Phase Transformation, Twinning, and Detwinning of NiTi Shape-Memory Alloy Subject to a Shock Wave Based on Molecular-Dynamics Simulation

Abstract

1. Introduction

2. Modeling and Methods

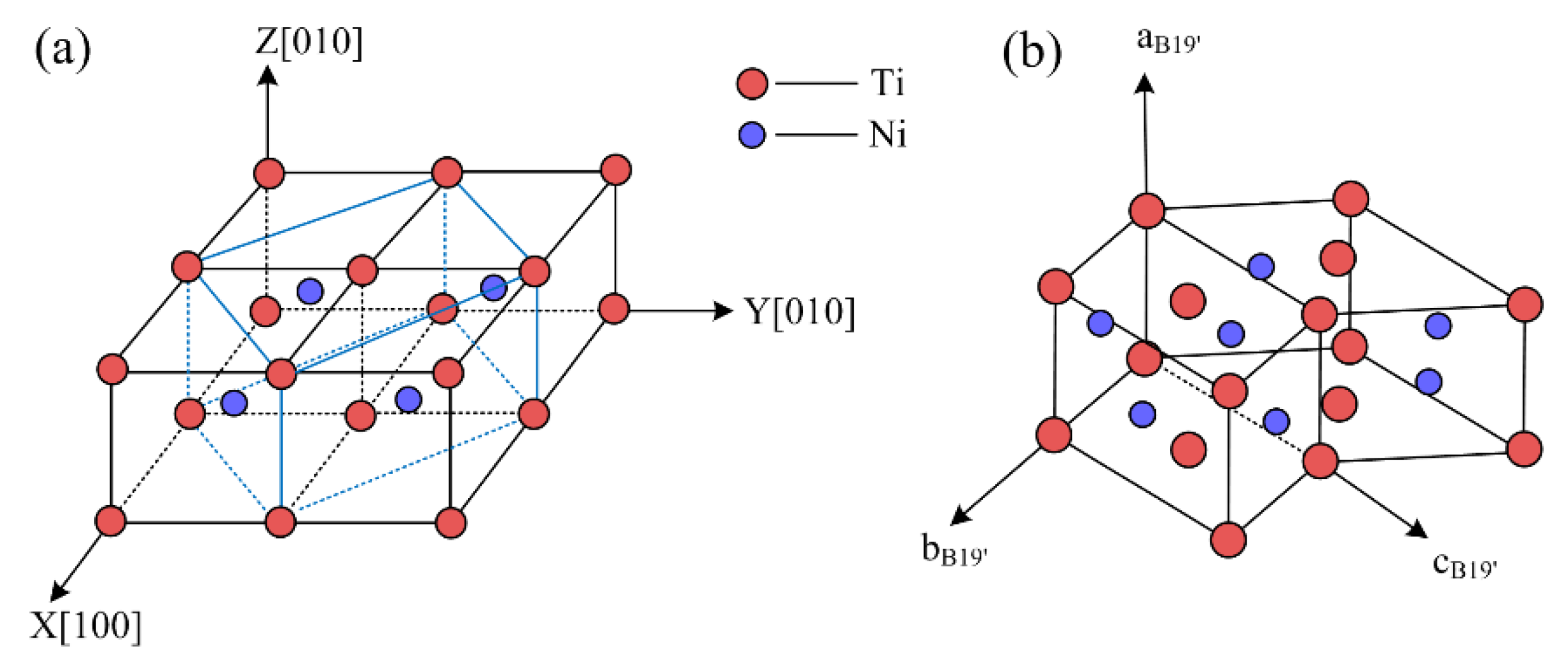

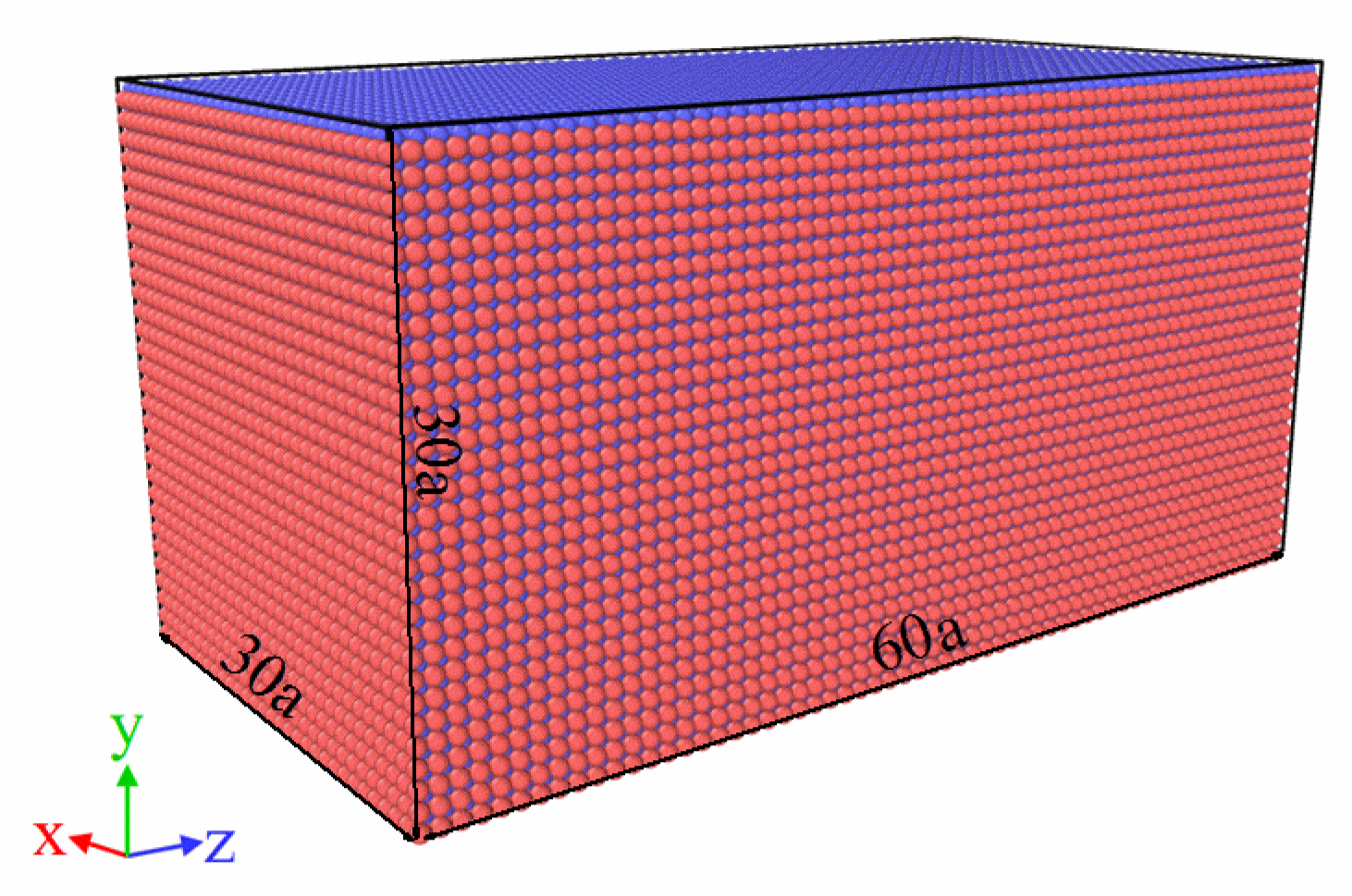

2.1. MD Model

2.2. Interatomic Potentials

2.3. Simulation Software

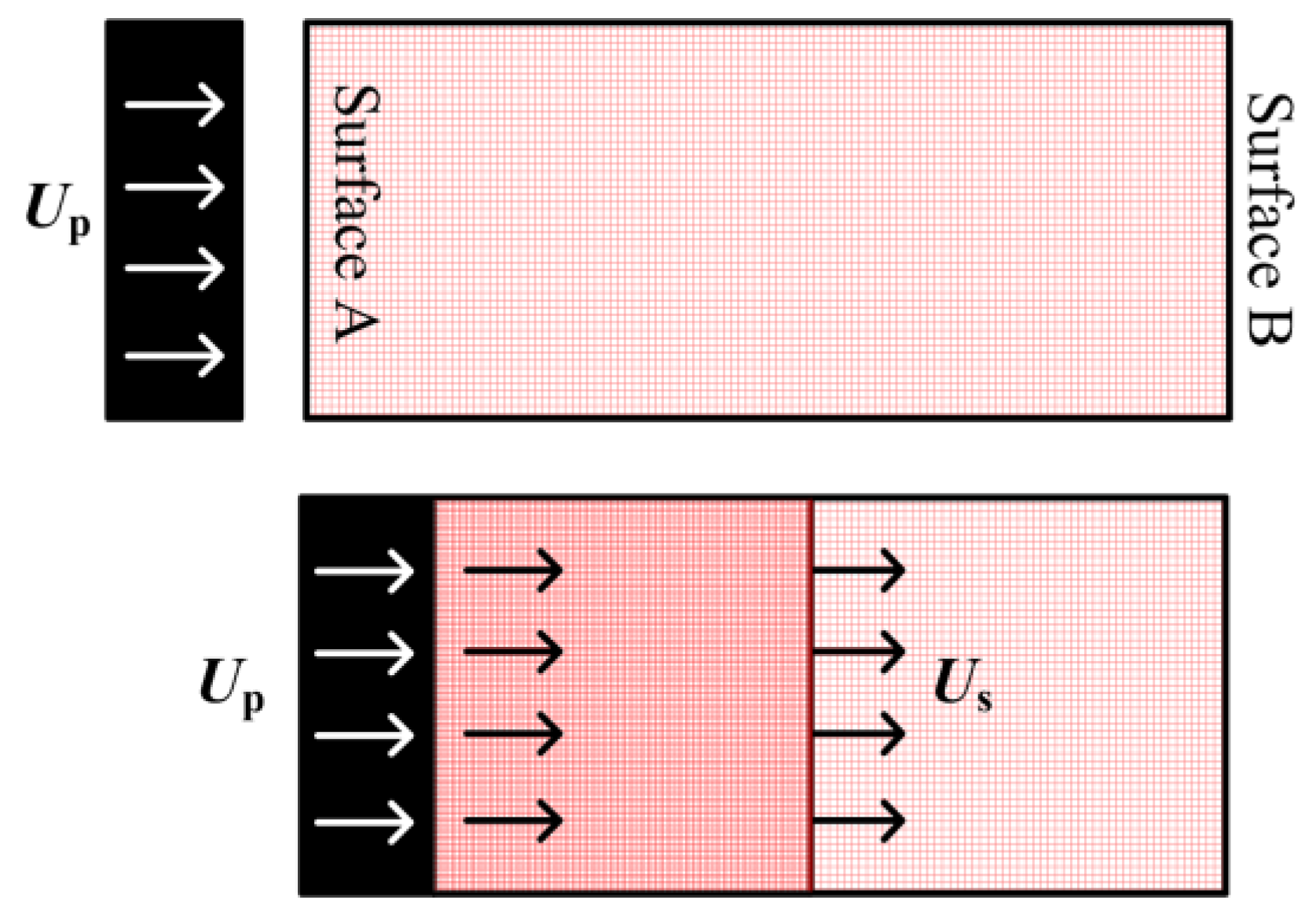

2.4. Shock Loading Conditions

3. Results and Discussion

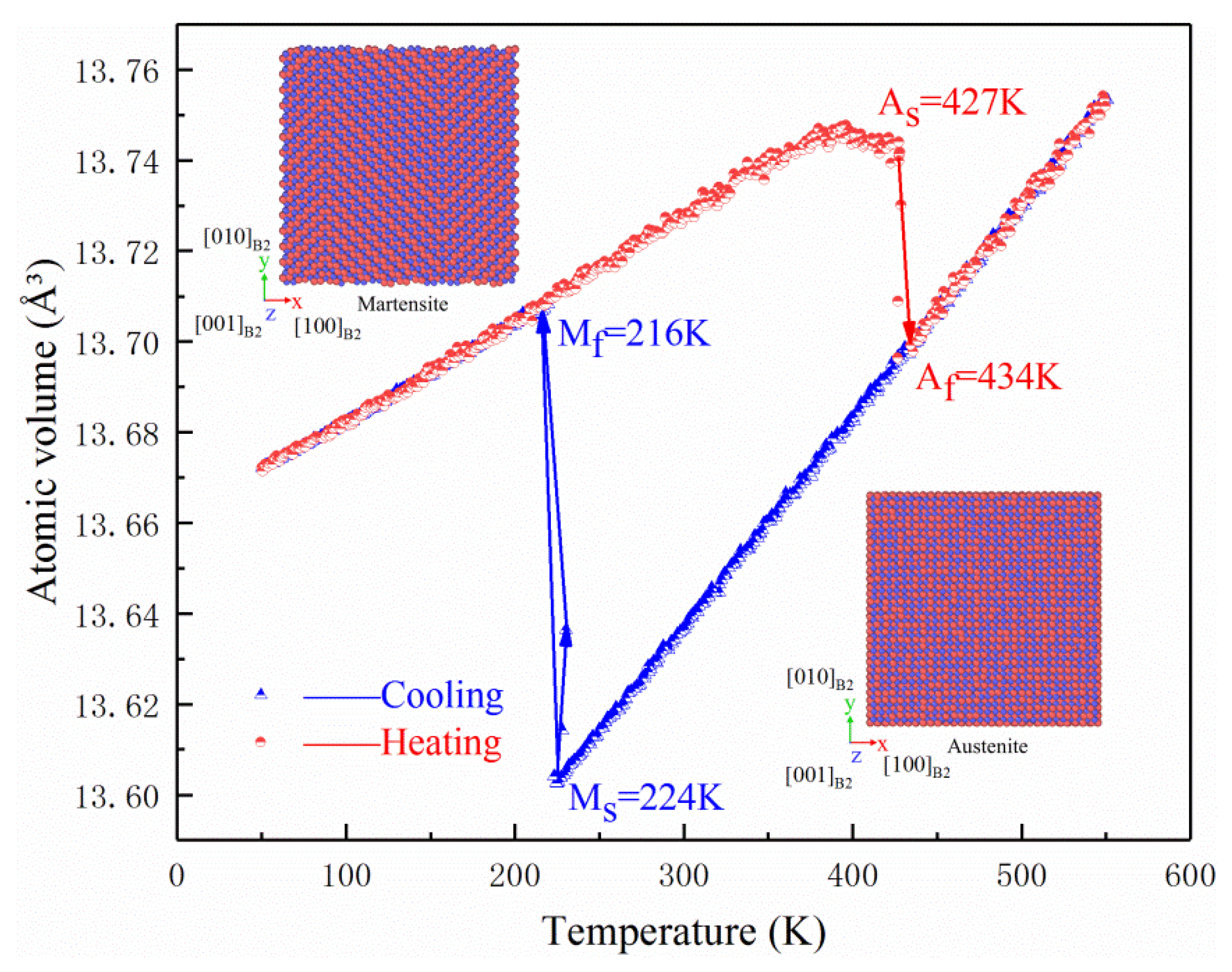

3.1. Determination of Shock Temperature

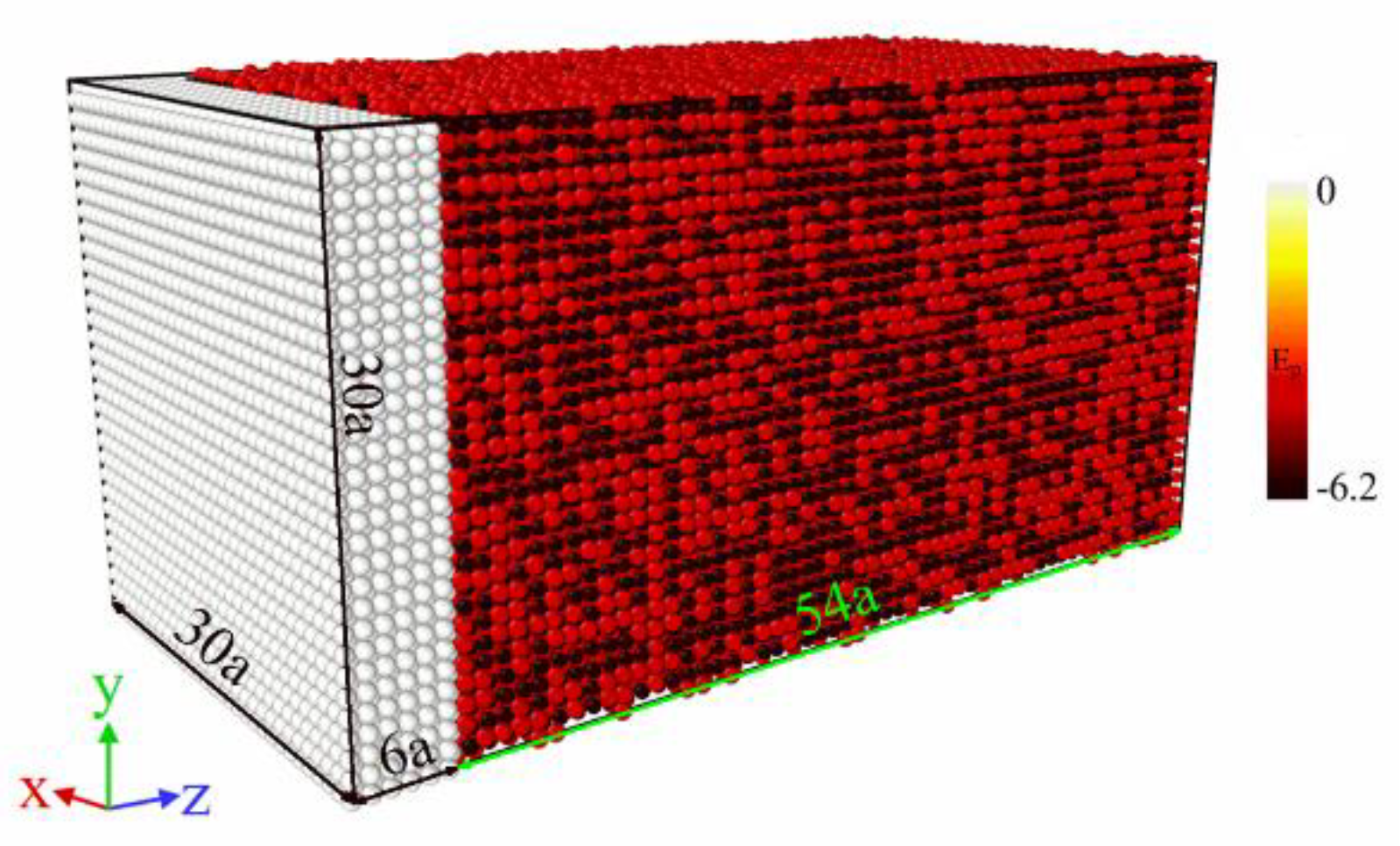

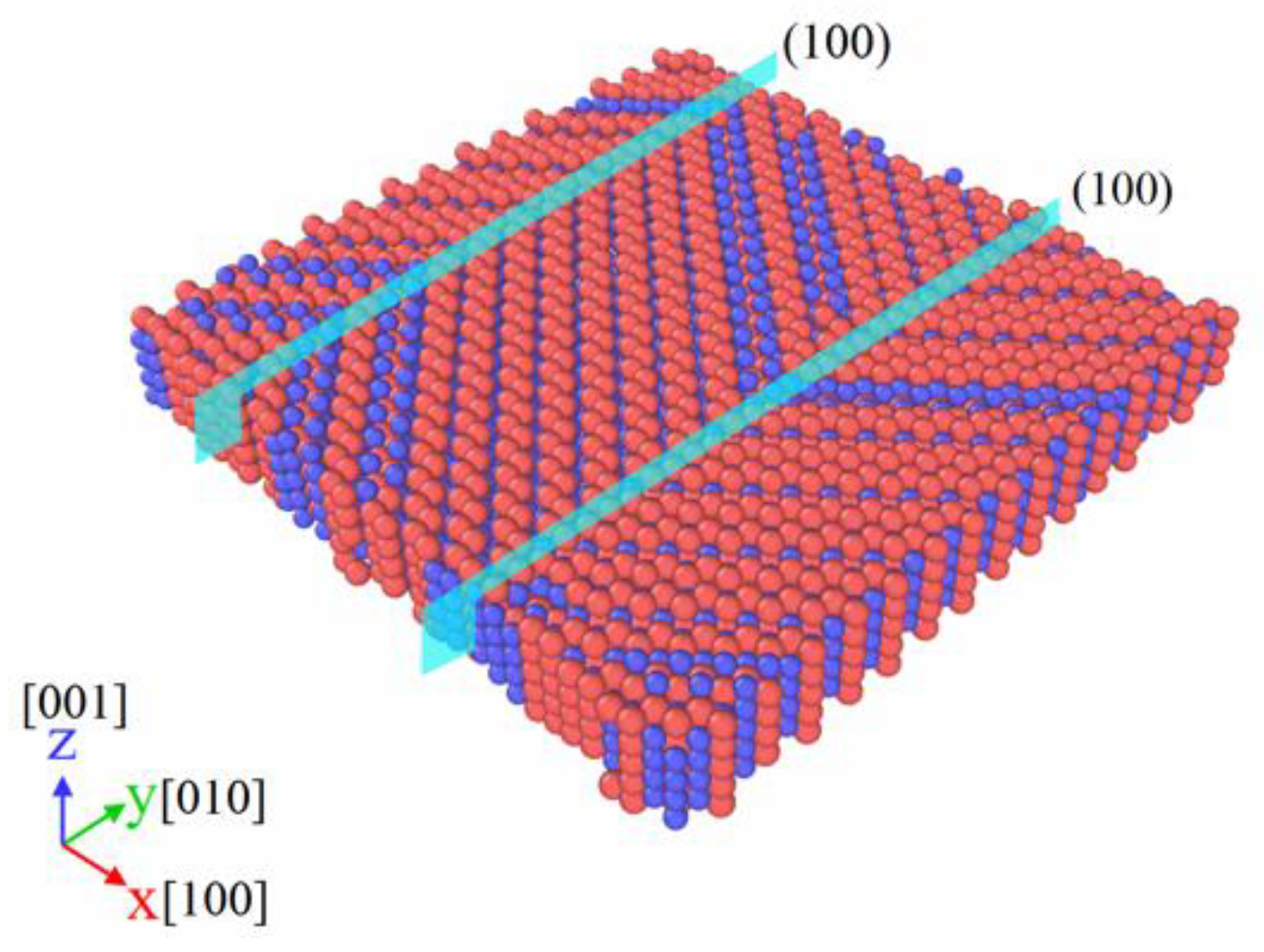

3.2. Propagation of Shock Wave

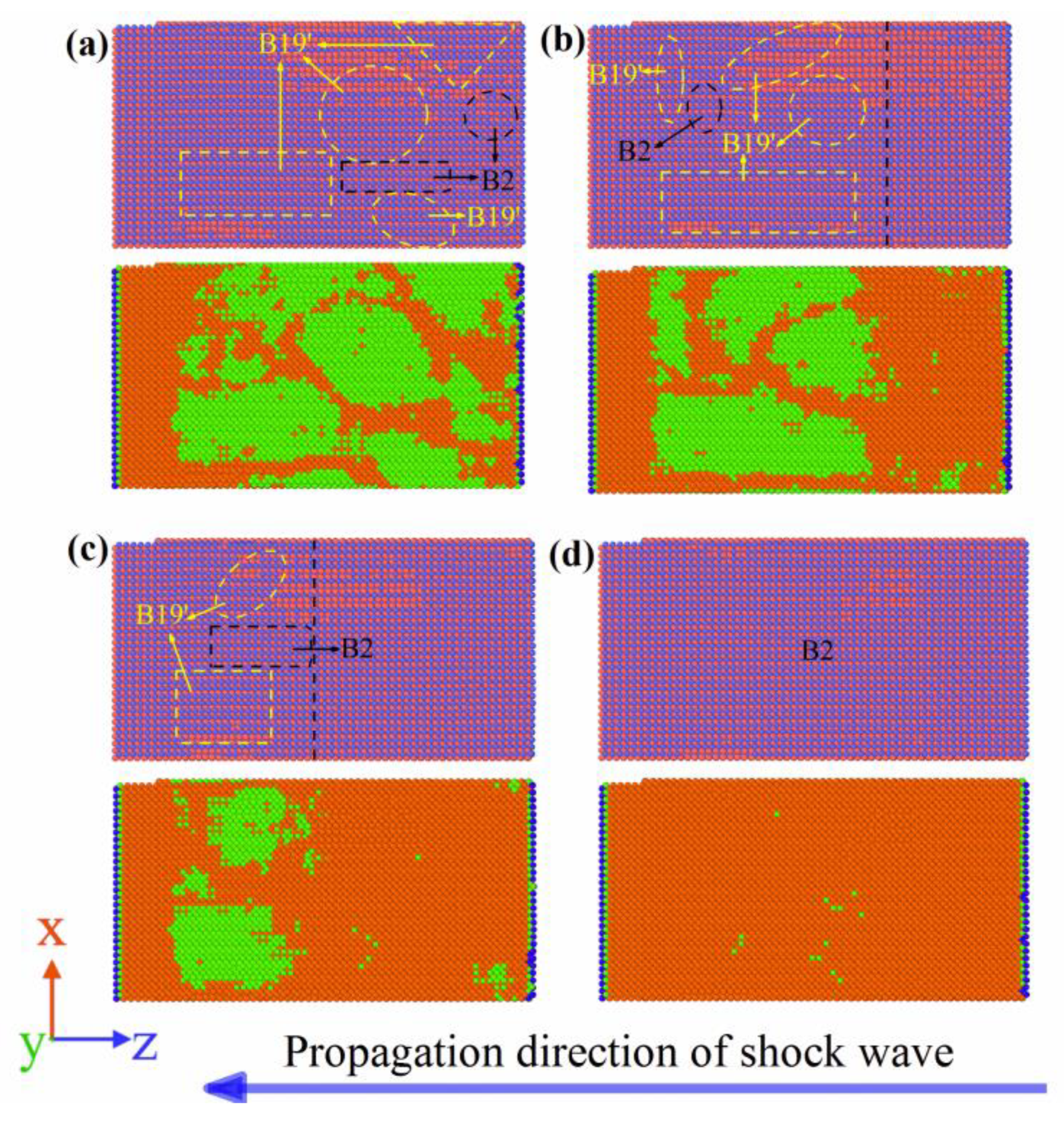

