Evaluating Hole Quality in Drilling of Al 6061 Alloys

Abstract

1. Introduction

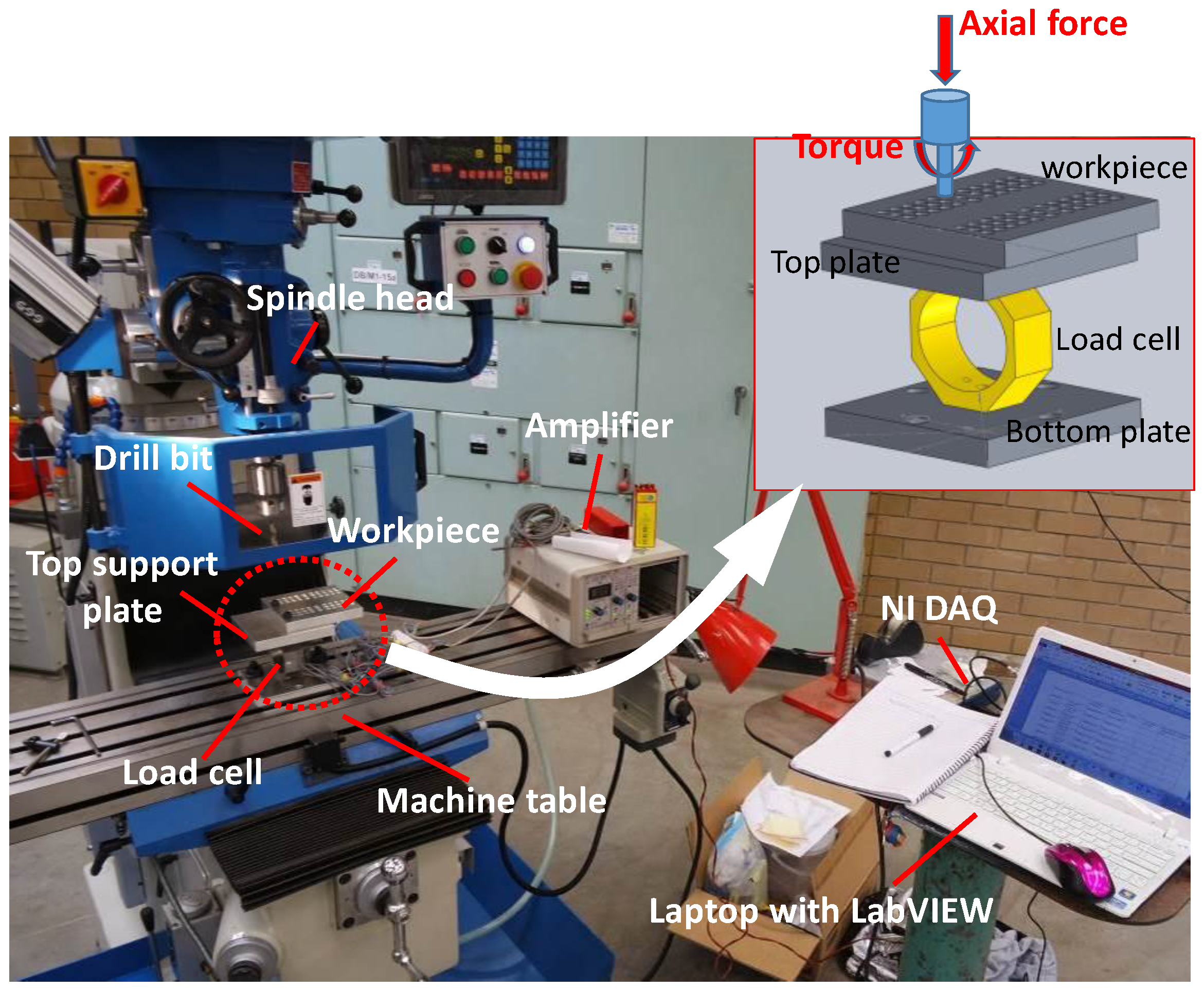

2. Materials and Methods

3. Results and Discussion

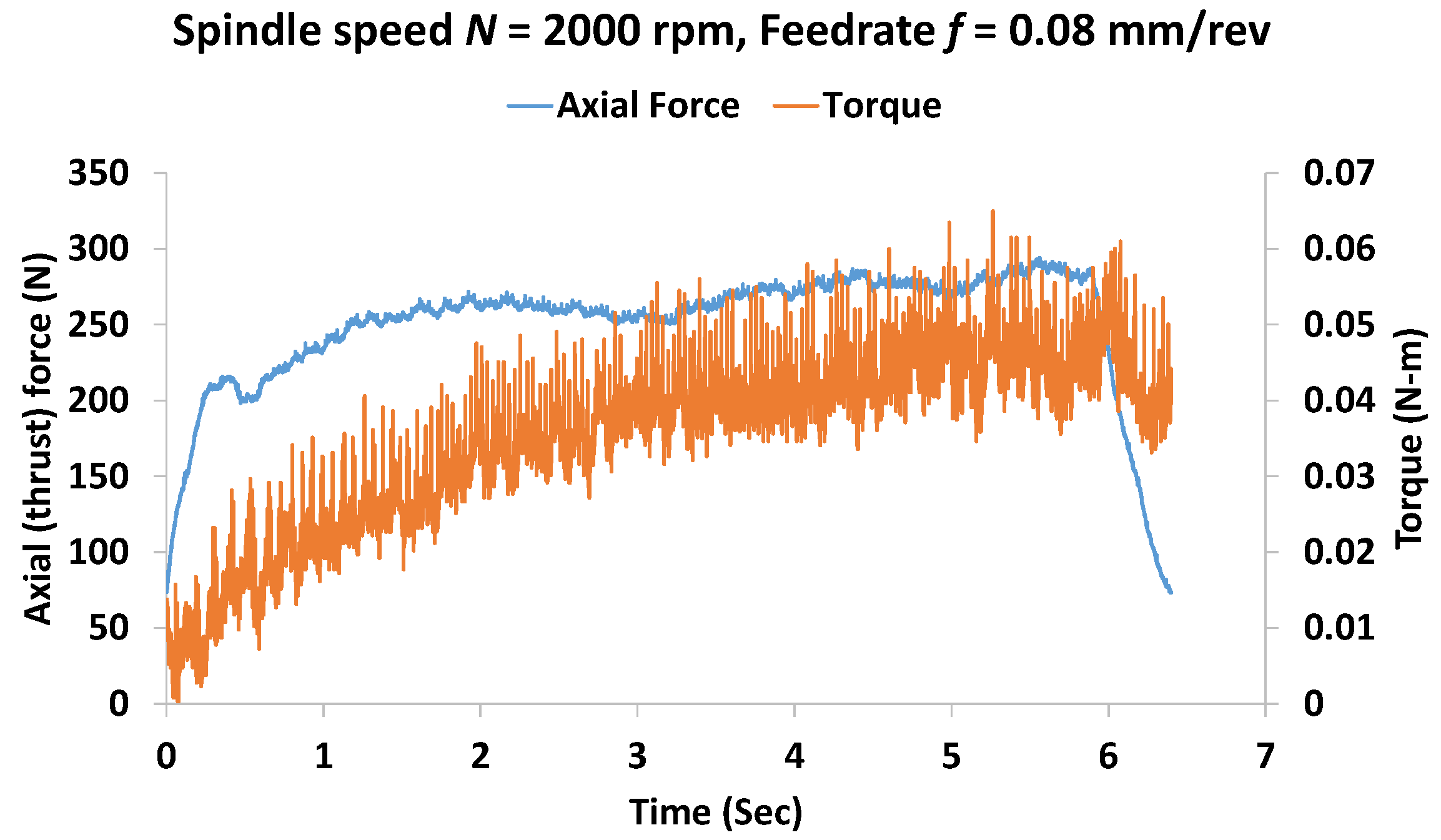

3.1. Axial Force and Torque

3.2. Tool Wear Mechanism

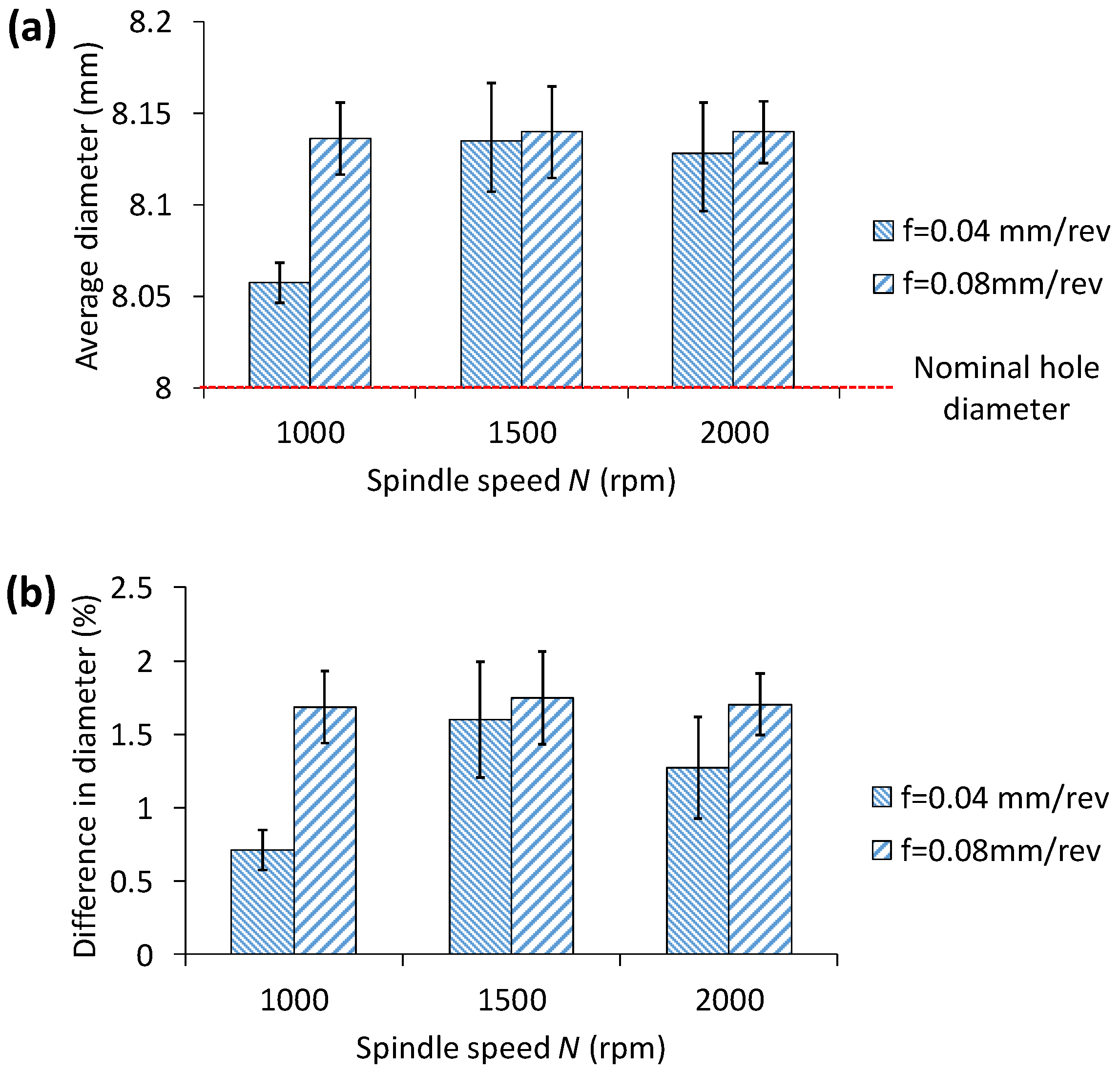

3.3. Hole Diameter

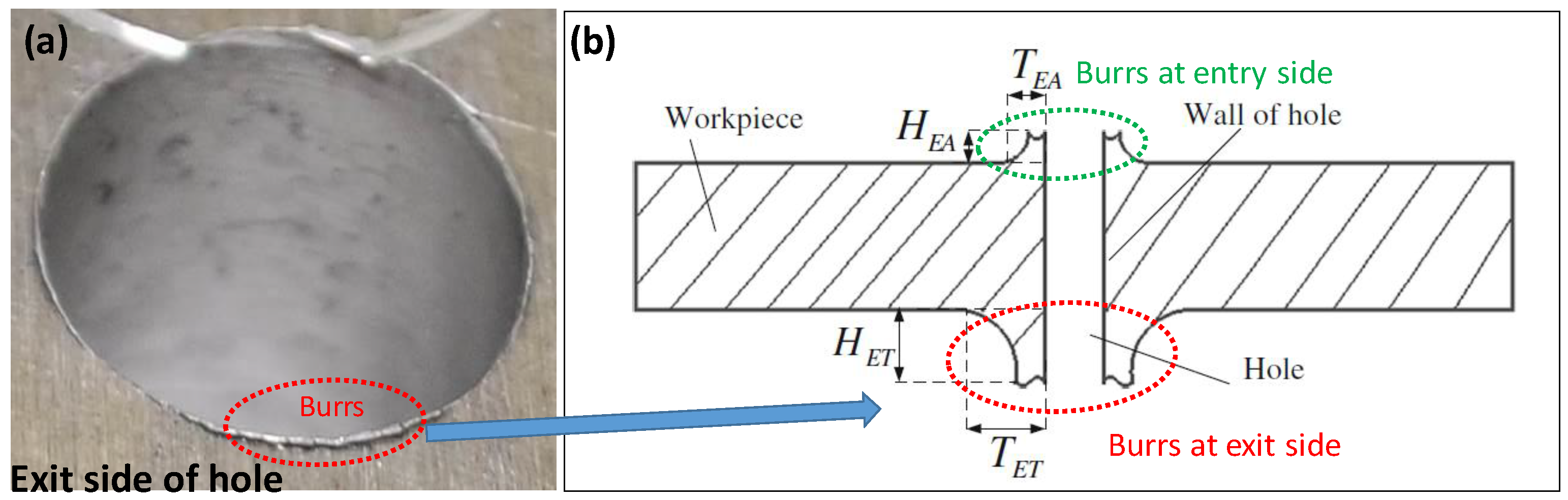

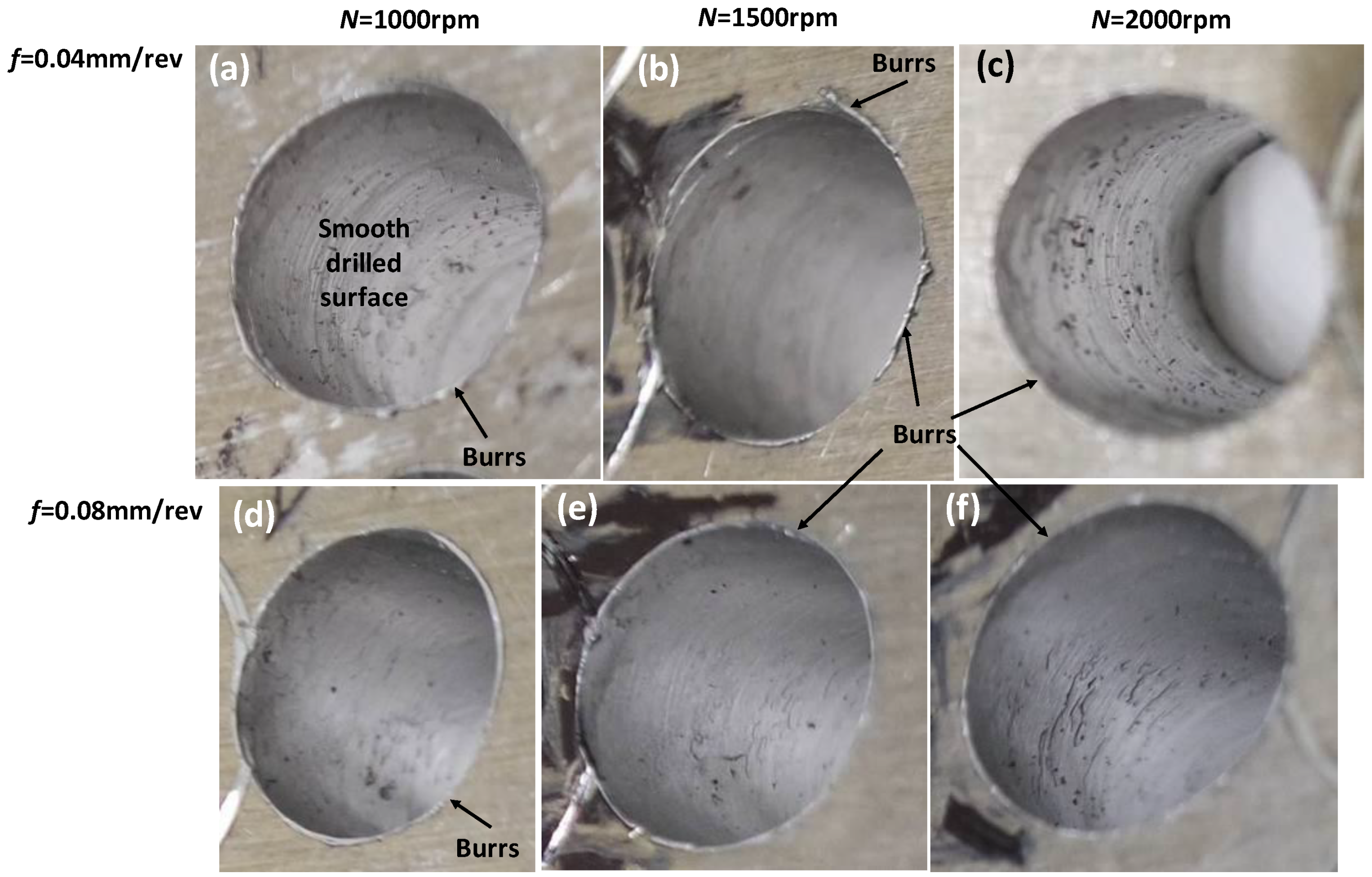

3.4. Burr Formation

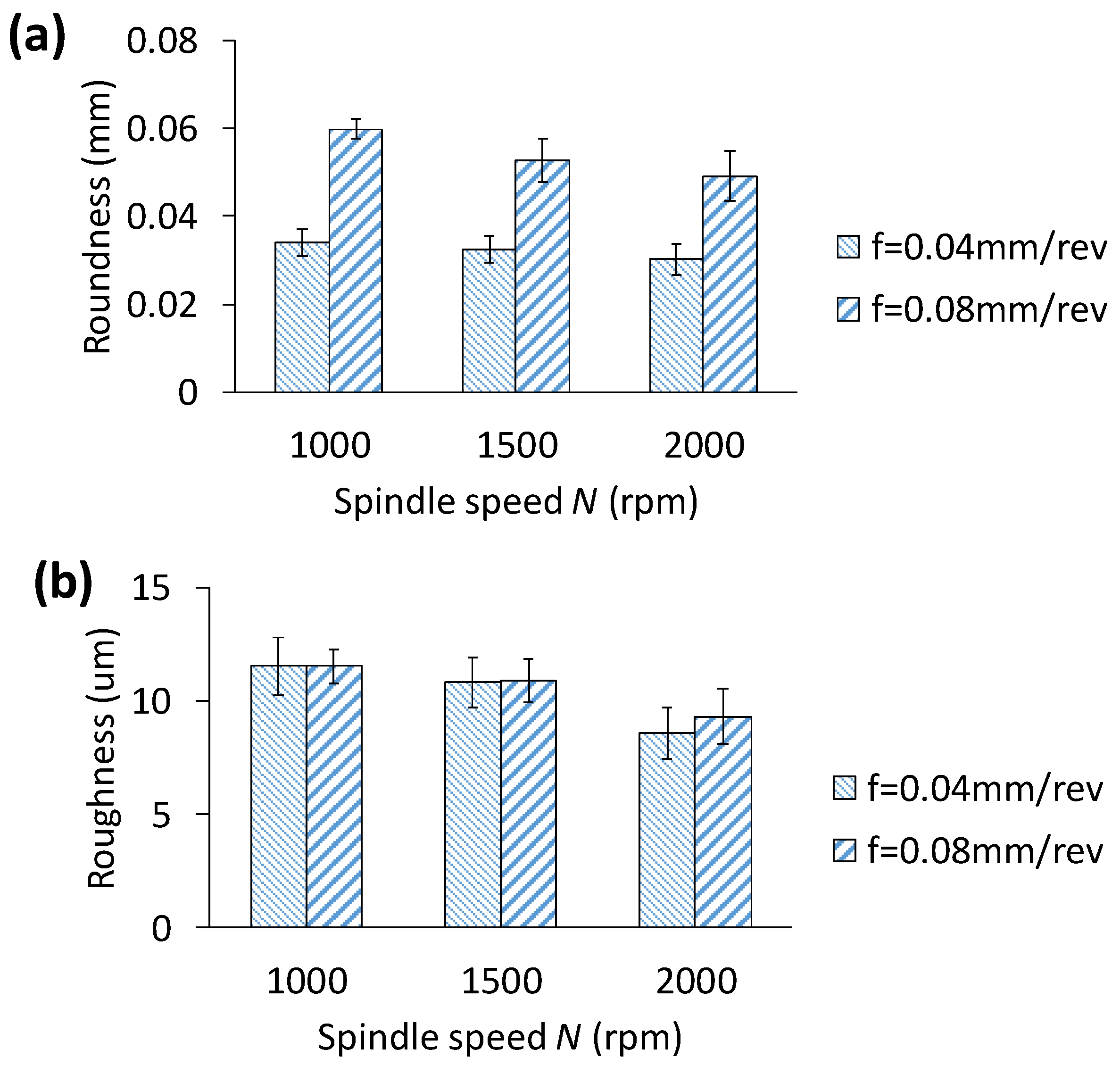

3.5. Roundness and Roughness

3.6. Chips Formation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D. Burr Formation and Hole