Influence of Beam Offset on Dissimilar Laser Welding of Molybdenum to Titanium

Abstract

1. Introduction

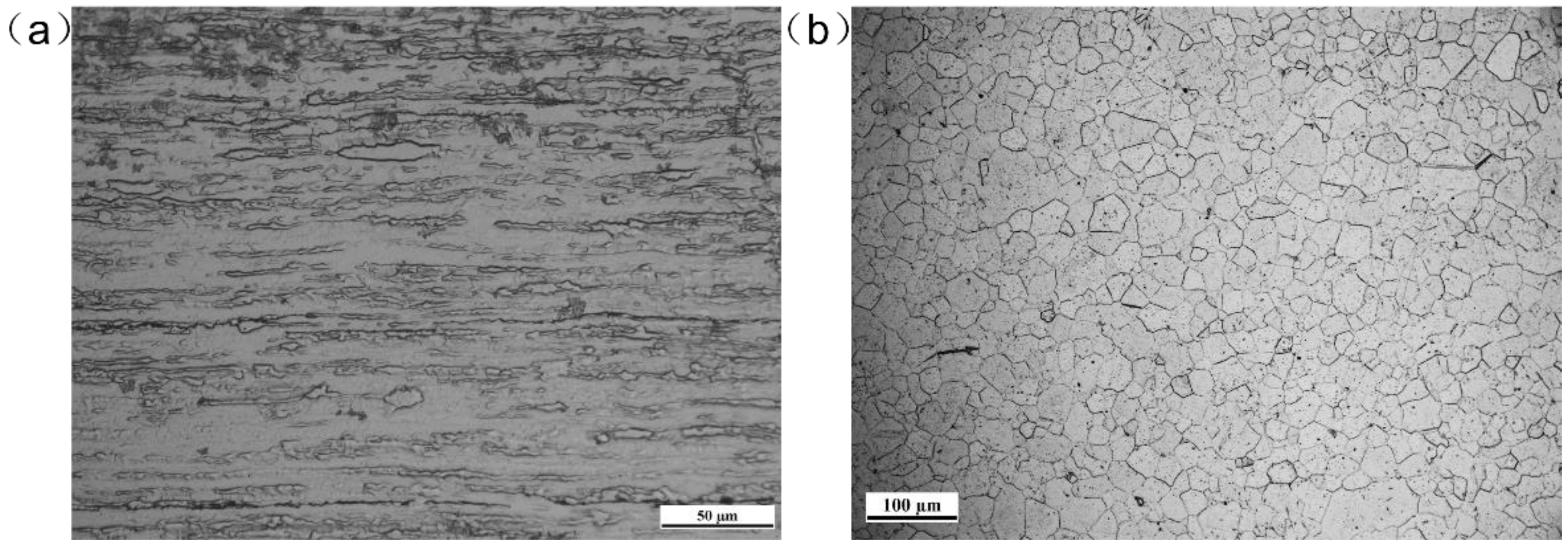

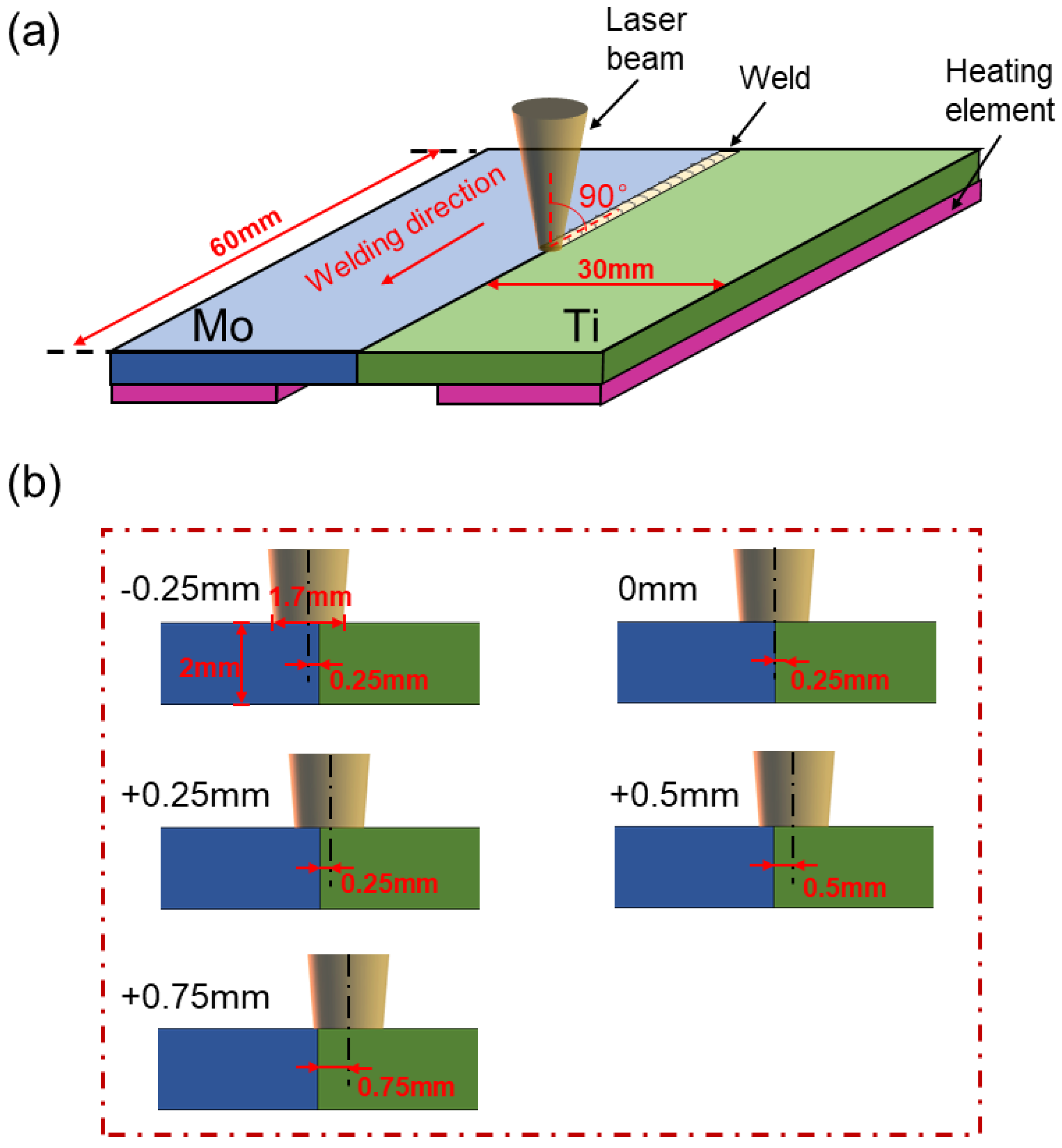

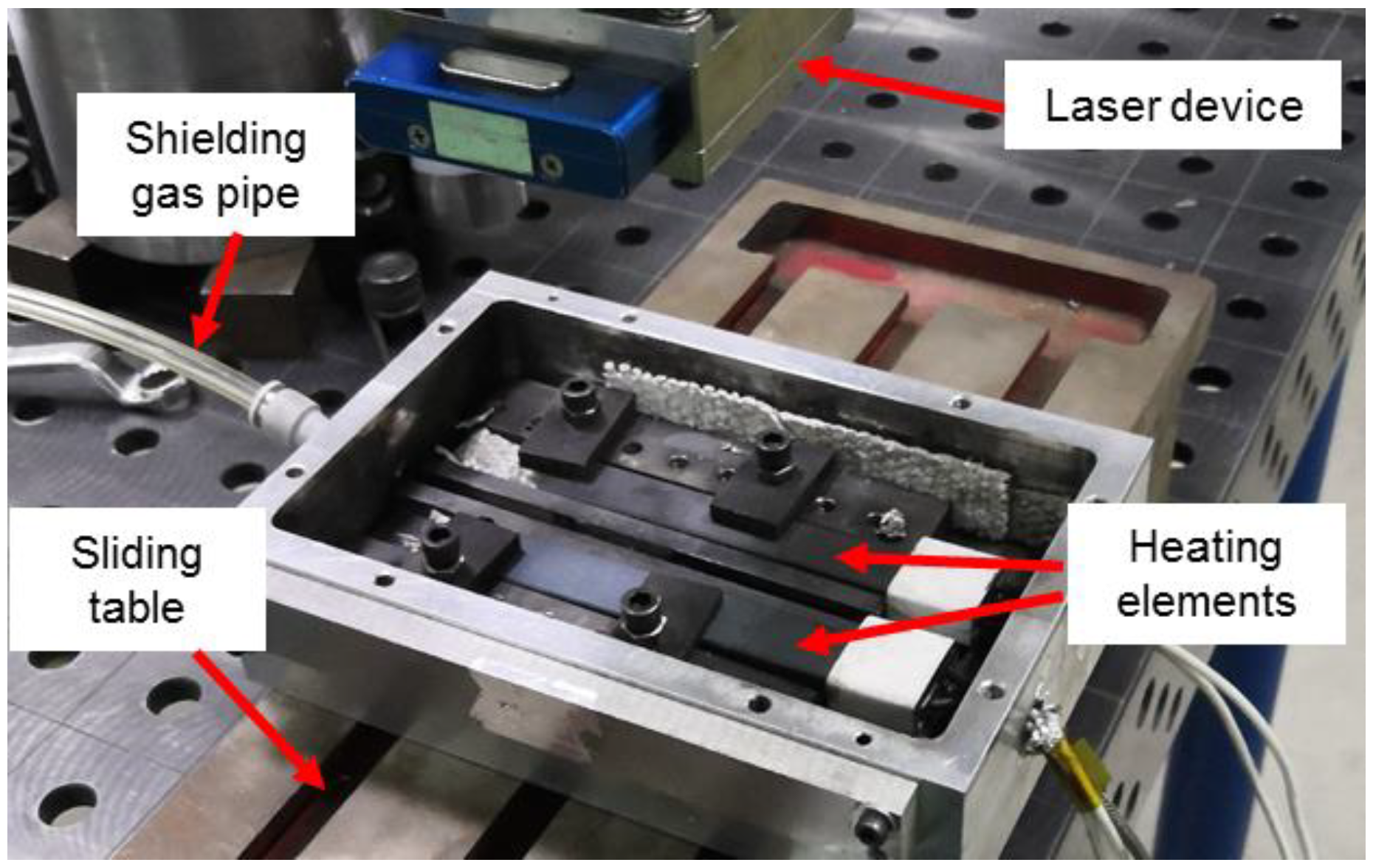