3.3. Martensitic Transformation and Reverse Martensitic Transformation

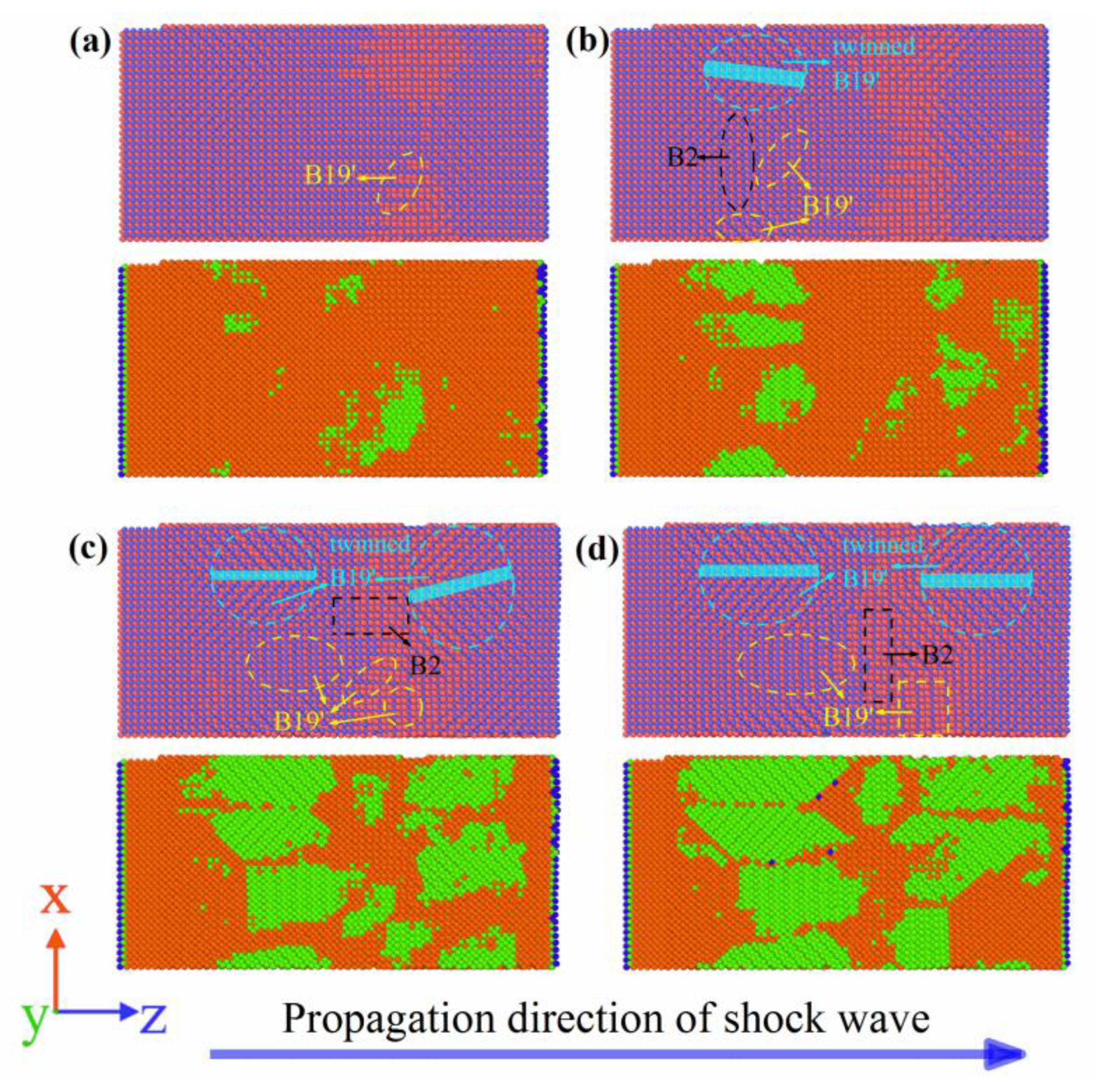

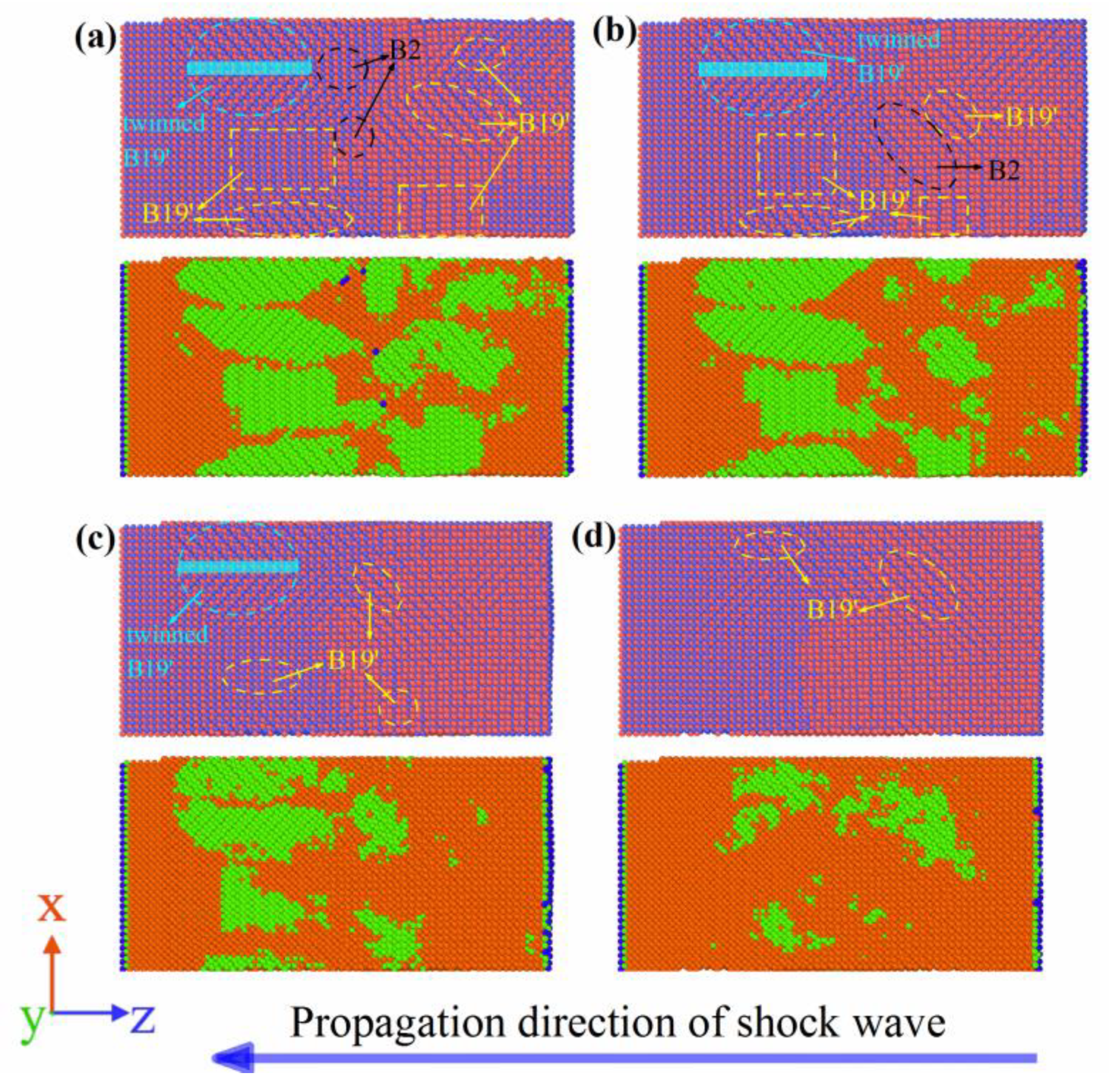

3.4. Twinning and Detwinning

4. Conclusions

- (1)

- In Stage I, namely, the loading process of the shock wave, B2 austenite was transformed into B19’ martensite. In Stage II, namely, the unloading process of the shock wave, reverse martensitic transformation occurred, where the B19′ martensite phase was converted to the B2 austenite phase. In addition, twinning and detwinning were not observed in these two stages.

- (2)

- In Stage III, namely, the second loading process of the shock wave, B2 austenite was transformed into B19′ martensite, and, simultaneously, martensitic