Effects of Initial Water Content on Microstructure and Mechanical Properties of Lean Clay Soil Stabilized by Compound Calcium-Based Stabilizer

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Properties

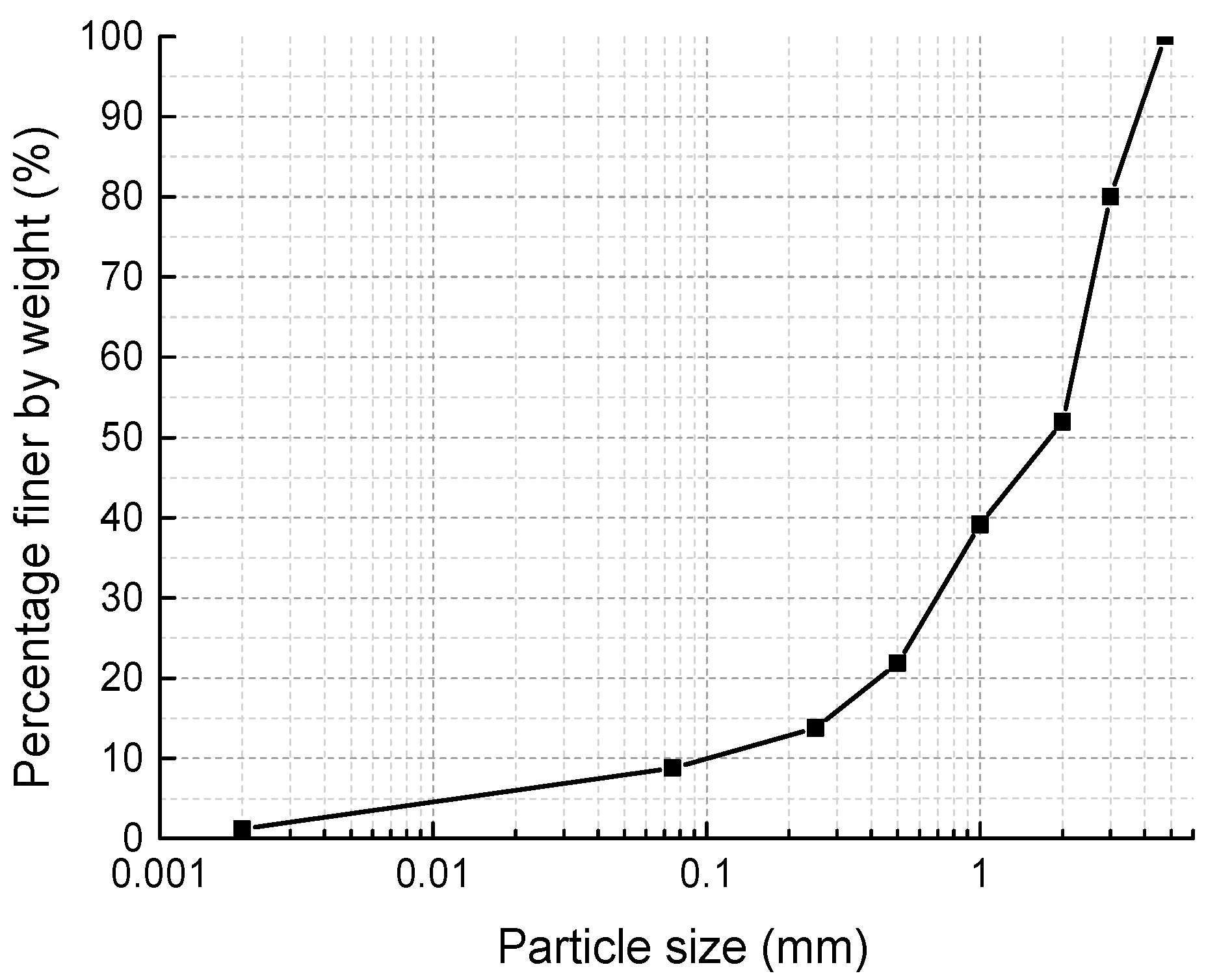

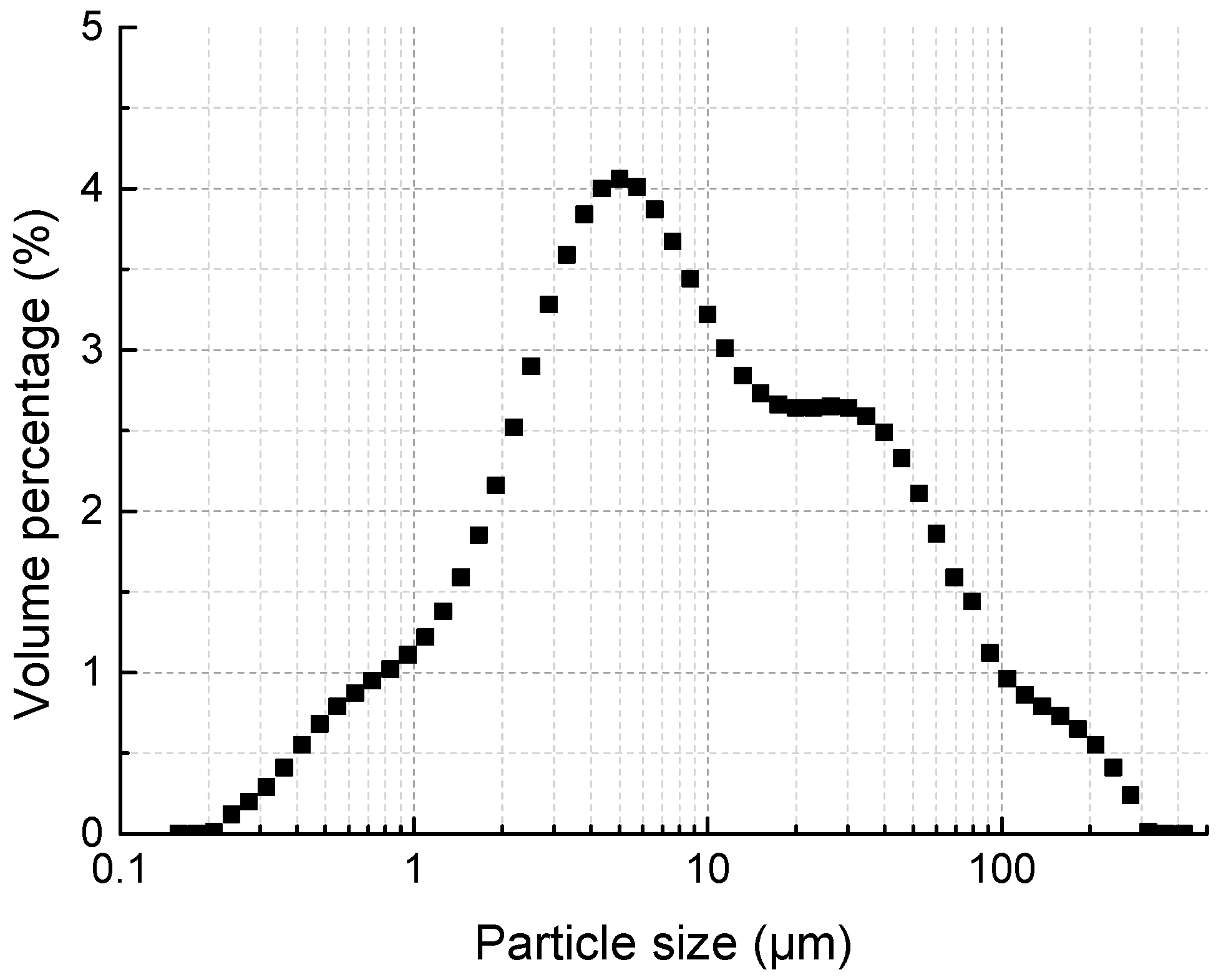

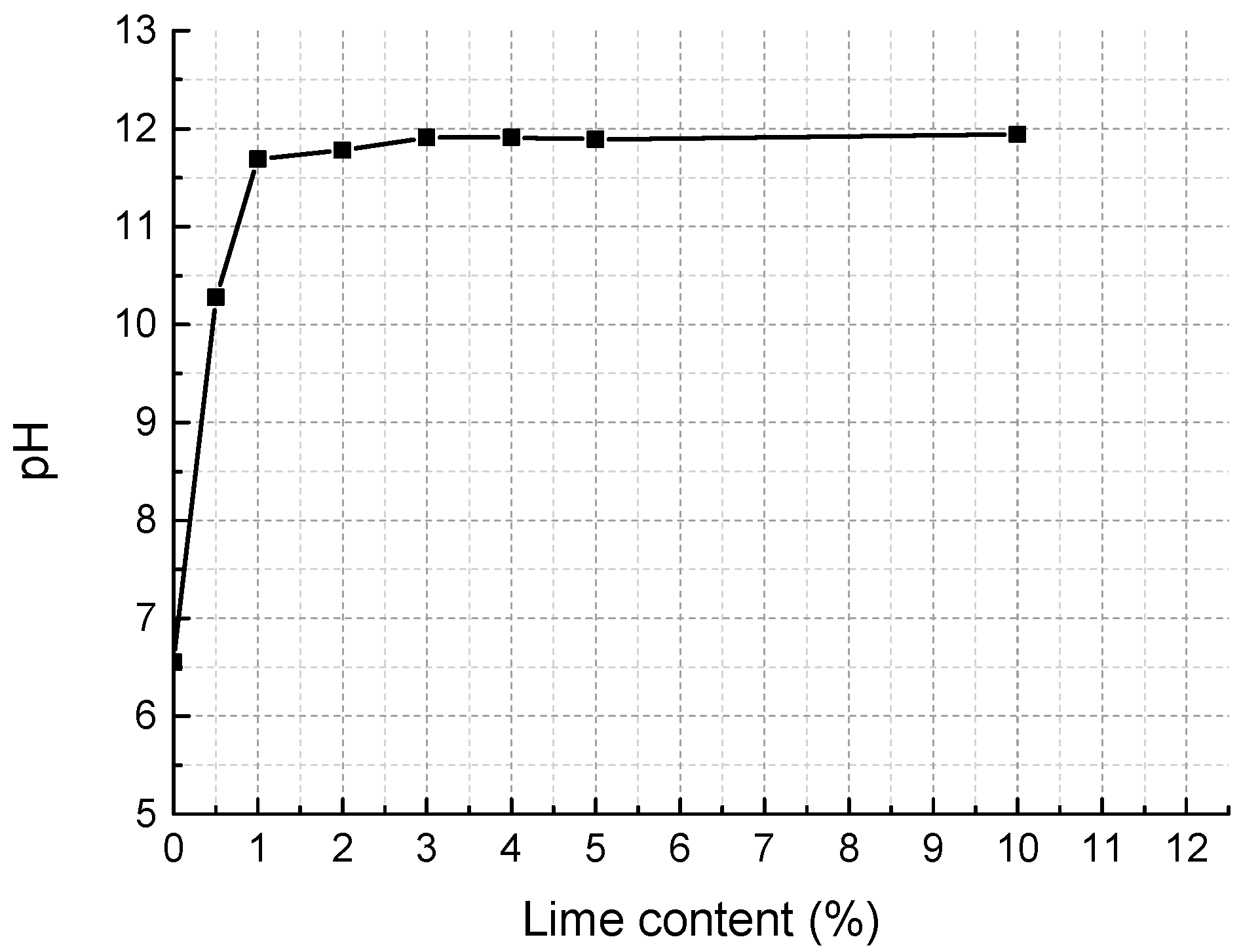

2.1.1. Soil

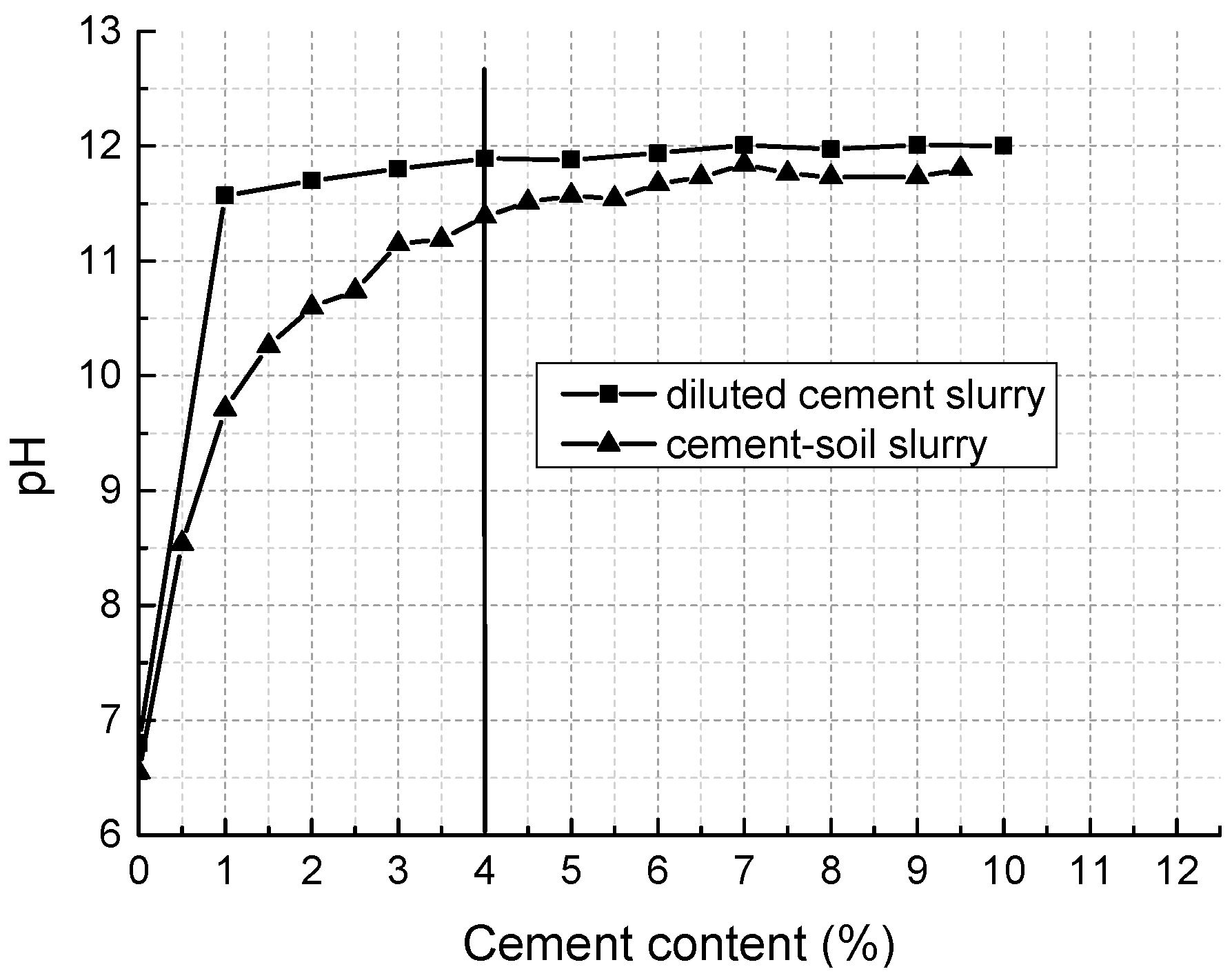

2.1.2. Compound Calcium-Based Stabilizer

2.2. Experimental Program

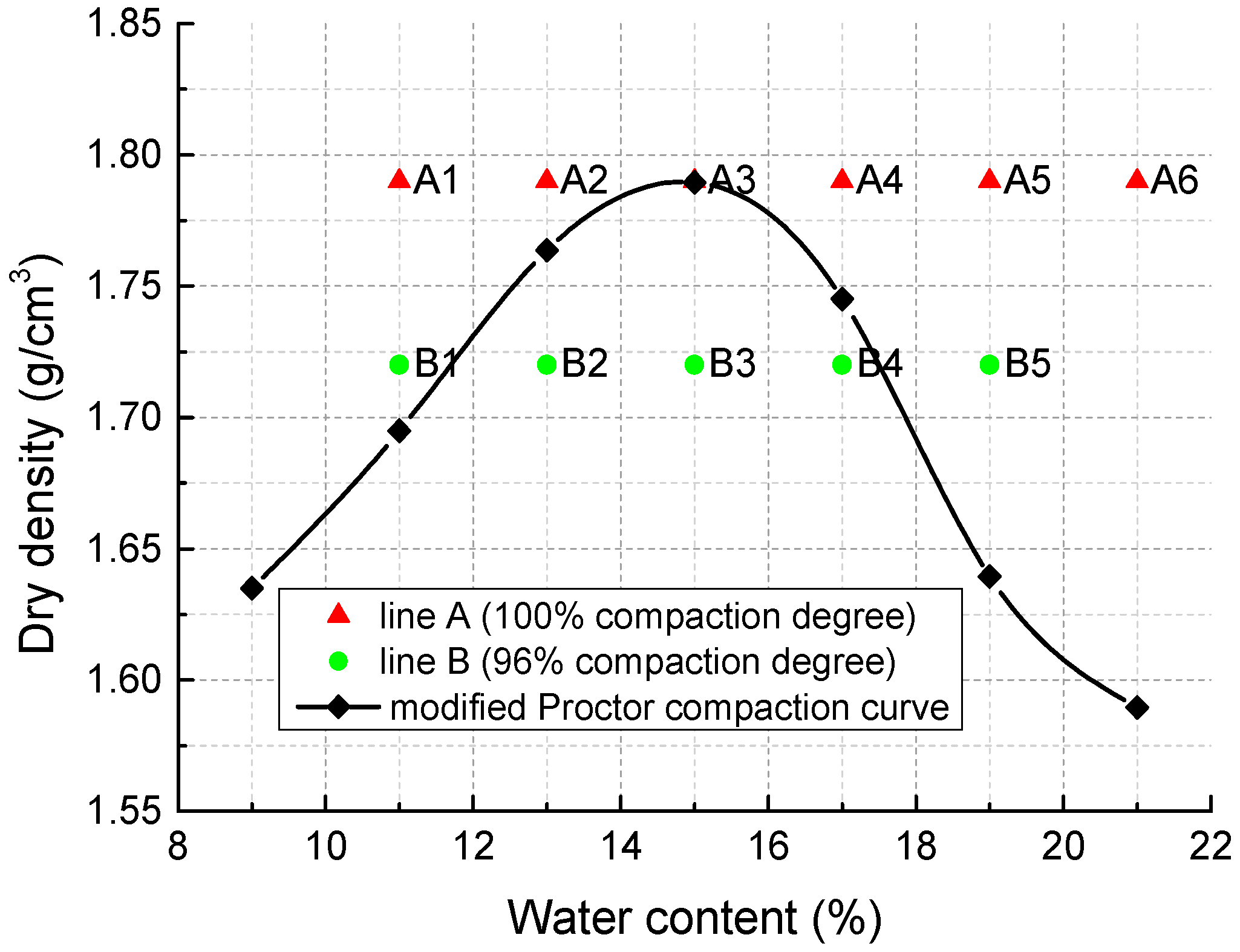

2.2.1. Mixture Design

2.2.2. Molding Points Design

2.2.3. Specimen Molding Procedures

- First, the water contents of the oven-dried soil and the calcium-based stabilizer were measured with the method of T0801-2009 in standard [44].

- Then, the amount of dry soil and stabilizer needed for 6 specimens (controlled by the blender used) was calculated, weighed, and mixed by the blender for about 5 min until the dry mixture was uniformly consistent.

- Next, the calculated volume of water was added and mixed for another 5 min until a homogenous soil-stabilizer mixture formed. After that, the mixture was carefully covered with a sealing film to prevent moisture loss.

- Finally, the quantity of the mixture for one specimen was weighed and put in the mold that had two cylindrical compaction blocks.

