Effects of Laser Welding and Post-Weld Heat Treatment on Microstructure and Mechanical Properties of Aged Ti55531 Alloy

Abstract

:1. Introduction

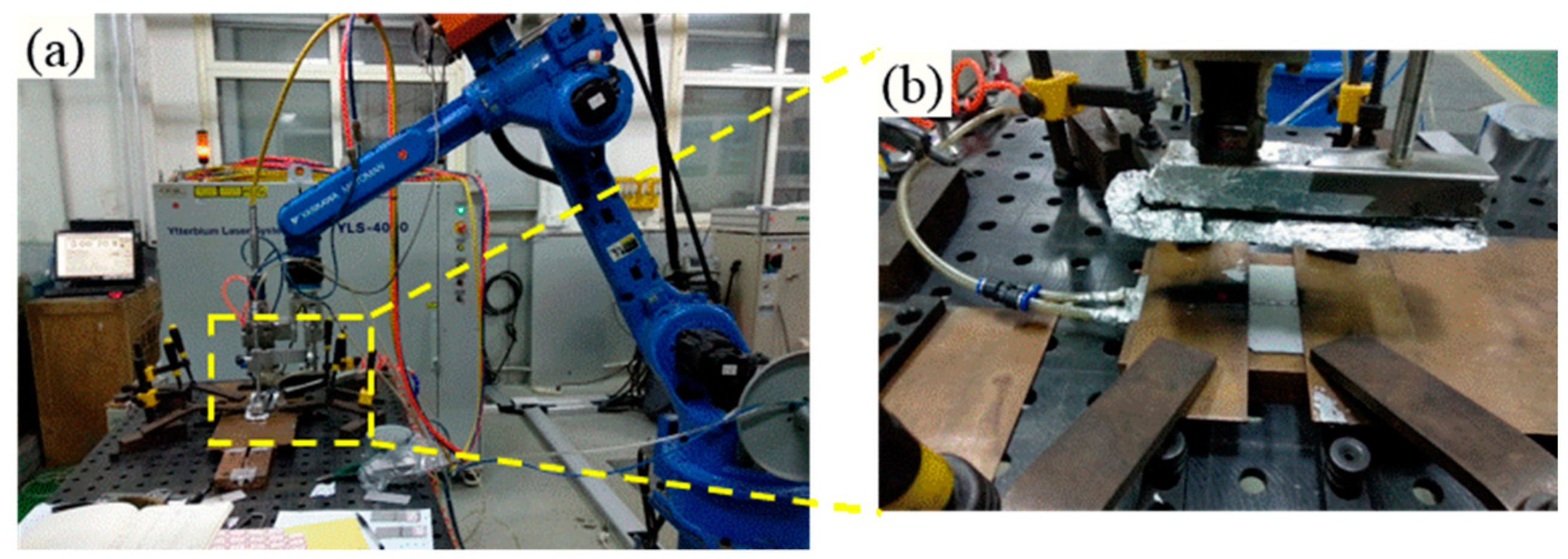

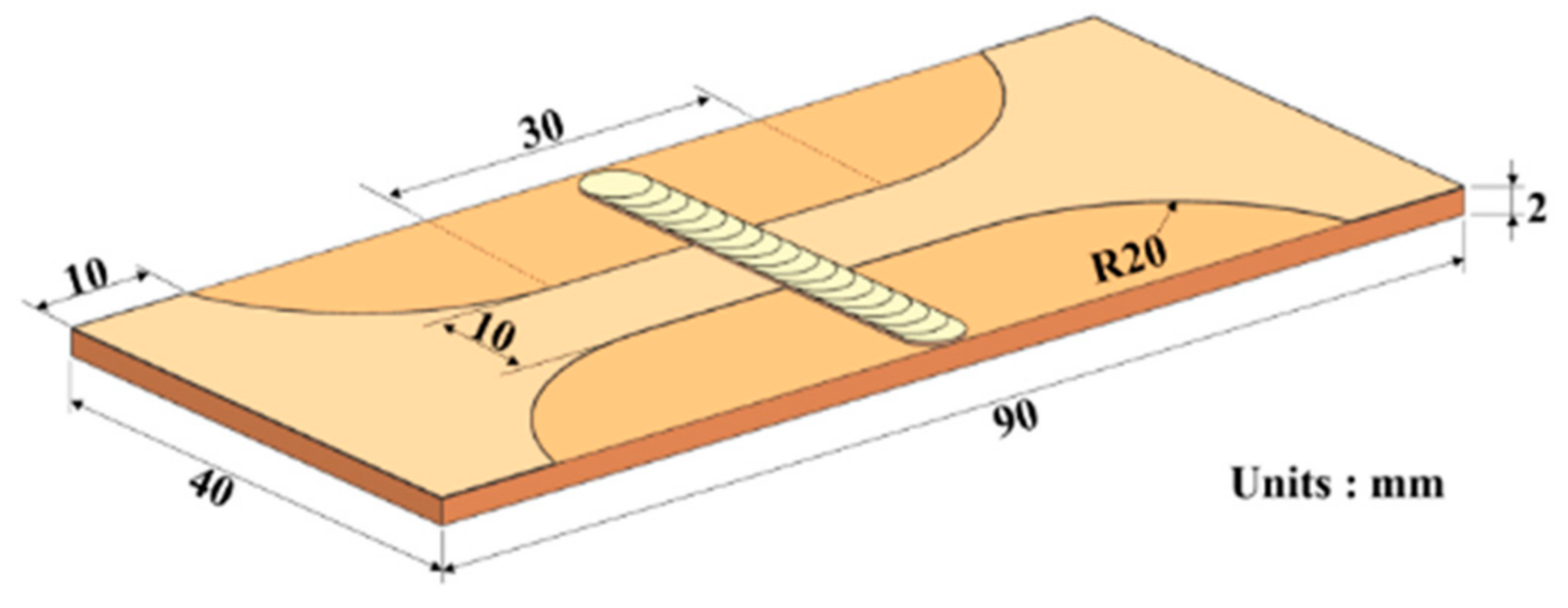

2. Materials and Methods

3. Results and Discussion

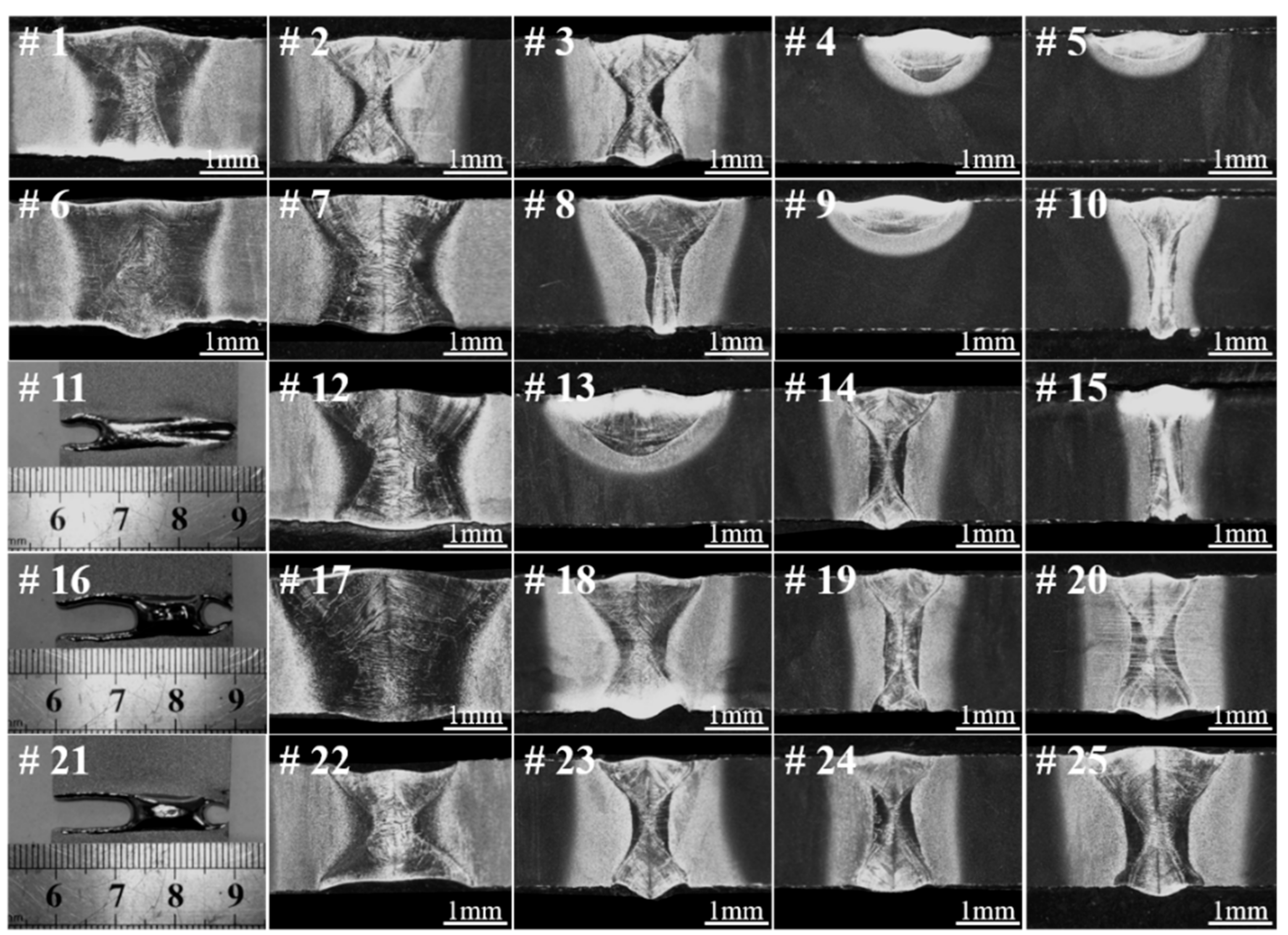

3.1. Optimization of Welding Parameters

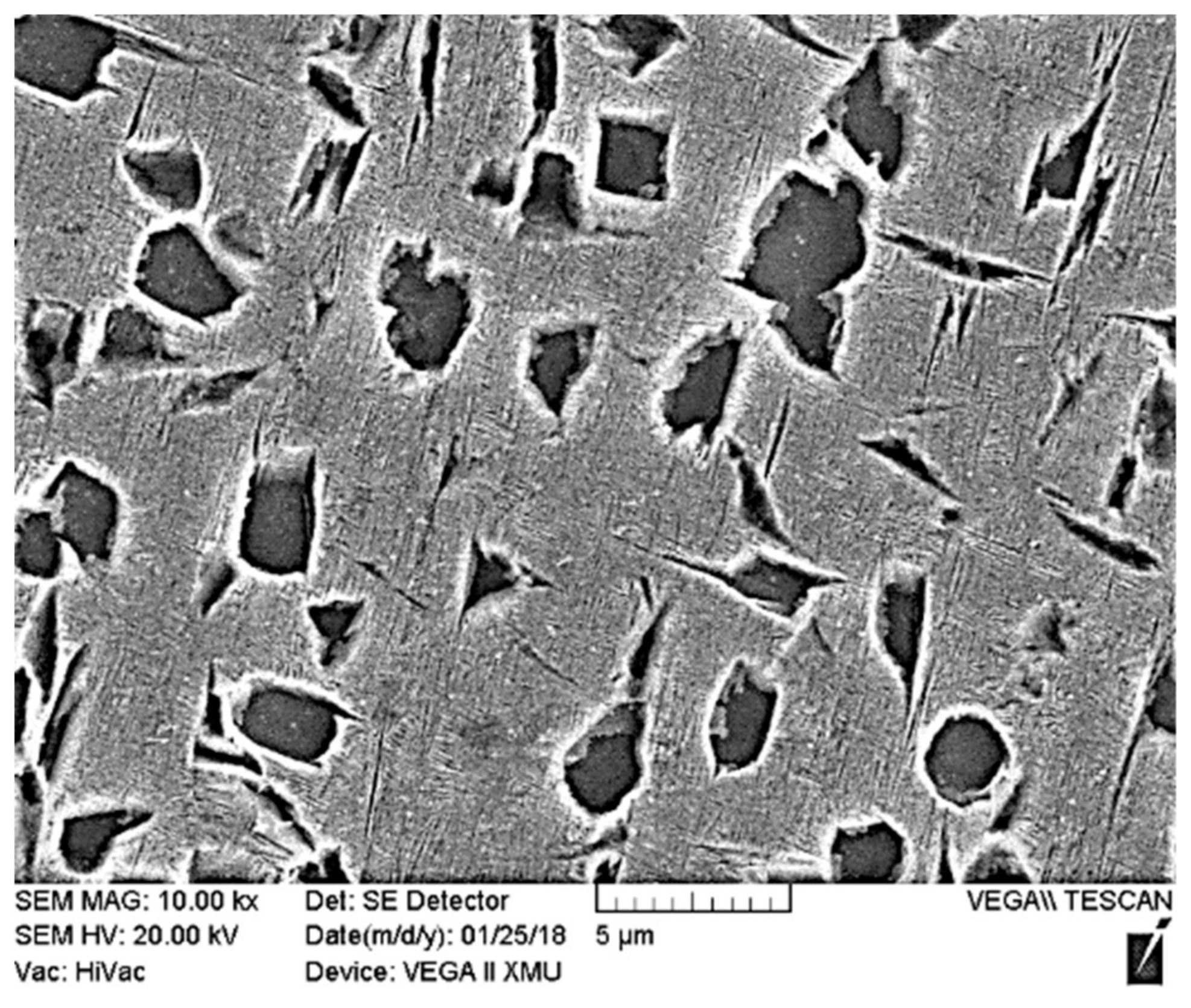

3.2. SEM Observation on Microstructure of Laser-Welded Ti55531 Joints

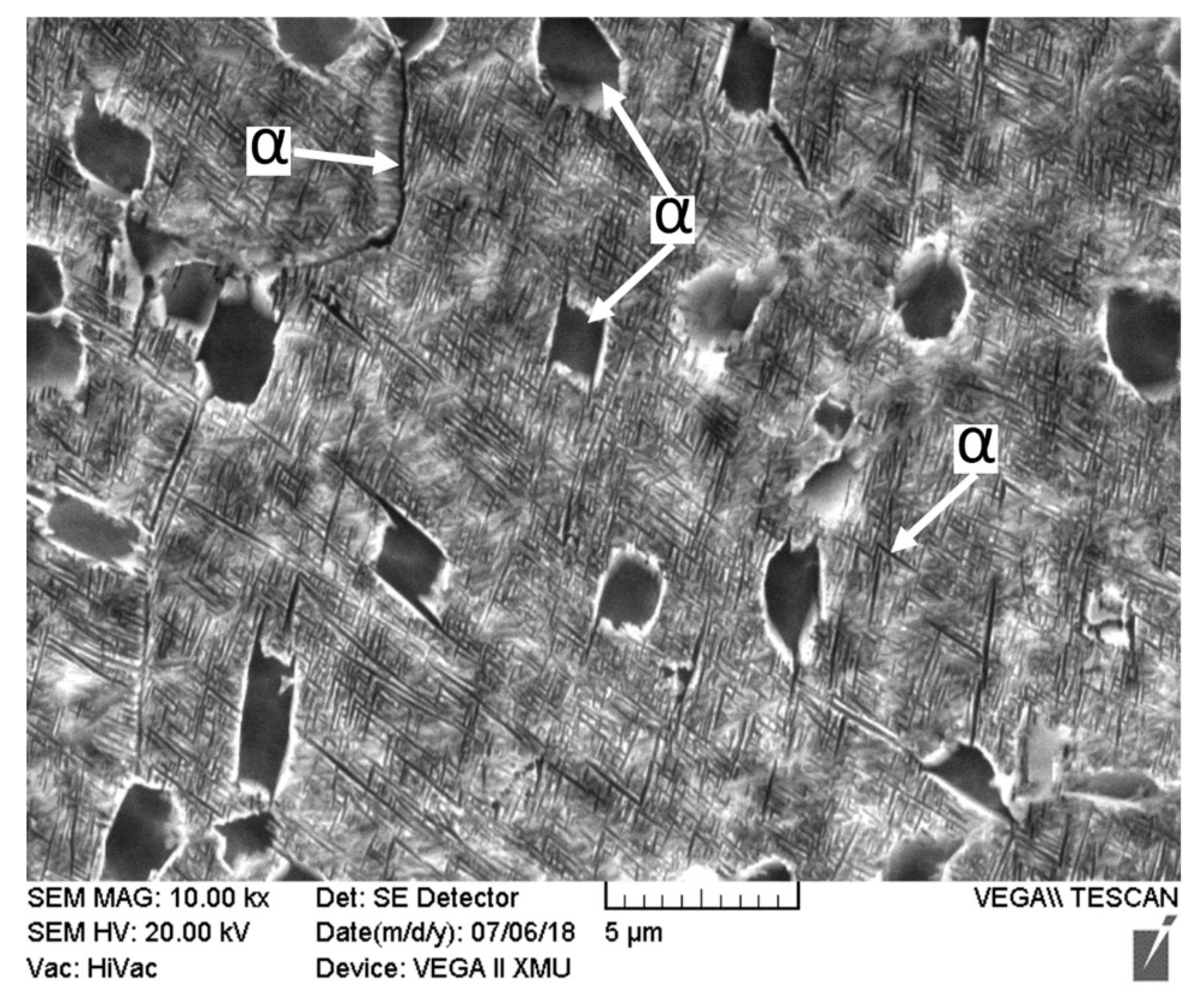

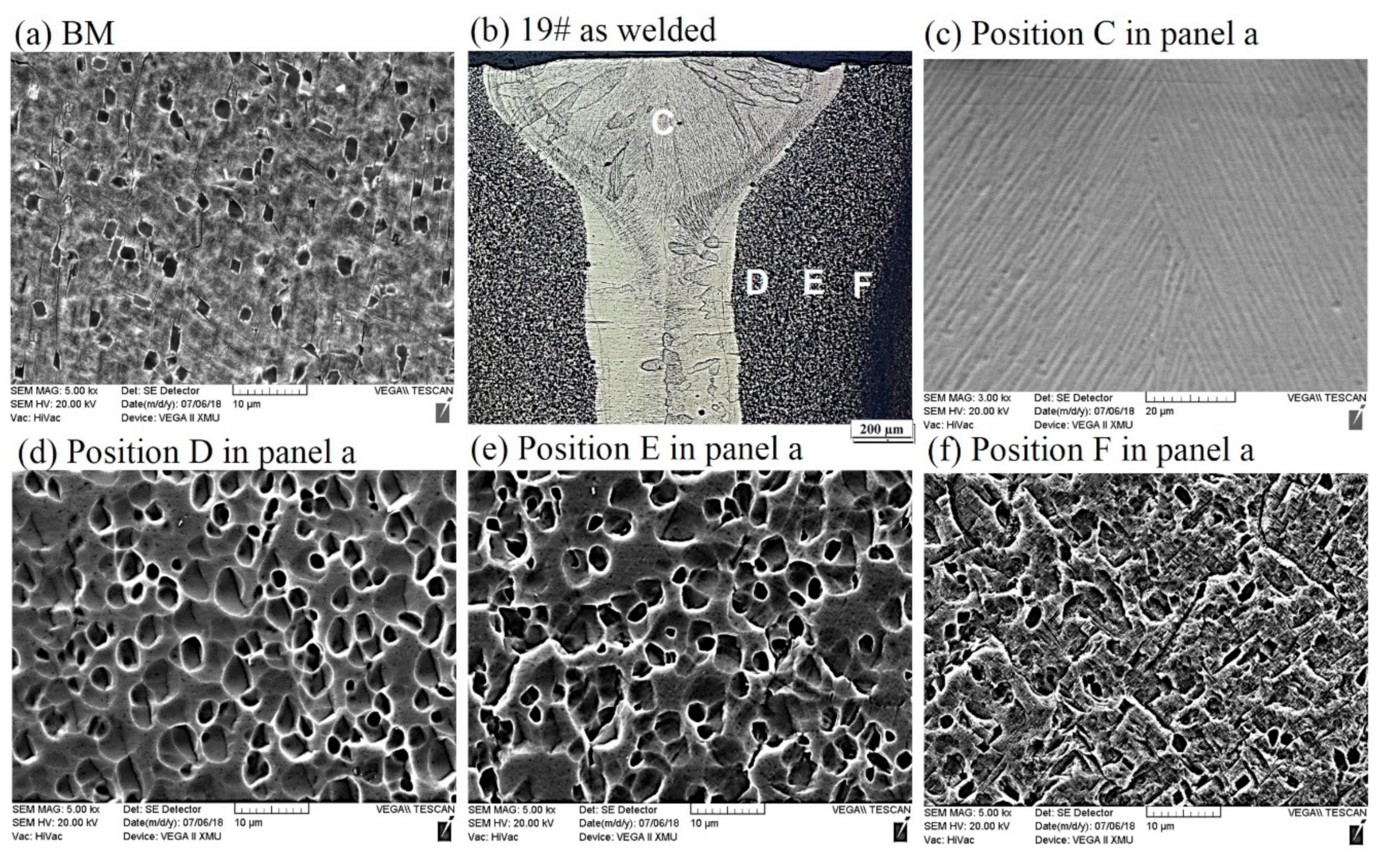

3.2.1. As-Welded Ti55531 Joint

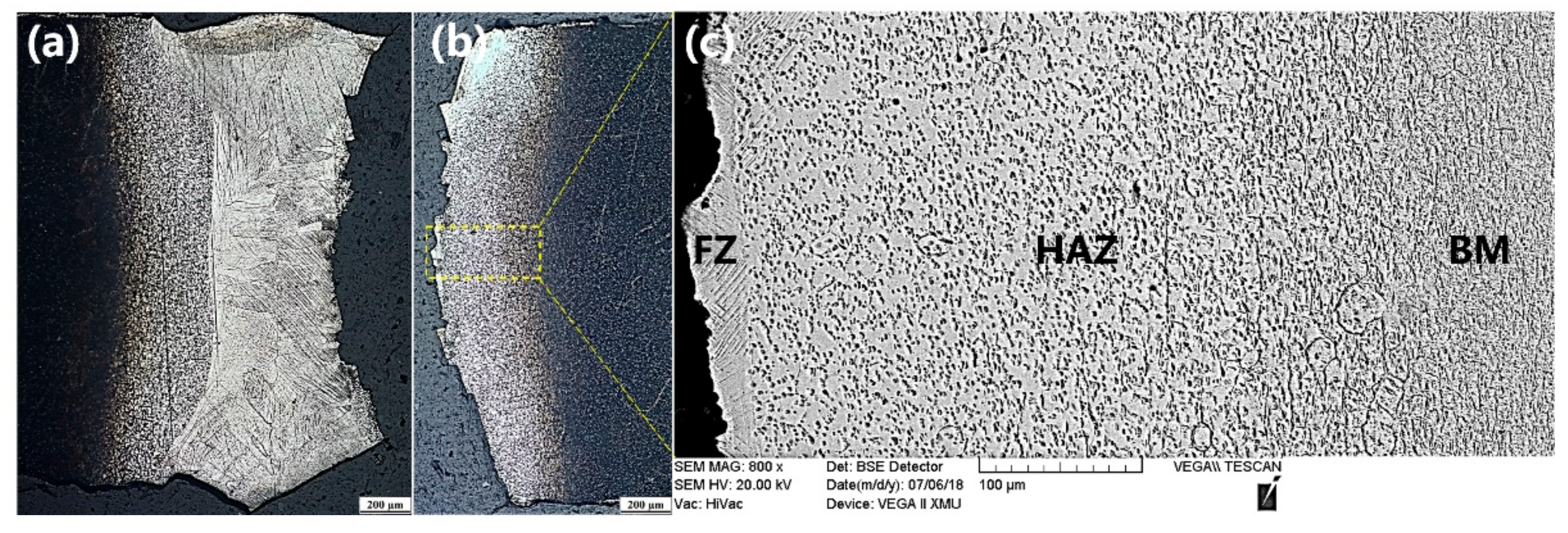

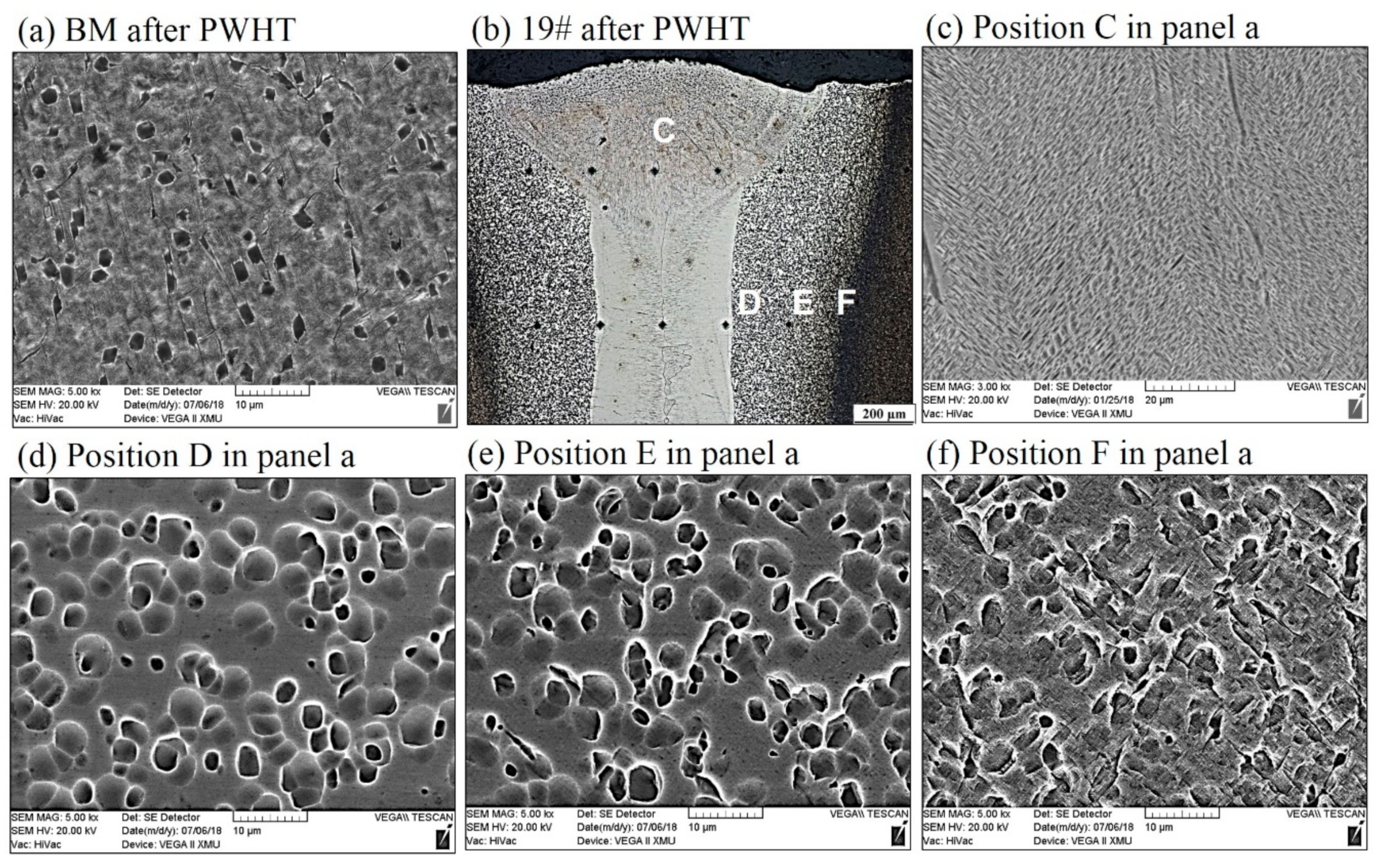

3.2.2. Ti55531 Joint after PWHT

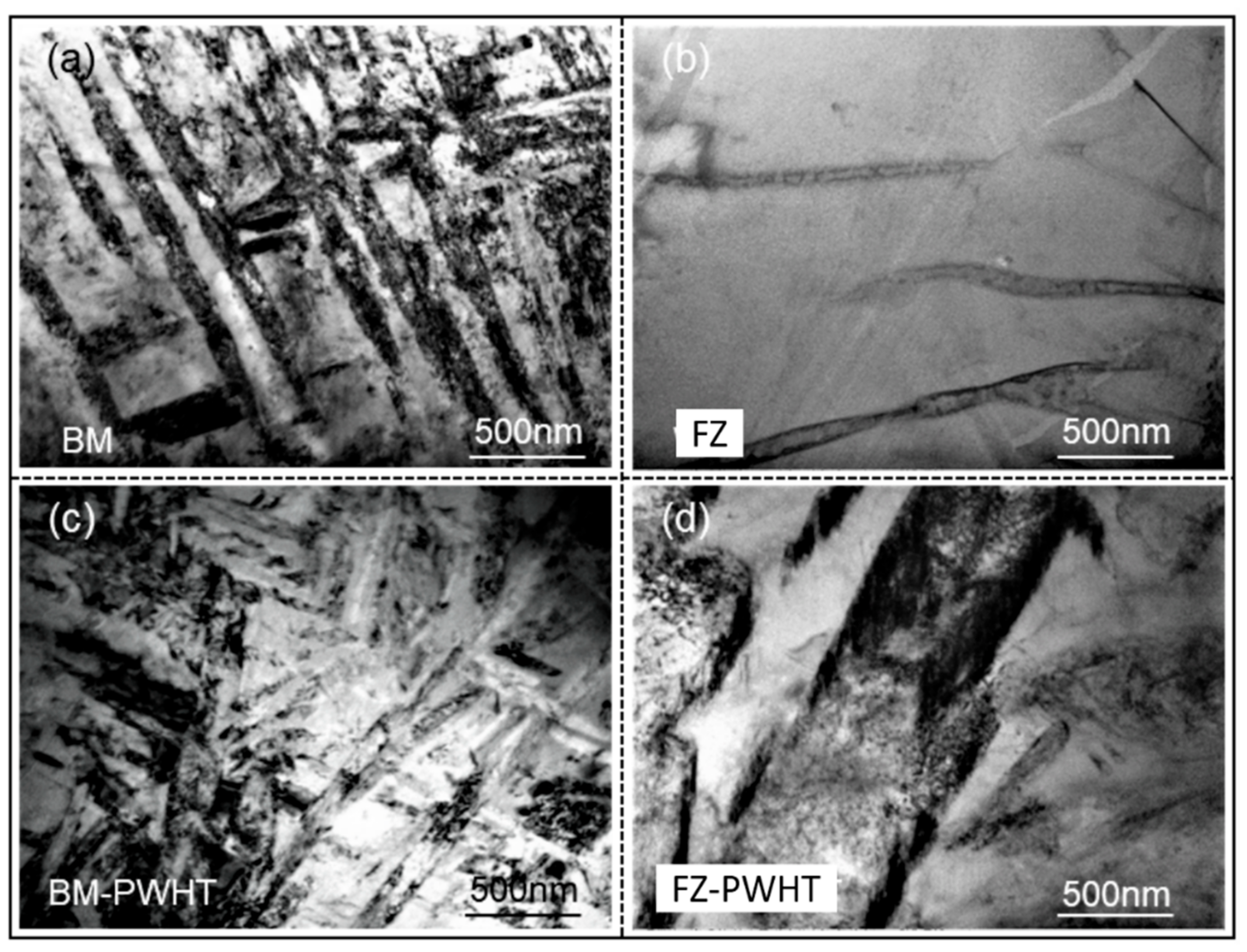

3.3. TEM Observation on Microstructure of Ti55531 Joint

