A Review on Flexible and Transparent Energy Storage System

Abstract

1. Introduction

2. Lithium-Ion Battery

2.1. Flexible Lithium-Ion Battery

2.2. Transparent Lithium-Ion Battery

3. Super Capacitor

3.1. Flexible Super Capacitor

3.2. Transparent Super Capacitor

3.3. Flexible and Transparent Super Capacitor

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Wu, Y.; Wu, H.; Luo, S.; Wang, K.; Zhao, F.; Wei, Y.; Liu, P.; Jiang, K.; Wang, J.; Fan, S. Entrapping electrode materials within ultrathin carbon nanotube network for flexible thin film lithium ion batteries. RSC Adv. 2014, 4, 20010–20016. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, Y.-H.; Lee, I.; Kim, T.-S.; Ryou, M.-H.; Choi, J.W. Large area multi-stacked lithium-ion batteries for flexible and rollable applications. J. Mater. Chem. A 2014, 2, 10862–10868. [Google Scholar] [CrossRef]

- Cao, S.; Feng, X.; Song, Y.; Xue, X.; Liu, H.; Miao, M.; Fang, J.; Shi, L. Integrated fast assembly of free-standing lithium titanate/carbon nanotube/cellulose nanofiber hybrid network film as flexible paper-electrode for lithium-ion batteries. ACS Appl. Mater. Interfaces 2015, 7, 10695–10718. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Manjunatha, R.; Kumar, R.; Mitra, S. A facile bottom-up approach to construct hybrid flexible cathode scaffold for high-performance lithium-sulfur batteries. ACS Appl. Mater. Interfaces 2016, 8, 33775–33785. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, G.; Seo, M.H.; Lui, G.; Hassan, F.M.; Feng, K.; Xiao, X.; Chen, Z. Carbon-coated silicon nanowires on carbon fabric as self-supported electrodes for flexible lithium-ion batteries. ACS Appl. Mater. Interfaces 2017, 9, 9551–9558. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.Q.; Xu, Z.L.; Abouali, S.; Garakani, M.A.; Kim, J.K. Porous graphene oxide/carbon nanotube hybrid films as interlayer for lithium-sulfur batteries. Carbon 2016, 99, 624–632. [Google Scholar] [CrossRef]

- Wang, K.; Wu, H.; Meng, Y.; Zhang, Y.; Wei, Z. Integrated energy storage and electrochromic function in one flexible device: An energy storage smart window. Energy Environ. Sci. 2012, 5, 8384–8389. [Google Scholar] [CrossRef]

- Niu, Z.; Du, J.; Cao, X.; Sun, Y.; Zhou, W.; Hng, H.H.; Ma, J.; Chen, X.; Xie, S. Electrophoretic build-up of alternately multilayered films and micropatterns based on graphene sheets and nanoparticles and their applications in flexible supercapacitors. Small 2012, 8, 3201–3208. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, J.; Navarrete, E.; Dalchiele, E.A.; Sánchez, L.; Ramos-Barrado, J.R.; Martín, F. Polyvinylpyrrolidone–LiClO4 solid polymer electrolyte and its application in transparent thin film supercapacitors. J. Power Sources 2013, 237, 270–276. [Google Scholar] [CrossRef]

- Chen, T.; Dai, L. Flexible supercapacitors based on carbon nanomaterials. J. Mater. Chem. A 2014, 2, 10756–10775. [Google Scholar] [CrossRef]

- Niu, Z.; Liu, L.; Zhang, L.; Zhou, W.; Chen, X.; Xie, S. Programmable nanocarbon-based architectures for flexible supercapacitors. Adv. Energy Mater. 2015, 5, 1500677–1500696. [Google Scholar] [CrossRef]

- Ju, S.; Li, J.; Liu, J.; Chen, P.C.; Ha, Y.G.; Ishikawa, F.; Chang, H.; Zhou, C.; Facchetti, A.; Janes, D.B.; et al. Transparent active matrix organic light-emitting diode displaysdriven by nanowire transistor circuitry. Nano Lett. 2007, 8, 997–1004. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yoon, M.H.; Lu, G.; Yang, Y.; Facchetti, A.; Marks, T.J. High-performance transparent inorganic-organic hybrid thin-film n-type transistors. Nat. Mater. 2006, 5, 893–900. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Guo, Y.; Wan, P.; Zhang, H.; Chen, X.; Sun, X. Flexible transparent electronic gas sensors. Small 2016, 12, 3748–3756. [Google Scholar] [CrossRef] [PubMed]

- Choi, I.Y.; Lee, J.; Ahn, H.; Lee, J.; Choi, H.C.; Park, M.J. High-conductivity two-dimensional polyaniline nanosheets developed on ice surfaces. Angew. Chem. Int. Ed. 2015, 54, 10497–10501. [Google Scholar] [CrossRef] [PubMed]

- Heo, G.; Pyo, K.H.; Lee, D.H.; Kim, Y.; Kim, J.W. Critical role of diels-adler adducts to realise stretchable transparent electrodes based on silver nanowires and silicone elastomer. Sci. Rep. 2016, 6, 25358–25367. [Google Scholar] [CrossRef] [PubMed]

- Pyo, J.B.; Kim, B.S.; Park, H.; Kim, T.A.; Koo, C.M.; Lee, J.; Son, J.G.; Lee, S.S.; Park, J.H. Floating compression of Ag nanowire networks for effective strain release of stretchable transparent electrodes. Nanoscale 2015, 7, 16434–16441. [Google Scholar] [CrossRef] [PubMed]

- Yao, B.; Huang, L.; Zhang, J.; Gao, X.; Wu, J.; Cheng, Y.; Xiao, X.; Wang, B.; Li, Y.; Zhou, J. Flexible transparent molybdenum trioxide nanopaper for energy storage. Adv. Mater. 2016, 28, 6353–6358. [Google Scholar] [CrossRef] [PubMed]

- Tarascon, J.M.; Armand, M. Issues and Challenges Facing Rechargeable Lithium Batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Etacheri, V.; Marom, R.; Elazari, R.; Salitra, G.; Aurbach, D. Challenges in the development of advanced Li-ion batteries: A review. Energy Environ. Sci. 2011, 4, 3243. [Google Scholar] [CrossRef]

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Seung-Min, P.; EunJoo, Y.; Itaru, H. Enhanced cyclic performance and lithium storage capacity of SnO2/graphene nanoporous electrodes with three-dimensionally delaminated flexible structure. Nano Lett. 2009, 9, 72–75. [Google Scholar]

