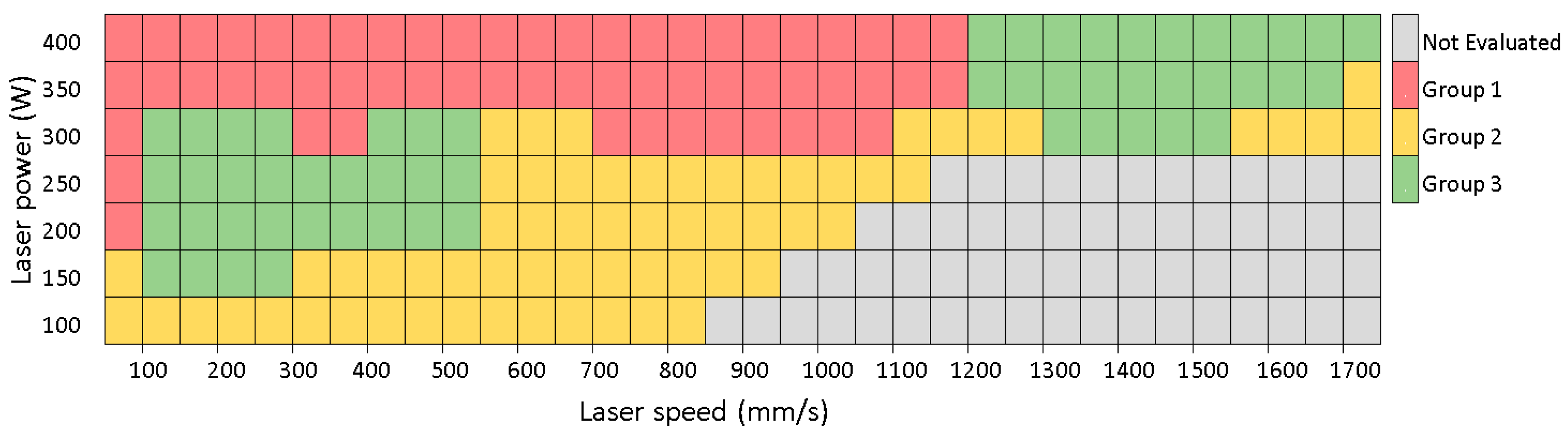

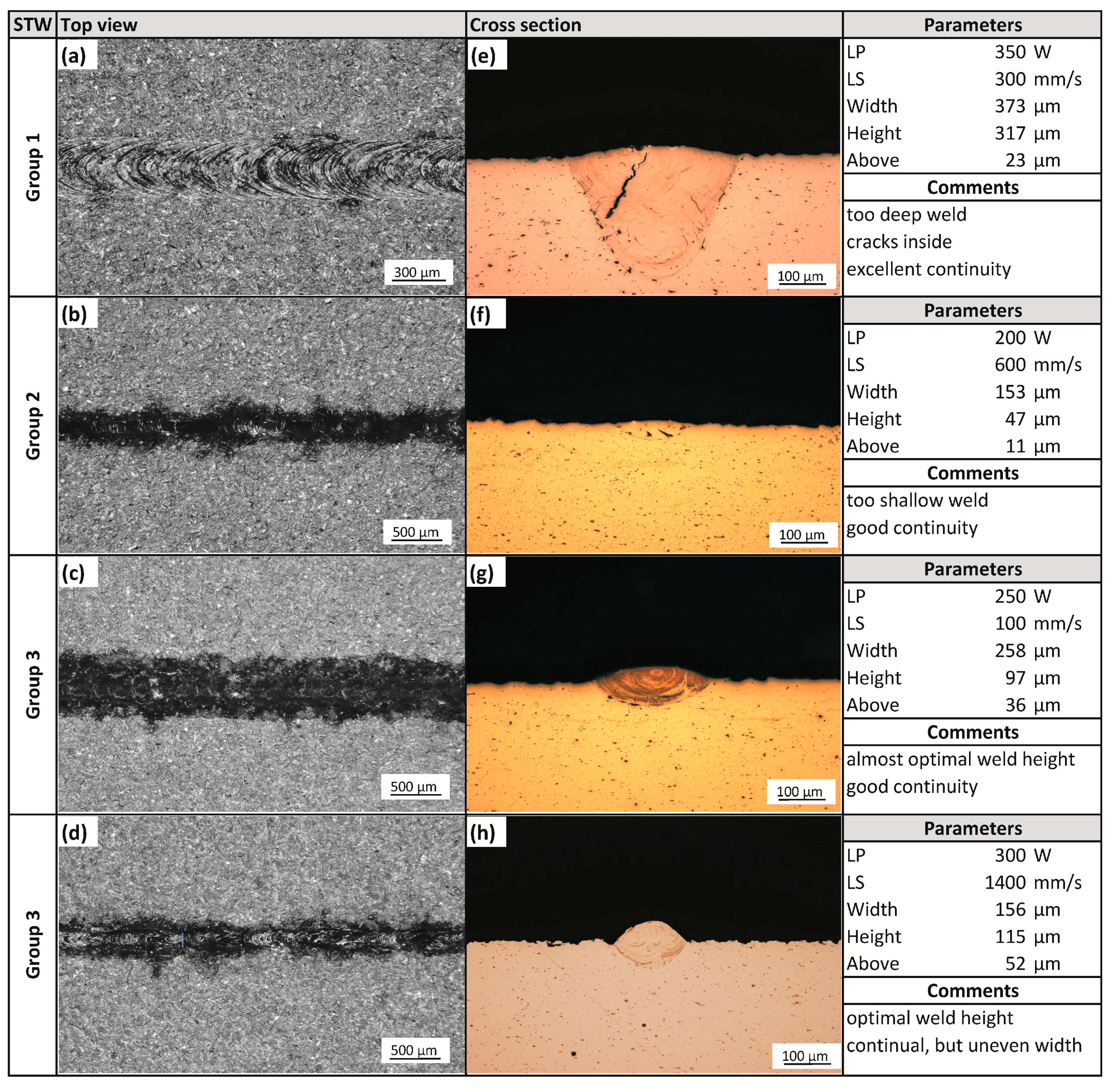

Single-track welds were used for the evaluation of a wide range of processing parameters (

Figure 3). Because there were only two laser-related parameter variables, laser power and laser speed, the influence of other parameters was excluded or minimized. Weld tracks were sorted into three groups according to the chosen criteria (

Figure 4). Group 1 welds are characterized as too deep and prone to cracking. In advance, deep welds can easily cause keyhole pores. Thus, this type of weld is not considered optimal for the fabrication of volumetric samples with low porosity. Group 2 welds are considered as too wide, with low depth and low height above the substrate that could result in being too large and often re-melting. Group 3 welds are those with a good height to width ratio suitable for producing low porosity material.