twins occurred. Furthermore, with the progression of the shock wave, noncoherent twin boundaries were gradually converted to coherent ones. In Stage IV, namely, the second unloading process of the shock wave, reverse martensitic transformation occurred, where B19′ martensite was transformed into B2 austenite and, simultaneously, detwinning took place.

- (3)

- (100) compound twins occurred along with stress-induced martensite transformation in the NiTi SMA subjected to the shock wave, whereas Type I and Type II twins were not observed. This is probably due to the limitation of interaction potential of NiTi SMA. It is a promising perspective for NiTi SMA to develop novel interaction potential and to establish a new MD model in the future.

Author Contributions

Funding

Conflicts of Interest

References

- Fang, C.; Yam, M.C.H.; Ma, H.; Chung, K.F. Tests on superelastic Ni–Ti SMA bars under cyclic tension and direct-shear: Towards practical recentring connections. Mater. Struct. 2015, 48, 1013–1030. [Google Scholar] [CrossRef]

- Namazu, T.; Hashizume, A.; Inoue, S. Thermomechanical tensile characterization of Ti–Ni shape memory alloy films for design of MEMS actuator. Sens. Actuators A 2007, 139, 178–186. [Google Scholar] [CrossRef]

- Aversa, R.; Tamburrino, F.; Petrescu, R.V.V.; Petrescu, F.I.T.; Artur, M.; Chen, G.; Apicella, A. Biomechanically inspired shape memory effect machines driven by muscle like acting NiTi alloys. Am. J. Appl. Sci. 2016, 13, 1264–1271. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Song, S.-H.; Lee, J.-Y.; Rodrigue, H.; Choi, I.-S.; Kang, Y.J.; Ahn, S.-H. 35 Hz shape memory alloy actuator with bending-twisting mode. Sci. Rep. 2016, 6, 211118. [Google Scholar] [CrossRef] [PubMed]

- Stachiv, I.; Sittner, P.; Olejnicek, J.; Landa, M.; Heller, L. Exploiting NiTi shape memory alloy films in design of tunable high frequency microcantilever resonators. Appl. Phys. Lett. 2017, 111, 213105. [Google Scholar] [CrossRef]

- Stachiv, I.; Sittner, P. Nanocantilevers with Adjustable Static Deflectionand Significantly Tunable Spectrum ResonantFrequencies for Applications in Nanomechanical Mass Sensors. Nanomaterials 2018, 8, 116. [Google Scholar] [CrossRef] [PubMed]

- Daly, S.; Ravichandran, G.; Bhattacharya, K. Stress-induced martensitic phase transformation in thin sheets of Nitinol. Acta Mater. 2007, 55, 3593–3600. [Google Scholar] [CrossRef]

- Waitz, T.; Antretter, T.; Fischer, F.D.; Karnthaler, H.P. Size effects on martensitic phase transformations in nanocrystalline NiTi shape memory alloys. Mater. Sci. Technol. 2008, 24, 934–940. [Google Scholar] [CrossRef]

- Ahadi, A.; Sun, Q. Stress hysteresis and temperature dependence of phase transition stress in nanostructured NiTi—Effects of grain size. Appl. Phys. Lett. 2013, 103, 021902. [Google Scholar] [CrossRef]

