Effects of CTCP Modification on Microstructure and Wear Behavior of CTCP-NiCrBSi/Heat Resistant Steel Composite Layer

Abstract

:1. Introduction

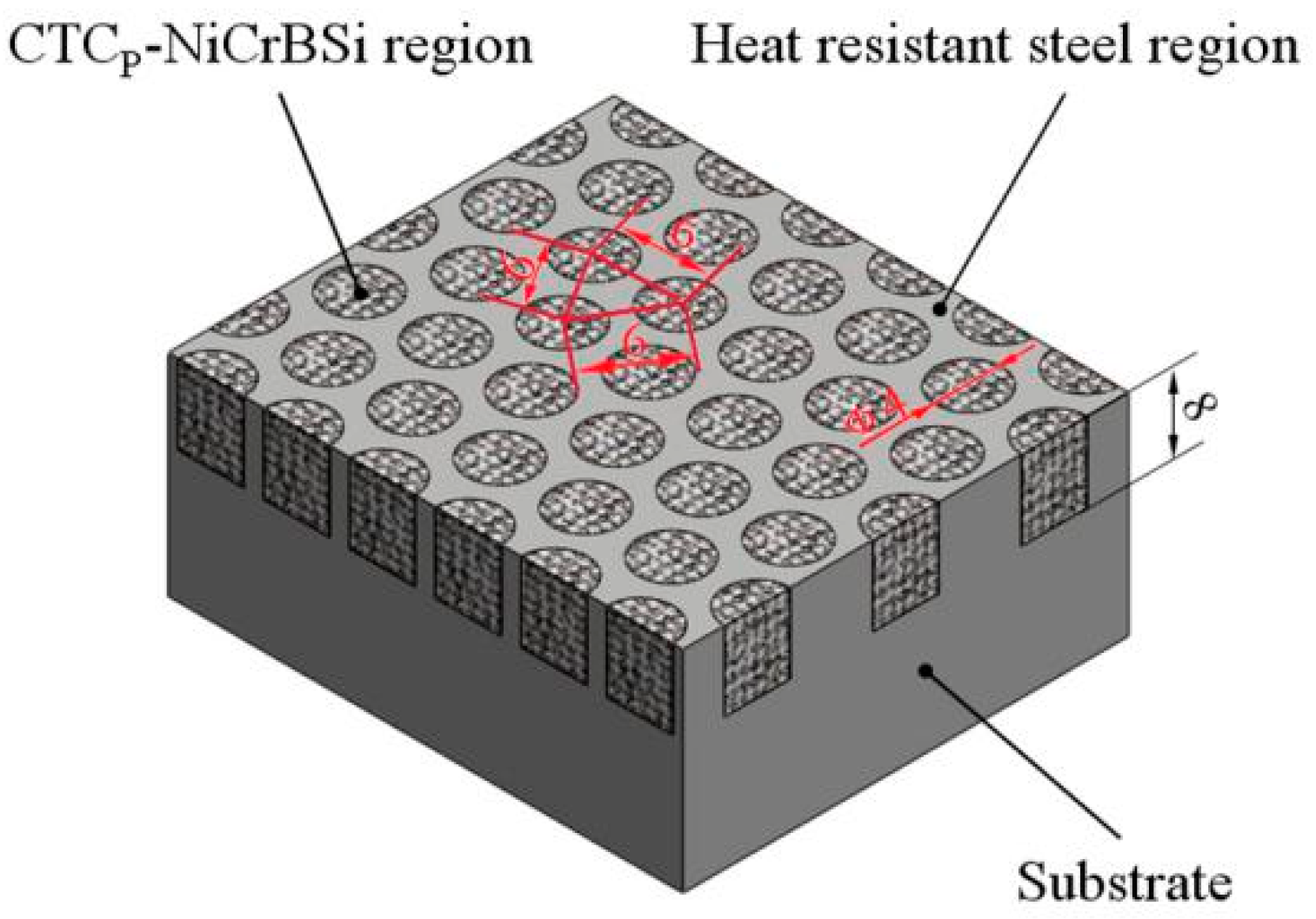

