Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Simulation Assessment

Abstract

1. Introduction

1.1. Motivation

1.2. State-of-the-Art

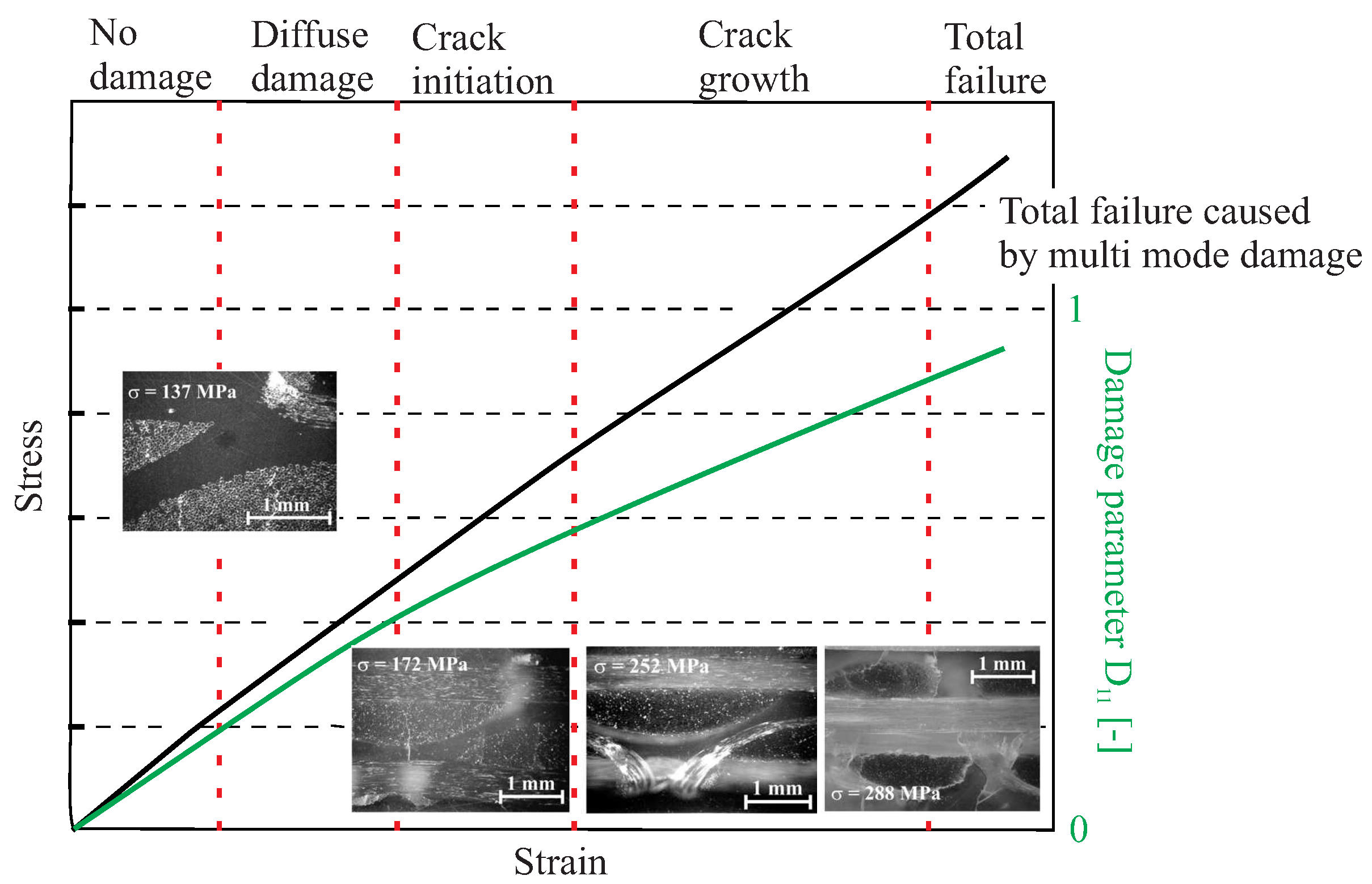

1.3. Gradual Damage Behaviour of Composite Materials

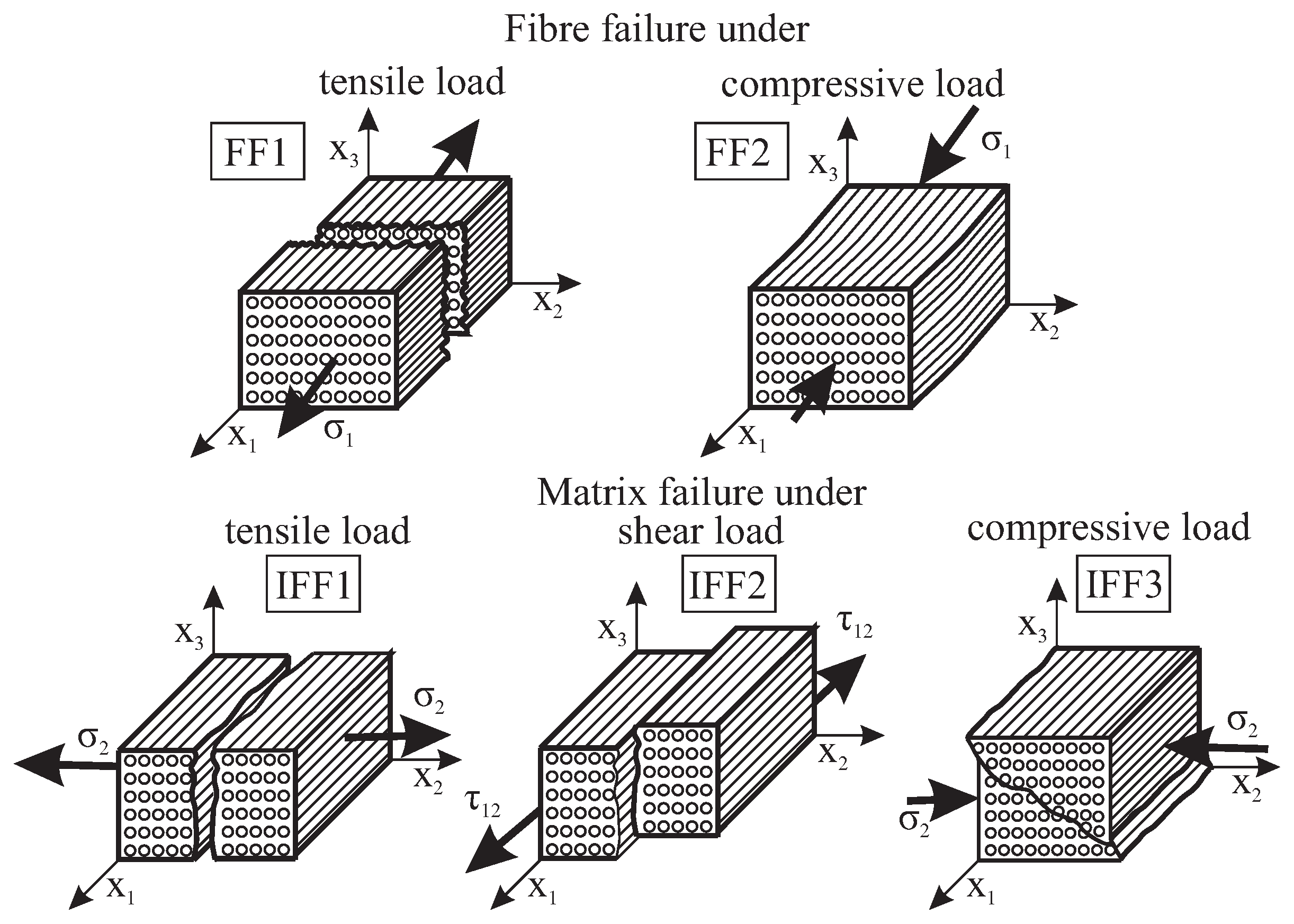

1.4. Damage Initiation Modes

1.5. Damage Evolution Approach

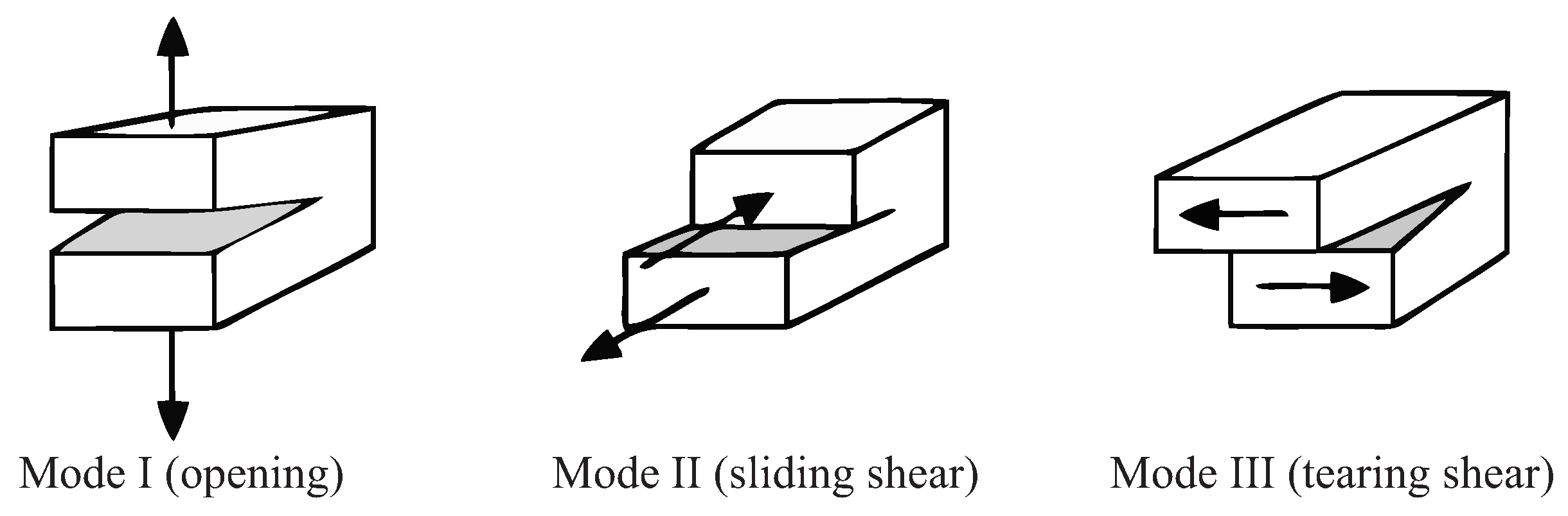

1.6. Delamination Mechanisms

1.7. Aim and Outline of the Paper

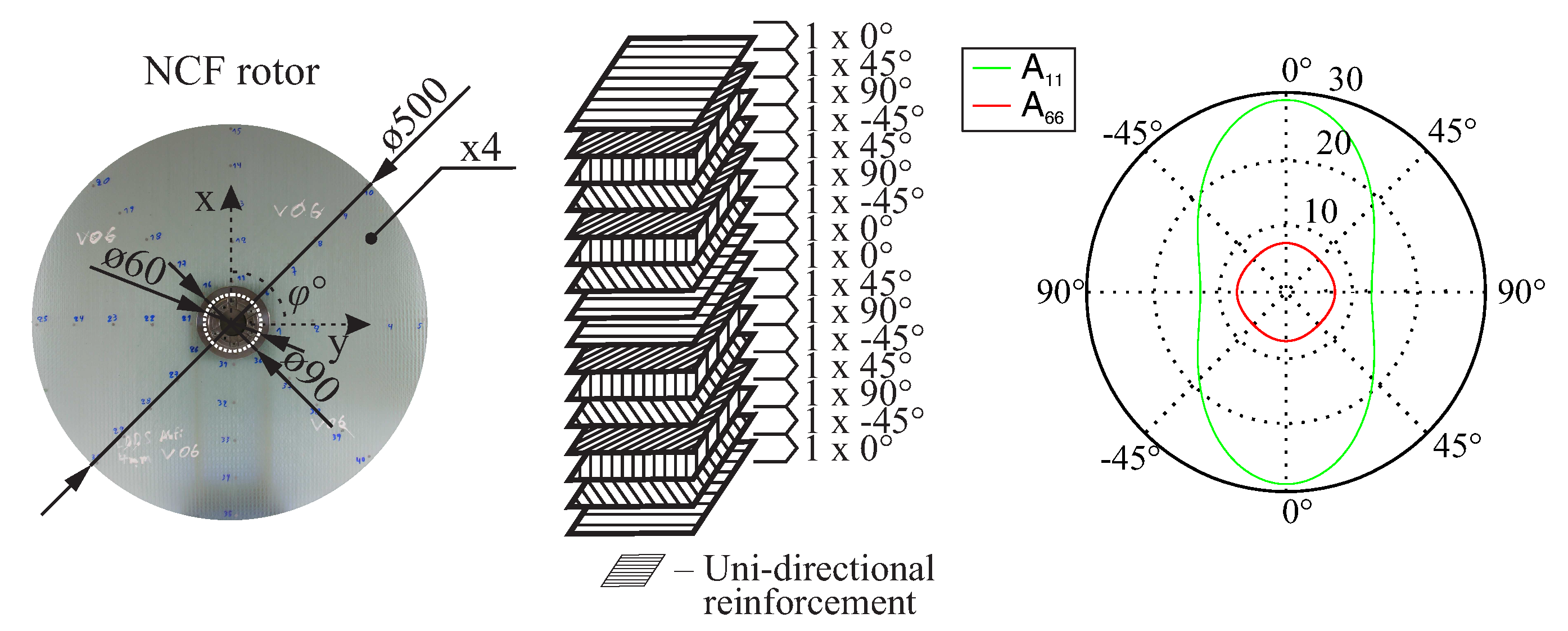

2. Selection of Representative Fibre Architecture for Composite Rotors and Manufacturing

2.1. Multi-Ply Multi-Axial Fabric

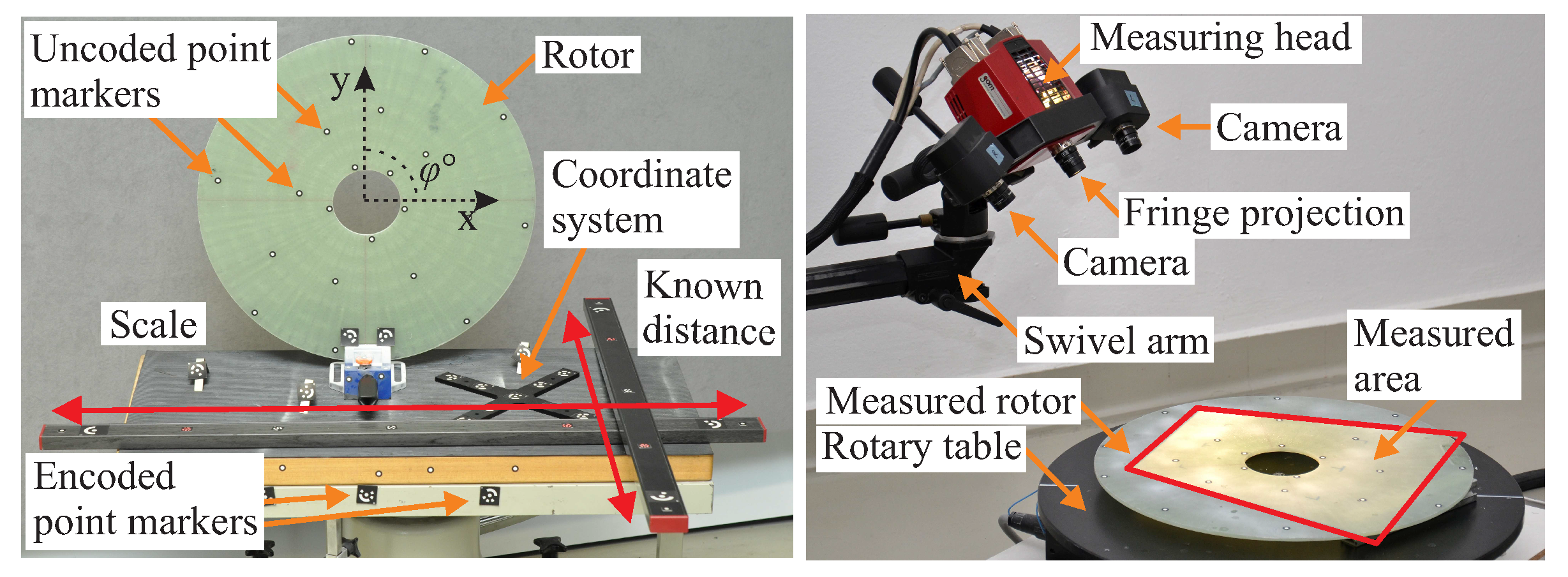

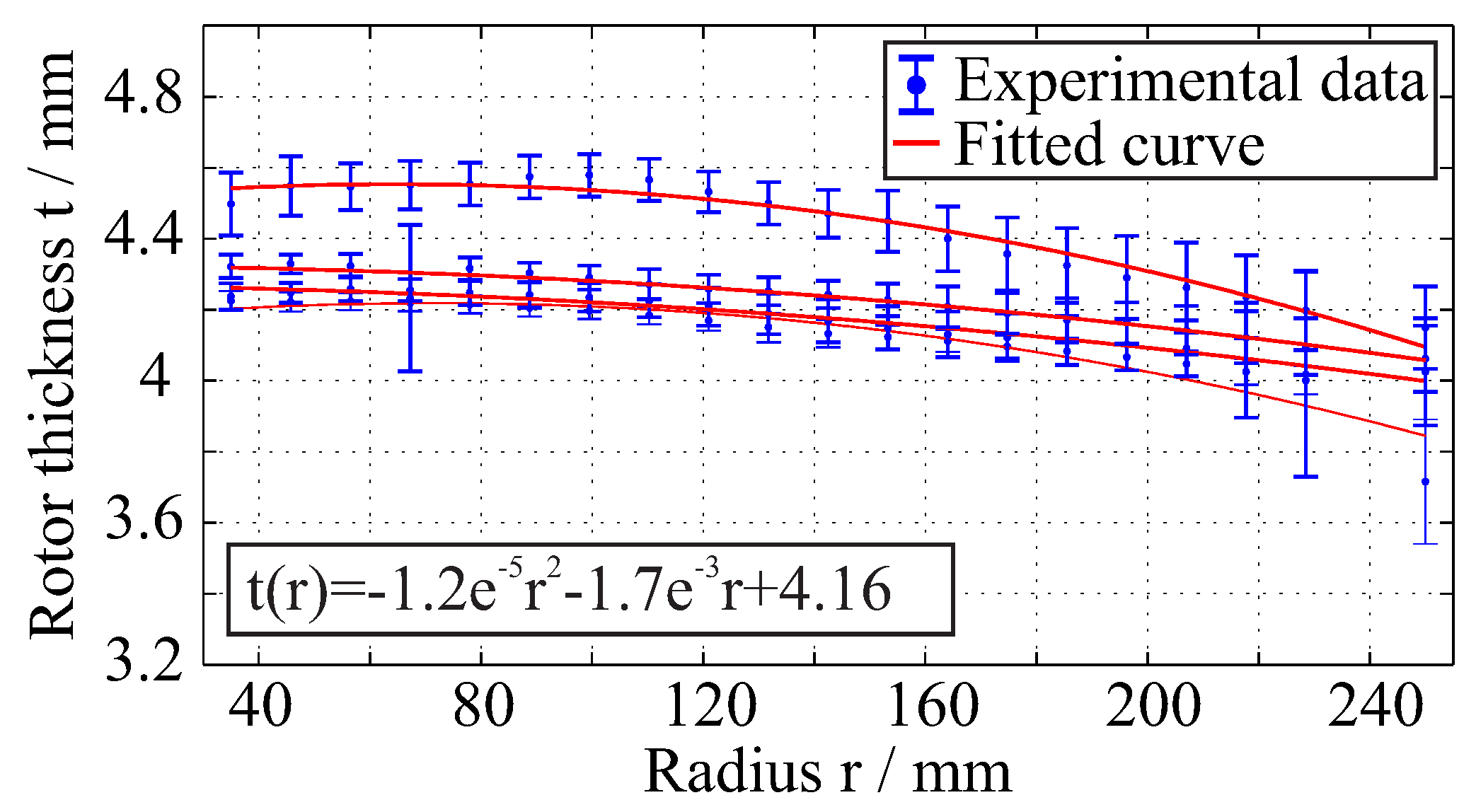

2.2. Quality Assessment of Manufactured Rotors