Figure 5 is complementary to

Figure 4 and shows the representative samples of weld tracks for each group of welds with top view, cross section, measured parameters and evaluation comments. Two promising processing windows with optimal shape of the track were found. The first one is in the area of lower LS (100–400 mm/s) and LP (200–250 W). The second one is in the area of higher LS (1200–1500 mm/s) and higher LP (350–400 W). These results correspond to the results of the cube samples within the initial study [

24,

25]. While in studies [

17,

19] the optimal values for aluminum alloys 2219 and 2024 were found only in the range of low scanning speeds, below 200 mm/s.

Minimization of the influence of other parameters has certain advantages and disadvantages. From the overview of weld track proportions and continuity, the process windows were found. Thus, the hatch distance could be set according to the desired overlap of the weld tracks. The optimum overlapping was considered as 60% which resulted in the use of a 110 µm hatch distance for the Group 3 welds with lower speeds and a 65 µm hatch distance for the Group 3 welds with lower speeds.

The disadvantage of the single-track weld evaluation is that for multiple tracks, arranged side-by-side, the thermal situation may be different. E.g., the measured parameters of the weld tracks may be changed due to a higher temperature during the build of volumetric samples.

A rapid change in the depth of the melt pool was observed (

Figure 3) within a higher laser power (300–400 W) and laser speed between 200–400 mm/s. This may be due to a change in the absorptivity of the material [

28], where more energy is absorbed by the melt pool within this area of the process parameters.

This behavior during processing is undesirable and in connection with the rise of the temperature during fabrication of the volumetric samples could cause a major shift of the optimal processing window far from the expected values.

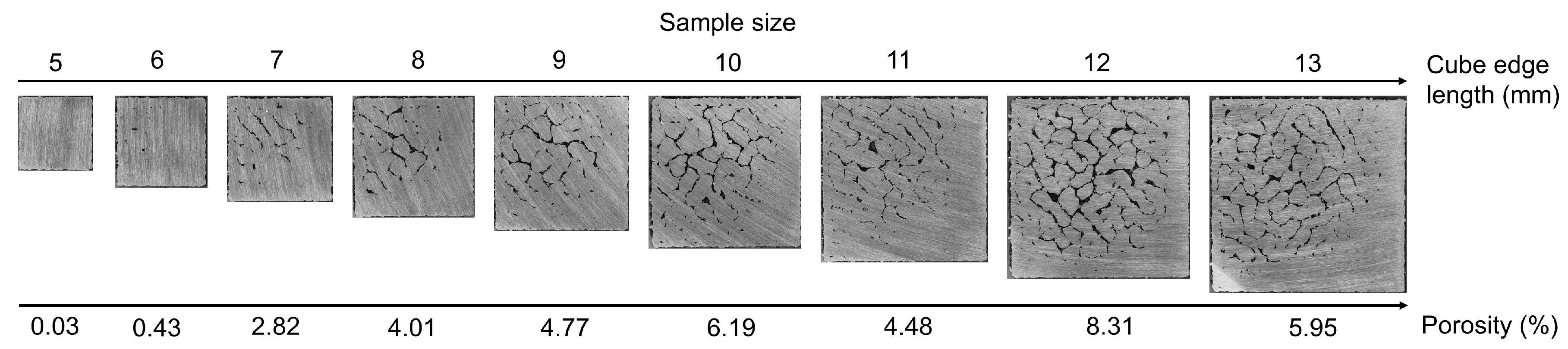

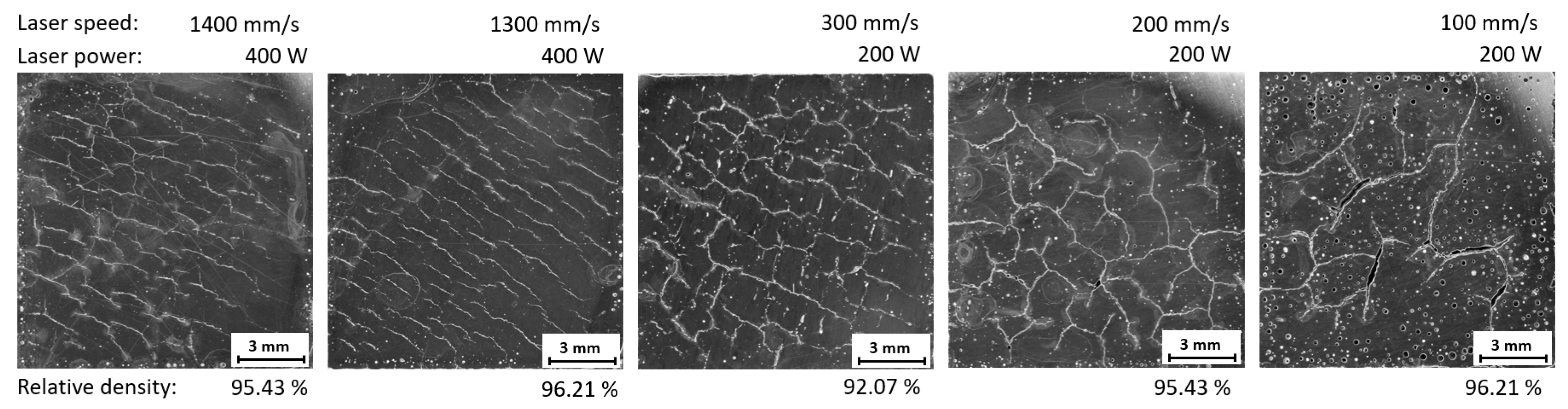

3.2. Meander Strategy

A wide range of processing parameters, with use of the meander strategy, were examined within the initial study [

26]. The results showed a relative porosity of over 99% for the samples with scanning speeds of 200 mm/s and laser power 200 W. However, only small cube samples (5 × 5 × 5 mm) with the meander strategy were examined. Therefore, the aim of the first volumetric test was to evaluate the influence of sample size on porosity. In this test, cube edge length varied from 5 mm to 13 mm. All samples within this test were fabricated with the same process parameters, and those with the best result in the initial study [

24] were used (LP = 200 W, LS = 200 mm/s and HD = 110 µm). The porosity of samples rapidly increased with increasing cube sizes (

Figure 6).

This implies that the temperature distribution during the sample fabrication changes. With elongation of the specimen edge, the time between the scanning of the neighbouring track is increased and the temperature drop of the track is higher, thus the supplied energy is probably insufficient in comparison to the small sample. It is apparent that the meander strategy is not optimal for samples with a larger volume. According to this finding, all following experiments were made with a cube size of 13 × 13 × 5 mm. Mostly, irregular shaped pores, probably induced by hot cracking, were observed (

Figure 6). However, the area that was scanned first was without pores.