2. Materials and Experimental Procedure

2.1. Raw Materials

2.2. Fabrication of the Composite Layer

2.3. Microstructure Characterization

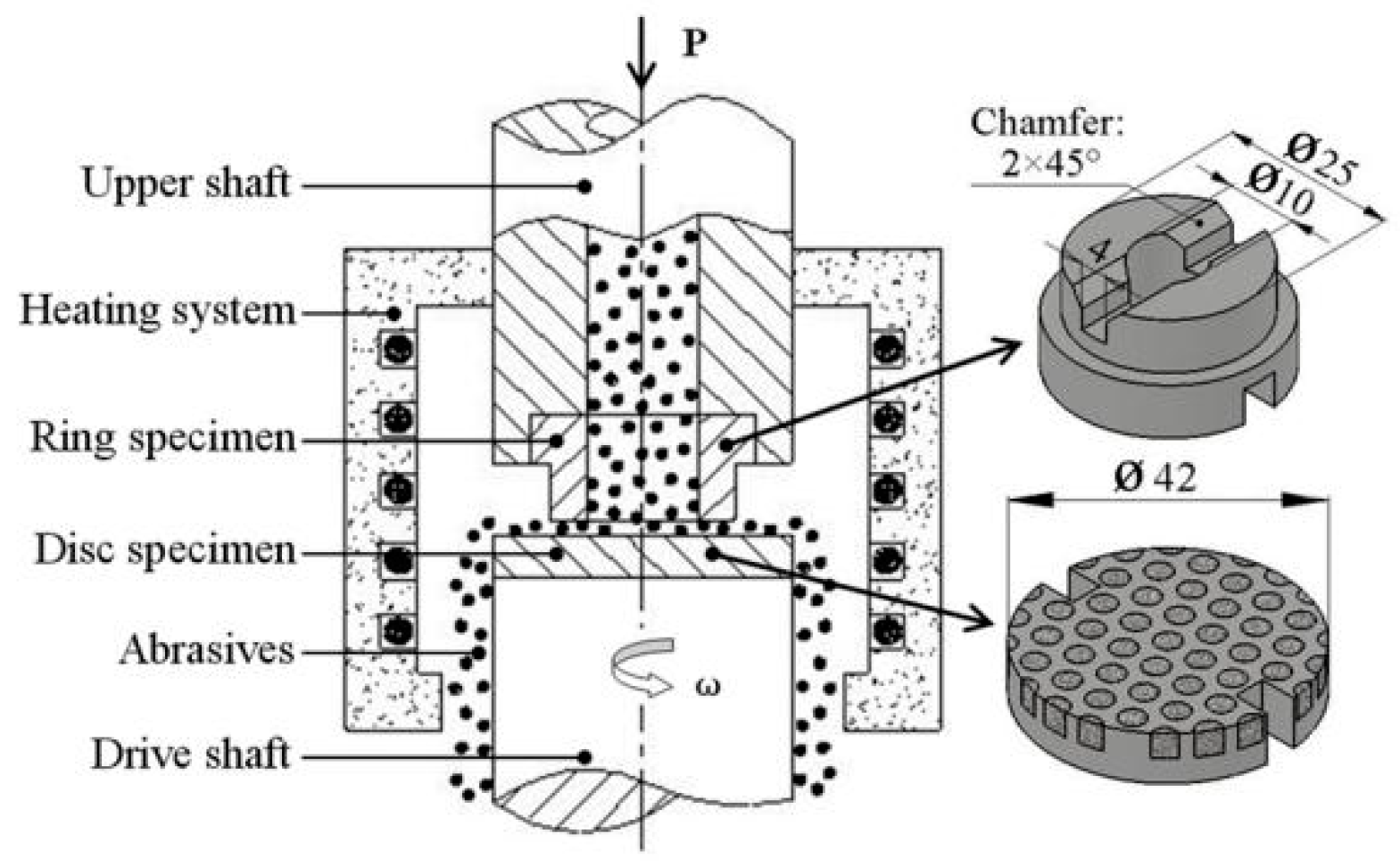

2.4. Abrasion Test

