In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process

Abstract

1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Obtaining of Different Initial Microstructures

2.3. In Situ Observation Tests

2.4. Characterizations on Optical Microscope and Transmission Electron Microscope

3. Results

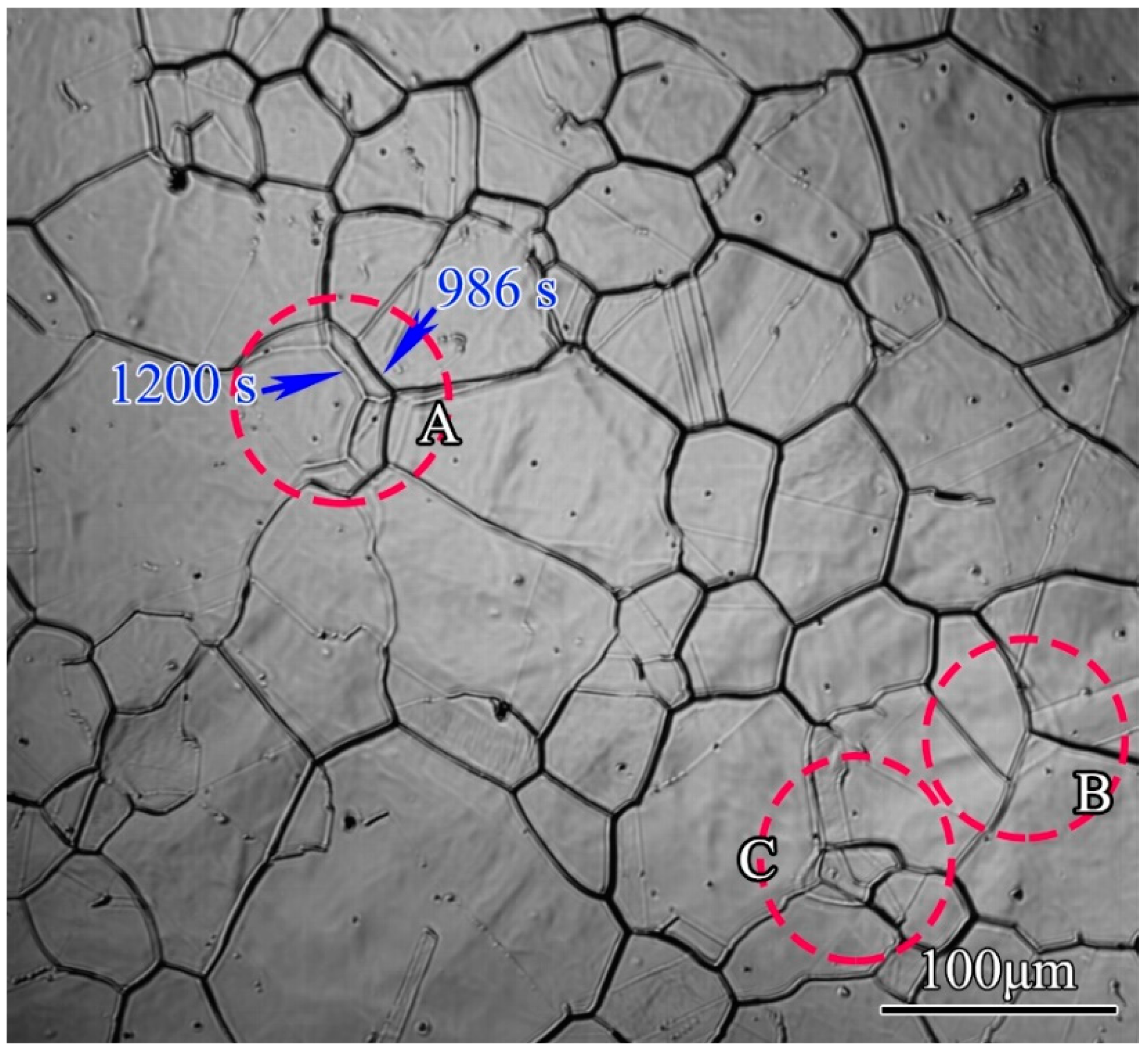

3.1. In Situ Observations of Grain Evolutions

3.2. Influence of Holding Temperature and Time

3.3. Influence of Initial Microstructures

3.4. Comparison with the Metallographic Results

4. Discussions

4.1. Mechanisms of Grain Refinement and Grain Growth

4.2. Modelling of Grain Size Evolutions

4.3. Industrial Implications

5. Conclusions

- (1)

- The microstructures of 300M steel underwent austenization and grain growth sequentially in holdings, and the small austenite grains grew by grain boundary discontinuous migrations and grain consumptions by surrounding grains. With the further increase of the holding time, the grain growth gradually slowed down, and the grains underwent only slight change.