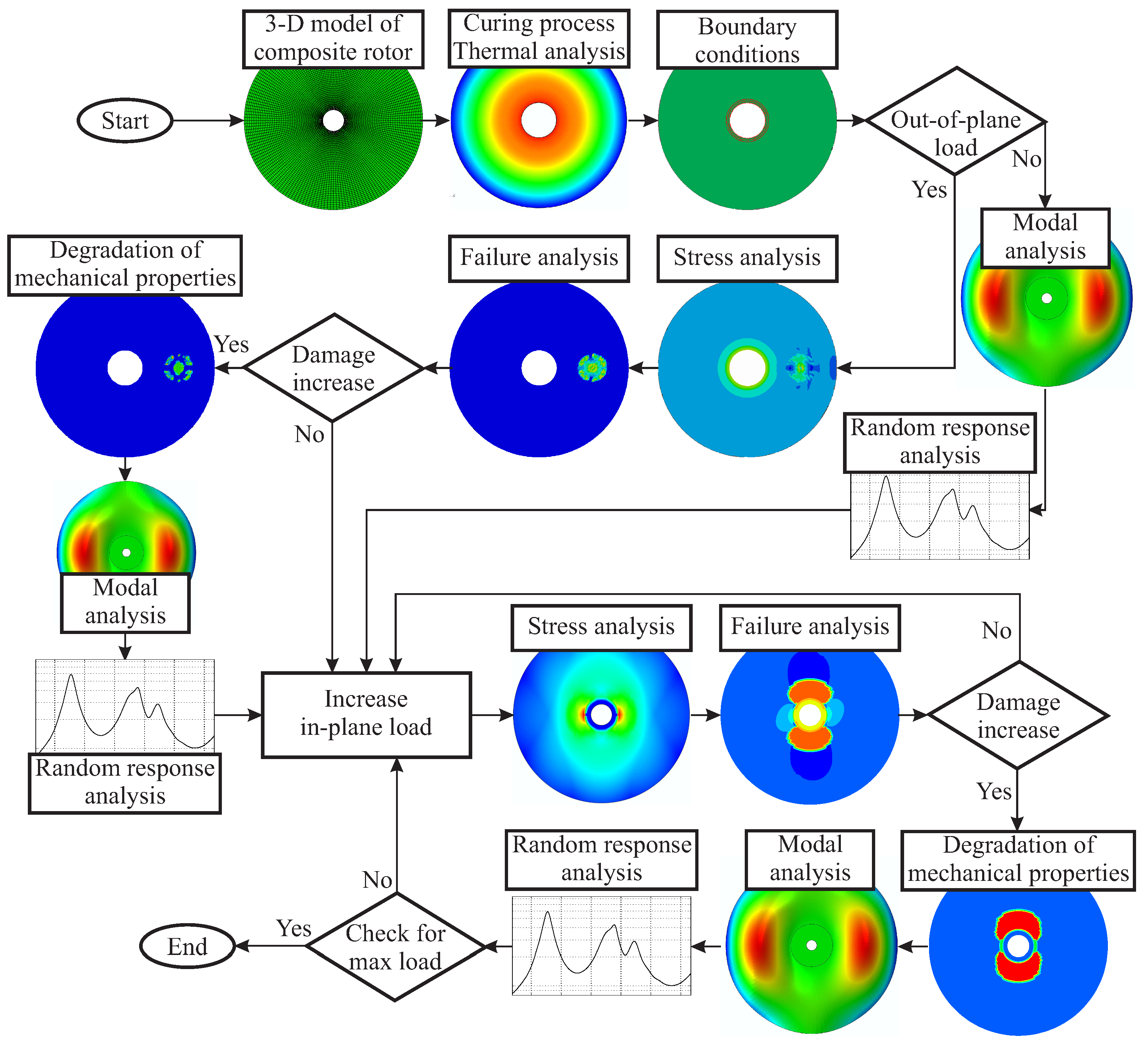

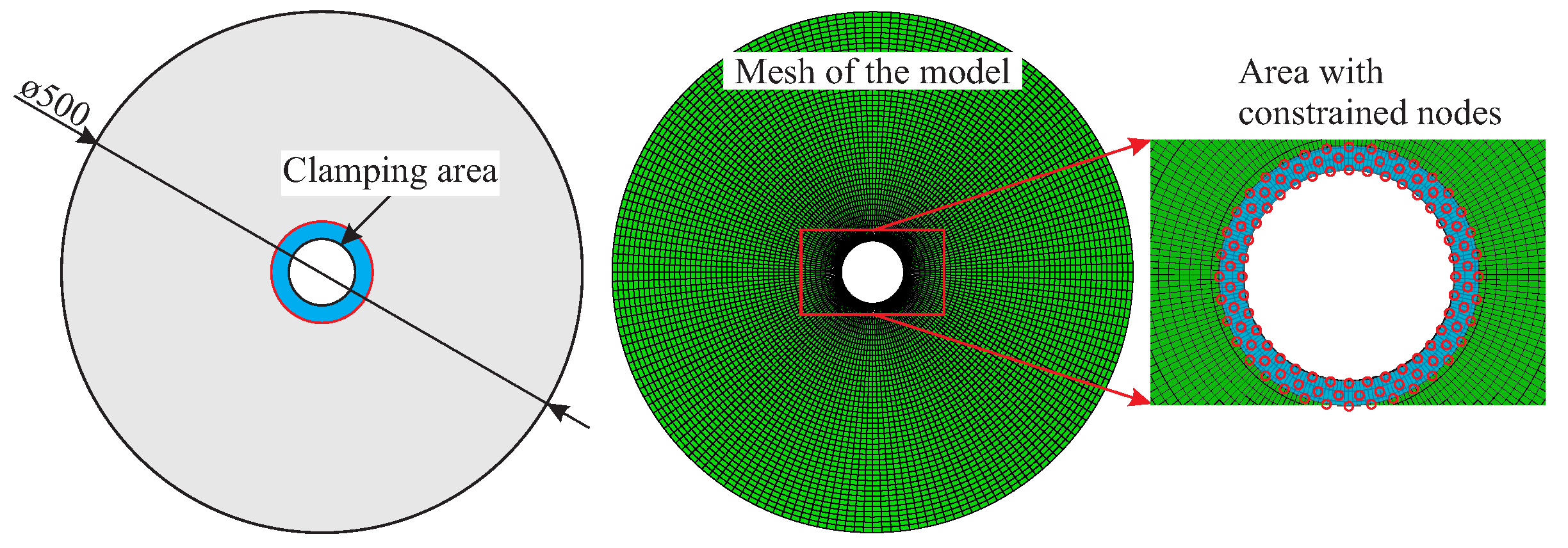

3. Development of a Parametric Simulation Model

4. Assessment of the Parametric Simulation Model

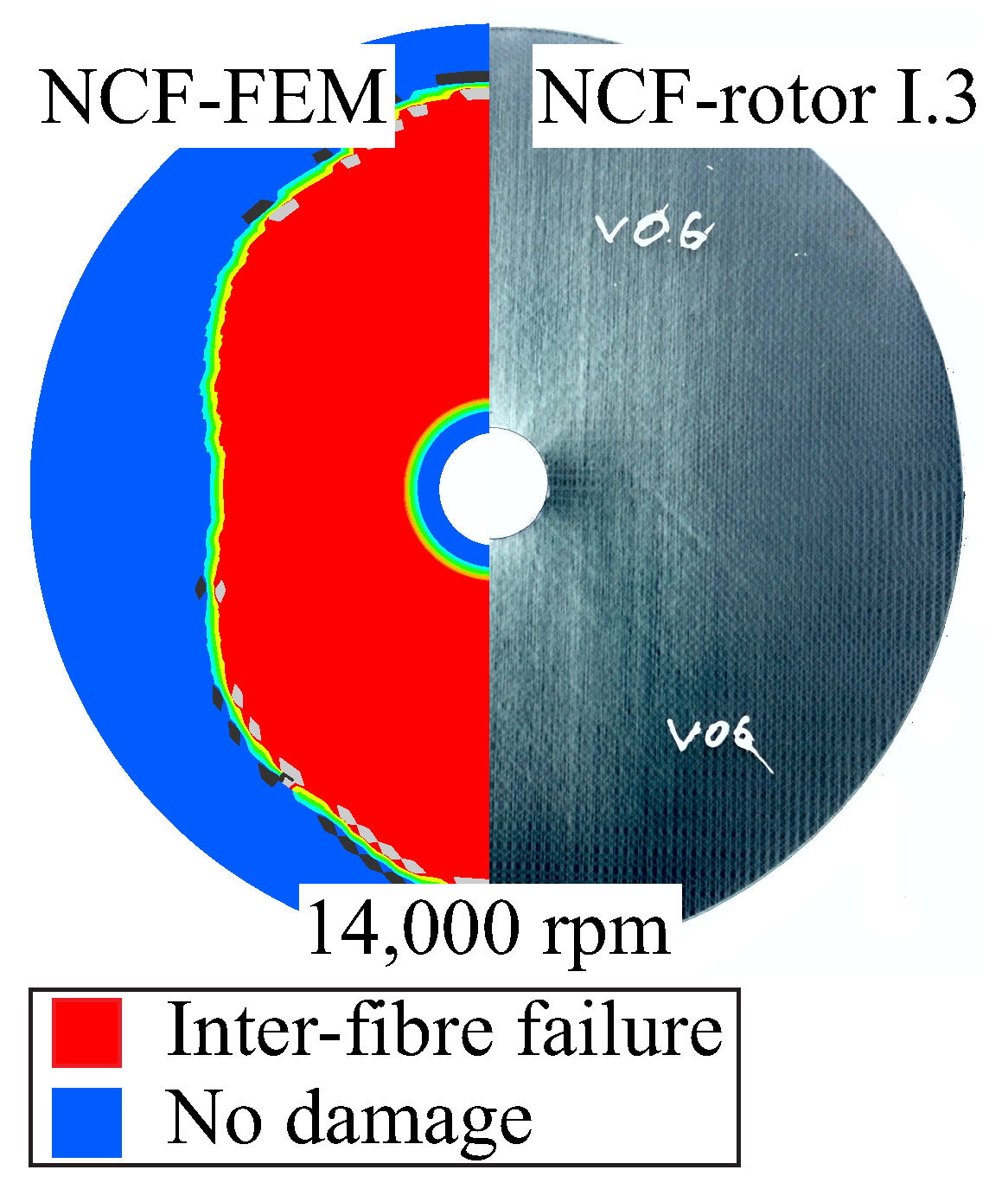

4.1. Damage State and Damage Evolution

4.2. Modal Properties

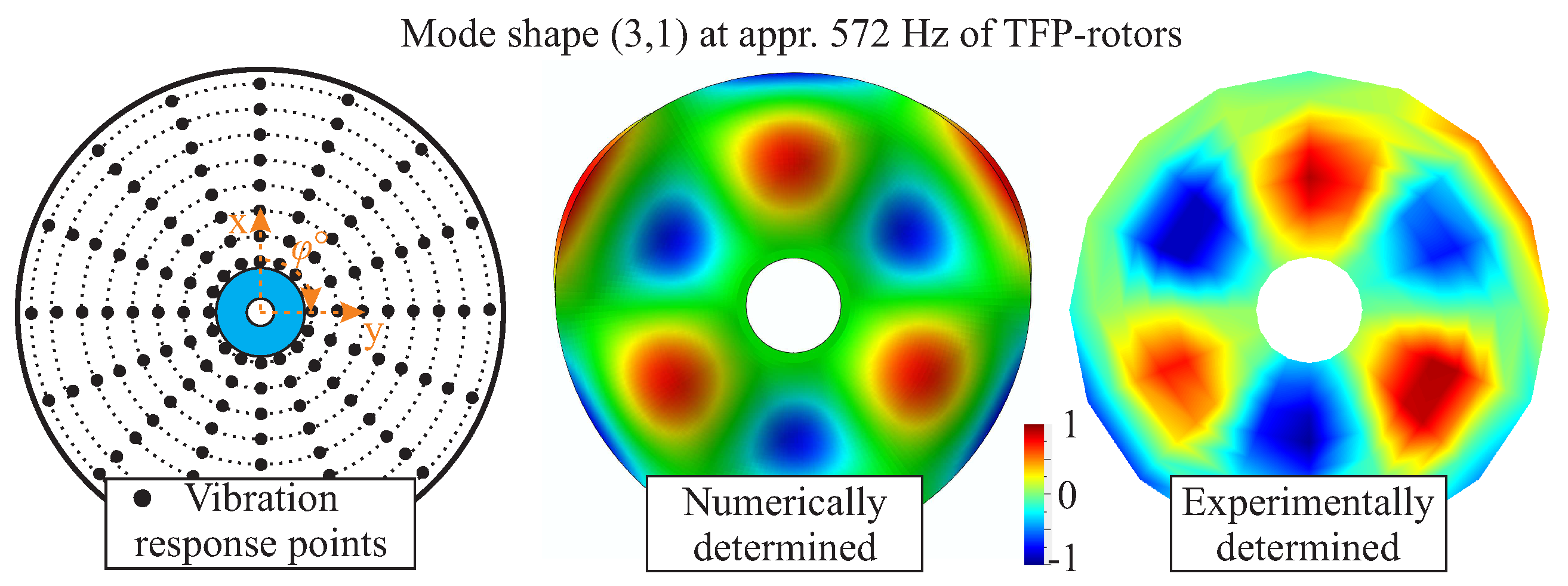

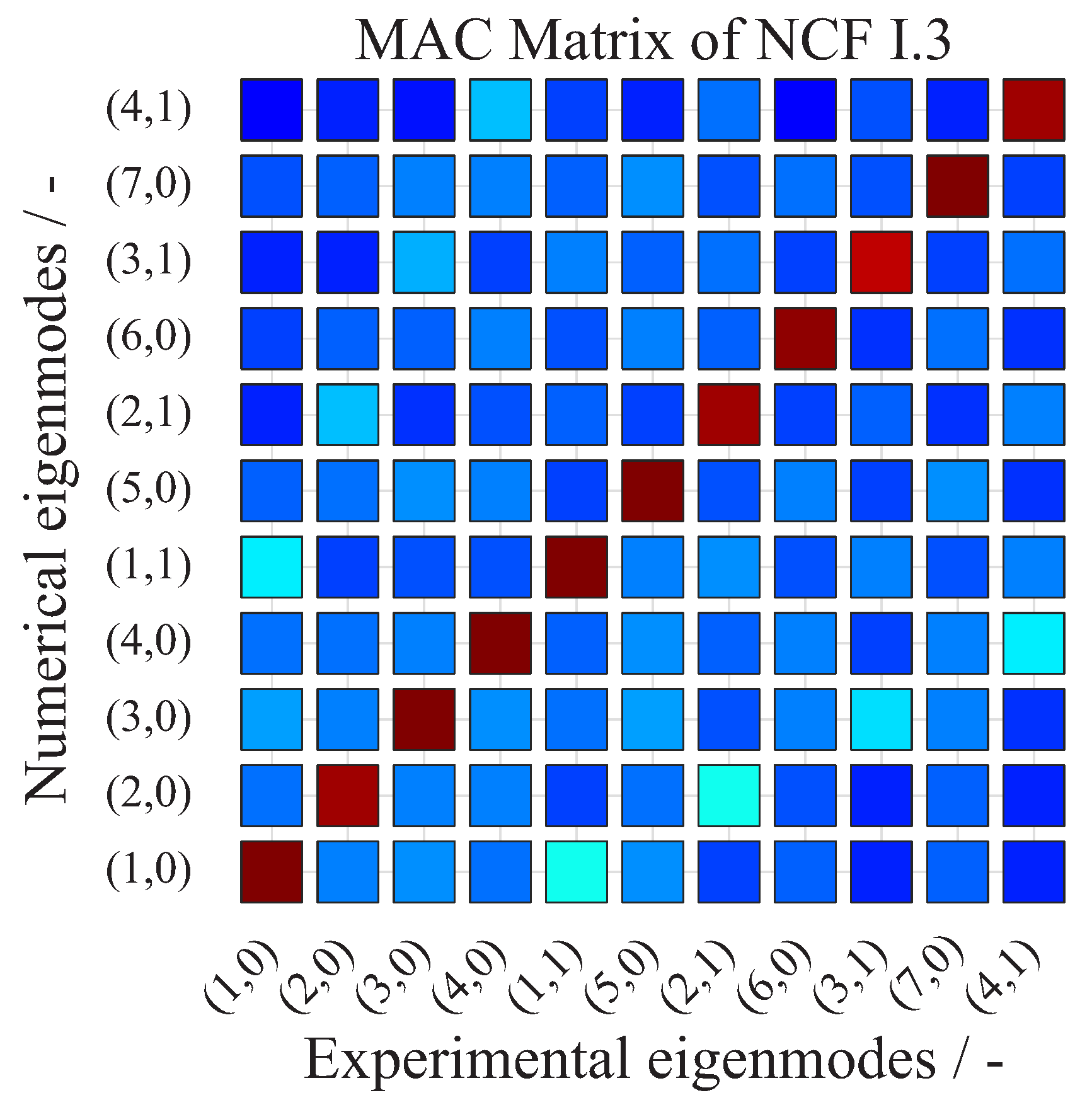

4.2.1. Mode Shapes of Intact Rotors

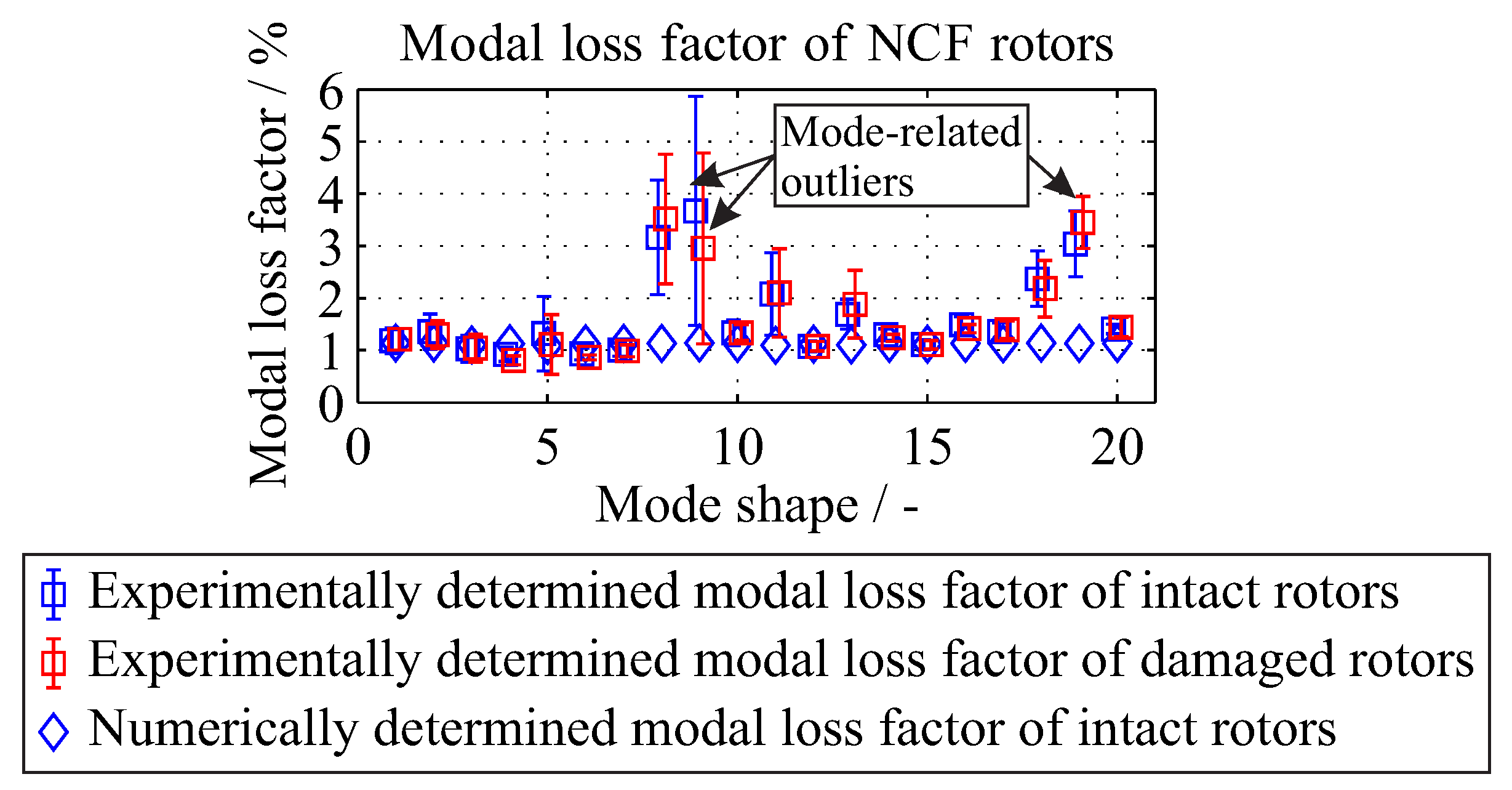

4.2.2. Modal Loss Factor

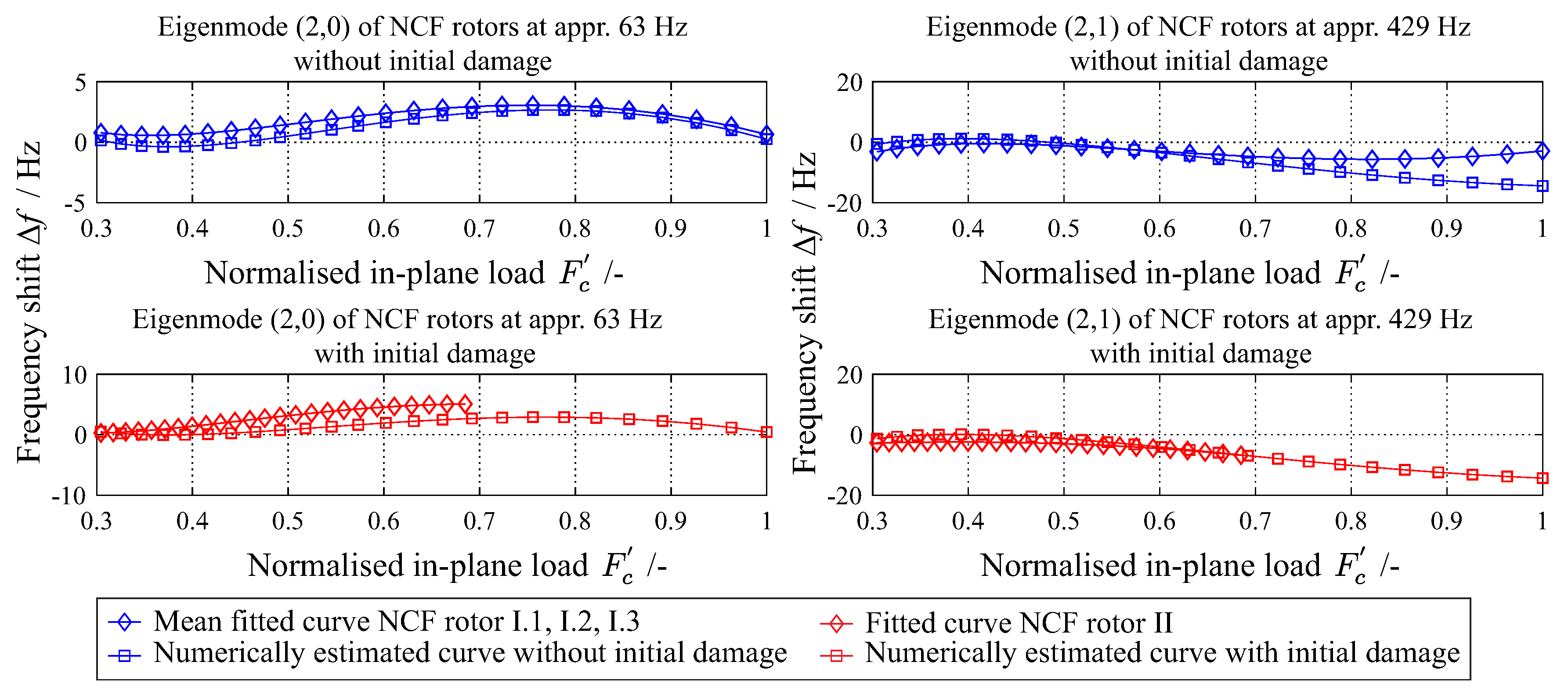

4.3. Change of Eigenfrequencies Due to Damage Increase

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| FMC | Failure Mode Concept |

| IFF | Inter-fibre failure |

| FF | Faibre failure |