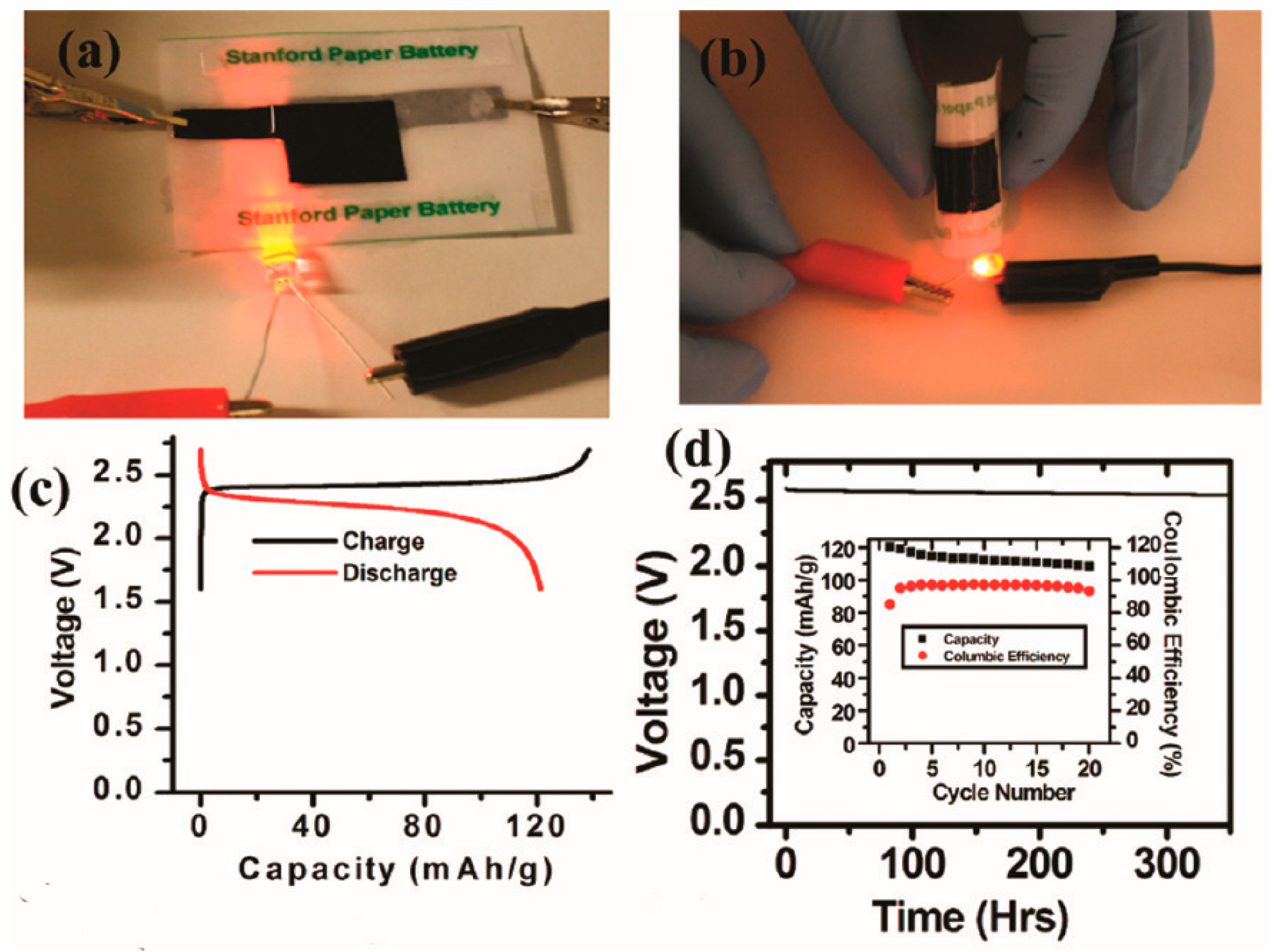

- Hu, L.; Wu, H.; La, M.F.; Yang, Y.; Cui, Y. Thin, flexible secondary Li-ion paper batteries. ACS Nano 2010, 4, 5843–5848. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Li, F.; Cheng, H.-M. Progress in flexible lithium batteries and future prospects. Energy Environ. Sci. 2014, 7, 1307–1338. [Google Scholar] [CrossRef]

- Wang, C.; Cao, Y.; Luo, Z.; Li, G.; Xu, W.; Xiong, C.; He, G.; Wang, Y.; Li, S.; Liu, H. Flexible potassium avnadate nanowires on Ti fabric as a binder-free cathode for high-performance advanced lithium-ion battery. Chem. Eng. J. 2016, 307, 382–388. [Google Scholar] [CrossRef]

- Park, M.; Cha, H.; Lee, Y.; Hong, J.; Kim, S.Y.; Cho, J. Postpatterned electrodes for flexible node-type lithium-ion batteries. Adv. Mater. 2017, 29, 1605773–1605780. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Song, K.; van Aken, P.A.; Maier, J.; Yu, Y. Self-supported Li4Ti5O12-C nanotube arrays as high-rate and long-life anode materials for flexible Li-ion batteries. Nano Lett. 2014, 14, 2597–2603. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Tang, H.; Huang, Z.; Zhou, J.; Ren, X.; Huang, K.; Qi, X.; Zhong, J. Flexible bismuth selenide/graphene composite paper for lithium-ion batteries. Ceram. Int. 2016, 43, 1437–1442. [Google Scholar] [CrossRef]

- Li, N.; Chena, Z.; Rena, W.; Lia, F.; Chenga, H.-M. Flexible graphene-based lithium ion batteries with ultrafast charge and discharge rates. Proc. Natl. Acad. Sci. USA 2012, 109, 17360–17365. [Google Scholar] [CrossRef] [PubMed]

- Mo, R.; Rooney, D.; Sun, K.; Yang, H.Y. 3D nitrogen-doped graphene foam with encapsulated germanium/nitrogen-doped graphene yolk-shell nanoarchitecture for high-performance flexible Li-ion battery. Nat. Commun. 2017, 8, 13949–13958. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Jiang, H.; Hu, Y.; Liu, Y.; Zhang, L.; Liu, H.; Li, C. 3D ordered macroporous MoS2@C nanostructure for flexible Li-ion batteries. Adv. Mater. 2017, 29, 1603020–1603026. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Baca, A.J.; Park, S.I.; Elvikis, P.; Geddes, J.B., 3rd; Li, L.; Kim, R.H.; Xiao, J.; Wang, S.; Kim, T.H.; et al. Ultrathin silicon solar microcells for semitransparent, mechanically flexible and microconcentrator module designs. Nat. Mater. 2008, 7, 907–915. [Google Scholar] [CrossRef] [PubMed]

- Martín, F.; Navarrete, E.; Morales, J.; Roldán, C.; Ramos-Barrado, J.R.; Sánchez, L. High-energy, efficient and transparent electrode for lithium batteries. J. Mater. Chem. 2010, 20, 2847–2852. [Google Scholar] [CrossRef]