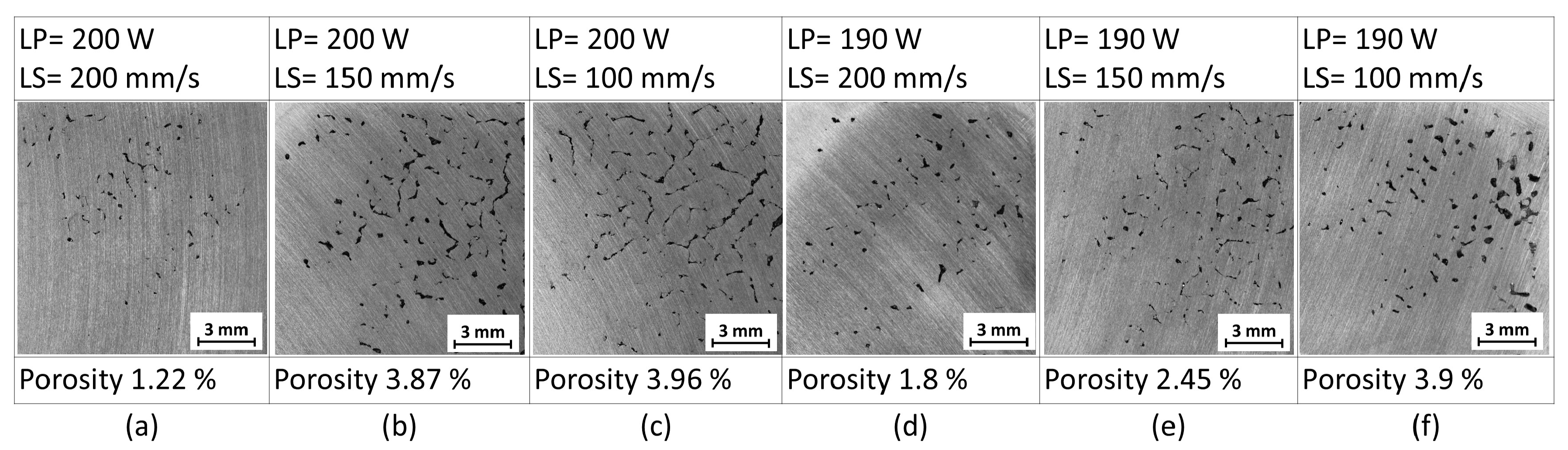

3.3. Chessboard Strategy

The influence of several process parameters within the chessboard strategy has been investigated. Firstly, the standard setup of the chessboard was used with LP variation between 190 and 200 W while LS varied in the range of 100–300 mm/s. Secondly, the scanning order of individual fields was changed, and lastly the influence of the chessboard field size, which varied from 5 × 5 to 1 × 1 mm, was evaluated.

Results of the first test show bands with a high number of defects alternating with bands without a major occurrence of defects (

Figure 7a–f). From that behavior, there was obvious dependence on the chessboard scanning strategy. The lowest values of porosity were achieved with the LP = 200 W and LS = 200 mm/s.

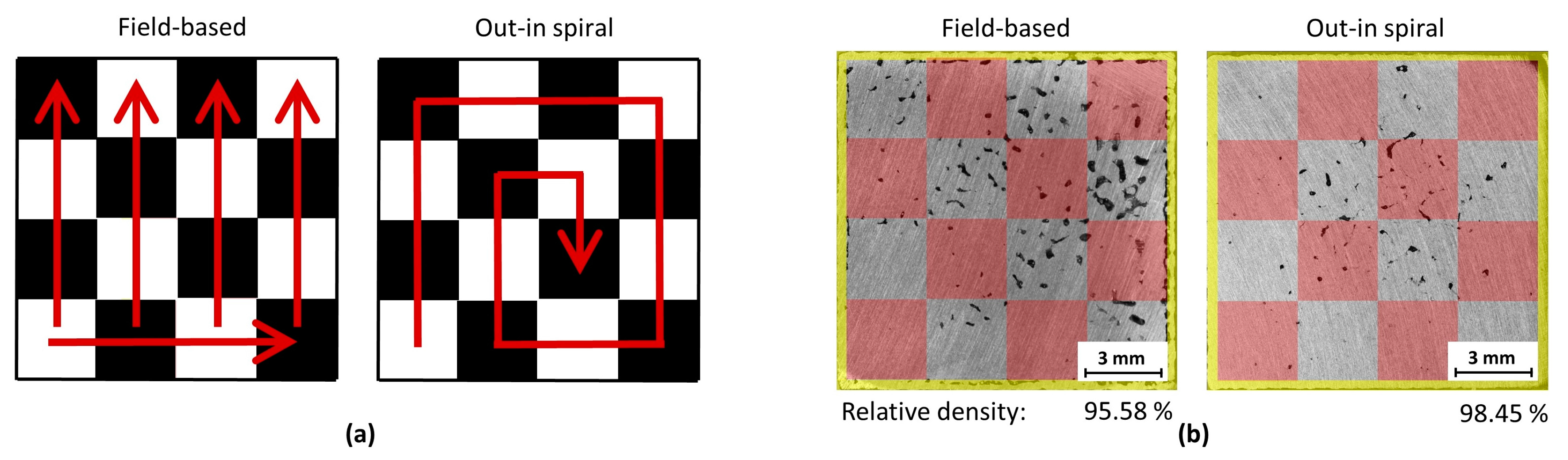

The presence of alternating bands of defects can be explained by the field-based scanning order of the chessboard strategy (

Figure 8a). With the field-based setting, fields are scanned from the bottom-left corner to the top-right corner. The “white” fields are scanned in the first run over the actual layer, and then the black fields are scanned in the second run over the actual layer. This scanning order of white and black fields is used in all cases of the variants of the chessboard strategy. With the setting out-in the spiral, fields are scanned from the bottom-left corner to the center of the sample.

The influence of different scanning order settings on the porosity value and defect distribution is shown in

Figure 8b. In general, the measured porosity of samples with the field-based setting was 2% greater than out-in spiral setting and up to 75% of irregular shaped pores in the sample were located within the “black” fields, therefore in the area that is scanned last. With the out-in spiral setting, the irregular pores were smaller in size and located near the center of the sample, again the area which is scanned last.

