Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites

Abstract

1. Introduction

2. Materials and Methods

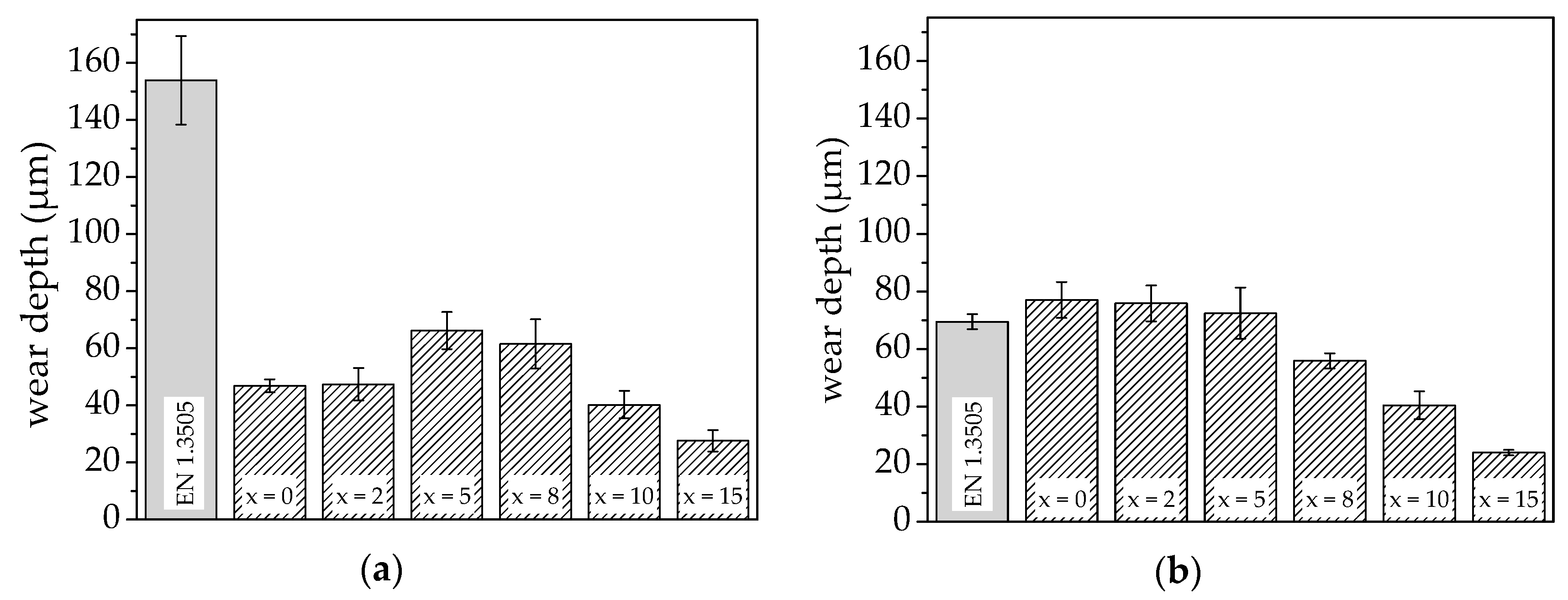

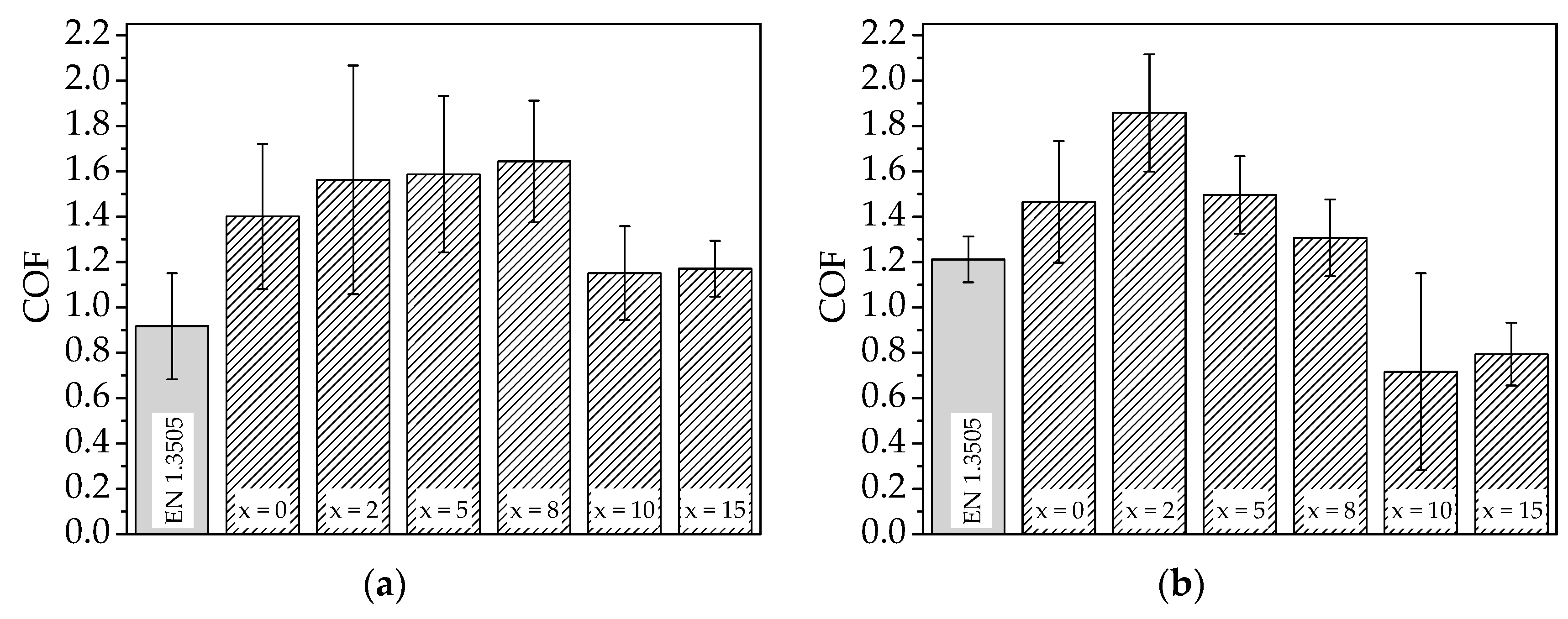

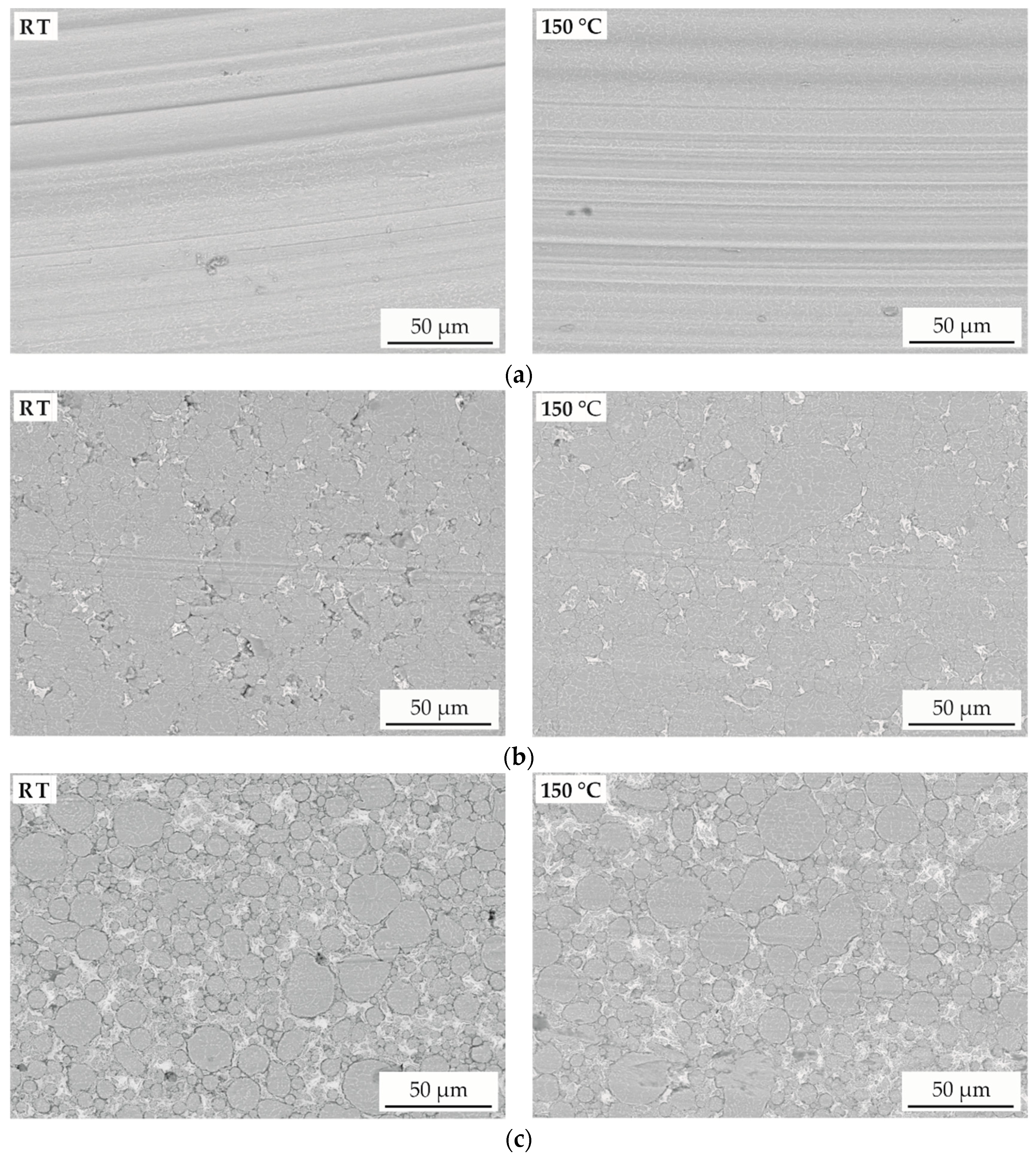

3. Results and Discussion

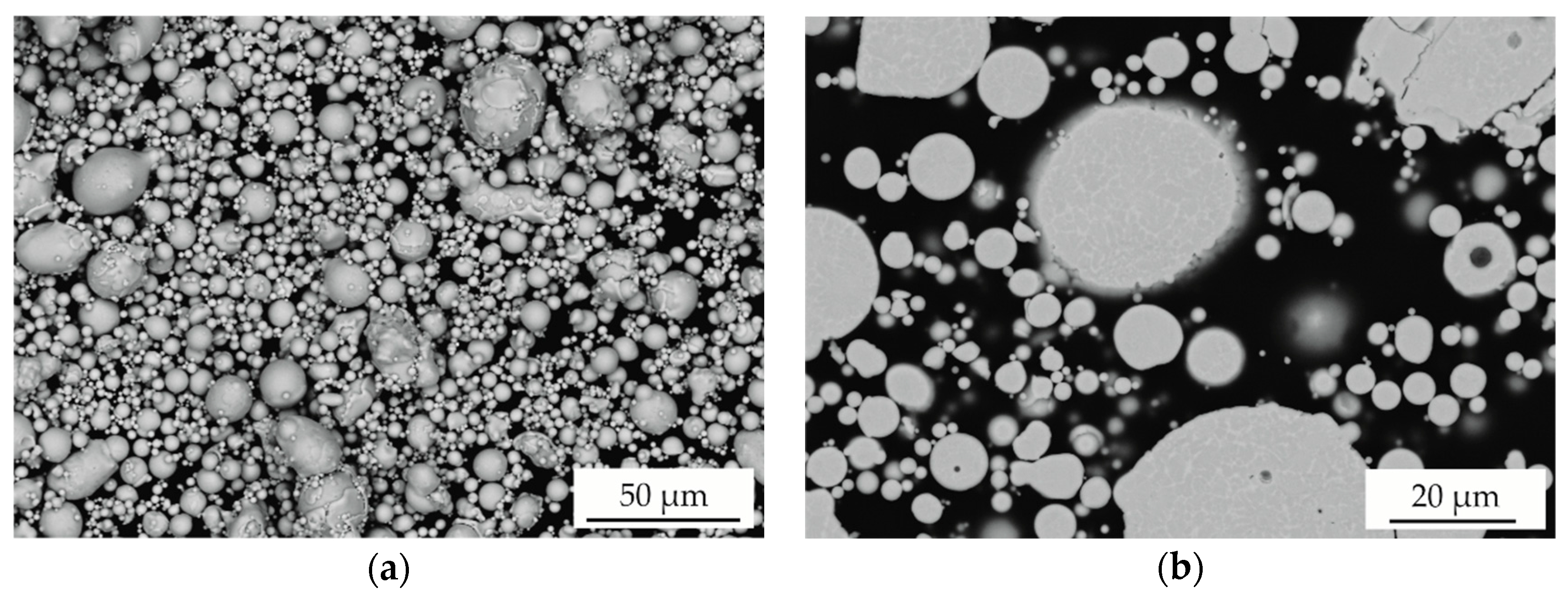

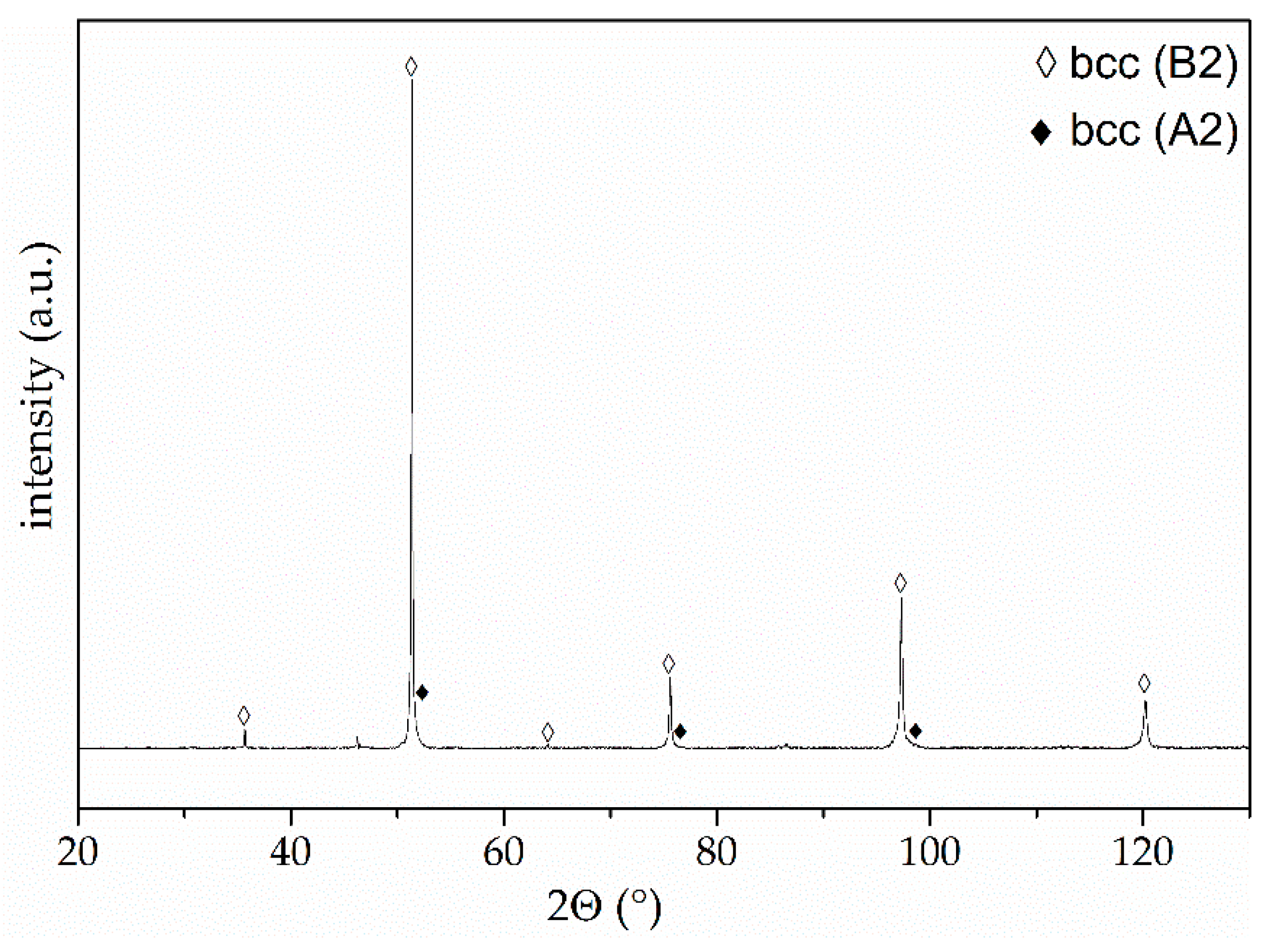