- Jung, S.; Lee, S.; Song, M.; Kim, D.-G.; You, D.S.; Kim, J.-K.; Kim, C.S.; Kim, T.-M.; Kim, K.-H.; Kim, J.-J.; et al. Extremely Flexible Transparent Conducting Electrodes for Organic Devices. Adv. Energy Mater. 2014, 4, 1300474. [Google Scholar] [CrossRef]

- Yang, Y.; Jeong, S.; Hu, L.; Wu, H.; Lee, S.W.; Cui, Y. Transparent lithium-ion batteries. Proc. Natl. Acad. Sci. USA 2011, 108, 13013–13018. [Google Scholar] [CrossRef] [PubMed]

- Gittleson, F.S.; Hwang, D.; Ryu, W.H.; Hashmi, S.M.; Hwang, J.; Goh, T.; Taylor, A.D. Ultrathin nanotube/nanowire electrodes by spin–spray layer-by-layer assembly: A concept for transparent energy storage. ACS Nano 2015, 9, 10005–10017. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Luan, P.; Shao, Q.; Dong, H.; Li, J.; Chen, J.; Zhao, D.; Cai, L.; Zhou, W.; Chen, X. A “skeleton/skin” strategy for preparing ultrathin free-standing single-walled carbon nanotube/polyaniline films for high performance supercapacitor electrodes. Energy Environ. Sci. 2012, 5, 8726–8733. [Google Scholar] [CrossRef]

