In Vivo Evaluation of 3D-Printed Polycaprolactone Scaffold Implantation Combined with β-TCP Powder for Alveolar Bone Augmentation in a Beagle Defect Model

Abstract

:1. Introduction

2. Materials and Methods

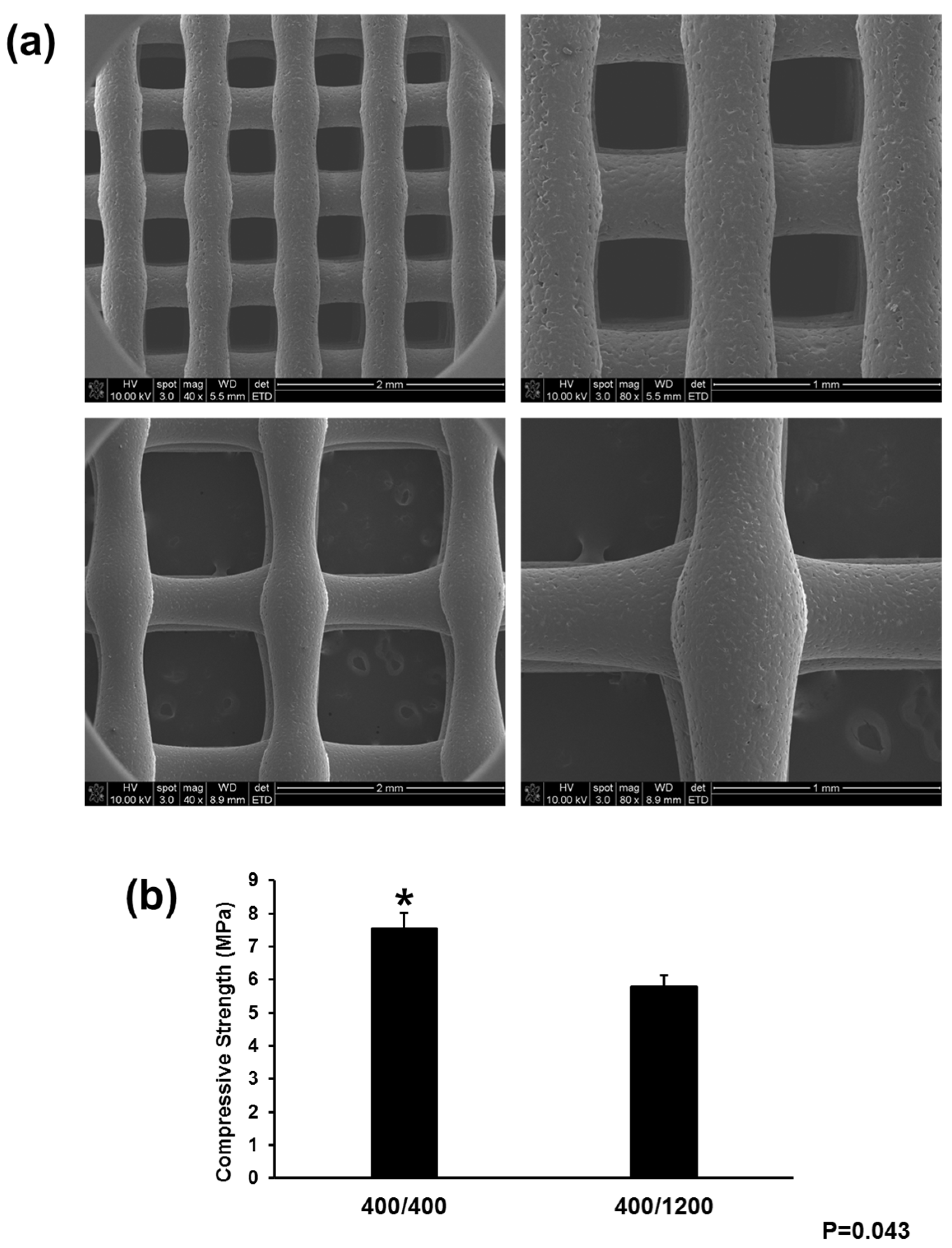

2.1. Scaffold Fabrication

2.2. Scaffold Characterization

2.3. Animal Experiments

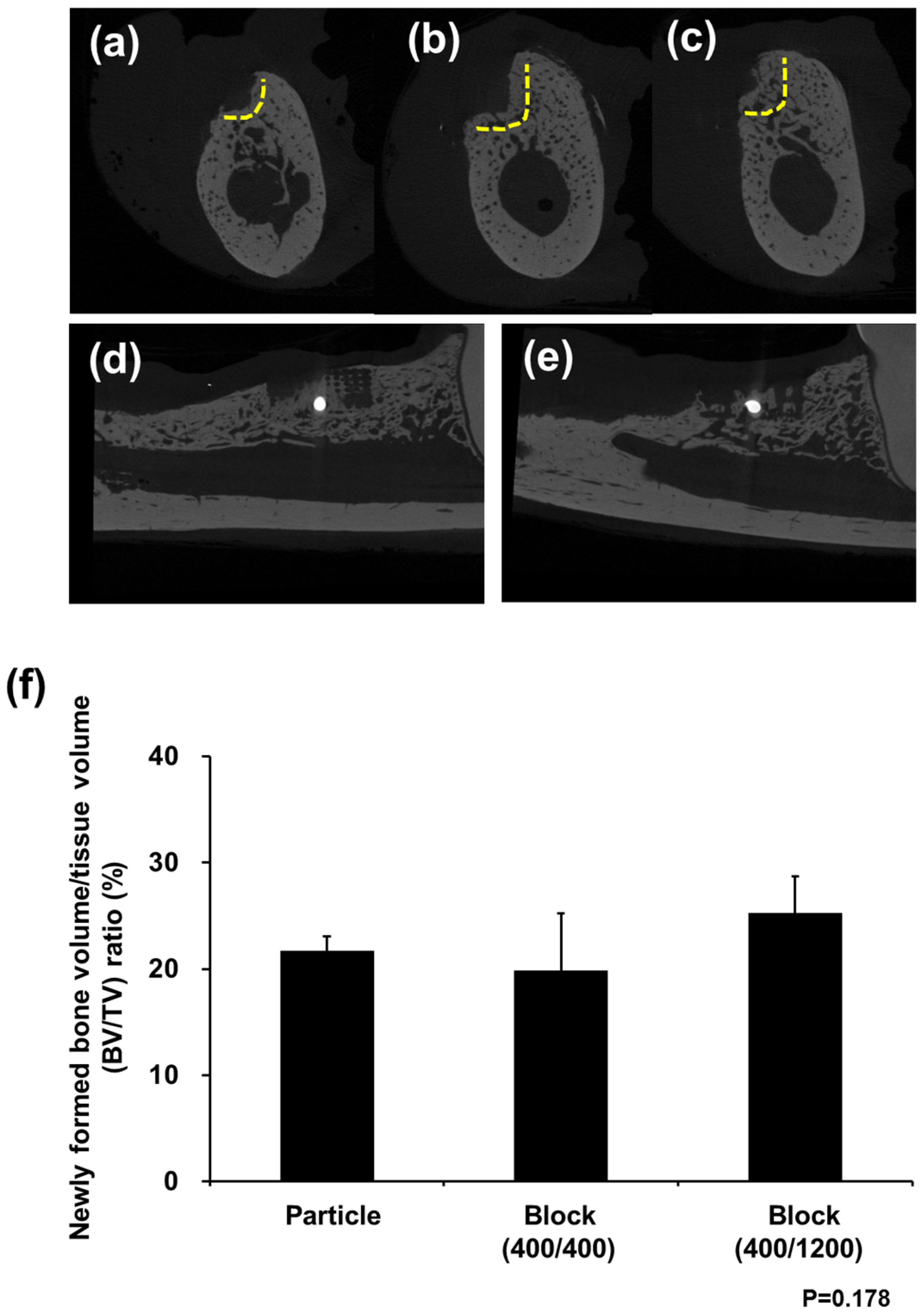

2.4. Micro CT Examination

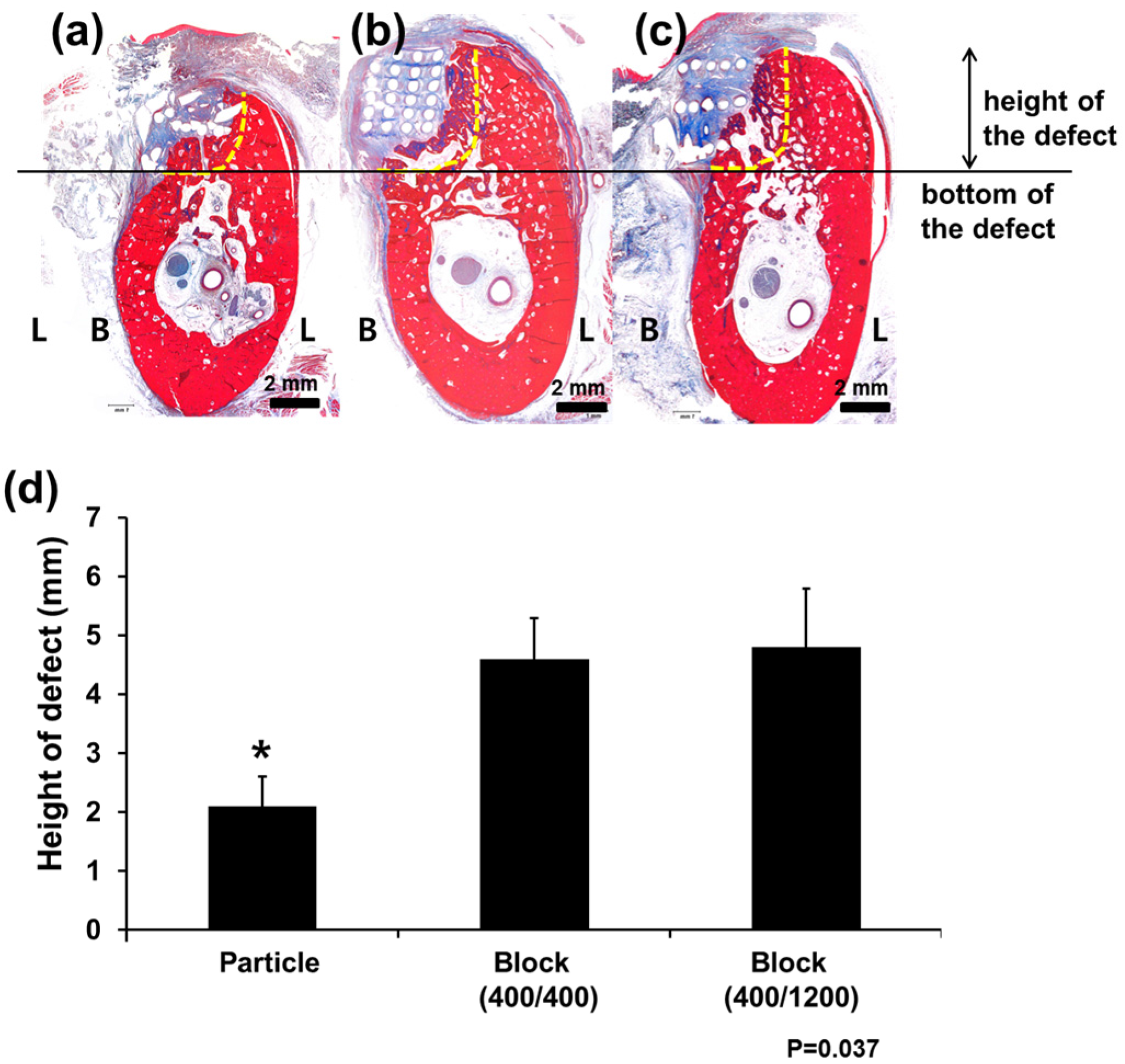

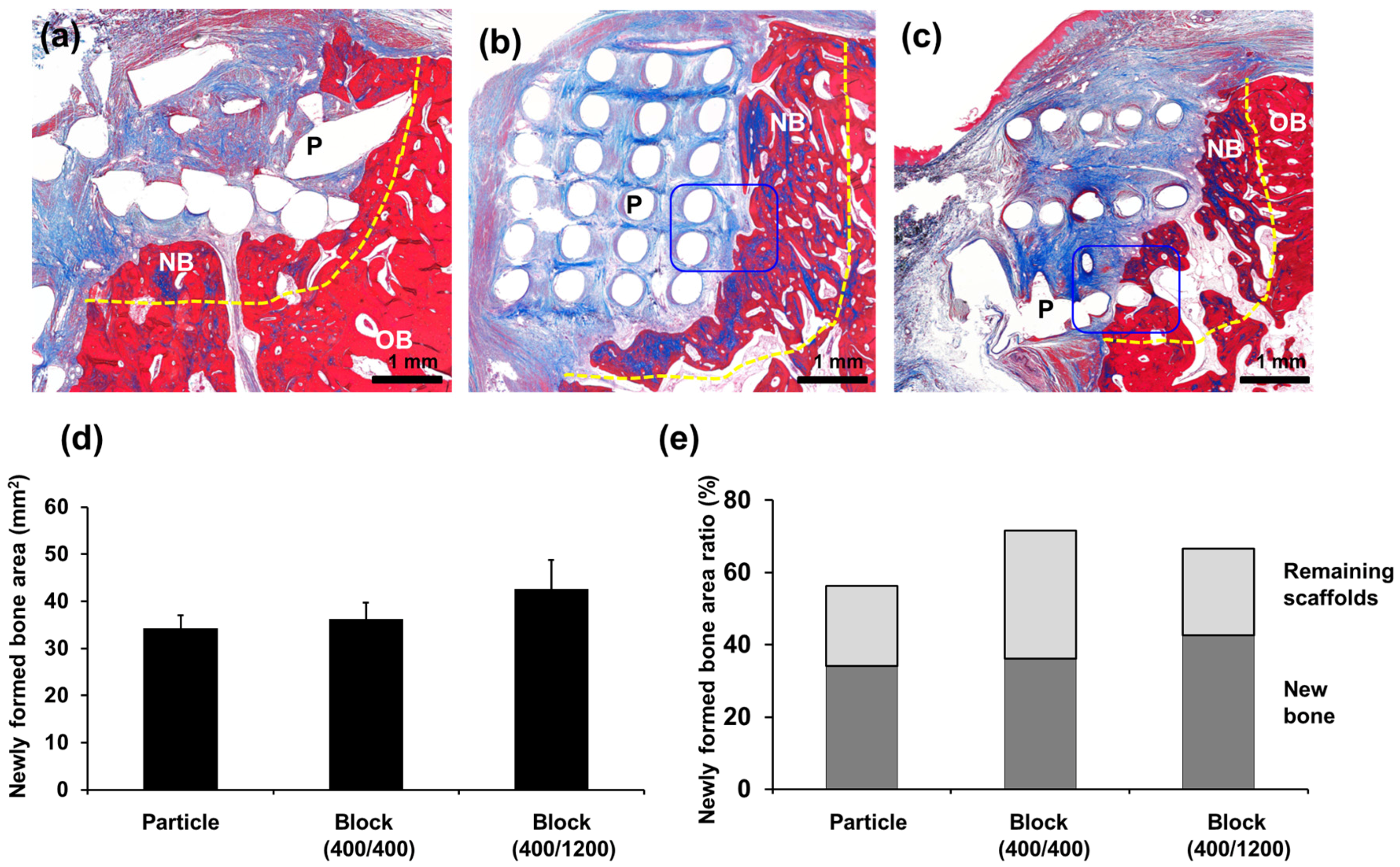

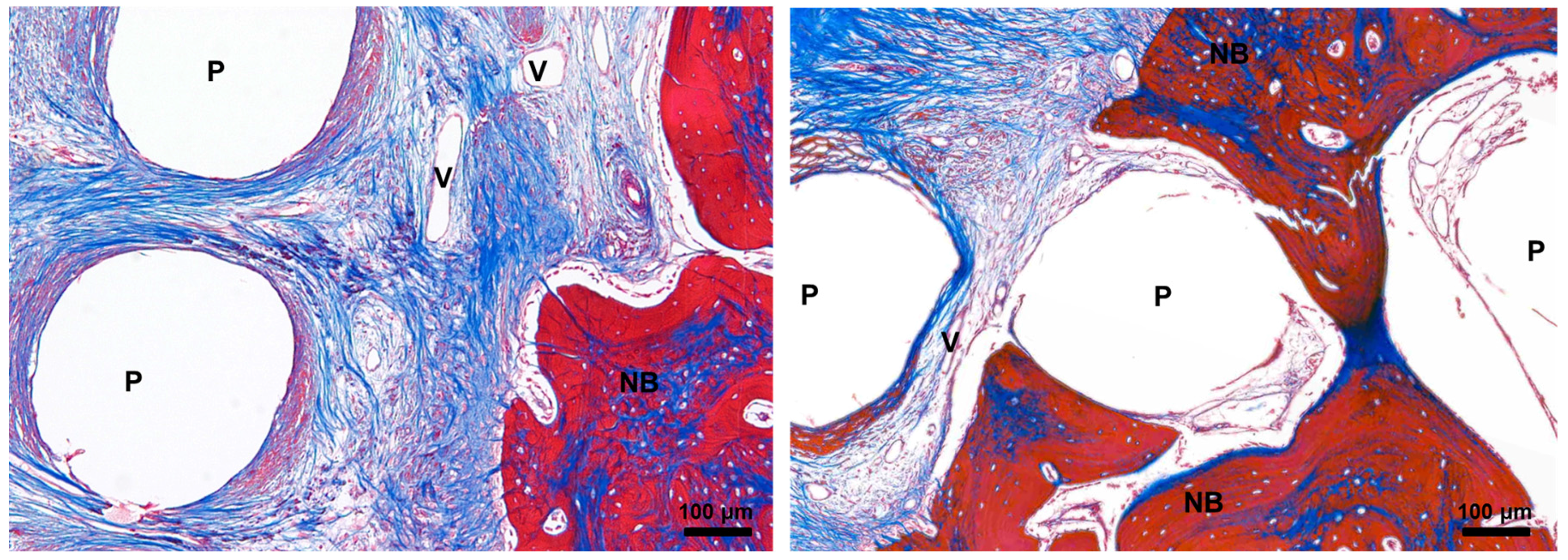

2.5. Histology and Histomorphometric Analysis