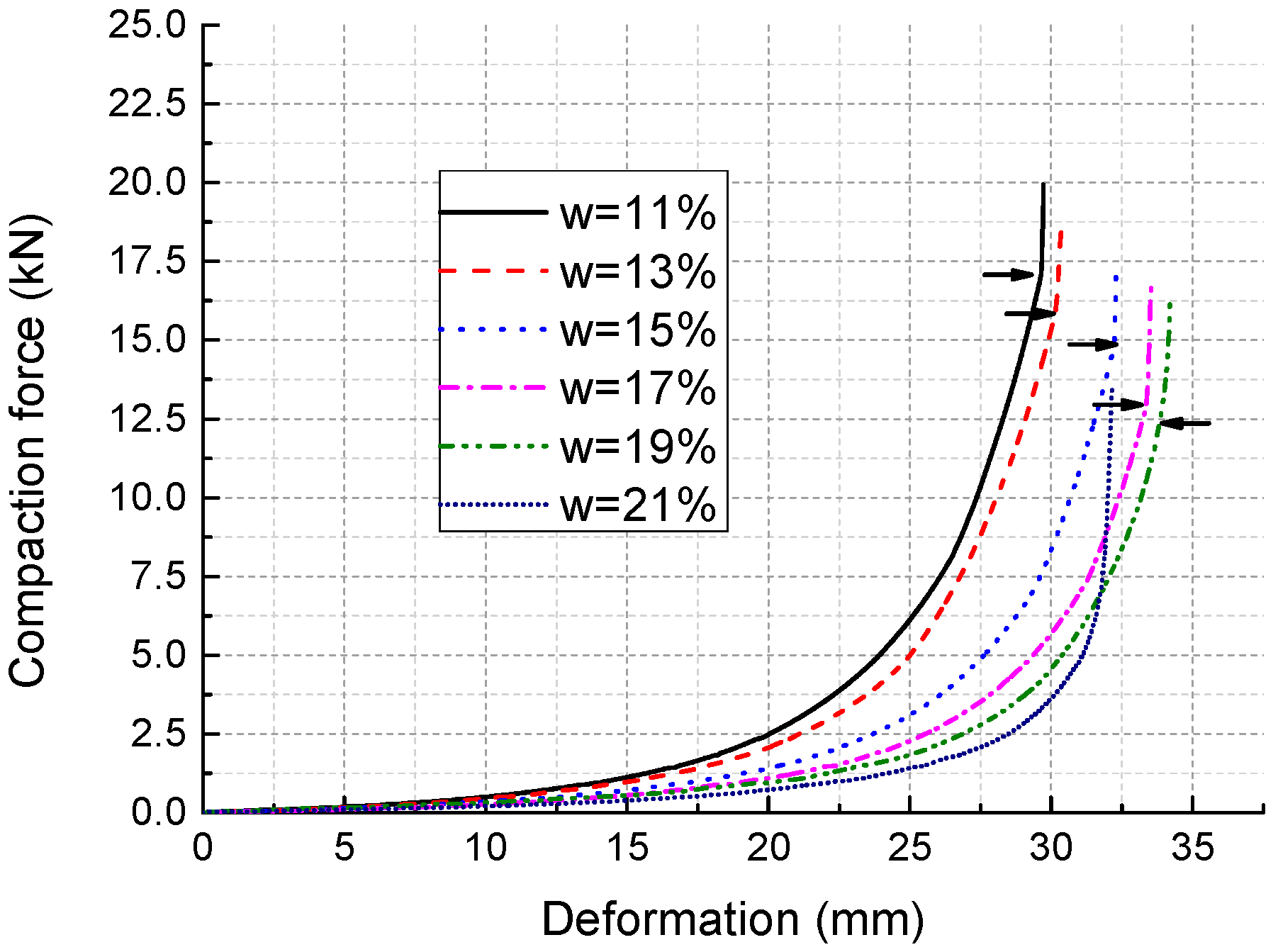

2.2.4. Static Compaction Test

2.2.5. Specimen Curing Process

2.2.6. Unconfined Compression Test

2.3. Microstructure and Composition Research

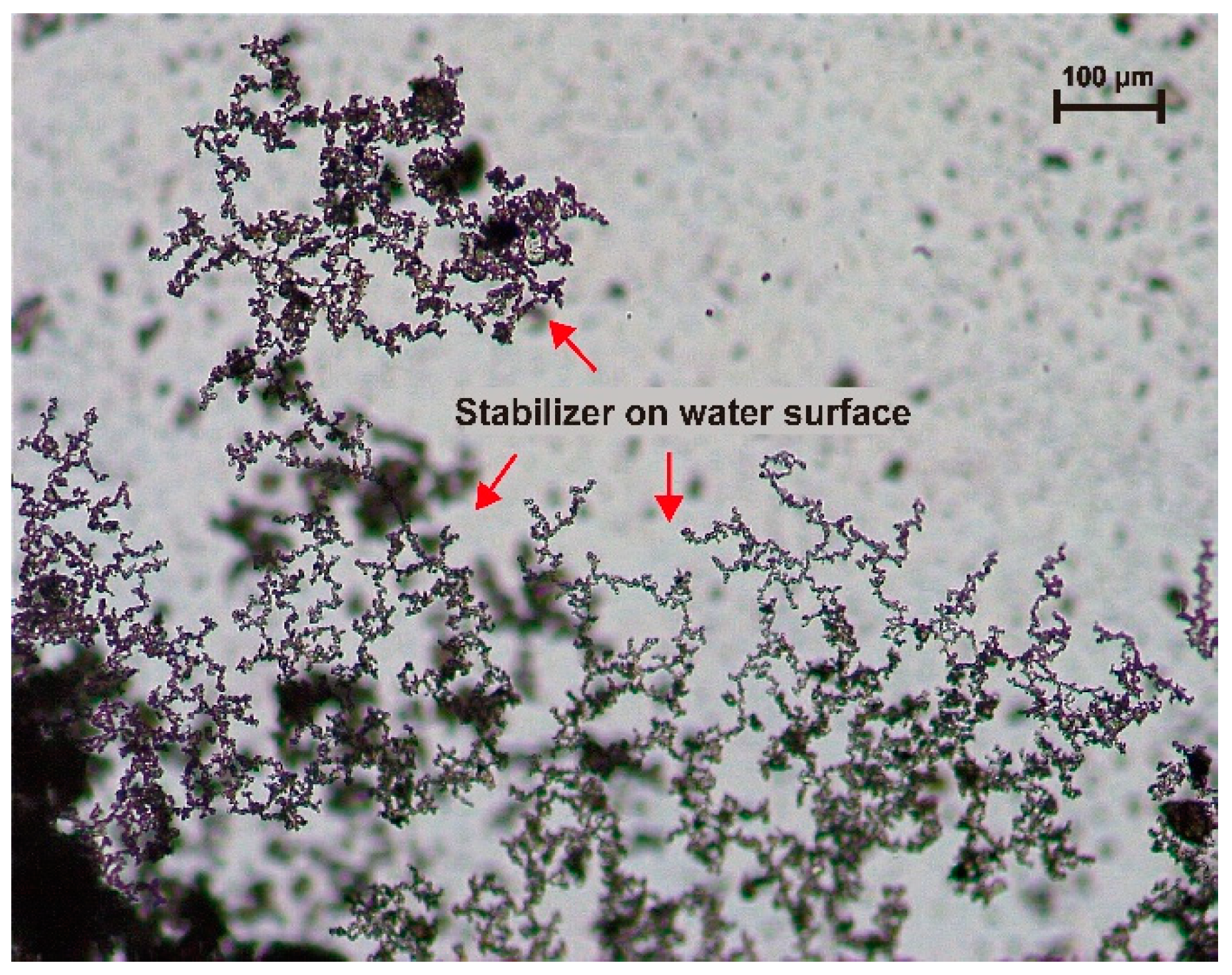

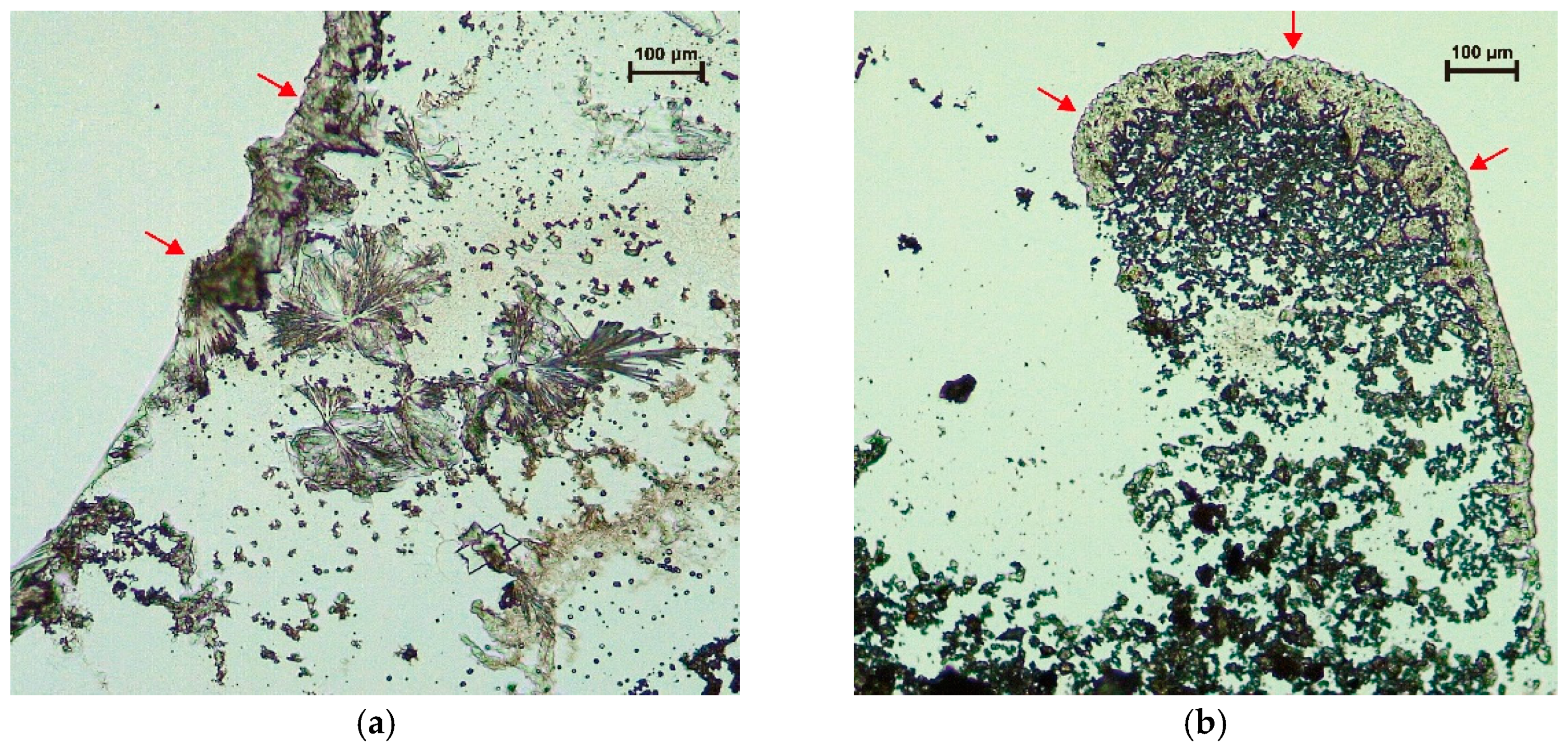

2.3.1. Optical Microscope Observation

