On the High Formability of AZ31-0.5Ca Magnesium Alloy

Abstract

:1. Introduction

2. Methods

2.1. Materials and Characterization

2.2. VPSC Modeling

3. Results

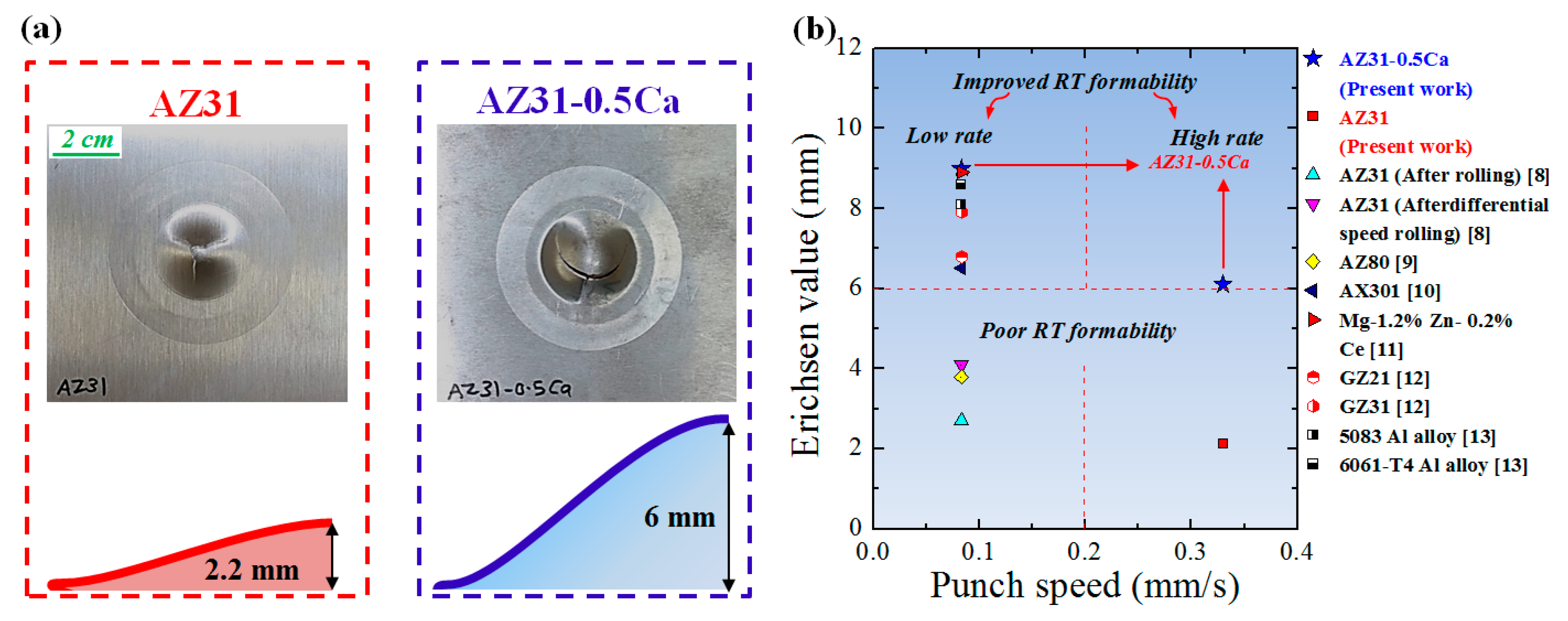

3.1. Formability

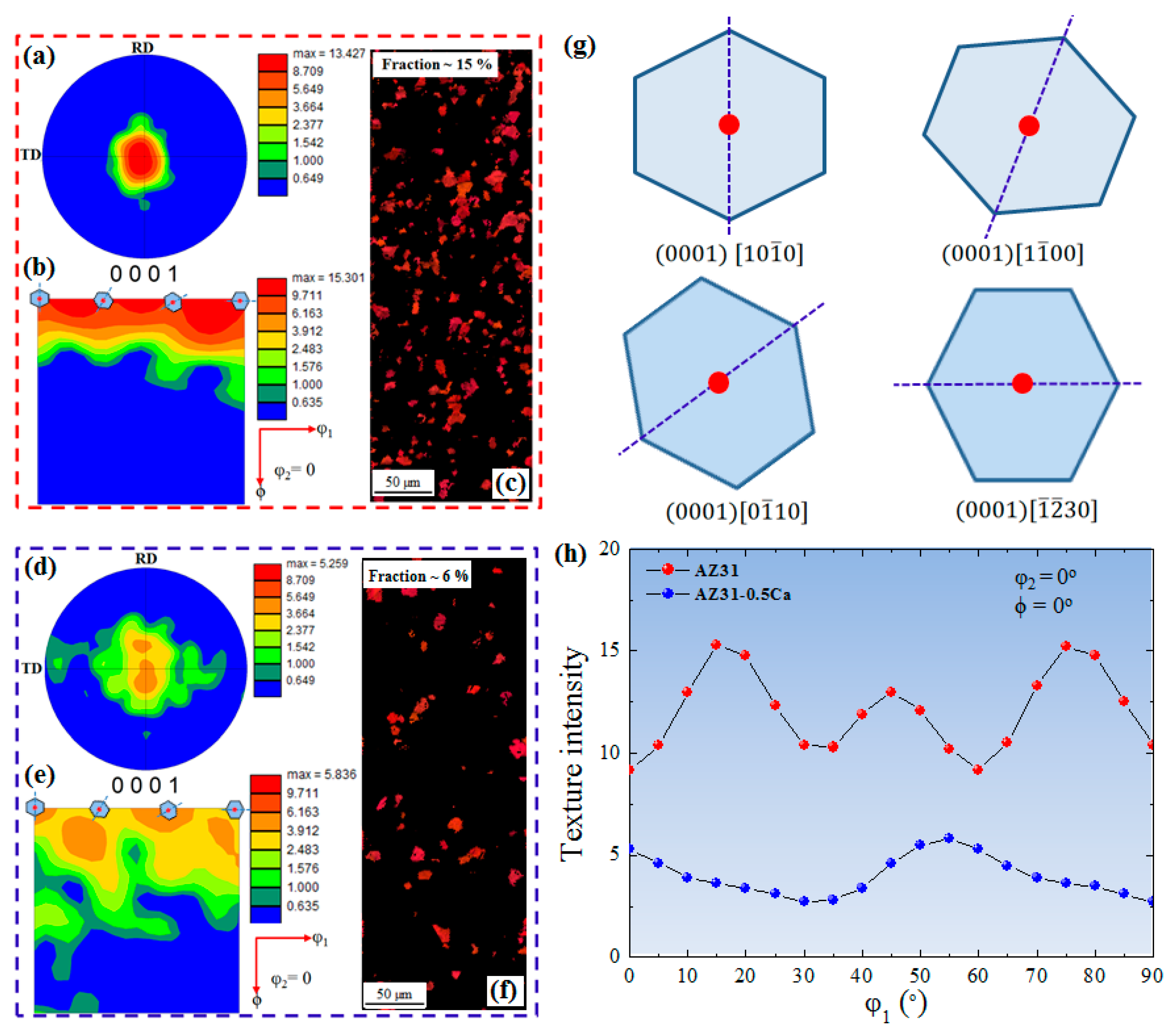