2.6. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reynolds, M.A.; Aichelmann-Reidy, M.E.; Branch-Mays, G.L.; Gunsolley, J.C. The efficacy of bone replacement grafts in the treatment of periodontal osseous defects. A systematic review. Ann. Periodontol. 2003, 8, 227–265. [Google Scholar] [CrossRef] [PubMed]

- Haggerty, C.J.; Vogel, C.T.; Fisher, G.R. Simple bone augmentation for alveolar ridge defects. Oral Maxillofac. Surg. Clin. N. Am. 2015, 27, 203–226. [Google Scholar] [CrossRef] [PubMed]

- De Carvalho, P.S.; de Carvalho, M.C.; Ponzoni, D. Reconstruction of alveolar bone defect with autogenous bone particles and osseointegrated implants: Histologic analysis and 10 years monitoring. Ann. Maxillofac. Surg. 2015, 5, 135–139. [Google Scholar] [CrossRef] [PubMed]

- Daga, D.; Mehrotra, D.; Mohammad, S.; Singh, G.; Natu, S.M. Tentpole technique for bone regeneration in vertically deficient alveolar ridges: A review. J. Oral Biol. Craniofac. Res. 2015, 5, 92–97. [Google Scholar] [CrossRef] [PubMed]

- Maiorana, C.; Beretta, M.; Rancitelli, D.; Grossi, G.B.; Cicciu, M.; Herford, A.S. Histological features