Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al–Mg–Mn Alloy

Abstract

1. Introduction

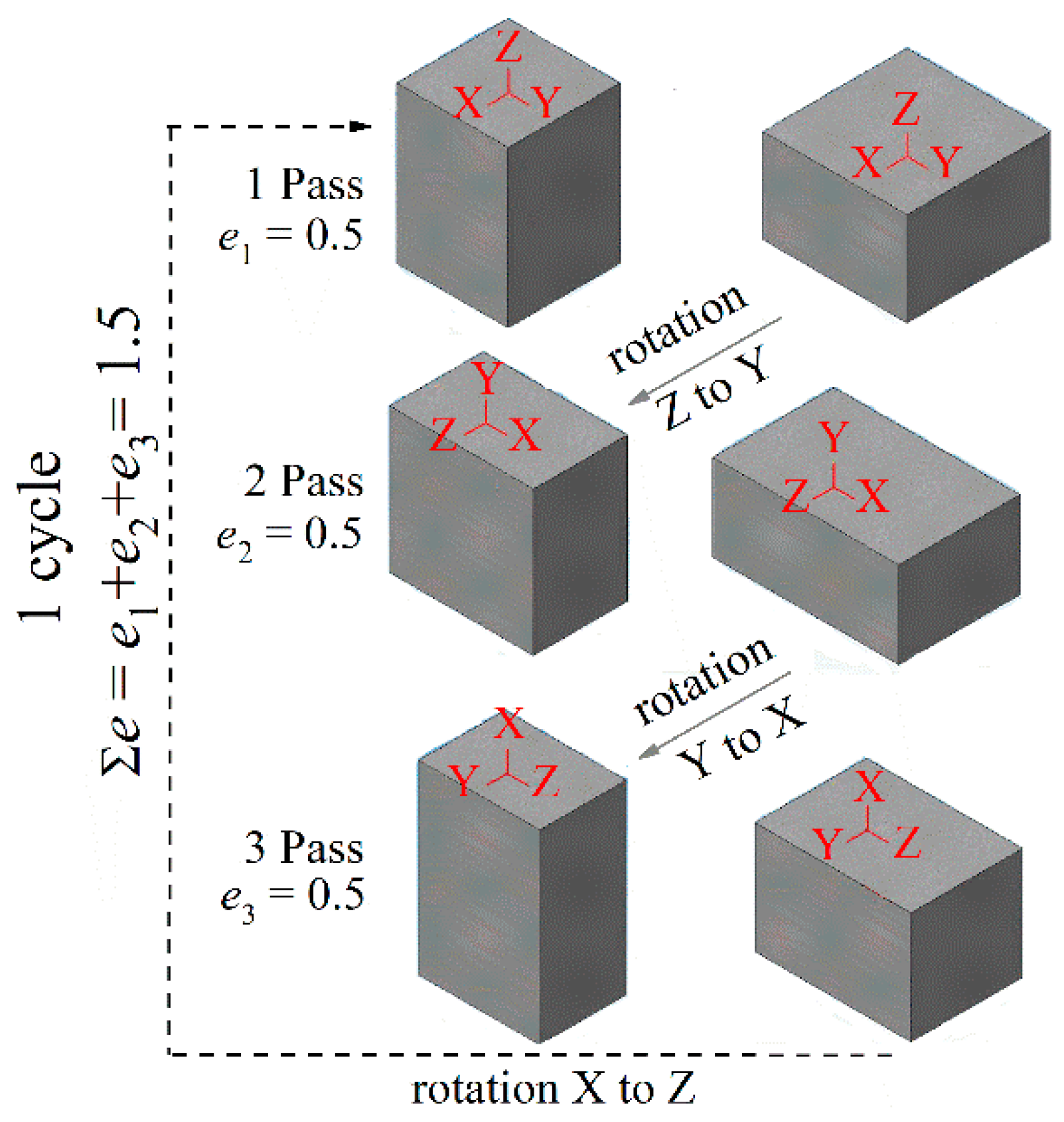

2. Materials and Methods

2.1. Materials and Processing

2.2. Microstructures Analyses

2.3. Tensile Tests

3. Results

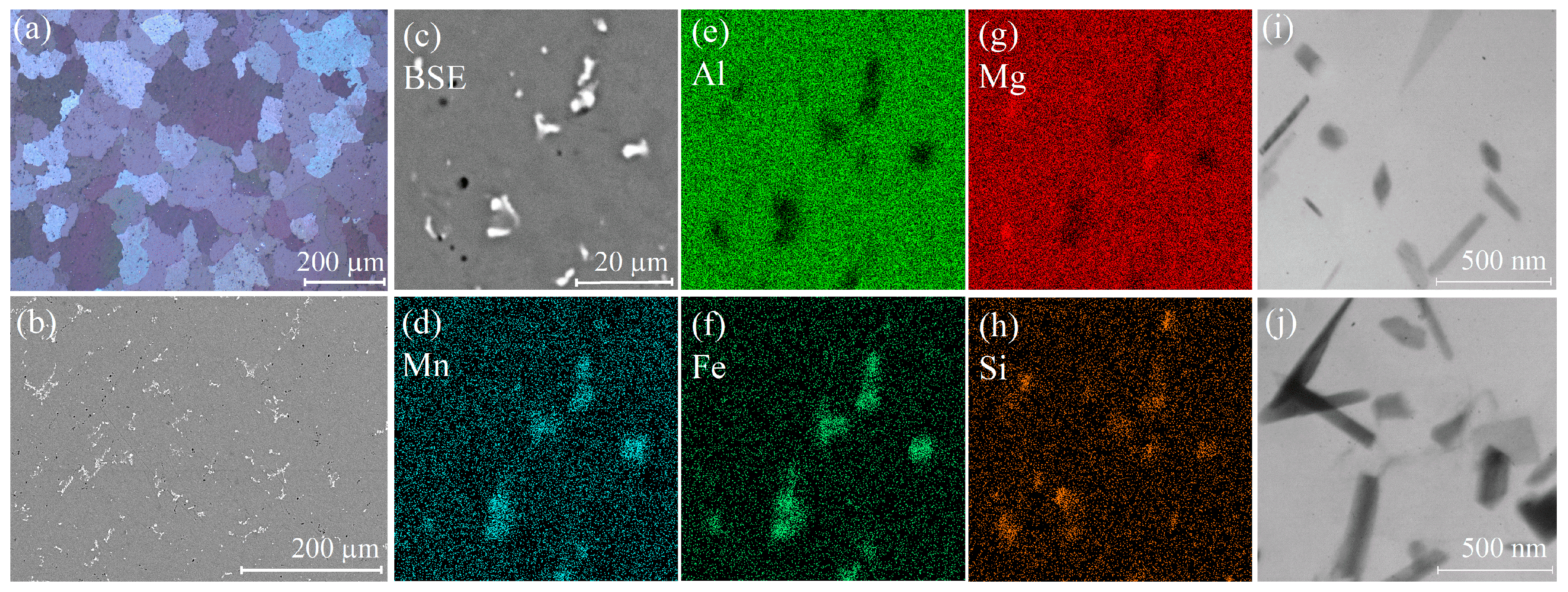

3.1. Microstructure after Homogenization Annealing