3.4. Mechanical Properties

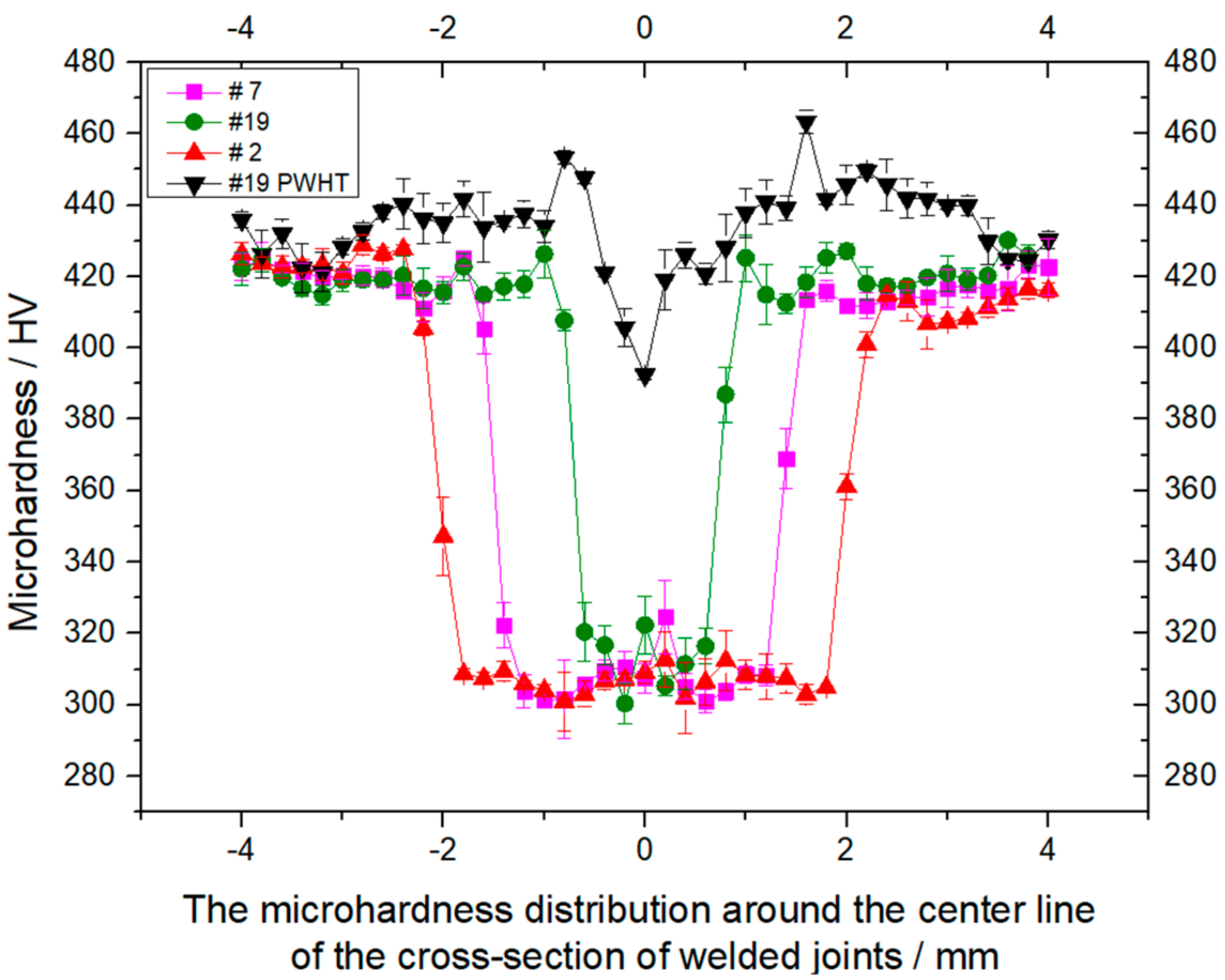

3.4.1. Microhardness

3.4.2. Tensile Test

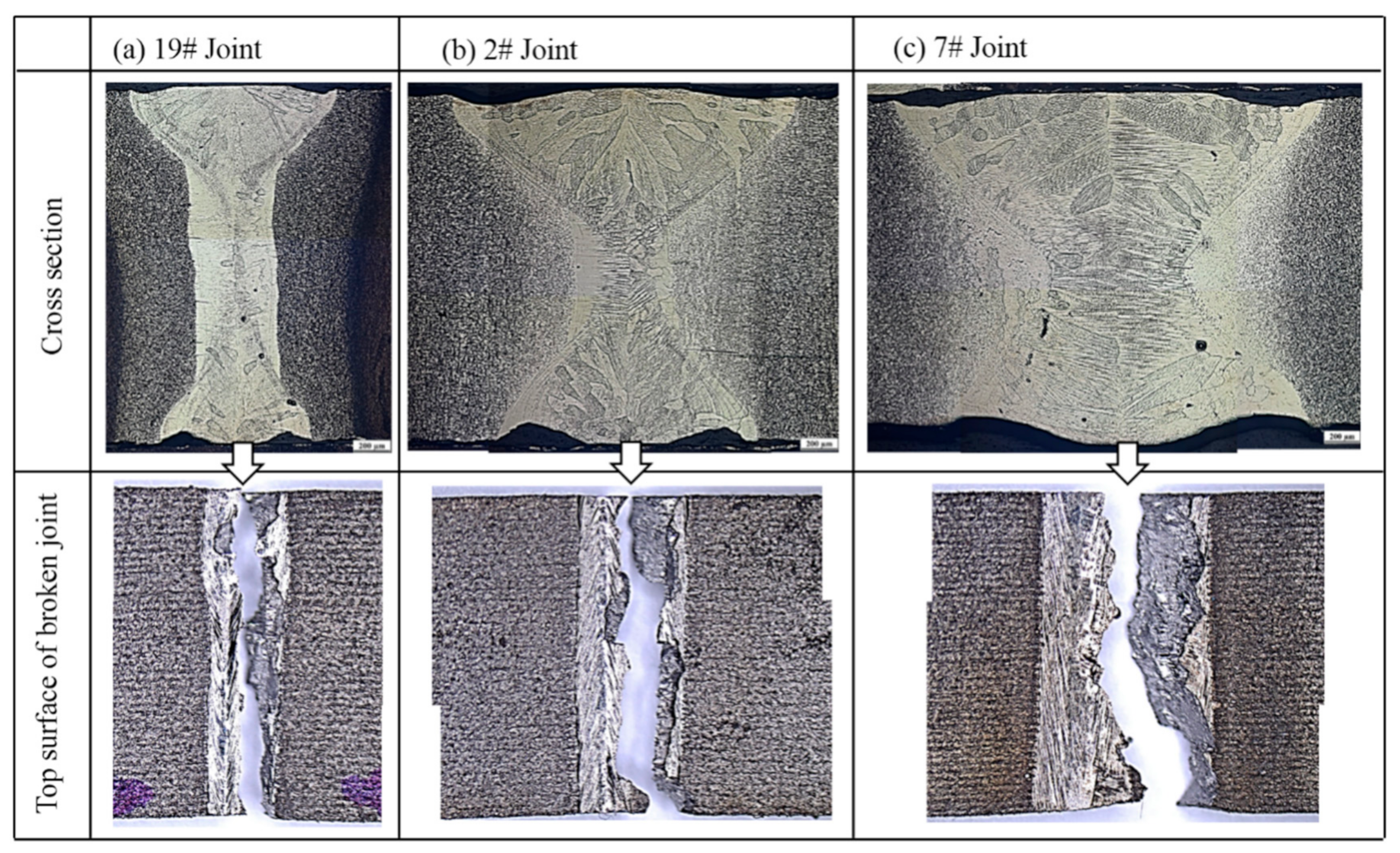

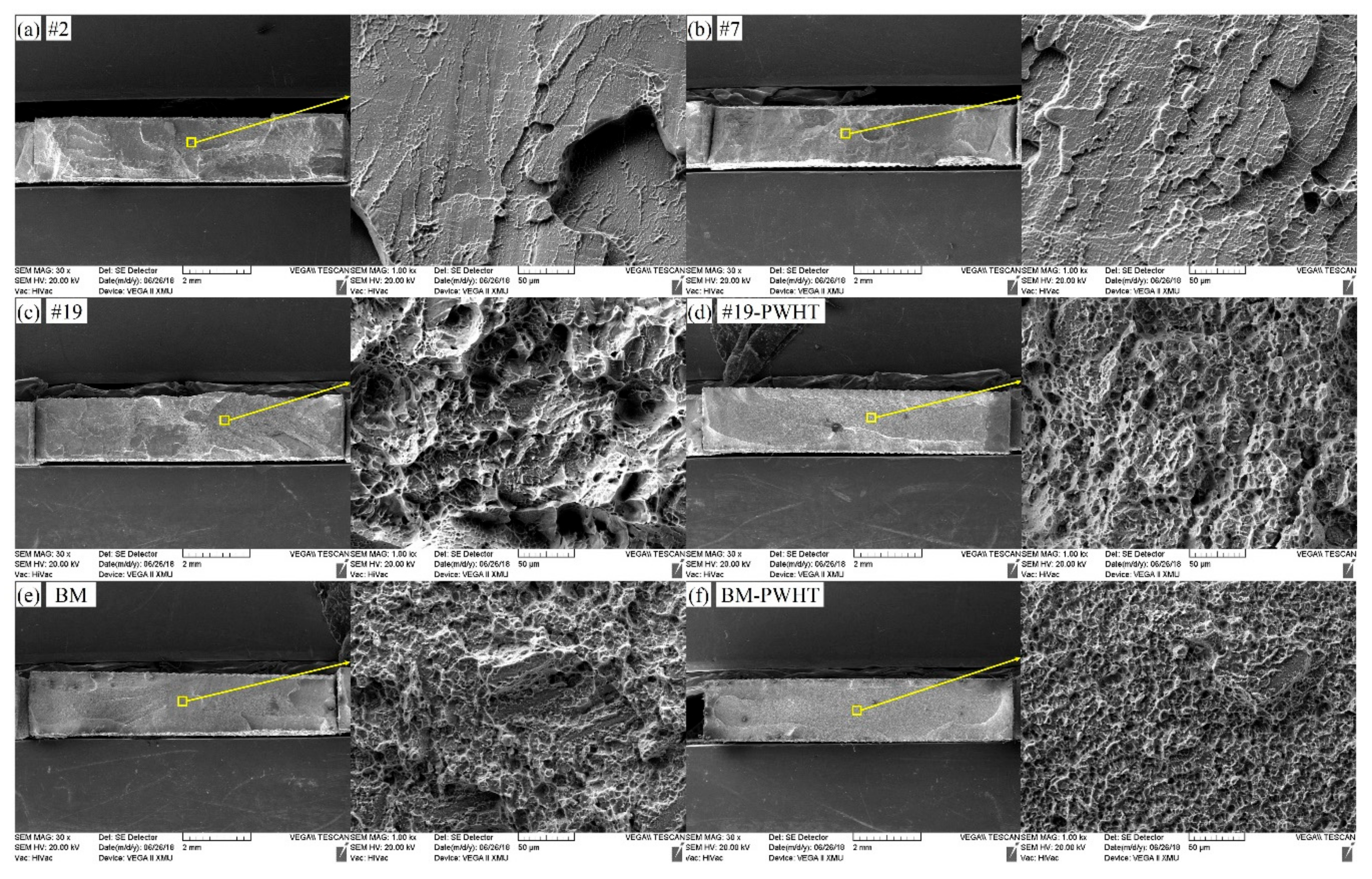

3.4.3. Fracture Morphology

4. Conclusions

- Three kinds of α phases were observed in the BM of Ti55531 alloy: equiaxial primary αp phase, lamellar secondary αS phase precipitated from β-phase matrix, and αGB phase at grain boundaries. The boundary line between α and β phases was clear. After laser welding, β phase in the FZ failed to be transformed into α phase and appeared in the whole of the FZ of the as-welded joint. The lamellar secondary αS phases and αGB phases at grain boundary in the HAZ of as-welded joints were nearly completely dissolved. The edge of equiaxial αp phase in the HAZ of as-welded joint was significantly dissolved and the closer to the FZ, the more sufficiently the α phases in the HAZ were dissolved.

