Preliminary Investigation of Poly-Ether-Ether-Ketone Based on Fused Deposition Modeling for Medical Applications

Abstract

:1. Introduction

2. Materials and Method

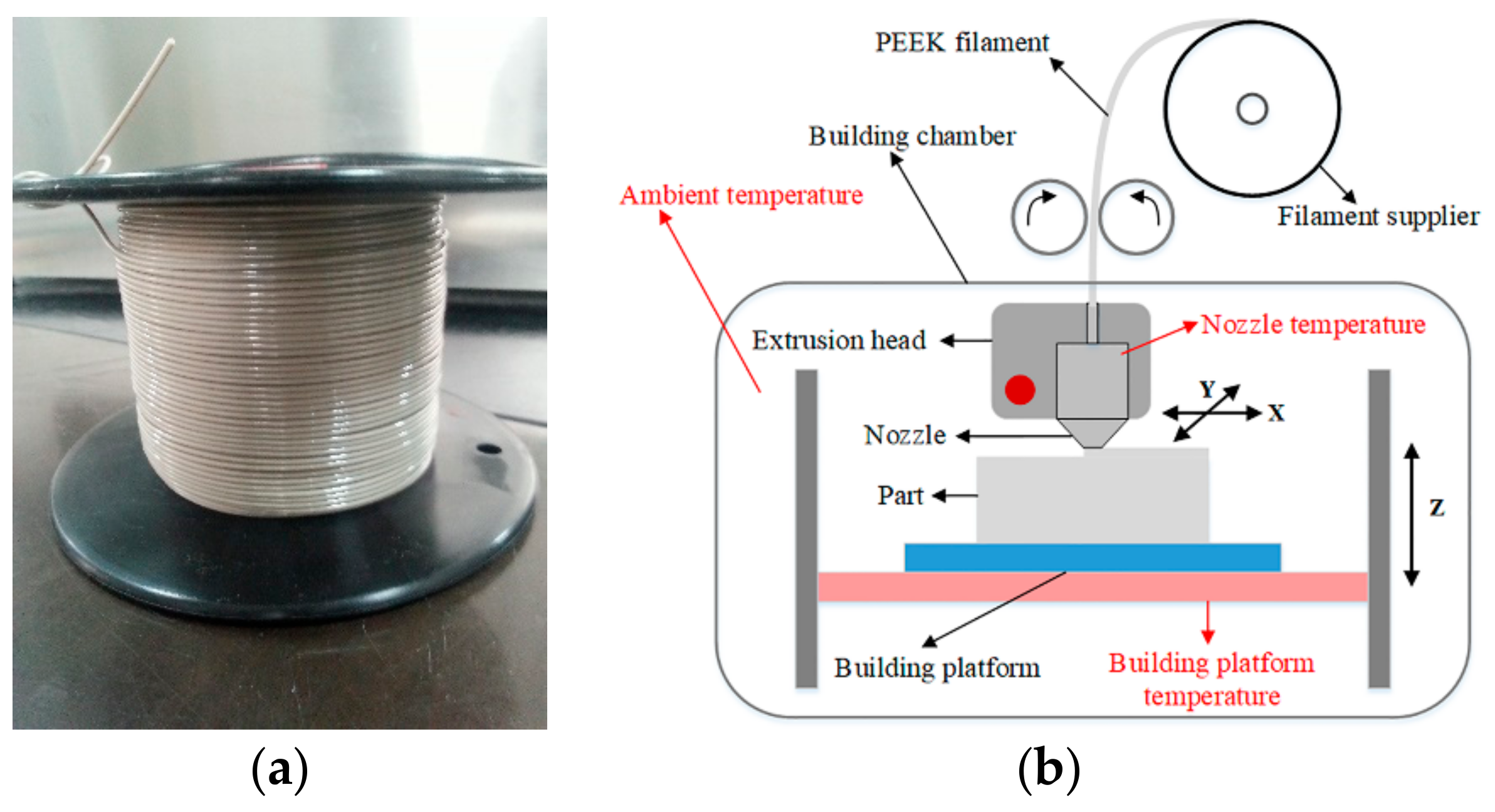

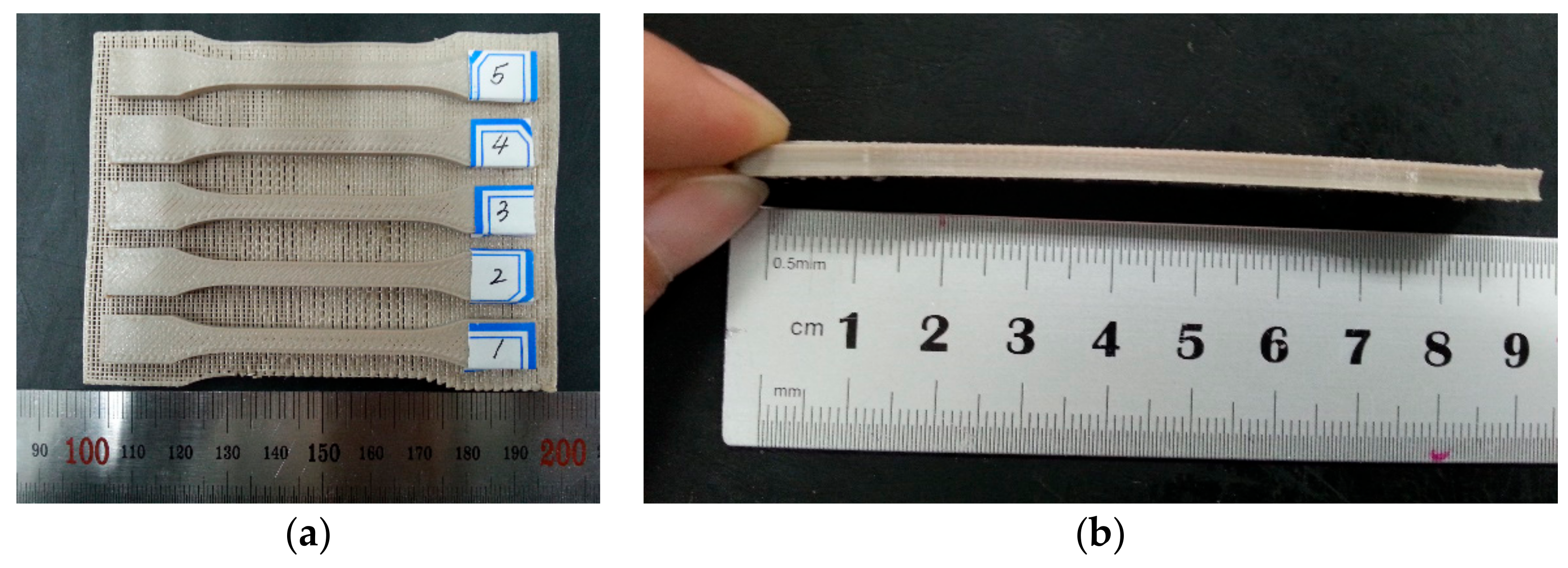

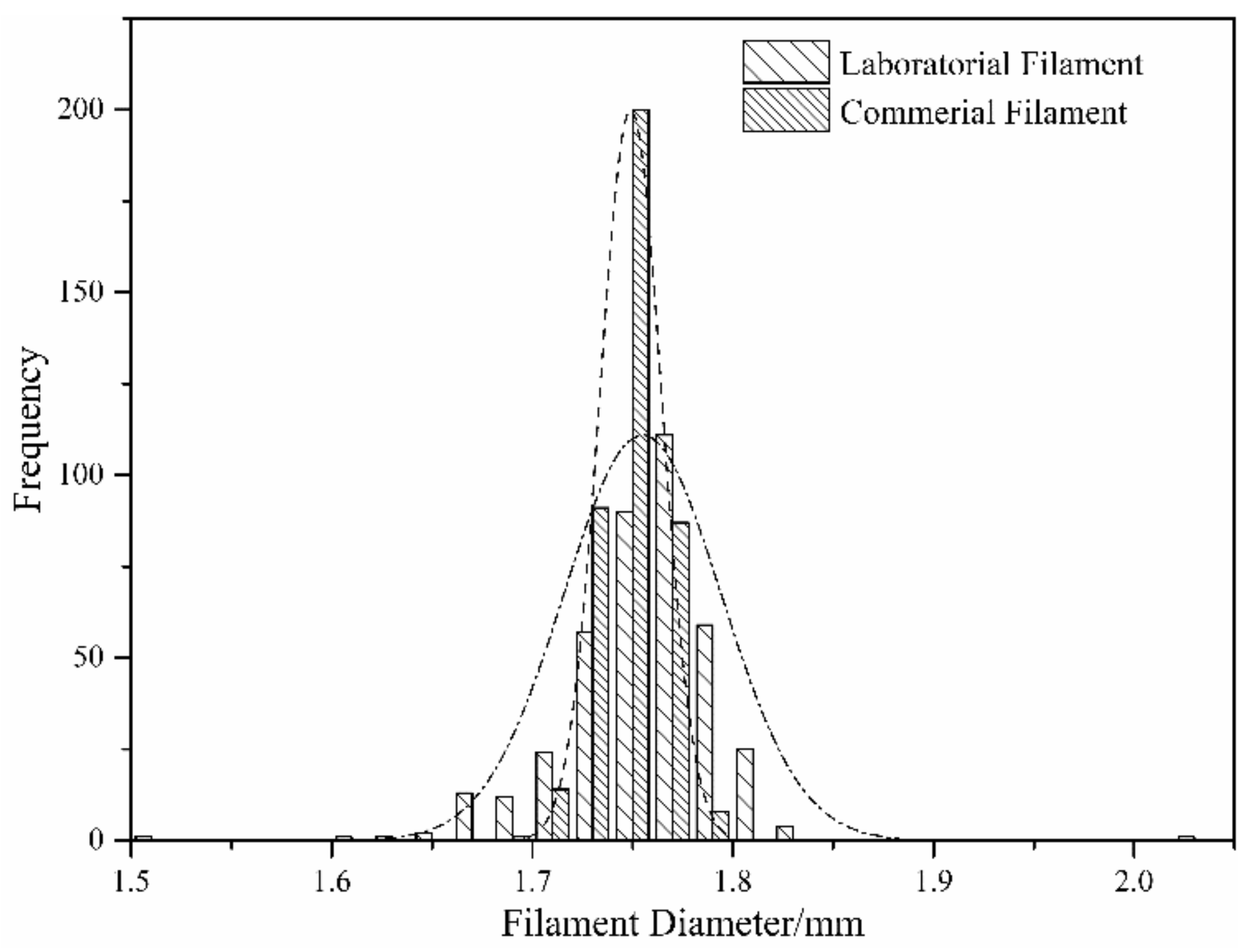

2.1. Filament Preparation and Printer Design

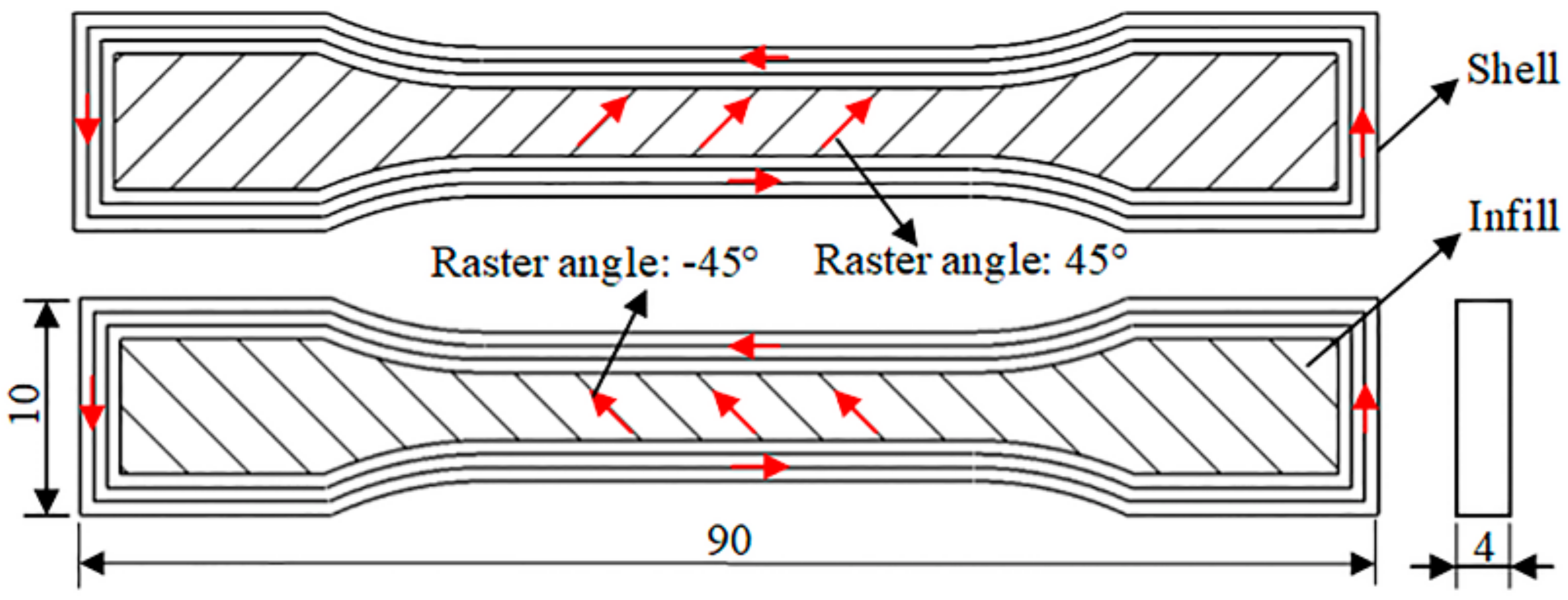

2.2. Significance Analysis of Thermo-Parameters