and biocompatibility of bone and soft tissue substitutes in the atrophic alveolar ridge reconstruction. Case Rep. Dent. 2016, 2016, 3608602. [Google Scholar] [CrossRef] [PubMed]

- Damien, C.J.; Parsons, J.R. Bone graft and bone graft substitutes: A review of current technology and applications. J. Appl. Biomater. 1991, 2, 187–208. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Lan, L.; Miron, R.J.; Wei, L.; Zhang, M.; Zhang, Y. Variability in particle degradation of four commonly employed dental bone grafts. Clin. Implant Dent. Relat. Res. 2015, 17, 996–1003. [Google Scholar] [CrossRef] [PubMed]

- D’Amato, S.; Tartaro, G.; Itro, A.; Nastri, L.; Santagata, M. Block versus particulate/titanium mesh for ridge augmentation for mandibular lateral incisor defects: Clinical and histologic analysis. Int. J. Periodontics Restor. Dent. 2015, 35, e1–e8. [Google Scholar] [CrossRef] [PubMed]

- Rasperini, G.; Pilipchuk, S.P.; Flanagan, C.L.; Park, C.H.; Pagni, G.; Hollister, S.J.; Giannobile, W.V. 3D-printed bioresorbable scaffold for periodontal repair. J. Dent. Res. 2015, 94, 153S–157S. [Google Scholar] [CrossRef] [PubMed]

