Correlations between Microstructure Characteristics and Mechanical Properties in 5183 Aluminium Alloy Fabricated by Wire-Arc Additive Manufacturing with Different Arc Modes

Abstract

:1. Introduction

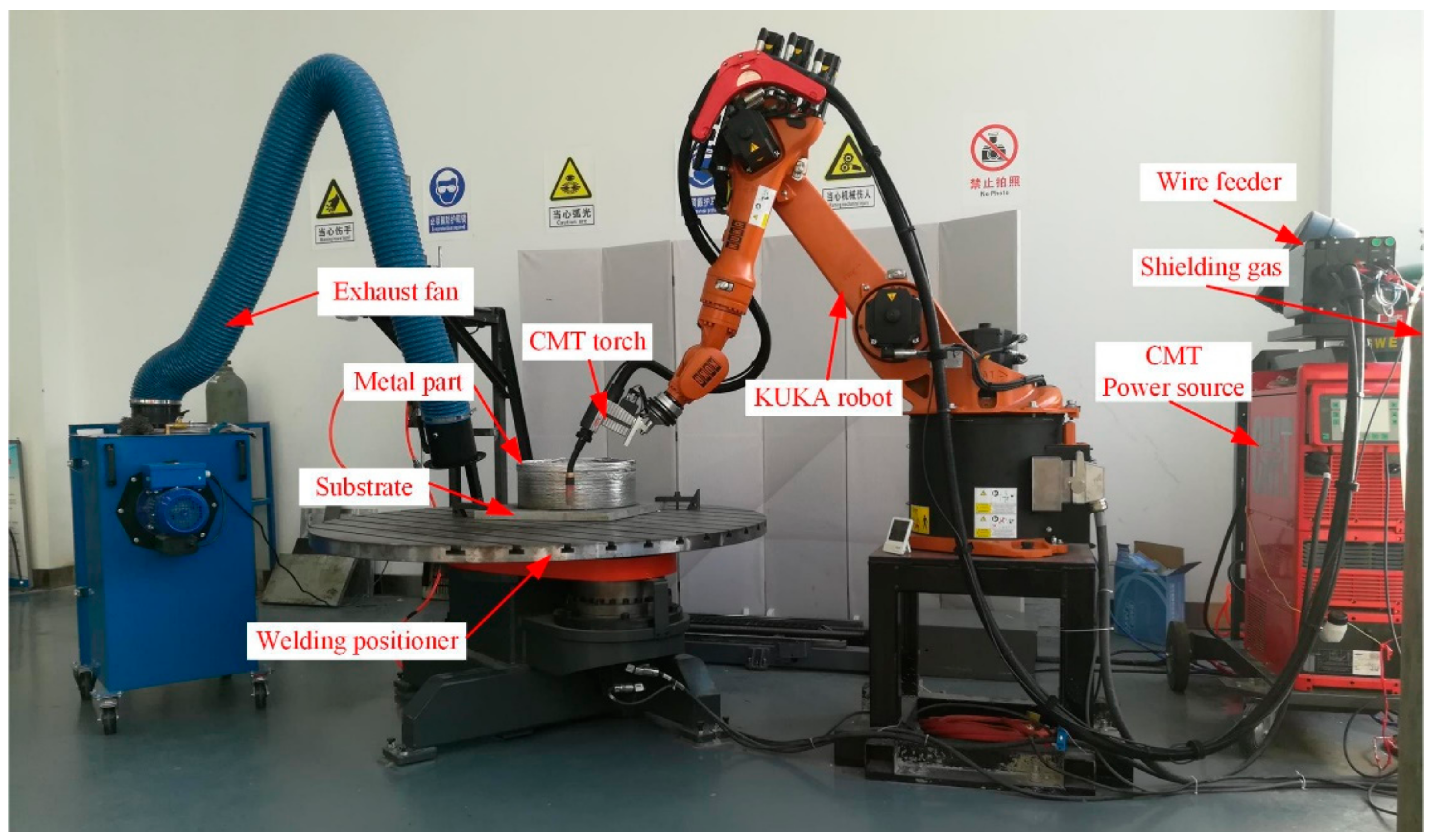

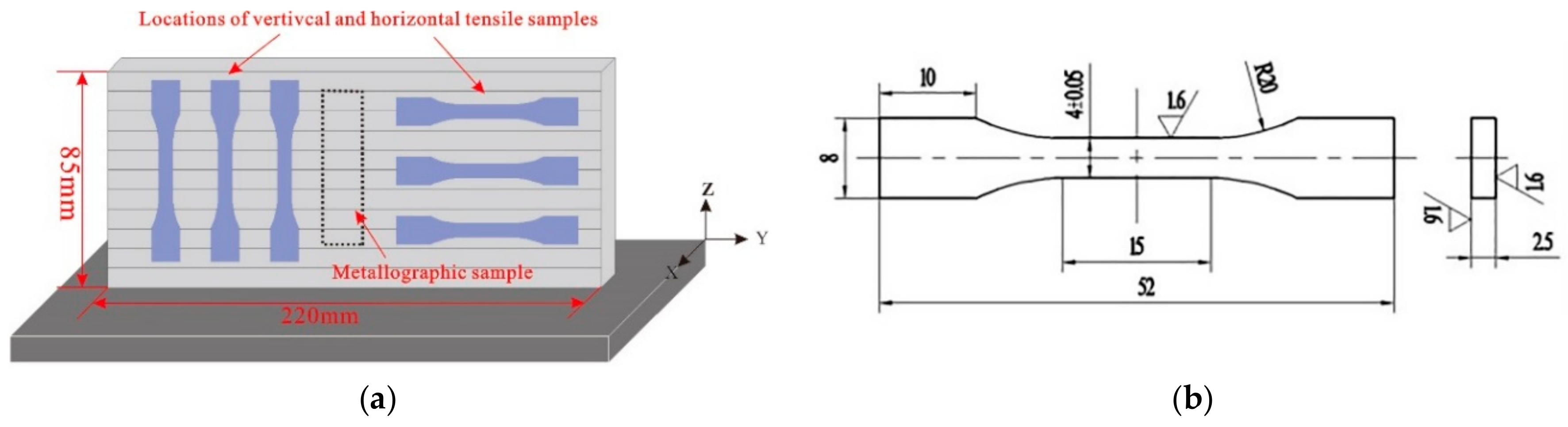

2. Experimental Methods

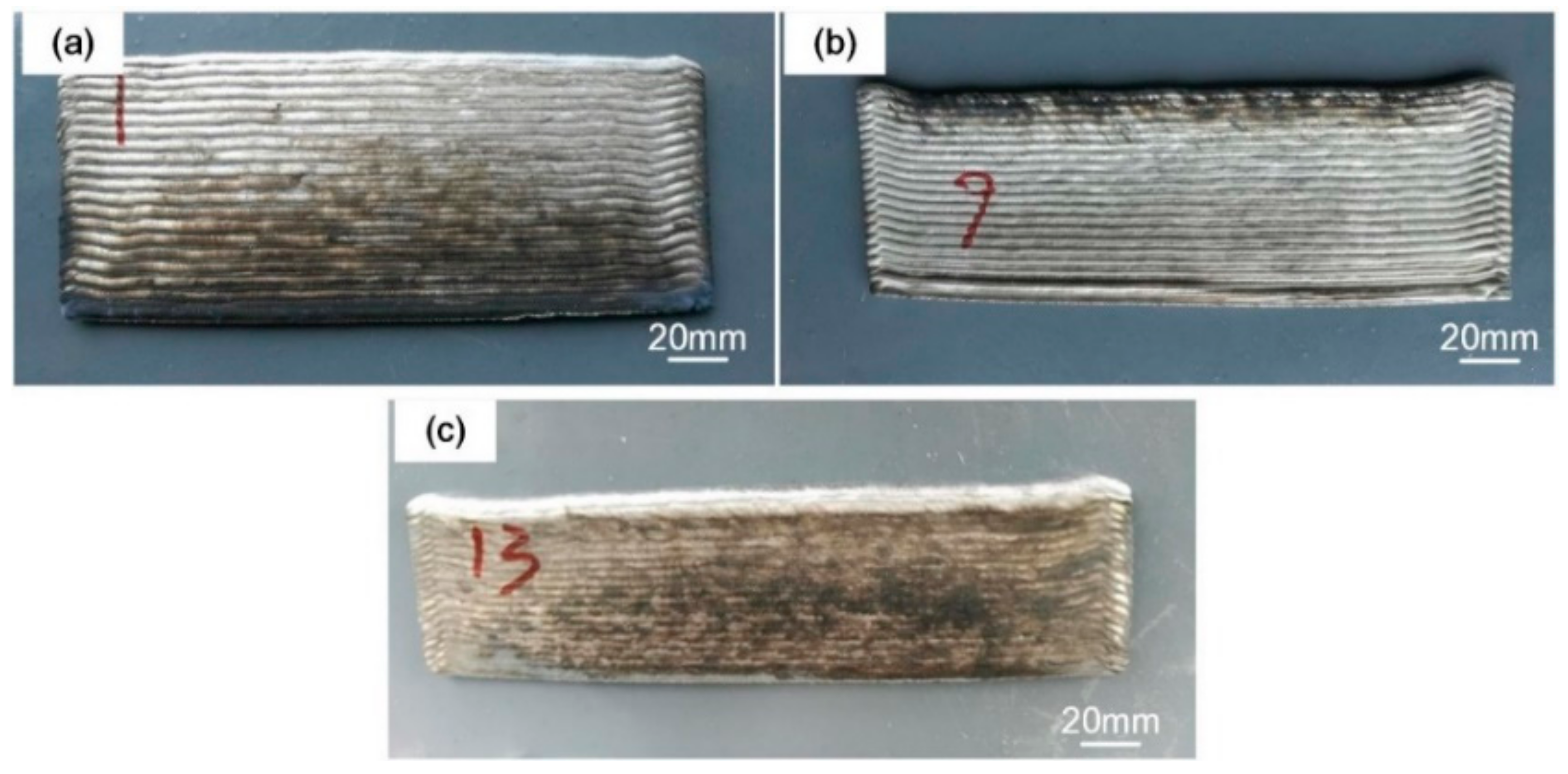

3. Results and Discussion

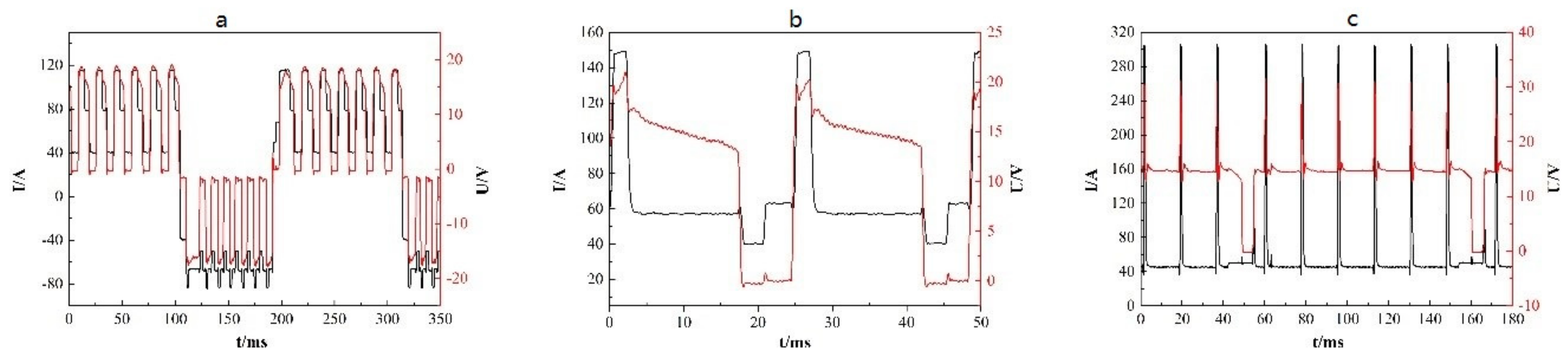

