Bitumen Foaming Optimisation Process on the Basis of Rheological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Bitumen

2.2. Sampling

2.3. Dynamic Viscosity

2.4. Rheological Tests in Oscillation

2.5. Experimental Design 3(3−1)

- Air pressure: 100 kPa, 400 kPa, and 700 kPa;

- Bitumen temperature: 110 °C, 145 °C, and 180 °C; and

- Water content: 1%, 2.5%, and 5%.

3. New Testing Method for Foam Decay Determination

3.1. Laser Measurement of HL and ER

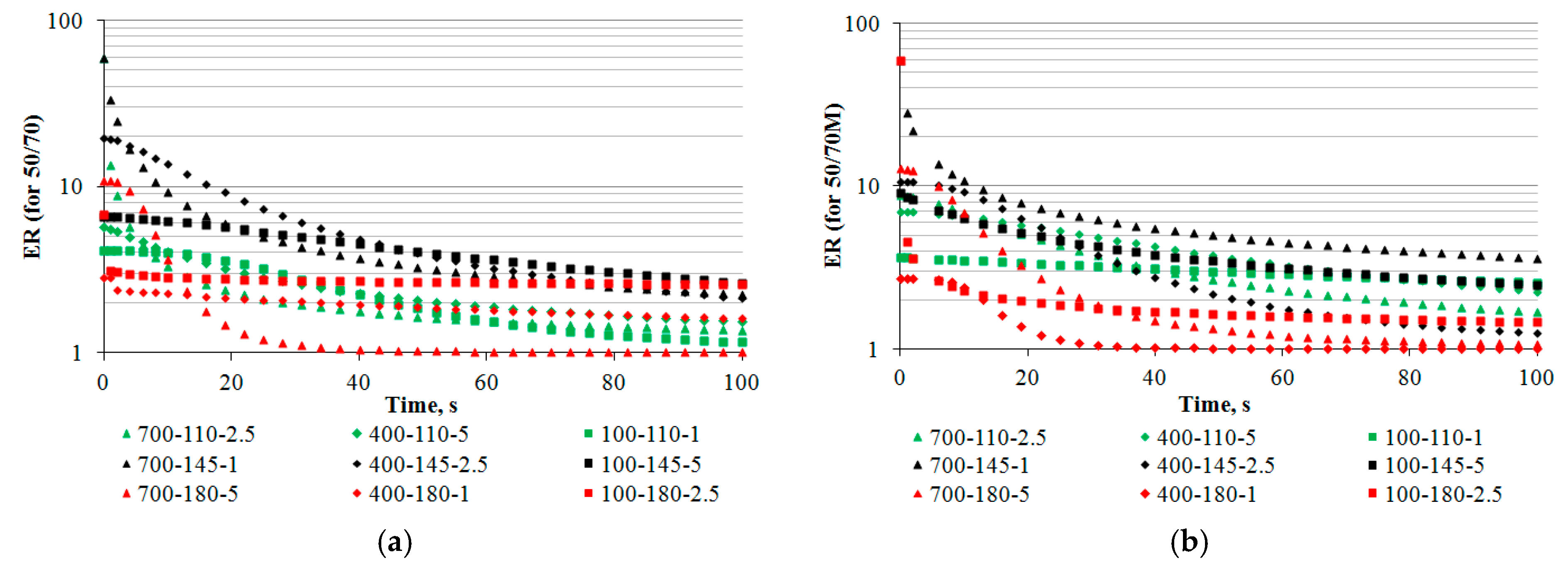

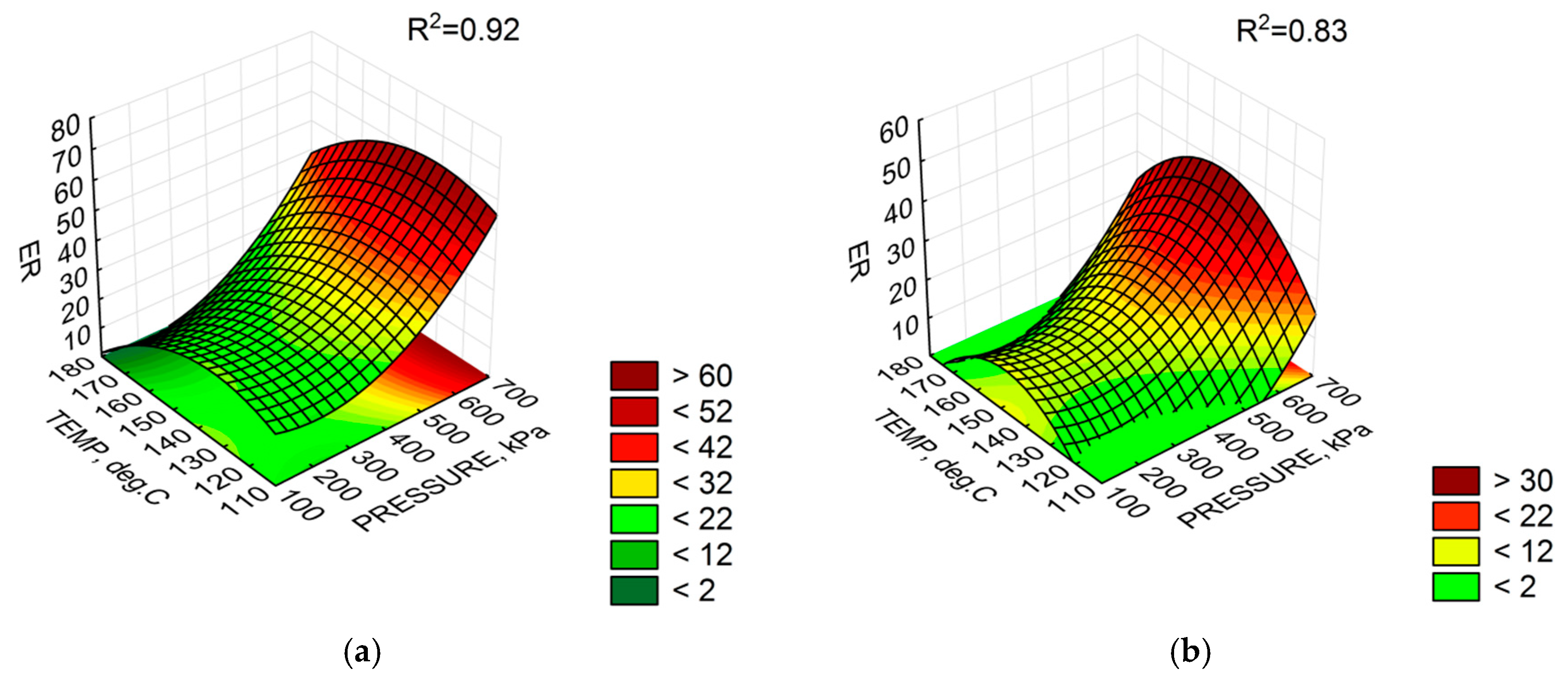

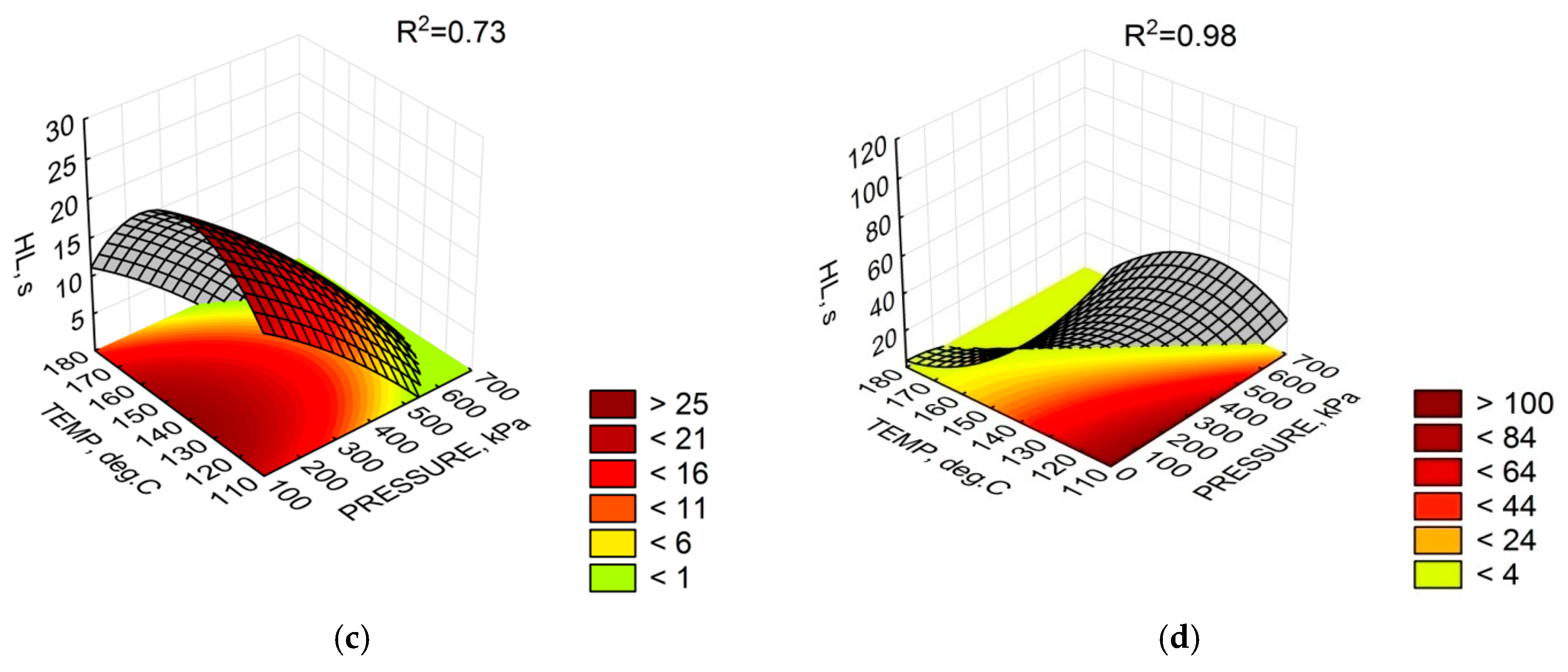

3.2. Bitumen Foam Distribution Model

4. Results of Rheological Parameters

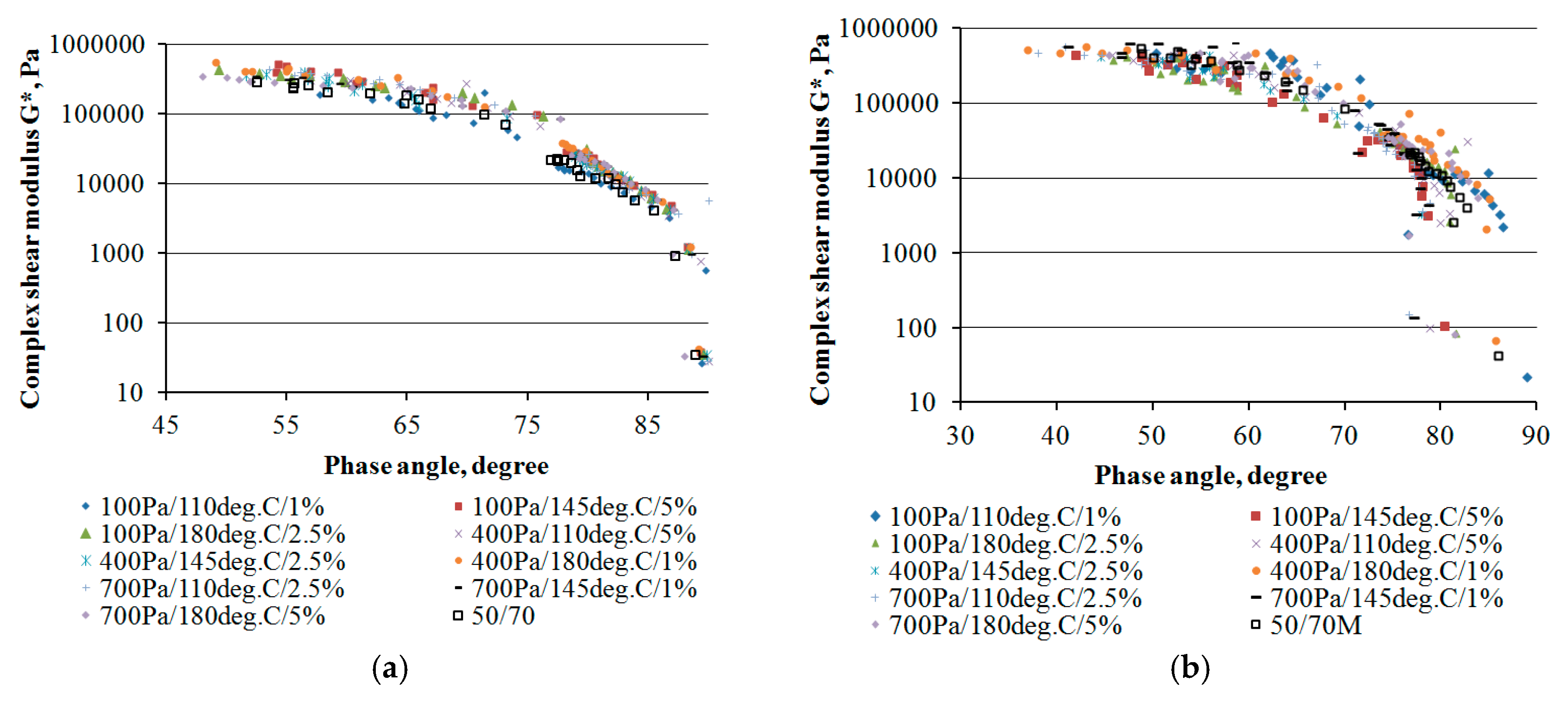

