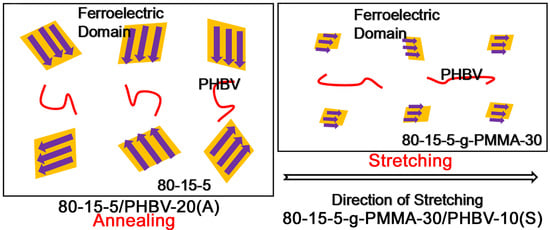

Annealing and Stretching Induced High Energy Storage Properties in All-Organic Composite Dielectric Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Characterization of Original Materials and Study of Dielectric Property

3.2. Mono-Polar and Bi-Polar D-E Loops of All As-Prepared Film Samples

3.3. Energy Storage Properties of All As-Prepared Film Samples

3.4. Comparison Study on All the As-Prepared Samples

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yao, Z.; Song, Z.; Hao, H.; Yu, Z.; Cao, M.; Zhang, S.; Lanagan, M.T.; Liu, H. Homogeneous/inhomogeneous-structured dielectrics and their energy-storage performances. Adv. Mater. 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, L.; Yuan, Q.; Chen, J.; Niu, Y.; Xu, X.; Cheng, Y.; Yao, B.; Wang, Q.; Wang, H. Ultrahigh energy density and greatly enhanced discharged efficiency of sandwich-structured polymer nanocomposites with optimized spatial organization. Nano Energy 2018, 44, 364–370. [Google Scholar] [CrossRef]

- Azizi, A.; Gadinski, M.R.; Li, Q.; Alsaud, M.A.; Wang, J.; Wang, Y.; Wang, B.; Liu, F.; Chen, L.Q.; Alem, N. High-performance polymers sandwiched with chemical vapor deposited hexagonal boron nitrides as scalable high-temperature dielectric materials. Adv. Mater. 2017, 29, 1701864. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Ma, J.; Ma, J.; Zhang, Q.; Liu, X.; Guan, B.; Gu, L.; Zhang, X.; Zhang, Y.J.; Li, L. Giant energy density and high efficiency achieved in bismuth ferrite-based film capacitors via domain engineering. Nat. Commun. 2018, 9, 1813. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Wang, C.; Lorenzini, R.G.; Ma, R.; Zhu, Q.; Sinkovits, D.W.; Pilania, G.; Oganov, A.R.; Kumar, S.; Sotzing, G.A. Rational design of all organic polymer dielectrics. Nat. Commun. 2014, 5, 4845. [Google Scholar] [CrossRef] [PubMed]

- Ritamäki, M.; Rytöluoto, I.; Lahti, K.; Vestberg, T.; Pasanen, S.; Flyktman, T. Large-area approach to evaluate DC electro-thermal ageing behavior of BOPP thin films for capacitor insulation systems. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 826–836. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, J.; Zhao, J.; Jin, K.; Sun, J.; Guo, X.; Fang, Q. A new fluoropolymer having triazine rings as a dielectric material: Synthesis and properties. Polym. Chem. 2017, 8, 6173–6180. [Google Scholar] [CrossRef]

- Qiao, Y.; Yin, X.; Zhu, T.; Li, H.; Tang, C. Dielectric polymers with novel chemistry, compositions and architectures. Prog. Polym. Sci. 2018, 80, 153–162. [Google Scholar] [CrossRef]

- Traore, B.; Pedesseau, L.; Assam, L.; Che, X.; Blancon, J.C.; Tsai, H.; Nie, W.; Stoumpos, C.C.; Kanatzidis, M.G.; Tretiak, S. Composite nature of layered hybrid perovskites: Assessment on quantum and dielectric confinements and band alignment. ACS Nano 2018, 12, 3321–3332. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Zhang, J.; Teng, B.; Ji, C.; Zhang, W.; Sun, Z.; Luo, J. Inorganic–organic hybrid switchable dielectric materials with the coexistence of magnetic anomalies induced by reversible high-temperature phase transition. J. Mater. Chem. C 2017, 5, 8509–8515. [Google Scholar] [CrossRef]

- Xu, W.; Yang, G.; Jin, L.; Liu, J.; Zhang, Y.; Zhang, Z.; Jiang, Z. High-k polymer nanocomposites filled with hyperbranched phthalocyanine coated BaTiO3 for high temperature and elevated field applications. ACS Appl. Mater. Interfaces 2018, 10, 11233–11241. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chi, Q.; Liu, L.; Zhang, C.; Chen, C.; Wang, X.; Lei, Q. Enhanced electric polarization and breakdown strength in the all-organic sandwich-structured poly(vinylidene fluoride)-based dielectric film for high energy density capacitor. APL Mater. 2017, 5, 076109. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Lu, X.; Yang, G.; Zhang, X.; Cheng, Z.Y. Nano-clip based composites with a low percolation threshold and high dielectric constant. Nano Energy 2016, 26, 550–557. [Google Scholar] [CrossRef]