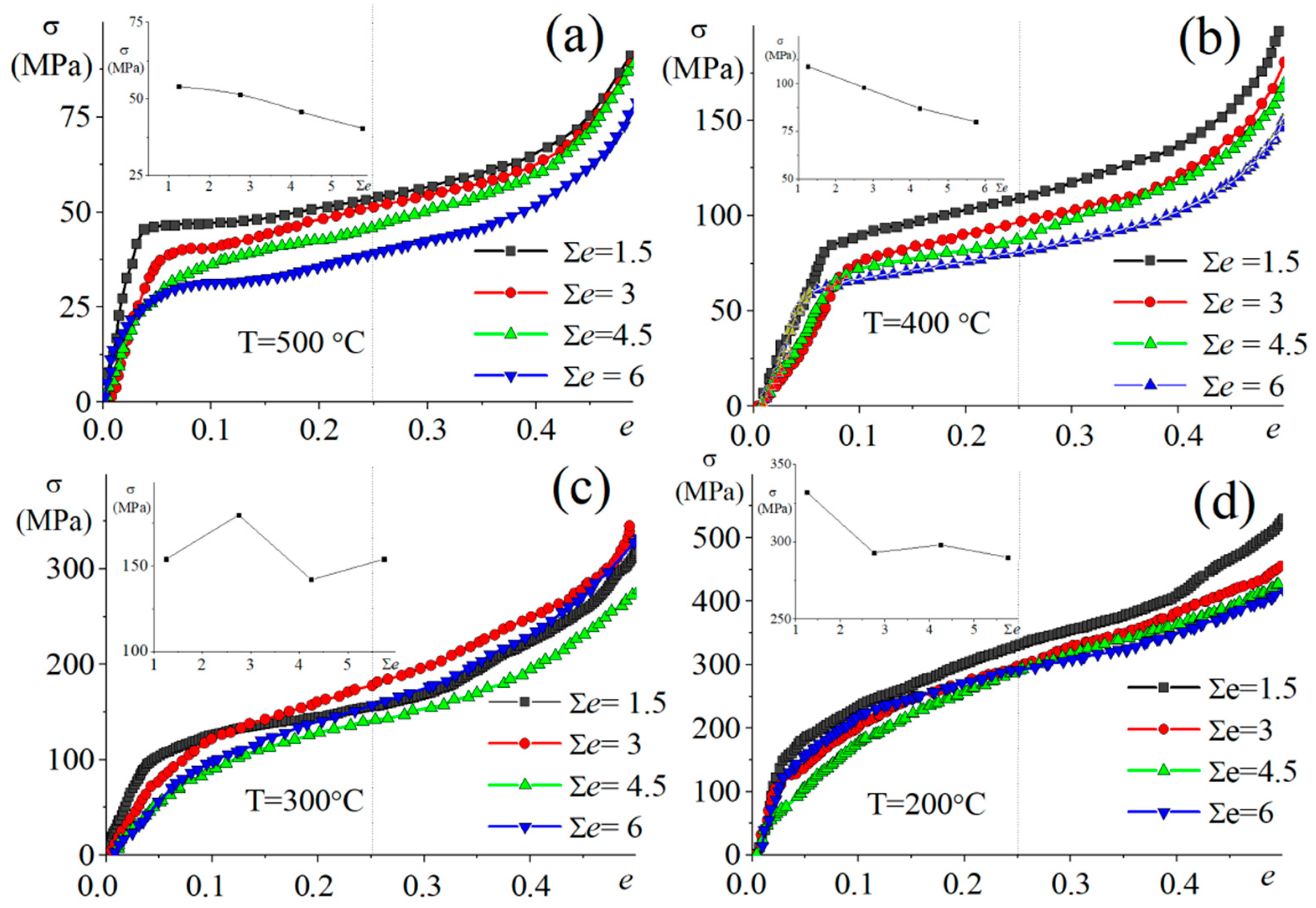

3.2. Stress–Strain Behavior at IMF

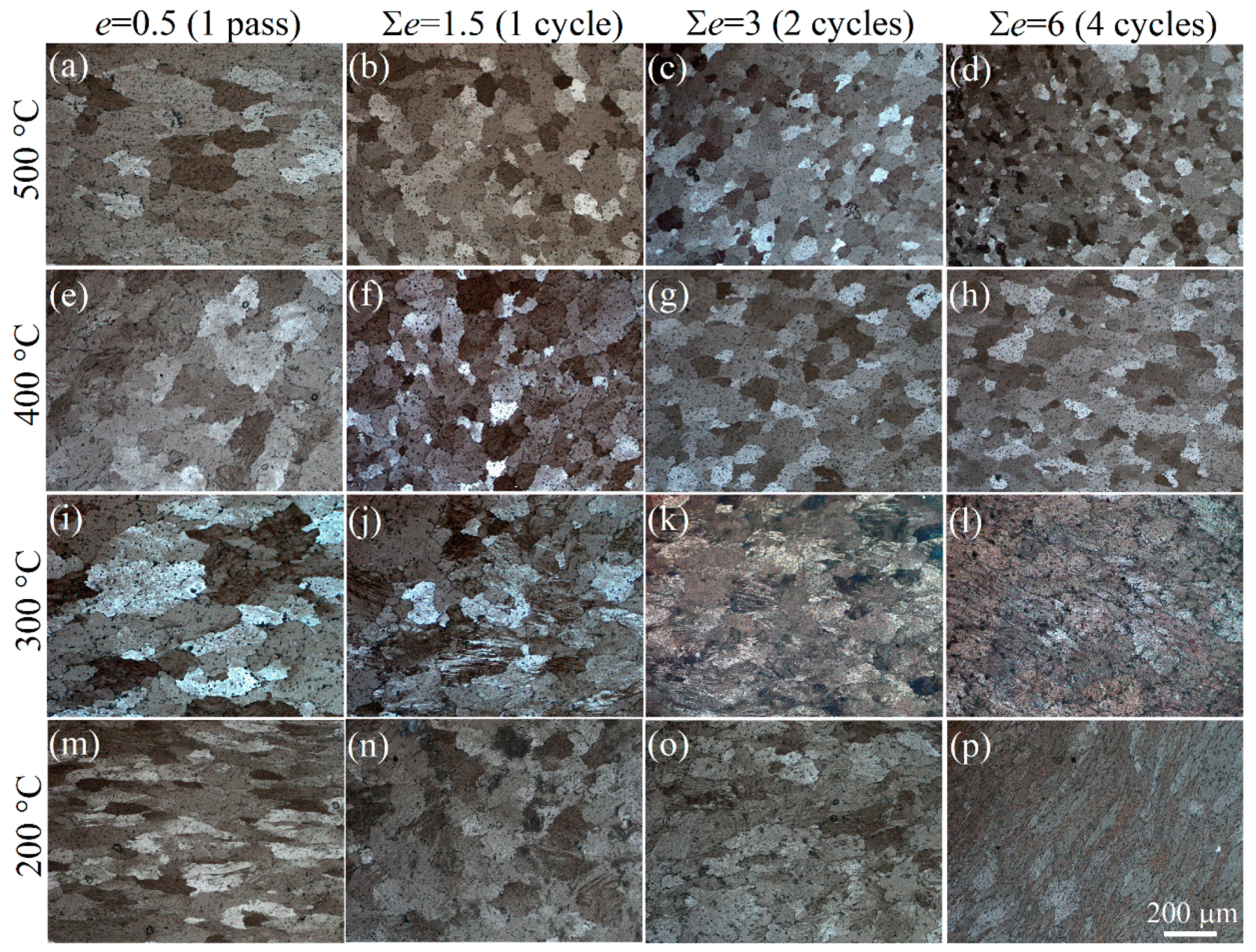

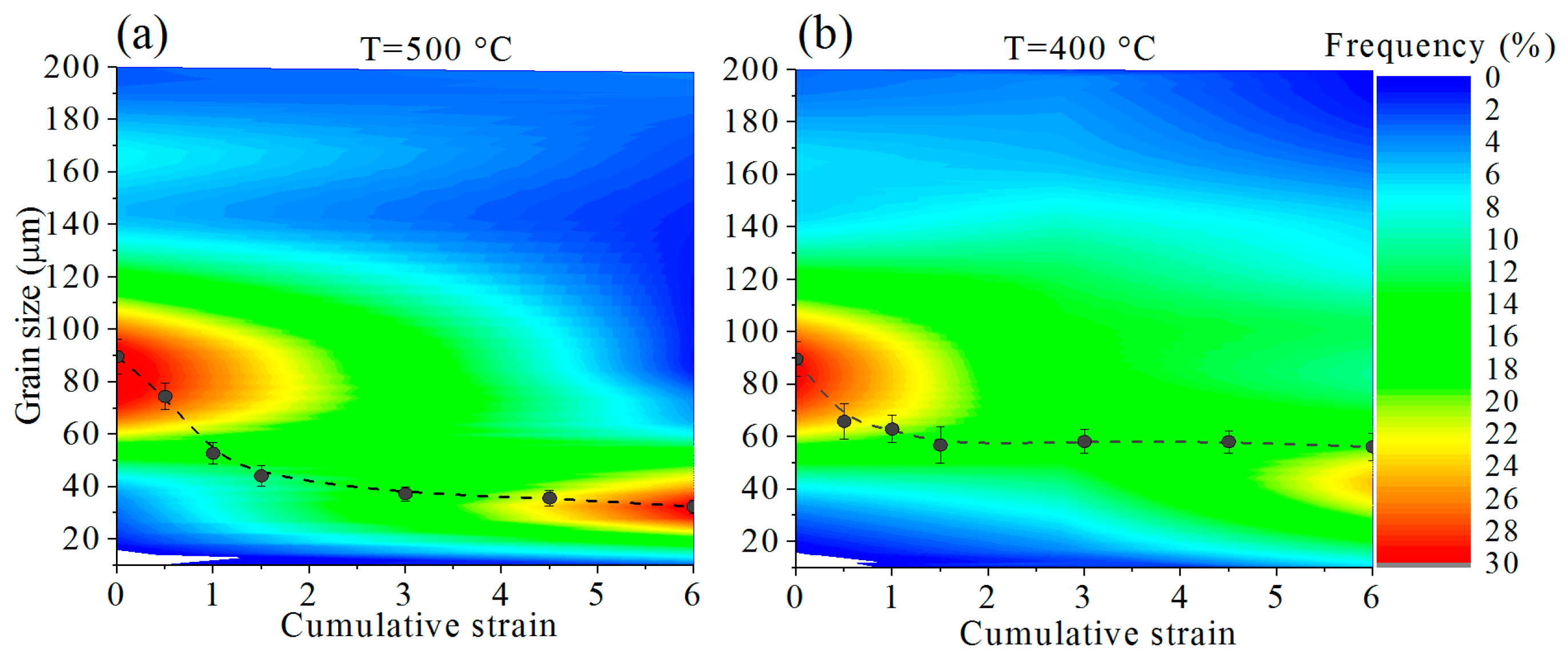

3.3. Microstructure Evolution during IMF

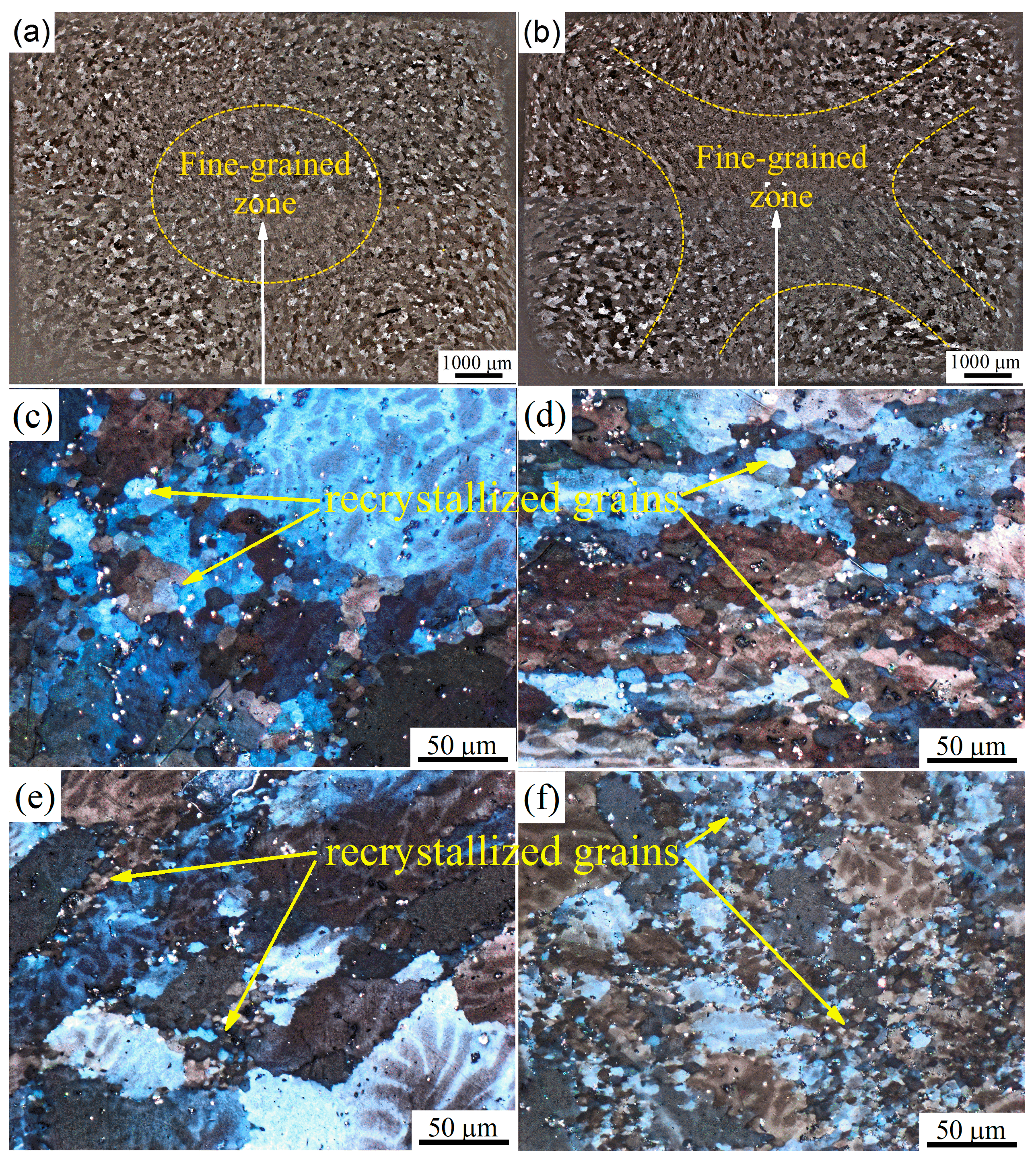

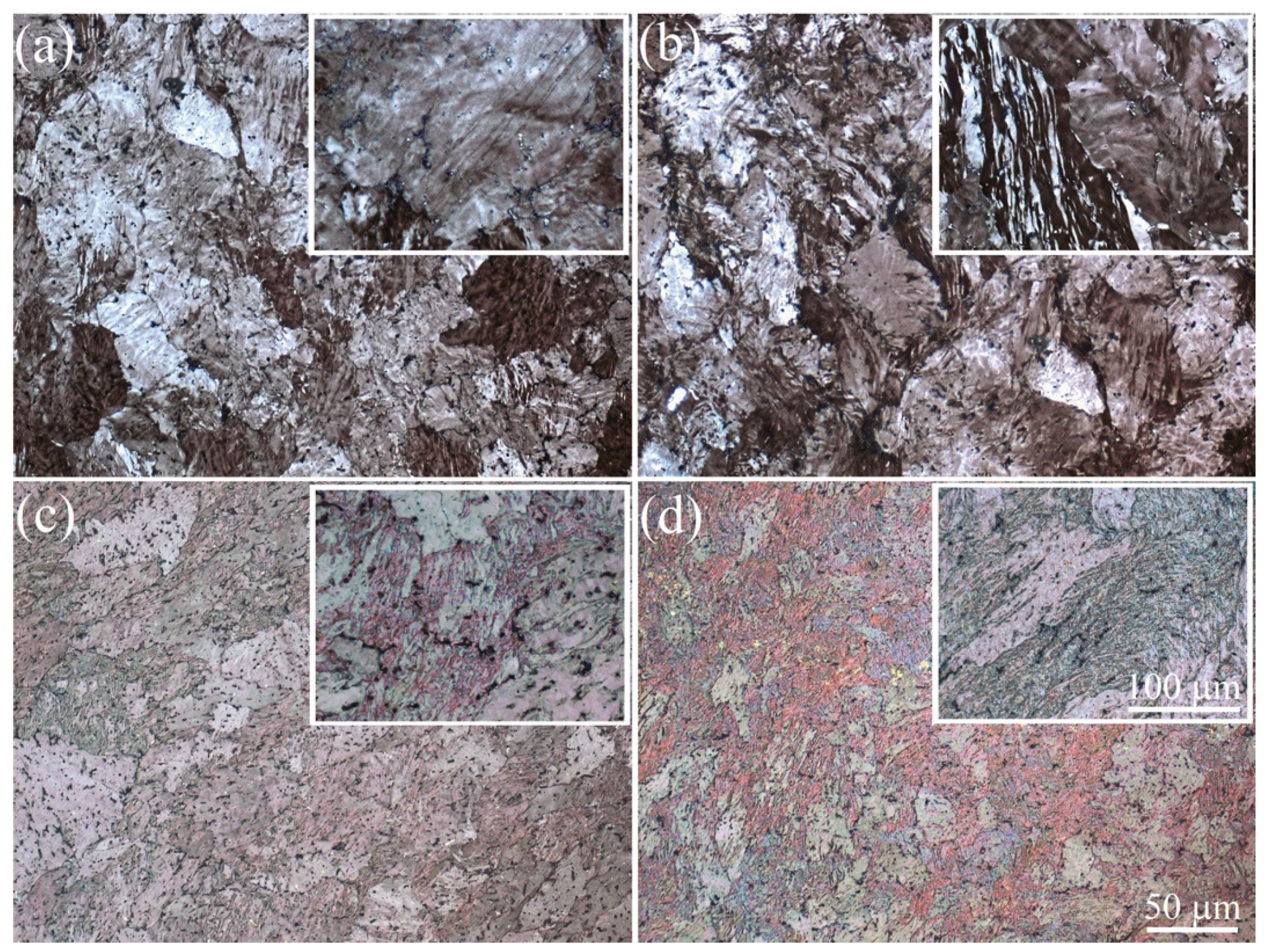

3.3.1. Grain Structure of the Near-Surface Layer

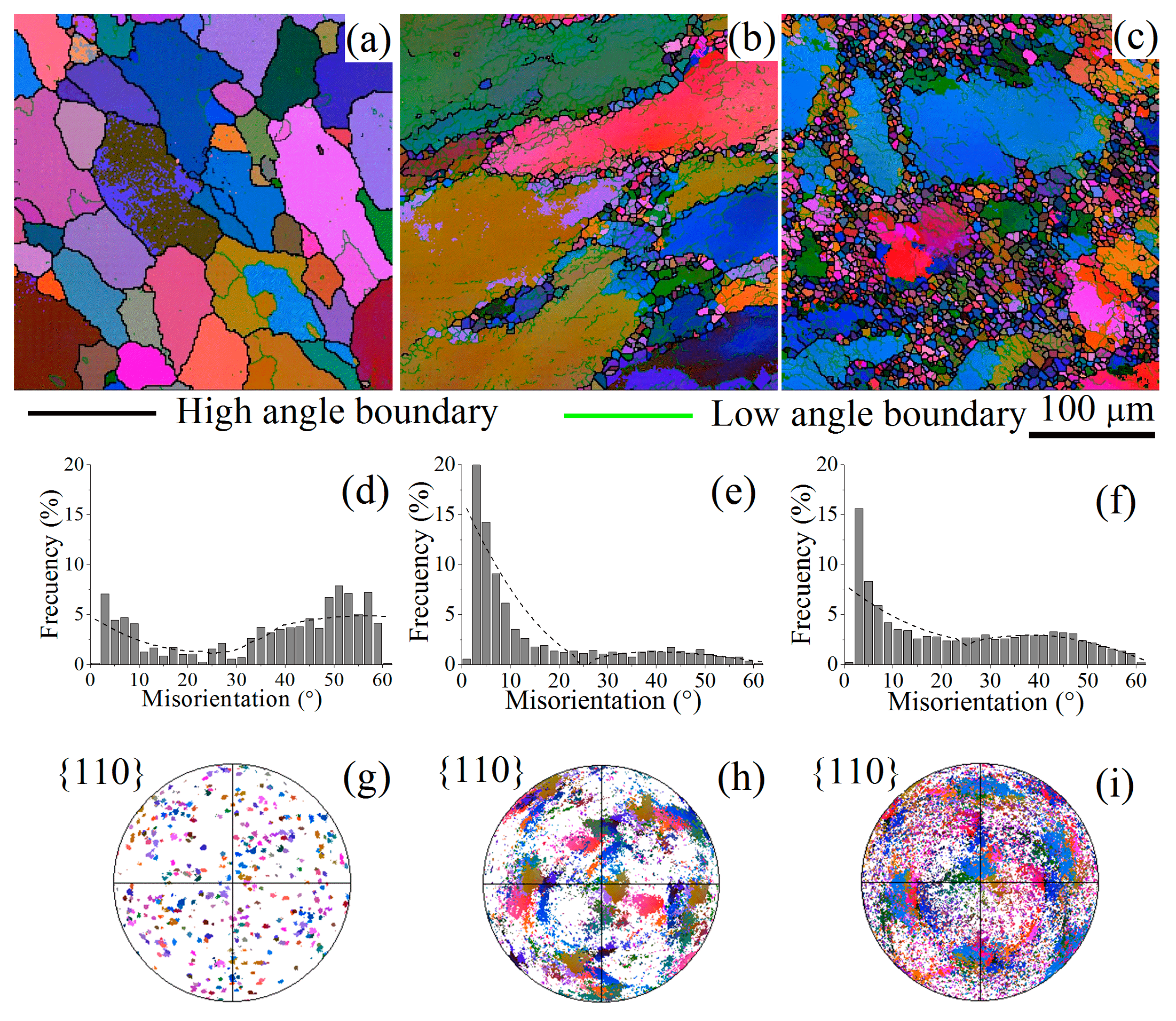