4.1. Viscoelastic Characterisation of Bitumen Foam

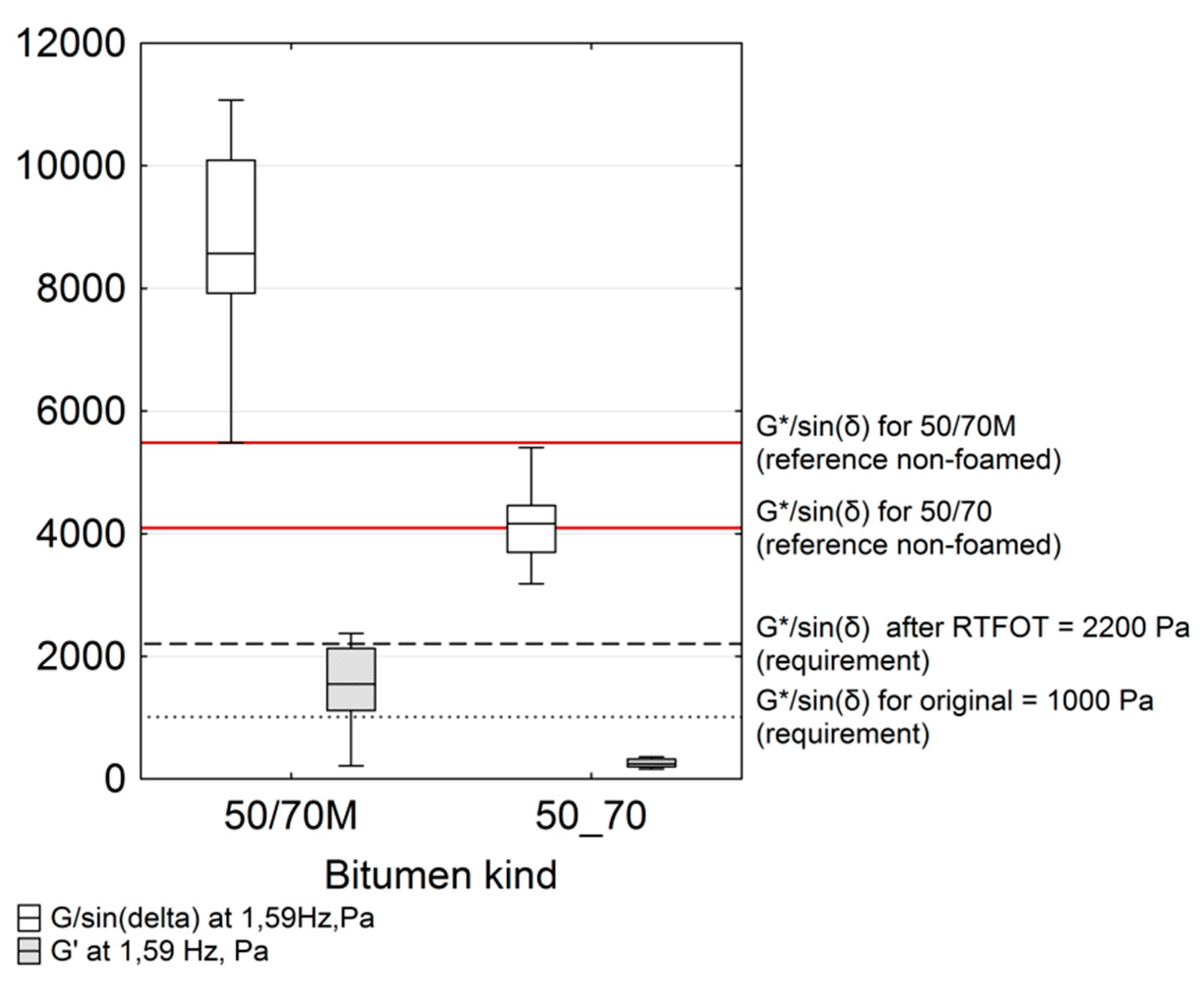

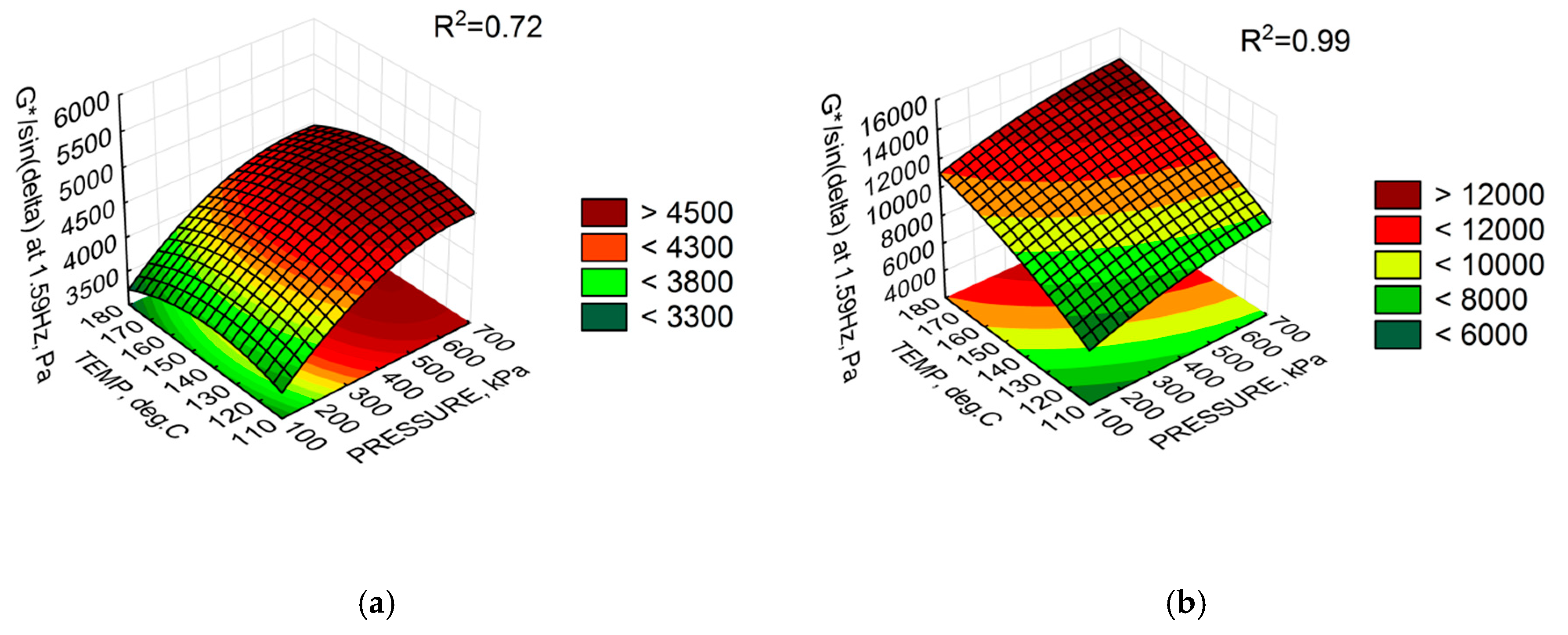

4.2. Effect of Foaming on Stiffness Modulus G*/sin(δ)

4.3. Effect of Foaming on the Ageing Index (IS)

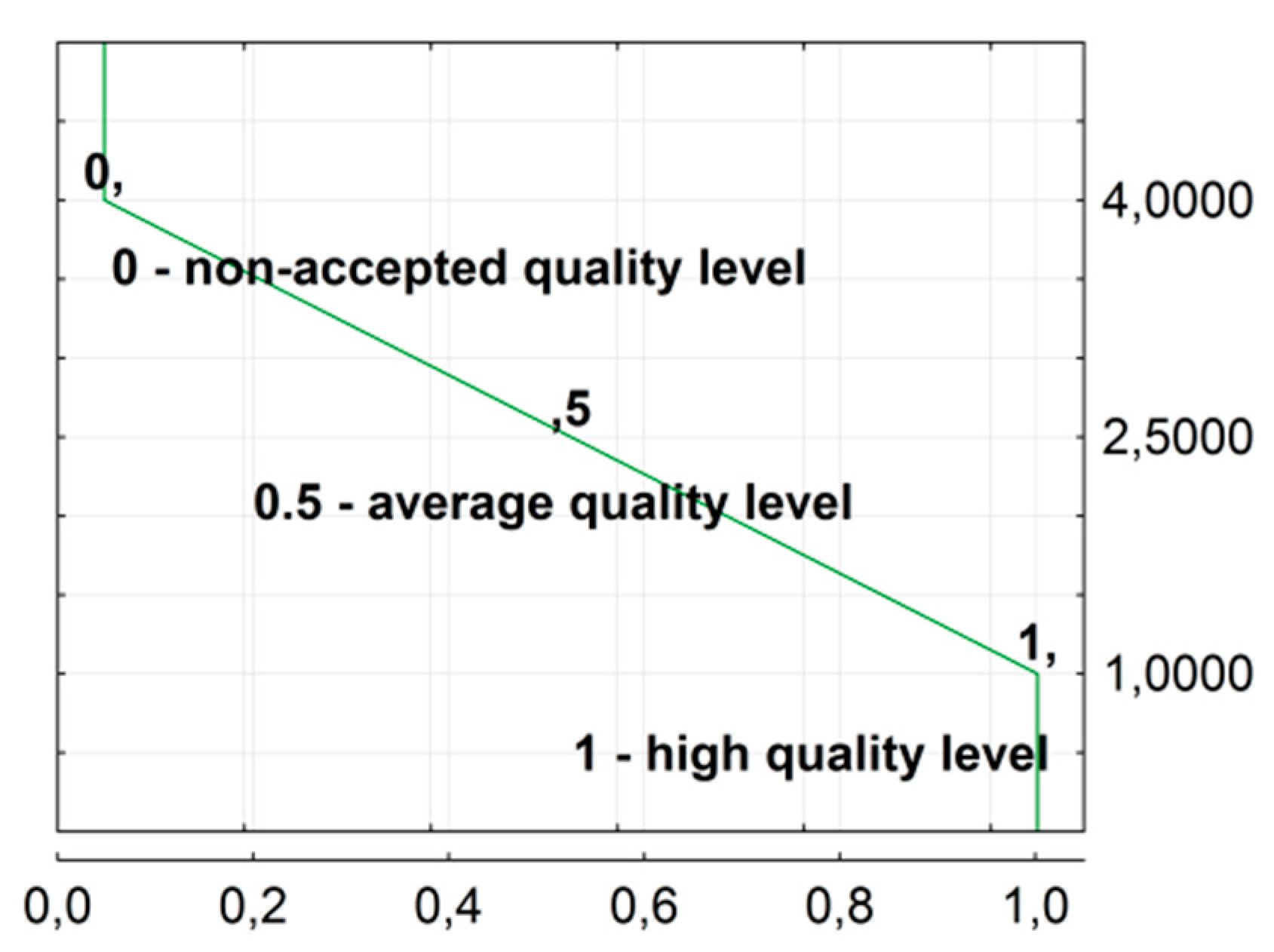

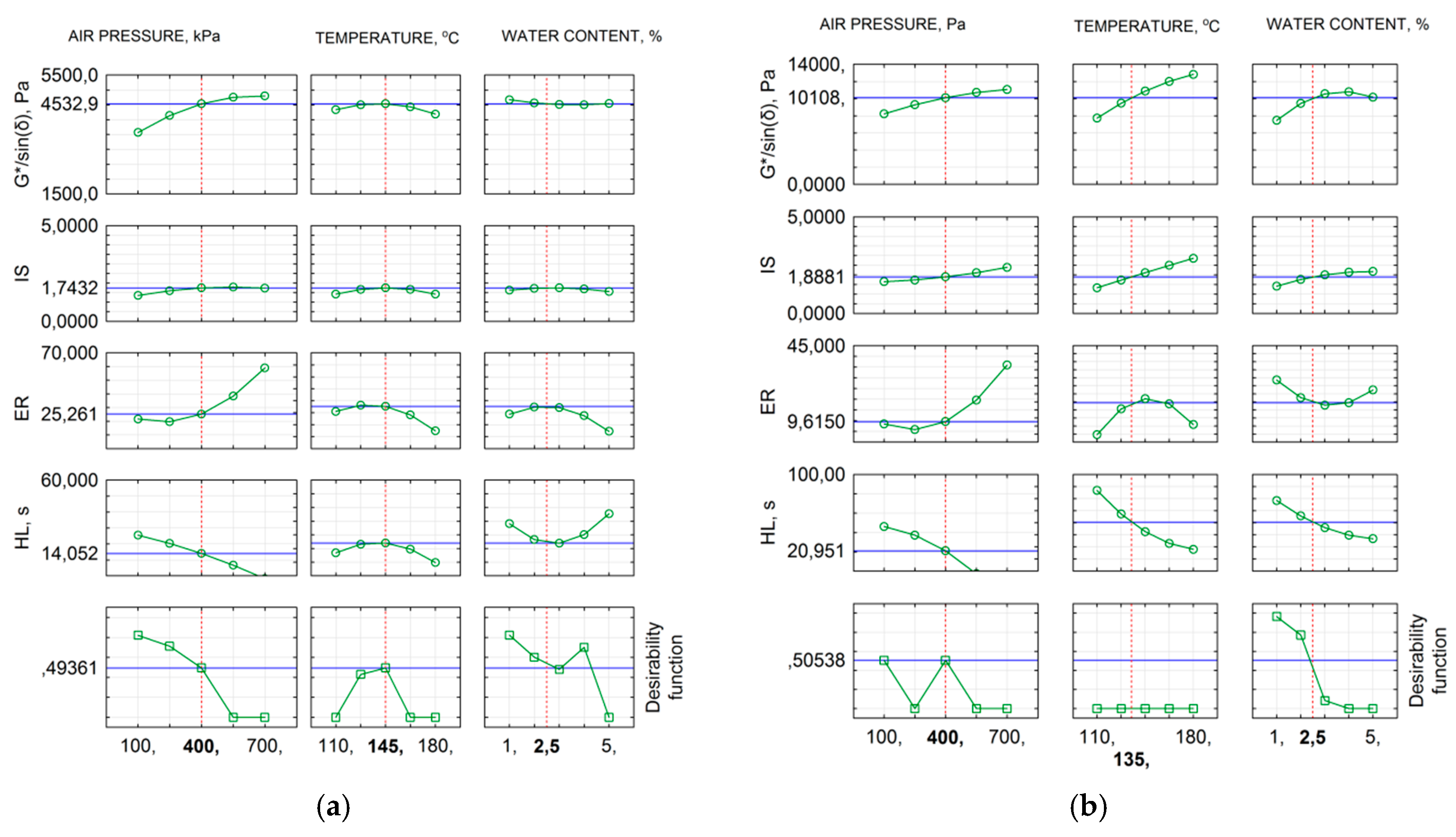

5. Optimisation Process

- The basic limitation of this method is the lack of validation in terms of reproducibility. However, repeatability results make this method promising and more accurate in comparison with common calibrated rod method.

- A 3(3−1) experimental design does not take into account the interaction. Therefore, additional explanation of the model variability, coming from interactions, was not possible.