- Sedmák, P.; Pilch, J.; Heller, L.; Kopeček, J.; Wright, J.; Sedlák, P.; Frost, M.; Šittner, P. Grain-resolved analysis of localized deformation in nickel-titanium wire under tensile load. Science 2016, 353, 559–562. [Google Scholar] [CrossRef] [PubMed]

- Waitz, T.; Tsuchiya, K.; Antretter, T.; Fischer, F.D. Phase transformations of Nanocrystalline martensitic materials. MRS Bull. 2009, 34, 814–821. [Google Scholar] [CrossRef]

- Ahadi, A.; Sun, Q. Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi. Acta Mater. 2014, 76, 186–197. [Google Scholar] [CrossRef]

- Ahadi, A.; Sun, Q. Stress-induced nanoscale phase transition in superelastic NiTi by in situ X-ray diffraction. Acta Mater. 2015, 90, 272–281. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Lin, D.; Suslov, S.; Cheng, G.J. Deformation induced martensite in NiTi and its shape memory effects generated by low temperature laser shock peening. J. Appl. Phys. 2012, 112, 178–186. [Google Scholar] [CrossRef]

- Ye, C.; Suslov, S.; Fei, X.; Cheng, G.J. Bimodal nanocrystallization of NiTi shape memory alloy by laser shock peening and post-deformation annealing. Acta Mater. 2011, 59, 7219–7227. [Google Scholar] [CrossRef]

- Kastner, O.; Eggeler, G.; Weiss, W.; Ackland, G.J. Molecular dynamics simulation study of microstructure evolution during cyclic martensitic transformations. J. Mech. Phys. Solids 2011, 59, 1888–1908. [Google Scholar] [CrossRef]

- Babicheva, R.I.; Baimova, J.A.; Dmitriev, S.V.; Pushin, V.G. Two-dimensional model of the ordered alloy for the investigation of martensitic transformations. Lett. Mater. 2015, 5, 359–363. [Google Scholar] [CrossRef]

- Baimova, J.A.; Babicheva, R.I.; Lukyanov, A.V.; Pushin, V.G.; Gunderov, D.V.; Dmitriev, S.V. Molecular dynamics for investigation of martensitic transformation. Rev. Adv. Mater. Sci. 2016, 47, 86–94. [Google Scholar]

- Dmitriev, S.V.; Kashchenko, M.P.; Baimova, J.A.; Babicheva, R.I.; Gunderov, D.V.; Pushin, V.G. Molecular dynamics simulation of the effect of dislocations on the martensitic transformations in a two-dimensional model. Lett. Mater. 2017, 7, 442–446. [Google Scholar] [CrossRef]

- Baimova, Y.A.; Dmitriev, S.V.; Kuranova, N.N.; Mulyukov, R.R.; Pushin, A.V.; Pushin, V.G. Molecular dynamics study of the deformation processes of metallic materials in structural and phase (martensitic) transformations. Phys. Met. Metallogr. 2018, 119, 589–597. [Google Scholar] [CrossRef]

- Zhong, Y.; Gall, K.; Zhu, T. Atomistic characterization of pseudoelasticity and shape memory in NiTi nanopillars. Acta Mater. 2012, 59, 6301–6311. [Google Scholar] [CrossRef]

- Lai, W.S.; Liu, B.X. Letter to the editor: Lattice stability of some Ni-Ti alloy phases versus their chemical composition and disordering. J. Phys. Condens. Matter 2000, 12, L53–L60. [Google Scholar] [CrossRef]

- Mutter, D.; Nielaba, P. Simulation of the shape memory effect in a NiTi nano model system. J. Alloy Compd. 2013, 577, S83–S87. [Google Scholar] [CrossRef]

- Ko, W.-S.; Grabowski, B.; Neugebauer, J. Development and application of a Ni-Ti interatomic potential with high predictive accuracy of the martensitic phase transition. Phys. Rev. B 2015, 92, 134107. [Google Scholar] [CrossRef]

- Srinivasan, P.; Nicola, L.; Simone, A. Modeling pseudo-elasticity in NiTi: Why the MEAM potential outperforms the EAM-FS potential. Comput. Mater. Sci. 2017, 134, 145–152. [Google Scholar] [CrossRef]

- Zhong, Y.; Gall, K.; Zhu, T. Atomistic study of nanotwins in NiTi shape memory alloys. J. Appl. Phys. 2011, 110, 033532. [Google Scholar] [CrossRef]

- Ko, W.-S.; Maisel, S.B.; Grabowski, B.; Jeon, J.B. Atomic scale processes of phase transformations in nanocrystalline NiTi shape-memory alloys. Acta Mater. 2017, 123, 90–101. [Google Scholar] [CrossRef]

- Wang, B.; Kang, G.; Kan, Q.; Wu, W.; Zhou, K.; Yu, C. Atomistic study on the super-elasticity of single crystal bulk NiTi shape memory alloy under adiabatic condition. Comput. Mater. Sci. 2018, 142, 38–46. [Google Scholar] [CrossRef]

- Chen, X.; Liu, T.; Li, R.; Liu, J.; Zhao, Y. Molecular dynamics simulation on the shape memory effect and superelasticity in NiTi shape memory alloy. Comput. Mater. Sci. 2018, 146, 61–69. [Google Scholar] [CrossRef]

- Parrill, A.L.; Lipkowitz, K.B. Reviews in Computational Chemistry; Wiley Interscience: Hoboken, NJ, USA, 2017; pp. 43–63. [Google Scholar]

- Holian, B.L. Molecular dynamics comes of age for shockwave research. Shock Waves 2004, 13, 489–495. [Google Scholar] [CrossRef]

- Lee, B.-J.; Shim, J.-H.; Baskes, M.I. Semi-empirical atomic potentials for the FCC metals Cu, Ag, Au, Ni, Pd, Pt, Al and Pb based on first and second nearest-neighbor modified embedded atom method. Phys. Rev. B 2003, 68, 144112. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Lee, B.-J.; Baskes, M.I. Modified embedded atom method interatomic potentials for Ti and Zr. Phys. Rev. B 2006, 74, 014101. [Google Scholar] [CrossRef]

- Ercolessi, F.; Adams, J.B. Interatomic potentials from first-principles calculations: The Force-Matching Method. Europhys. Lett. 1994, 26, 583–588. [Google Scholar] [CrossRef]

- Plimpton, S.; Parallel, F. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Larsen, P.M.; Schmidt, S.; Schiøtz, J. Robust structural identification via polyhedral template matching. Model. Simul. Mater. Sci. Eng. 2016, 24, 055007. [Google Scholar] [CrossRef]