- Yao, Q.; Wei, B.; Guo, Y.; Jin, C.; Du, X.; Yan, C.; Yan, J.; Hu, W.; Xu, Y.; Zhou, Z.; et al. Design, construction and mechanical testing of digital 3D anatomical data-based PCL-HA bone tissue engineering scaffold. J. Mater. Sci. Mater. Med. 2015, 26, 5360. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.W.; Bae, J.H.; Park, S.A.; Kim, W.D.; Park, M.S.; Ko, Y.J.; Jang, H.S.; Park, J.H. Combination therapy with BMP-2 and BMSCs enhances bone healing efficacy of PCL scaffold fabricated using the 3D plotting system in a large segmental defect model. Biotechnol. Lett. 2012, 34, 1375–1384. [Google Scholar] [CrossRef] [PubMed]

- Park, C.H.; Rios, H.F.; Taut, A.D.; Padial-Molina, M.; Flanagan, C.L.; Pilipchuk, S.P.; Hollister, S.J.; Giannobile, W.V. Image-based, fiber guiding scaffolds: A platform for regenerating tissue interfaces. Tissue Eng. Part C Methods 2014, 20, 533–542. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.S.; Shin, Y.S.; Park do, Y.; Choi, J.W.; Park, J.K.; Kim, D.H.; Kim, C.H.; Park, S.A. The application of three-dimensional printing in animal model of augmentation rhinoplasty. Ann. Biomed. Eng. 2015, 43, 2153–2162. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Kim, G.; Jeon, Y.C.; Koh, Y.; Kim, W. 3D polycaprolactone scaffolds with controlled pore structure using a rapid prototyping system. J. Mater. Sci. Mater. Med. 2009, 20, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, L.; Lv, S.; Li, S.; Wang, N.; Zhang, Z. Fabrication of individual scaffolds based on a patient-specific alveolar bone defect model. J. Biotechnol. 2011, 151, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Cai, L.; Sonawane, B.; Wang, S.; Dong, J. High-precision flexible fabrication of tissue engineering scaffolds using distinct polymers. Biofabrication 2012, 4, 025009. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Park, D.S.; Shin, J.W.; Kang, Y.G.; Kim, H.K.; Yoon, T.R.; Shin, J.W. Scaffolds for bone tissue engineering fabricated from two different materials by the rapid prototyping technique: PCL versus PLGA. J. Mater. Sci. Mater. Med. 2012, 23, 2671–2678. [Google Scholar] [CrossRef] [PubMed]

- Hamid, Q.; Snyder, J.; Wang, C.; Timmer, M.; Hammer, J.; Guceri, S.; Sun, W. Fabrication of three-dimensional scaffolds using precision extrusion deposition with an assisted cooling device. Biofabrication 2011, 3, 034109. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.H.; Lee, L.J.; Kim, J.Y.; Cho, D.W. Bioprinting of a mechanically enhanced three-dimensional dual cell-laden construct for osteo-chondral tissue engineering using a multi-head tissue/organ building system. J. Micromech. Microeng. 2012, 22, 085014. [Google Scholar] [CrossRef]

- Park, S.A.; Lee, S.H.; Kim, W.D. Fabrication of porous polycaprolactone/hydroxyapatite (PCL/HA) blend scaffolds using a 3D plotting system for bone tissue engineering. Bioprocess Biosyst. Eng. 2011, 34, 505–513. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.M.; Adewunmi, A.; Schek, R.M.; Flanagan, C.L.; Krebsbach, P.H.; Feinberg, S.E.; Hollister, S.J.; Das, S. Bone tissue engineering using polycaprolactone scaffolds fabricated via selective laser sintering. Biomaterials 2005, 26, 4817–4827. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.H.; Park, I.K.; Kim, J.M.; Lee, J.H. In vitro and in vivo characteristics of PCL scaffolds with pore size gradient fabricated by a centrifugation method. Biomaterials 2007, 28, 1664–1671. [Google Scholar] [CrossRef] [PubMed]

- Araújo, M.G.; Sukekava, F.; Wennström, J.L.; Lindhe, J. Ridge alterations following implant placement in fresh extraction sockets: An experimental study in the dog. J. Clin. Periodontol. 2005, 32, 645–652. [Google Scholar] [CrossRef] [PubMed]

- Kohal, R.J.; Gubik, S.; Strohl, C.; Stampf, S.; Bachle, M.; Hurrle, A.A.; Patzelt, S.B. Effect of two different healing times on the mineralization of newly formed bone using a bovine bone substitute in sinus floor augmentation: A randomized, controlled, clinical and histological investigation. J. Clin. Periodontol. 2015, 42, 1052–1059. [Google Scholar] [CrossRef] [PubMed]