2.3. FTIR

2.4. Test for In Vitro Cytotoxicity

3. Results and Discussion

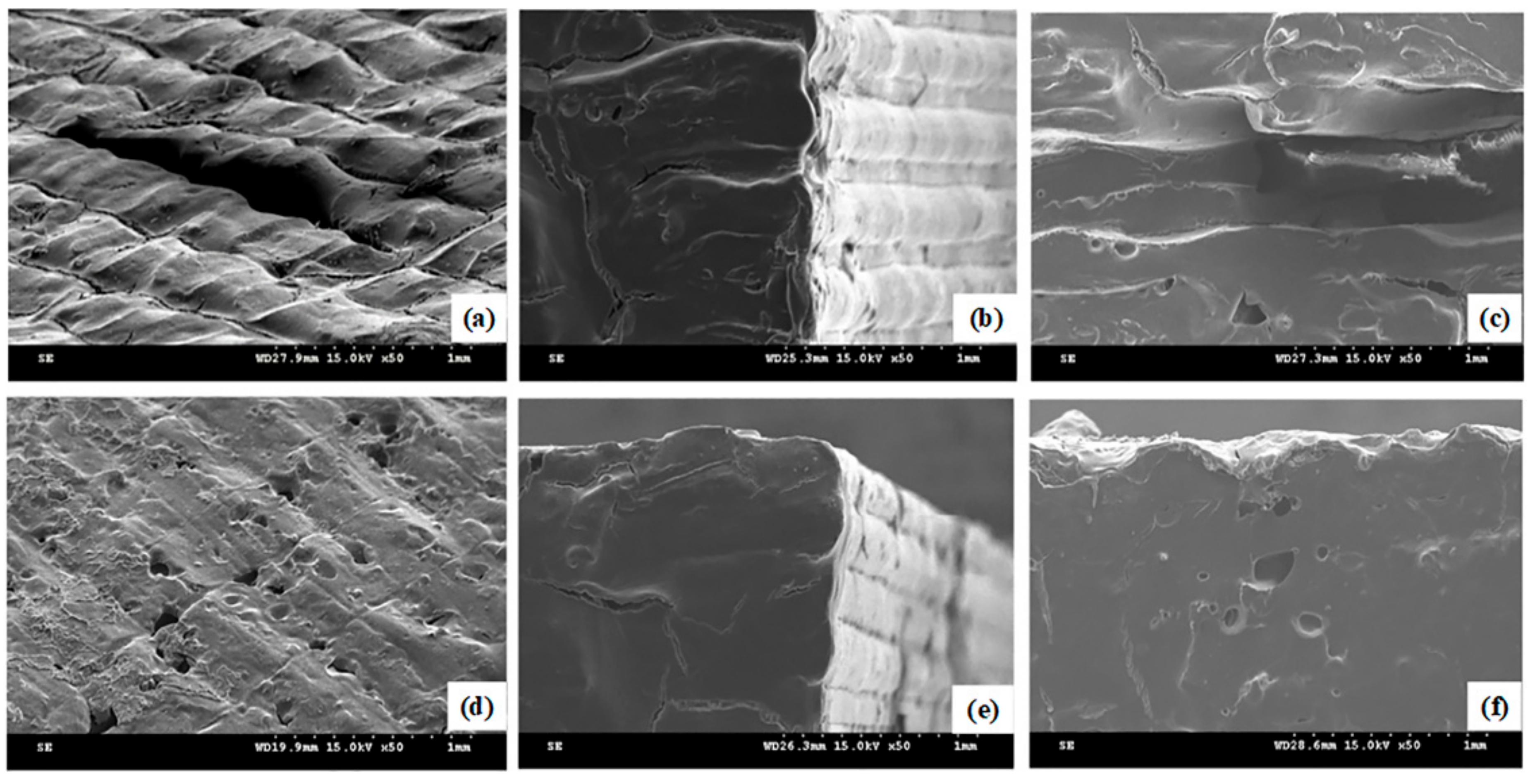

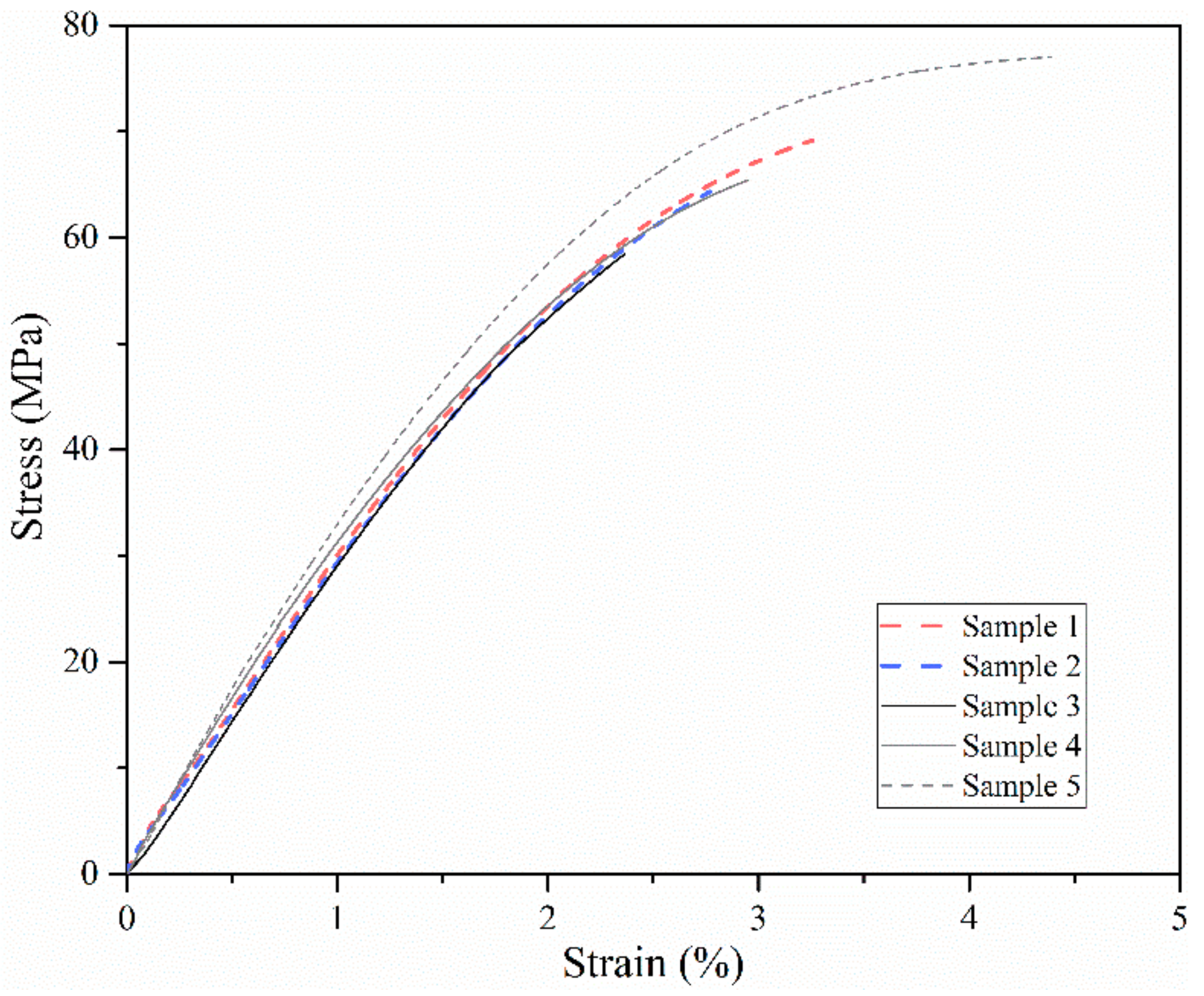

3.1. Significance Analysis of Thermo-Parameters

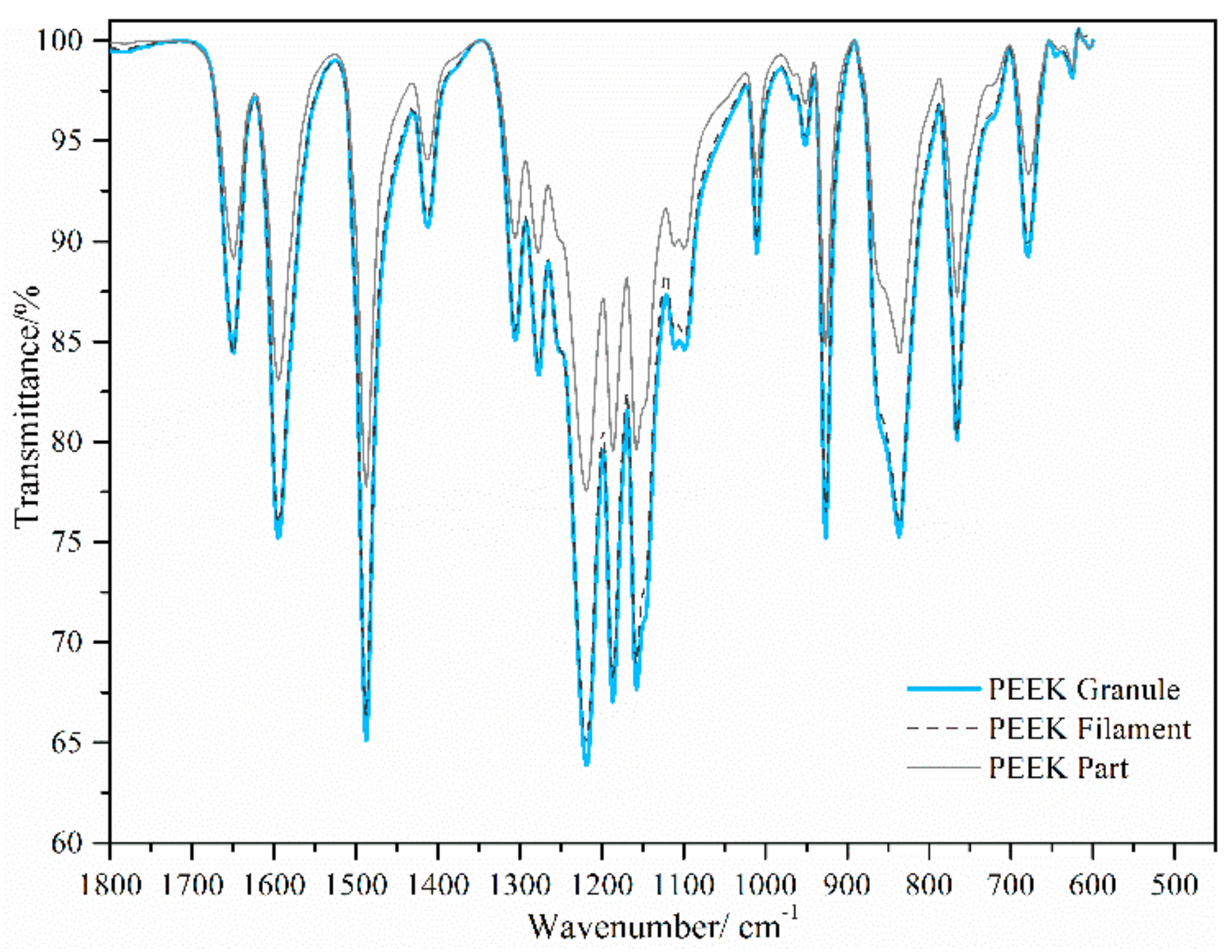

3.2. FTIR

3.3. Test for In Vitro Cytotoxicity

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Experiment No. | Impactor Factors | ||