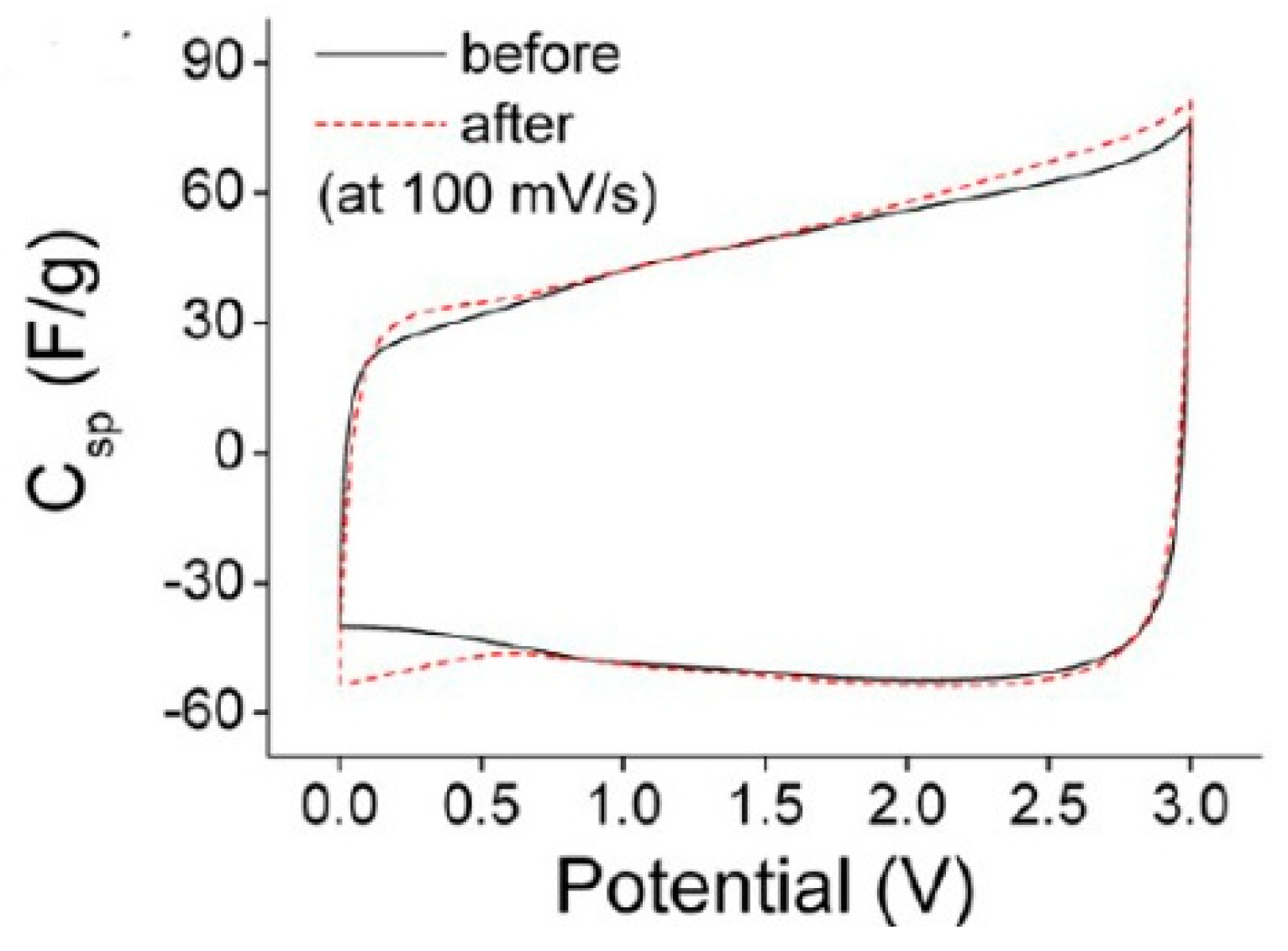

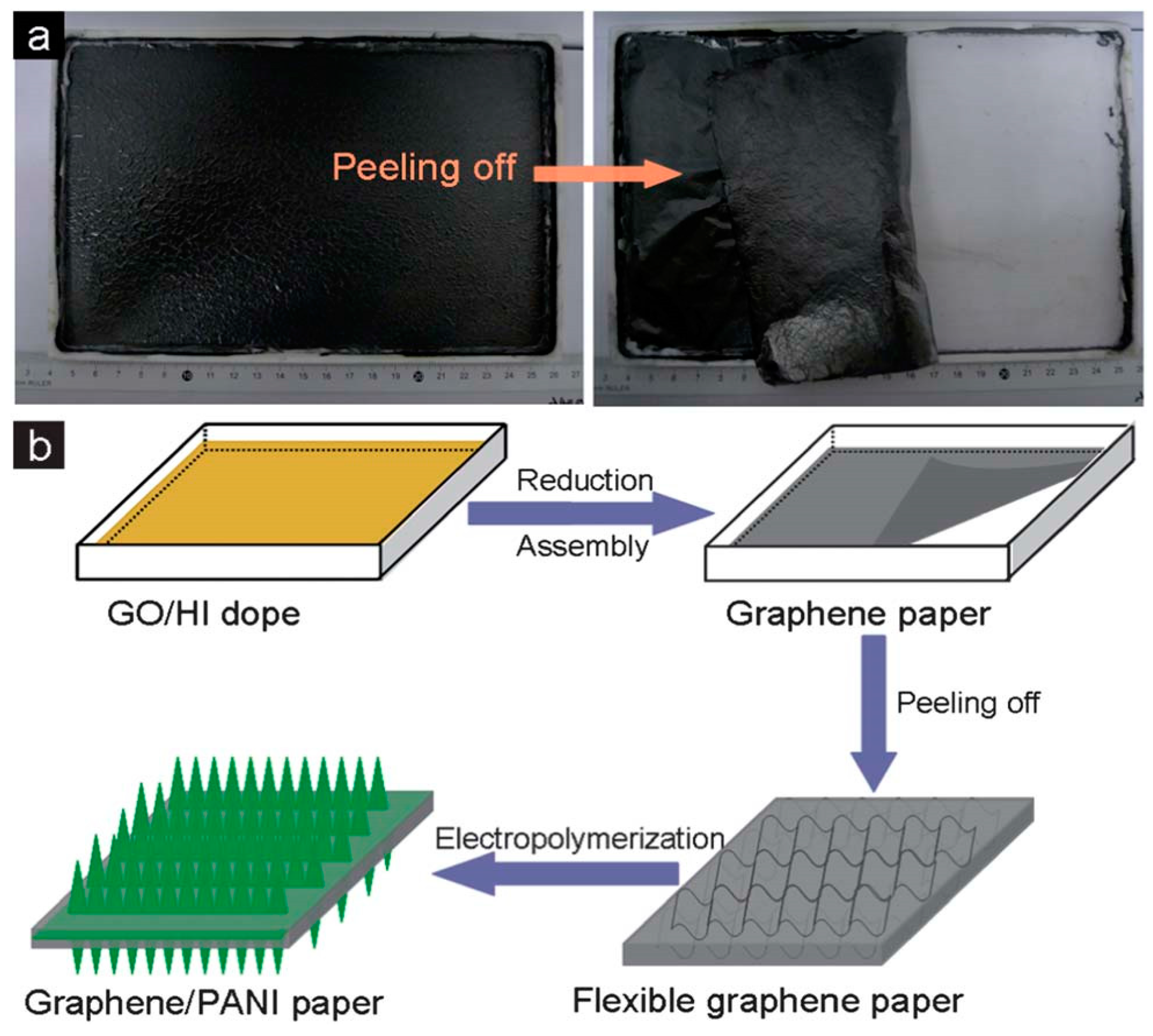

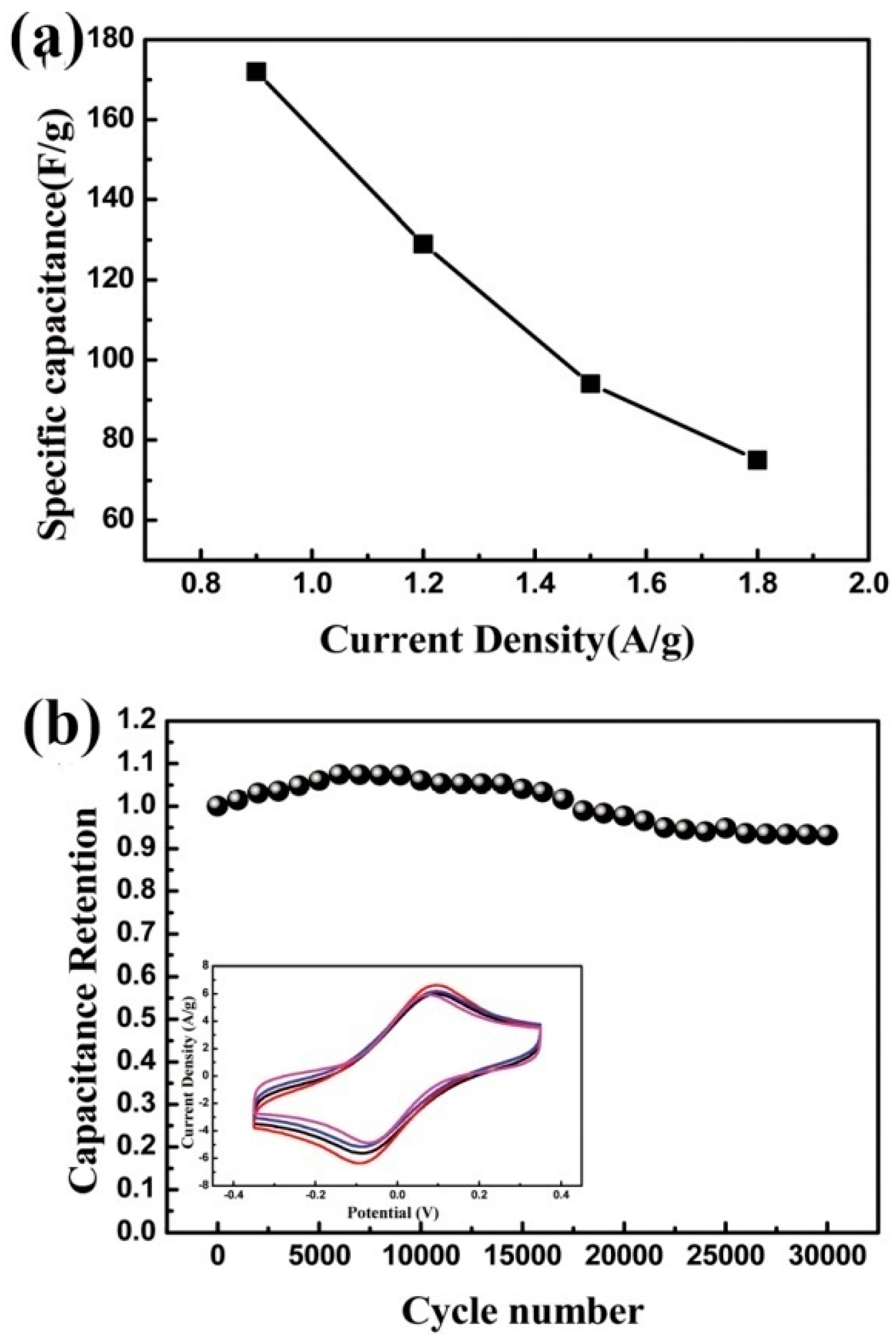

- Cong, H.P.; Ren, X.C.; Wang, P.; Yu, S.H. Flexible graphene–polyaniline composite paper for high-performance supercapacitor. Energy Environ. Sci. 2013, 6, 1185–1191. [Google Scholar] [CrossRef]

- Liu, L.; Niu, Z.; Zhang, L.; Zhou, W.; Chen, X.; Xie, S. Nanostructured graphene composite papers for highly flexible and foldable supercapacitors. Adv. Mater. 2014, 26, 4855–4862. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Yang, C.; Xue, Y.; Wang, C.; Cao, J.; Chen, Z. Facile synthesis of novel metal-organic nickel hydroxide nanorods for high performance supercapacitor. Electrochim. Acta 2016, 211, 595–602. [Google Scholar] [CrossRef]