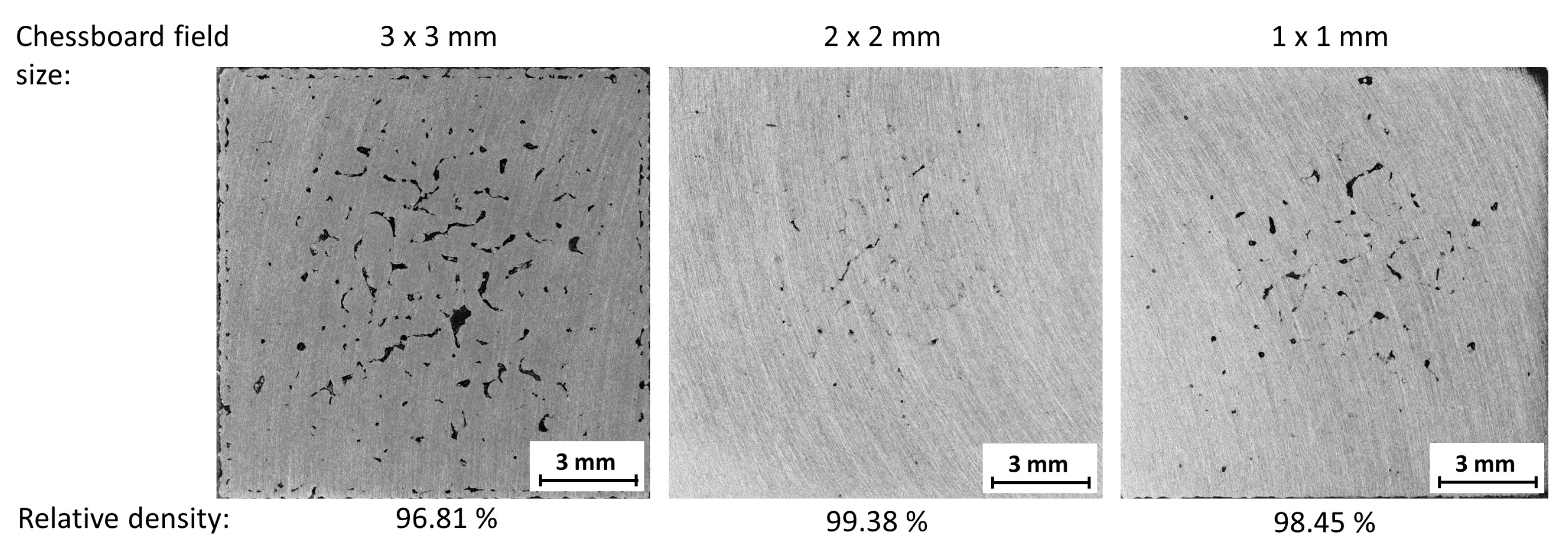

With the chosen out in spiral scanning order, the last part of the test was conducted. It was expected that with a smaller chessboard field size a better heat distribution over the layer could be achieved, which could be beneficial to minimize the amount of defects. The lowest porosity values were reached with a field size of 2 mm, while the most defects were localized in the center of the sample (

Figure 9).

3.4. Hull and Core Strategy

Because the results of the chessboard field size test (

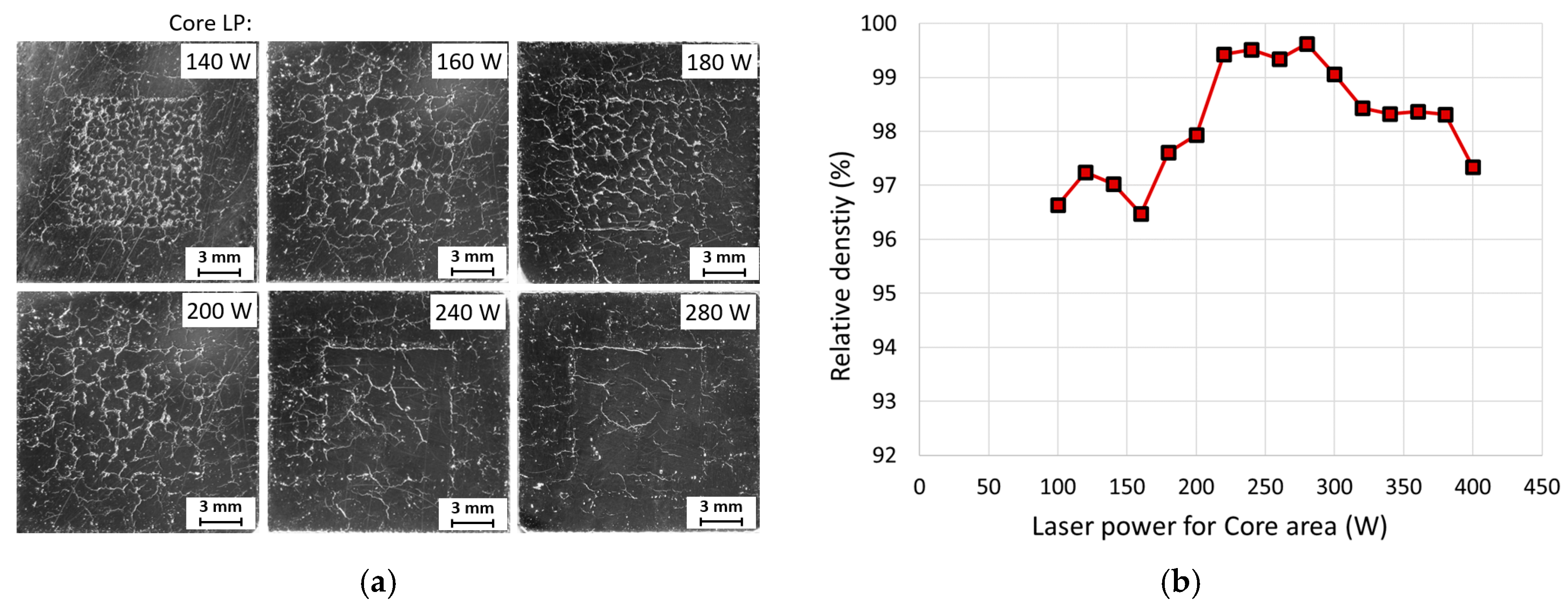

Figure 8b) showed an area of about 3 mm in thickness around the sample without major defects, for the test the hull thickness was set to 3 mm. Thus, the aim was to preserve these conditions in the hull area and optimize the core area parameters only. The hull parameters remained the same as in the best chessboard experiments (LP = 200 W and LS = 200 mm/s). The laser speed for the core area was set at constant value of 100 mm/s. This was due to the known poor results for 200 mm/s and the prospective porosity values achieved in previous tests at lower speeds. The LP varied from 100 W to 400 W.

As can be seen from

Figure 10, the best result was achieved with LP = 280 W. Samples below this value showed hot cracking defects and above it showed increased gas pores. The relative density for the best achieved sample was 99.62%. However, these samples showed crack occurrence mostly on the border between the hull and core area (

Figure 5a).