3.3.2. Grain Structure of Medium Cross-Section after ∑e = 3 and ∑e = 6

3.3.3. Evolution of the Secondary Phases

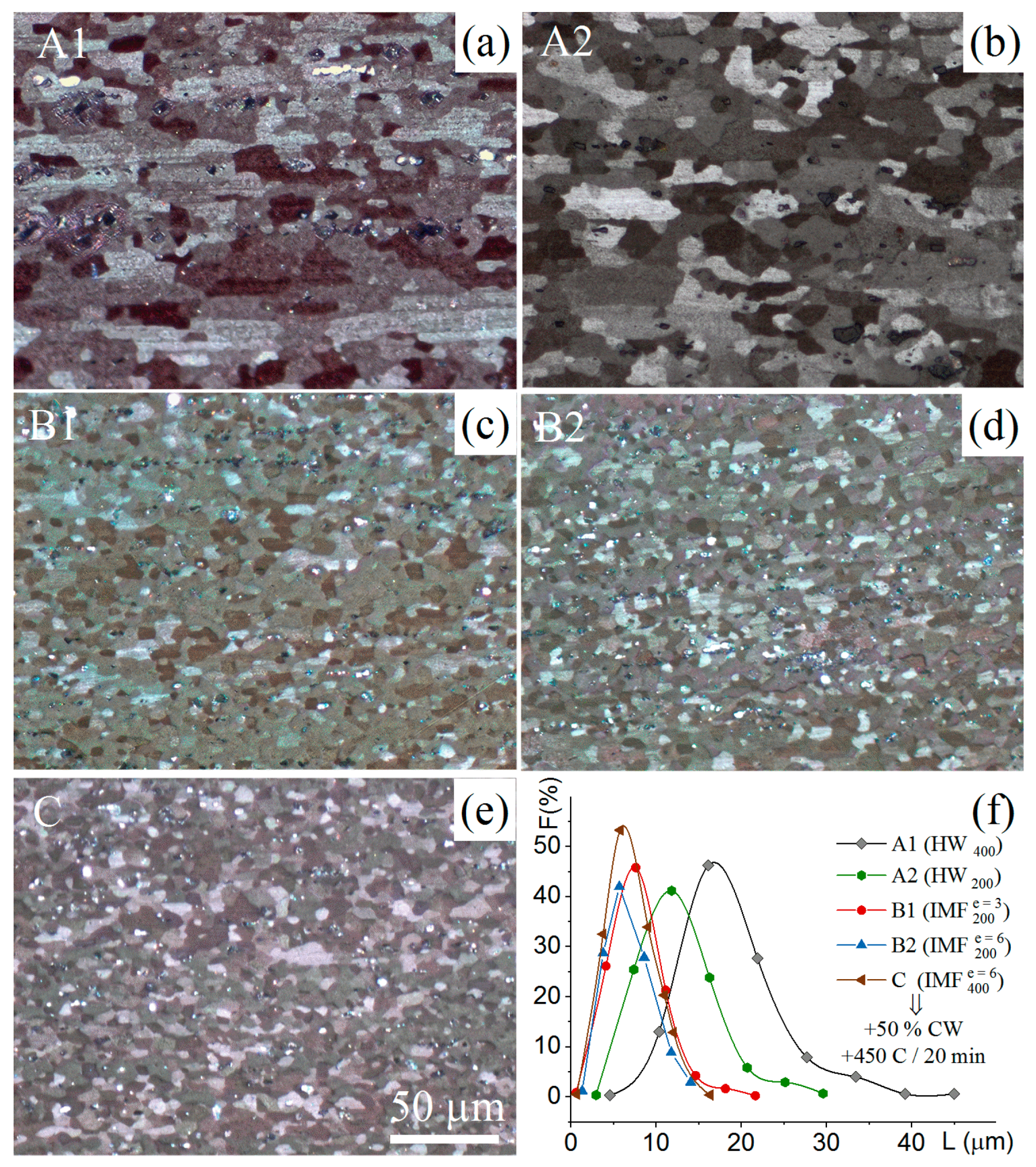

3.4. Grain Structure and Mechanical Properties of the Sheets

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nikulin, I.; Kipelova, A.; Malopheyev, S.; Kaibyshev, R. Effect of second phase particles on grain refinement during equal-channel angular pressing of an Al-Mg-Mn alloy. Acta Mater. 2012, 60, 487–497. [Google Scholar] [CrossRef]

- Robson, J.D. Microstructural evolution in aluminium alloy 7050 during processing. Mater. Sci. Eng. A 2004, 382, 112–121. [Google Scholar] [CrossRef]

- Shabani, M.J.; Emamy, M.; Nemati, N. Effect of grain refinement on the microstructure and tensile properties of thin 319 Al castings. Mater. Des. 2011, 32, 1542–1547. [Google Scholar] [CrossRef]

- Grains, U.; Zhemchuzhnikova, D.; Lebyodkin, M. Peculiar Spatiotemporal Behavior of Unstable Plastic Flow in an AlMgMnScZr Alloy with Coarse and Ultrafine Grains. Metals 2017, 7, 325. [Google Scholar] [CrossRef]