3.1. Heat Input Evaluation of Different Arc Modes

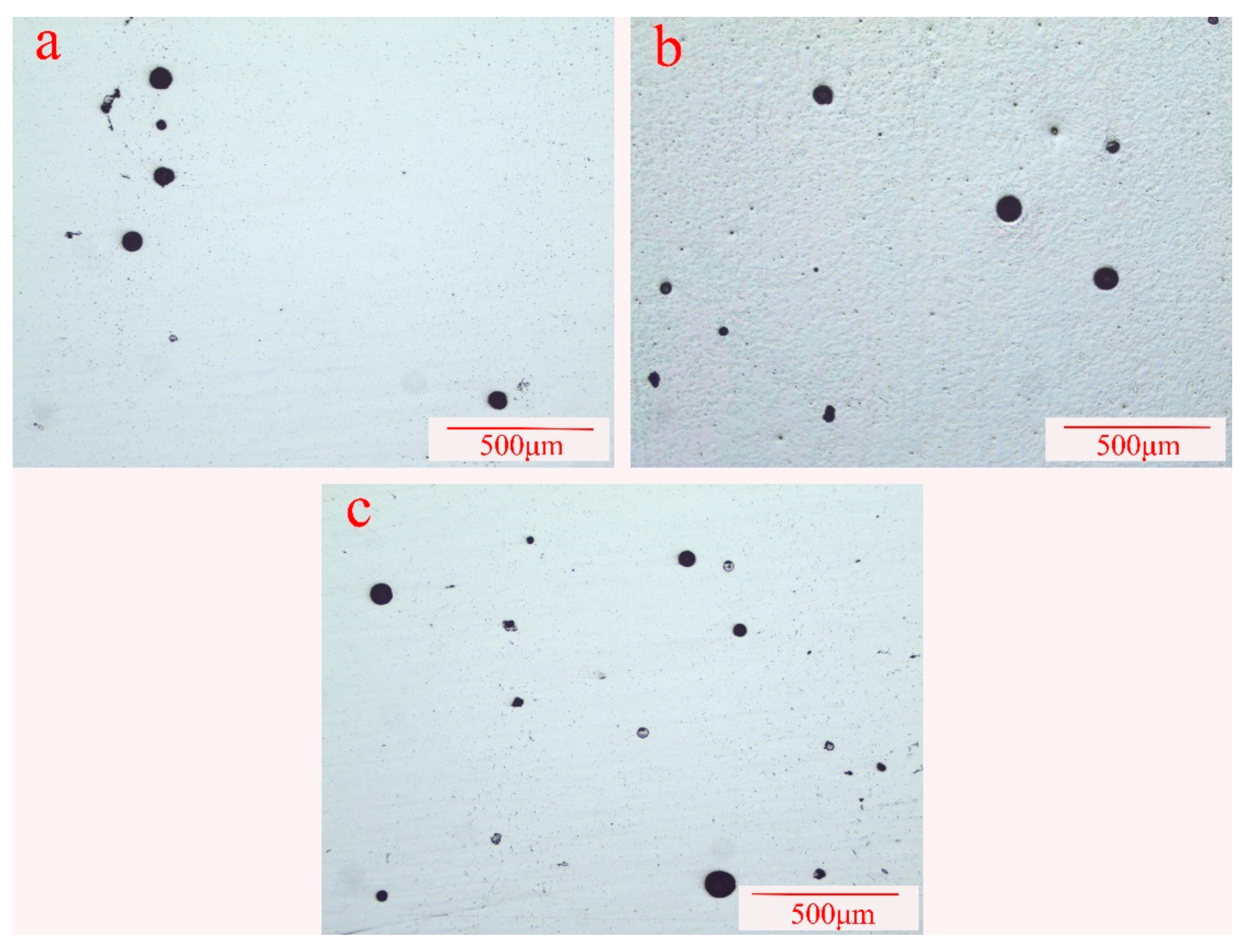

3.2. Porosity Characteristics

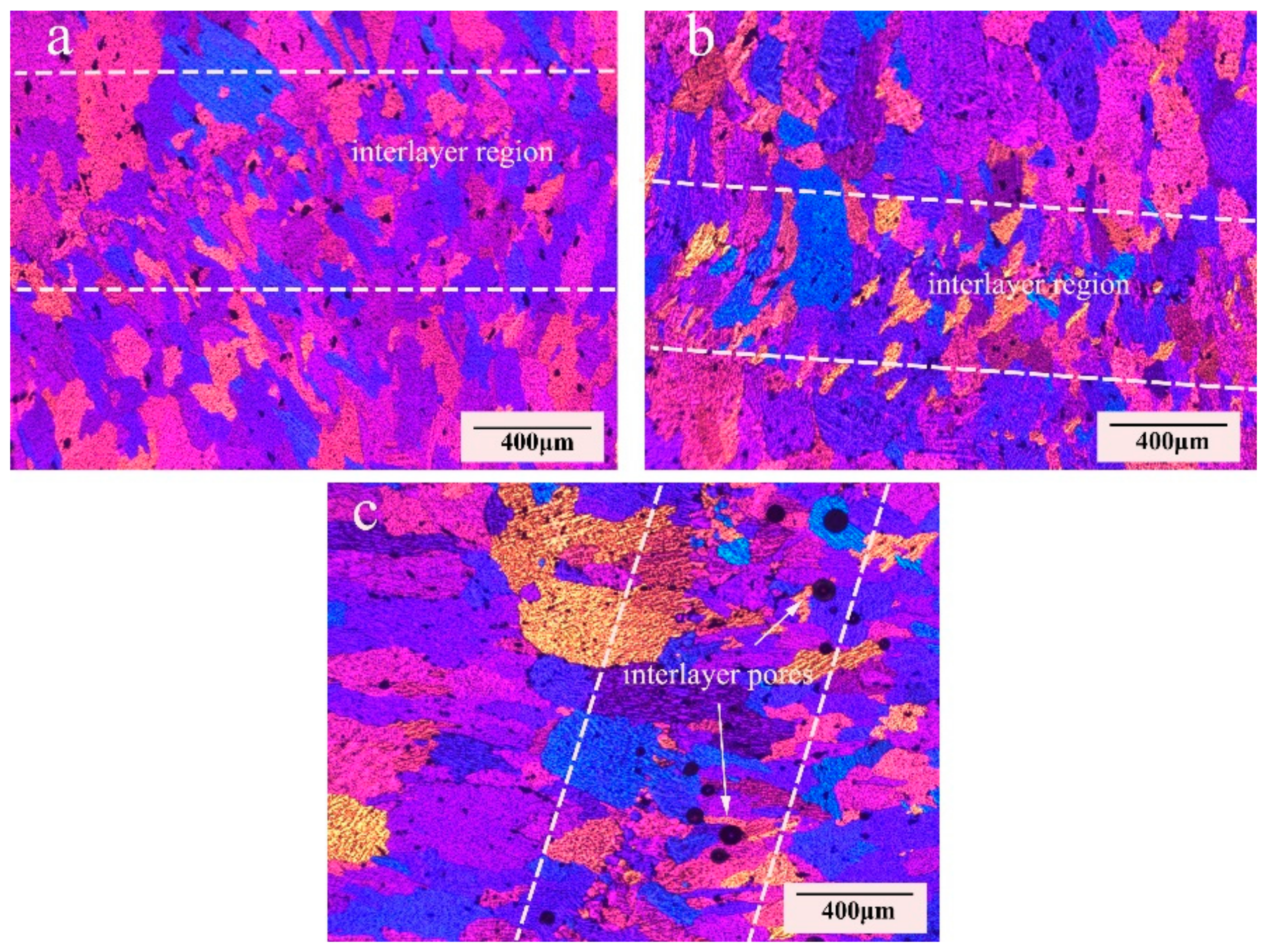

3.3. Microstructure Characteristics