2. Experiment

3. Results and Discussion

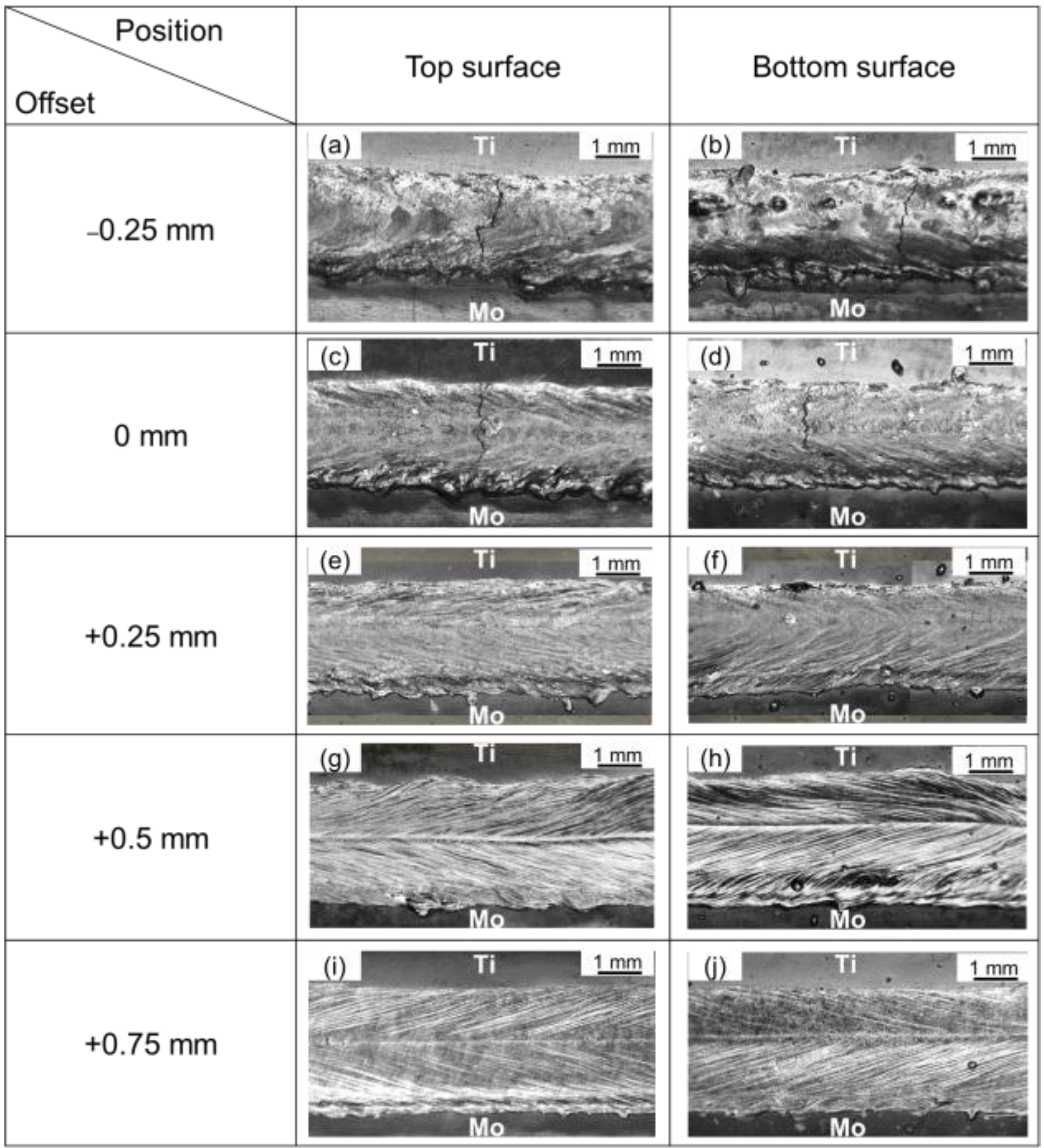

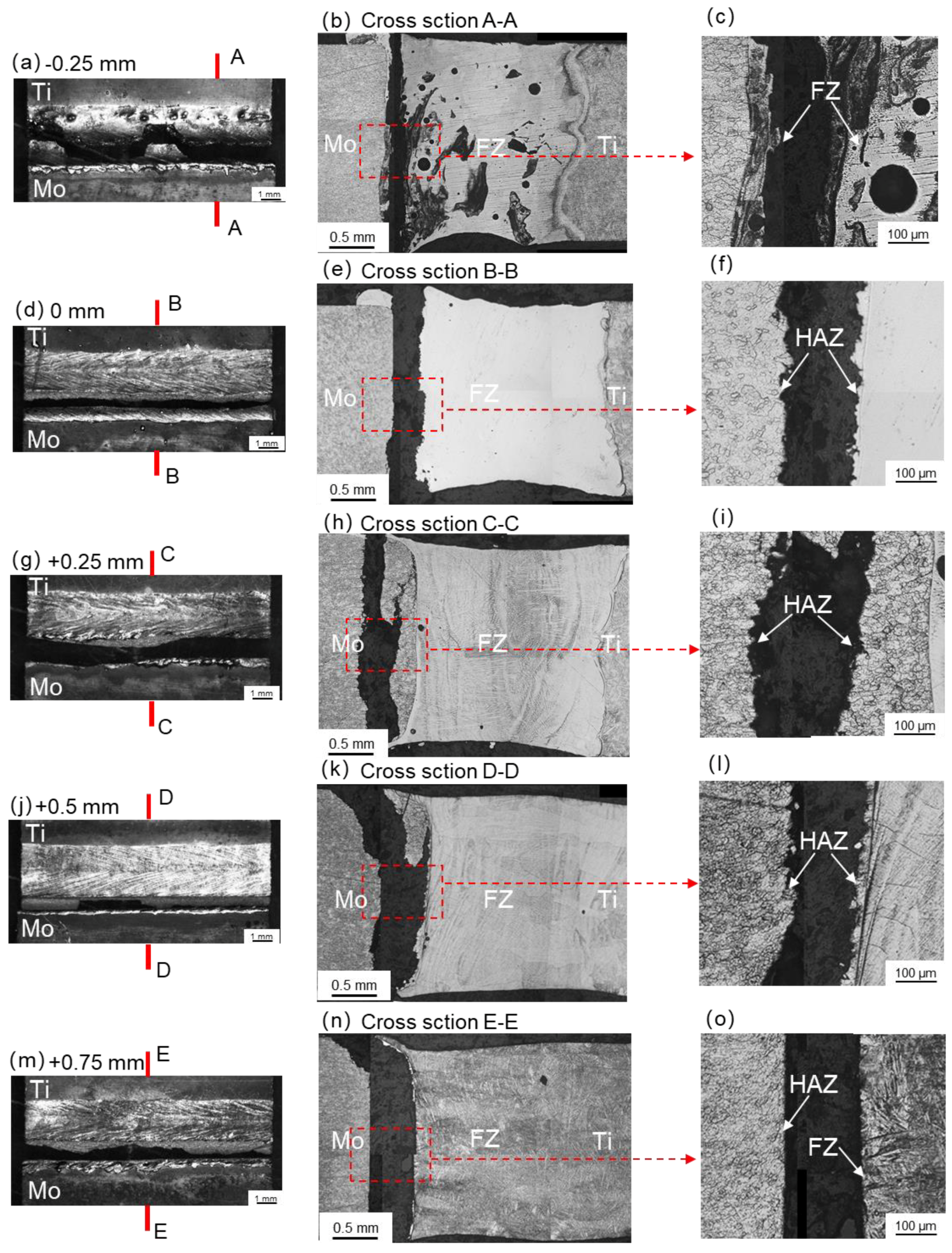

3.1. Surface Morphologies of Dissimilar Mo/Ti Joints