3. Results and Discussion

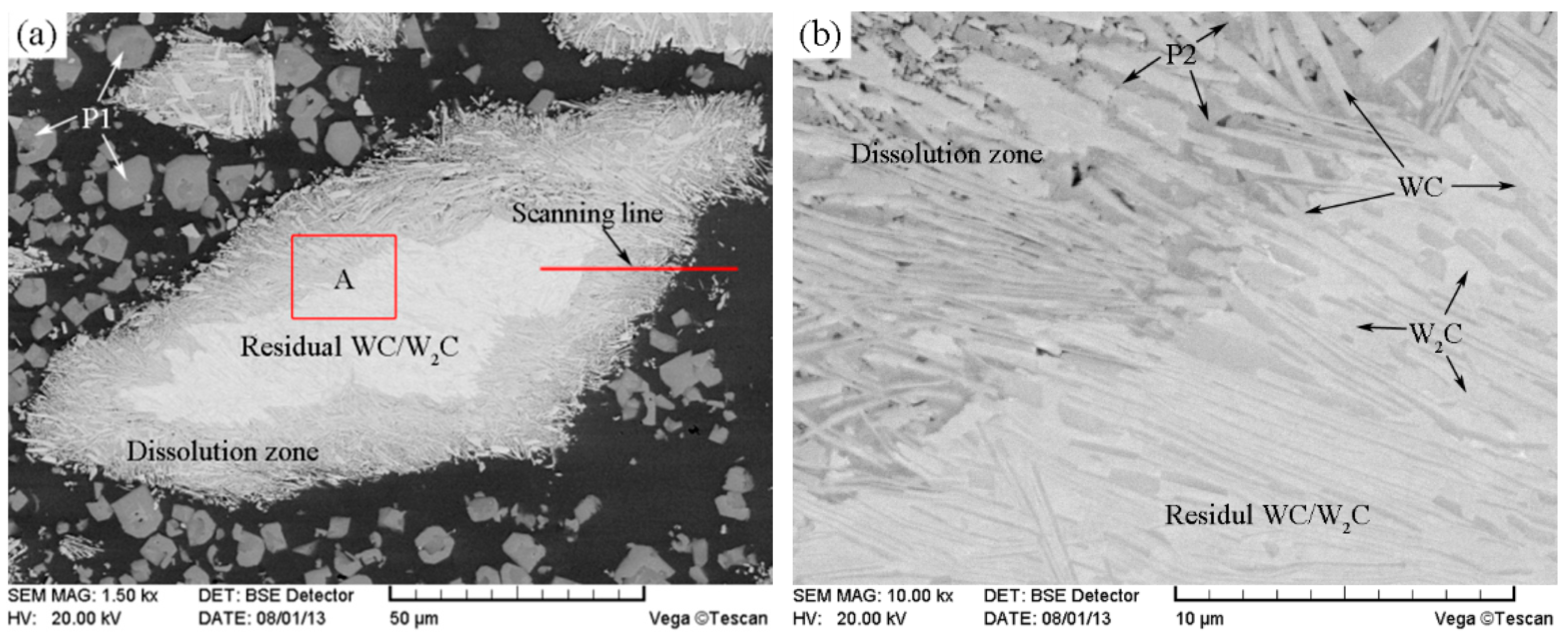

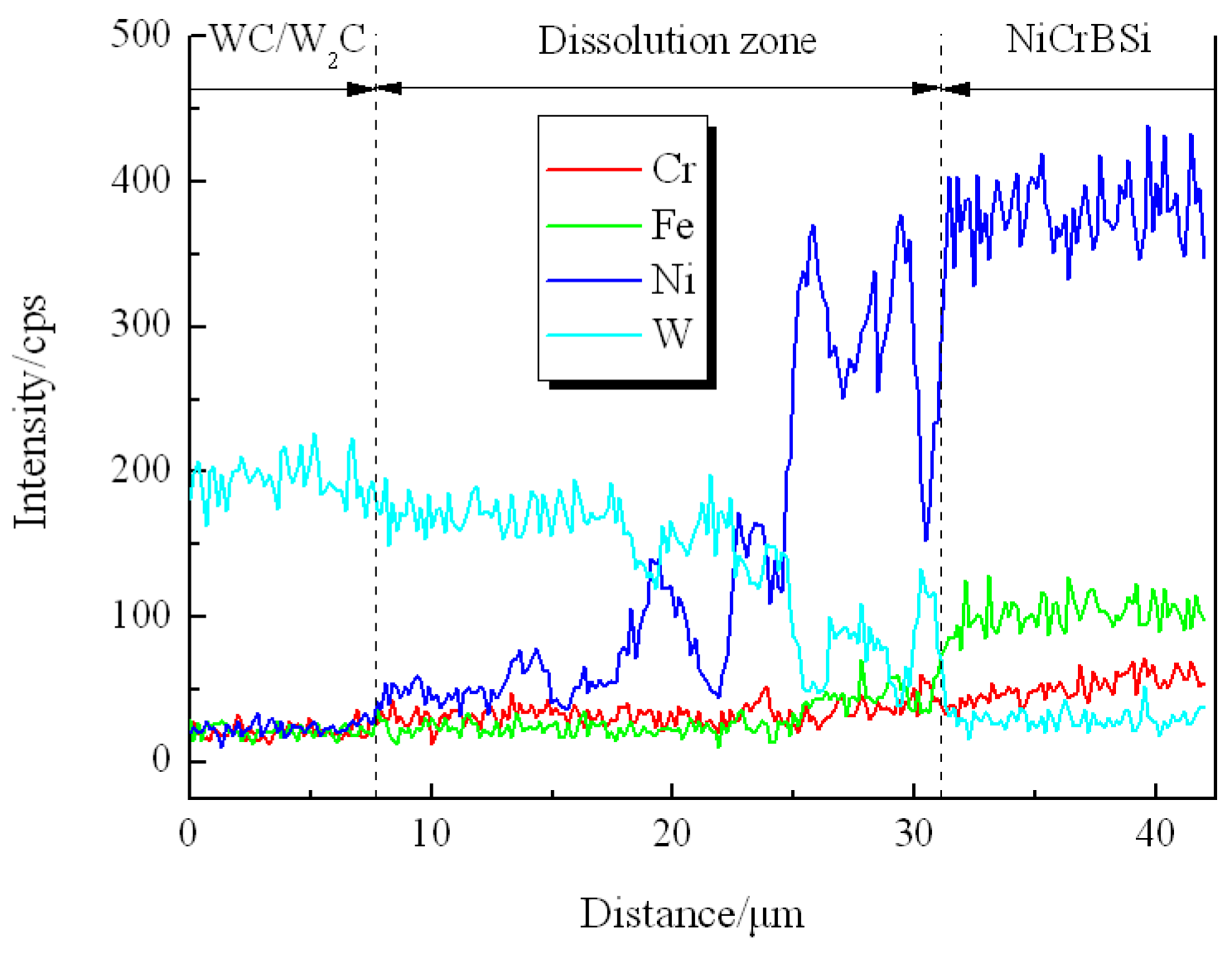

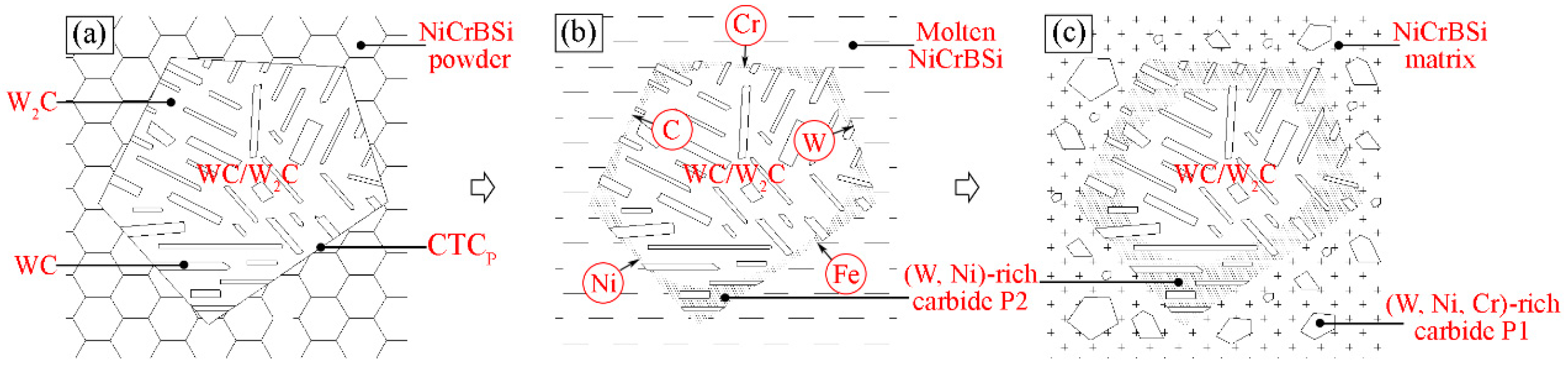

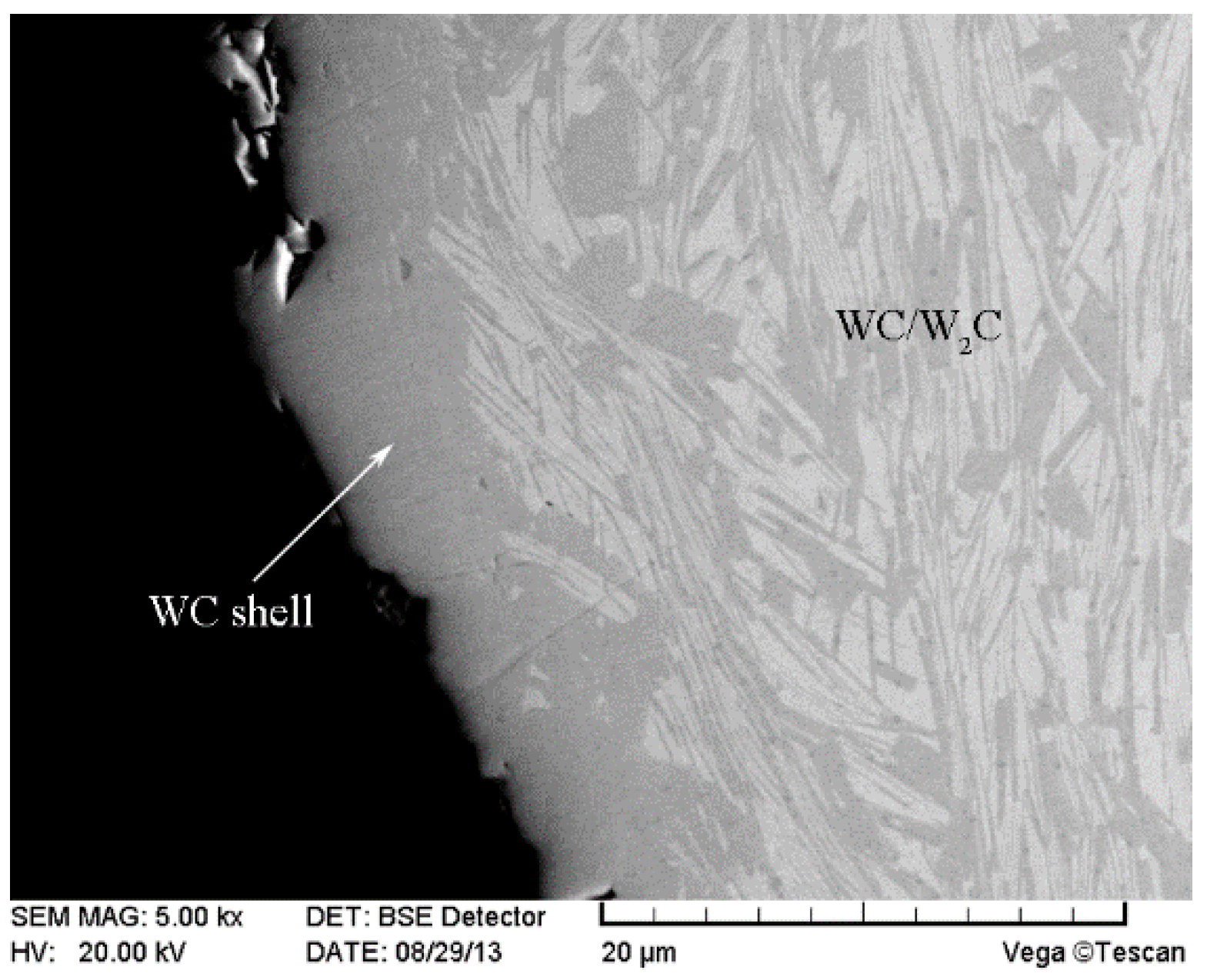