3.5. Pre-Sintering Strategy

For AlSi10Mg alloy, Aboulkhair et al. [

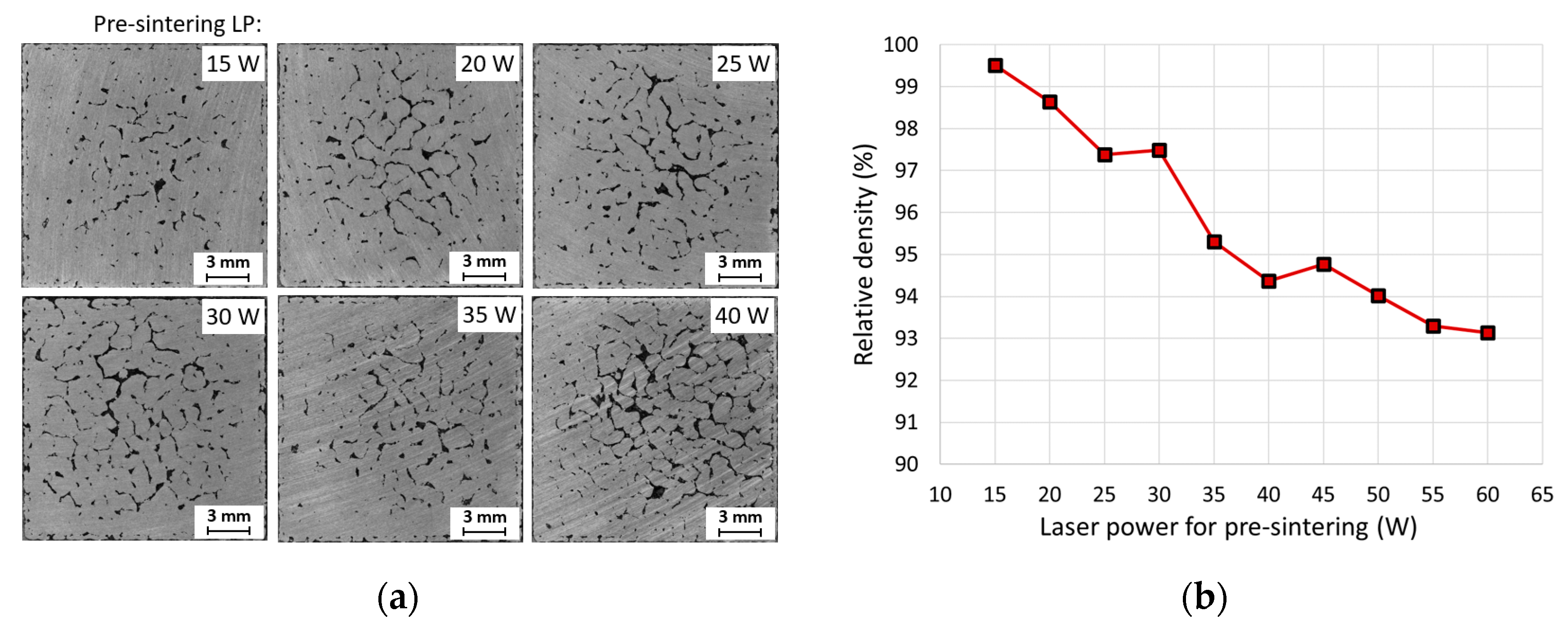

5] achieved best results of relative density with the pre-sintering strategy, therefore the pre-sintering strategy was chosen to explore if there is a positive effect on the relative density of EN AW 2618 alloy. Within this strategy, every layer is scanned twice before the next layer of powder is applied. The first scanning (pre-sintering) had a lower laser power setting, thus the powder was only sintered. The second scanning (melting) had standard parameters and thus the powder was fully melted. Ten samples with melting parameters of LP = 200 W and LS = 200 mm/s with the chessboard 2 × 2 mm strategy were fabricated. For pre-sintering, LP varied from 15 W up to 60 W, while a scanning strategy and laser speed identical to the melting was used.

Figure 11 shows that with increasing pre-sintering laser power, the porosity of samples increased. Samples without pre-sintering achieved better relative density, therefore pre-sintering has a negative impact on the quality of samples.

3.6. Influence of Support Structures

Ahuja et al. [

18] and Karg et al. [

17] both observed an increase in the relative density of samples that were built on support structures compared to those that were built directly on a build platform. In the initial study for EN AW 2618 [

24,

25] this influence was examined, but no change in the sample’s quality was observed. However, for larger cube samples this influence has not yet been evaluated.

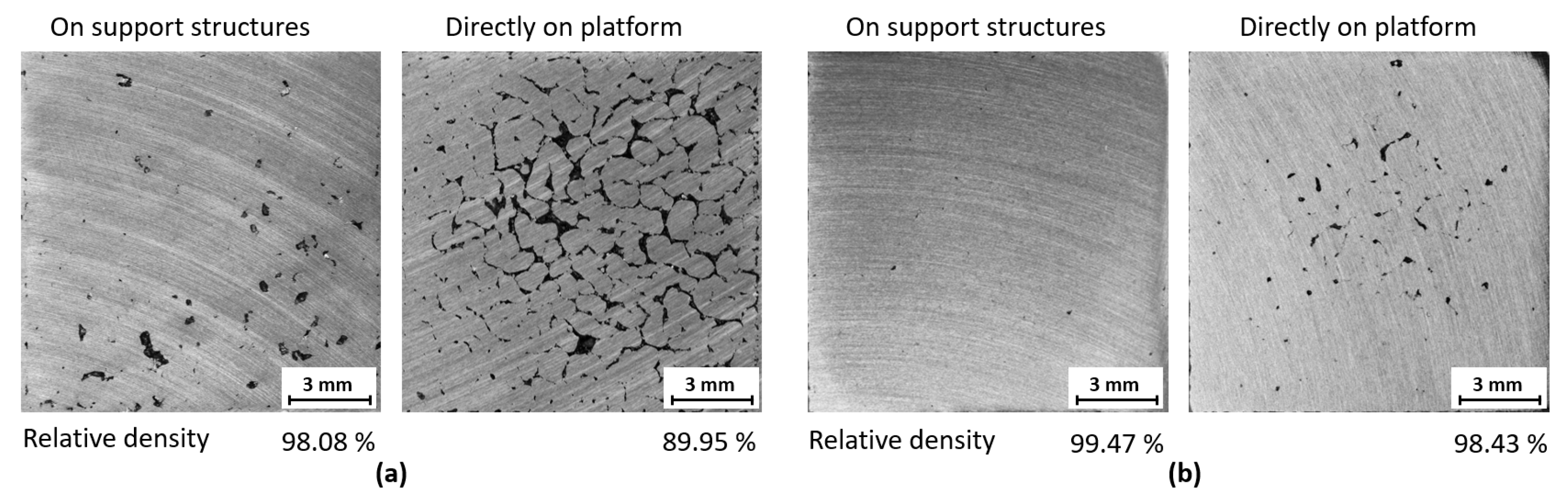

Support structures were created in the Materialise Magics software (21.11, Materialise nv, Leuven, Belgium). The type of support used was block support. Within the first test, the geometry of support structures was optimized. The best results were observed for hatching (distance between two lines of block support) 0.9 mm. To increase the toughness of support structures 5 cone supports were added, four to the corners and one to the center of sample.

Samples with the meander and the chessboard strategy were fabricated to compare them with samples fabricated directly on the build platform. Results showed a decrease in porosity for both scanning strategies. For the meander strategy porosity decreased on average by 6% (

Figure 12a), for the chessboard strategy the reduction was not so significant. On average by 1.5% (

Figure 12b). The decrease in defects was probably caused by the lower temperature gradient. The support structures act as isolation of the processed material from the built platform because it has lower heat capacity than a much larger solid block represented by the built platform. Heat transfer is then much slower.

3.7. Samples with Higher Platform Heating

The main goal of this experiment was to heat up the platform to higher temperatures in order to avoid the occurrence of cracks in the sample due to the reduced temperature gradient between the sample and the platform and reduced heat dissipation from the sample. To achieve higher temperatures of the build platform, a high temperature unit (SLM Solutions Group AG, Lubeck, Germany) was used. This unit allows the build platform to be heated up to 550 °C; for this experiment the platform was heated up only to 400 °C to avoid damage of the heating cylinder due to platform expansion at higher temperatures. To withstand this higher temperature of the platform, a ceramic recoating blade came into use instead of a standard silicone one. As for the protective atmosphere, there was a change to the use of argon.