Quality when Drilling Titanium and Aluminium Alloys. Procedia CIRP 2015, 37, 230–235. [Google Scholar] [CrossRef]

- Pilný, L.; De Chiffre, L.; Píška, M.; Villumsen, M.F. Hole quality and burr reduction in drilling aluminium sheets. CIRP J. Manuf. Sci. Technol. 2012, 5, 102–107. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Vilches, F.J.T.; Hurtado, L.S.; Fernández, F.M.; Gamboa, C.B. Analysis of the Chip Geometry in Dry Machining of Aeronautical Aluminum Alloys. Appl. Sci. 2017, 7, 132. [Google Scholar] [CrossRef]

- Gautam, G.D.; Pandey, A.K. Pulsed Nd:YAG laser beam drilling: A review. Opt. Laser Technol. 2018, 100, 183–215. [Google Scholar] [CrossRef]

- Rahamathullah, I.; Shunmugam, M. Analyses of forces and hole quality in micro-drilling of carbon fabric laminate composites. J. Compos. Mater. 2013, 47, 1129–1140. [Google Scholar] [CrossRef]

- Niknam, S.A.; Davoodi, B.; Davim, J.P.; Songmene, V. Mechanical deburring and edge-finishing processes for aluminum parts—a review. Int. J. Adv. Manuf. Technol. 2018, 95, 1101–1125. [Google Scholar] [CrossRef]

- Sultan, A.Z.; Sharif, S.; Kurniawan, D. Effect of Machining Parameters on Tool Wear and Hole Quality of AISI 316L Stainless Steel in Conventional Drilling. Procedia Manuf. 2015, 2, 202–207. [Google Scholar] [CrossRef]