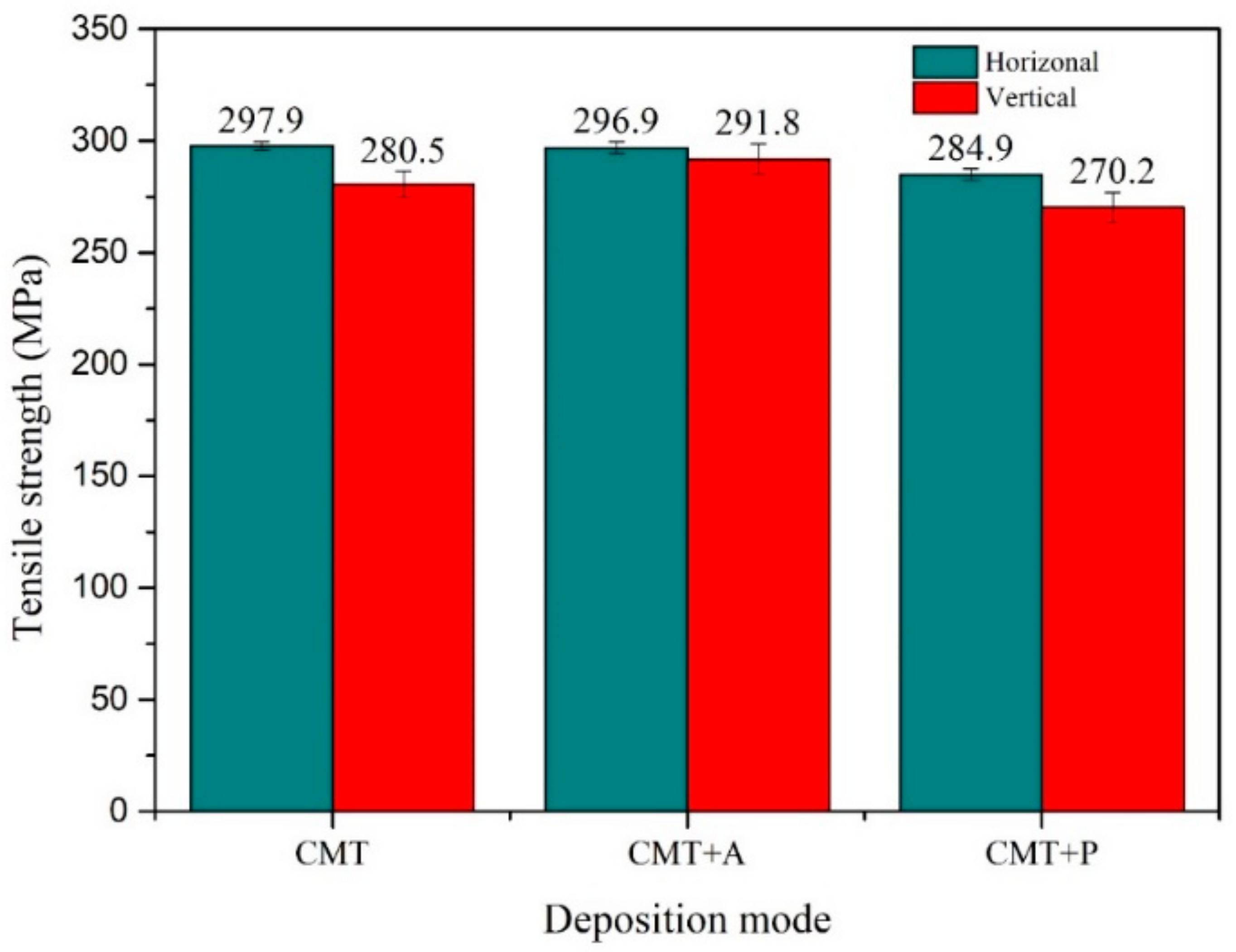

3.4. Mechanical Properties of Different Welding Modes

4. Conclusions

- (1)

- The microstructure of CMT and CMT+A samples consists of interlayer fine grain region and layer column grains zone. The highest heat input of the CMT+P process contributes to production of column grains. Columnar grains of the CMT+P sample at internal layers are larger than that for the CMT+A and CMT samples.