The samples were built on the variation of the two relevant process windows identified in single-track welds (LP = 400 W, LS = 1300–1400 mm/s; LP = 200–300 W, LS = 100–300 mm/s). These variations were done either with the meander strategy or the chessboard strategy and the results can be seen in

Figure 13 and

Figure 14. Due to the build process, elevated edges could be observed in all samples, but the samples made with the chessboard strategy apparently show a higher trend to these imperfections. In several instances this fact even led to a stop in the processing in order to avoid damage to the ceramic recoating blade. Thus, not all samples were successfully built and analyzed.

In comparison with samples built at a lower platform temperature, an increased incidence of round pores induced by local ablation was observed in all samples. The meander strategy did not show a significant reduction in crack occurrence (see

Figure 13). For samples with the chessboard strategy and laser power of 200 W a reduced occurrence of cracks was observed when working alongside decreased laser speed. However, this lower laser speed raised the gas porosity considerably (see

Figure 14). The cracks were visible in all samples and no significant change in their quantity was observed; however, a different direction of crack propagation between strategies was observed. For the meander strategy the cracks spread along the diagonal of the sample and for the chessboard strategy cracks spread in all directions.

3.8. Mechanical Properties

Fabrication of larger samples for tensile testing was performed after the evaluation of cube samples and the fixation of parameters for each tested strategy. The results of the tensile test are summarized in

Table 2. In the case of the meander strategy, the achieved UTS was far below expected values, which prompted the search for other strategies suitable for a more even distribution of heat in the layer. The chessboard strategy showed partial improvement, but the amount of defects was still too high to be comparable with extruded material. The hull and core strategy minimized the large defects, thus the improvement of mechanical properties was expected. However, the cracking on the interface of the hull and core was shown to be the major limiting type of defect. One of the samples was even broken during the machining of the final shape for tensile testing. All samples fabricated directly on the platform exhibited fragile behavior and the yield strength could not be estimated. The pre-sintering strategy showed no improvement in defect minimization, thus the fabrication of larger samples and their tensile testing was not performed.

The best results were achieved for the meander strategy and the samples built on support structures, which is associated with a decrease in the temperature gradient between the previous and fabricated layer. The smaller difference in UTS between the meander and chessboard strategy in the case of the samples built on support structures shows that the effect of the lower temperature gradient between the layers is more significant than the influence of the temperature gradient across the layer.

Unfortunately, the tensile samples under high temperatures were not fabricated due to partial damage of the ceramic blade. To evaluate the influence on the mechanical properties during high temperature processing it is necessary to eliminate the elevated edges in the future.

Generally, material in the SLM state exhibited significantly lower tensile properties in comparison with the extruded state.

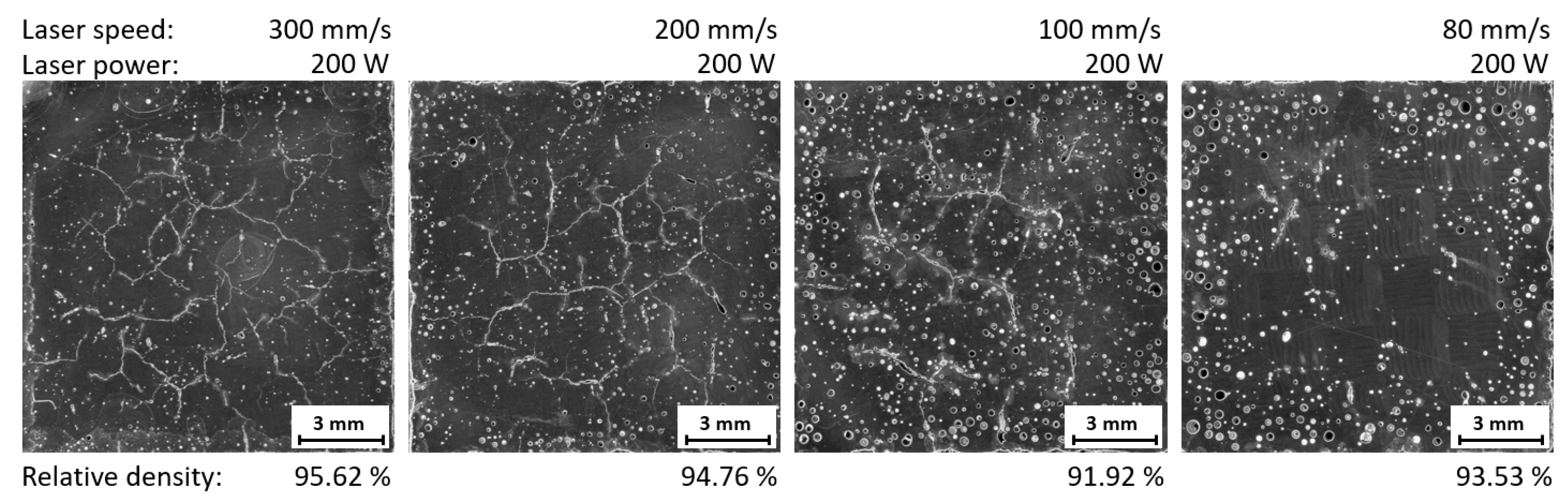

3.9. Metallographic Analysis

Microstructural analyses of samples prepared from cylindrical specimens after tensile tests (of its threaded heads) were conducted. In

Figure 15 the microstructure after the etching of material in the extruded state can be seen. Both the transverse and longitudinal directions are shown (with respect to the cylindrical sample main axis). The preferential orientation of grains and intermediary particles typical for wrought aluminum alloy can be seen. This preferential orientation is connected to the working process of the rod. Intermediary phases of rather a coarse character are present in and out of individual grains.