|---|---|---|---|

| 1 | 355 | 230 | 130 |

| 2 | 355 | 240 | 140 |

| 3 | 355 | 250 | 150 |

| 4 | 355 | 260 | 160 |

| 5 | 355 | 270 | 170 |

| 6 | 360 | 230 | 140 |

| 7 | 360 | 240 | 150 |

| 8 | 360 | 250 | 160 |

| 9 | 360 | 260 | 170 |

| 10 | 360 | 270 | 130 |

| 11 | 365 | 230 | 150 |

| 12 | 365 | 240 | 160 |

| 13 | 365 | 250 | 170 |

| 14 | 365 | 260 | 130 |

| 15 | 365 | 270 | 140 |

| 16 | 370 | 230 | 160 |

| 17 | 370 | 240 | 170 |

| 18 | 370 | 250 | 130 |

| 19 | 370 | 260 | 140 |

| 20 | 370 | 270 | 150 |

| 21 | 375 | 230 | 170 |

| 22 | 375 | 240 | 130 |

| 23 | 375 | 250 | 140 |

| 24 | 375 | 260 | 150 |

| 25 | 375 | 270 | 160 |

Appendix B

| Experiment No. | Item | Reading 1 | Reading 2 | Reading 3 | Reading 4 | Reading 5 | Mean |

|---|---|---|---|---|---|---|---|

| 1 | Tensile strength/MPa | 61.1 | 57.9 | 54 | 62.2 | 62.6 | 59.6 |

