Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites

Abstract

:1. Introduction

2. Materials and Methods

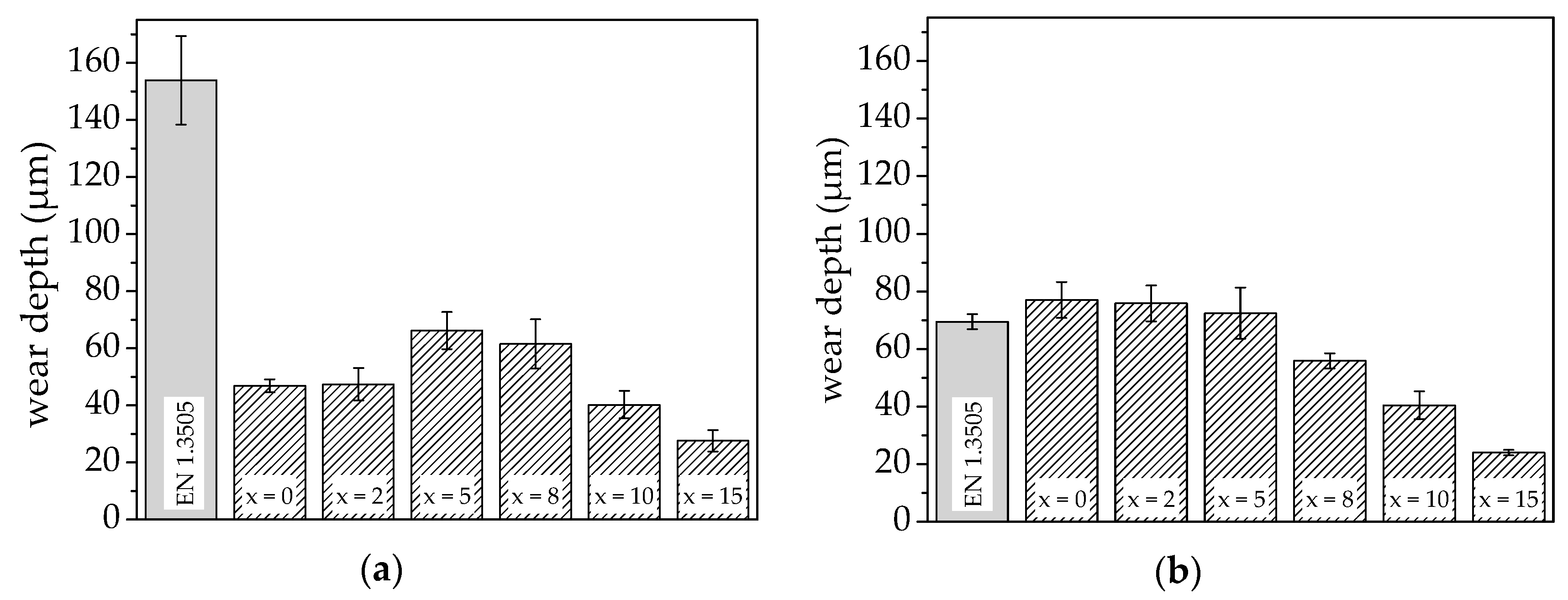

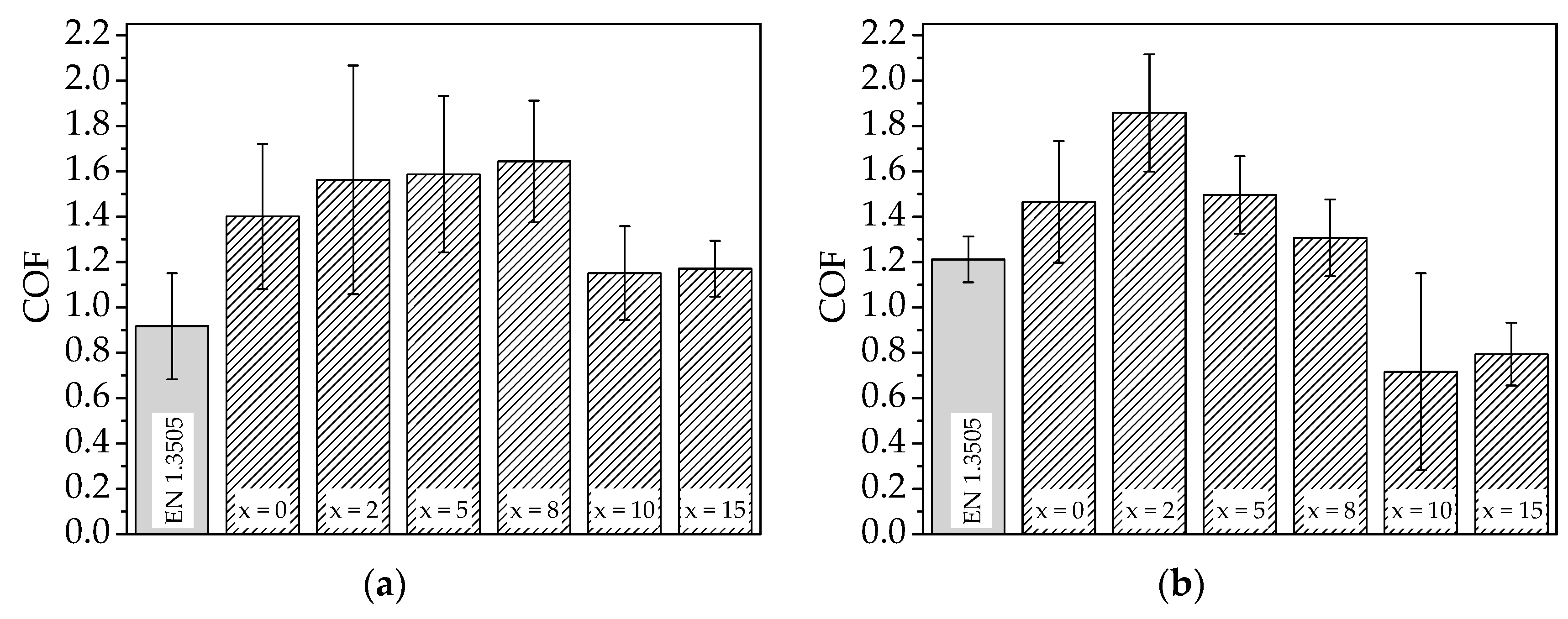

3. Results and Discussion

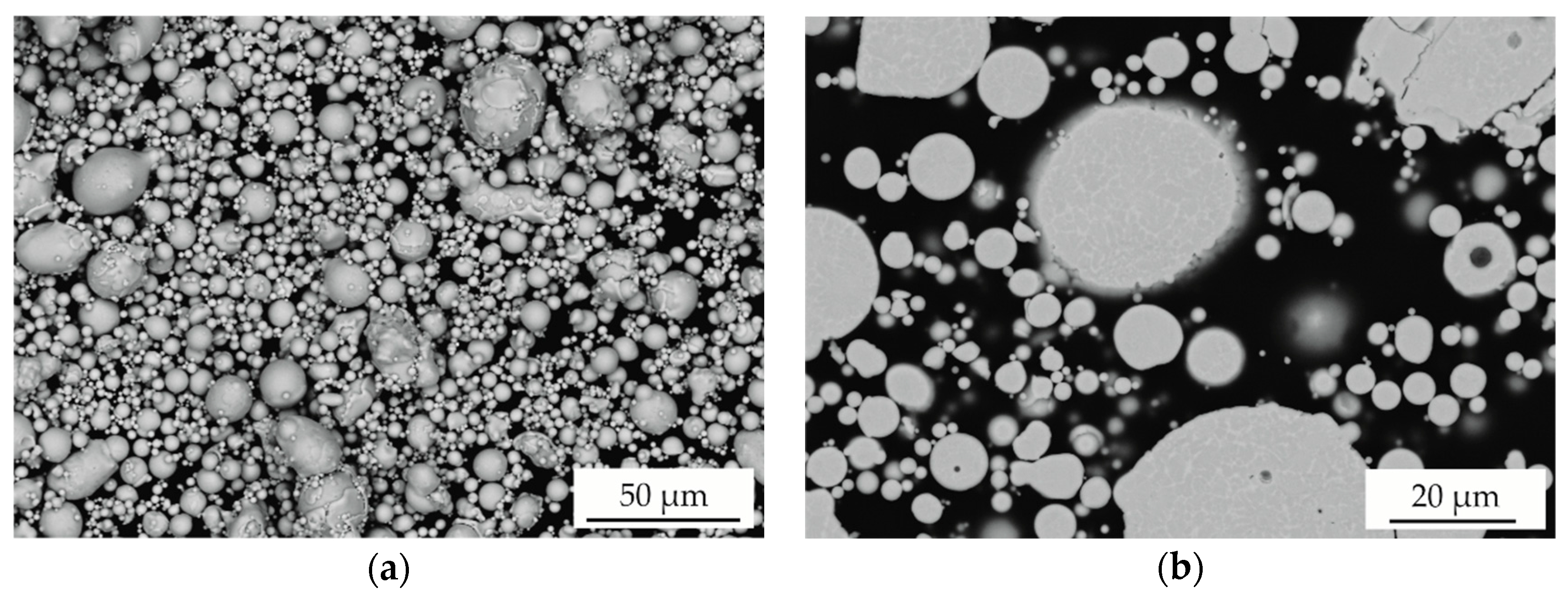

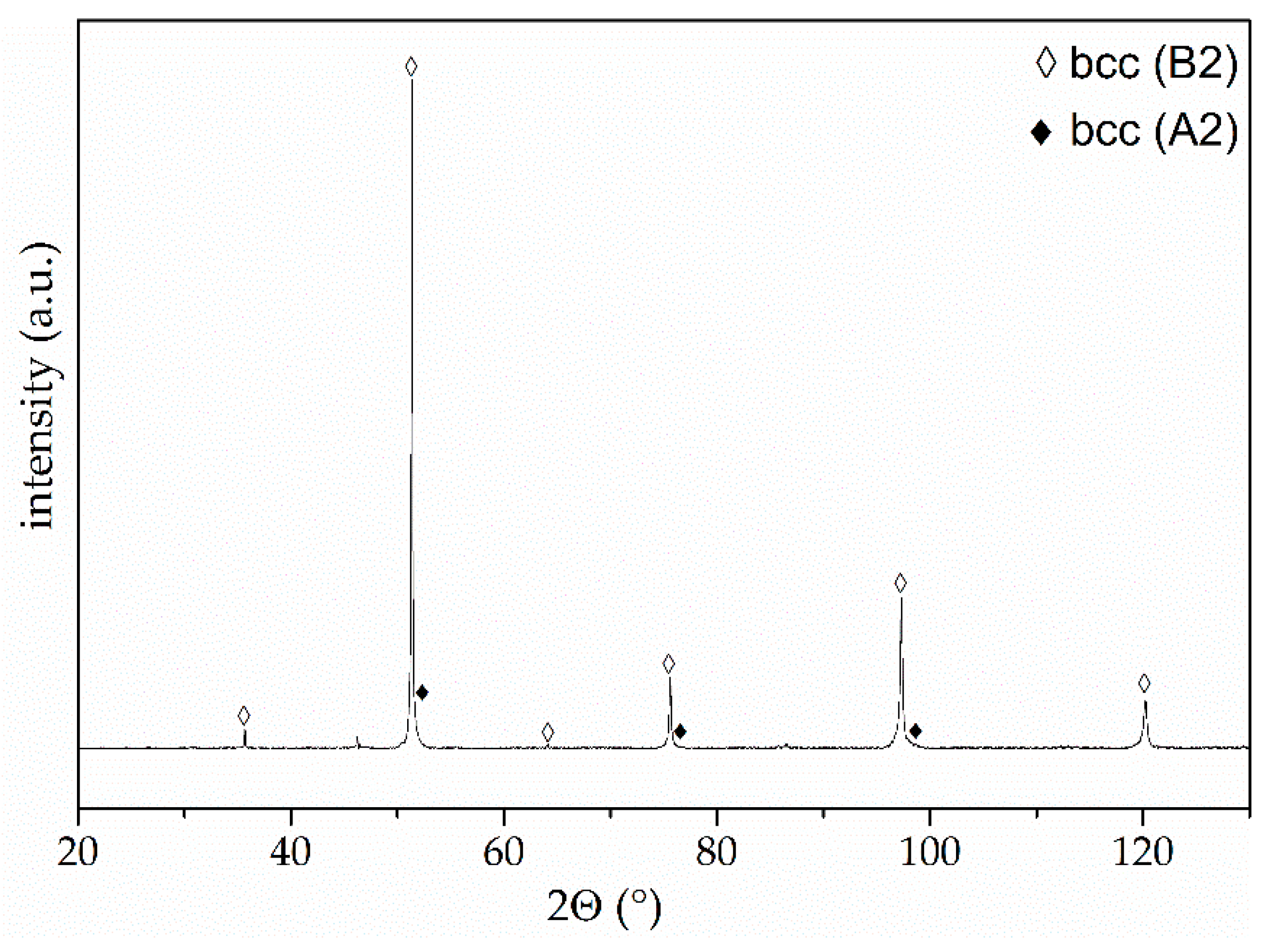

3.1. Feedstock Characterisation

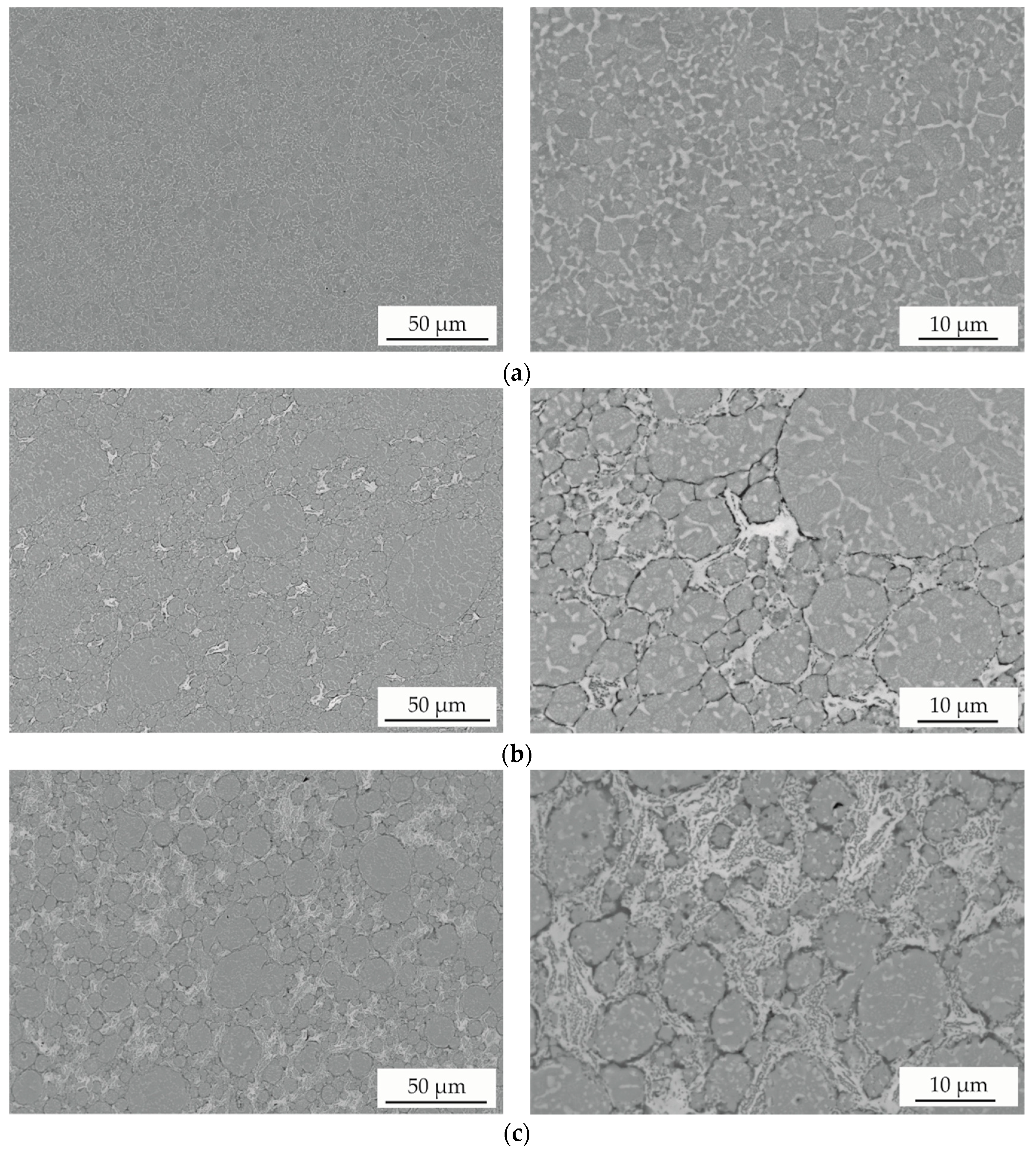

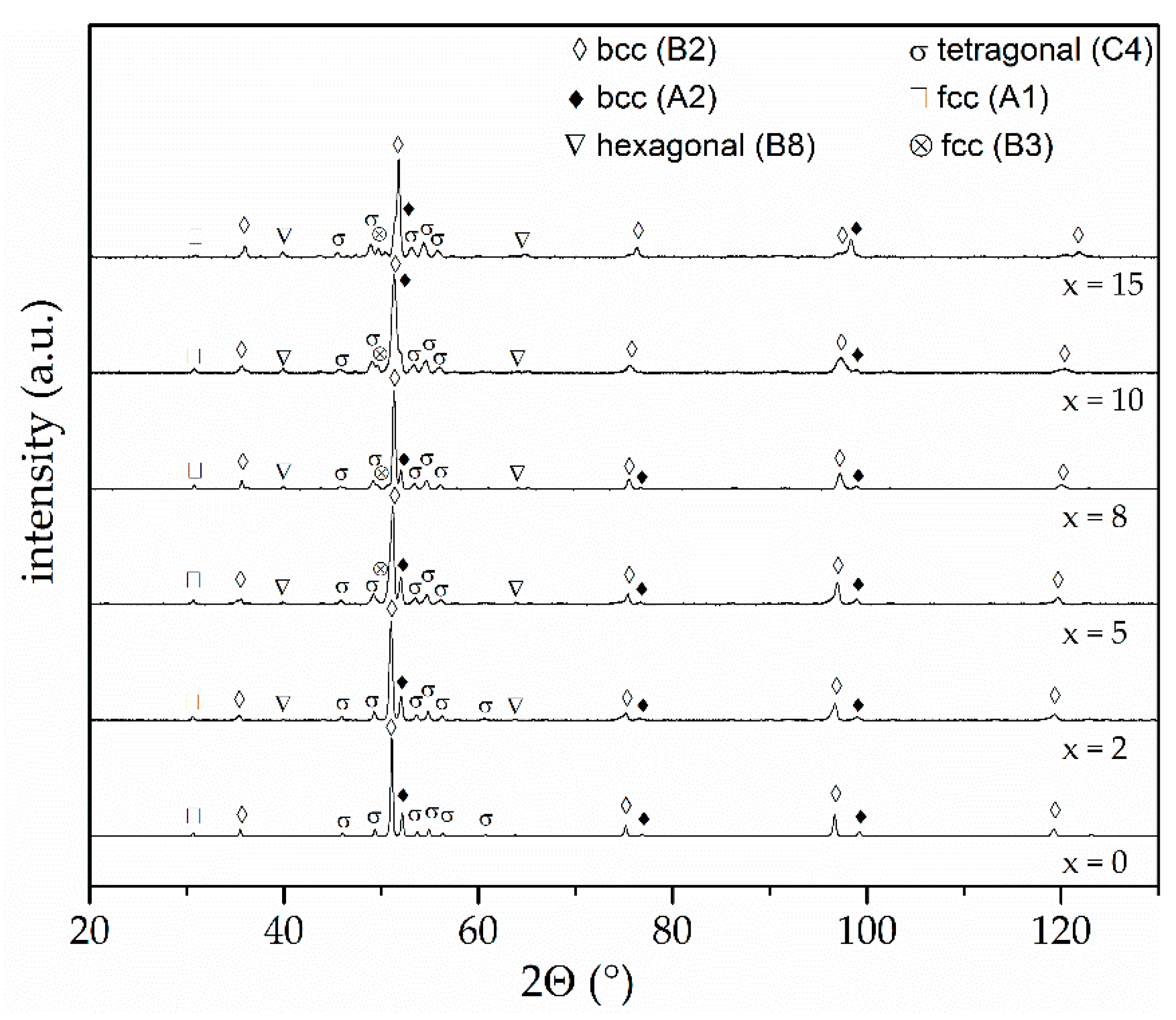