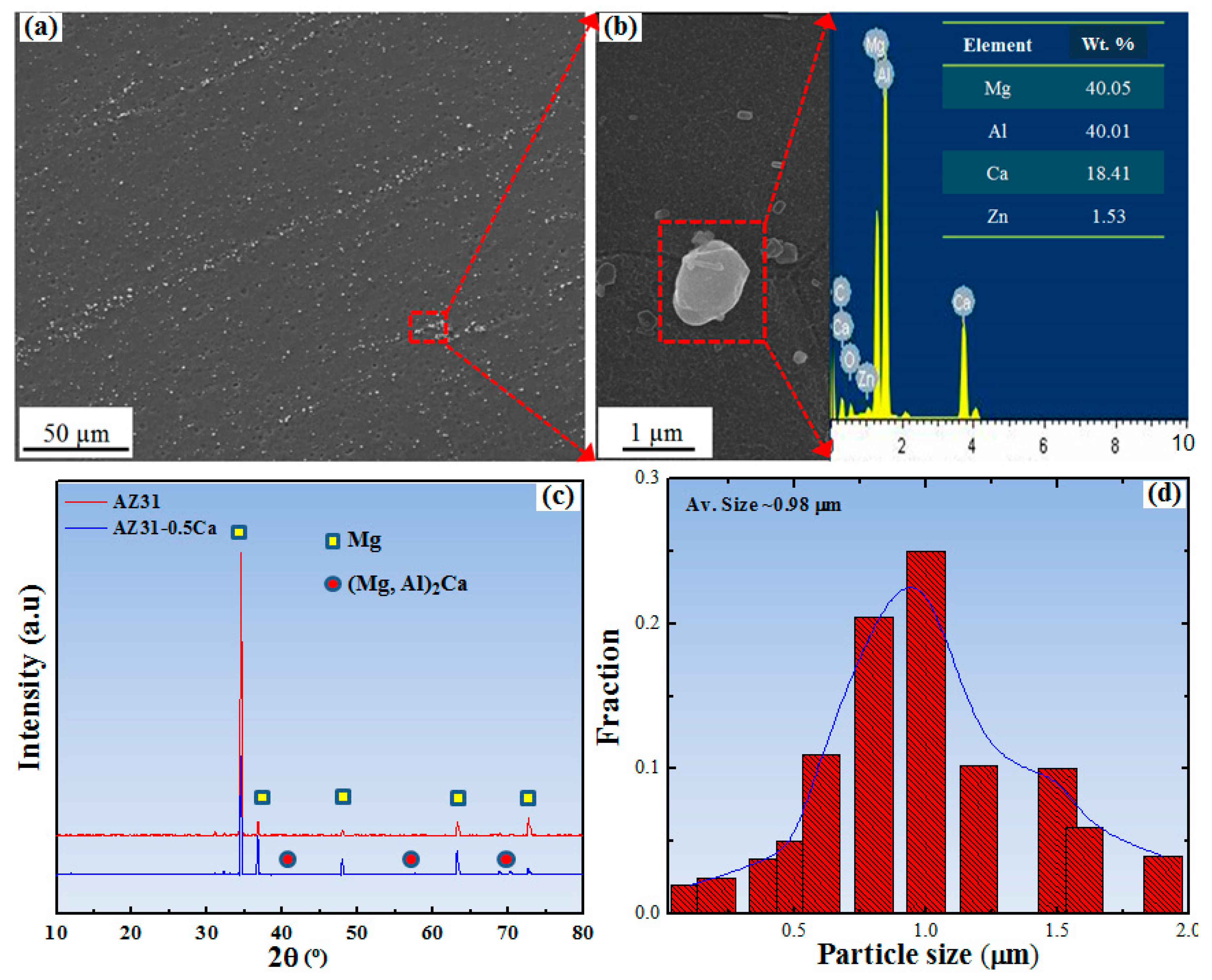

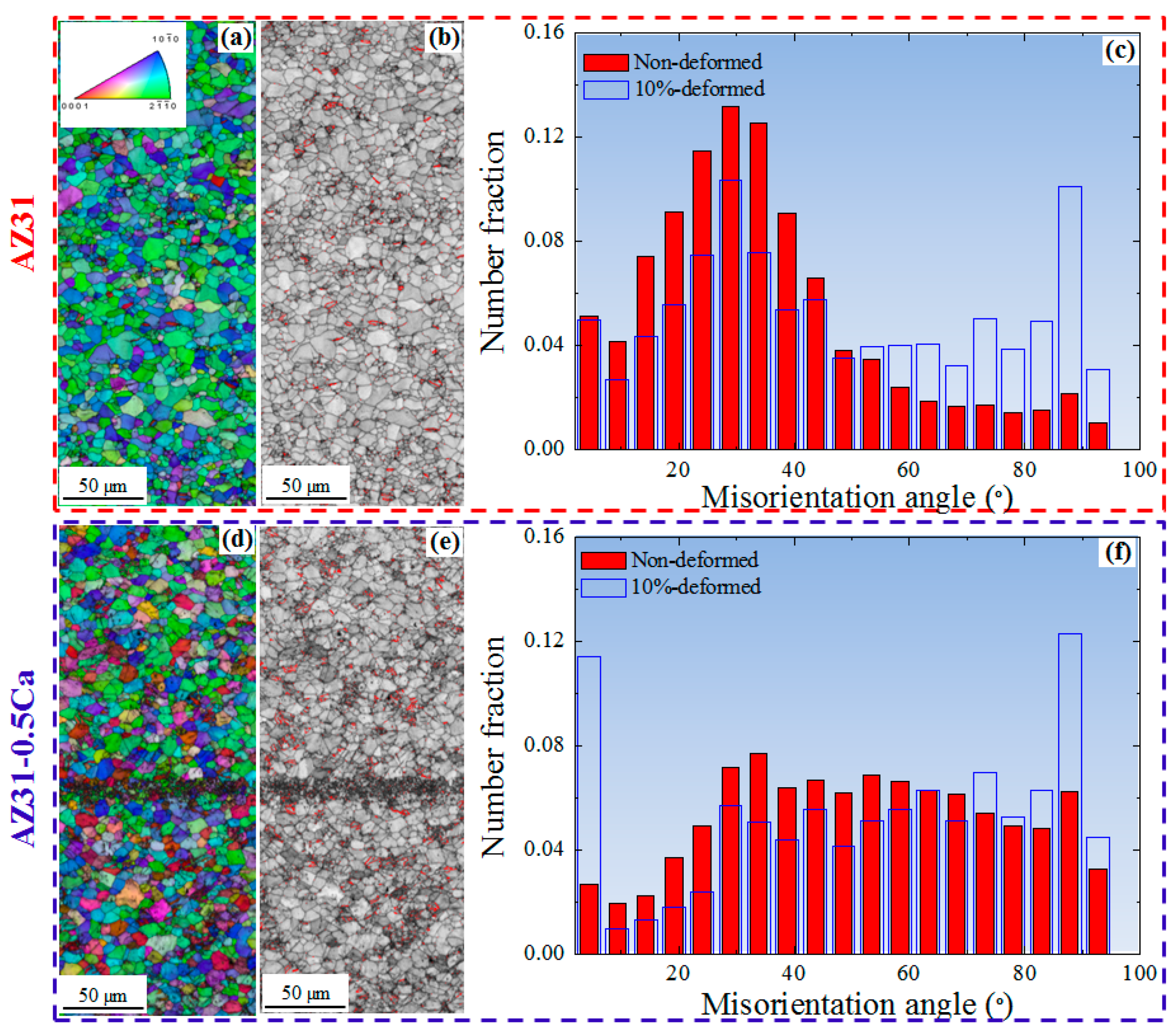

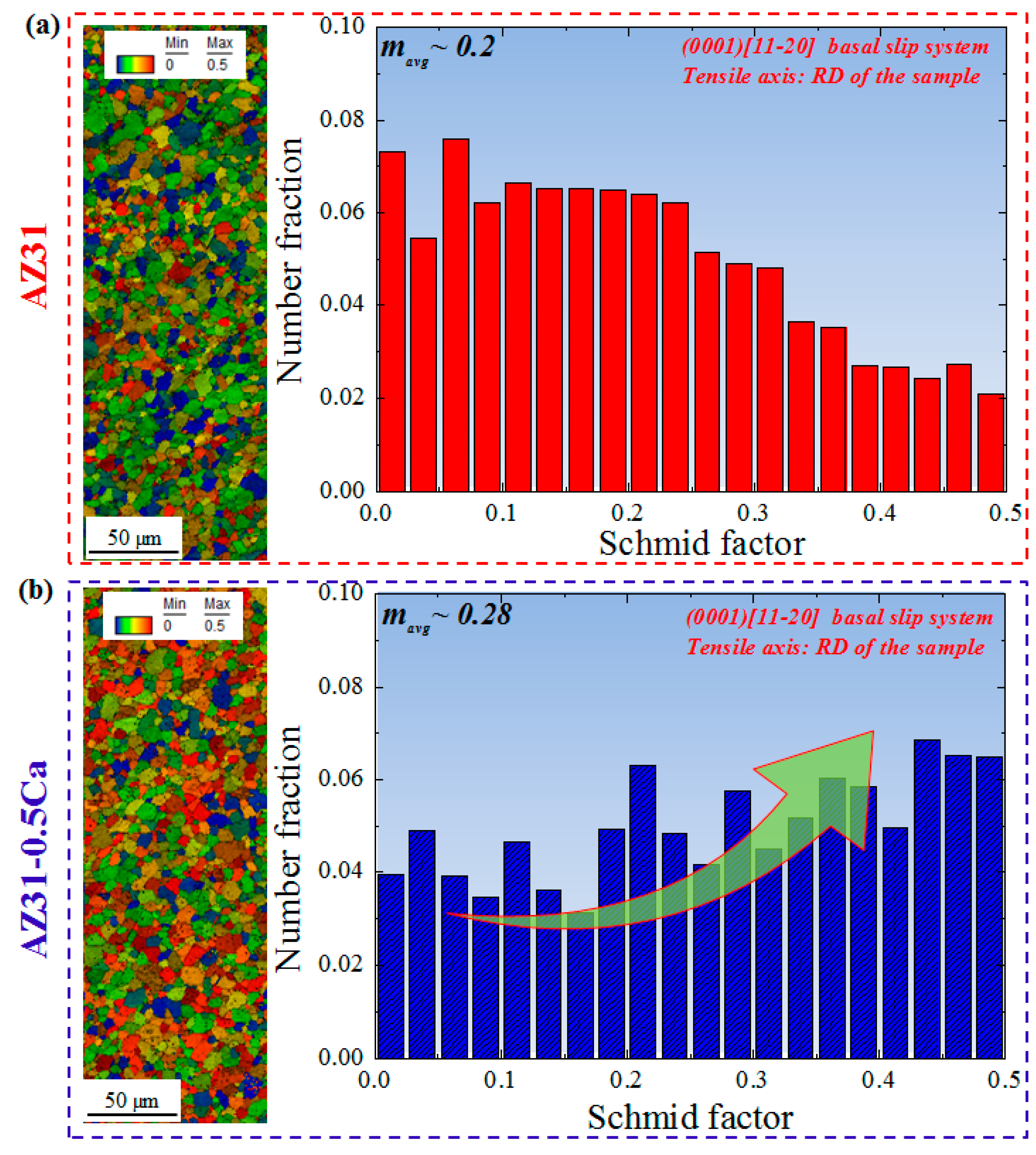

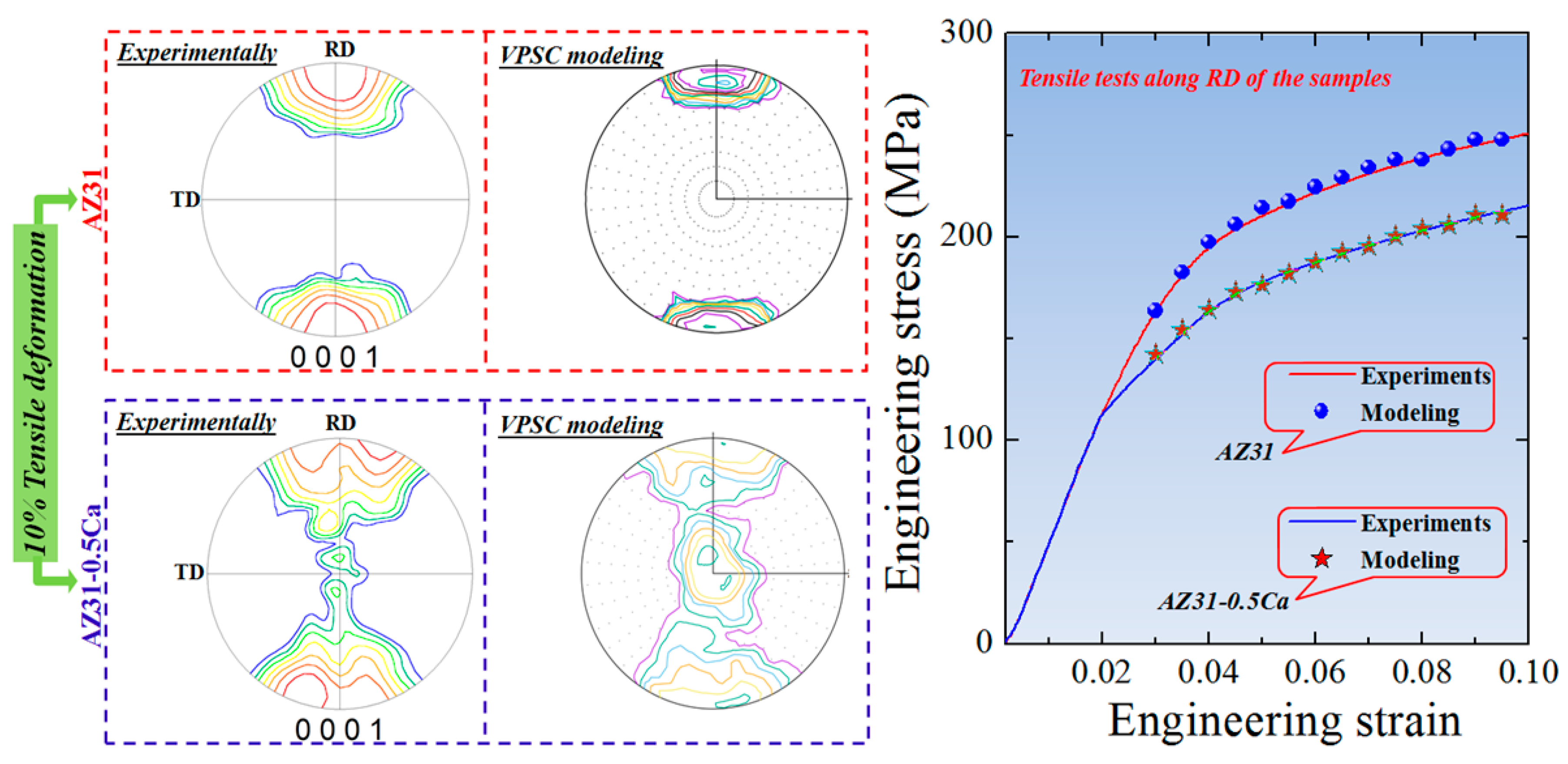

3.2. Microstructure and Texture

3.3. Mechanical Performance

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miller, V.M.; Berman, T.D.; Beyerlein, I.J.; Jones, J.W.; Pollock, T.M. Prediction of the plastic anisotropy of Magnesium alloys with synthetic texture and implications for the effect of texture on formability. Mater. Sci. Eng. A 2016, 675, 345–360. [Google Scholar] [CrossRef]

- Hamad, K.; Ko, Y.G. A cross-shear deformation for optimizing the strength and ductility of AZ31 magnesium alloys. Sci. Rep. 2016, 6, 29954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zeng, Z.; Nie, J.; Xu, S.; Davies, C.H.J.; Birbilis, N. Super-formable pure magnesium at room temperature. Nat. Commun. 2017, 8, 972. [Google Scholar] [CrossRef] [PubMed]

- Al-Samman, T.; Li, X. Sheet texture modification in magnesium-based alloys by selective rare earth alloying. Mater. Sci. Eng. A 2011, 528, 3809–3822. [Google Scholar] [CrossRef]