| Elongation/% | 3 | 4 | 2 | 3 | 3 | 3 | |

| Young’s modulus/GPa | 2.9 | 2.7 | 2.7 | 3.2 | 3.1 | 2.9 | |

| 2 | Tensile strength/MPa | 53.7 | 58.7 | 54.7 | 52 | 48.9 | 53.6 |

| Elongation/% | 3 | 3 | 3 | 4 | 4 | 3 | |

| Young’s modulus/GPa | 2.9 | 3.0 | 2.9 | 2.6 | 2.6 | 2.8 | |

| 3 | Tensile strength/MPa | 64.3 | 67 | 63.3 | 62.3 | 60.2 | 63.4 |

| Elongation/% | 3 | 3 | 4 | 3 | 3 | 3 | |

| Young’s modulus/GPa | 3.2 | 3.2 | 3.2 | 3.1 | 3.4 | 3.2 | |

| 4 | Tensile strength/MPa | 48.7 | 41.8 | 49.5 | 47.3 | 44.5 | 46.4 |

| Elongation/% | 3 | 2 | 3 | 3 | 3 | 3 | |

| Young’s modulus/GPa | 3.0 | 2.9 | 3.0 | 3.0 | 2.9 | 3.0 | |

| 5 | Tensile strength/MPa | 46.4 | 54.9 | 48.9 | 52 | 52.6 | 51.0 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.1 | 3.0 | 3.2 | 3.1 | 3.1 | 3.1 | |