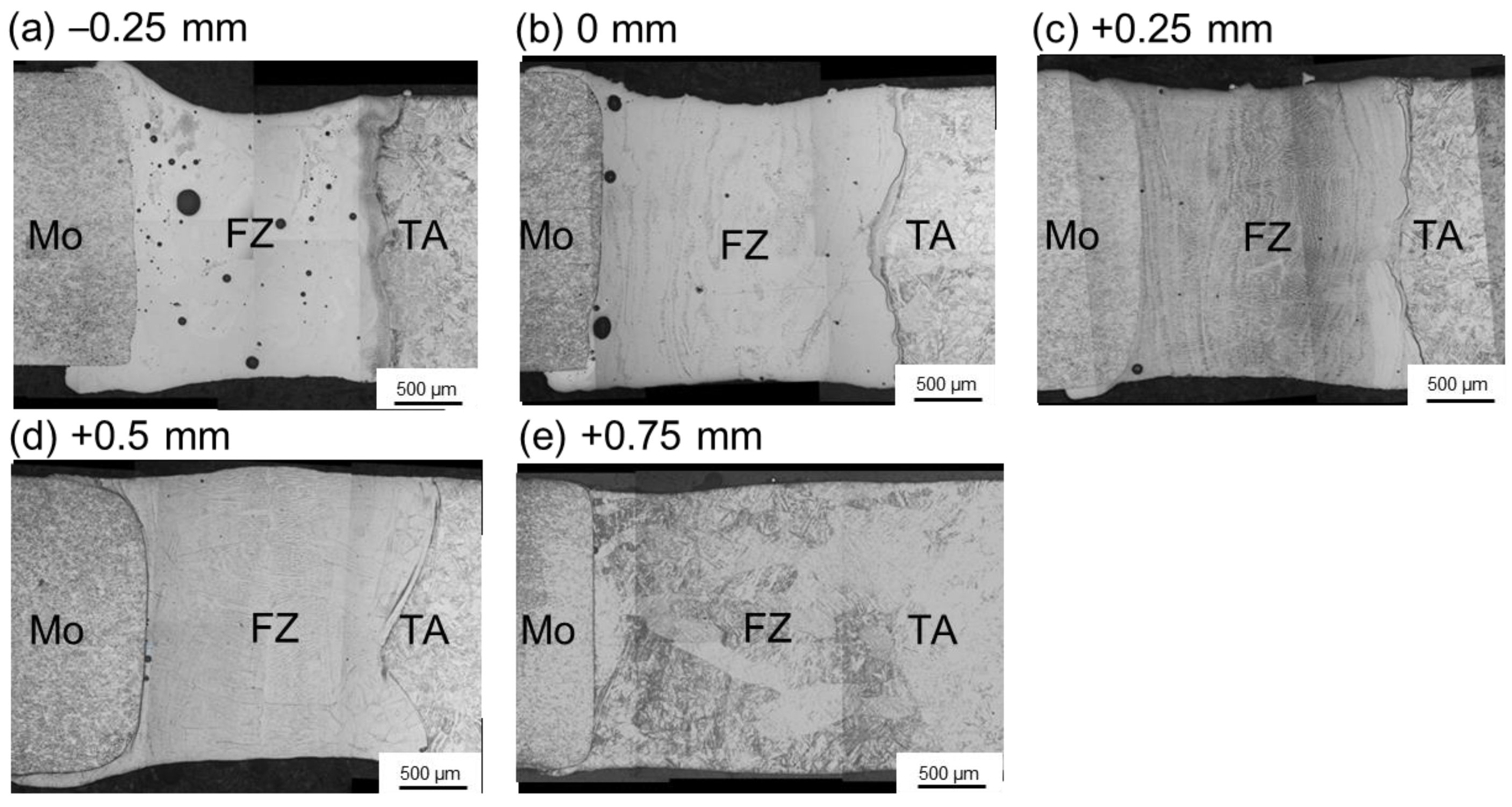

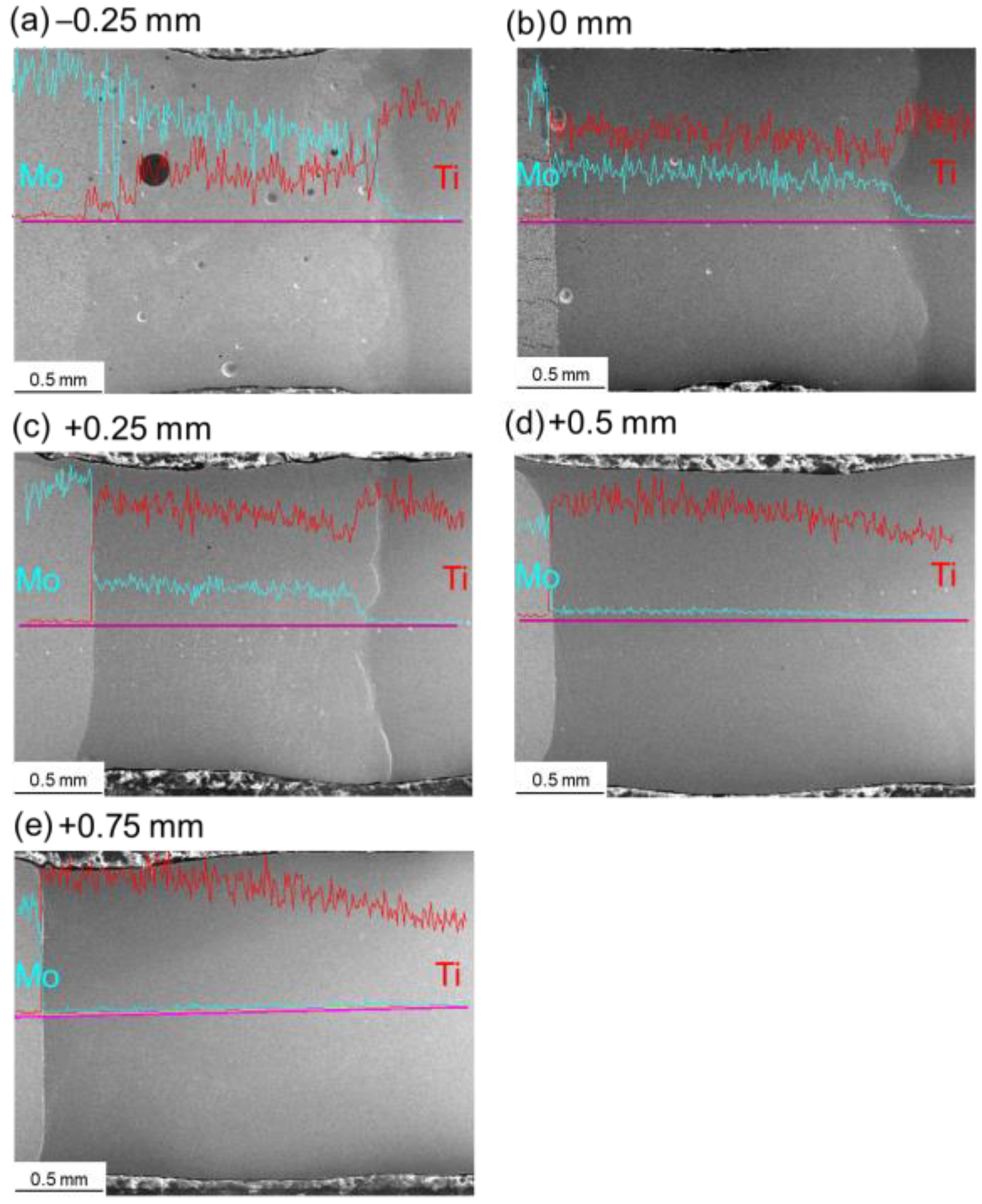

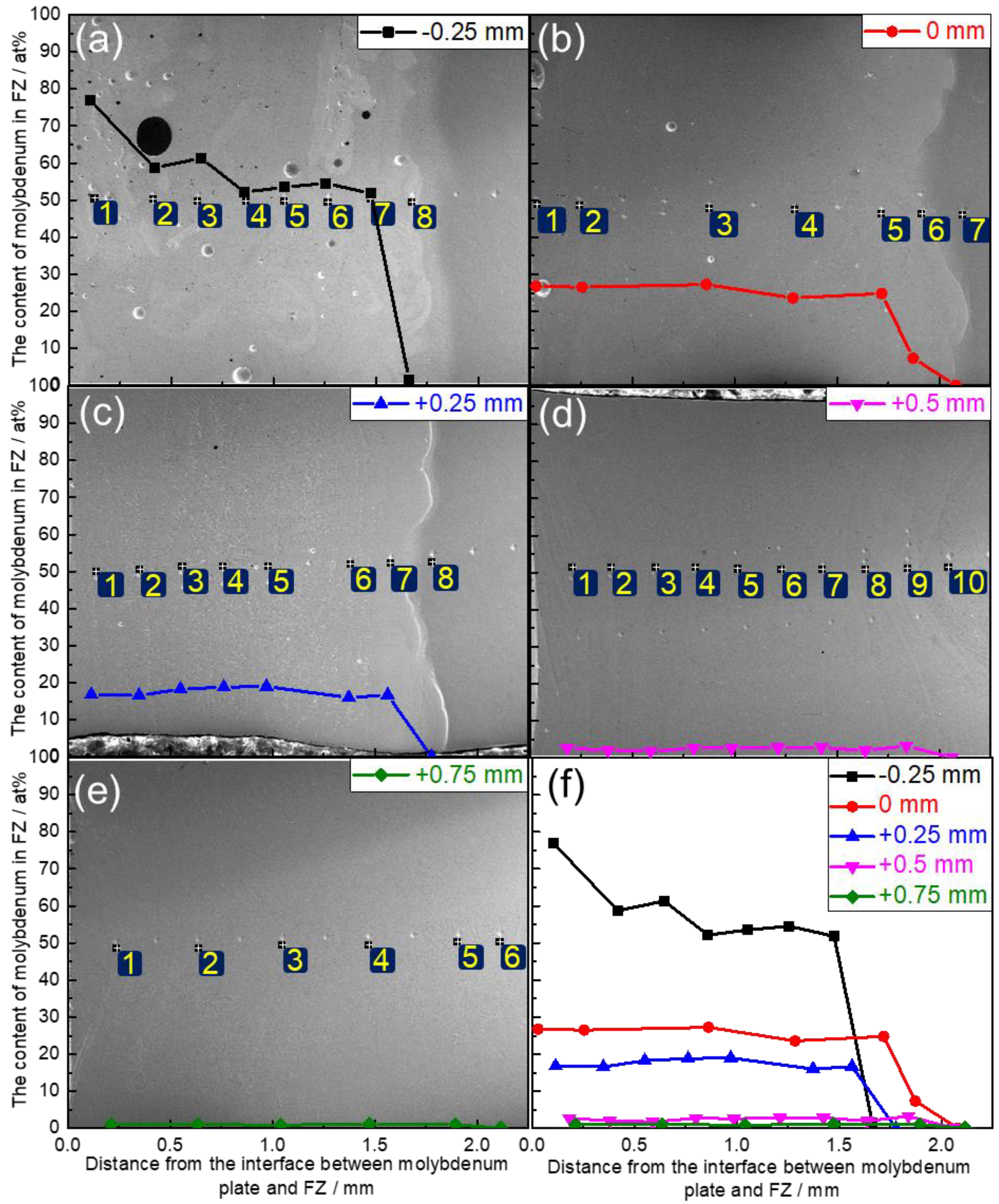

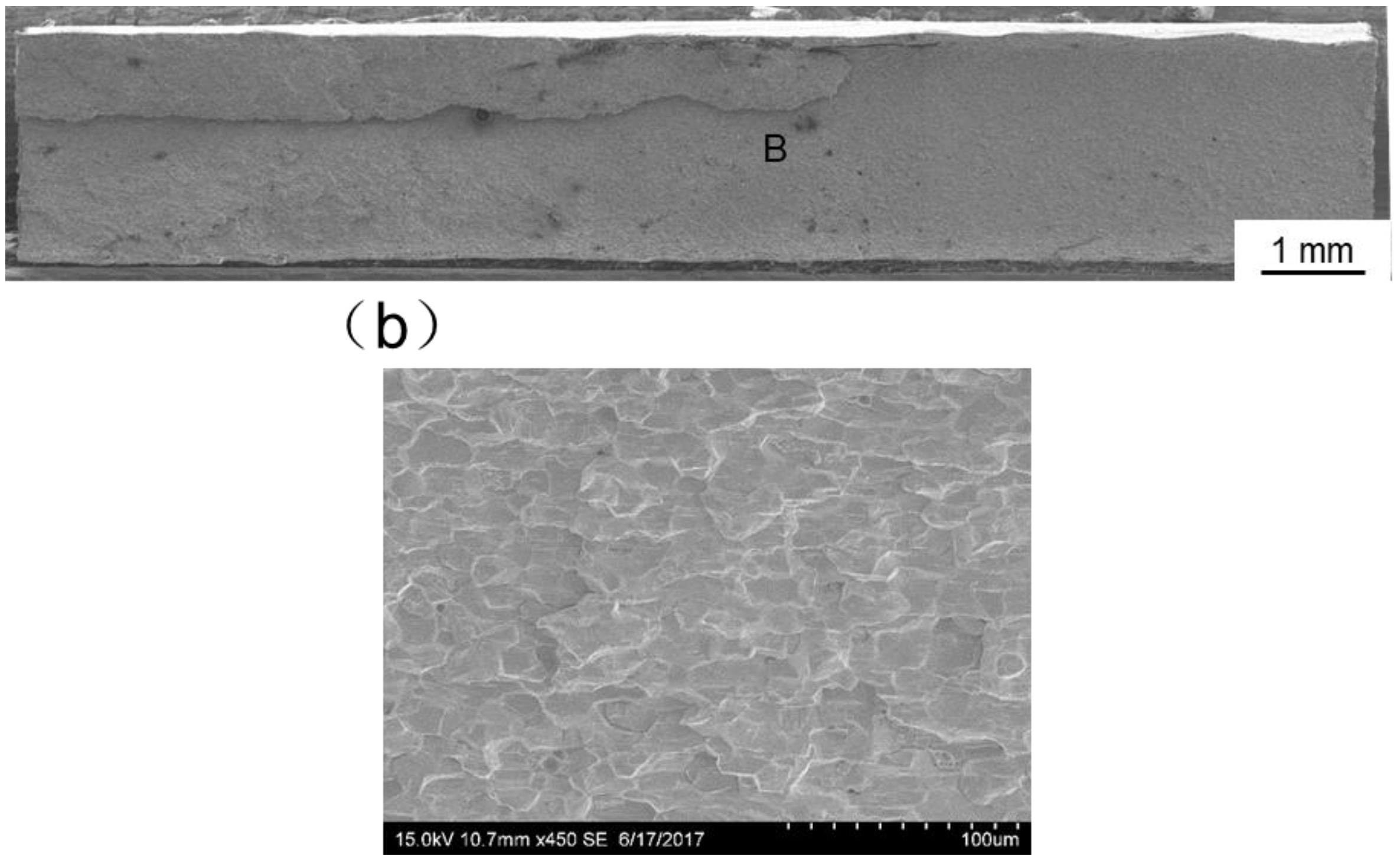

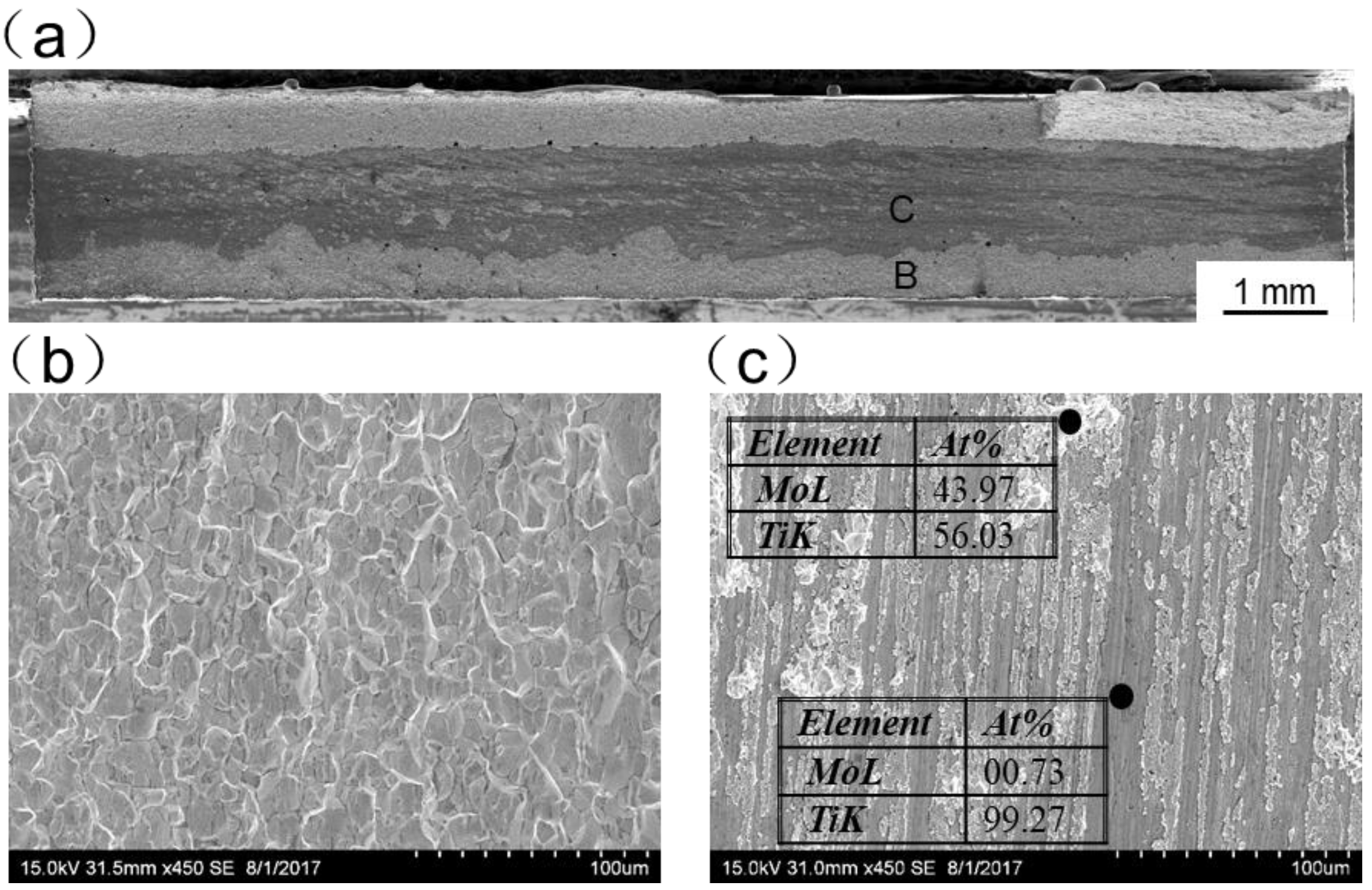