| NCF | Non-crimp fabric |

| VARTM | vacuum-assisted resin transfer moulding |

| ATOS | Advanced topometric optical sensor |

| FE | Finite element |

| USDFLD | user-defined field subroutine |

| MAC | Modal assurance criterion |

| EF | Eigenfrequency |

References

- Sohn, H.; Farrar, C.R.; Hemez, F.M.; Shunk, D.D.; Stinemates, D.W.; Nadler, B.R.; Czarnecki, J.J. A Review of Structural Health Monitoring Literature: 1996–2001; Los Alamos National Laboratory: Los Alamos, NM, USA, 2004.

- Mitchell, T.M. Machine Learning; McGraw Hill: New York, NY, USA, 1997. [Google Scholar]

- Deo, R.B.; Starnes, J.H., Jr.; Holzwarth, R.C. Low-cost composite materials and structures for aircraft applications. In Proceedings of the RTO Applied Vehicle Technology Panel Specialists Meeting on Low Cost Composite Structures, Loen, Norway, 7–11 May 2003; Volume 1, pp. 1–11. [Google Scholar]

- James, G.; Mayes, R.; Carne, T.; Reese, G. Damage Detection and Health Monitoring of Operational Structures; Sandia National Labs.: Albuquerque, NM, USA, 1994; pp. 1–10.

- Kostka, P.; Filippatos, A.; Höhne, R.; Hufenbach, W. A simulation-based monitoring of a composite plate using an integrated vibration measurement system. Key Eng. Mater. 2013, 569–570, 64–71. [Google Scholar] [CrossRef]

- Böhm, R.; Gude, M.; Hufenbach, W. A phenomenologically based damage model for textile composites with crimped reinforcement. Compos. Sci. Technol. 2010, 70, 81–87. [Google Scholar] [CrossRef]