3.1. Feedstock Characterisation

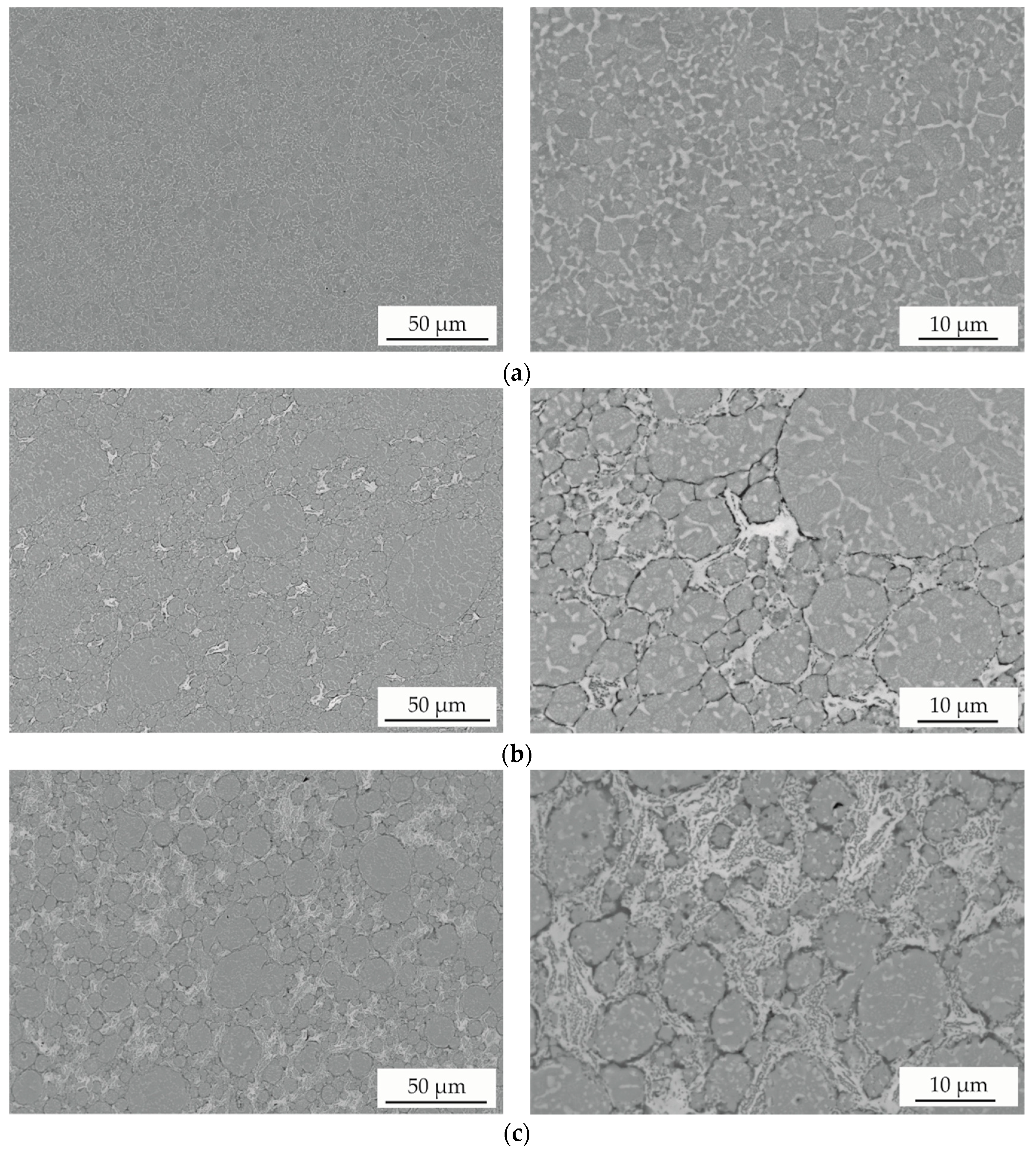

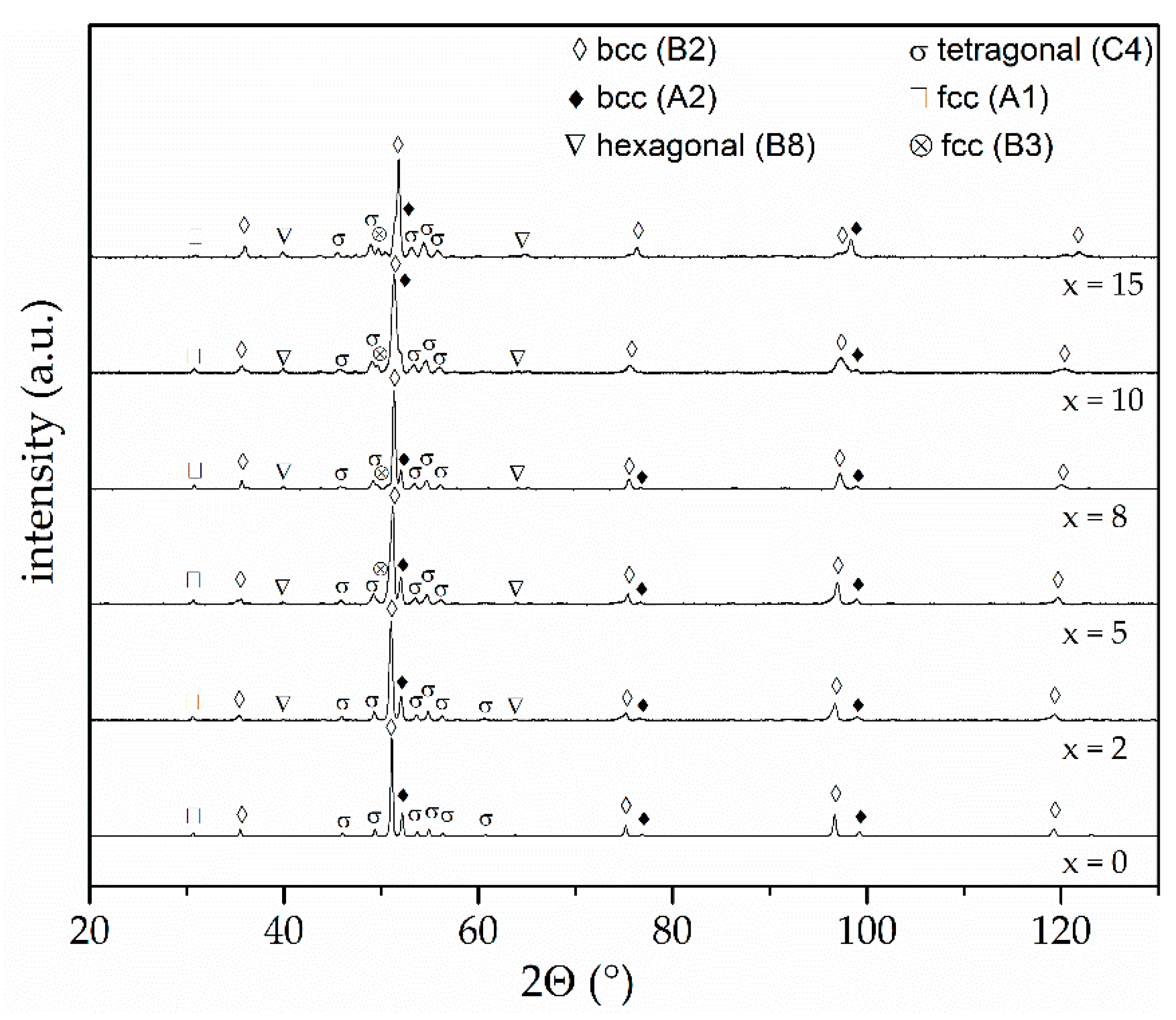

3.2. Composite Characterisation

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W.; Lin, S.-J.; Chin, T.-S.; Gan, J.-Y.; Chen, S.-K.; Shun, T.-T.; Tsau, C.-H.; Chou, S.-Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Miracle, D.B.; Miller, J.D.; Senkov, O.N.