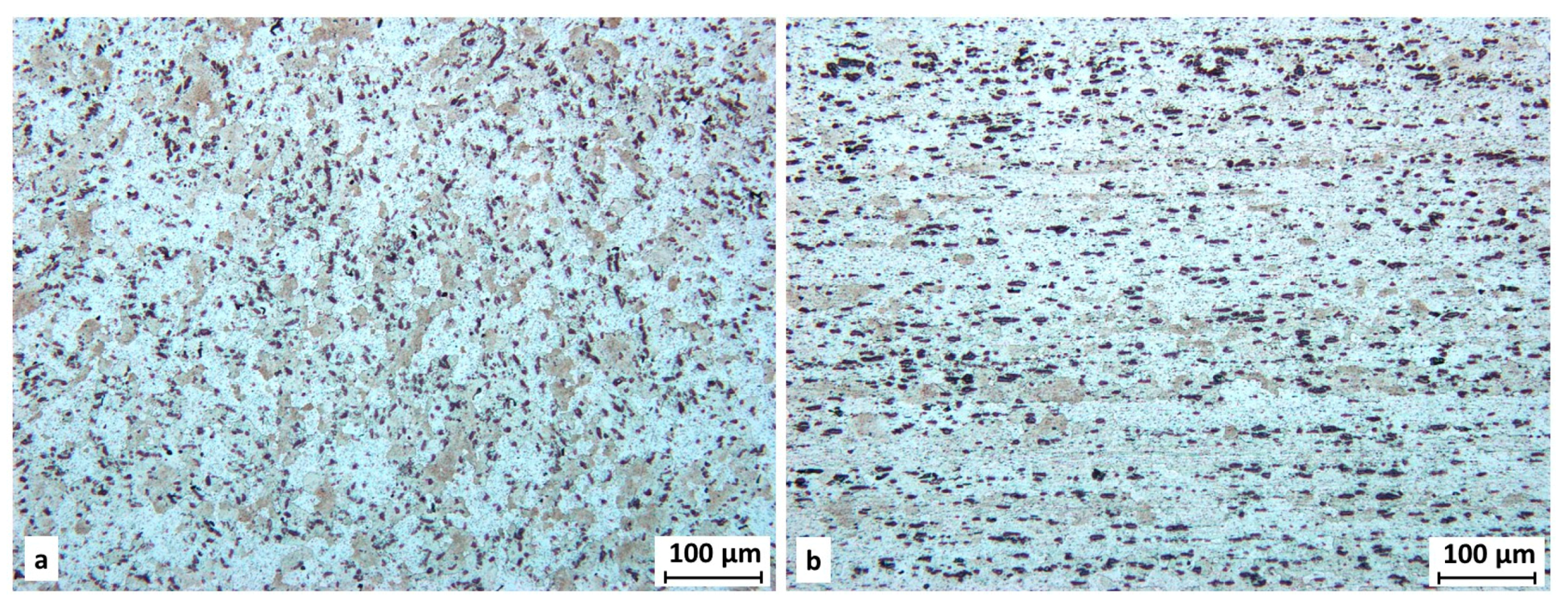

As expected, the microstructure of SLM-processed material is different (

Figure 16a,b). On the samples there is a visible lack of fusion porosity, cracks and gas porosity. At higher magnification (

Figure 16c,d) individual weld tracks can be observed. Alongside these tracks intermediary particles can be found. In comparison with the extruded state they are very fine. In this area the initiation of solidification cracks (also known as hot cracking) occurs.

According to Olakanmi et al. [

29] the mechanisms behind hot cracking are not entirely understood and there are several theories as to why they occur. One of them is the creation of tensile stress between the solid and liquid phases during the solidification process due to high temperature differences between solid and liquid.

3.10. Fractographic Analysis

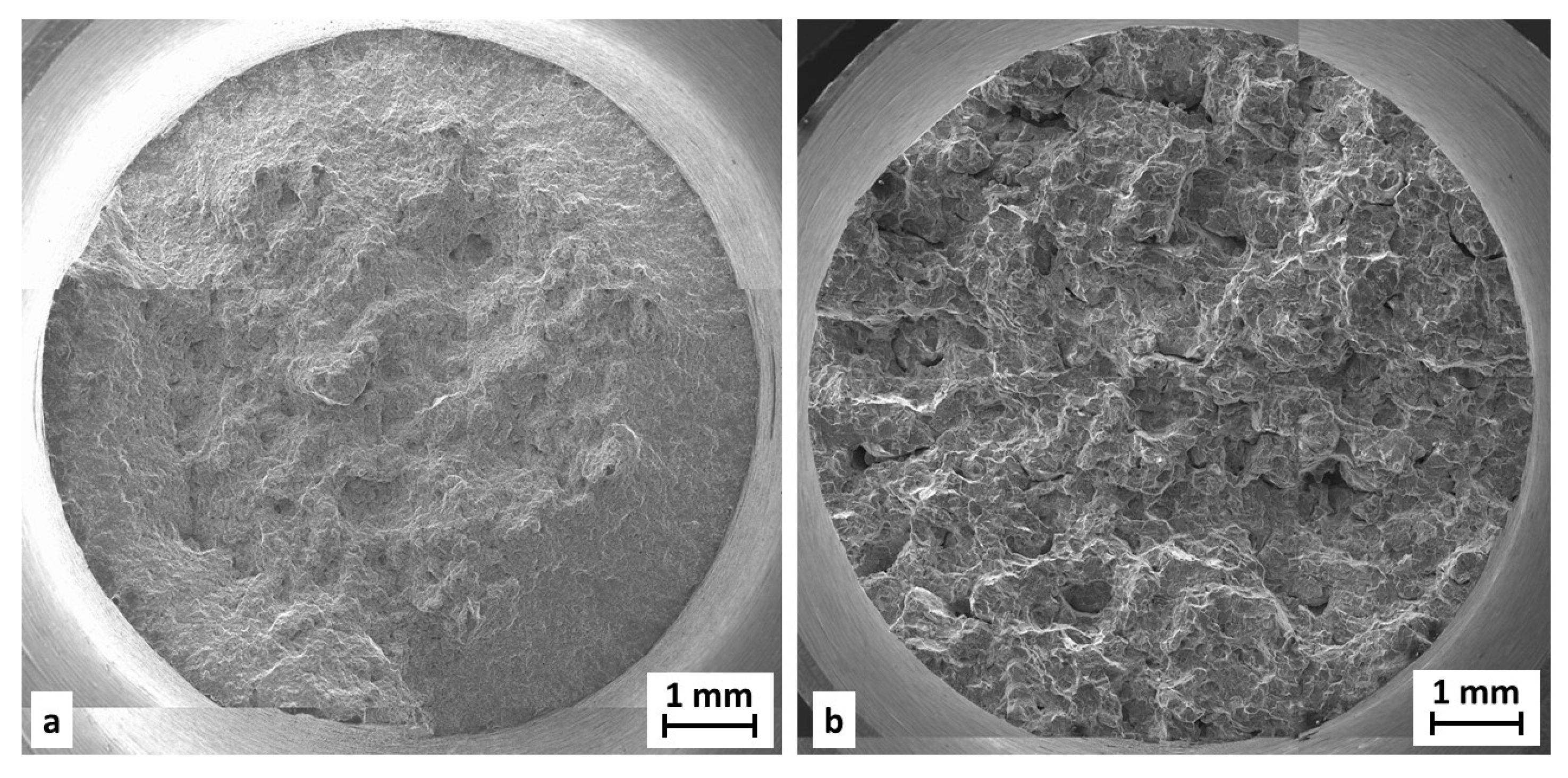

Fractographic analysis was performed on samples (both wrought and SLM) after the tensile test. A comparison of the fracture surface of the material in both states can be seen in

Figure 17.