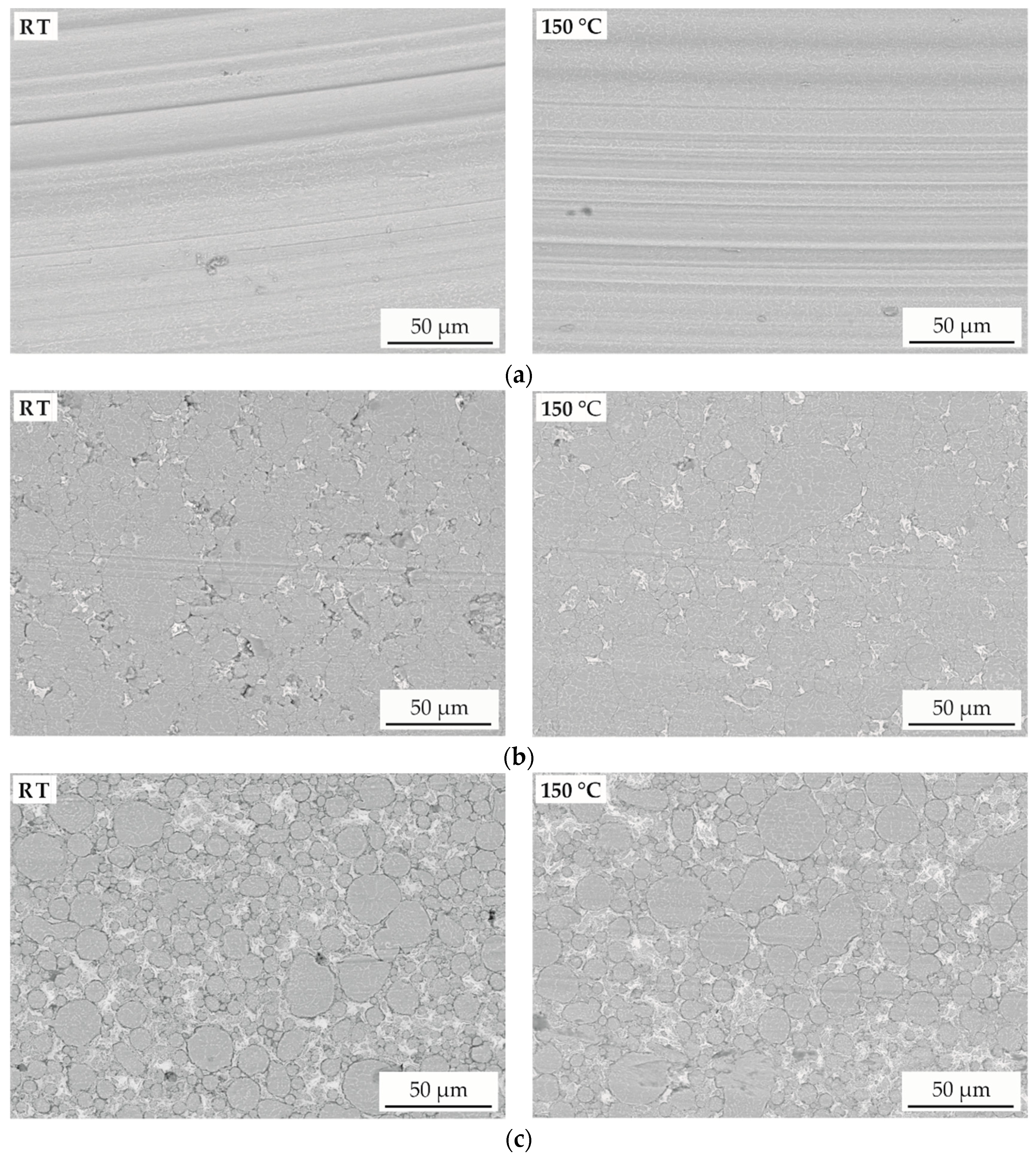

3.2. Composite Characterisation

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.-W.; Lin, S.-J.; Chin, T.-S.; Gan, J.-Y.; Chen, S.-K.; Shun, T.-T.; Tsau, C.-H.; Chou, S.-Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 2004, 35, 2533–2536. [Google Scholar] [CrossRef] [Green Version]

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Miracle, D.B.; Miller, J.D.; Senkov, O.N.