- Mao, X.; Guo, W.; Li, C.; Yang, J.; Du, L.; Hu, W.; Tang, X. Low-temperature synthesis of polyimide/poly(vinylidene fluoride) composites with excellent dielectric property. Mater. Lett. 2017, 193, 213–215. [Google Scholar] [CrossRef]

- Soulestin, T.; Ladmiral, V.; Santos, F.D.D.; Améduri, B. Vinylidene fluoride- and trifluoroethylene-containing fluorinated electroactive copolymers. How does chemistry impact properties? Prog. Polym. Sci. 2017, 72, 16–20. [Google Scholar] [CrossRef]

- Ferreguell, A.; Winterburn, J. Biosynthesis and characterisation of polyhydroxyalkanoates with controlled composition and microstructure. Biomacromolecules 2018, 19, 996–1005. [Google Scholar] [CrossRef] [PubMed]

- Jing, Z.L.; Rondeau, E.; Trau, M.; Cooper-White, J.; Grøndahl, L. Characterisation of amine functionalised poly(3-hydroxybuturate-co-3-hydroxyvalerate) surfaces. Polymer 2011, 52, 3251–3258. [Google Scholar] [CrossRef]

- Ten, E.; Long, J.; Wolcott, M.P. Preparation and properties of aligned poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhiskers composites. Carbohydr. Polym. 2013, 92, 206–213. [Google Scholar] [CrossRef] [PubMed]

- Kechaou, B.; Salvia, M.; Benzarti, K.; Turki, C.; Fakhfakh, Z.; Treheux, D. Role of fiber/matrix interphases on dielectric, friction, and mechanical properties of glass fiber-reinforced epoxy composites. J. Compos. Mater. 2014, 46, 131–144. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Żuk, T.; Markiewicz, E. Triboelectric series and electrostatic separation of some biopolymers. Polym. Test. 2015, 42, 192–198. [Google Scholar] [CrossRef]

- Huang, T.; Lu, M.; Yu, H.; Zhang, Q.; Wang, H.; Zhu, M. Enhanced power output of a triboelectric nanogenerator composed of electrospun nanofiber mats doped with graphene oxide. Sci. Rep. 2015, 5, 13942. [Google Scholar] [CrossRef] [PubMed]

- Rožič, B.; Kutnjak, Z.; Neese, B.; Lu, S.; Zhang, Q.M. Electrocaloric effect in the relaxor ferroelectric polymer composition P(VDF-TrFE-CFE)-P(VDF-CTFE). Phase Transit. 2010, 83, 819–823. [Google Scholar] [CrossRef]

- Shingne, N.; Geuss, M.; Hartmann-Azanza, B.; Steinhart, M.; Thurn-Albrecht, T. Formation, morphology and internal structure of one-dimensional nanostructures of the ferroelectric polymer P(VDF-TrFE). Polymer 2013, 54, 2737–2744. [Google Scholar] [CrossRef]

- Smith, O.L.; Kim, Y.; Kathaperumal, M.; Gadinski, M.R.; Pan, M.J.; Wang, Q.; Perry, J.W. Enhanced permittivity and energy density in neat poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) terpolymer films through control of morphology. ACS Appl. Mater. Interfaces 2014, 6, 9584–9589. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Xiang, L.; Xu, T.; Wang, W.; Xie, W.; Zhou, D. Low-voltage operating flexible ferroelectric organic field-effect transistor nonvolatile memory with a vertical phase separation P(VDF-TrFE-CTFE)/PS dielectric. Appl. Phys. Lett. 2017, 111, 183302. [Google Scholar] [CrossRef]

- Kim, T.H.; Jee, K.Y.; Yong, T.L. The improvement of water flux and mechanical strength of PVDF hollow fiber membranes by stretching and annealing conditions. Macromol. Res. 2015, 23, 592–600. [Google Scholar] [CrossRef]

- Sun, J.; Yao, L.; Zhao, Q.L.; Huang, J.; Song, R.; Ma, Z.; He, L.H.; Huang, W.; Hao, Y.M. Modification on crystallization of poly(vinylidene fluoride) (PVDF) by solvent extraction of poly(methyl methacrylate) (PMMA) in PVDF/PMMA blends. Front. Mater. Sci. 2011, 5, 388–400. [Google Scholar] [CrossRef]

- Yano, T.; Higaki, Y.; Tao, D.; Murakami, D.; Kobayashi, M.; Ohta, N.; Koike, J.I.; Horigome, M.; Masunaga, H.; Ogawa, H. Orientation of poly(vinyl alcohol) nanofiber and crystallites in non-woven electrospun nanofiber mats under uniaxial stretching. Polymer 2012, 53, 4702–4708. [Google Scholar] [CrossRef]

- Nakashima, T.; Xu, C.; Bin, Y.; Matsuo, M. Morphology and orientation of crystallites of simultaneous biaxially stretching ultra-high molecular weight polyethylene films prepared by gelation/crystallization from solutions. Polym. J. 2001, 33, 54–68. [Google Scholar] [CrossRef]