- Uddin, M.S.; Songyi, D. On the design and analysis of an octagonal–ellipse ring based cutting force measuring transducer. Measurement 2016, 90, 168–177. [Google Scholar] [CrossRef]

- Wei, Y.; An, Q.; Ming, W.; Chen, M. Effect of drilling parameters and tool geometry on drilling performance in drilling carbon fiber–reinforced plastic/titanium alloy stacks. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Glaa, N.; Mehdi, K.; Zitoune, R. Numerical modeling and experimental analysis of thrust cutting force and torque in drilling process of titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2018, 96, 2815–2824. [Google Scholar] [CrossRef]

- Ko, S.-L.; Chang, J.-E.; Yang, G.-E. Burr minimizing scheme in drilling. J. Mater. Process. Technol. 2003, 140, 237–242. [Google Scholar] [CrossRef]

- Ko, S.-L.; Lee, J.-K. Analysis of burr formation in drilling with a new-concept drill. J. Mater. Process. Technol. 2001, 113, 392–398. [Google Scholar] [CrossRef]

- Lauderbaugh, L.K. Analysis of the effects of process parameters on exit burrs in drilling using a combined simulation and experimental approach. J. Mater. Process. Technol. 2009, 209, 1909–1919. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Bagci, E. Evaluation of drilled hole quality in Al 2024 alloy. Int. J. Adv. Manuf. Technol. 2008, 37, 1051–1060. [Google Scholar] [CrossRef]

- Chaanthini, M.K.; Murugappan, S.; Arul, S. Study on Hole Quality in Drilling AA 6063 Plate under Cryogenic Pre-Cooling Environment. Mater. Today Proc. 2017, 4, 7476–7483. [Google Scholar] [CrossRef]

- Islam, M.N.; Boswell, B. Effect of cooling methods on hole quality in drilling of aluminium 6061-6T. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012022. [Google Scholar] [CrossRef]