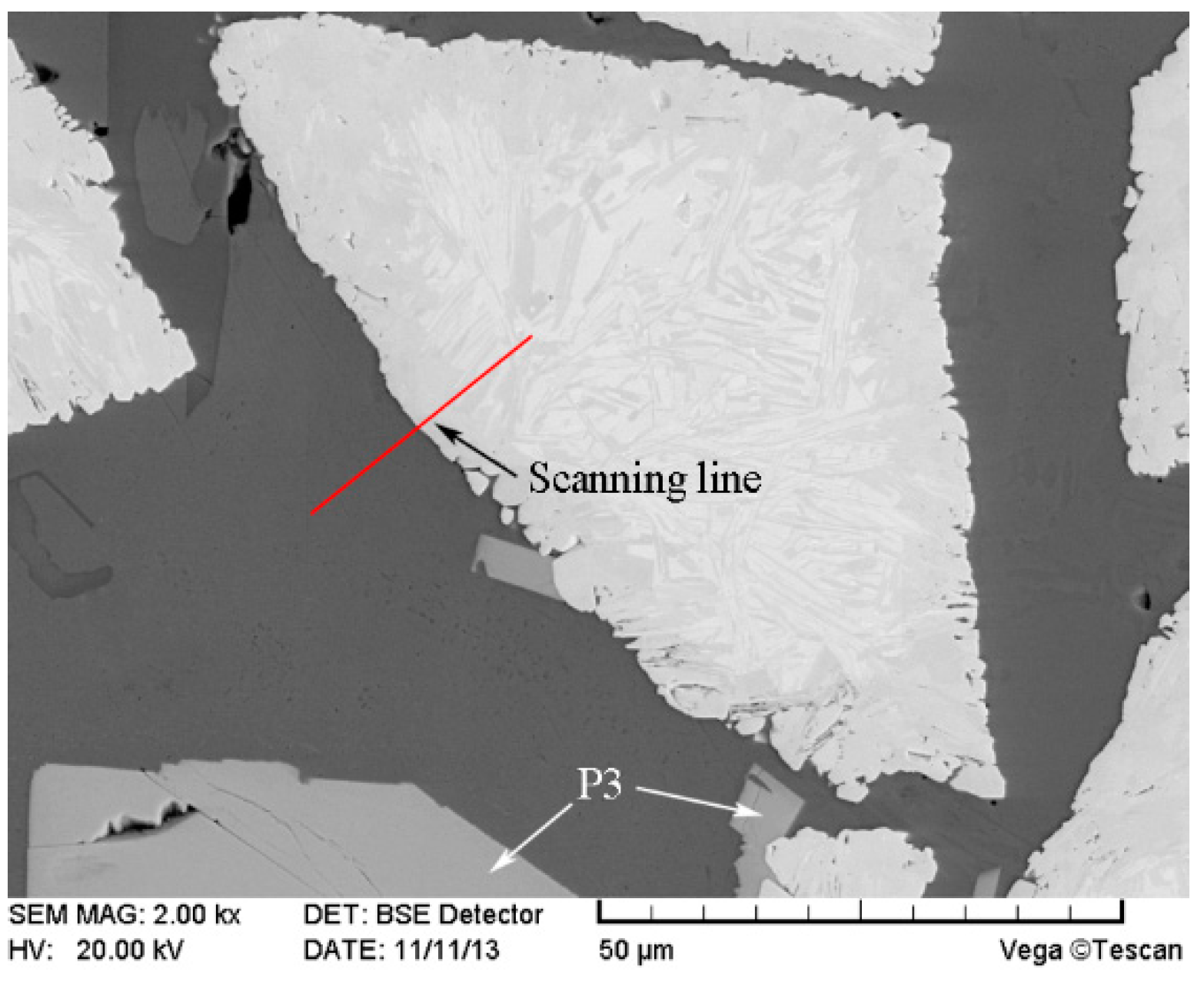

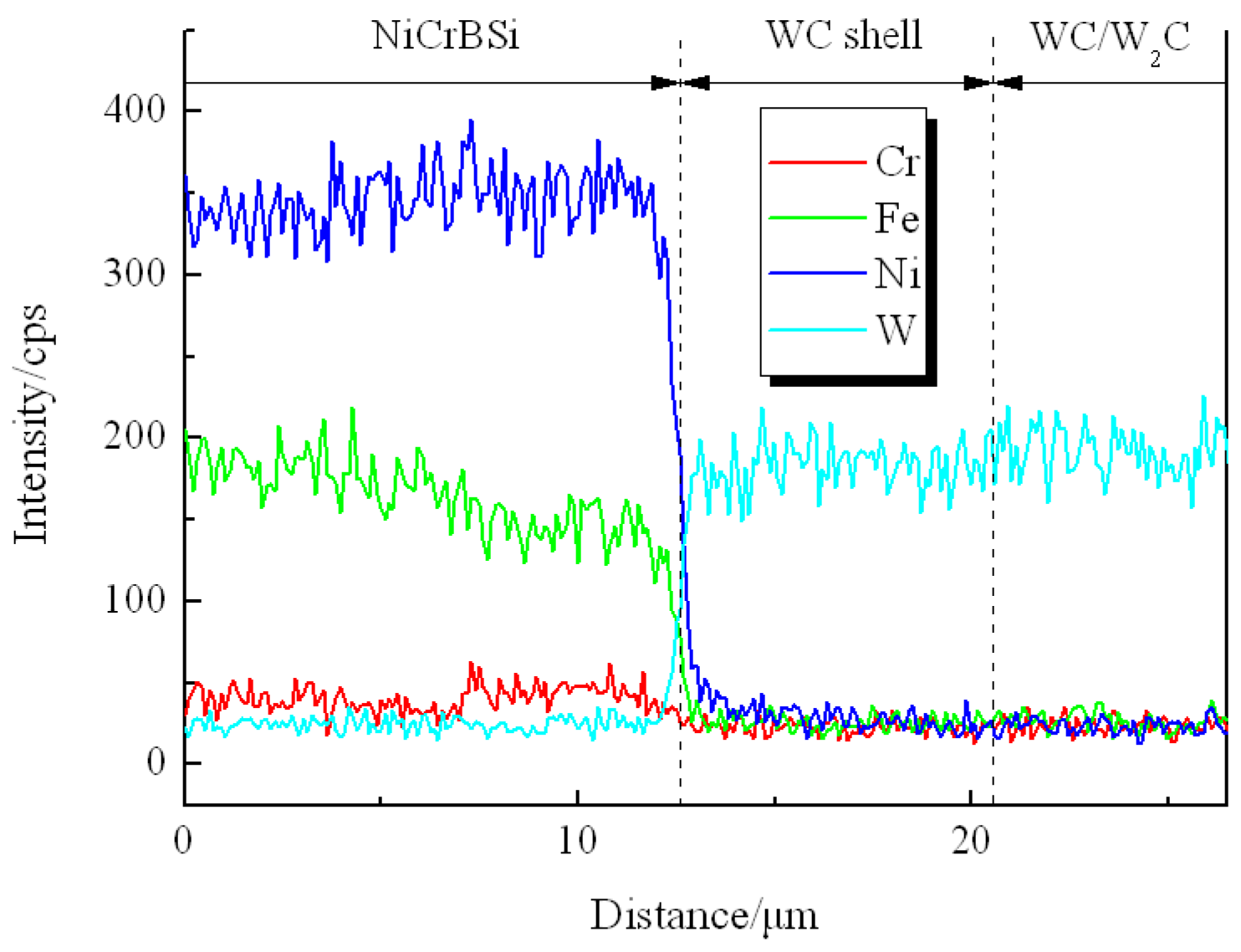

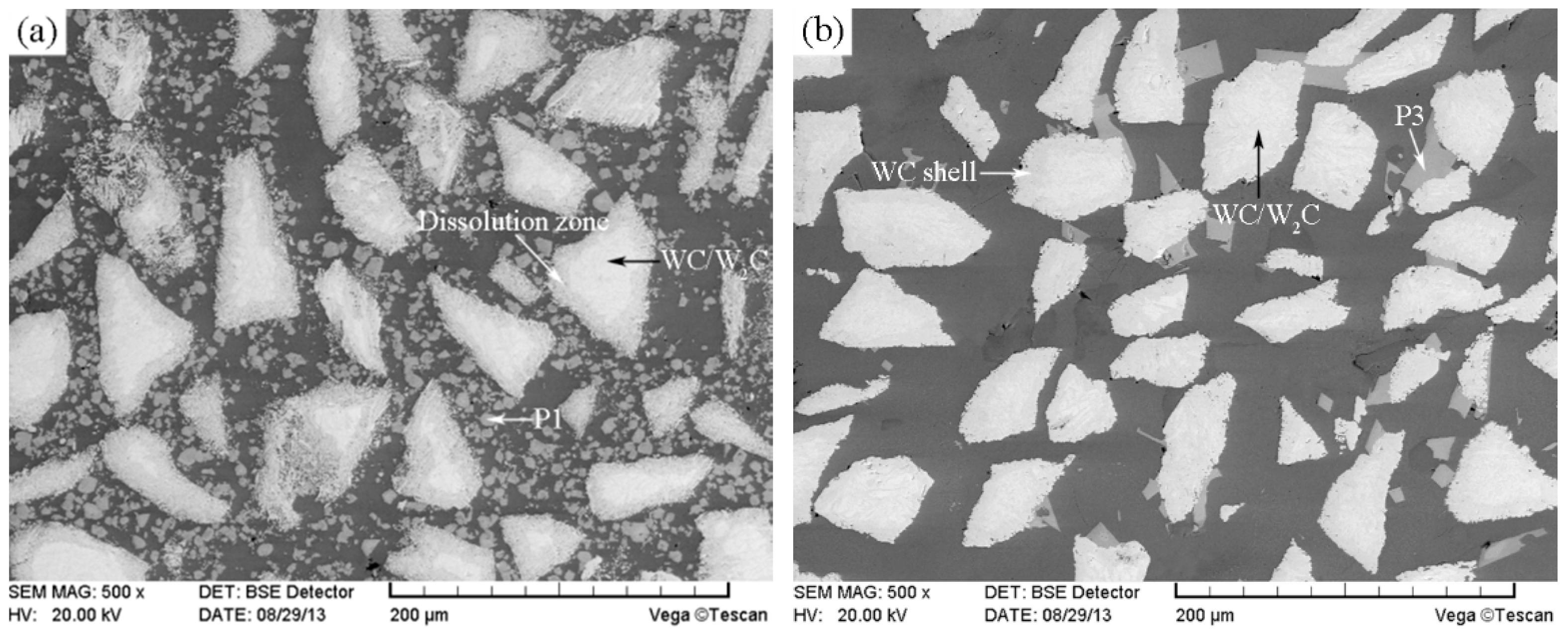

3.1. Microstructure of the CTCP-NiCrBSi Region

3.2. Volume Fraction and Microhardness of the Microstructure Constituent