- Mendoza-Sanchez, B.; Gogotsi, Y. Synthesis of two-dimensional materials for capacitive energy storage. Adv. Mater. 2016, 28, 6104–6135. [Google Scholar] [CrossRef] [PubMed]

- Lv, T.; Yao, Y.; Li, N.; Chen, T. Highly stretchable supercapacitors based on aligned carbon nanotube/molybdenum disulfide composites. Angew. Chem. 2016, 128, 9191–9195. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Xu, P.; Liu, B.; Wu, C.; Xie, Y.; Yu, G. Ultrathin two-dimensional MnO2/graphene hybrid nanostructures for high-performance, flexible planar supercapacitors. Nano Lett. 2013, 13, 2151–2157. [Google Scholar] [CrossRef] [PubMed]

- Qi, D.; Liu, Z.; Liu, Y.; Leow, W.R.; Zhu, B.; Yang, H.; Yu, J.; Wang, W.; Wang, H.; Yin, S. Suspended wavy graphene microribbons for highly stretchable microsupercapacitors. Adv. Mater. 2015, 27, 5559–5566. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, C.; Xin, S.; Yang, Z.; Li, Y.; Zhang, D.; Yao, P. A facile synthesis of MoS2/reduced graphene oxide@polyaniline for high-performance supercapacitors. ACS Appl. Mater. Interfaces 2016, 8, 21373–21380. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.J.; Chun, S.J.; Lee, S.S.; Kim, B.Y.; Kim, J.H.; Chung, H.; Lee, S.Y.; Kim, W. All-solid-state flexible supercapacitors fabricated with bacterial nanocellulose papers, carbon nanotubes, and triblock-copolymer ion gels. ACS Nano 2012, 6, 6400–6406. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Pasta, M.; Mantia, F.L.; Cui, L.; Jeong, S.; Deshazer, H.D.; Choi, J.W.; Han, S.M.; Cui, Y. Stretchable, porous, and conductive energy textiles. Nano Lett. 2010, 10, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhou, J.; Chen, L.; Zhang, P.; Fu, W.; Zhao, H.; Ma, Y.; Pan, X.; Zhang, Z.; Han, W. Highly flexible freestanding porous carbon nanofibers for electrodes materials of high-performance all-carbon supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 23515–23520. [Google Scholar] [CrossRef] [PubMed]

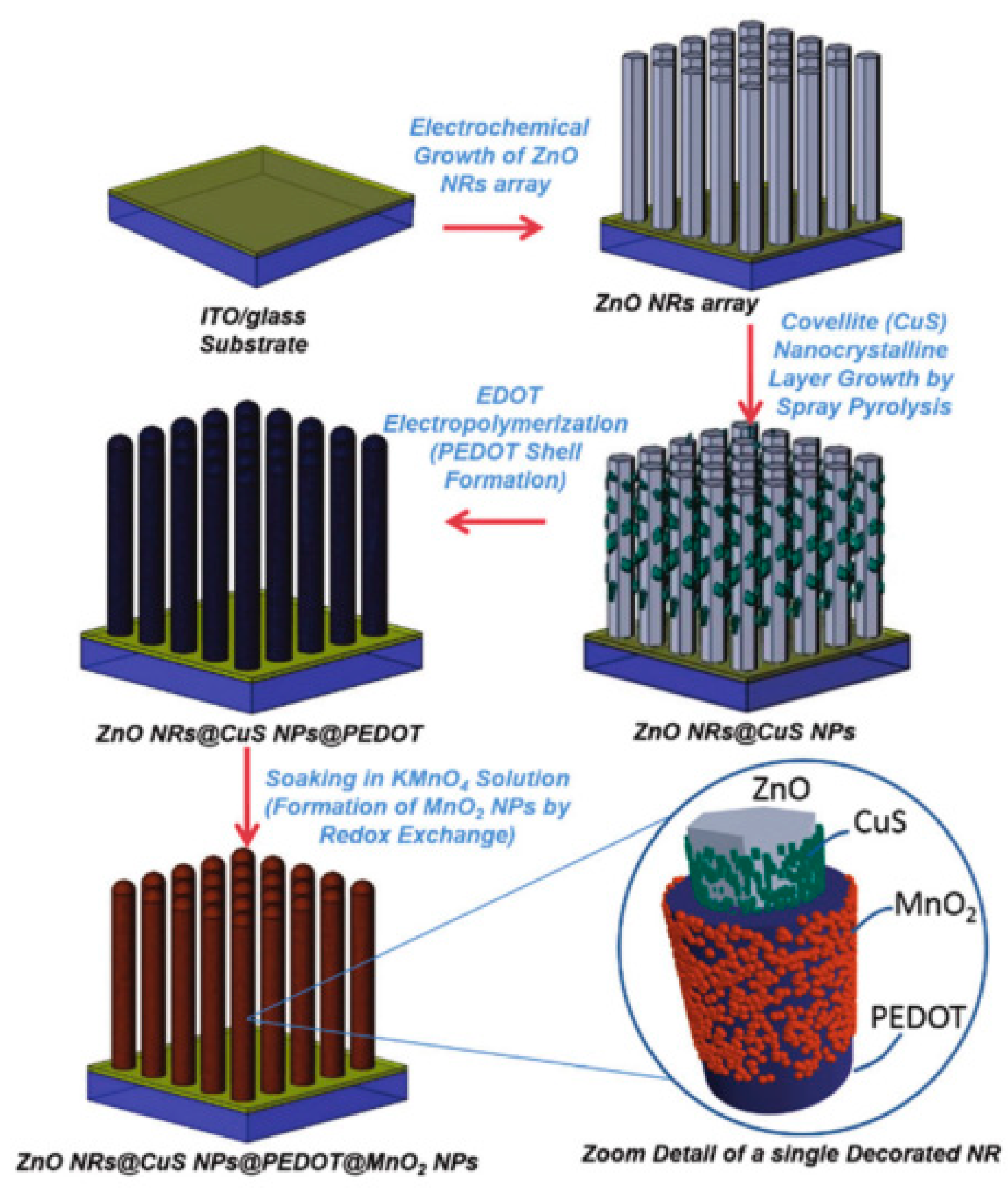

- Rodríguez-Moreno, J.; Navarrete-Astorga, E.; Dalchiele, E.A.; Schrebler, R.; Ramos-Barrado, J.R.; Martín, F. Vertically aligned ZnO@CuS@PEDOTcore@shellnanorod arrays decorated with MnO2 nanoparticles for a high-performance and semi-transparent supercapacitor electrode. Chem. Commun. 2014, 50, 5652–5655. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Zhou, W.; Chen, J.; Feng, G.; Hong, L.; Hu, Y.; Ma, W.; Dong, H.; Li, J.; Xie, S. A repeated halving approach to fabricate ultrathin single-walled carbon nanotube films for transparent supercapacitors. Small 2013, 9, 518–524. [Google Scholar] [CrossRef] [PubMed]