- (2)

- The pore area fraction in the CMT+P sample is the largest and the CMT+A sample is the smallest. Pore formation of the CMT+P process is mainly caused by the large heat input during deposition. The formed large column grain morphology prevents the escaping of pores from the molten pool.

- (3)

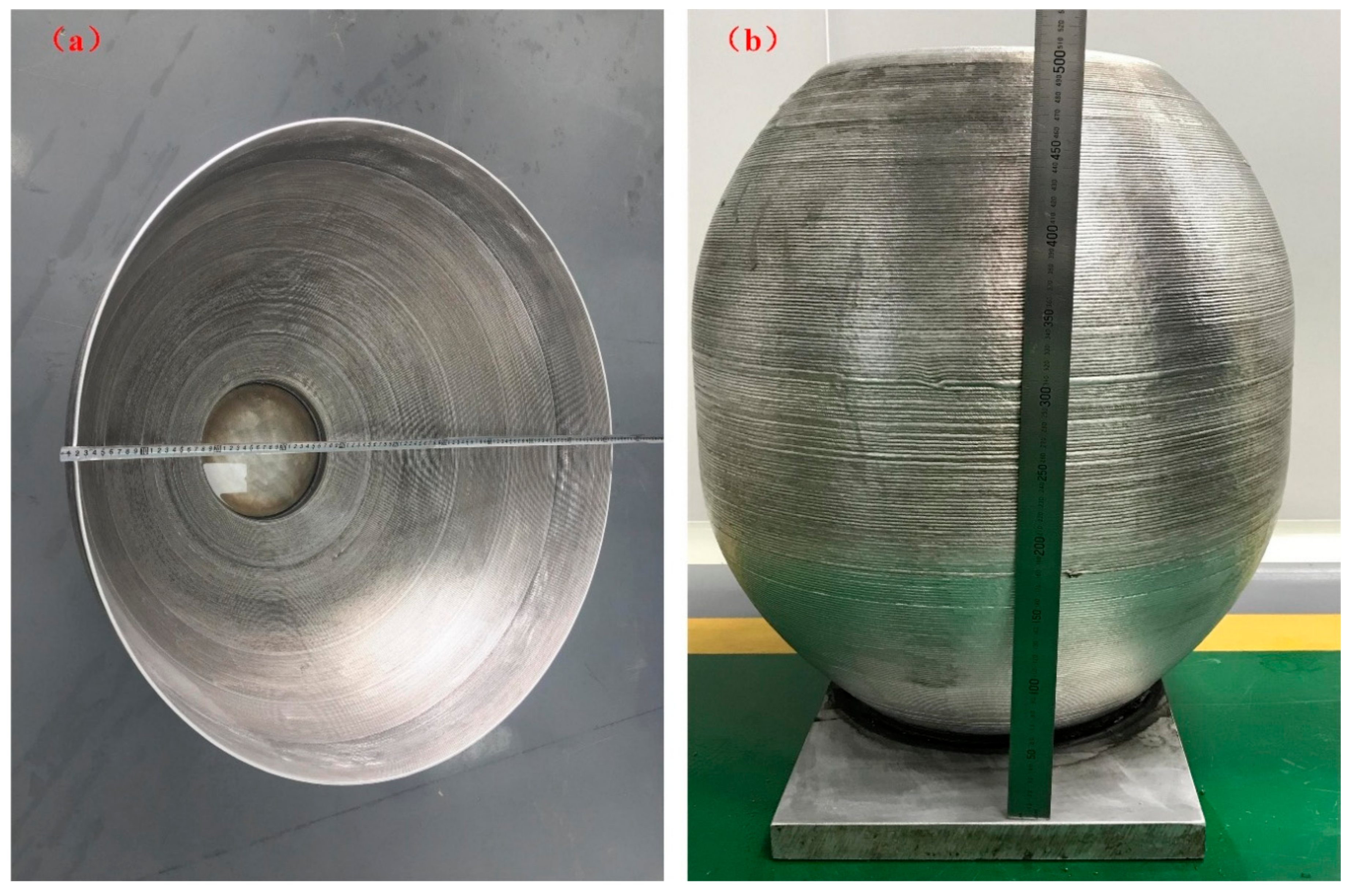

- The best mechanical property greater than 290 MPa is obtained from the CMT+A arc mode compared with CMT and CMT+P arc modes. The tensile strength of the horizontal and vertical direction is more consistent for the CMT+A mode than the other two arc modes. The successfully manufactured large aluminium parts prove that the CMT+A arc mode is suitable for building 5183-Al components.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Coules, H.E.; Fairman, J.; Martina, F.; Kashoob, T.; Mamash, H.; Cozzolino, L.D. Microstructure and residual stress improvement in wire and arc additively manufactured parts through high-pressure rolling. J. Mater. Process. Technol. 2013, 213, 1782–1791. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tool Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shahabi, H.S.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Musin, F.; Lesuer, D.R.; Nieh, T.G. Superplastic behavior of an Al–Mg alloy at elevated temperatures. J. Mater. Sci. Eng. A 2003, 342, 169–177. [Google Scholar] [CrossRef]