| 6 | Tensile strength/MPa | 55.4 | 54 | 53 | 62.9 | 55.2 | 56.1 |

| Elongation/% | 3 | 6 | 2 | 6 | 2 | 4 | |

| Young’s modulus/GPa | 2.9 | 2.8 | 3.1 | 2.7 | 3.0 | 2.9 | |

| 7 | Tensile strength/MPa | 55.5 | 57.2 | 59.8 | 48.6 | 52.6 | 54.7 |

| Elongation/% | 2 | 3 | 3 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 2.8 | 3.0 | 3.1 | 2.9 | 3.1 | 3.0 | |

| 8 | Tensile strength/MPa | 46.7 | 49 | 50.8 | 47.9 | 63 | 51.5 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 2.9 | 3.0 | 3.2 | 3.0 | 3.2 | 3.1 | |

| 9 | Tensile strength/MPa | 48.2 | 47.4 | 48.8 | 45.4 | 51.4 | 48.2 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.1 | 2.9 | 3.0 | 2.9 | 3.0 | 3.0 | |

| 10 | Tensile strength/MPa | 52.8 | 55.4 | 53.1 | 48.9 | 57.6 | 53.6 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.1 | 3.2 | 3.1 | 3.1 | 3.2 | 3.1 | |

| 11 | Tensile strength/MPa | 50.7 | 53 | 58.3 | 53.2 | 49.7 | 53.0 |

| Elongation/% | 3 | 3 | 3 | 2 | 2 | 3 | |

| Young’s modulus/GPa | 2.8 | 2.7 | 2.9 | 2.7 | 3.0 | 2.8 | |

| 12 | Tensile strength/MPa | 55.7 | 48.7 | 57.4 | 48.7 | 52.1 | 52.5 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 2.7 | 2.8 | 2.7 | 2.8 | 3.0 | 2.8 | |

| 13 | Tensile strength/MPa | 58.2 | 56.6 | 54.9 | 52.5 | 52.8 | 55.0 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.1 | 3.1 | 3.1 | 2.9 | 3.2 | 3.1 | |

| 14 | Tensile strength/MPa | 60 | 58.2 | 63.1 | 46.9 | 53.9 | 56.4 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.3 | 3.4 | 3.6 | 3.3 | 3.4 | 3.4 | |

| 15 | Tensile strength/MPa | 48.4 | 66.1 | 55.8 | 50.8 | 53.7 | 55.0 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2.0 | |

| Young’s modulus/GPa | 2.9 | 2.9 | 3.1 | 2.9 | 3.1 | 3.0 | |

| 16 | Tensile strength/MPa | 58.3 | 54.1 | 55.8 | 48.4 | 51.5 | 53.6 |

| Elongation/% | 3 | 3 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.0 | 3.0 | 3.0 | 2.9 | 3.0 | 3.0 | |

| 17 | Tensile strength/MPa | 49.2 | 49 | 59.3 | 50.4 | 51.9 | 52.0 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 2.90 | 2.90 | 3.00 | 2.90 | 3.00 | 2.9 | |

| 18 | Tensile strength/MPa | 56.4 | 50.2 | 56.3 | 53.4 | 49.5 | 53.2 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.0 | 3.1 | 3.2 | 2.9 | 3.0 | 3.0 | |

| 19 | Tensile strength/MPa | 49.7 | 51.3 | 46.4 | 42.3 | 49.6 | 47.9 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 2.9 | 3.1 | 3.1 | 2.9 | 3.1 | 3.0 | |

| 20 | Tensile strength/GPa | 51.7 | 52.4 | 44.2 | 48.3 | 55.3 | 50.4 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.0 | 2.9 | 3.2 | 3.1 | 3.2 | 3.1 | |

| 21 | Tensile strength/MPa | 54 | 71.5 | 60 | 60.3 | 59.7 | 61.1 |

| Elongation% | 3 | 4 | 3 | 3 | 3 | 3 | |

| Young’s modulus/GPa | 2.9 | 3.1 | 3.1 | 2.9 | 3.0 | 3.0 | |

| 22 | Tensile strength/MPa | 60.1 | 57.9 | 51 | 48.2 | 52 | 53.8 |

| Elongation/% | 2 | 2 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.2 | 3.2 | 3.0 | 2.9 | 2.9 | 3.0 | |

| 23 | Tensile strength/MPa | 46.4 | 55.3 | 49.1 | 49.4 | 59.34 | 51.9 |

| Elongation/% | 2 | 3 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 2.7 | 2.7 | 2.9 | 2.9 | 2.9 | 2.8 | |

| 24 | Tensile strength/MPa | 49.6 | 54.4 | 51 | 52.4 | 55.4 | 52.6 |

| Elongation/% | 2 | 3 | 2 | 2 | 2 | 2 | |

| Young’s modulus/GPa | 3.2 | 3.0 | 3.0 | 3.0 | 3.2 | 3.1 | |

| 25 | Tensile strength/MPa | 69.2 | 64.3 | 58.4 | 66.3 | 77 | 67.0 |

| Elongation/% | 3 | 3 | 2 | 3 | 4 | 3 | |

| Young’s modulus/GPa | 3.0 | 2.9 | 3.0 | 3.1 | 3.1 | 3.0 |

References

- Godara, A.; Raabe, D.; Green, S. The influence of sterilization processes on the micromechanical properties of carbon fiber-reinforced PEEK composites for bone implant applications. Acta Biomater. 2007, 3, 209–220. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M. PEEK Biomaterials Handbook; William Andrew: Oxfordd, UK, 2011. [Google Scholar]