- Kholmanov, I.N.; Domingues, S.H.; Chou, H.; Wang, X.; Tan, C.; Kim, J.Y.; Li, H.; Piner, R.; Zarbin, A.J.; Ruoff, R.S. Reduced graphene oxide/copper nanowire hybrid films as high-performance transparent electrodes. ACS Nano 2013, 7, 1811–1816. [Google Scholar] [CrossRef] [PubMed]

- Yu, A.; Roes, I.; Davies, A.; Chen, Z. Ultrathin, transparent, and flexible graphene films for supercapacitor application. Appl. Phys. Lett. 2010, 96, 253105. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, H.; Wang, J.; Chen, Z. Synthesis of layered birnessite-type manganese oxide thin films on plastic substrates by chemical bath deposition for flexible transparent supercapacitors. J. Alloys Compd. 2011, 509, 10234–10240. [Google Scholar] [CrossRef]

- Gao, K.; Shao, Z.; Wu, X.; Wang, X.; Zhang, Y.; Wang, W.; Wang, F. Paper-based transparent flexible thin film supercapacitors. Nanoscale 2013, 5, 5307–5311. [Google Scholar] [CrossRef] [PubMed]

- Qiu, T.; Luo, B.; Giersig, M.; Akinoglu, E.M.; Hao, L.; Wang, X.; Shi, L.; Jin, M.; Zhi, L. Au@MnO2 core-shell nanomesh electrodes for transparent flexible supercapacitors. Small 2014, 10, 4136–4141. [Google Scholar] [PubMed]

- Cai, G.; Darmawan, P.; Cui, M.; Wang, J.; Chen, J.; Magdassi, S.; Lee, P.S. Highly stable transparent conductive silver grid/PEDOT:PSS electrodes for integrated bifunctional flexible electrochromic supercapacitors. Adv. Energy Mater. 2016, 6, 1501882–1501889. [Google Scholar] [CrossRef]

- Mukesh, C.; Gupta, R.; Srivastava, D.N.; Nataraj, S.K.; Prasad, K. Preparation of a natural deep eutectic solvent mediated self polymerized highly flexible transparent gel having super capacitive behaviour. RSC Adv. 2016, 6, 28586–28592. [Google Scholar] [CrossRef]

- Ge, J.; Cheng, G.; Chen, L. Transparent and flexible electrodes and supercapacitors using polyaniline/single-walled carbon nanotube composite thin films. Nanoscale 2011, 3, 3084–3088. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Feng, Y.; Lv, P.; Lei, D.; Shen, Y.; Li, Y.; Feng, W. Transparent, conductive, and flexible multiwalled carbon nanotube/graphene hybrid electrodes with two three-dimensional microstructures. J. Phys. Chem. C 2012, 116, 4970–4978. [Google Scholar] [CrossRef]

- Jung, H.Y.; Karimi, M.B.; Hahm, M.G.; Ajayan, P.M.; Jung, Y.J. Transparent, flexible supercapacitors from nano-engineered carbon films. Sci. Rep. 2012, 2, 773–778. [Google Scholar] [CrossRef] [PubMed]

- Kanninen, P.; Luong, N.D.; Anoshkin, I.V.; Tsapenko, A.; Seppala, J.; Nasibulin, A.G.; Kallio, T. Transparent and flexible high-performance supercapacitors based on single-walled carbon nanotube films. Nanotechnology 2016, 27, 235403–235409. [Google Scholar] [CrossRef] [PubMed]

- Sansom, E.B.; Rinderknecht, D.; Gharib, M. Controlled partial embedding of carbon nanotubes within flexible transparent layers. Nanotechnology 2008, 19, 035302. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Jia, Y.; Wei, J.; Wang, K.; Shu, Q.; Gui, X.; Zhu, H.; Cao, A.; Wu, D. Large area, highly transparent carbon nanotube spiderwebs for energy harvesting. J. Mater. Chem. 2010, 20, 7236–7240. [Google Scholar] [CrossRef]

- Lin, H.; Li, L.; Ren, J.; Cai, Z.; Qiu, L.; Yang, Z.; Peng, H. Conducting polymer composite film incorporated with aligned carbon nanotubes for transparent, flexible and efficient supercapacitor. Sci. Rep. 2013, 3, 1353. [Google Scholar] [CrossRef] [PubMed]

- Yuksel, R.; Sarioba, Z.; Cirpan, A.; Hiralal, P.; Unalan, H.E. Transparent and flexible supercapacitors with single walled carbon nanotube thin film electrodes. ACS Appl. Mater. Interfaces 2014, 6, 15434–15439. [Google Scholar] [CrossRef] [PubMed]