- Engler, O.; Miller-Jupp, S. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083. J. Alloys Compd. 2016, 689, 998–1010. [Google Scholar] [CrossRef]

- Martina, F.; Colegrove, P.A.; Williams, S.W.; Meyer, J. Microstructure of interpass rolled wire + arc additive manufacturing Ti-6Al-4V components. Metall. Trans. A 2015, 46, 6103–6118. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Martina, F.; Ding, J.; Wang, X.; Williams, S.W. Fracture toughness and fatigue crack growth rate properties in wire + arc additive manufactured Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2016, 40, 790–803. [Google Scholar] [CrossRef] [Green Version]

- Xiong, X.; Zhang, H.; Wang, G. Metal direct prototyping by using hybrid plasma deposition and milling. J. Mater. Process. Technol. 2009, 209, 124–130. [Google Scholar] [CrossRef]

- Wu, Q.; Lu, J.; Liu, C.; Shi, X.; Ma, Q.; Tang, S.; Ma, S. Obtaining uniform deposition with variable wire feeding direction during wire-feed additive manufacturing. Mater. Manuf. Process. 2017, 32, 1881–1886. [Google Scholar] [CrossRef]

- Pickin, C.G.; Williams, S.W.; Lunt, M. Characterization of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Mater. Process. Technol. 2011, 211, 496–502. [Google Scholar] [CrossRef] [Green Version]

- Gerhard, P.; Ferdinand, K.; Heinz, H.; Harald, C. Manufacturing of Turbine Blades by Shape Giving CMT-Welding. In Proceedings of the Metal Additive Manufacturing Conference, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Pickin, C.G.; Young, K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 583–585. [Google Scholar] [CrossRef]

- Wang, H.; Kovacevic, R. Rapid prototyping based on variable polarity gas tungsten arc welding for a 5356 aluminium alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2001, 215, 1519–1527. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X. Optimization of interpass temperature and heat input for wire and arc additive manufacturing 5A06 Aluminium alloy. Sci. Technol. Weld. Join. 2017, 22, 472–483. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Geometric limitation and tensile properties of wire and arc additive manufacturing 5A06 aluminum alloy parts. J. Mater. Eng. Perform. 2017, 26, 621–629. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, L.; Li, H.; Li, C.; Huang, K.; Lu, B. Microstructure evolution and mechanical behavior of 2219 aluminium alloys additively fabricated by the cold metal transfer process. Materials 2018, 11, 812. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source. Mater. Sci. Eng. A 2018, 711, 415–423. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Ma, P.; Zhai, Y. The effect of inter-layer cold working and post-deposition heat treatment on porosity in additively manufactured aluminum alloys. J. Mater. Process. Technol. 2016, 230, 26–34. [Google Scholar] [CrossRef]

- Pang, J.; Hu, S.; Shen, J.; Wang, P.; Liang, Y. Arc characteristics and metal transfer behavior of CMT + P welding process. J. Mater. Process. Technol. 2016, 238, 212–217. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3% Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Toda, H.; Hidaka, T.; Kobayashi, M.; Uesugi, K.; Takeuchi, A.; Horikawa, K. Growth behavior of hydrogen micropores in aluminium alloys during high-temperature exposure. Acta Mater. 2009, 57, 2277–2290. [Google Scholar] [CrossRef]

- Atwood, R.C.; Lee, P.D. Simulation of the three-dimensional morphology of solidification porosity in an aluminium–silicon alloy. Acta Mater. 2003, 51, 5447–5466. [Google Scholar] [CrossRef]

- Mazur, M. Porosity in aluminium welds. Weld. Int. 1992, 6, 929–931. [Google Scholar] [CrossRef]

- Zhu, C.; Tang, X.; He, Y.; Lu, F.; Cui, H. Characteristics and formation mechanism of sidewall pores in NG-GMAW of 5083 Al-alloy. J. Mater. Process. Technol. 2016, 238, 274–283. [Google Scholar] [CrossRef]

- Ashton, R.F.; Wesley, R.P.; Dixon, C.R. The effect of porosity on 5086-H116 aluminium alloy welds. Weld. J. 1975, 54, 96s–98s. [Google Scholar]

- Chaijaruwanich, A.; Lee, P.D.; Dashwood, R.J.; Youssef, Y.M.; Nagaumi, H. Evolution of pore morphology and distribution during the homogenization of direct chill cast Al–Mg alloys. Acta Mater. 2007, 55, 285–293. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Xie, J.; Sun, S.; Wang, L.; Qian, Y.; Meng, Y.; Wei, Y. Microstructure and mechanical properties of aluminium 5083 weldments by gas tungsten arc and gas metal arc welding. Mater. Sci. Eng. A 2012, 549, 7–13. [Google Scholar] [CrossRef]