- The model used for determining ER and HL took into consideration only neat bitumen 50/70 penetration grade. Certain singularities associated with the foaming process for other bitumens with a different penetration grade may be omitted. For this reason, more sophisticated mathematical models would be needed. Such research and analyses are still ongoing.

6. Conclusions

- Digital registration of ER and HL values improves the accuracy of the measurement and minimises the impact on the part of operators. The indicative increase in measurement accuracy is six times that of the classical approach.

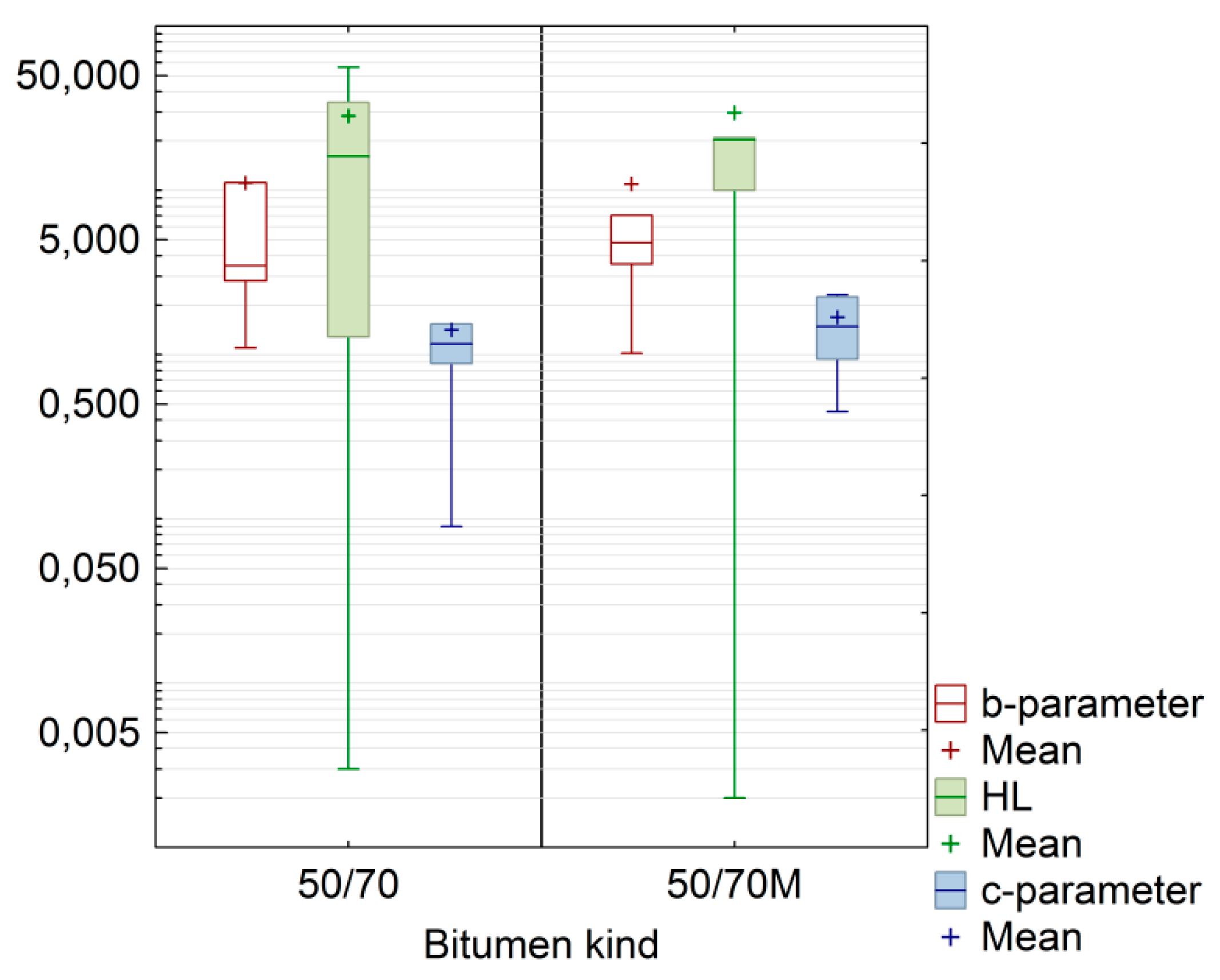

- Comparative analysis of foam distribution function parameters indicates that the presence of FT wax stabilises the foam decay rate over time.

- The G*/sin(δ) parameter is particularly sensitive to bitumen temperature and air pressure changes. Regardless of the bitumen type, G*/sin(δ) increased considerably after foaming, compared to the non-foamed reference bitumen.