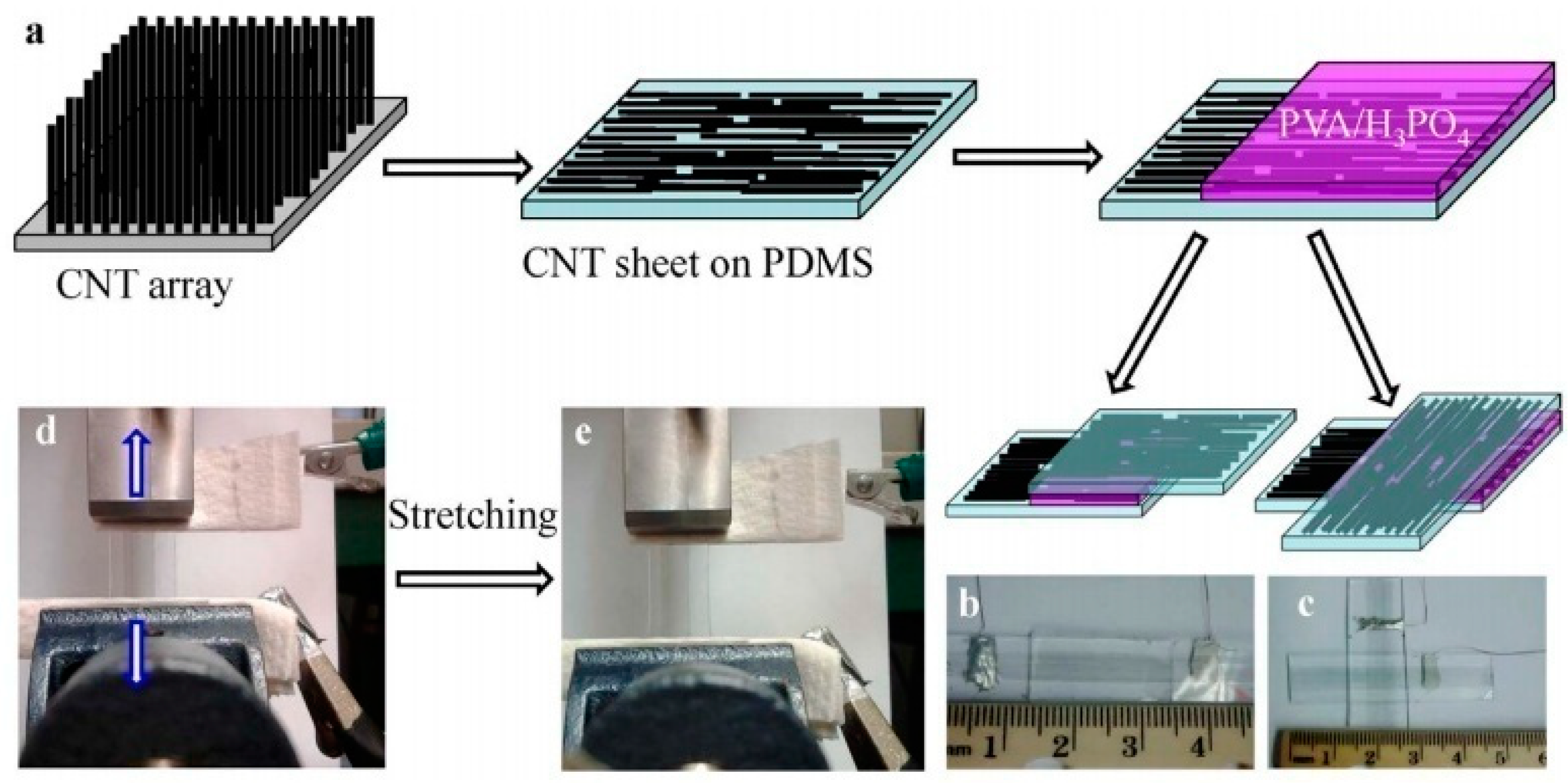

- Chen, T.; Peng, H.; Durstock, M.; Dai, L. High-performance transparent and stretchable all-solid supercapacitors based on highly aligned carbon nanotube sheets. Sci. Rep. 2014, 4, 3612–3618. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhao, D.; Alvarez, N.; Shanov, V.N.; Heineman, W.R. Optically transparent carbon nanotube film electrode for thin layer spectroelectrochemistry. Anal. Chem. 2015, 87, 9687–9695. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Kang, J.; Choi, J.B.; Suhr, J.; Yu, J.; Li, F.; Byun, J.H.; Kim, B.S.; Chou, T.W. Laminated ultrathin chemical vapor deposition graphene films based stretchable and transparent high-rate supercapacitor. ACS Nano 2014, 8, 9437–9445. [Google Scholar] [CrossRef] [PubMed]

- Ashis, K.S.; Jong-Dal, H. Flexible and transparent plastic electrodes composed of reduced graphene oxide-polyaniline films for supercapacitor application. Bull. Korean Chem. Soc 2014, 35, 1799–1805. [Google Scholar]

- Chen, T.; Xue, Y.; Roy, A.K.; Dai, L. Transparent and stretchable high-performance supercapacitors based on wrinkled graphene electrodes. Acs Nano 2014, 8, 1039–1046. [Google Scholar] [CrossRef] [PubMed]

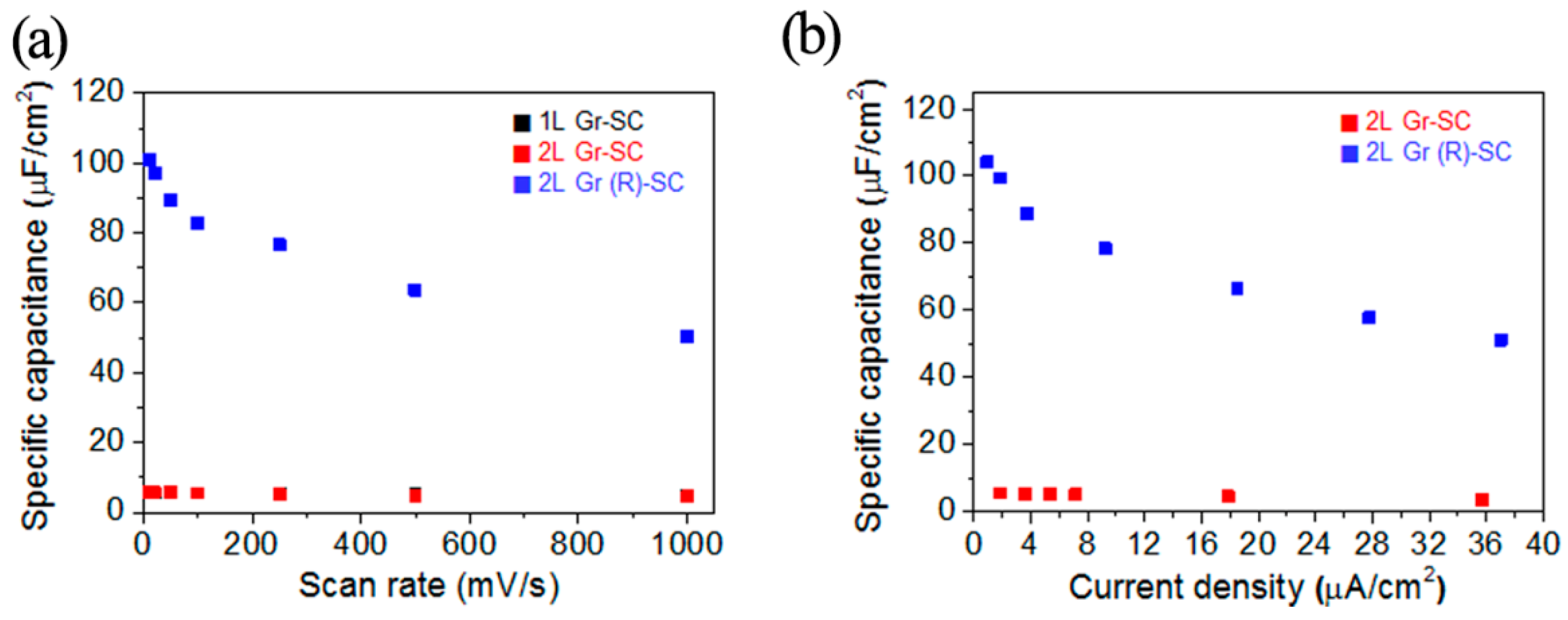

- Jo, K.; Lee, S.; Kim, S.M.; In, J.B.; Lee, S.M.; Kim, J.H.; Lee, H.J.; Kim, K.S. Stacked bilayer graphene and redox-active interlayer for transparent and flexible high-performance supercapacitors. Chem. Mater. 2015, 27, 3621–3627. [Google Scholar] [CrossRef]