- Murashkin, M.; Medvedev, A.; Kazykhanov, V.; Krokhin, A.; Raab, G.; Enikeev, N.; Valiev, R.Z. Enhanced Mechanical Properties and Electrical Conductivity in Ultrafine-Grained Al 6101 Alloy. Processed via ECAP-Conform. Metals 2015, 5, 2148–2164. [Google Scholar] [CrossRef]

- Barnes, A.J. Industrial Applications of Superplastic Forming: Trends and Prospects. Mater. Sci. Forum 2001, 357–359, 3–16. [Google Scholar] [CrossRef]

- Grimes, R.; Dashwood, R.J.; Flower, H.M. High Strain Rate Superplastic Aluminium Alloys: The Way Forward. Mater. Sci. Forum 2001, 357–359, 357–362. [Google Scholar] [CrossRef]

- Langdon, T.G. Achieving superplasticity in ultrafine-grained metals. Mech. Mater. 2013, 67, 2–8. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. Developing superplasticity and a deformation mechanism map for the Zn–Al eutectoid alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2011, 528, 6140–6145. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Markushev, M.V.; Avtokratova, E.V.; Sitdikov, O.S. Effect of the initial state on nanostructuring and strengthening of middle- and high-strength age-hardenable aluminum alloys under severe plastic deformation (Review). Lett. Mater. 2017, 7, 459–464. [Google Scholar] [CrossRef]

- Kawasaki, M.; Ahn, B.; Kumar, P.; Jang, J.; Langdon, T.G. Nano- and Micro-Mechanical Properties of Ultrafine-Grained Materials Processed by Severe Plastic Deformation Techniques. Adv. Eng. Mater. 2017, 19, 1–17. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Ning, J.L.; Jiang, D.M. Influence of Zr addition on the microstructure evolution and thermal stability of Al-Mg-Mn alloy processed by ECAP at elevated temperature. Mater. Sci. Eng. A 2007, 452–453, 552–557. [Google Scholar] [CrossRef]

- Ning, J.L.; Jiang, D.M.; Fan, X.G.; Lai, Z.H.; Meng, Q.C.; Wang, D.L. Mechanical properties and microstructure of Al-Mg-Mn-Zr alloy processed by equal channel angular pressing at elevated temperature. Mater. Charact. 2008, 9, 306–311. [Google Scholar] [CrossRef]

- Zhao, S.; Meng, C.; Mao, F.; Hu, W.; Gottstein, G. Influence of severe plastic deformation on dynamic strain aging of ultrafine grained Al-Mg alloys. Acta Mater. 2014, 76, 54–67. [Google Scholar] [CrossRef]

- Fritsch, S.; Wagner, M.F. On the Effect of Natural Aging Prior to Low Temperature ECAP of a High-Strength Aluminum Alloy. Metals 2018, 8, 63. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Q.; Hu, N.; Huang, Y.; Langdon, T.G. Using an Al–Cu binary alloy to compare processing by multi-axial compression and high-pressure torsion. Mater. Sci. Eng. A 2013, 588, 280–287. [Google Scholar] [CrossRef]

- Xu, C.; Horita, Z.; Langdon, T.G. The evolution of homogeneity in an aluminum alloy processed using high-pressure torsion. Acta Mater. 2008, 56, 5168–5176. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Murashkin, M.; Sabirov, I.; Prosvirnin, D.; Ovid, I.; Terentiev, V.; Valiev, R.; Dobatkin, S. Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion. Metals 2015, 5, 578–590. [Google Scholar] [CrossRef]

- Thangapandian, N.; Balasivanandha, S.P.; Padmanabhan, K.A. Effects of die profile on grain refinement in Al-Mg alloy processed by repetitive corrugation and straightening. Mater. Sci. Eng. A 2016, 649, 229–238. [Google Scholar] [CrossRef]

- Daneshvar, F.; Reihanian, M.; Gheisari, K. Al-based magnetic composites produced by accumulative roll bonding (ARB). Mater. Sci. Eng. B 2016, 206, 45–54. [Google Scholar] [CrossRef]

- Kavosi, J.; Saei, M.; Kazeminezhad, M.; Dodangeh, A. Modeling of dislocation density and strength on rheoforged A356 alloy during multi-directional forging. Comput. Mater. Sci. 2014, 81, 284–289. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, J. Microstructure and Mechanical properties of AZ31 magnesium alloy processed by multi-directional forging at different temperatures. Mater. Sci. Eng. A 2016, 674, 52–58. [Google Scholar] [CrossRef]

- Miura, H.; Nakao, Y.; Sakai, T. Enhanced Grain Refinement by Mechanical Twinning in a Bulk Cu-30 mass%Zn during Multi-Directional Forging. Mater. Trans. 2007, 48, 2539–2541. [Google Scholar] [CrossRef]

- Nakao, Y.; Miura, H. Nano-grain evolution in austenitic stainless steel during multi-directional forging. Mater. Sci. Eng. A 2011, 528, 1310–1317. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Huang, W. Severe deformation based process for grain subdivision and resulting microstructures. In Investigations and Applications of Severe Plastic Deformation; Springer: Dordrecht, The Netherland, 2000; pp. 29–36. ISBN 978-0-7923-6281-4. [Google Scholar]

- Belyakov, A.; Sakai, T.; Miura, H. Microstructure and deformation behaviour of submicrocrystalline 304 stainless steel produced by severe plastic deformation. Mater. Sci. Eng. A 2001, 319–321, 867–871. [Google Scholar] [CrossRef]

- Sitdikov, O.S.; Avtokratova, E.V.; Mukhametdinova, O.E.; Garipova, R.N.; Markushev, M.V. Effect of the Size of Al3(Sc,Zr) Precipitates on the Structure of Multi-Directionally Isothermally Forged Al-Mg-Sc-Zr Alloy. Phys. Met. Metallogr. 2017, 118, 1215–1224. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Miura, H.; Hama, C. Temperature effect on fine-grained structure formation in high-strength Al alloy 7475 during hot severe deformation. Mater. Sci. Eng. A 2009, 516, 180–188. [Google Scholar] [CrossRef]

- Dziubińskaa, A.; Gontarz, A.; Horzelska, K.; Pieśko, P. The microstructure and mechanical properties of AZ31 magnesium alloy aircraft brackets produced by a new forging technology. Procedia Manuf. 2015, 2, 337–341. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H.; Gharah Shiran, M.K.; Khalajd, G.; Shirazie, M. On the effect of non-isothermal annealing and multi-directional forging on the microstructural evolutions and correlated mechanical and electrical characteristics of hot-deformed Al-Mg alloy. Mater. Sci. Eng. A 2016, 657, 431–440. [Google Scholar] [CrossRef]

- Asadi, S.; Kazeminezhad, M. Multi Directional Forging of 2024 Al Alloy After Different Heat Treatments: Microstructural and Mechanical Behavior. Trans. Indian Inst. Met. 2017, 70, 1707–1719. [Google Scholar] [CrossRef]

- Moghanaki, K.S.; Kazeminezhad, M. Effects of non-isothermal annealing on microstructure and mechanical properties of severely deformed 2024 aluminum alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 1–9. [Google Scholar] [CrossRef]