- Levi, G.; Avraham, S.; Zilberov, A.; Bamberger, M. Solidification, solution treatment and age hardening of a Mg-1.6 wt. % Ca-3.2 wt. % Zn alloy. Acta Mater. 2006, 54, 523–530. [Google Scholar] [CrossRef]

- Agnew, S.R.; Nie, J.F. Preface to the viewpoint set on: The current state of magnesium alloy science and technology. Scr. Mater. 2010, 63, 671–673. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, T.H.; Park, S.D.; Kim, Y.S.; Hamad, K.; Kim, J.G. Effects of calcium on the activity of slip systems in AZ31 magnesium alloy. Mater. Sci. Eng. A 2018, 739, 289–294. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Watazu, A.; Shigematsu, I.; Saito, N. Improvement of formability of Mg-Al-Zn alloy sheet at low temperatures using differential speed rolling. J. Alloys Compd. 2009, 470, 263–268. [Google Scholar] [CrossRef]

- Huang, X.; Suzuki, K.; Saito, N. Microstructure and mechanical properties of AZ80 magnesium alloy sheet processed by differential speed rolling. Mater. Sci. Eng. A 2009, 508, 226–233. [Google Scholar] [CrossRef]

- Chino, Y.; Ueda, T.; Otomatsu, Y.; Sassa, K.; Huang, X.; Suzuki, K.; Mabuchi, M. Effects of Ca on tensile properties and stretch formability at room temperature in Mg-Zn and Mg-Al alloys. Metall. Mater. Trans. A 2011, 52, 1477–1482. [Google Scholar] [CrossRef]

- Chino, Y.; Huang, X.; Suzuki, K.; Sassa, K.; Mabuchi, M. Influence of Zn concentration on stretch formability at room temperature of Mg-Zn-Ce alloy. Mater. Sci. Eng. A 2010, 528, 566–572. [Google Scholar] [CrossRef]

- Gao, L.; Yan, H.; Luo, J.; Luo, A.A.; Chen, R. Microstructure and mechanical properties of a high ductility Mg-Zn-Mn-Ce magnesium alloy. J. Mag. Alloys 2013, 1, 283–291. [Google Scholar] [CrossRef]

- Nakata, T.; Xu, C.; Ajima, R.; Shimizu, K.; Kamado, S. Strong and ductile age-hardening Mg-Al-Ca-Mn alloy that can be extruded as fast as aluminum alloys. Acta Mater. 2017, 130, 261–270. [Google Scholar] [CrossRef]

- Gröbner, J.; Schmid-Fetzer, R. Key issues in a thermodynamic Mg alloy database. Metall. Mater. Trans. A 2013, 44, 2918–2934. [Google Scholar] [CrossRef]

- Yi, S.B.; Park, J.H.; Letzig, D.; Kwon, O.D.; Kainer, K.U.; Kim, J.J. Microstructure and mechanical properties of Ca containing AZX310 alloy sheets produced via twin roll casting technology. Mag. Technol. 2016, 389–393. [Google Scholar]

- Rzychoń, T.; Chmiela, B. The influence of tin on the microstructure and creep properties of Mg-5Al-3Ca-0.7Sr-0.2Mn magnesium alloy. Solid State Pheom. 2012, 191, 151–158. [Google Scholar] [CrossRef]

- Robson, J.; Henry, D.; Davis, B. Particle effects on recrystallization in magnesium-manganese alloys: Particle-stimulated nucleation. Acta Mater. 2009, 57, 2739–2747. [Google Scholar] [CrossRef]

- Chun, Y.B.; Battaini, M.; Davies, C.H.J.; Hwang, S.K. Distribution characteristics of in-grain misorientation axes in cold-rolled commercially pure titanium and their correlation with active slip modes. Metall. Mater. Trans. A 2010, 41, 3473–3487. [Google Scholar] [CrossRef]

- Davies, C.H.J.; Chun, Y.B. The evolution of In-Grain Misorientation Axes (IGMA) during deformation of wrought magnesium alloy AZ31. Mag. Technol. 2016, 345–349. [Google Scholar]

- Hadorn, J.P.; Hantzsche, K.; Yi, S.; Bohlen, J.; Letzig, D.; Wollmershauser, J.A.; Agnew, S.R. Role of solute in texture modification during hot deformation of Mg-rare earth alloys. Metall. Mater. Trans. A 2012, 43, 1347–1362. [Google Scholar] [CrossRef]

- Chino, Y.; Kado, M.; Mabuchi, M. Enhancement of tensile ductility and stretch formability of magnesium by addition of 0.2 wt. %(0.035 at %) Ce. Mater. Sci. Eng. A 2008, 494, 343–349. [Google Scholar] [CrossRef]