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mater. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.-W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys: Fundamentals and Applications, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Murty, B.S.; Yeg, J.-W.; Ranganathan, S. High-Entropy Alloys; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Tsai, K.-Y.; Tsai, M.-H.; Yeh, J.-W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yeh, J.-W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Mehner, T.; Lampke, T. Influence of Titanium on Microstructure, Phase Formation and Wear Behaviour of AlCoCrFeNiTix High-Entropy Alloy. Entropy 2018, 20, 505. [Google Scholar] [CrossRef]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behaviour of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, S.; Chen, X.; Shi, J.; Zhang, Y.; Qiao, J. Optimizing mechanical properties of AlCoCrFeNiTix high-entropy alloys by tailoring microstructures. Acta Mater. 2013, 26, 277–284. [Google Scholar]

- Yu, Y.; Wang, J.; Li, J.; Kou, H.; Duan, H.; Li, J.; Liu, W. Tribological behavior of AlCoCrCuFeNi and AlCoCrFeNiTi0.5 high entropy alloys under hydrogen peroxide solution against different counterparts. Tribol. Int. 2015, 92, 203–210. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Kohrt, C.; Lampke, T. Processing of AlCoCrFeNiTi high entropy alloy by atmospheric plasma spraying. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 12015. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Ji, W.; Fu, Z.; Wang, W.; Wang, H.; Zhang, J.; Wang, Y.; Zhang, F. Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy. J. Alloy Compd. 2014, 589, 61–66. [Google Scholar] [CrossRef]