- After PWHT: The number of equiaxial αp phases in β phase matrix of the BM increased and the interface between equiaxial αp phases and β phase matrix became blurred, the size of αp phases in BM significantly rose, and the lamellar secondary αS phases and αGB phase at grain boundary in β phase matrix nearly totally disappeared. After carrying out the PWHT, compact lamellar α phases re-occurred in the FZ and the interface between granular phases and β phase matrix in the HAZ became more blurred. Moreover, the size of granular phases in the HAZ increased.

- Welding condition had a significant influence on microstructures and the performance of laser-welded Ti55531 joints. Under a large weld heat input, the surface of tensile fracture of the welded joint was even, with typical cleavage step morphology. Under a low weld heat input, the tensile fractures of as-welded joints and joints being subjected to PWHT exhibited uneven morphology.

- Under the experimental conditions considered in the study, the microhardness of the BM was about 420 HV. The microhardness of the FZ in as-welded joints was in the range of 300~320 HV and increased to 390~440 HV after carrying out PWHT. Moreover, the tensile strength of as-welded joints was about 940 MPa, which took up 78.41% of that of the BM, while accounting for 96.8% after conducting PWHT.

Author Contributions

Funding

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2003; pp. 1–513. [Google Scholar]

- Dikovits, M.; Poletti, C.; Warchomicka, F. Deformation Mechanisms in the Near-β, Titanium Alloy Ti-55531. Metall. Mater. Trans. A 2014, 45, 1586–1596. [Google Scholar] [CrossRef]

- Yolton, C.F.; Froes, F.H.; Malone, R.F. Alloying element effects in metastable beta titanium alloys. Metall. Mater. Trans. A 1979, 10, 132–134. [Google Scholar] [CrossRef]

- Warchomicka, F.; Poletti, C.; Stockinger, M. Study of the hot deformation behaviour in Ti–5Al–5Mo–5V–3Cr–1Zr. Mater. Sci. Eng. A 2011, 528, 8277–8285. [Google Scholar] [CrossRef]

- Bykov, V.A.; Kulikova, T.V.; Vedmid’, L.B.; Fishman, A.Y.; Shunyaev, K.Y.; Tarenkova, N.Y. Thermophysical properties of Ti-5Al-5V-5Mo-3Cr-1Zr titanium alloy. Phys. Metals Metall. 2014, 115, 705–709. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Requena, G.; Schwarz, S.; Warchomicka, F.; Buslaps, T. Influence of phase transformation kinetics on the formation of α in a β-quenched Ti–5Al–5Mo–5V–3Cr–1Zr alloy. Acta Mater. 