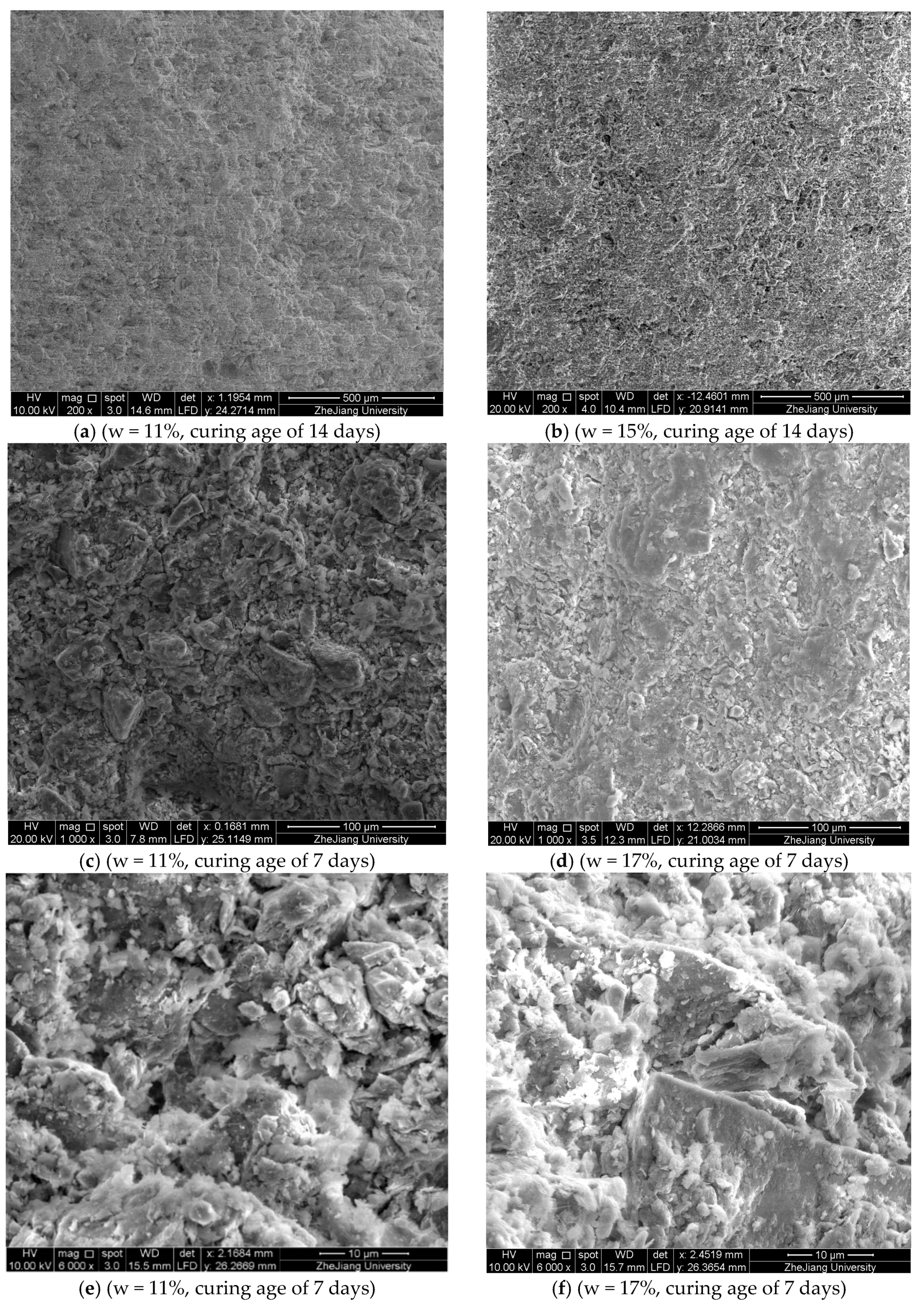

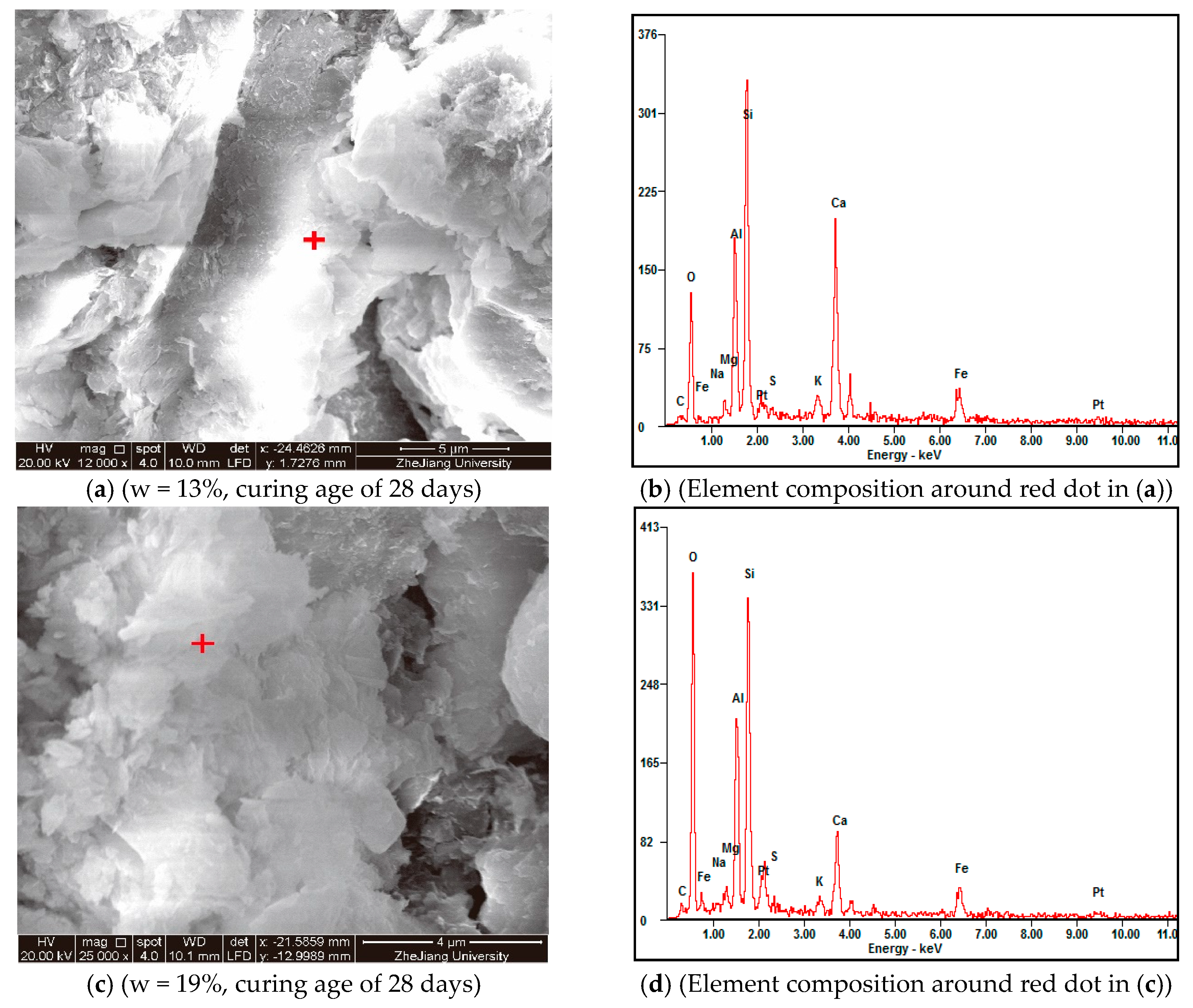

2.3.2. ESEM Scanning and ESEM-EDAX Analysis

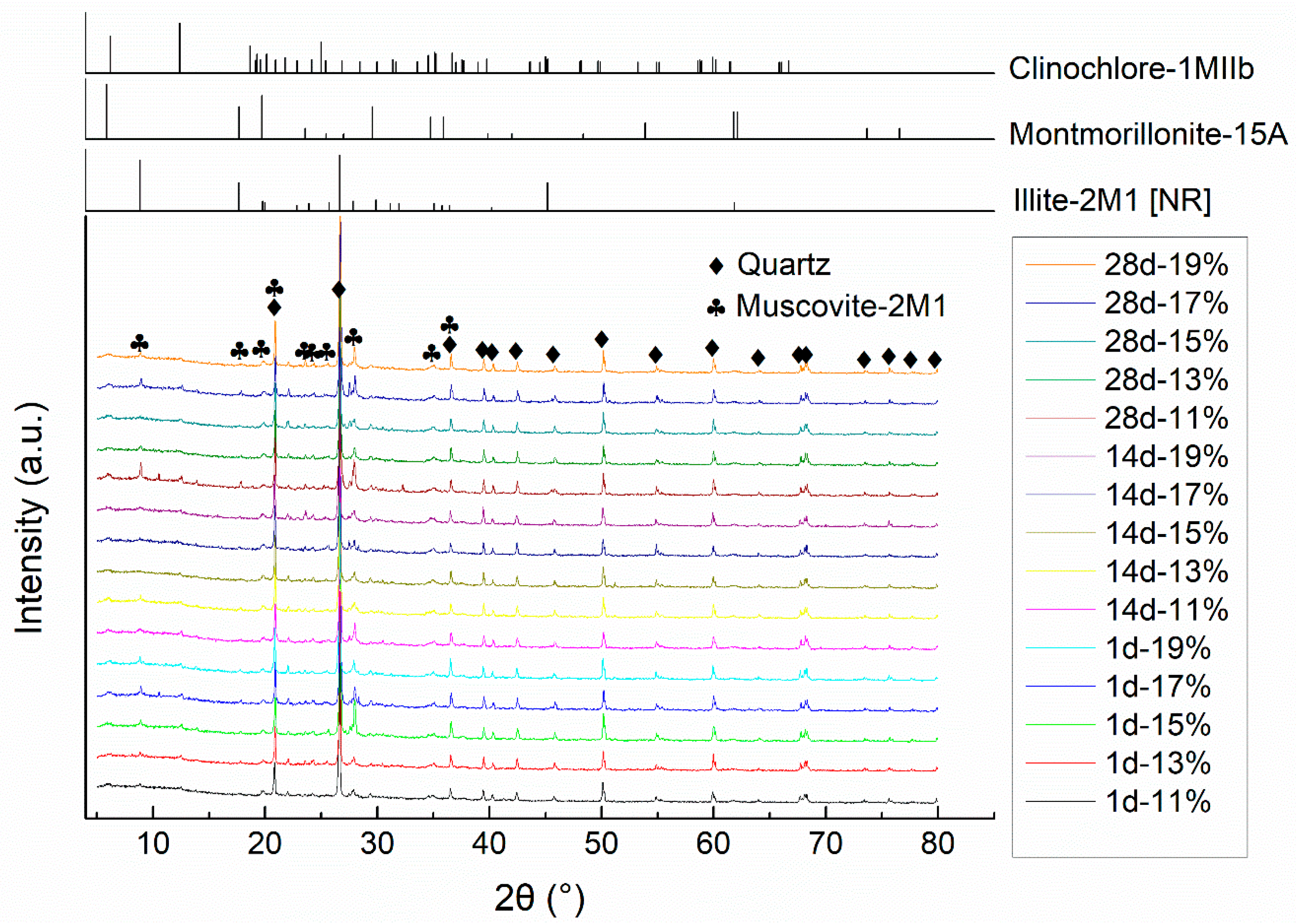

2.3.3. XRD Analysis

3. Results

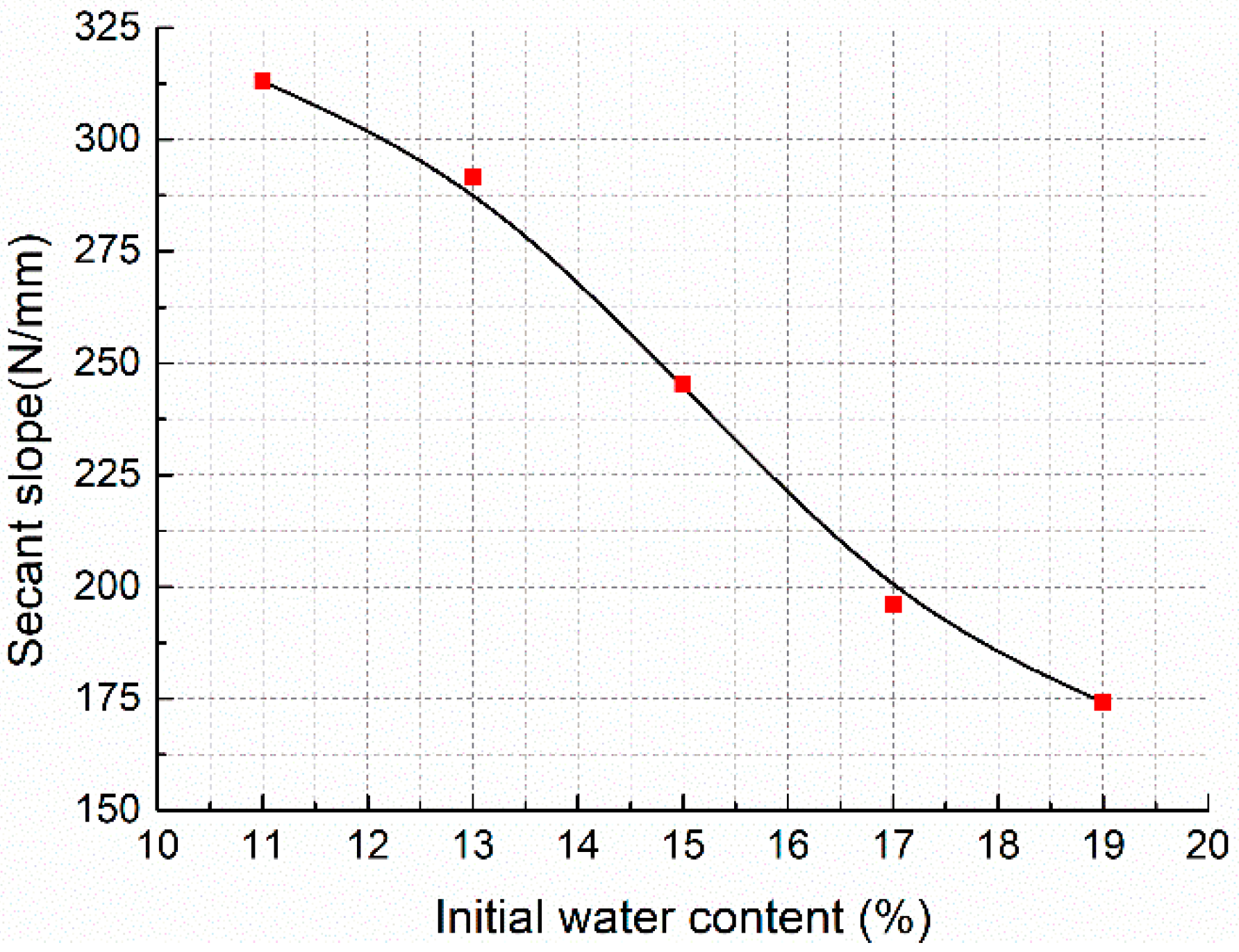

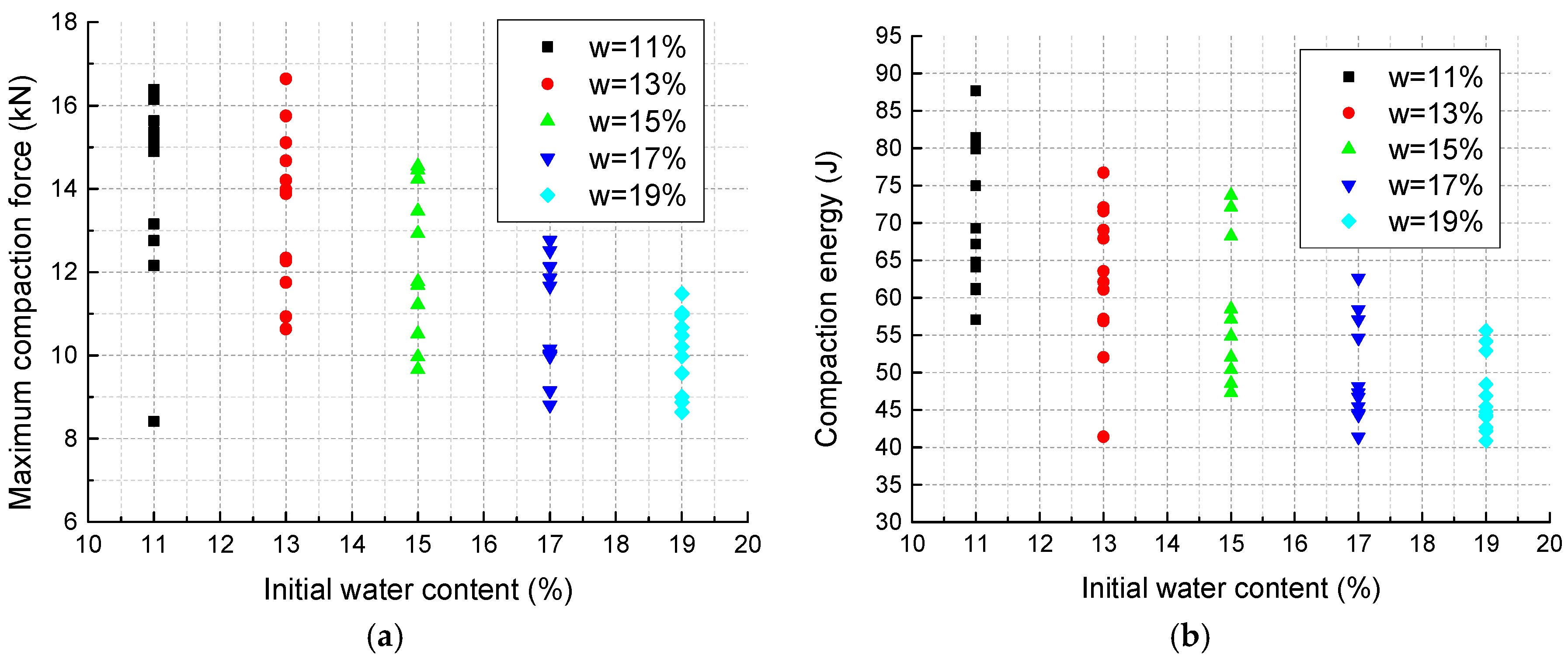

3.1. Static Compaction Test Results