- Ramulu, M.; Branson, T.; Kim, D. A study on the drilling of composite and titanium stacks. Compos. Struct. 2001, 54, 67–77. [Google Scholar] [CrossRef]

- Chen, W.S.; Ehmann, K.F. Experimental investigation on the wear and performance of micro-drills. In Proceedings of the 1994 International Mechanical Engineering Congress and Exposition, Chicago, IL, USA, 6–11 November 1994; Tribology in Manufacturing Processes: Chicago, IL, USA. [Google Scholar]

- Ghasemi, A.H.; Khorasani, A.M.; Gibson, I. Investigation on the Effect of a Pre-Center Drill Hole and Tool Material on Thrust Force, Surface Roughness, and Cylindricity in the Drilling of Al7075. Materials 2018, 11, 140. [Google Scholar] [CrossRef]

- Luo, B.; Li, Y.; Zhang, K.; Cheng, H.; Liu, S. A novel prediction model for thrust force and torque in drilling interface region of CFRP/Ti stacks. Int. J. Adv. Manuf. Technol. 2015, 81, 1497–1508. [Google Scholar] [CrossRef]

- Songmene, V.; Khettabi, R.; Zaghbani, I.; Kouam, J.; Djebara, A. Machining and Machinability of Aluminum Alloys. Alum. Alloys Theory Appl. 2011. [Google Scholar] [CrossRef]

- Braga, D.U.; Diniz, A.E.; Miranda, G.W.A.; Coppini, N.L. Using a minimum quantity of lubricant (MQL) and a diamond coated tool in the drilling of aluminum–silicon alloys. J. Mater. Process. Technol. 2002, 122, 127–138. [Google Scholar] [CrossRef]

- Bu, Y.; Liao, W.H.; Tian, W.; Shen, J.X.; Hu, J. An analytical model for exit burrs in drilling of aluminum materials. Int. J. Adv. Manuf. Technol. 2016, 85, 2783–2796. [Google Scholar] [CrossRef]

- Haddag, B.; Atlati, S.; Nouari, M.; Moufki, A. Dry Machining Aeronautical Aluminum Alloy AA2024-T351: Analysis of Cutting Forces, Chip Segmentation and Built-Up Edge Formation. Metals 2016, 6, 197. [Google Scholar] [CrossRef]

- Giasin, K. The effect of drilling parameters, cooling technology, and fiber orientation on hole perpendicularity error in fiber metal laminates. Int. J. Adv. Manuf. Technol. 2018, 97, 4081–4099. [Google Scholar] [CrossRef]

- Zitoune, R.; Krishnaraj, V.; Collombet, F.; Le Roux, S. Experimental and numerical analysis on drilling of carbon fibre reinforced plastic and aluminium stacks. Compos. Struct. 2016, 146, 148–158. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Spindle speed N (rpm) | 1000, 1500, 2000 |

| Feedrate f (mm/rev) | 0.04, 0.08 |

| Parameters | Values |

|---|---|

| Young’s modulus (GPa) | 68.9 |

| Poisson’s ratio | 0.33 |

| Tensile strength (MPa) | 124–290 |

| Density (g/cm3) | 2.7 |

| Thermal conductivity (W/m.K) | 151–202 |

| Specific heat capacity (J/Kg·K) | 897 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, M.; Basak, A.; Pramanik, A.; Singh, S.; Krolczyk, G.M.; Prakash, C. Evaluating Hole Quality in Drilling of Al 6061 Alloys. Materials 2018, 11, 2443. https://doi.org/10.3390/ma11122443

Uddin M, Basak A, Pramanik A, Singh S, Krolczyk GM, Prakash C. Evaluating Hole Quality in Drilling of Al 6061 Alloys. Materials. 2018; 11(12):2443. https://doi.org/10.3390/ma11122443

Chicago/Turabian StyleUddin, Mohammad, Animesh Basak, Alokesh Pramanik, Sunpreet Singh, Grzegorz M. Krolczyk, and Chander Prakash. 2018. "Evaluating Hole Quality in Drilling of Al 6061 Alloys" Materials 11, no. 12: 2443. https://doi.org/10.3390/ma11122443

APA StyleUddin, M., Basak, A., Pramanik, A., Singh, S., Krolczyk, G. M., & Prakash, C. (2018). Evaluating Hole Quality in Drilling of Al 6061 Alloys. Materials, 11(12), 2443. https://doi.org/10.3390/ma11122443