- (2)

- The average grain sizes gradually increased from 21 to 115 μm when the holding temperatures increased from 900 to 1200 °C. The grain size evolutions by in situ observations were different from the general expectations, and the grains could be refined at lower holding temperatures (~950 °C). It could be explained that the grain refinements were due to austenization.

- (3)

- The initial grain sizes and initial structures had no influences on grain growth of 300M steel in isothermal holdings. The grain sizes after austenization of 300M steel were determined by the holding temperatures and time, rather than by the microstructures at room temperatures.

- (4)

- It was shown by TEM results that the 300M steel underwent full recrystallization in the initial stage of holdings because of the strains and dislocations which were introduced by phase transitions.

- (5)

- A grain growth model which has considered the grain boundary migrations based on quantitative analysis of in situ results was established. The mean relative error was 5.36%, showing an advantage in the grain size prediction precision over the Burke and Turnbull model.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, R.C.; Hong, C.; Li, J.J.; Zhang, Z.Z.; Li, P.C. Austenite grain growth and grain size distribution in isothermal heat-treatment of 300M steel. Procedia Eng. 2017, 207, 663–668. [Google Scholar] [CrossRef]

- Zheng, C.; Raabe, D. Interaction between recrystallization and phase transformation during intercritical annealing in a cold-rolled dual-phase steel: A cellular automaton model. Acta Mater. 2013, 61, 5504–5517. [Google Scholar] [CrossRef]

- Karthikeyan, T.; Thomas Paul, V.; Saroja, S.; Moitra, A.; Sasikala, G.; Vijayalakshmi, M. Grain refinement to improve impact toughness in 9Cr-1Mo steel through a double austenitization treatment. J. Nucl. Mater. 2011, 419, 256–262. [Google Scholar] [CrossRef]

- Andreiev, A.; Grydin, O.; Schaper, M. Evolution of Microstructure and Properties of Steel 22MnB5 due to Short Austenitization with Subsequent Quenching. Steel Res. Int. 2016, 87, 1733–1741. [Google Scholar] [CrossRef]

- Fernández, J.; Illescas, S.; Guilemany, J.M. Effect of microalloying elements on the austenitic grain growth in a low carbon HSLA steel. Mater. Lett. 2007, 61, 2389–2392. [Google Scholar] [CrossRef]

- Schino, A.D.; Kenny, J.M.; Salvatori, I.; Abbruzzese, G. Modelling primary recrystallization and grain growth in a low nickel austenitic stainless steel. J. Mat. Sci. 2001, 36, 593–601. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Song, Y.; Kong, L.; Li, T.; Zhang, R. Austenitic Grain Growth Behavior during Austenization in an Aluminum-Alloyed 5% Cr–Mo–V Steel. Steel Res. Int. 2016, 87, 1450–1460. [Google Scholar] [CrossRef]

- Xu, Y.; Tang, D.; Song, Y.; Pan, X. Prediction model for the austenite grain growth in a hot rolled dual phase steel. Mater. Des. 2012, 36, 275–278. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Manchester, UK, 2004; pp. 1–10. [Google Scholar]

- Zhang, S.S.; Li, M.Q.; Liu, Y.G.; Liu, T.Q. The growth behavior of austenite grain in the heating process of 300M steel. Mat. Sci. Eng. A 2011, 528, 4967–4972. [Google Scholar] [CrossRef]

- Luo, J.; Liu, Y.G.; Li, M.Q. Three-dimensional Numerical Simulation and Experimental Analysis of Austenite Grain Growth Behavior in Hot Forging Processes of 300M Steel Large Components. Steel Res. Int. 2016, 23, 1012–1019. [Google Scholar] [CrossRef]