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef] [Green Version]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mater. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.-W.; Liaw, P.K.; Zhang, Y. High-Entropy Alloys: Fundamentals and Applications, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Murty, B.S.; Yeg, J.-W.; Ranganathan, S. High-Entropy Alloys; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Tsai, K.-Y.; Tsai, M.-H.; Yeh, J.-W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yeh, J.-W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef] [Green Version]

- Löbel, M.; Lindner, T.; Mehner, T.; Lampke, T. Influence of Titanium on Microstructure, Phase Formation and Wear Behaviour of AlCoCrFeNiTix High-Entropy Alloy. Entropy 2018, 20, 505. [Google Scholar] [CrossRef]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behaviour of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, S.; Chen, X.; Shi, J.; Zhang, Y.; Qiao, J. Optimizing mechanical properties of AlCoCrFeNiTix high-entropy alloys by tailoring microstructures. Acta Mater. 2013, 26, 277–284. [Google Scholar]

- Yu, Y.; Wang, J.; Li, J.; Kou, H.; Duan, H.; Li, J.; Liu, W. Tribological behavior of AlCoCrCuFeNi and AlCoCrFeNiTi0.5 high entropy alloys under hydrogen peroxide solution against different counterparts. Tribol. Int. 2015, 92, 203–210. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Kohrt, C.; Lampke, T. Processing of AlCoCrFeNiTi high entropy alloy by atmospheric plasma spraying. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 12015. [Google Scholar] [CrossRef] [Green Version]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef] [Green Version]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Ji, W.; Fu, Z.; Wang, W.; Wang, H.; Zhang, J.; Wang, Y.; Zhang, F. Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy. J. Alloy Compd. 2014, 589, 61–66. [Google Scholar] [CrossRef]

- Sriharitha, R.; Murty, B.S.; Kottada, R.S. Alloying, thermal stability and strengthening in spark plasma sintered AlxCoCrCuFeNi high entropy alloys. J. Alloy Compd. 2014, 583, 419–426. [Google Scholar] [CrossRef]