- Schlegel, K.A.; Fichtner, G.; Schultze-Mosgau, S.; Wiltfang, J. Histologic findings in sinus augmentation with autogenous bone chips versus a bovine bone substitute. Int. J. Oral Maxillofac. Implants 2003, 18, 53–58. [Google Scholar] [PubMed]

- Piattelli, M.; Favero, G.A.; Scarano, A.; Orsini, G.; Piattelli, A. Bone reactions to anorganic bovine bone (Bio-Oss) used in sinus augmentation procedures: A histologic long-term report of 20 cases in humans. Int. J. Oral Maxillofac. Implants 1999, 14, 835–840. [Google Scholar] [PubMed]

- Charles, L.F.; Shaw, M.T.; Olson, J.R.; Wei, M. Fabrication and mechanical properties of PLLA/PCL/HA composites via a biomimetic, dip coating, and hot compression procedure. J. Mater. Sci. Mater. Med. 2010, 21, 1845–1854. [Google Scholar] [CrossRef] [PubMed]

- Roh, H.S.; Myung, S.W.; Jung, S.C.; Kim, B.H. Fabrication of 3D scaffolds with nano-hydroxyapatite for improving the preosteoblast cell-biological performance. J. Nanosci. Nanotechnol. 2015, 15, 5585–5588. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.H.; Moon, T.S.; Yun, M.J.; Jeon, Y.C.; Jeong, C.M.; Cho, D.W.; Huh, J.B. Stimulation of healing within a rabbit calvarial defect by a PCL/PLGA scaffold blended with TCP using solid freeform fabrication technology. J. Mater. Sci. Mater. Med. 2012, 23, 2993–3002. [Google Scholar] [CrossRef] [PubMed]

- Heo, S.J.; Kim, S.E.; Wei, J.; Hyun, Y.T.; Yun, H.S.; Kim, D.H.; Shin, J.W.; Shin, J.W. Fabrication and characterization of novel nano- and micro-HA/PCL composite scaffolds using a modified rapid prototyping process. J. Biomed. Mater. Res. A 2009, 89, 108–116. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ye, M.; Liu, Z.; Wang, C. Precision of cortical bone reconstruction based on 3D CT scans. Comput. Med. Imaging Graph. 2009, 33, 235–241. [Google Scholar] [CrossRef] [PubMed]

- Lalone, E.A.; Willing, R.T.; Shannon, H.L.; King, G.J.; Johnson, J.A. Accuracy assessment of 3D bone reconstructions using CT: An intro comparison. Med. Eng. Phys. 2015, 37, 729–738. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.A.; Lee, H.-J.; Kim, K.-S.; Lee, S.J.; Lee, J.-T.; Kim, S.-Y.; Chang, N.-H.; Park, S.-Y. In Vivo Evaluation of 3D-Printed Polycaprolactone Scaffold Implantation Combined with β-TCP Powder for Alveolar Bone Augmentation in a Beagle Defect Model. Materials 2018, 11, 238. https://doi.org/10.3390/ma11020238

Park SA, Lee H-J, Kim K-S, Lee SJ, Lee J-T, Kim S-Y, Chang N-H, Park S-Y. In Vivo Evaluation of 3D-Printed Polycaprolactone Scaffold Implantation Combined with β-TCP Powder for Alveolar Bone Augmentation in a Beagle Defect Model. Materials. 2018; 11(2):238. https://doi.org/10.3390/ma11020238

Chicago/Turabian StylePark, Su A., Hyo-Jung Lee, Keun-Suh Kim, Sang Jin Lee, Jung-Tae Lee, Sung-Yeol Kim, Na-Hee Chang, and Shin-Young Park. 2018. "In Vivo Evaluation of 3D-Printed Polycaprolactone Scaffold Implantation Combined with β-TCP Powder for Alveolar Bone Augmentation in a Beagle Defect Model" Materials 11, no. 2: 238. https://doi.org/10.3390/ma11020238

APA StylePark, S. A., Lee, H.-J., Kim, K.-S., Lee, S. J., Lee, J.-T., Kim, S.-Y., Chang, N.-H., & Park, S.-Y. (2018). In Vivo Evaluation of 3D-Printed Polycaprolactone Scaffold Implantation Combined with β-TCP Powder for Alveolar Bone Augmentation in a Beagle Defect Model. Materials, 11(2), 238. https://doi.org/10.3390/ma11020238