2015, 95, 90–101. [Google Scholar] [CrossRef]

- Guimarães, R.P.M.; Oliveira, V.B.; Barriobero-Vila, P.; Requena, G.; Pinto, H.C. Preliminary studies on the aging kinetics of Ti-55531 alloy using high-energy synchrotron X-ray diffraction. In Proceedings of the SICEM 2016, Seoul, Korea, 28 April–1 May 2016. [Google Scholar]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W. High cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy with bimodal microstructure. J. Alloys Compd. 2017, 695, 1966–1975. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on tensile properties of Ti–5Al–5Mo–5V–3Cr–1Zr alloy. Mater. Sci. Eng. A 2017, 693, 582–591. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Tan, C.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on high cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy. Int. J. Fatigue 2017, 94, 30–40. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Becker, D.W.; Baeslack, W.A. Property-microstructure relationships in metastable-beta titanium alloy weldments. Weld. J. Res. Suppl. 1980, 59, 85–92. [Google Scholar]

- Pasang, T.; Amaya, J.M.S.; Tao, Y. Comparison of Ti–5Al–5V–5Mo–3Cr Welds Performed by Laser Beam, Electron Beam and Gas Tungsten Arc Welding. Procedia Eng. 2013, 63, 397–404. [Google Scholar] [CrossRef]

- Sabol, J.C. Analysis of Microstructural Evolution and Fracture Mechanisms in Ti–5Al–5V–5Mo–3Cr–0.4Fe in Response to Electron Beam Welding and Post Weld Heat Treatments. Ph.D. Thesis, Lehigh University, Bethlehem, PA, USA, 2014. [Google Scholar]