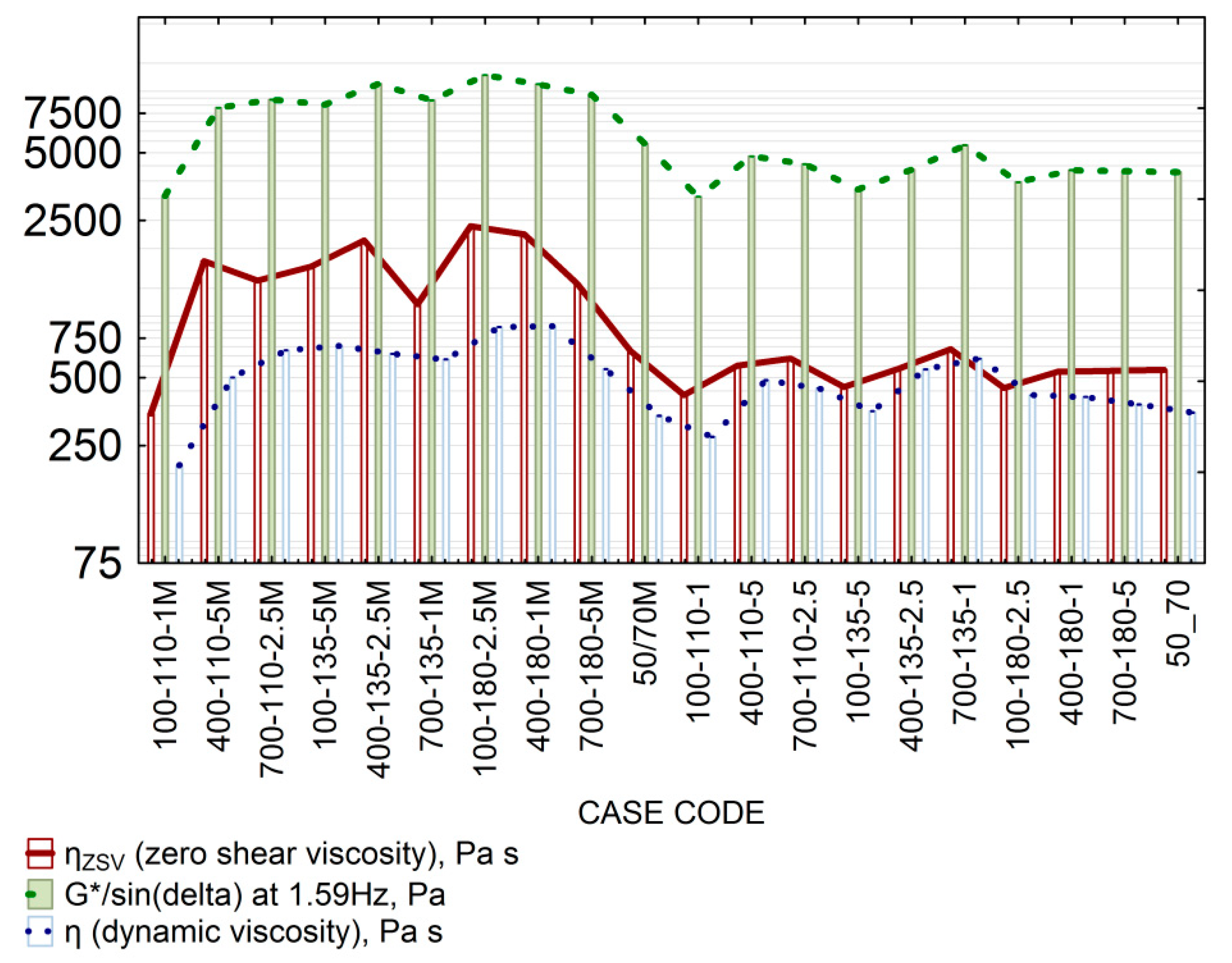

- Significant differences were observed between dynamic viscosity and zero shear viscosity at the test temperature of 60 °C. The largest differences were found in bitumen 50/70 M due to the presence of crystallites of the synthetic wax.

- The foaming process causes a horizontal shift of the Black curve to lower values of phase angle δ. The same characteristics are exhibited by road bitumen subjected to simulated ageing.

- The significance of the adopted mathematical models of bitumen rheological performance indicates that foaming strongly affects rheological parameters of the control bitumen.

- Evaluation of the increase in stiffness of the bitumen after foaming, using the ageing index, revealed that foaming increases bitumen viscosity. This suggests that the foaming process distillates the oil fractions from the bitumen. The process intensifies with increasing temperature, water amount and air pressure.

- A certain singularity was identified in bitumen behaviour for the 100-110-1.0 combination, regardless of the bitumen type. For a given combination of the foaming apparatus settings, a stiffness decline was recorded, attributed to the presence of air bubbles in the bitumen, which at the negligible impact of ageing caused an increase in bitumen susceptibility to shear.

- The fractional experimental design considerably facilitates the optimisation of foaming parameters. Optimisation in terms of water alone does not guarantee good results. The findings in this study reveal that the foam distribution changes noticeably also with air pressure and temperature change, which may lead to an adjustment of the amount of water during foaming.

- The best foaming parameters for bitumen 50/70 were obtained for the 400-145-2.5 combination. The best combination for bitumen 50/70 M was 400-135-2.5.

- The optimisation results at the adopted utility function level of about 0.5 indicate that bitumen 50/70 M had a lower but acceptable expansion compared to bitumen 50/70. Bitumen 50/70 M had a longer and more stable foam decay rate and G*/sin(δ) that was 2.23 times higher than that for bitumen 50/70. This level of stiffness will have a beneficial effect on the resistance to permanent deformations in the mixtures produced with this bitumen. These results were obtained for the low ageing index in the range 1.7–1.9.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, Y.R. Modeling of Asphalt Concrete; ASCE Press: Reston, VA, USA; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Stefańczyk, B.; Mieczkowski, S. Mieszanki Mineralno−Asfaltowe: Wykonawstwo i Badania; WKŁ: Warsaw, Poland, 2009. (In Polish) [Google Scholar]

- Buczyński, P.; Iwański, M. Complex modulus change within the linear viscoelastic region of the mineral−Cement mixture with foamed bitumen. Constr. Build. Mater. 2018, 172, 52–62. [Google Scholar] [CrossRef]

- Hailesilassie, B.W.; Hugener, M.; Partl, M.N. Influence of foaming water content on foam asphalt mixtures. Constr. Build. Mater. 2015, 85, 65–77. [Google Scholar] [CrossRef]

- Jenkins, K.J.; de Groot, J.L.A.; van de Ven, M.F.C.; Molenaar, A. Half−warm foamed bitumen treatment, a new process. In Proceedings of the 7th Conference on Asphalt Pavements for Southern Africa, August–September 1999. [Google Scholar]

- Chomicz-Kowalska, W.; Gardziejczyk, M.; Iwański, M. Analysis of IT−CY stiffness modulus of foamed bitumen asphalt concrete compacted at 95 °C. Procedia Eng. 2017, 172, 550–559. [Google Scholar] [CrossRef]

- Jenkins, K.J. Mix Design Considerations for Cold and Half-Warm Bituminous Mixes with Emphasis on Foamed Bitumen. Ph.D. Thesis, Department of Civil Engineering, Faculty of Engineering, University of Stellenbosch, Stellenbosch, South Africa, 2000. [Google Scholar]

- Ozturk, H.I.; Kutay, M.E. Novel Testing Procedure for Assessment of Quality of Foamed Warm Mix Asphalt Binders. J. Mater. Civil Eng. 2014, 26, 04014042. [Google Scholar] [CrossRef]

- He, G.; Wong, W. Decay properties of the foamed bitumens. Constr. Build. Mater. 2006, 20, 866–877. [Google Scholar] [CrossRef]

- Saleh, M. Characterisation of Foam Bitumen Quality and the Mechanical Properties of Foam Stabilised Mixes; University of Canterbury Research Repository: Christchurch, New Zealand, 2006. [Google Scholar]

- Woszuk, A.; Zofka, A.; Bandura, L.; Franus, W. Effect of zeolite properties on asphalt foaming. Constr. Build. Mater. 2017, 139, 247–255. [Google Scholar] [CrossRef]

- Iwański, M.; Chomicz-Kowalska, A.; Maciejewski, K. Application of synthetic wax for improvement of foamed bitumen parameters. Constr. Build. Mater. 2015, 83, 62–69. [Google Scholar] [CrossRef]

- Brainov, E.N. Formation and properties of bituminous foams. Chem. Technol. Fuels Oils 1990, 26, 544–548. [Google Scholar] [CrossRef]

- Martinez-Arguelles, G.; Giustozzi, F.; Crispino, M.; Flintsch, G.W. Investigating physical and rheological properties of foamed bitumen. Constr. Build. Mater. 2014, 72, 423–433. [Google Scholar] [CrossRef]

- Standard Specification for Performance-Graded Asphalt Binder; AASHTO M 320-05; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2005.

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G. Structuring role of F−T synthetic wax in bitumen. Bull. Pol. Acad. Sci. Tech. Sci. 2014, 62, 525–534. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G. Optimization of the Synthetic Wax Content on Example of Bitumen 35/50. Procedia Eng. 2013, 57, 414–423. [Google Scholar]

- Sunarjono, S. The Infuence of Foamed Bitumen Characteristic on Cold-Mix Asphalt Properties. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2008. [Google Scholar]

- Bitumen and Bituminous Binder—Determination of Complex Shear Modulus and Phase Angle—Dynamic Shear Rheometer; PN-EN 13302-09; PKN: Warsaw, Poland, 2009.

- Morea, F.; Zerbino, R.; Agnusdei, J. Improvements on asphalt mixtures rutting performance characterization by the use of low shear viscosity. Mater. Struct. 2013, 46, 267–276. [Google Scholar] [CrossRef]

- Bitumen and Bituminous Binder—Determination of Complex Shear Modulus and Phase Angle; PN-EN 14770-12; PKN: Warsaw, Poland, 2012.