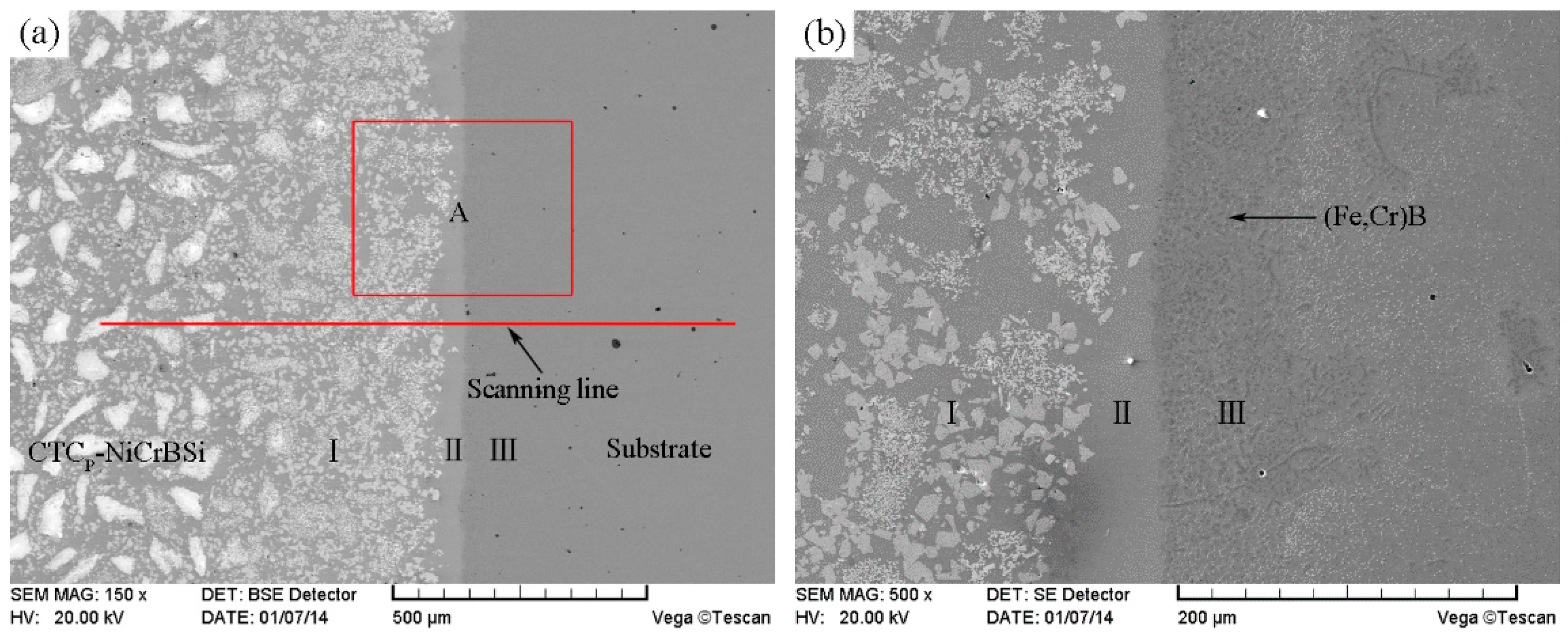

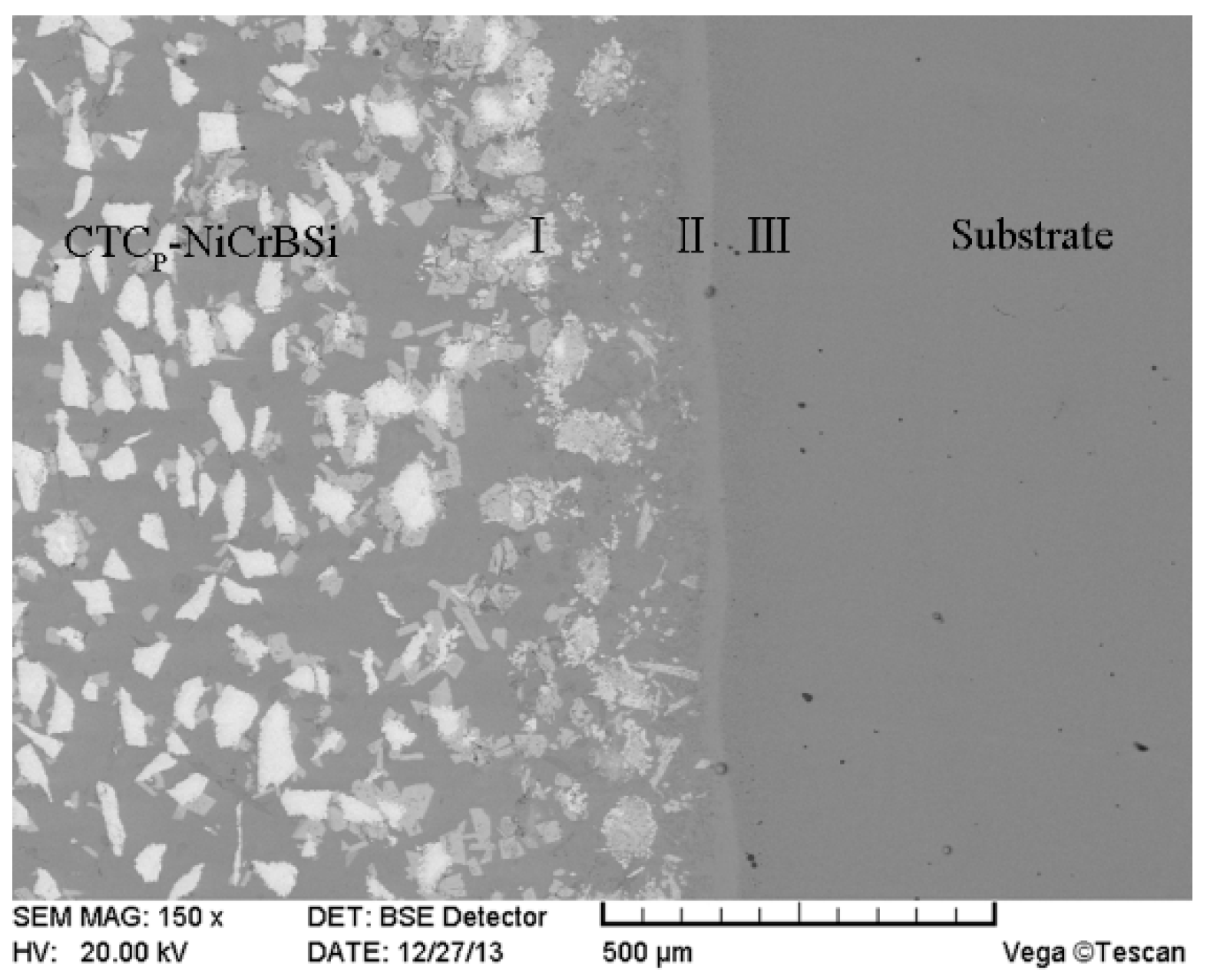

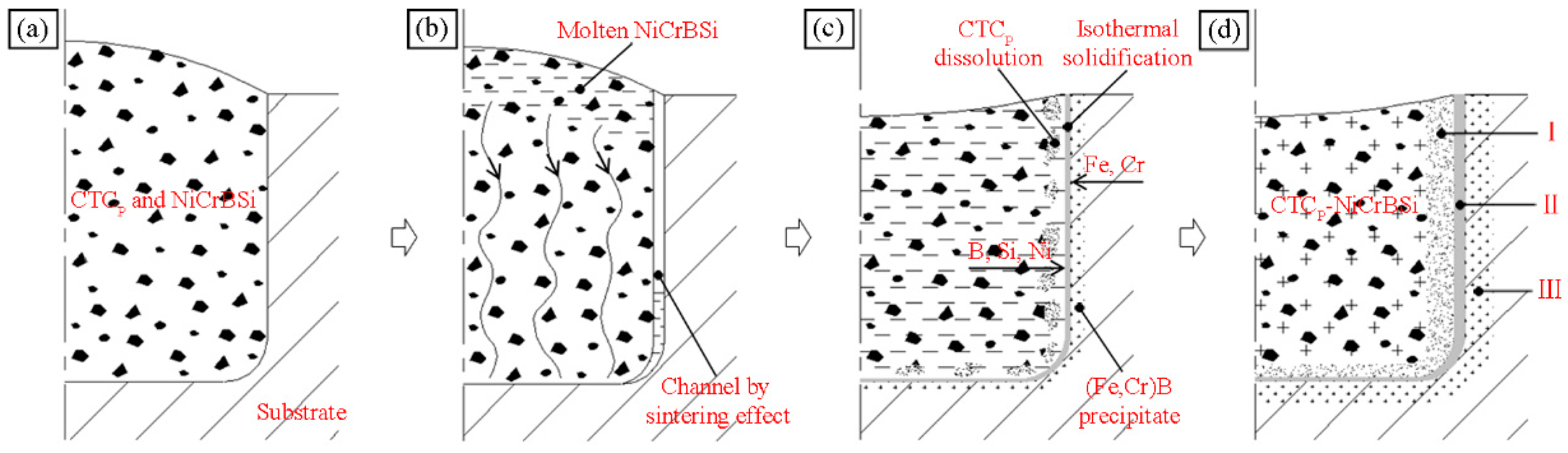

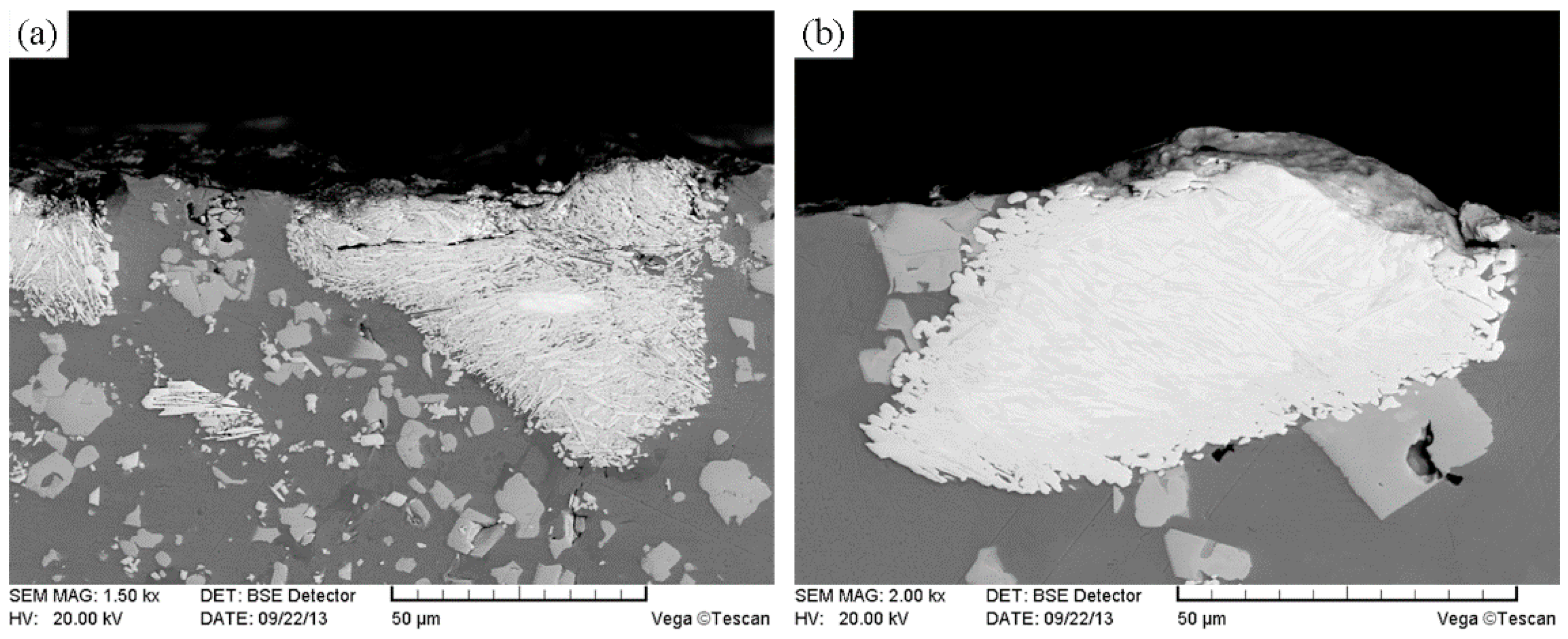