- Zhang, A.; Han, J.; Su, B.; Meng, J. A novel CoCrFeNi high entropy alloy matrix self-lubricating composite. J. Alloy Compd. 2017, 725, 700–710. [Google Scholar] [CrossRef]

- Ji, X.; Zhao, J.; Wang, H.; Luo, C. Sliding wear of spark plasma sintered CrFeCoNiCu high entropy alloy coatings with MoS2 and WC additions. Int. J. Adv. Manuf. Technol. 2017, 6, 299. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Liu, X.; Shi, X.; Wu, C.; Yang, K.; Huang, Y.; Deng, X.; Yan, Z.; Xue, B. Tribological behavior of M50-MoS2 self-lubricating composites from 150 to 450 °C. Mater. Chem. Phys. 2017, 198, 145–153. [Google Scholar] [CrossRef]

- Cao, M.; Zhao, L.; Wu, L.; Wang, W. Tribological Properties of New Cu-Al/MoS2 Solid Lubricant Coatings Using Magnetron Sputter Deposition. Coatings 2018, 8, 134. [Google Scholar] [CrossRef]

- Moravcik, I.; Cizek, J.; Gavendova, P.; Sheikh, S.; Guo, S.; Dlouhy, I. Effect of heat treatment on microstructure and mechanical properties of spark plasma sintered AlCoCrFeNiTi0.5 high entropy alloy. Mater. Lett. 2016, 174, 53–56. [Google Scholar] [CrossRef]

| Ball-on-Disk Test | |

|---|---|

| Force | 20 N |

| Radius | 5 mm |

| Speed | 96 rpm |

| Cycles | 15,916 |

| Counter Body | Al2O3 |

| Diameter | 6 mm |

| Temperature | 22 °C; 150 °C |

| Sample | Atomised Powder | SPS |

|---|---|---|

| Al | 18.3 | 18.1 |

| Co | 16.0 | 16.3 |

| Cr | 16.9 | 16.8 |

| Fe | 16.7 | 16.5 |

| Ni | 16.1 | 16.4 |

| Ti | 16.0 | 16.0 |

| Struktur-bericht | Lattice | Structure Type | Pearson Symbol | Space Group | Lattice Parameter (Å) | Detected for x |

|---|---|---|---|---|---|---|

| B2 | bcc | CsCl | cP2 | m (221) | 2.92 | P, 0, 2, 5, 8, 10, 15 |

| A2 | bcc | W | cI2 | m (229) | 2.88 | P, 0, 2, 5, 8, 10, 15 |

| A1 | fcc | Cu | cF4 | m (225) | 5.86 | P, 0, 2, 5, 8, 10, 15 |

| C4 | tetragonal | Ti02 | tP6 | P42/mnm (136) | a = 8.86 c = 4.60 | P, 0, 2, 5, 8, 10, 15 |

| B8 | hexagonal | NiAs | hP4 | P63/mmc (194) | a = 3.39 c = 5.93 | 2, 5, 8, 10, 15 |

| B3 | fcc | ZnS | cF8 | 3m (216) | - | 5, 8, 10, 15 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Löbel, M.; Lindner, T.; Lampke, T. Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites. Materials 2018, 11, 2225. https://doi.org/10.3390/ma11112225

Löbel M, Lindner T, Lampke T. Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites. Materials. 2018; 11(11):2225. https://doi.org/10.3390/ma11112225

Chicago/Turabian StyleLöbel, Martin, Thomas Lindner, and Thomas Lampke. 2018. "Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites" Materials 11, no. 11: 2225. https://doi.org/10.3390/ma11112225

APA StyleLöbel, M., Lindner, T., & Lampke, T. (2018). Enhanced Wear Behaviour of Spark Plasma Sintered AlCoCrFeNiTi High-Entropy Alloy Composites. Materials, 11(11), 2225. https://doi.org/10.3390/ma11112225