- Gude, M. Modellierung von Faserverstärkten Verbundwerkstoffen und Funktionsintegrierenden Leichtbaustrukturen für komplexe Beanspruchungen; Habilitation, Technische Universität Dresden: Dresden, Germany, 2008. [Google Scholar]

- Hashin, Z. Failure criteria for unidirectional fiber composites. J. Appl. Mech. Trans. ASME 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Puck, A. Festigkeitsanalyse von Faser-Matrix-Laminaten: Modelle für die Praxis; Hanser München: Munich, Germany, 1996. [Google Scholar]

- Cuntze, R.; Freund, A. The predictive capability of failure mode concept-based strength criteria for multidirectional laminates. Compos. Sci. Technol. 2004, 64, 343–377. [Google Scholar] [CrossRef]

- Böhm, R.; Hufenbach, W. Experimentally based strategy for damage analysis of textile-reinforced composites under static loading. Compos. Sci. Technol. 2010, 70, 1330–1337. [Google Scholar] [CrossRef]

- Kuschmierz, R.; Filippatos, A.; Günther, P.; Langkamp, A.; Hufenbach, W.; Czarske, J.; Fischer, A. In-process, non-destructive, dynamic testing of high-speed polymer composite rotors. Mecha. Syst. Signal Process. 2015, 54-55, 325–335. [Google Scholar] [CrossRef]

- Chang, F.K. Structural Health Monitoring 2000; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Simulia, D.S. Abaqus 6.13 User’s Manual; Dassault Systémes Simulia Corp.: Providence, RI, USA, 2013. [Google Scholar]

- Kostka, P.; Filippatos, A.; Hufenbach, W. A numerical analysis of the dynamic behaviour of a composite rotor considering its sequential damage process. In Proceedings of the 6th European Workshop on Structural Health Monitoring, Dresden, Germany, 3–6 July 2012; pp. 251–260. [Google Scholar]

- Hufenbach, W.; Kroll, L.; Gude, M.; Langkamp, A. Novel lightweight solutions by load-adapted textile reinforcements. In Proceedings of the 11th International Scientific Conference Achievements in Mechanical & Material Engineering, Gliwice & Zakopane, Poland, 15–18 December 2002; Volume 15, pp. 237–242. [Google Scholar]

- Hufenbach, W.; Köhler, K. Textile Verbundbauweisen und Fertigungstechnologien für Leichtbaustrukturen des Maschinen-und Fahrzeugbaus; Technische Universität Dresden: Dresden, Germany, 2008. [Google Scholar]