- Rao, P.N.; Singh, D.; Jayaganthan, R. Mechanical properties and microstructural evolution of Al 6061 alloy processed by multidirectional forging at liquid nitrogen temperature. Mater. Des. 2014, 56, 97–104. [Google Scholar] [CrossRef]

- Sitdikov, O.; Garipova, R.; Avtokratova, E.; Mukhametdinova, O.; Markushev, M. Effect of temperature of isothermal multidirectional forging on microstructure development in the Al-Mg alloy with nano-size aluminides of Sc and Zr. J. Alloys Compd. 2018, 746, 520–531. [Google Scholar] [CrossRef]

- Armstrong, P.E.; Hockett, J.E.; Sherby, O.D. Large Deformation of 1100 Aluminum at 300 K. J. Mech. Phys. Solids 1982, 30, 37–58. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Cui, Z. Microstructures and mechanical properties of AZ61 magnesium alloy after isothermal multidirectional forging with increasing rate. Mater. Sci. Eng. A 2015, 643, 32–36. [Google Scholar] [CrossRef]

- Miura, H.; Yu, G.; Yang, X. Multi-directional forging of AZ61Mg alloy under decreasing temperature conditions and improvement of its mechanical properties. Mater. Sci. Eng. A 2011, 528, 6981–6992. [Google Scholar] [CrossRef]

- Xing, J.; Soda, H.; Yang, X.; Miura, H.; Sakai, T. Ultra-Fine Grain Development in an AZ31 Magnesium Alloy during Multi-Directional Forging under Decreasing Temperature Conditions. Mater. Trans. 2005, 46, 1646–1650. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, L.; Ban, C.; Zhao, Z.; Zuo, Y.; Cui, J. Structure uniformity and limits of grain refinement of high purity aluminum during multi-directional forging process at room temperature. Trans. Nonferrous Met. Soc. China 2014, 24, 1301–1306. [Google Scholar] [CrossRef]

- Łyszkowski, R.; Czujko, T.; Varin, R.A. Multi-axial forging of Fe3Al-base intermetallic alloy and its mechanical properties. J. Mater. Sci. 2017, 52, 2902. [Google Scholar] [CrossRef]

- Bereczki, P.; Szombathely, V.; Krallics, G. Production of ultrafine grained aluminum by cyclic severe plastic deformation at ambient temperature. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012140. [Google Scholar] [CrossRef]

- Padap, A.K.; Chaudhari, G.P.; Nath, S.K.; Pancholi, V. Ultrafine-grained steel fabricated using warm multiaxial forging: Microstructure and mechanical properties. Mater. Sci. Eng. A 2009, 527, 110–117. [Google Scholar] [CrossRef]

- Petryk, H.; Stupkiewicz, S.; Kuziak, R. Grain refinement and strain hardening in IF steel during multi-axis compression: Experiment and modelling. J. Mater. Process. Technol. 2008, 204, 255–263. [Google Scholar] [CrossRef]

- Moghanaki, K.S.; Kazeminezhad, M.; Loge, R. Effect of concurrent precipitation on the texture evolution during continuous heating of multi directionally forged solution treated Al-Cu-Mg alloy. Mater. Charact. 2017, 131, 399–405. [Google Scholar] [CrossRef]

- Ringeva, S.; Piot, D.; Desrayaud, C.; Driver, J.H. Texture and microtexture development in an Al–3Mg–Sc(Zr) alloy deformed by triaxial forging. Acta Mater. 2006, 54, 3095–3105. [Google Scholar] [CrossRef]

- Maruff, H.; Rao, P.N.; Dharmendra, S.; Jayaganthan, R.; Singh, S. Comparative Study of Microstructure and Mechanical Properties of Al 6063 alloy Processed by Multi Axial Forging at 77K and Cryorolling. Procedia Eng. 2014, 75, 129–133. [Google Scholar]

- Nakao, Y.; Miura, H.; Sakai, T. Microstructural evolution and recrystallization behavior in copper multi-directionally forged at 77 K. Adv. Mater. Res. 2007, 15-17, 649–654. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Cheverikin, V.V.; Kotov, A.D.; Portnoy, V.K. Superplastic behaviour of Al-Mg-Zn-Zr-Sc-based alloys at high strain rates. Mater. Sci. Eng. A 2016, 659, 225–233. [Google Scholar] [CrossRef]

- Kotov, A.D.; Mikhaylovskaya, A.V.; Kishchik, M.S.; Tsarkov, A.A.; Aksenov, S.A.; Portnoy, V.K. Superplasticity of high-strength Al-based alloys produced by thermomechanical treatment. J. Alloys Compd. 2016, 688, 336–344. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Mikhaylovskaya, A.V.; Kotov, A.D.; Rofman, O.V.; Portnoy, V.K. Al-Mg-Fe-Ni based alloy for high strain rate superplastic forming. Mater. Sci. Eng. A 2018, 718, 190–197. [Google Scholar] [CrossRef]

- Buranova, Y.; Kulitskiy, V.; Peterlechner, M.; Mogucheva, A.; Kaibyshev, R.; Divinski, S.V.; Wilde, G. Al3(Sc,Zr)-based precipitates in Al–Mg alloy: Effect of severe deformation. Acta Mater. 2017, 124, 210–224. [Google Scholar] [CrossRef]

- Smith, C.S. Grains, Phases, and Interfaces—An Interpretation of Microstructure. Metall. Mater. Trans. A 1948, 175, 15. [Google Scholar]

- Manohar, P.A.; Ferry, M.; Chandra, T. Five decades of the Zener equation. ISIJ Int. 1998, 38, 913–924. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mikhailovskaya, A.V.; Levchenko, V.S.; Kotov, A.D.; Drits, A.M.; Portnoy, V.K. Formation of Fine-Grained Structure and Superplasticity in Commercial Aluminum Alloy 1565ch. Met. Sci. Heat Treat. 2017, 58, 543–547. [Google Scholar] [CrossRef]

- Engler, O.; Miller-Jupp, S. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083. J. Alloys Compd. 2016, 689, 998–1010. [Google Scholar] [CrossRef]

- Lucadamo, G.; Yang, N.Y.C.; SanMarchi, C.; Lavernia, E.J. Microstructure characterization in cryomilled Al 5083. Mater. Sci. Eng. A 2006, 430, 230–241. [Google Scholar] [CrossRef]

- Engler, O.; Kuhnke, K.; Westphal, K.; Hasenclever, J. Impact of chromium on the microchemistry evolution during solidification and homogenization of the Al-Mg alloy AA 5052. J. Alloys Compd. 2018, 744, 561–573. [Google Scholar] [CrossRef]

- Engler, O.; Liu, Z.; Kuhnke, K. Impact of homogenization on particles in the Al–Mg–Mn alloy AA 5454–Experiment and simulation. J. Alloy. Compd. 2013, 560, 111–122. [Google Scholar] [CrossRef]

- Yi, G.; Sun, B.; Poplawsky, J.D.; Zhu, Y.; Free, M.L. Investigation of pre-existing particles in Al 5083 alloys. J. Alloys Compd. 2018, 740, 461–469. [Google Scholar] [CrossRef]