3.3. Interface between CTCP-NiCrBSi and Substrate

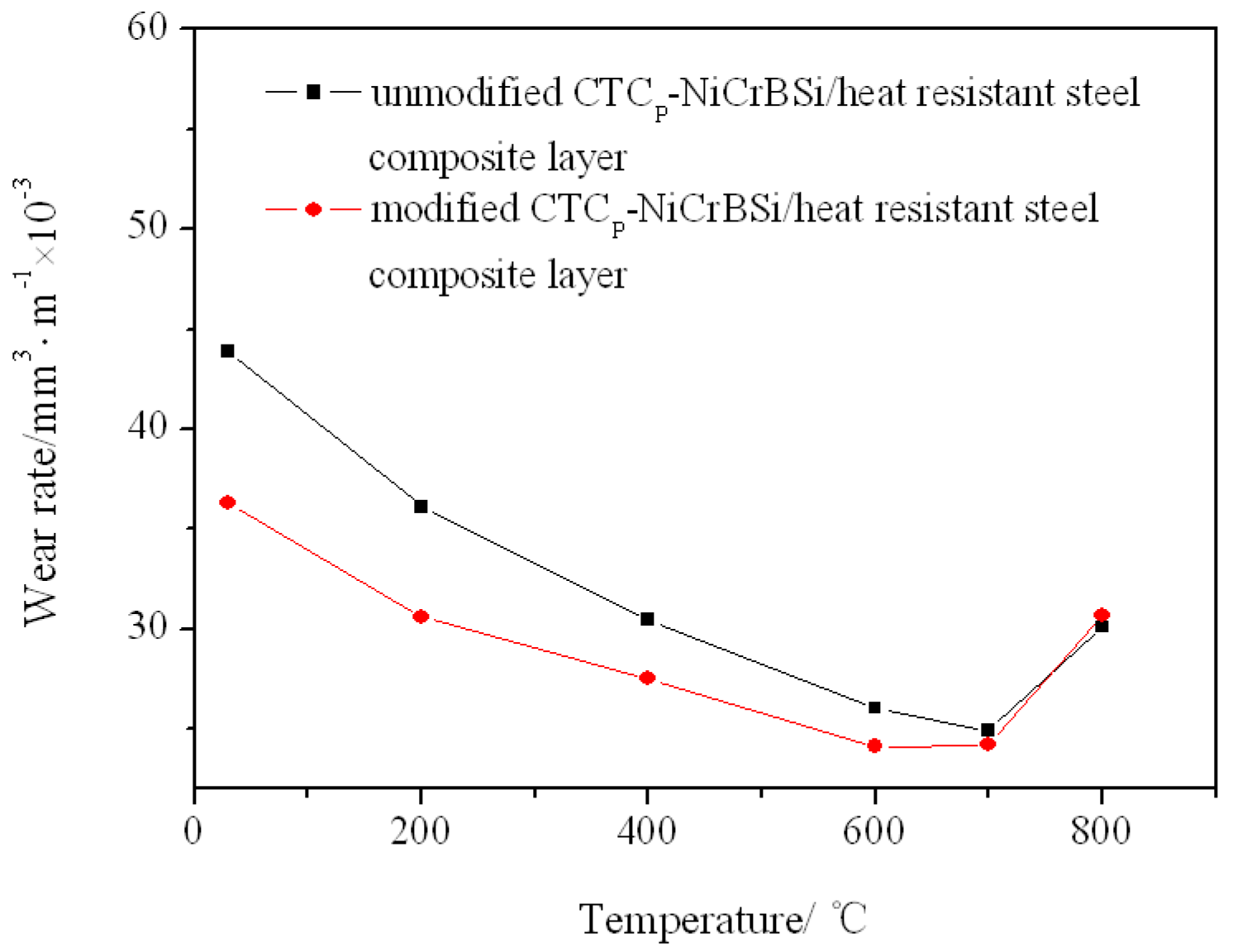

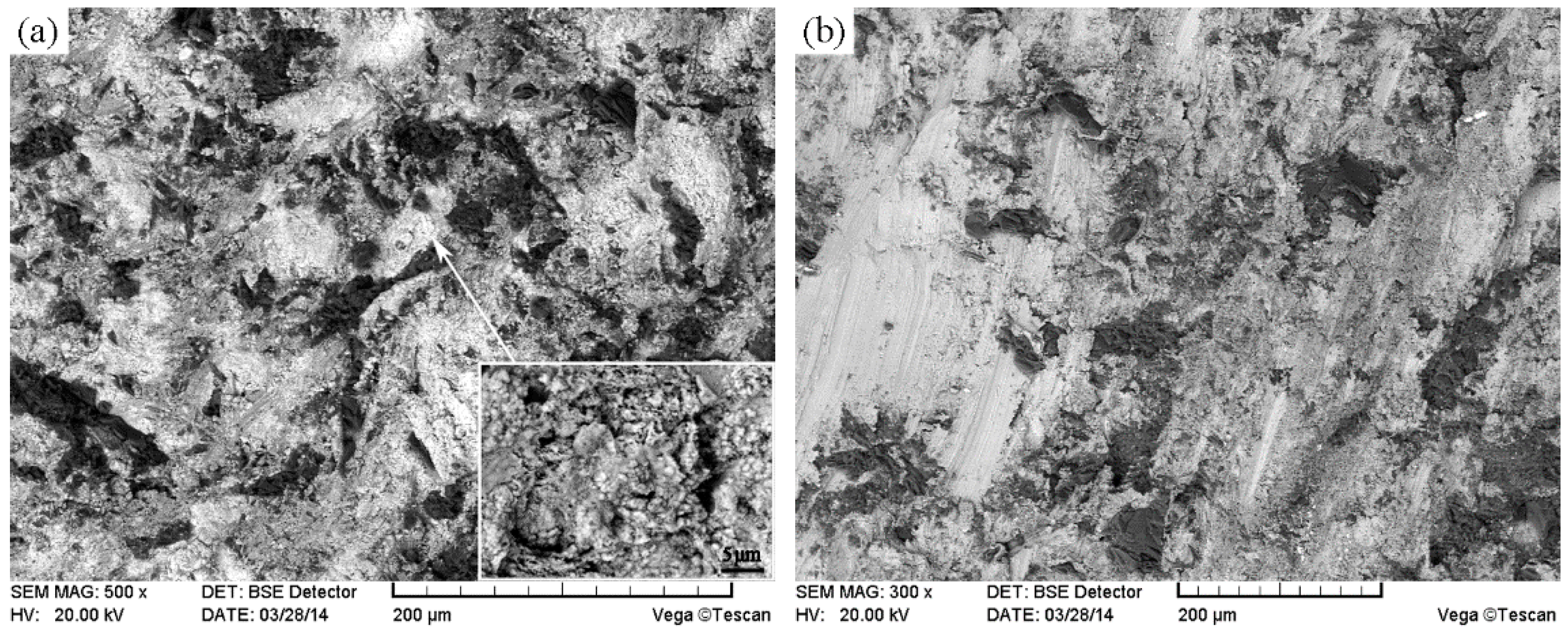

4. Wear Behavior

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Berns, H.; Koch, S. Influence of Abrasive Particles on Wear Mechanism and Wear Resistance in Sliding Abrasion Tests at Elevated Temperatures. Wear 1999, 233–235, 424–430. [Google Scholar] [CrossRef]