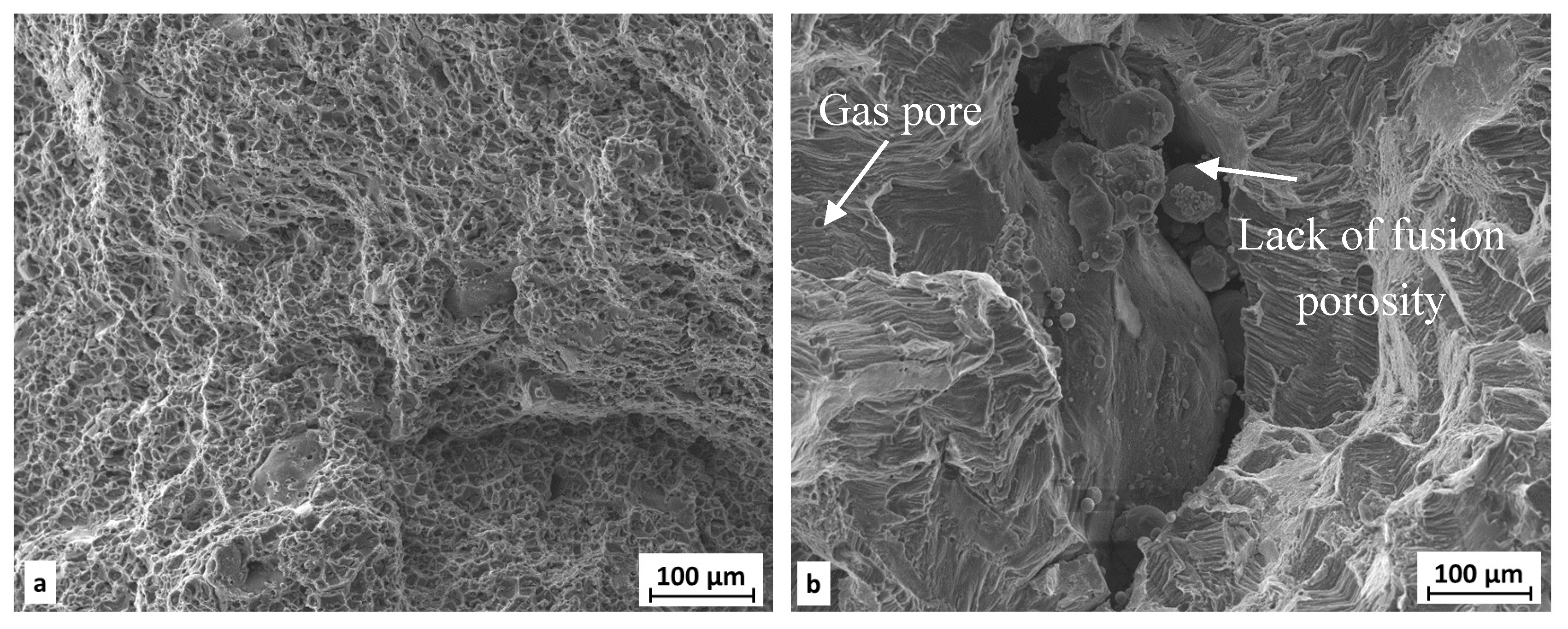

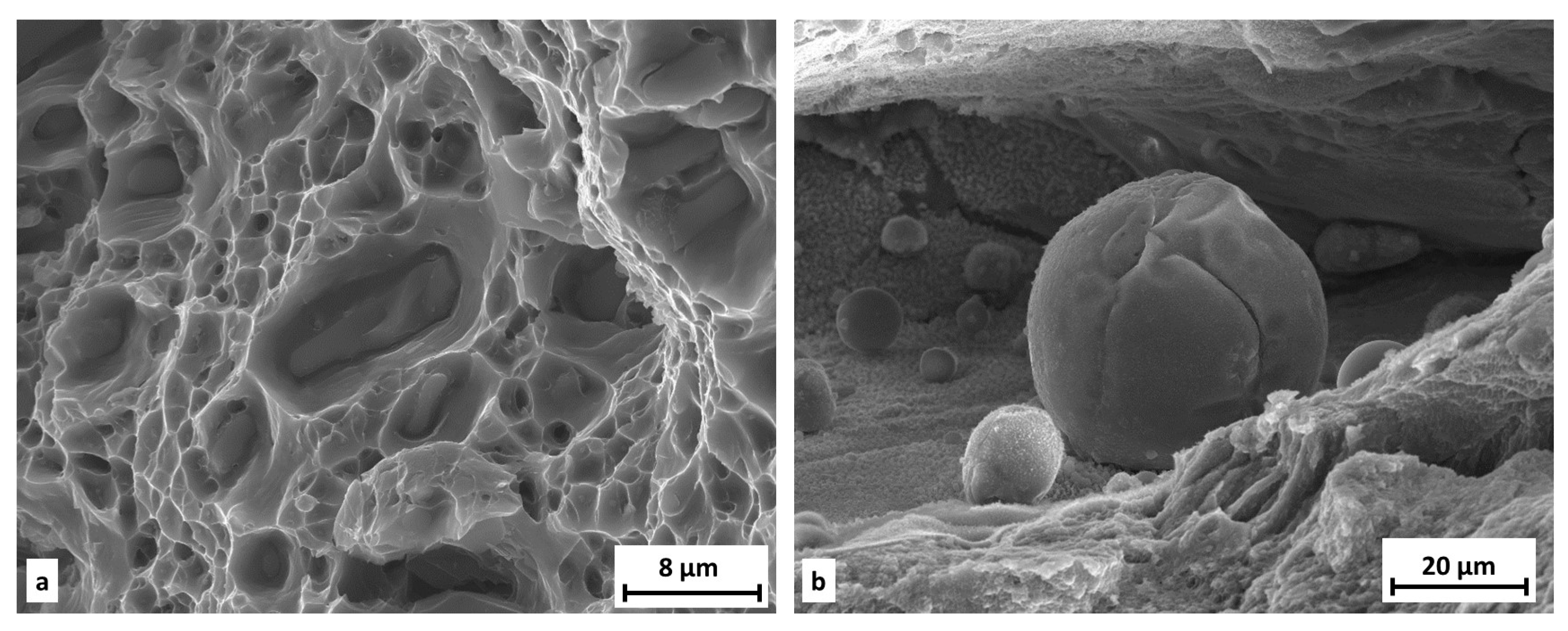

The fracture surface of extruded material is not as rough as fracture surface of SLM-processed samples. In both states the ductile character of the damage mechanism with dimple morphology was observed. For the SLM state, the dimples are tiny and shallow (

Figure 18b), unlike in the extruded state, where the dimples are more pronounced (

Figure 18a); moreover intermediate particles in dimples are visible (

Figure 19a). For the SLM state, a lack of fusion porosity and gas pores are present on the fracture surface. Inside these defects, unmelted particles of metal powder can be seen (

Figure 19b). The surfaces of these pores are covered by an oxide layer.

The results showed some differences in the microstructure of extruded and SLM state material, however hardness measurements for both states are almost identical (100 HV 0.3 for SLM, and 104 HV 0.3 for extruded state). This suggests that the main reason for the different tensile properties is the defects observed in the SLM state. Most of these defects are solidification cracks which were present in samples for all evaluated scanning strategies.

A first experiment with higher platform heating suggests that the reduction of the temperature gradient between the sample and platform may have a positive effect on cracking reduction; however, enormous amount of pores were observed for these samples. A more detailed study with smoother steps between process parameters needs to be performed to fully describe the behavior of crack occurrence with higher processing temperatures.