- Schork, N.J. Personalized medicine: Time for one-person trials. Nature 2015, 520, 609–611. [Google Scholar] [CrossRef] [PubMed]

- Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implant Applications; ASTM International: West Conshohocken, PA, USA, 2017.

- Biological Evaluation of Medical Devices, Parts 1–12; ISO. 10993; International Organization for Standardization: Geneva, Switzerland, 2009.

- Valentan, B.; Kadivnik, Z.; Brajlih, T.; Anderson, A.; Igor, D. Processing poly (ether etherketone) on a 3D printer for thermoplastic modelling. Mater. Technol. 2013, 47, 715–721. [Google Scholar]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Geng, P.; Zhao, J.; Zhang, Y.; Rosen, D.; Zhang, H. Manufacture and thermal deformation analysis of semicrystalline polymer polyether ether ketone by 3D printing. Mater. Res. Innov. 2014, 18, S2–S16. [Google Scholar] [CrossRef]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Jain, P.K.; Pandey, P.M.; Rao, P. Experimental investigations for improving part strength in selective laser sintering. Virtual Phys. Prototyp. 2008, 3, 177–188. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Victrex. Available online: https://www.victrex.com/en/ (accessed on 7 February 2018).

- Al Lafi, A.G. FTIR spectroscopic analysis of ion irradiated poly (ether ether ketone). Polym. Degrad. Stab. 2014, 105, 122–133. [Google Scholar] [CrossRef]

- Nguyen, H.X.; Ishida, H. Molecular analysis of the melting behaviour of poly(aryl-ether-ether-ketone). Polymer 1986, 27, 1400–1405. [Google Scholar] [CrossRef]

- Standard Test Method for Measurement of Percent Crystallinity of Polyetheretherketone (PEEK) Polymers by Means of Specular Reflectance Fourier Transform Infrared Spectroscopy (R-FTIR); ASTM F2778; ASTM International: West Conshohocken, PA, USA, 2015.

- Mark, J.E. Physical Properties of Polymers Handbook; Springer: Berlin, Germany, 2007; Volume 1076. [Google Scholar]

- Rusen, L.; Dinca, V.; Mustaciosu, C.; Icriverzi, M.; Sima, L.E.; Bonciu, A.; Brajnicov, S.; Mihailescu, N.; Dumitrescu, N.; Popovici, A.I.; et al. Smart Thermoresponsive Surfaces Based on pNIPAm Coatings and Laser Method for Biological Applications. In Modern Technologies for Creating the Thin-Film Systems and Coatings; Nikitenkov, N.N., Ed.; InTech: London, UK, 2017; Volume 10. [Google Scholar]

| Factors | Sum of Squares (SS) | Degrees of Freedom | Mean Square (MS) | F-Ratio | Percent Contribution (P) (100%) |

|---|---|---|---|---|---|

| 490.94 | 4 | 122.74 | 4.07 | 10.74 | |

| 604.27 | 4 | 151.07 | 5.01 | 13.22 | |

| 96.78 | 4 | 24.20 | 0.80 | 2.12 | |

| Other/errors | 3377.50 | 112 | 30.16 | 73.91 | |

| Total | 4569.49 | 124 | 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; Li, D.; Jin, Z. Preliminary Investigation of Poly-Ether-Ether-Ketone Based on Fused Deposition Modeling for Medical Applications. Materials 2018, 11, 288. https://doi.org/10.3390/ma11020288

Zhao F, Li D, Jin Z. Preliminary Investigation of Poly-Ether-Ether-Ketone Based on Fused Deposition Modeling for Medical Applications. Materials. 2018; 11(2):288. https://doi.org/10.3390/ma11020288

Chicago/Turabian StyleZhao, Feng, Dichen Li, and Zhongmin Jin. 2018. "Preliminary Investigation of Poly-Ether-Ether-Ketone Based on Fused Deposition Modeling for Medical Applications" Materials 11, no. 2: 288. https://doi.org/10.3390/ma11020288

APA StyleZhao, F., Li, D., & Jin, Z. (2018). Preliminary Investigation of Poly-Ether-Ether-Ketone Based on Fused Deposition Modeling for Medical Applications. Materials, 11(2), 288. https://doi.org/10.3390/ma11020288