- Razavi, S.M.; Foley, D.C.; Karaman, I.; Hartwig, K.T.; Hammond, V.H. Effect of grain size on prismatic slip in Mg-3Al-1Zn alloy. Scr. Mater. 2012, 67, 439–442. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Zaefferer, S.; Schestakow, I.; Yi, I.; Gonzalez-Martinez, R. On the role of non basal deformation mechanisms for the ductility of Mg and Mg-Y alloys. Acta Mater. 2011, 59, 429–439. [Google Scholar] [CrossRef]

- Yuasa, M.; Miyazawa, N.; Hayashi, M.; Abuchi, M.; Chino, Y. Effect of group II elements on the cold stretch formability of Mg-Zn alloys. Acta Mater. 2015, 83, 294–303. [Google Scholar] [CrossRef]

- Lee, J.Y.; Yun, Y.S.; Suh, B.C.; Kim, N.J.; Kim, D.H. Comparison of static recrystallization behavior in hot rolled Mg-3Al-1Zn and Mg-3Zn-0.5Ca sheets. J. Alloys Compd. 2014, 589, 240–246. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of grain size on the compressive deformation of wrought Mg–3Al–1Zn. Acta Mater. 2004, 54, 4841–4852. [Google Scholar] [CrossRef]

- Hutchinson, W.B.; Barnett, M.R. Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other Hcp metals. Scr. Mater. 2010, 63, 737–740. [Google Scholar] [CrossRef]

- Agnew, S.R.; Yoo, M.H.; Tomé, C.N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater. 2001, 49, 4277–4289. [Google Scholar] [CrossRef]

- Tang, T.; Shao, Y.; Li, D.; Peng, L.; Wu, P. Polycrystal plasticity simulation of extrusion of magnesium alloy round bar: Effect of strain path non uniformity. J. Alloys Compd. 2018, 730, 161–181. [Google Scholar] [CrossRef]

- Sánchez-Martín, R.; Pérez-Prado, M.T.; Segurado, J.; Bohlen, J.; Molina-Aldareguia, J.M. Measuring the critical resolved shear stresses in Mg alloys by instrumented nanoindentation. Acta Mater. 2014, 71, 283–292. [Google Scholar] [CrossRef] [Green Version]

- Hidalgo-Manrique, P.; Yi, S.B.; Bohlen, J.; Letzig, D.; Pérez-Prado, M.T. Effect of Nd additions on extrusion texture development and on slip activity in a Mg-Mn alloy. Metall. Mater. Trans. A 2013, 44, 4819–4829. [Google Scholar] [CrossRef]

- Akhtar, A.; Teghtsoonian, E. Solid Solution strengthening of magnesium single crystals-I alloying behavior in basal slip. Acta Metall. 1969, 17, 1339–1349. [Google Scholar] [CrossRef]

- Akhtar, A.; Teghtsoonian, E. Substitutional solution hardening of magnesium single crystals. Philos. Mag. 1971, 25, 897–916. [Google Scholar] [CrossRef]

- Angnew, S.R. Plastic Anisotropy of magnesium alloy AZ31b sheet. Mag. Technol. 2002, 1, 165–167. [Google Scholar]

- Agnew, S.R.; Tomé, C.N.; Brown, D.W.; Holden, T.M.; Vogel, S.C. Study of slip mechanisms in a magnesium alloy by neutron diffraction and modeling. Scr. Mater. 2003, 48, 1003–1008. [Google Scholar] [CrossRef]

- Agnew, S.R.; Brown, D.W.; Tomé, C.N. Validating a polycrystal model for the elastoplastic response of magnesium alloy AZ31 using in situ neutron diffraction. Acta Mater. 2006, 54, 4841–4852. [Google Scholar] [CrossRef]

- Muránsky, O.; Carr, D.G.; Barnett, M.R.; Oliver, E.C.; Šittner, P. Investigation of deformation mechanisms involved in the plasticity of AZ31 Mg alloy: In situ neutron diffraction and EPSC modelling. Mater. Sci. Eng. A 2008, 496, 14–24. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Ma, X. A semi analytical sachs model for the flow stress of a magnesium alloy. Metall. Mater. Trans. A 2006, 37, 2283–2293. [Google Scholar] [CrossRef]

- Muránsky, O.; Barnett, M.R.; Carr, D.G.; Vogel, S.C.; Oliver, E.C. Investigation of deformation twinning in a fine-grained and coarse grained ZM20 Mg alloy: Combined in situ neutron diffraction and acoustic emission. Acta Mater. 2010, 58, 1503–1517. [Google Scholar] [CrossRef]

- Herrera-Solaz, V.; Hidalgo-Manrique, P.; Pérez-Prado, M.T.; Letzig, D.; Segurado, J. Effect of rare earth additions on the critical resolved shear stresses of magnesium alloys. Mater. Lett. 2014, 128, 199–203. [Google Scholar] [CrossRef] [Green Version]