- Superpave Asphalt Mixture Design & Analysis (NATC−SP 101); FHWA-SA-95-003; National Technical Information Service: Springfield, VA, USA, 1995.

- Petersen, J.C. Binder Characterization and Evaluation; Strategic Highway Research Program (U.S.); National Research Council: Washington, DC, USA, 1994. [Google Scholar]

- Lazić, Ž.R. Design of Experiments in Chemical Engineering: A Practical Guide; Wiley-VCH: Weinheim, Germany, 2004. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Newcomb, D.E.; Arambula, E.; Yin, F.; Zhang, J.; Bhasin, A.; Li, W.; Arega, Z. Properties of Foamed Asphalt for Warm Mix Asphalt Application; Transportation Research Board: Washington, DC, USA, 2015. [Google Scholar]

- Abreu, L.S.F.; Oliveira, J.R.M.; Silva, H.M.R.D.; Palha, D.; Fonseca, S.V. Suitability of different foamed bitumens for warm mix asphalts with increasing recycling rates. Constr. Build. Mater. 2017, 142, 342–353. [Google Scholar] [CrossRef]

- Saleh, M.F. Effect of rheology on the bitumen foamability and mechanical properties of foam bitumen stabilised mixes. Int. J. Pavement Eng. 2007, 8, 99–110. [Google Scholar] [CrossRef]

- Taylor, N.; Kuyatt, C.E. Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results; NIST Technical Note 1297; National Institute of Standards and Technology: Washington, DC, USA, 1994. [Google Scholar]

- Airey, G. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Iwański, M.; Cholewińska, M.; Mazurek, G. Viscoelastic Properties of Polymer Modified Bitumen in Warm Mix Asphalt Technology in Terms of Ageing. Procedia Eng. 2017, 172, 401–408. [Google Scholar]

- Sybilski, D. Zastosowanie Metody SHRP do Oocenay Nawierzchni w Polsce Metodami SHRP [Application of SHRP Methods for Evalutation of Road Pavements in Poland]; IBDiM: Warsaw, Poland, 2000. (In Polish) [Google Scholar]

- Anderson, A.; Kennedy, T.W. Development of SHRP binder specification. J. Assoc. Asph. Paving Technol. 1993, 62, 481–501. [Google Scholar]

- Anderson, A. Understanding the MSCR Test and Its Use in the PG Asphalt Binder Specyfication; Asphalt Institute: Lexington, KY, USA, 2011. [Google Scholar]

- Król, J.B.; Kowalski, K.J.; Radziszewski, S.; Sarnowski, M. Rheological behaviour of n-alkane modified bitumen in aspect of Warm Mix Asphalt technology. Constr. Build. Mater. 2015, 93, 703–710. [Google Scholar]

- Gonzalez, A.A. An Experimental Study of the Deformational and Performance Characteristics of Foamed Bitumen Stabilized Pavement. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2009. [Google Scholar]

- Silva, H.M.R.D.; Oliveira, J.R.M.; Peralta, J.; Zoorob, S.E. Optimization of warm mix asphalts using different blends of binders and synthetic paraffin wax contents. Constr. Build. Mater. 2010, 24, 1621–1631. [Google Scholar] [CrossRef]

- Klabińska, M.; Piłat, J. Reologia Asfaltów i mas Mineralno-Asfaltowych [Rheology of Bitumen and Bituminous Mixture]; WKŁ: Warsaw, Poland, 1982. (In Polish) [Google Scholar]

- Wirtgen Group. Cold Recycling Technology; Wirtgen GmbH: Windhagen, Germany, 2012. [Google Scholar]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 14, 214–219. [Google Scholar] [CrossRef]

- Asphalt Academy. Technical Guideline: Bitumen Stabilized Materials; Asphalt Academy: Cape Town, South Africca, 2009. [Google Scholar]

- Muthen, K.M.; Lewis, R.M.; Vos, R.M. Foamed asphalt mixes, mix design procedure. Proceedings of 7th Conference on Asphalt Pavements for Southern Africa, Pretoria, South Africa, August–September 1999. [Google Scholar]

- Milton, L.J.; Earland, M. Design Guide and Specification for Structural Maintenance of Highway Pavements by Cold In-Situ Recycling; TRL386; Transport Research Laboratory: Berkshire, UK, 1999. [Google Scholar]

- Leek, C.; Jameson, G. Review of Foamed Bitumen Stabilisation Mix Design Method; Austroads: Sydney, Australia, 2011. [Google Scholar]

| Parameter | u·m | Standard | Results | |

|---|---|---|---|---|

| 50/70 | 50/70 M (2.5% FT wax) | |||

| Penetration | 0.1 mm | PN-EN 1426 | 65 | 58 |

| Softening point | °C | PN-EN 1427 | 49 | 73 |

| G*/sinδ at 60 °C and 1.59 Hz | Pa | PN-EN 14770 | 4093 | 5483 |

| η at 60 °C | Pa·s | PN-EN 12596 | 350 | 339 |

| ηZSV at 60 °C | Pa·s | CEN/TS 15325 | 542 | 656 |

| Standard Run | 3(3−1) Fractional Factorial Design, 1 Block, 9 Runs | ||

|---|---|---|---|

| Air Pressure, kPa | Temperature, °C | Water Proportion, % | |

| 1 | 100 | 110 | 1 |

| 4 | 400 | 110 | 5 |

| 7 | 700 | 110 | 2.5 |

| 2 | 100 | 145 | 5 |

| 5 | 400 | 145 | 2.5 |

| 8 | 700 | 145 | 1 |

| 3 | 100 | 180 | 2.5 |

| 6 | 400 | 180 | 1 |

| 9 | 700 | 180 | 5 |

| Method | Source of Uncertainty | Distribution of Measurands | Partial Uncertainty |

|---|---|---|---|

| Original Method (prototype) | Sensor resolution (±5 µm at the measured distance of 50 cm) | rectangular | 0.001 mm |

| Accuracy class (0.05% measured quantity + 0.01% measurement range) | rectangular | 0.104 mm | |

| Sensor repeatability of measurement (±15 µm at the measured distance of 50 cm) | rectangular | 0.009 mm | |

| Linearity error (±20 µm at the measured distance of 50 cm) | rectangular | 0.004 mm | |

| Amplitude of readings due to measured sample surface irregularity based on the max RMSE of the estimated regression functions (read for 700-110-2.5) | normal | 1.87 mm | |

| Expanded Uncertainty (k = 2) of ER U(ER) = 0.51 | |||

| Classical Method | Measuring rod resolution (every 5 ER units in the calibrated container) | rectangular | 1.44 (ER) |

| Expanded Uncertainty (k = 2) of ER U(ER) = 2.9 | |||

| CASE | Bitumen Type | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 50/70 (a = 0.6 cm) | 50/70 M (a = 0.6 cm) | |||||||||

| b50/70, cm | HL50/70, s | c50/70 | RMSE(b50/70), cm | R2 | b50/70M, cm | HL50/70M, s | c50/70M | RMSE(b50/70M), cm | R2 | |

| 100-110-1 | 1.86 | 34.25 | 2.74 | 0.48 | 0.99 | 1.58 | 135.22 | 1.10 | 0.28 | 0.97 |

| 100-145-5 | 3.33 | 56.13 | 1.54 | 1.38 | 0.98 | 4.80 | 20.48 | 0.94 | 0.97 | 0.99 |