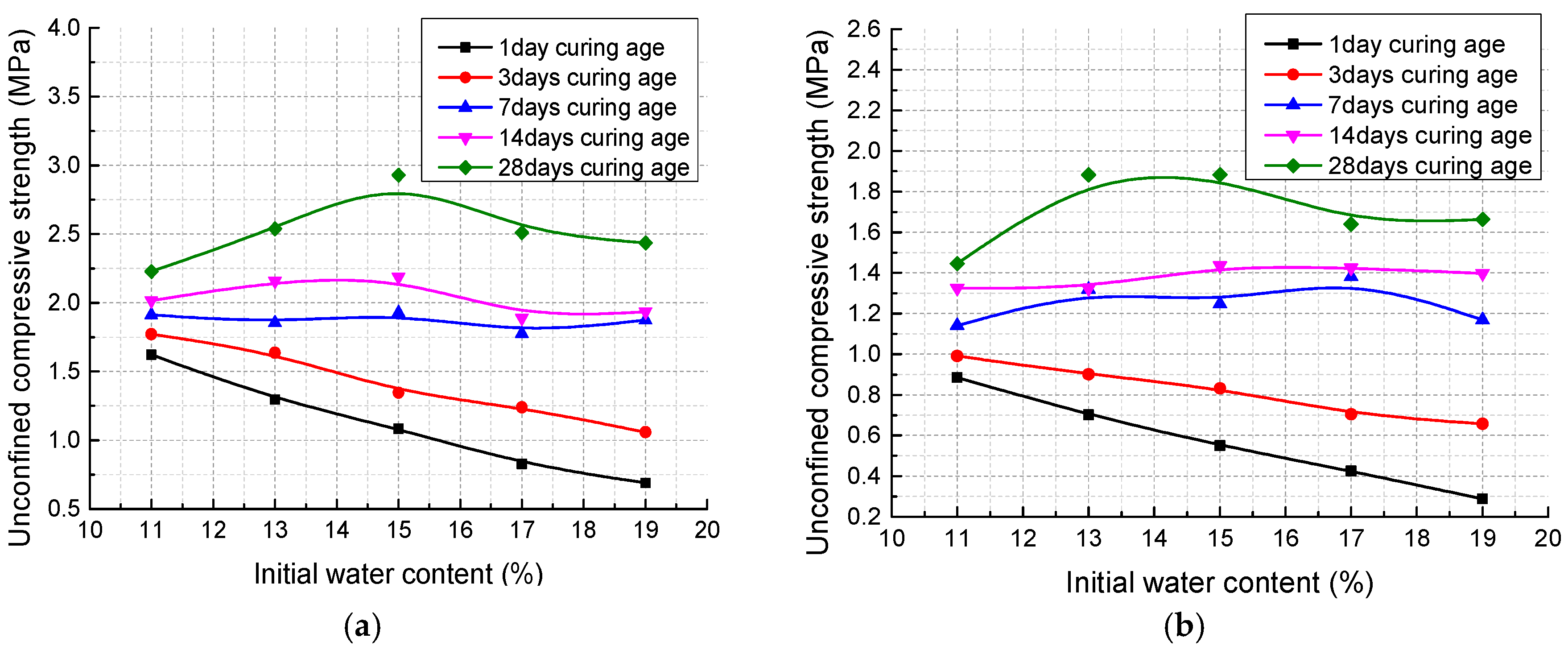

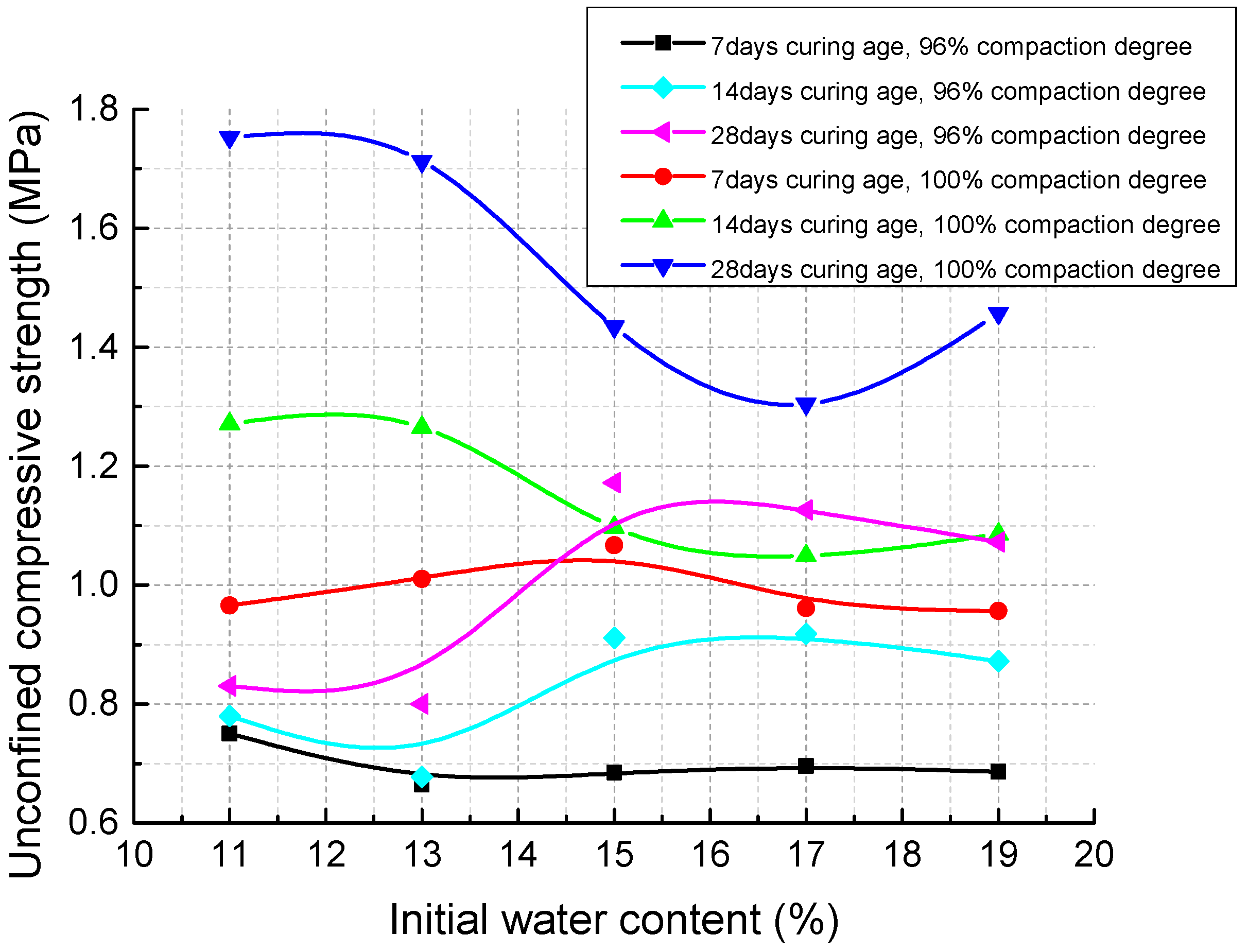

3.2. Unconfined Compression Test Results

- At early curing age (1 day and 3 days) the UCS decreases linearly as IWC increases from 11% to 19%;

- After curing for 7 days and 14 days, the UCS value does not change significantly with the variation of IWC;

- Through a curing time of 28 days, a parabolic relationship between UCS and IWC can be observed: the UCS first increases and then decreases with the increase of IWC, reaching peak value at 15% IWC, which is equal to the optimum water content derived from the modified Proctor compaction test.