- Chen, K.; Qavi, S.; Foudazi, R. Double-stage phase separation in dynamically asymmetric ternary polymer blends. RSC Adv. 2016, 6, 92104–92114. [Google Scholar] [CrossRef]

- Yoshioka, T.; Tashiro, K.; Ohta, N. The molecular orientation enhancement of silk by the hot-stretching-induced transition from α-helix-HFIP complex to β-sheet. Biomacromolecules 2016, 17, 1437–1448. [Google Scholar] [CrossRef] [PubMed]

- Kanuga, K.; Cakmak, M. Role of nanoparticles and relaxation on strain-induced crystallization behavior in uniaxially stretched polyethylene naphthalate films: A mechano-optical study. Macromolecules 2013, 46, 6300–6308. [Google Scholar] [CrossRef]

- Fenouillot, F.; Cassagnau, P.; Majesté, J.C. Uneven distribution of nanoparticles in immiscible fluids: Morphology development in polymer blends. Polymer 2009, 50, 1333–1350. [Google Scholar] [CrossRef]

- Marega, C.; Marigo, A. Influence of annealing and chain defects on the melting behaviour of poly(vinylidene fluoride). Eur. Polym. J. 2003, 39, 1713–1720. [Google Scholar] [CrossRef]

- Yang, L.; Li, X.; Allahyarov, E.; Taylor, P.L.; Zhang, Q.M.; Zhu, L. Novel polymer ferroelectric behavior via crystal isomorphism and the nanoconfinement effect. Polymer 2013, 54, 1709–1728. [Google Scholar] [CrossRef]

- Kang, J.; Xiong, B.; Liu, D.; Cao, Y.; Chen, J.; Yang, F.; Xiang, M. Understanding in the morphology and tensile behavior of isotactic polypropylene cast films with different stereo-defect distribution. J. Polym. Res. 2014, 21, 485. [Google Scholar] [CrossRef]

- Tiwari, V.; Srivastava, G. Effect of thermal processing conditions on the structure and dielectric properties of PVDF films. J. Polym. Res. 2014, 21, 587. [Google Scholar] [CrossRef]

| Samples | Breakdown Strength (MV·m−1) | Maximum Displacement (µC·cm−2) | Residual Displacement (µC·cm−2) | Energy Density (J·cm−3) | Energy Efficiency (%) |

|---|---|---|---|---|---|

| 80-15-5 | 300 | 6.7 | 1.4 | 6.0 | 60 |

| 80-15-5(A) | 300 | 7.5 | 1.5 | 6.4 | 60 |

| PHBV | 200 | 1.5 | ~0 | 1.5 | 97 |

| 80-15-5/PHBV-20 | 150 | 3.4 | 1.9 | 0.6 | 20 |

| 80-15-5/PHBV-20(A) | 350 | 6.8 | 1.1 | 8.1 | 68 |

| 80-15-5-g-PMMA-20/PHBV-10 | 400 | 4.1 | 0.4 | 7.1 | 84 |

| 80-15-5-g-PMMA-30/PHBV-5 | 225 | 2.7 | ~0 | 2.9 | 92 |

| 80-15-5-g-PMMA-30/PHBV-5(S) | 350 | 4.0 | 0.4 | 5.5 | 75 |

| 80-15-5-g-PMMA-30/PHBV-10 | 400 | 5.4 | 1.4 | 5.6 | 67 |

| 80-15-5-g-PMMA-30/PHBV-10(S) | 450 | 5.8 | 0.9 | 9.4 | 70 |

| PMMA/PHBV-10 | 350 | 3.6 | ~0 | 5.9 | 92 |

| PMMA/PHBV-10(S) | 350 | 2.8 | ~0 | 4.4 | 92 |

| PMMA | 275 | 3.9 | ~0 | 4.8 | 88 |

| PMMA(S) | 425 | 3.9 | ~0 | 7.8 | 94 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Peng, C.; Deng, Q.; Li, Y.; Hu, J.; Wu, Q. Annealing and Stretching Induced High Energy Storage Properties in All-Organic Composite Dielectric Films. Materials 2018, 11, 2279. https://doi.org/10.3390/ma11112279

Feng Y, Peng C, Deng Q, Li Y, Hu J, Wu Q. Annealing and Stretching Induced High Energy Storage Properties in All-Organic Composite Dielectric Films. Materials. 2018; 11(11):2279. https://doi.org/10.3390/ma11112279

Chicago/Turabian StyleFeng, Yefeng, Cheng Peng, Qihuang Deng, Yandong Li, Jianbing Hu, and Qin Wu. 2018. "Annealing and Stretching Induced High Energy Storage Properties in All-Organic Composite Dielectric Films" Materials 11, no. 11: 2279. https://doi.org/10.3390/ma11112279

APA StyleFeng, Y., Peng, C., Deng, Q., Li, Y., Hu, J., & Wu, Q. (2018). Annealing and Stretching Induced High Energy Storage Properties in All-Organic Composite Dielectric Films. Materials, 11(11), 2279. https://doi.org/10.3390/ma11112279