| 100-180-2.5 | 3.48 | 0.001 | 0.09 | 0.91 | 0.61 | 35.00 | 0.002 | 0.45 | 1.50 | 0.65 |

| 400-110-5 | 2.82 | 16.99 | 1.16 | 0.56 | 0.98 | 3.56 | 44.79 | 1.66 | 1.19 | 0.98 |

| 400-145-2.5 | 11.18 | 16.14 | 1.50 | 1.58 | 0.98 | 5.77 | 20.95 | 2.32 | 1.40 | 0.98 |

| 400-145-2.5 (additional) | 12.42 | 15.05 | 1.50 | 1.68 | 0.98 | 5.62 | 22.41 | 2.21 | 1.65 | 0.99 |

| 400-145-2.5 (additional) | 11.01 | 15.89 | 1.53 | 1.84 | 0.97 | 5.52 | 19.02 | 2.32 | 1.45 | 0.98 |

| 400-180-1 | 1.10 | 123.00 | 0.90 | 1.04 | 0.78 | 1.02 | 14.08 | 4.37 | 0.40 | 0.65 |

| 700-110-2.5 | 35.0 | 0.20 | 0.82 | 1.54 | 0.93 | 4.68 | 20.37 | 1.48 | 1.87 | 0.97 |

| 700-145-1 | 35.0 | 1.28 | 0.88 | 1.42 | 0.98 | 35.00 | 0.78 | 0.63 | 1.50 | 0.98 |

| 700-180-5 | 5.89 | 7.20 | 3.10 | 0.98 | 0.87 | 7.03 | 10.00 | 2.25 | 0.46 | 0.99 |

| Regression Model Parameters | Bitumen Type | |||||||

|---|---|---|---|---|---|---|---|---|

| Bitumen 50/70 | Bitumen 50/70 M (2.5% FT wax) | |||||||

| Variable—ER R2 = 0.92 RMSE(ER) = 4.0 | Variable—HL R2 = 0.73 RMSE(HL) = 5.8 s | Variable—ER R2 = 0.83 RMSE(ER) = 1.3 | Variable—HL R2 = 0.98 RMSE(HL) = 8.9 s | |||||

| Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | Coefficient | p-Value | |

| Mean/Const. | −168.356 | 0.001611 | −107.349 | 0.080420 | −294.983 | <0.0001 | 638.2769 | 0.000074 |

| (1) PRESSURE (L **) | −0.072 | 0.003419 | −0.026 | 0.350907 | −0.066 | <0.0001 | −0.0022 | 0.960100 |

| PRESSURE (Q ***) | 0.000 | <0.0001 | −0.000 | 0.466805 | 0.000 | <0.0001 | −0.0002 | 0.017506 |

| (2) TEMP (L) | 2.670 | 0.000712 | 2.450 | 0.010745 | 4.632 | <0.0001 | −6.0151 | 0.001159 |

| TEMP (Q) | −0.010 | 0.000366 | −0.009 | 0.008153 | −0.016 | <0.0001 | 0.0159 | 0.005498 |

| (3) WATER (L) | 15.446 | 0.001344 | −25.045 | 0.000603 | −20.245 | <0.0001 | −35.7525 | 0.001552 |

| WATER (Q) | −3.174 | 0.000239 | 4.477 | 0.000277 | 3.118 | <0.0001 | 3.3096 | 0.031701 |

| Regression Model Parameters | Bitumen Type | |||

|---|---|---|---|---|

| Bitumen 50/70 | Bitumen 50/70 M (2.5% FT Wax) | |||

| Regression Coefficients R2 = 0.72 RMSE(G*/sin(δ)) = 137.3 Pa | Regression Coefficients R2 = 0.99 RMSE(G*/sin(δ)) = 128.3 Pa | |||

| Coefficient | p-Value | Coefficient | p-Value | |

| Mean/Const. | −935.887 ** | 0.823416 ** | −18160.0 | 0.000000 |

| (1) PRESSURE (L) | 5.165 | 0.024038 | 8.8 | 0.000000 |

| PRESSURE (Q) | −0.004 ** | 0.134533 ** | −0.001 | 0.000132 |

| (2) TEMP (L) | 61.657 ** | 0.305960 ** | 214.8 | 0.000001 |

| TEMP (Q) | −0.220 | 0.0485013 | −0.5 | 0.000022 |

| (3) WATER (L) | −177.080 ** | 0.637377 ** | 3270.2 | 0.000000 |

| WATER (Q) | 24.229 ** | 0.686761 ** | −432.0 | 0.000000 |

| Regression Model Parameters | Bitumen Type | |||

|---|---|---|---|---|

| Bitumen 50/70 | Bitumen 50/70 M (2.5 FT Wax) | |||

| Variable IS R2 = 0.74 RMSE(IS) = 0.17 | Variable IS R2 = 0.96 RMSE(IS) = 0.14 | |||

| Coefficient | p-Value | Coefficient | p-Value | |

| Mean/Constant | −4.64698 | 0.020737 | −2.49385 ** | 0.112468 ** |

| (1) PRESSURE (L) | 0.00240 | 0.014726 | 0.00014 ** | 0.840934 ** |

| PRESSURE(Q) | 0 | 0.053273 ** | 0 | 0.164181 ** |

| (2) TEMP (L) | 0.07574 | 0.009483 | 0.02506 | 0.048073 |

| TEMP (Q) | −0.00026 | 0.008850 | −0.00001 ** | 0.875894 ** |

| (3) WATER (L) | 0.21186 ** | 0.195377 ** | 0.49955 | 0.003225 |

| WATER (Q) | −0.03816 ** | 0.149286 ** | −0.05180 | 0.035854 |

| Level | ER | HL, s | G*/sin(δ), Pa | IS |

|---|---|---|---|---|

| Low (0) | <8 [4,40,42] | ≤12 [4,43,44] | <2200 [34,35] | ≥4 [39] |

| High (1) | >15 [4,45] | ≥45 [4,45] | ≥2200 [34,35] | <1.5 [39] |

| Parameter | Bitumen Type | |

|---|---|---|

| Bitumen 50/70 | Bitumen 50/70 M | |

| Optimisation Outcome | 400 kPa-145 °C-2.5% | 400 kPa-135 °C-2.5% |

| ER | 25.3 | 9.6 |

| HL, s | 14.1 | 21 |

| G*/sin(δ), Pa | 4533 | 10108 |

| IS | 1.7 | 1.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iwański, M.; Mazurek, G.; Buczyński, P. Bitumen Foaming Optimisation Process on the Basis of Rheological Properties. Materials 2018, 11, 1854. https://doi.org/10.3390/ma11101854

Iwański M, Mazurek G, Buczyński P. Bitumen Foaming Optimisation Process on the Basis of Rheological Properties. Materials. 2018; 11(10):1854. https://doi.org/10.3390/ma11101854

Chicago/Turabian StyleIwański, Marek, Grzegorz Mazurek, and Przemysław Buczyński. 2018. "Bitumen Foaming Optimisation Process on the Basis of Rheological Properties" Materials 11, no. 10: 1854. https://doi.org/10.3390/ma11101854

APA StyleIwański, M., Mazurek, G., & Buczyński, P. (2018). Bitumen Foaming Optimisation Process on the Basis of Rheological Properties. Materials, 11(10), 1854. https://doi.org/10.3390/ma11101854