- Stukowski, A. Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 2012, 20, 45021–45035. [Google Scholar] [CrossRef]

- Kadau, K.; Germann, T.C.; Lomdahl, P.S.; Holian, B.L. Atomistic simulations of shock-induced transformations and their orientation dependence in bcc Fe single crystals. Phys. Rev. B 2005, 72, 064120. [Google Scholar] [CrossRef]

- Holian, B.L.; Lomdahl, P.S. Plasticity induced by shock waves in nonequilibrium molecular-dynamics simulations. Science 1998, 280, 2085–2088. [Google Scholar] [CrossRef] [PubMed]

- Holian, B.L. Atomistic computer simulations of shock waves. Shock Waves 1995, 5, 149–157. [Google Scholar] [CrossRef]

- Antoun, T.; Curran, D.R.; Razorenov, S.V.; Seaman, L.; Kanel, G.I.; Utkin, A.V. Spall Fracture; Springer Inc.: New York, NY, USA, 2003; pp. 37–57. [Google Scholar]

- Elibol, C.; Wagner, M.F.-X. Strain rate effects on the localization of the stress-induced martensitic transformation in pseudoelastic NiTi under uniaxial tension, compression and compression–shear. Mater. Sci. Eng. A 2015, 643, 194–202. [Google Scholar] [CrossRef]

- Katanchi, B.; Choupani, N.; Khalil-Allafi, J.; Baghani, M. Photostress analysis of stress-induced martensite phase transformation in superelastic NiTi. Mater. Sci. Eng. A 2017, 688, 202–209. [Google Scholar] [CrossRef]

- Ng, K.L.; Sun, Q.P. Stress-induced phase transformation and detwinning in NiTi polycrystalline shape memory alloy tubes. Mech. Mater. 2006, 38, 41–56. [Google Scholar] [CrossRef]

- Adharapurapu, R.R.; Jiang, F.; Vecchio, K.S.; Gray, G.T. Response of NiTi shape memory alloy at high strain rate: A systematic investigation of temperature effects on tension-compression asymmetry. Acta Mater. 2006, 54, 4609–4620. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Choi, J.Y.; Guo, W.G.; Isaacs, J.B. High strain-rate. small strain response of a NiTi shape-memory alloy. J. Eng. Mater. Technol. 2005, 127, 83–89. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Choi, J.Y.; Guo, W.G.; Isaacs, J.B. Very high strain-rate response of a NiTi shape-memory alloy. Mech. Mater. 2005, 37, 287–298. [Google Scholar] [CrossRef]

- Wang, X.; Xia, W.; Wu, X.; Wei, P.; Huang, C. Microstructure and mechanical properties of an austenite NiTi shape memory alloy treated with laser induced shock. Mater. Sci. Eng. A 2013, 578, 1–5. [Google Scholar] [CrossRef]

- Wang, X.; Xia, W.; Wu, X.; Wei, P.; Huang, C. In-situ investigation of dynamic deformation in NiTi shape memory alloys under laser induced shock. Mech. Mater. 2017, 114, 69–75. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.; Humbeeck, J.V.; Delaey, L. Asymmetry of stress-strain curves under tension and compression for NiTi shape memory alloys. Acta Mater. 1998, 46, 4325–4338. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.; Liu, S.; Zhang, Y.; Zhao, Y.; Zhao, C. Transformation twinning and deformation twinning of NiTi shape memory alloy. Mater. Sci. Eng. A 2016, 660, 1–10. [Google Scholar] [CrossRef]

- Waitz, T. The self-accommodated morphology of martensite in nanocrystalline NiTi shape memory alloys. Acta Mater. 2005, 53, 2273–2283. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Šesták, P.; Černý, M.; Pokluda, J. Can twinning stabilize B19′ structure in NiTi martensite. Intermetallics 2011, 19, 1567–1572. [Google Scholar] [CrossRef]

- Ezaz, T.; Sehitoglu, H.; Maier, H.J. Energetics of twinning in martensitic NiTi. Acta Mater. 2011, 59, 5893–5904. [Google Scholar] [CrossRef]

- Nishida, M.; Ii, S.; Kitamura, K.; Furukawa, T.; Chiba, A.; Hara, T.; Hiraga, K. New deformation twinning mode of B19′ martensite in Ti-Ni shape memory alloy. Scr. Mater. 1998, 39, 1749–1754. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.; Humbeeck, J.V.; Delaey, L. Some results on the detwinning process in NiTi shape memory alloys. Scr. Mater. 1999, 41, 1273–1281. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z. Twinning and detwinning of <0 1 1> type II twin in shape memory alloy. Acta Mater. 2003, 51, 5529–5543. [Google Scholar] [CrossRef]

- Dilibal, S. Investigation of nucleation and growth of detwinning mechanism in martensitic single crystal NiTi using digital image correlation. Metallogr. Microstruct. Anal. 2013, 2, 242–248. [Google Scholar] [CrossRef]

| min | max | min | max | min | max | min | max | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| –0.36 | 4.96 | 2.612 | 1.2818 | 0.025 | 1:1 | 0.25 | 1.7 | 0.09 | 1.7 | 0.49 | 1.4 | 1.6 | 1.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Jiang, S.; Zhang, Y. Phase Transformation, Twinning, and Detwinning of NiTi Shape-Memory Alloy Subject to a Shock Wave Based on Molecular-Dynamics Simulation. Materials 2018, 11, 2334. https://doi.org/10.3390/ma11112334

Wang M, Jiang S, Zhang Y. Phase Transformation, Twinning, and Detwinning of NiTi Shape-Memory Alloy Subject to a Shock Wave Based on Molecular-Dynamics Simulation. Materials. 2018; 11(11):2334. https://doi.org/10.3390/ma11112334

Chicago/Turabian StyleWang, Man, Shuyong Jiang, and Yanqiu Zhang. 2018. "Phase Transformation, Twinning, and Detwinning of NiTi Shape-Memory Alloy Subject to a Shock Wave Based on Molecular-Dynamics Simulation" Materials 11, no. 11: 2334. https://doi.org/10.3390/ma11112334

APA StyleWang, M., Jiang, S., & Zhang, Y. (2018). Phase Transformation, Twinning, and Detwinning of NiTi Shape-Memory Alloy Subject to a Shock Wave Based on Molecular-Dynamics Simulation. Materials, 11(11), 2334. https://doi.org/10.3390/ma11112334