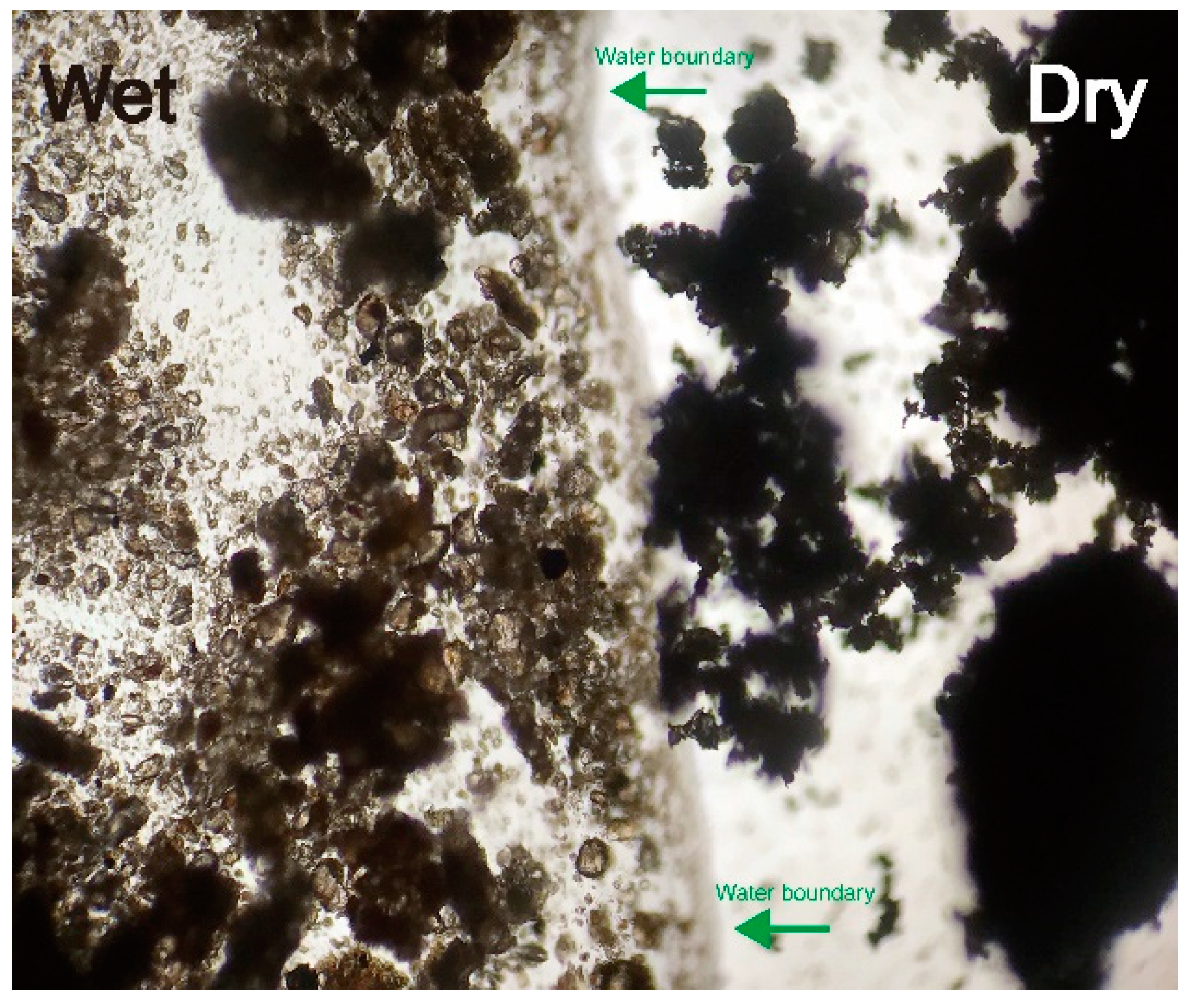

3.3. Optical Microscope Observations

3.4. ESEM Scanning and ESEM-EDAX Analysis

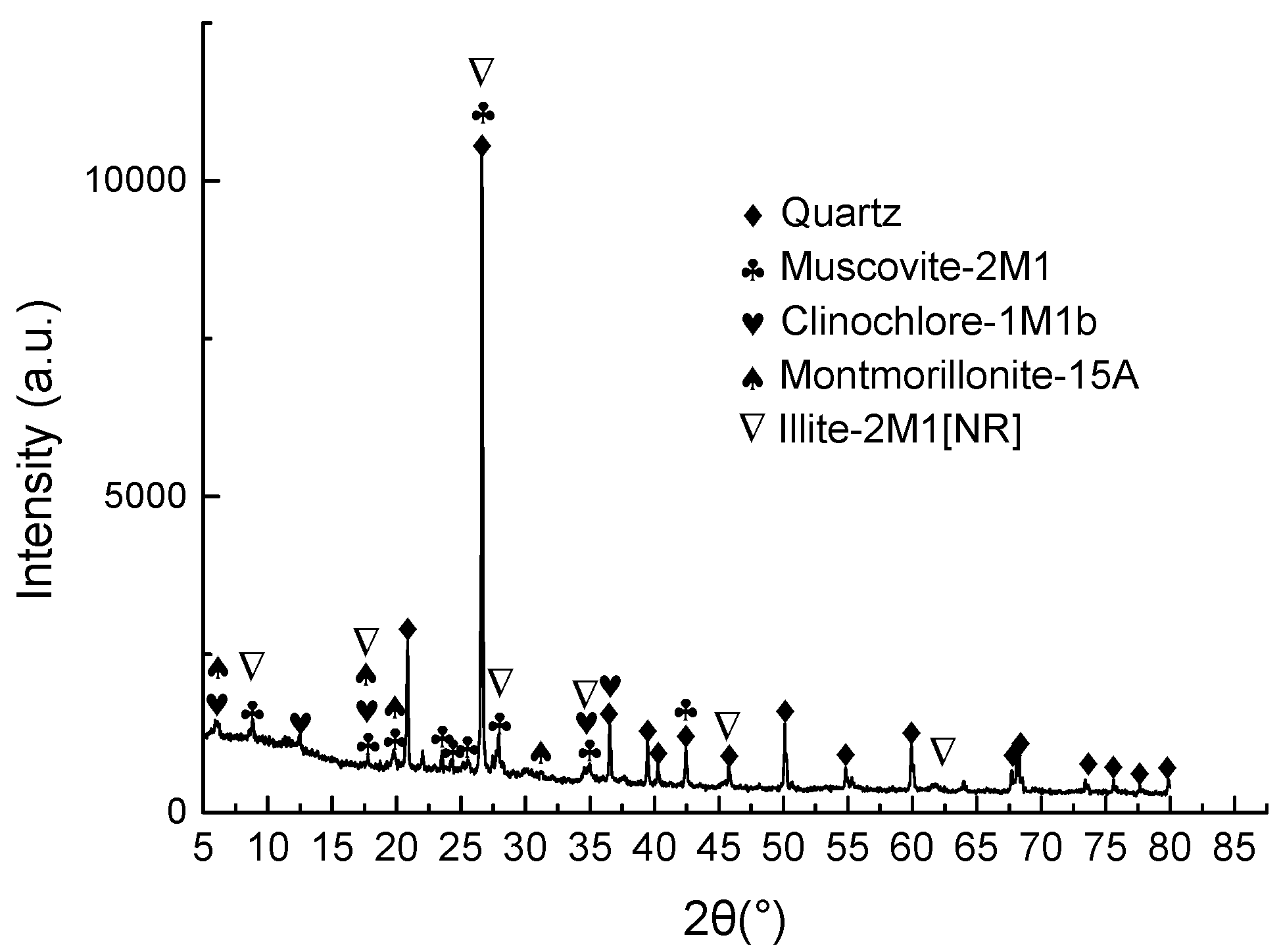

3.5. XRD Results

4. Discussion

4.1. The Effects of Initial Water Content on the Compaction Process

4.2. The Effects of Initial Water Content on Strength Development

5. Conclusions

- In the range of initial water content studied, both the compaction energy and the maximum compaction force decrease linearly with the increase of initial water content, and the largest reduction is 53.4% and 45.9%, respectively.

- As the initial water content increases from 11% to 19%, there are less soil aggregates or agglomerations, and a smaller proportion of large pores in the mixture structure after compaction.

- For specimens cured without external water supply, regardless of the compaction degree, after a curing age of 28 days, the highest unconfined compressive strengths were acquired at initial water content of 15%, which is equal to the optimum water content derived from the modified Proctor compaction test. Higher initial water content enlarges the increase rate of the unconfined compressive strength in the first 7 days; after that, the increase rate first increases then decreases, and acquires maximum at initial water content of 15%.

- For specimens cured in moist air, the optimum initial water contents are 11% under 100% compaction degree, and 15% under 96% compaction degree, respectively.

- As the initial water content increases, the percentage of the oxygen element tends to increase in the reaction products of the calcium-based stabilizer.

- In the curing ages studied, the initial water content did not notably change the primary mineral composition of the soil-stabilizer mixture.

Author Contributions

Funding

Conflicts of Interest

References

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; Wiley: Hoboken, NJ, USA, 2005; pp. 5–7. ISBN 978-0-471-46302-3. [Google Scholar]

- Grim, R.E. Applied Clay Mineralogy, 1st ed.; McGraw-Hill: New York, NY, USA, 1962; p. 39. [Google Scholar]

- Barbour, S.L.; Fredlund, D.G. Mechanisms of osmotic flow and volume change in clay soils. Can. Geotech. J. 1989, 26, 551–562. [Google Scholar] [CrossRef]

- Chang, R.K.; Warkentin, B.P. Volume Change of Compacted Clay Soil Aggregates. Soil Sci. 1968, 105, 106–111. [Google Scholar] [CrossRef]

- Escolano, F.; Sánchez, J.; Pacheco-Torres, R.; Cerro-Prada, E. Strategies on Reuse of Clayey Expansive Soils as Embankment Material in Urban Development Areas: A Case Study in New Urbanized Zones. Appl. Sci. 2018, 8. [Google Scholar] [CrossRef]

- Lytton, R.L. Prediction of movement in expansive clays. Geotech. Spec. Pub. 1994, 2, 1827–1845. [Google Scholar]

- Petry, T.M.; Little, D.N. Review of Stabilization of Clays and Expansive Soils in Pavements and Lightly Loaded Structures—History, Practice, and Future. J. Mater. Civ. Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Glenn, G.R.; Handy, R.L. Lime-clay mineral reaction products. Highw. Res. Rec. 1963, 29, 70–82. [Google Scholar]

- Hilt, G.H.; Davidson, D.T. Lime fixation in clayey soils. Highw. Res. Board Bull. 1960, 262, 1–19. [Google Scholar]

- Mitchell, J.K.; Hooper, D.R. Influence of time between mixing and compaction on properties of lime stabilized expansive clay. Highw. Res. Board Bull. 1961, 231, 60–66. [Google Scholar]

- Bateman, J.; Hutchison, R.; Dijkstra, T.; Beetham, P.; Dixon, N.; Fleming, P. Lime stabilisation for earthworks: A UK perspective. Proc. Inst. Civ. Eng. Ground Improv. 2015, 168, 1–15. [Google Scholar]

- Bulletin, H.B. Cement-soil stabilization. Highw. Res. Board Bull. 1958, 198, 55–64. [Google Scholar]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Mills, W.H.; Levison, A.A. Cement-Soil Stabilization. Highw. Res. Board Proc. 1938, 17, 513–520. [Google Scholar]

- Zhang, T.; Yue, X.; Deng, Y.; Zhang, D.; Liu, S. Mechanical behaviour and micro-structure of cement-stabilised marine clay with a metakaolin agent. Constr. Build. Mater. 2014, 73, 51–57. [Google Scholar] [CrossRef]

- Holman, F.L. Lime and Lime-Fly Ash Soil Stabilization. Benkelman Beam 1900, 193, 47–48. [Google Scholar]

- Thornton, S.I.; Parker, D.G.; White, D.N. Soil Stabilization Using A Western Coal High Calcium Fly Ash. In Proceedings of the 4th International Ash Utilization Symposium, St. Louis, MO, USA, 24–25 March 1976. [Google Scholar]

- Goodarzi, A.R.; Salimi, M. Stabilization treatment of a dispersive clayey soil using granulated blast furnace slag and basic oxygen furnace slag. Appl. Clay Sci. 2015, 108, 61–69. [Google Scholar] [CrossRef]

- Higgins, D.D.; Kinuthia, J.M.; Wild, S. Soil Stabilization Using Lime-Activated Ground Granulated Blast Furnace Slag. In Proceedings of the CANMET/ACI international Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, Bangkok, Thailand, 5 June 1998; pp. 1057–1074. [Google Scholar]

- Wild, S.; Kinuthia, J.M.; Robinson, R.B.; Humphreys, I. Effects of Ground Granulated Blast Furnace Slag (GGBS) on the Strength and Swelling Properties of Lime-Stabilized Kaolinite in the Presence of Sulphates. Clay Miner. 1996, 31, 423–433. [Google Scholar] [CrossRef]

- Miller, G.A.; Azad, S. Influence of soil type on stabilization with cement kiln dust. Constr. Build. Mater. 2000, 14, 89–97. [Google Scholar] [CrossRef]

- Bandara, N.; Grazioli, M.J. Cement Kiln Dust Stabilized Test Section on I-96/I-75 in Wayne County—Construction Report; Michigan Department of Transportation: Lansing, MI, USA, 2009.