- Sriharitha, R.; Murty, B.S.; Kottada, R.S. Alloying, thermal stability and strengthening in spark plasma sintered AlxCoCrCuFeNi high entropy alloys. J. Alloy Compd. 2014, 583, 419–426. [Google Scholar] [CrossRef]

- Zhang, A.; Han, J.; Su, B.; Meng, J. A novel CoCrFeNi high entropy alloy matrix self-lubricating composite. J. Alloy Compd. 2017, 725, 700–710. [Google Scholar] [CrossRef]

- Ji, X.; Zhao, J.; Wang, H.; Luo, C. Sliding wear of spark plasma sintered CrFeCoNiCu high entropy alloy coatings with MoS2 and WC additions. Int. J. Adv. Manuf. Technol. 2017, 6, 299. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Liu, X.; Shi, X.; Wu, C.; Yang, K.; Huang, Y.; Deng, X.; Yan, Z.; Xue, B. Tribological behavior of M50-MoS2 self-lubricating composites from 150 to 450 °C. Mater. Chem. Phys. 2017, 198, 145–153. [Google Scholar] [CrossRef]

- Cao, M.; Zhao, L.; Wu, L.; Wang, W. Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition. Coatings 2018, 8, 134. [Google Scholar] [CrossRef]

- Moravcik, I.; Cizek, J.; Gavendova, P.; Sheikh, S.; Guo, S.; Dlouhy, I. Effect of heat treatment on microstructure and mechanical properties of spark plasma sintered AlCoCrFeNiTi0.5 high entropy alloy. Mater. Lett. 2016, 174, 53–56. [Google Scholar] [CrossRef]

| Ball-on-Disk Test | |

|---|---|

| Force | 20 N |

| Radius | 5 mm |

| Speed | 96 rpm |

| Cycles | 15,916 |

| Counter Body | Al2O3 |

| Diameter | 6 mm |

| Temperature | 22 °C; 150 °C |

| Sample | Atomised Powder | SPS |

|---|---|---|

| Al | 18.3 | 18.1 |

| Co | 16.0 | 16.3 |

| Cr | 16.9 | 16.8 |

| Fe | 16.7 | 16.5 |

| Ni | 16.1 | 16.4 |

| Ti | 16.0 | 16.0 |

| Struktur-bericht | Lattice | Structure Type | Pearson Symbol | Space Group | Lattice Parameter (Å) | Detected for x |

|---|---|---|---|---|---|---|

| B2 | bcc | CsCl | cP2 | m (221) | 2.92 | P, 0, 2, 5, 8, 10, 15 |

| A2 | bcc | W | cI2 | m (229) | 2.88 | P, 0, 2, 5, 8, 10, 15 |

| A1 | fcc | Cu | cF4 | m (225) | 5.86 | P, 0, 2, 5, 8, 10, 15 |

| C4 | tetragonal | Ti02 | tP6 | P42/mnm (136) | a = 8.86 c = 4.60 | P, 0, 2, 5, 8, 10, 15 |

| B8 | hexagonal | NiAs | hP4 | P63/mmc (194) | a = 3.39 c = 5.93 | 2, 5, 8, 10, 15 |

| B3 | fcc | ZnS | cF8 | 3m (216) | - | 5, 8, 10, 15 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Löbel, M.; Lindner, T.; Lampke, T. Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites. Materials 2018, 11, 2225. https://doi.org/10.3390/ma11112225

Löbel M, Lindner T, Lampke T. Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites. Materials. 2018; 11(11):2225. https://doi.org/10.3390/ma11112225

Chicago/Turabian StyleLöbel, Martin, Thomas Lindner, and Thomas Lampke. 2018. "Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites" Materials 11, no. 11: 2225. https://doi.org/10.3390/ma11112225

APA StyleLöbel, M., Lindner, T., & Lampke, T. (2018). Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites. Materials, 11(11), 2225. https://doi.org/10.3390/ma11112225