- Maalekian, M.; Radis, R.; Militzer, M.; Moreau, A.; Poole, W. In situ measurement and modeling of austenite grain growth in a Ti/Nb microalloyed steel. Acta Mater. 2012, 60, 1015–1026. [Google Scholar] [CrossRef]

- Dubois, M.; Militzer, M.; Moreau, A.; BussiÃre, J.F. New technique for the quantitative real-time monitoring of austenite grain growth in steel. Scripta Mater. 2000, 42, 867–874. [Google Scholar] [CrossRef]

- Kamyabi-Gol, A.; Clark, S.J.; Gibbs, J.W.; Sridhar, S.; Mendez, P. Quantification of evolution of multiple simultaneous phase transformations using dilation curve analysis (DCA). Acta Mater. 2016, 102, 231–240. [Google Scholar] [CrossRef]

- Birol, Y. Effect of cooling rate on precipitation during homogenization cooling in an excess silicon AlMgSi alloy. Mater. Charact. 2012, 73, 37–42. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, N.; Li, J.J.; Feng, F. In-situ investigation of phase transformation behaviors of 300M steel in continuous cooling process. Mater. Charact. 2018, 144, 400–410. [Google Scholar] [CrossRef]

- Andrés, C.G.D.; Caballero, F.G.; Capdevila, C.; San-Martín, D. Revealing austenite grain boundaries by thermal etching: advantages and disadvantages. Mater Charact. 2002, 49, 121–127. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, S.G.; Inoue, A. In situ observation of solidification behavior in undercooled Pd–Cu–Ni–P alloy by using a confocal scanning laser microscope. Acta Mater. 2001, 49, 615–622. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, Z.; Li, J.; Feng, F. Constitutive Modelling and Hot Workability Analysis by Microstructure Examination of GH4169 Alloy. Crystals 2018, 8, 282. [Google Scholar] [CrossRef]

- Chen, R.; Guo, P.; Zheng, Z.; Li, J.; Feng, F. Dislocation Based Flow Stress Model of 300M Steel in Isothermal Compression Process. Materials 2018, 11, 972. [Google Scholar] [CrossRef] [PubMed]

- Wan, X.L.; Wu, K.M.; Huang, G.; Wei, R.; Cheng, L. In situ observation of austenite grain growth behavior in the simulated coarse-grained heat-affected zone of Ti-microalloyed steels. Int. J. Min. Met. Mater. 2014, 21, 878–885. [Google Scholar] [CrossRef]

- Han, M.A.; Liao, S. Prediction on Austenite Grain Growth in High Carbon Steel. J. Mater. Eng. 2017, 45, 78–84. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Nakai, K.; Ohmori, Y. Pearlite to austenite transformation in an Fe–2.6Cr–1C alloy. Acta Mater. 1999, 47, 2619–2632. [Google Scholar] [CrossRef]

- Grey, E.A.; Higgins, G.T. Solute limited grain boundary migration: A rationalisation of grain growth. Acta Metall. 1973, 21, 309–321. [Google Scholar] [CrossRef]

- Burke, J.E.; Turnbull, D. Recrystallization and grain growth. Prog. Metal Phys. 1951, 3, 220–292. [Google Scholar] [CrossRef]

| Element | C | Mn | V | Ni | Mo | Si | Cr | S | Fe |

| Content | 0.39 | 0.808 | 0.086 | 1.824 | 0.435 | 2.562 | 0.896 | 0.017 | Bal. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Zheng, Z.; Li, J.; Li, N.; Feng, F. In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process. Materials 2018, 11, 1862. https://doi.org/10.3390/ma11101862

Chen R, Zheng Z, Li J, Li N, Feng F. In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process. Materials. 2018; 11(10):1862. https://doi.org/10.3390/ma11101862

Chicago/Turabian StyleChen, Rongchuang, Zhizhen Zheng, Jianjun Li, Ning Li, and Fei Feng. 2018. "In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process" Materials 11, no. 10: 1862. https://doi.org/10.3390/ma11101862

APA StyleChen, R., Zheng, Z., Li, J., Li, N., & Feng, F. (2018). In Situ Investigation of Grain Evolution of 300M Steel in Isothermal Holding Process. Materials, 11(10), 1862. https://doi.org/10.3390/ma11101862