- Gassmann, R.C. Laser Cladding with (WC+W2C)/Co-Cr-C and (WC+W2C)/Ni-B-Si Composites for Enhanced Abrasive Wear Resistance. Mater. Sci. Technol. 1996, 12, 690–696. [Google Scholar] [CrossRef]

- Harsha, S.; Dwivedi, D.K.; Agarwal, A. Performance of Flame Sprayed Ni-WC Coating under Abrasive Wear Conditions. J. Mater. Eng. Perform. 2008, 17, 104–109. [Google Scholar] [CrossRef]

- Fu, S.; Xu, H. Microstructure and Wear Behavior of (Ti,V)C Reinforced Ferrous Composite. J. Mater. Eng. Perform. 2010, 19, 825–827. [Google Scholar] [CrossRef]

- Garcia-Cordovilla, C.; Narciso, J.; Louis, E. Abrasive Wear Resistance of Aluminium Alloy/ceramic Particulate Composites. Wear 1996, 192, 170–177. [Google Scholar] [CrossRef]

- Zheng, K.; Gao, Y.; Tang, S.; Li, Y.; Ma, S.; Yi, D.; Zhang, Z. Interface Structure and Wear Behavior of Cr26 Ferrous Matrix Surface Composites Reinforced with CTCP. Tribol. Lett. 2014, 54, 15–23. [Google Scholar] [CrossRef]

- Zhou, S.; Dai, X. Laser Induction Hybrid Rapid Cladding of WC Particles Reinforced NiCrBSi Composite Layers. Appl. Surf. Sci. 2010, 256, 4708–4714. [Google Scholar] [CrossRef]

- Zhou, S.; Zeng, X.; Hu, Q.; Huang, Y. Analysis of Crack Behavior for Ni-based WC Composite Layers by Laser Cladding and Crack-free Realization. Appl. Surf. Sci. 2008, 255, 1646–1653. [Google Scholar] [CrossRef]

- Pandey, A.B.; Majumdar, B.S.; Miracle, D.B. Laminated Particulate-reinforced Aluminum Composites with Improved Toughness. Acta. Mater. 2001, 49, 405–417. [Google Scholar]

- Qin, S.; Zhang, G. Preparation of High Fracture Performance SiCp-6061A1/6061A1 Composite. Mater. Sci. Eng. A 2000, 279, 231–236. [Google Scholar] [CrossRef]

- Jamali, M.; Farokhzadeh, K.; Bagheri, R.; Seyed Reihani, S.M. Architecturally Modified Al-DRA Composites: The Effect of Size and Shape of the DRA Rods on Fracture Behavior. J. Mater. Sci. 2010, 45, 2852–2861. [Google Scholar] [CrossRef]

- Hou, S.; Bao, C.; Zhang, Z.; Bai, Y. Microstructure and Wear Behavior of High-Cr WCI Matrix Surface Composite Reinforced with Cemented Carbide Rods. J. Mater. Eng. Perform. 2013, 22, 2064–2072. [Google Scholar] [CrossRef]

- Gerk, C.; Wernicke, K.-D. Dual-phase Hard Material Comprising Tungsten Carbide, Process for the Production Thereof and Its Use. U.S. Patent 7541090B2, 2 June 2009. [Google Scholar]

- Jones, M.; Waag, U. The Influence of Carbide Dissolution on the Erosion-corrosion Properties of Cast Tungsten Carbide/Ni-based PTAW Overlays. Wear 2011, 271, 1314–1324. [Google Scholar] [CrossRef]

- Yi, D.; Xing, J.; Ma, S.; Fu, H.; Chen, W.; Li, Y.; Yan, J.; Zhang, J.; Liu, Z.; Zhu, J. Three-body Abrasive Wear Behavior of Low Carbon Fe-B Cast Alloy and Its Microstructures under Different Casting processes. Tribol. Lett. 2011, 42, 67–77. [Google Scholar] [CrossRef]

- Molina, J.M.; Saravanan, R.A.; Narciso, J.; Louis, E. Surface Modification of 2014 Aluminium Alloy–Al2O3 Particles Composites by Nickel Electrochemical Deposition. Mater. Sci. Eng. A 2004, 383, 299–306. [Google Scholar] [CrossRef]

- Wu, N.; Li, Y.; Wang, J. Microstructure of Ni-NiCr Laminated Composite and Cr18-Ni8 steel Joint by Vacuum Brazing. Vacuum 2012, 86, 2059–2063. [Google Scholar] [CrossRef]

- Yuan, X.; Kang, C.Y.; Kim, M.B. Microstructure and XRD Analysis of Brazing Joint for Duplex Stainless Steel Using a Ni-Si-B Filler Metal. Mater. Charact. 2009, 60, 923–931. [Google Scholar] [CrossRef]

- Fischer, A. Mechanisms of High Temperature Sliding Abrasion of Metallic Materials. Wear 1992, 152, 151–159. [Google Scholar] [CrossRef]

- Winkelmann, H.; Badisch, E.; Varga, M.; Danninger, H. Wear Mechanisms at High Temperatures. Part 3: Changes of the Wear Mechanism in the Continuous Impact Abrasion Test with Increasing Testing Temperature. Tribol. Lett. 2010, 37, 419–429. [Google Scholar] [CrossRef]

- Venicatesan, K.; Subramanian, C.; Surnmerville, E. Three-body Abrasion of Surface Engineered Die Steel at Elevated Temperatures. Wear 1997, 203–204, 129–138. [Google Scholar] [CrossRef]

- Duarte, M.; Vragovic, I.; Molina, J.M.; Prieto, R.; Narciso, J.; Louis, E. 1/f Noise in Sliding Friction under Wear Conditions: The Role of Debris. Phys. Rev. Lett. 2009, 102, 045501. [Google Scholar] [CrossRef] [PubMed]

- Berns, H.; Koch, S. High Temperature Sliding Abrasion of a Nickel-base Alloy and Composite. Wear 1999, 225–229, 154–162. [Google Scholar] [CrossRef]

| CTCP-NiCrBSi Regions | Constituent Content (vol. %) | |||||

|---|---|---|---|---|---|---|

| WC/W2C | Dissolution Zone | WC Shell | P1 | P3 | NiCrBSi Matrix | |

| Unmodified | 7.5 | 32.7 | - | 18.2 | - | balance |

| Modified | 19.5 | - | 20.1 | - | 3.2 | balance |

| CTCP-NiCrBSi Regions | Constituent Microhardness, HV | ||||

|---|---|---|---|---|---|

| WC/W2C | Dissolution Zone | WC Shell | P1 | P3 | |

| Unmodified | 2256 | 1488 | - | 1084 | - |

| Modified | 2231 | - | 1577 | - | 1262 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Hou, S. Effects of CTCP Modification on Microstructure and Wear Behavior of CTCP-NiCrBSi/Heat Resistant Steel Composite Layer. Materials 2018, 11, 2202. https://doi.org/10.3390/ma11112202

Zhang J, Hou S. Effects of CTCP Modification on Microstructure and Wear Behavior of CTCP-NiCrBSi/Heat Resistant Steel Composite Layer. Materials. 2018; 11(11):2202. https://doi.org/10.3390/ma11112202

Chicago/Turabian StyleZhang, Jianjun, and Shuzeng Hou. 2018. "Effects of CTCP Modification on Microstructure and Wear Behavior of CTCP-NiCrBSi/Heat Resistant Steel Composite Layer" Materials 11, no. 11: 2202. https://doi.org/10.3390/ma11112202