- Jandaghi, M.R.; Pouraliakbar, H. Study on the Effect of Post-Annealing on the Microstructural Evolutions and Mechanical Properties of Rolled CGPed Aluminum-Manganese-Silicon alloy. Mater. Sci. Eng. A 2017, 679, 493–503. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Goloborodko, A.; Miura, H. Grain fragmentation in a coarse-grained 7475 Al alloy during hot deformation. Scr. Mater. 2004, 51, 175–179. [Google Scholar] [CrossRef]

- Nes, E. Primary Recrystallization in Two-phase Alloys. Encycl. Mater. Sci. Technol. 2001, 13, 7850–7854. [Google Scholar]

- Humphreys, J.; Rohrer, G.S.; Rollett, A. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2004; p. 658. ISBN 9780080540412. [Google Scholar]

- Churyumov, A.Y.; Mikhaylovskaya, A.V.; Bazlov, A.I.; Tsarkov, A.A.; Kotov, A.D.; Aksenov, S.A. Influence of Al3Ni crystallisation origin particles on hot deformation behaviour of aluminium based alloys. Philos. Mag. 2017, 97, 572–590. [Google Scholar] [CrossRef]

- Nes, E.; Ryum, N.; Hunderi, O. On the Zener Drag. Acta. Metall. 1985, 33, 11–22. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Li, J. Formation and Microstructure of Ultrafine-Grained Titanium Processed by Multi-Directional Forging. J. Mater. Eng. Perform. 2016, 25, 2521–2527. [Google Scholar] [CrossRef]

- Popovic, M.; Verlinden, B. Microstructure and mechanical properties of Al–4·4 wt-%Mg alloy (AA5182) after equal channel angular pressing. Mater. Sci. Technol. 2013, 29, 370–375. [Google Scholar] [CrossRef]

- Sakai, T.; Jonas, J.J. Plastic deformation: Role of recovery and recrystallization. Encycl. Mater. Sci. Technol. 2001, 7, 7079. [Google Scholar]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Sitdikov, O.; Sakai, T.; Goloborodko, A.; Miura, H.; Kaibyshev, R. Effect of Pass Strain on Grain Refinement in 7475 Al Alloy during Hot Multidirectional Forging. Mater. Trans. 2004, 45, 2232–2238. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Sitdikov, O.; Goloborodko, A.; Sakai, T. Grain refinement in as-cast 7475 aluminum alloy under hot deformation. Mater. Sci. Eng. A 2003, 344, 348–356. [Google Scholar] [CrossRef]

- Gazizov, M.; Malopheyev, S.; Kaibyshev, R. The effect of second-phase particles on grain refinement during equal-channel angular pressing in an Al–Cu–Mg–Ag alloy. J. Mater. Sci. 2014, 50, 990–1005. [Google Scholar] [CrossRef]

- Buckingham, R.C.; Argyrakis, C.; Hardy, M.C.; Birosca, S. The effect of strain distribution on microstructural developments during forging in a newly developed nickel base superalloy. Mater. Sci. Eng. A 2016, 654, 317–328. [Google Scholar] [CrossRef]

- Murashkin, M.Y.; Sabirov, I.; Medvedev, A.E.; Enikeev, N.A.; Lefebvre, W.; Valiev, R.Z.; Sauvage, X. Mechanical and electrical properties of an ultra-fine grained Al–8.5 wt % RE (RE = 5.4 wt % Ce, 3.1 wt % La) alloy processed by severe plastic deformation. Mater. Des. 2016, 90, 433–442. [Google Scholar] [CrossRef]

- Portnoy, V.K.; Rylov, D.S.; Levchenko, V.S.; Mikhaylovskaya, A.V. The influence of chromium on the structure and superplasticity of Al-Mg-Mn alloys. J. Alloys Compd. 2013, 581, 313–317. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Murashkin, M.Y.; Enikeev, N.A.; Valiev, R.Z.; Hodgson, P.D.; Lapovok, R. Optimization of Strength-Electrical Conductivity Properties in Al–2Fe Alloy by Severe Plastic Deformation and Heat Treatment. Adv. Eng. Mater. 2018, 20, 1700867. [Google Scholar] [CrossRef]

| Element | Mg | Mn | Zn | Fe | Si | Zr | Cr | Al |

| Concentration (wt %) | 5.7 | 0.8 | 0.7 | <0.2 | <0.1 | 0.1 | 0.1 | Base |

| Parameter | e = 0.5 (1 pass) | Σe = 3 (2 cycles) | Σe = 6 (4 cycles) |

| Grain size (μm) | 45.1 | 5.5/fine grained area | 5.3/fine grained area |

| LAGBs volume fraction (%) | 24.2 | 73.5 | 44.0 |

| Modes A1 and A2 | Modes B1 and B2 | Mode C |

|---|---|---|

| Rolling at 400 °C (A1) or at 200 °C (A2), ∑e = 2.1; Cold rolling, e = 0.69 | IMF at 200 °C, ∑e = 3 (B1), ∑e = 6 (B2); Cold rolling, e = 0.69 | IMF at 400 °C, ∑e = 6; Cold rolling, e = 0.69 |

| Scheme of Thermomechanical Treatment | Mean Grain Size (µm) | Mechanical Property | ||

|---|---|---|---|---|

| Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | ||

| A1 | 15.6 ± 0.8 | 150 ± 3 | 360 ± 3 | 21 ± 1 |

| A2 | 10.4 ± 0.5 | 160 ± 2 | 362 ± 3 | 22 ± 1 |

| B1 | 7.1 ± 0.3 | 205 ± 1 | 362 ± 1 | 27 ± 1 |

| B2 | 5.1 ± 0.2 | 205 ± 2 | 368 ± 4 | 27 ± 1 |

| C | 5.0 ± 0.3 | 200 ± 2 | 363 ± 4 | 27 ± 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kishchik, M.S.; Mikhaylovskaya, A.V.; Kotov, A.D.; Mosleh, A.O.; AbuShanab, W.S.; Portnoy, V.K. Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al–Mg–Mn Alloy. Materials 2018, 11, 2166. https://doi.org/10.3390/ma11112166

Kishchik MS, Mikhaylovskaya AV, Kotov AD, Mosleh AO, AbuShanab WS, Portnoy VK. Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al–Mg–Mn Alloy. Materials. 2018; 11(11):2166. https://doi.org/10.3390/ma11112166

Chicago/Turabian StyleKishchik, Mikhail S., Anastasia V. Mikhaylovskaya, Anton D. Kotov, Ahmed O. Mosleh, Waheed S. AbuShanab, and Vladimir K. Portnoy. 2018. "Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al–Mg–Mn Alloy" Materials 11, no. 11: 2166. https://doi.org/10.3390/ma11112166

APA StyleKishchik, M. S., Mikhaylovskaya, A. V., Kotov, A. D., Mosleh, A. O., AbuShanab, W. S., & Portnoy, V. K. (2018). Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al–Mg–Mn Alloy. Materials, 11(11), 2166. https://doi.org/10.3390/ma11112166