- Sabol, J.C.; Pasang, T.; Misiolek, W.Z. Localized tensile strain distribution and metallurgy of electron beam welded Ti–5Al–5V–5Mo–3Cr titanium alloys. J. Mater. Process. Technol. 2012, 212, 2380–2385. [Google Scholar] [CrossRef]

- Marvel, C.J.; Sabol, J.C.; Pasang, T.; Watanabe, M.; Misiolek, W.Z. Improving the Mechanical Properties of the Fusion Zone in Electron-Beam Welded Ti–5Al–5Mo–5V–3Cr Alloys. Metall. Mater. Trans. A 2017, 48, 1921–1930. [Google Scholar] [CrossRef]

- Shi, Y.; Fei, Z.; Li, X.; Gong, S.; Chen, L. Effect of laser beam welding on fracture toughness of a Ti–6.5Al–2Zr–1Mo–1V alloy sheet. J. Mater. Sci. 2007, 42, 6651–6657. [Google Scholar] [CrossRef]

- Shariff, T.; Chromik, R.R.; Wanjara, P.; Cuddy, J.; Birur, A. Effect of joint gap on the quality of laser beam welded near-β Ti-5553 alloy with the addition of Ti–6Al–4V filler wire. J. Mater. Sci. 2012, 47, 866–875. [Google Scholar] [CrossRef]

- Nunes, A.C. A Comparison of the Physics of Gas Tungsten Arc Welding (GTAW), Electron Beam Welding (EBW), and Laser Beam Welding (LBW); NASA Marshall Space Flight Center: Huntsville, AL, USA, 1985.

- Sánchez-Amaya, J.M.; Pasang, T.; Amaya-Vazquez, M.R.; Lopez-Castro, J.D.D.; Churiaque, C.; Tao, Y.; Pedemonte, F.J.B. Microstructure and Mechanical Properties of Ti5553 Butt Welds Performed by LBW under Conduction Regime. Metals 2017, 7, 269. [Google Scholar] [CrossRef]

- Shariff, T.; Cao, X.; Chromik, R.R.; Baradari, J.G.; Wanjara, P.; Cuddy, J.; Birur, A. Laser welding of Ti–5Al–5V–5Mo–3Cr. Can. Metall. Q. 2011, 50, 263–272. [Google Scholar] [CrossRef]

- Zhang, L.J.; Zhang, J.X.; Gumenyuk, A.; Rethmeier, M.; Na, S.J. Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser. J. Mater. Process. Technol. 2014, 214, 1710–1720. [Google Scholar] [CrossRef]

- Liu, J.; Gao, X.L.; Zhang, L.J.; Zhang, J.X. A study of fatigue damage evolution on pulsed Nd:YAG Ti6Al4V laser welded joints. Eng. Fract. Mech. 2014, 117, 84–93. [Google Scholar] [CrossRef]

- Shao, C.D.; Lu, F.G.; Cui, H.C.; Li, Z.G. Characterization of high-gradient welded microstructure and its failure mode in fatigue test. Int. J. Fatigue 2018, 113, 1–10. [Google Scholar] [CrossRef]

| Number | Laser Power P (kW) | Welding Speed V (m/min) | Defocusing Amount f (mm) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 1 | 2 | 1 | −3 | 692.89 |

| 2 | 2 | 2 | 0 | 841.75 |

| 3 | 2 | 3 | 3 | 782.06 |

| 4 | 2 | 4 | 6 | Lack of penetration |

| 5 | 2 | 5 | 9 | Lack of penetration |

| 6 | 2.5 | 1 | 0 | 784.13 |

| 7 | 2.5 | 2 | 3 | 814.97 |

| 8 | 2.5 | 3 | 6 | 803.31 |

| 9 | 2.5 | 4 | 9 | Lack of penetration |

| 10 | 2.5 | 5 | −3 | 725.26 |

| 11 | 3 | 1 | 3 | Weld leakage |

| 12 | 3 | 2 | 6 | 790.12 |

| 13 | 3 | 3 | 9 | Lack of penetration |

| 14 | 3 | 4 | −3 | 808.27 |

| 15 | 3 | 5 | 0 | 856.10 |

| 16 | 3.5 | 1 | 6 | Weld leakage |

| 17 | 3.5 | 2 | 9 | 741.44 |

| 18 | 3.5 | 3 | −3 | 817.92 |

| 19 | 3.5 | 4 | 0 | 940.52 |

| 20 | 3.5 | 5 | 3 | 703.78 |

| 21 | 4 | 1 | 9 | Weld leakage |

| 22 | 4 | 2 | −3 | 843.90 |

| 23 | 4 | 3 | 0 | 720.41 |

| 24 | 4 | 4 | 3 | 853.88 |

| 25 | 4 | 5 | 6 | 880.09 |

| Range | Laser Power P | Welding Speed V | Defocusing Amount f |

|---|---|---|---|

| K1 | 463.32 | 295.39 | 777.65 |

| K2 | 625.53 | 806.43 | 828.56 |

| K3 | 346.90 | 624.74 | 630.93 |

| K4 | 640.63 | 520.53 | 494.70 |

| K5 | 659.66 | 632.21 | 148.29 |

| R (range) | 312.76 | 511.04 | 680.27 |

| Factor | Degree of Freedom | F-Value | p-Value | Significance |

|---|---|---|---|---|

| Power | 4 | 0.53 | 0.714 | Not significant |

| Welding speed | 4 | 2.23 | 0.126 | Not significant |

| Defocusing amount | 4 | 4.72 | 0.016 | Not significant |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.-J.; Pei, J.-Y.; Long, J.; Xie, M.-X.; Shang, X.-T.; Wu, J. Effects of Laser Welding and Post-Weld Heat Treatment on Microstructure and Mechanical Properties of Aged Ti55531 Alloy. Materials 2018, 11, 1907. https://doi.org/10.3390/ma11101907

Zhang L-J, Pei J-Y, Long J, Xie M-X, Shang X-T, Wu J. Effects of Laser Welding and Post-Weld Heat Treatment on Microstructure and Mechanical Properties of Aged Ti55531 Alloy. Materials. 2018; 11(10):1907. https://doi.org/10.3390/ma11101907

Chicago/Turabian StyleZhang, Lin-Jie, Jun-Yu Pei, Jian Long, Miao-Xia Xie, Xiang-Tao Shang, and Jun Wu. 2018. "Effects of Laser Welding and Post-Weld Heat Treatment on Microstructure and Mechanical Properties of Aged Ti55531 Alloy" Materials 11, no. 10: 1907. https://doi.org/10.3390/ma11101907

APA StyleZhang, L.-J., Pei, J.-Y., Long, J., Xie, M.-X., Shang, X.-T., & Wu, J. (2018). Effects of Laser Welding and Post-Weld Heat Treatment on Microstructure and Mechanical Properties of Aged Ti55531 Alloy. Materials, 11(10), 1907. https://doi.org/10.3390/ma11101907