- Choobbasti, A.J.; Ghodrat, H.; Vahdatirad, M.J.; Firouzian, S.; Barari, A.; Torabi, M.; Bagherian, A. Influence of using rice husk ash in soil stabilization method with lime. Front. Earth Sci. China 2010, 4, 471–480. [Google Scholar] [CrossRef]

- Qasim, M.; Bashir, A.; Tanvir, M.; Anees, M.M. Effect of Rice Husk Ash on Soil Stabilization. Bull. Energy Econ. 2015, 3, 10–17. [Google Scholar]

- Ferruzzi, G.G.; Pan, N.; Casey, W.H. Mechanical properties of gellan and polyacrylamide gels with implications for soil stabilization. Soil Sci. 2000, 165, 778–792. [Google Scholar] [CrossRef]

- Orts, W.J.; Roa-Espinosa, A.; Sojka, R.E.; Glenn, G.M.; Imam, S.H.; Kurt, E.; Skov, J. Use of Synthetic Polymers and Biopolymers for Soil Stabilization in Agricultural, Construction, and Military Applications. J. Mater. Civ. Eng. 2007, 19, 58–66. [Google Scholar] [CrossRef]

- Ceylan, H.; Gopalakrishnan, K.; Kim, S.H. Soil stabilization with bioenergy coproduct. J. Transp. Res. Board 2010, 2186, 130–137. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S.; Puppala, A.J. Stabilization of Silt Using a Lignin-Based Bioenergy Coproduct. In Proceedings of the Transportation Research Board 93rd Annual Meeting, Washington, DC, USA, 12–16 January 2014. [Google Scholar]

- Puppala, A.J. Advances in Ground Modification with Chemical Additives: From Theory to Practice. Transp. Geotech. 2016, 9, 123–138. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Kumar, P.P. Cement stabilised rammed earth. Part A: Compaction: Compaction characteristics and physical properties of compacted cement stabilised soils. Mater. Struct. 2011, 44, 681–693. [Google Scholar] [CrossRef]

- Terashi, M. Deep Mixing Method—Brief State of the art. In Proceedings of the Fourteenth International Conference on Soil Mechanics and Foundation Engineering, Hamburg, Germany, 6–12 September 1997. [Google Scholar]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Richardson, I.G. The nature of the hydration products in hardened cement pastes. Cem. Concr. Compos. 2000, 22, 97–113. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J.M. Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Thom, R.; Sivakumar, R.; Sivakumar, V.; Murray, E.J.; Mackinnon, P. Pore size distribution of unsaturated compacted kaolin: The initial states and final states following saturation. Géotechnique 2007, 57, 469–474. [Google Scholar] [CrossRef]

- Chapman, D.L. LI. A contribution to the theory of electrocapillarity. Philos. Mag. 1913, 25, 475–481. [Google Scholar] [CrossRef]

- Gouy, G. Sur la constitution de la charge electrique a la surface d’ un electrolyte. J. Phys. Théor. Appl. 1910, 9, 457–468. [Google Scholar] [CrossRef]

- Ramesh, H.N.G.; Sivapullaiah, P.V. Role of moulding water content in lime stabilisation of soil. Proc. Inst. Civ. Eng. Ground Improv. 2011, 164, 15–19. [Google Scholar] [CrossRef]

- Guo, A.G.; Kong, L.W.; Ming-Jian, H.U.; Gang, G.; Wang, Q. On determination of optimum water content of lime-treated expansive soil. Rock Soil Mech. 2007, 28, 517–521. [Google Scholar]

- Consoli, N.C.; Lopes, L.D.S.; Heineck, K.S. Key Parameters for the Strength Control of Lime Stabilized Soils. J. Mater. Civ. Eng. 2009, 21, 210–216. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Arora, S.; Aydilek, A.H. Class F Fly-Ash-Amended Soils as Highway Base Materials. J. Mater. Civ. Eng. 2005, 17, 640–649. [Google Scholar] [CrossRef]

- ASTM International. Standard Guide for Direct Push Soil Sampling for Environmental Site Characterizations; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar] [CrossRef]

- The Standardization Administration of the People’s Republic of China. Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering (JTG E51-2009); China Communications Press: Beijing, China, 2009. [Google Scholar]

- ASTM International. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- Croft, J.B. The Influence of Soil Mineralogical Composition on Cement Stabilization. Géotechnique 1967, 17, 119–135. [Google Scholar] [CrossRef]

- Cherian, C.; Arnepalli, D.N. A Critical Appraisal of the Role of Clay Mineralogy in Lime Stabilization. Int. J. Geosynth. Ground Eng. 2015, 1, 8. [Google Scholar] [CrossRef]

- Eades, J.; Grim, R.E. A Quick Test to Determine Lime Requirements for Lime Stabilization; Highway Research Board: Washington, DC, USA, 1966; Issue 139. [Google Scholar]

- ASTM International. Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Shainberg, I.; Kemper, W.D. In electrostatic forces between clay and cations as calculated and inferred from electrical conductivity. In Clays & Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CA, USA, 1 January 1966; Bailey, S.W., Ed.; Pergamon Press Ltd.: Oxford, UK, 1996; pp. 117–132. [Google Scholar]

- Defay, R.; Prigogine, I.; Sanfeld, A. Surface thermodynamics. J. Colloid Interface Sci. 1977, 58, 498–510. [Google Scholar] [CrossRef]

- Mutaftschiev, B. Surface Thermodynamics; Springer: Amsterdam, The Netherlands, 1982. [Google Scholar]

- Neumann, A.W.; David, R.; Zuo, Y. Applied surface thermodynamics. Focus Surf. 2011, 2011, 6. [Google Scholar]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physicochemical, microstructural and mechanical characteristics of a plastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Christopher, B.; Daniela, C. Effect of compaction water content on the strength of cement-stabilize. Can. Geotech. J. 2014, 51, 583–590. [Google Scholar]

- Musso, G.; Romero, E.; Vecchia, G.D. Double-structure effects on the chemo-hydro-mechanical behaviour of a compacted active clay. Géotechnique 2013, 63, 206–220. [Google Scholar] [CrossRef]

- Romero, E.; Vecchia, G.D.; Jommi, C. An insight into the water retention properties of compacted clayey soils. Géotechnique 2011, 61, 313–328. [Google Scholar] [CrossRef]

- Casini, F. Consequences on water retention properties of double-porosity features in a compacted silt. Acta Geotech. 2012, 7, 139–150. [Google Scholar] [CrossRef]

- Delage, P.; Lefebvre, G. Study of the structure of a sensitive Champlain clay and of its evolution during consolidation. Can. Geotech. J 1984, 21, 21–35. [Google Scholar] [CrossRef]

- Lapierre, C.; Leroueil, S.; Locat, J. Mercury intrusion and permeability of Louiseville clay. Can. Geotech. J 1990, 27, 761–773. [Google Scholar] [CrossRef]

| Natural Dry Density (g/cm3) | Dried Moisture Content (%) | Specific Gravity | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) | Activity of Clay | pH |

|---|---|---|---|---|---|---|---|

| 1.64 | 2.94 | 2.69 | 37.8 | 19.3 | 18.5 | 2.02 | 6.55 |

| Materials | Chemical Compositions (Mass Fraction, %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | K2O | MgO | TiO2 | SO3 | |

| Portland cement | 18.04 | 8.79 | 4.96 | 54.14 | 0.12 | 0.32 | 3.56 | - | 1.77 |

| Lime | - | - | - | 86.26 | - | - | 0.68 | - | - |

| Fly ash | 11.61 | 21.73 | 1.75 | 40.28 | 0.95 | 1.36 | 0.49 | 1.66 | 0.61 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, C.; Zhang, W.; Jiang, X.; Huang, Z. Effects of Initial Water Content on Microstructure and Mechanical Properties of Lean Clay Soil Stabilized by Compound Calcium-Based Stabilizer. Materials 2018, 11, 1933. https://doi.org/10.3390/ma11101933

Yin C, Zhang W, Jiang X, Huang Z. Effects of Initial Water Content on Microstructure and Mechanical Properties of Lean Clay Soil Stabilized by Compound Calcium-Based Stabilizer. Materials. 2018; 11(10):1933. https://doi.org/10.3390/ma11101933

Chicago/Turabian StyleYin, Chenglong, Wei Zhang, Xunli Jiang, and Zhiyi Huang. 2018. "Effects of Initial Water Content on Microstructure and Mechanical Properties of Lean Clay Soil Stabilized by Compound Calcium-Based Stabilizer" Materials 11, no. 10: 1933. https://doi.org/10.3390/ma11101933

APA StyleYin, C., Zhang, W., Jiang, X., & Huang, Z. (2018). Effects of Initial Water Content on Microstructure and Mechanical Properties of Lean Clay Soil Stabilized by Compound Calcium-Based Stabilizer. Materials, 11(10), 1933. https://doi.org/10.3390/ma11101933