- Cuntze, R.G. Neue Bruchkriterien und Festigkeitsnachweise für Unidirektionalen Faserkunststoffverbund unter Mehrachsiger Beanspruchung: Modellbildung und Experimente; VDI-Verlag: Düsseldorf, Germany, 1997; Volume 506. [Google Scholar]

- Böhm, R.; Gude, M.; Hufenbach, W. A phenomenologically based damage model for 2D and 3D-textile composites with non-crimp reinforcement. Mater. Des. 2011, 32, 2532–2544. [Google Scholar] [CrossRef]

- Hufenbach, W.; Langkamp, A.; Kostka, P.; Böhm, R. Damage behaviour of high speed textile reinforced composite rotors. Kompoz.-Compos. 2005, 2, 23–28. [Google Scholar]

- Hufenbach, W.; Gude, M.; Freund, A. Realitätsnahe Simulation des Schädigungsverhaltens von Blindnietverbindungen in CFK/Al-Strukturen infolge thermomechanischer Beanspruchung. In Proceedings of the NAFEMS Seminar “Simulation von Verbunden: Material und Strukturen”, Bad Kissingen, Germany, 6–7 November 2007; pp. 1–8. [Google Scholar]

- Wisnom, M.R. The role of delamination in failure of fibre-reinforced composites. Philos. Trans. R. Soc. Lond. Ser. A 2012, 370, 1850–1870. [Google Scholar] [CrossRef]

- Turon, A.; Costa, J.; Camanho, P.P.; Dávila, C.G. Simulation of delamination in composites under high-cycle fatigue. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2270–2282. [Google Scholar] [CrossRef]

- Krueger, R. Virtual crack closure technique: History, approach, and applications. Appl. Mech. Rev. 2004, 57, 109–143. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Lessard, L.B. Progressive fatigue damage modeling of composite materials, Part I: Modeling. J. Compos. Mater. 2000, 34, 1056–1080. [Google Scholar] [CrossRef]

- Hufenbach, W.; Hornig, A.; Gude, M.; Böhm, R.; Zahneisen, F. Influence of interface waviness on delamination characteristics and correlation of through-thickness tensile failure with mode I energy release rates in carbon fibre textile composites. Mater. Des. 2013, 50, 839–845. [Google Scholar] [CrossRef]

- Brewer, J.C.; Lagace, P.A. Quadratic stress criterion for initiation of delamination. J. Compos. Mater. 1988, 22, 1141–1155. [Google Scholar] [CrossRef]

- Johnson, A.F.; Pickett, A.K.; Rozycki, P. Computational methods for predicting impact damage in composite structures. Compos. Sci. Technol. 2001, 61, 2183–2192. [Google Scholar] [CrossRef]

- Petrossian, Z.; Wisnom, M.R. Prediction of delamination initiation and growth from discontinuous plies using interface elements. Compos. Part A Appl. Sci. Manuf. 1998, 29, 503–515. [Google Scholar] [CrossRef]

- Kutlu, Z.; Chang, F.K. Modeling compression failure of laminated composites containing multiple through-the-width delaminations. J. Compos. Mater. 1992, 26, 350–387. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Lessard, L.B.; Poon, C. Three-dimensional progressive failure analysis of pin/bolt loaded composite laminates. In Proceedings of the AGARD Conference, Florence, Italy, 2–3 September 1996; Volume 590, pp. 1–10. [Google Scholar]

- Chang, F.K.; Kutlu, Z. Strength and response of cylindrical composite shells subjected to out-of-plane loadings. J. Compos. Mater. 1989, 23, 11–31. [Google Scholar] [CrossRef]

- Filippatos, A.; Gude, M. Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Experimental Investigations. Materials 2018, 11, 2421. [Google Scholar] [CrossRef]

- Hufenbach, W.; Archodoulakis, G.; Grothaus, R.; Kroll, L.; Langkamp, A. Variable-axial composites for complexly loaded high-speed rotors. In Proceedings of the 12th International Conference on Composite Materials (ICCM 12), Paris, France, 5–9 July 1999; Volume 5, pp. 1–8. [Google Scholar]

- Hufenbach, W.; Kroll, L.; Grothaus, R. New design methods for complexly loaded high-speed composite rotors. In Proceedings of the 8th European Conference on Composite Materials, Naples, Italy, 3–6 June 1998; pp. 511–518. [Google Scholar]

- Filippatos, A.; Dannemann, M.; Wohlfahrt, D.; Modler, N.; Schmidt, T. Design of a highly damped fibre-reinforced lightweight mast for automated storage systems in logistics. In Proceedings of the 23rd International Congress on Sound and Vibration, Athens, Greece, 10–14 July 2016; pp. 1–8. [Google Scholar]

- Wollmann, T.; Modler, N.; Dannemann, M.; Langkamp, A.; Nitschke, S.; Filippatos, A. Design and testing of composite compressor blades with focus on the vibration behaviour. Compos. Part A Appl. Sci. Manuf. 2017, 92, 183–189. [Google Scholar] [CrossRef]

- Ungar, E.E.; Kerwin, E.M., Jr. Loss factors of viscoelastic systems in terms of energy concepts. J. Acoust. Soc. Am. 1962, 34, 954–957. [Google Scholar] [CrossRef]

- Berthelot, J.M.; Assarar, M.; Sefrani, Y.; El Mahi, A. Damping analysis of composite materials and structures. Compos. Struct. 2008, 85, 189–204. [Google Scholar] [CrossRef]

- Kostka, P.; Holeczek, K.; Höhne, R.; Filippatos, A.; Modler, N. Extension and application of dynamic mechanical analysis for the estimation of spatial distribution of material properties. Polym. Test. 2016, 52, 184–191. [Google Scholar] [CrossRef]

- Schedlinski, C.; Wagner, F.; Bohnert, K.; Frappier, J.; Irrgang, A.; Lehmann, R.; Müller, A. Experimental modal analysis and computational model updating of a car body in white. In Proceedings of the International Conference on Noise and Vibration Engineering ISMA, Leuven, Belgium, 15–17 September 2004; pp. 1–12. [Google Scholar]

- Dannemann, M.; Täger, O.; Modler, N. Combined semi-analytical and numerical vibro-acoustic design approach for anisotropic fibre-reinforced composite structures. J. Sound Vib. 2017, 404, 1–14. [Google Scholar] [CrossRef]

- Holeczek, K.; Kostka, P.; Modler, N. Dry friction contribution to damage-caused increase of damping in fiber-reinforced polymer-based composites. Adv. Eng. Mater. 2014, 16, 1284–1292. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filippatos, A.; Langkamp, A.; Gude, M. Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Simulation Assessment. Materials 2018, 11, 2453. https://doi.org/10.3390/ma11122453

Filippatos A, Langkamp A, Gude M. Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Simulation Assessment. Materials. 2018; 11(12):2453. https://doi.org/10.3390/ma11122453

Chicago/Turabian StyleFilippatos, Angelos, Albert Langkamp, and Maik Gude. 2018. "Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Simulation Assessment" Materials 11, no. 12: 2453. https://doi.org/10.3390/ma11122453

APA StyleFilippatos, A., Langkamp, A., & Gude, M. (2018). Influence of Gradual Damage on the Structural Dynamic Behaviour of Composite Rotors: Simulation Assessment. Materials, 11(12), 2453. https://doi.org/10.3390/ma11122453