- Pan, H.; Wang, F.; Feng, M.; Jin, J.; Wu, P. Mechanical behavior and microstructural evolution in rolled Mg-3Al-1Zn-0.5Mn alloy under large strain simple shear. Mat. Sci. Eng. A 2018, 712, 585–591. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Z.; Wang, H.; Maldar, A.; Zeng, X. Study of slip activity in Mg-Y alloy by in situ high energy X-ray diffraction microscopy and elastic viscoplastic self-consistent modeling. Acta Mater. 2018, 155, 138–152. [Google Scholar] [CrossRef]

- Steglich, D.; Jeong, Y. Texture-based forming limit prediction for Mg sheet alloys ZE10 and AZ31. Int. J. Mech. Sci. 2016, 117, 102–114. [Google Scholar] [CrossRef]

- Bohlen, J.; Nurnberg, M.R.; Senn, J.W.; Letzig, D.; Agnew, S.R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets. Acta Mater. 2007, 55, 2101–2112. [Google Scholar] [CrossRef]

- Sun, J.; Jin, L.; Dong, S.; Dong, J.; Zhang, Z.; Wang, F.; Ding, W.; Luo, A.A. A combined electron backscattered diffraction and visco-plastic self consistent analysis on the anisotropic deformation behavior in a Mg-Gd-Y alloy. Mater. Des. 2017, 122, 164–171. [Google Scholar] [CrossRef]

| Alloy | Al | Zn | Ca | Si | Mn | Fe | Cu | Mg |

|---|---|---|---|---|---|---|---|---|

| AZ31 | 2.99 | 0.73 | - | 0.024 | 0.20 | 0.0026 | 0.0003 | Bal. |

| AZ31-0.5Ca | 3.12 | 0.76 | 0.5 | 0.023 | 0.31 | 0.0042 | 0.0012 | Bal. |

| Load (kN) | Punch Size (mm) | Punch Speed (mm/s) | Specimen Size (mm) | Specification |

|---|---|---|---|---|

| 350 | 20 | 0.33 | 90 × 90 | ISO 20482 |

| Alloy | Tensile Direction | YS (MPa) | UTS (MPa) | UE (%) | TE (%) | n | r | ravg | Δr |

|---|---|---|---|---|---|---|---|---|---|

| AZ31 | RD | 176 | 275 | 24 | 32 | 0.2 | 2.34 | 2.3 | 0.72 |

| 45° | 161 | 272 | 22 | 29 | 0.17 | 2.7 | |||

| TD | 171 | 283 | 23 | 27 | 0.21 | 1.62 | |||

| AZ31-0.5Ca | RD | 147 | 248 | 31 | 38 | 0.28 | 0.71 | 0.6 | 0.16 |

| 45° | 125 | 237 | 30 | 35 | 0.27 | 0.52 | |||

| TD | 139 | 251 | 30 | 32 | 0.26 | 0.69 |

| Alloy | Deformation Mode | τ0 | τ1 | θ0 | θ1 |

|---|---|---|---|---|---|

| AZ31 | <a> basal slip | 49 | 8 | 122 | 35 |

| <a> prismatic slip | 108 | 31 | 155 | 11 | |

| <a + c> pyramidal slip | 311 | 76 | 88 | 18 | |

| Tension twin | 6 | 97 | 109 | 25 | |

| AZ31-0.5Ca | <a> basal slip | 57 | 9 | 115 | 62 |

| <a> prismatic slip | 91 | 37 | 148 | 8 | |

| <a + c> pyramidal slip | 305 | 44 | 64 | 22 | |

| Tension twin | 15 | 185 | 110 | 55 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masood Chaudry, U.; Hoo Kim, T.; Duck Park, S.; Sik Kim, Y.; Hamad, K.; Kim, J.-G. On the High Formability of AZ31-0.5Ca Magnesium Alloy. Materials 2018, 11, 2201. https://doi.org/10.3390/ma11112201

Masood Chaudry U, Hoo Kim T, Duck Park S, Sik Kim Y, Hamad K, Kim J-G. On the High Formability of AZ31-0.5Ca Magnesium Alloy. Materials. 2018; 11(11):2201. https://doi.org/10.3390/ma11112201

Chicago/Turabian StyleMasood Chaudry, Umer, Tae Hoo Kim, Sang Duck Park, Ye Sik Kim, Kotiba Hamad, and Jung-Gu Kim. 2018. "On the High Formability of AZ31-0.5Ca Magnesium Alloy" Materials 11, no. 11: 2201. https://doi.org/10.3390/ma11112201

APA StyleMasood Chaudry, U., Hoo Kim, T., Duck Park, S., Sik Kim, Y., Hamad, K., & Kim, J.-G. (2018). On the High Formability of AZ31-0.5Ca Magnesium Alloy. Materials, 11(11), 2201. https://doi.org/10.3390/ma11112201