- Lee, K.; Lee, H.; Shin, Y.; Yoon, Y.; Kim, D.; Lee, H. Highly transparent and flexible supercapacitors using graphene-graphene quantum dots chelate. Nano Energy 2016, 26, 746–754. [Google Scholar] [CrossRef]

- Xueliu, F.; Tao, C.; Liming, D. Graphene networks for high-performance flexible and transparent supercapacitors. RSC Adv. 2014, 4, 36996–37002. [Google Scholar]

- Li, N.; Huang, X.; Zhang, H. High energy density transparent and flexible asymmetric supercapacitor based on a transparent metal hydroxides@graphene micro-structured film via a scalable gas-liquid diffusion method. J. Alloys Compd. 2017, 712, 194–203. [Google Scholar] [CrossRef]

- Liu, X.Y.; Gao, Y.Q.; Yang, G.W. A flexible, transparent and super-long-life supercapacitor based on ultrafine Co3O4 nanocrystal electrodes. Nanoscale 2016, 8, 4227–4235. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, J.; Yang, G. Transparent, flexible, and high-performance supercapacitor based on ultrafine nickel cobaltite nanospheres. Appl. Phys. A 2017, 123, 997–1007. [Google Scholar] [CrossRef]

- Lee, H.; Hong, S.; Lee, J.; Suh, Y.D.; Kwon, J.; Moon, H.; Kim, H.; Yeo, J.; Ko, S.H. Highly stretchable and transparent supercapacitor by Ag-Au core-shell nanowire network with high electrochemical stability. ACS Appl. Mater. Interfaces 2016, 8, 15449–15458. [Google Scholar] [CrossRef] [PubMed]

- Devarayan, K.; Lei, D.; Kim, H.-Y.; Kim, B.-S. Flexible transparent electrode based on PANi nanowire/nylon nanofiber reinforced cellulose acetate thin film as supercapacitor. Chem. Eng. J. 2015, 273, 603–609. [Google Scholar] [CrossRef]

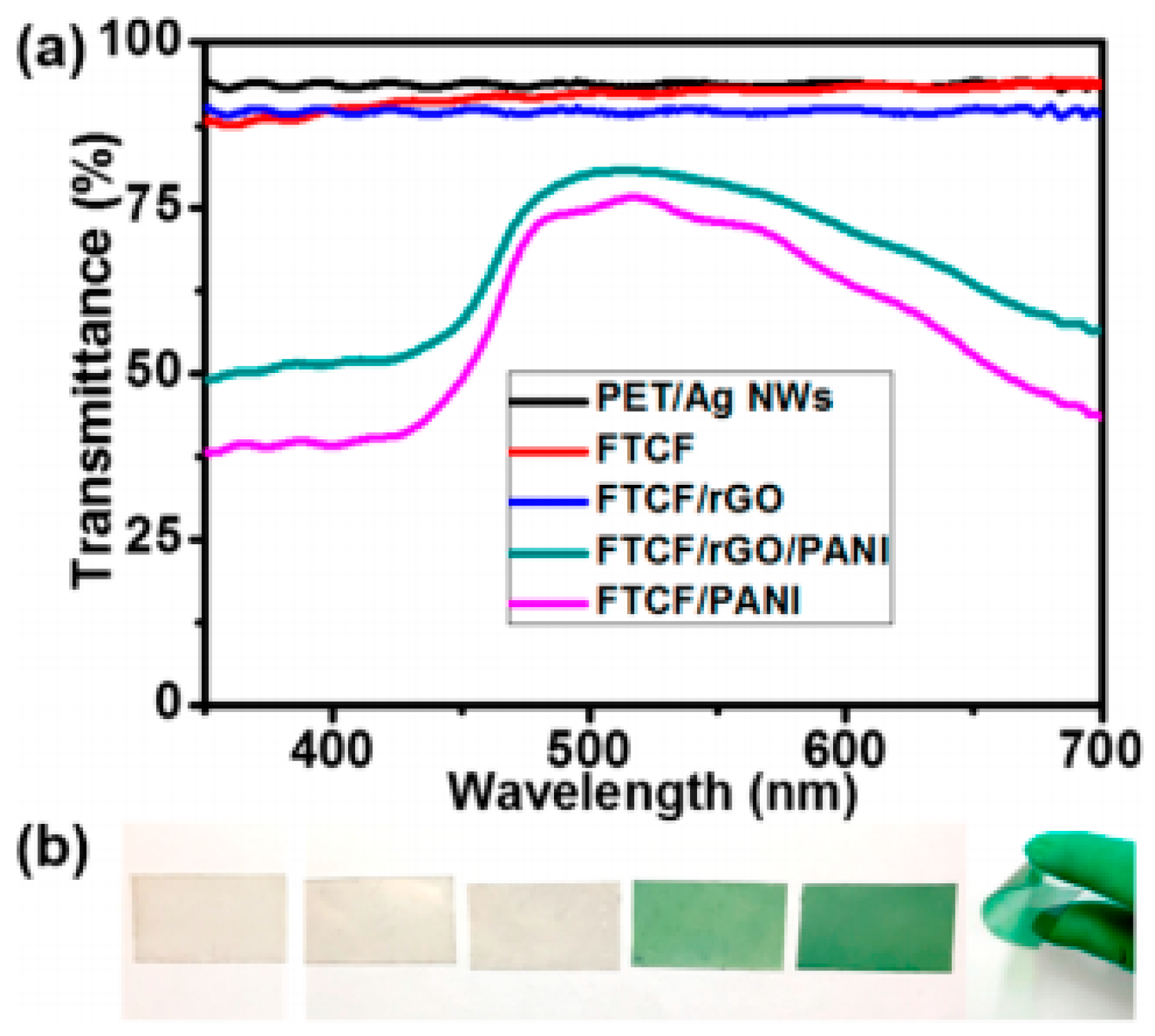

- Chen, F.; Wan, P.; Xu, H.; Sun, X. Flexible transparent supercapacitors based on hierarchical nanocomposite films. ACS Appl. Mater. Interfaces 2017, 9, 17865–17871. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Jiang, Q.; Yuan, N.; Tang, J. A Review on Flexible and Transparent Energy Storage System. Materials 2018, 11, 2280. https://doi.org/10.3390/ma11112280

Li J, Jiang Q, Yuan N, Tang J. A Review on Flexible and Transparent Energy Storage System. Materials. 2018; 11(11):2280. https://doi.org/10.3390/ma11112280

Chicago/Turabian StyleLi, Jie, Qianqian Jiang, Nannan Yuan, and Jianguo Tang. 2018. "A Review on Flexible and Transparent Energy Storage System" Materials 11, no. 11: 2280. https://doi.org/10.3390/ma11112280

APA StyleLi, J., Jiang, Q., Yuan, N., & Tang, J. (2018). A Review on Flexible and Transparent Energy Storage System. Materials, 11(11), 2280. https://doi.org/10.3390/ma11112280