- Steurer, W. The Samson phase, β-Mg2Al3, revisited. Z. Krist. 2007, 222, 259–288. [Google Scholar] [CrossRef] [Green Version]

- Flemings, M.C. Solidification processing. Mater. Sci. Technol. 2006. [Google Scholar] [CrossRef]

- Lathabai, S.; Lloyd, P.G. The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al–Mg alloy. Acta Mater. 2002, 50, 4275–4292. [Google Scholar] [CrossRef]

- Liu, Y.L.; Kang, S.B. Solidification and segregation of Al-Mg alloys and influence of alloy composition and cooling rate. Mater. Sci. Technol. 1997, 13, 331–336. [Google Scholar] [CrossRef]

- Benoit, A.; Paillard, P.; Baudin, T.; Klosek, V.; Mottin, J.B. Comparison of four arc welding processes used for aluminium alloy cladding. Sci. Technol. Weld. Join. 2015, 20, 75–81. [Google Scholar] [CrossRef]

- Huskins, E.L.; Cao, B.; Ramesh, K.T. Strengthening mechanisms in an Al–Mg alloy. Mater. Sci. Eng. A 2010, 527, 1292–1298. [Google Scholar] [CrossRef]

- Huang, K.; Zhao, Q.; Li, Y.; Marthinsen, K. Two-stage annealing of a cold-rolled Al–Mn–Fe–Si alloy with different microchemistry states. J. Mater. Process. Technol. 2015, 221, 87–99. [Google Scholar] [CrossRef]

- Huang, K.; Marthinsen, K.; Zhao, Q.; Logé, R.E. The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials. Prog. Mater. Sci. 2017. [Google Scholar] [CrossRef]

- Dutra, J.C.; e Silva, R.H.G.; Savi, B.M.; Marques, C.; Alarcon, O.E. Metallurgical characterization of the 5083H116 aluminium alloy welded with the cold metal transfer process and two different wire-electrodes (5183 and 5087). Weld. World 2015, 59, 797–807. [Google Scholar] [CrossRef]

- Rudy, J.F.; Rupert, E.J. Effects of porosity on mechanical properties of aluminium welds. Weld J. 1970, 49, 322. [Google Scholar]

| Alloys | Chemical Composition (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | Al | |

| 5183-Al | 0.4 | 0.4 | 0.1 | 0.5–1 | 4.3–5.2 | 0.05–0.25 | 0.25 | 0.15 | 0.0003 | Bal. |

| 5083-H112 | 0.4 | 0.4 | 0.1 | 0.4–0.1 | 4.0–4.9 | 0.05–0.25 | 0.25 | 0.15 | -- | |

| Deposition Mode | Pore Numbers | Mean Diameter (μm) | Area Percentage (%) |

|---|---|---|---|

| CMT | 65 | 32.96 | 0.63 ± 0.016 |

| CMT+P | 96 | 30.87 | 0.85 ± 0.015 |

| CMT+A | 54 | 29.42 | 0.36 ± 0.008 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, X.; Zhang, L.; Chen, G.; Dang, X.; Huang, K.; Wang, L.; Lu, B. Correlations between Microstructure Characteristics and Mechanical Properties in 5183 Aluminium Alloy Fabricated by Wire-Arc Additive Manufacturing with Different Arc Modes. Materials 2018, 11, 2075. https://doi.org/10.3390/ma11112075

Fang X, Zhang L, Chen G, Dang X, Huang K, Wang L, Lu B. Correlations between Microstructure Characteristics and Mechanical Properties in 5183 Aluminium Alloy Fabricated by Wire-Arc Additive Manufacturing with Different Arc Modes. Materials. 2018; 11(11):2075. https://doi.org/10.3390/ma11112075

Chicago/Turabian StyleFang, Xuewei, Lijuan Zhang, Guopeng Chen, Xiaofeng Dang, Ke Huang, Lei Wang, and Bingheng Lu. 2018. "Correlations between Microstructure Characteristics and Mechanical Properties in 5183 Aluminium Alloy Fabricated by Wire-Arc Additive Manufacturing with Different Arc Modes" Materials 11, no. 11: 2075. https://doi.org/10.3390/ma11112075

APA StyleFang, X., Zhang, L., Chen, G., Dang, X., Huang, K., Wang, L., & Lu, B. (2018). Correlations between Microstructure Characteristics and Mechanical Properties in 5183 Aluminium Alloy Fabricated by Wire-Arc Additive Manufacturing with Different Arc Modes. Materials, 11(11), 2075. https://doi.org/10.3390/ma11112075