3.2. Microstructure and Element Distribution

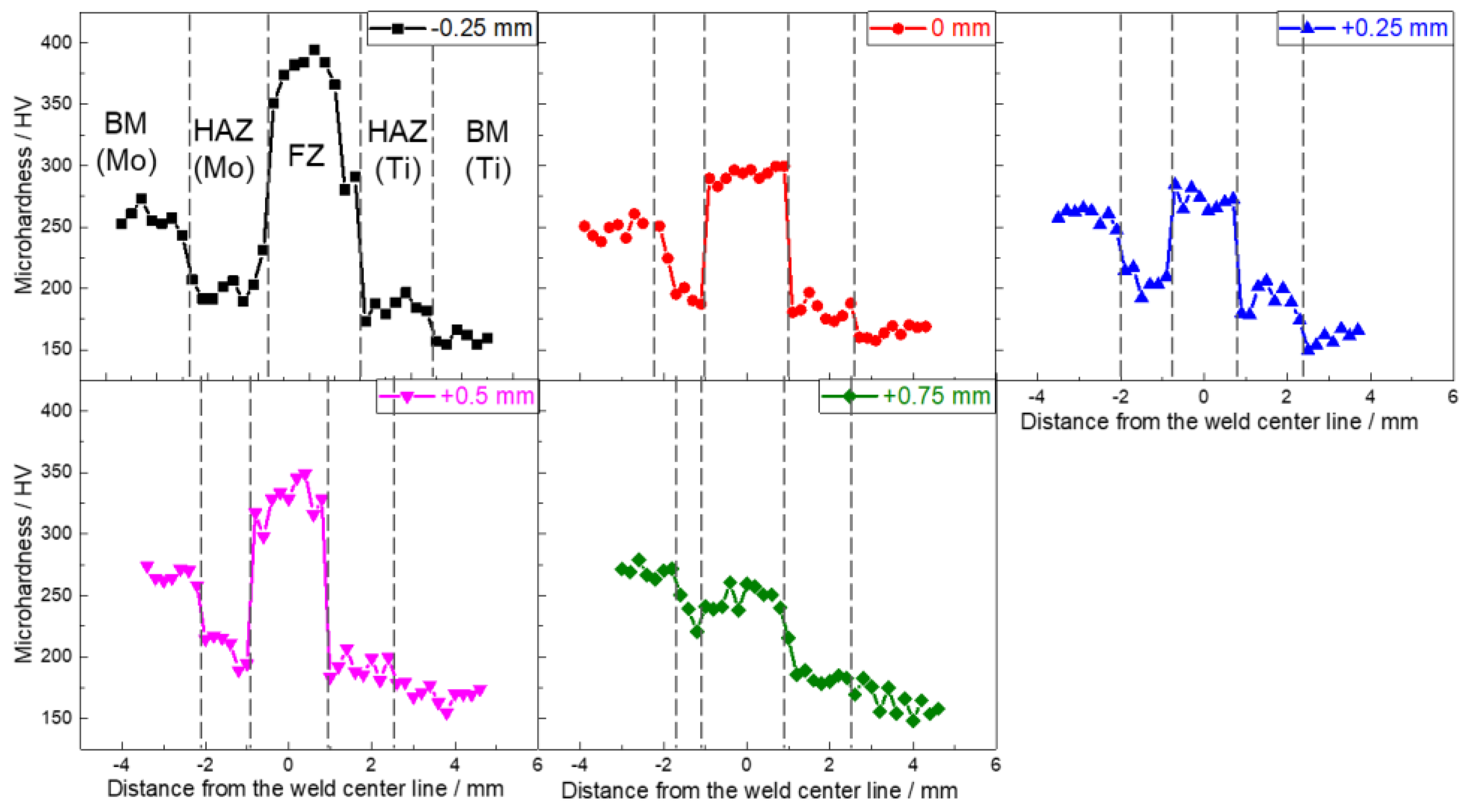

3.3. Microhardness

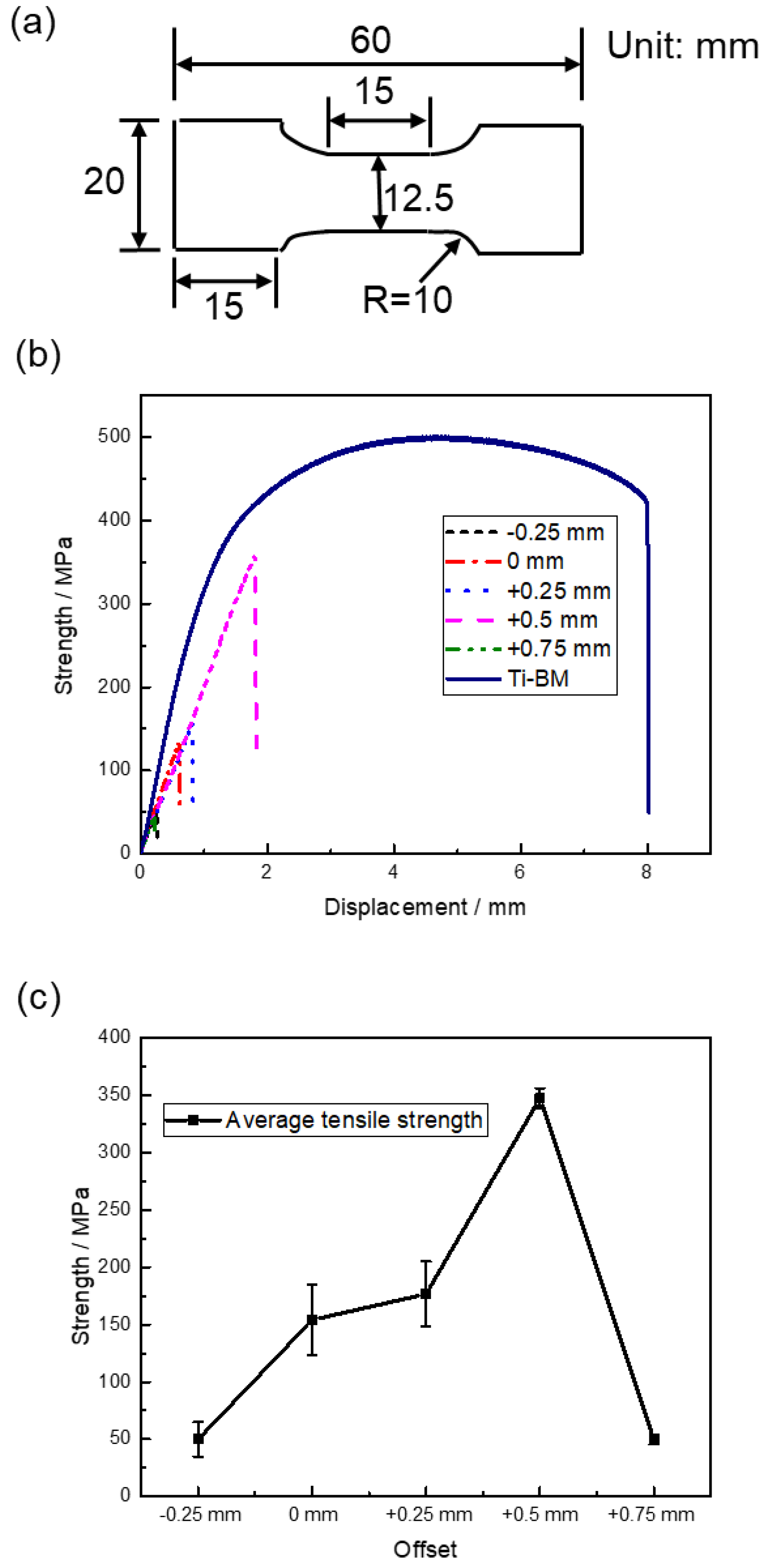

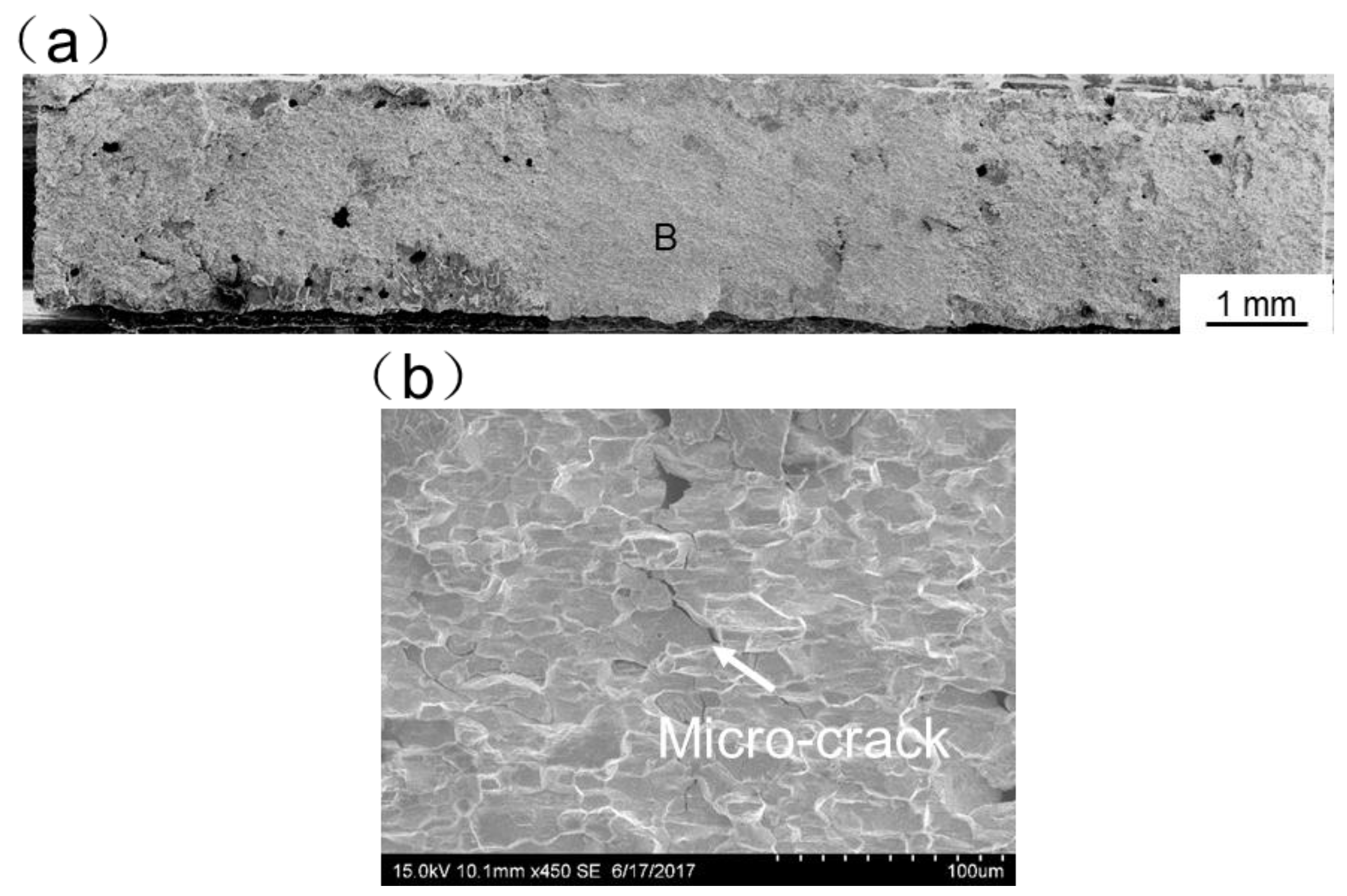

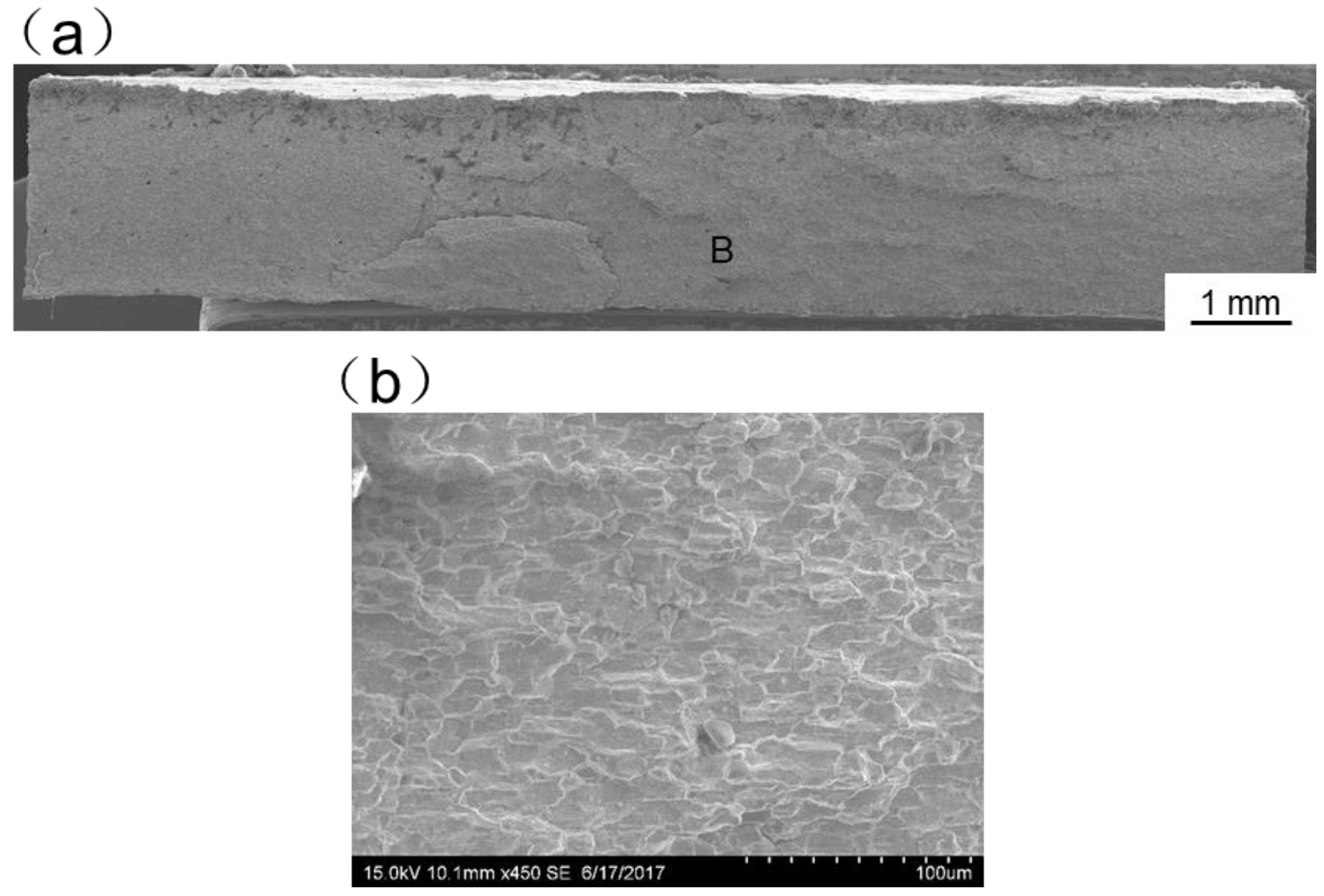

3.4. Tensile Strength and Fracture Observation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- ASM Handbok Volume 2: Properties and Selection: Nonferrous Alloys and Special Purpose Materials; ASM International: Geauga County, OH, USA, 1990.

- Schutz, R.W.; Watkins, H.B. Recent developments in titanium alloy application in the energy industry. Mater. Sci. Eng. A 1998, 243, 305–315. [Google Scholar] [CrossRef]

- Schutz, R.W.; Baxter, C.F.; Boster, P.L.; Fores, F.H. Applying titanium alloys in drilling and offshore production systems. JOM 2001, 53, 33–35. [Google Scholar] [CrossRef]

- Ambroziak, A. Friction welding of molybdenum to molybdenum and to other metals. Int. J. Refract. Met. Hard Mater. 2011, 29, 462–469. [Google Scholar] [CrossRef]

- Murray, J.L. Phase Diagrams of Binary Titanium Alloys; ASM International: Geauga County, OH, USA, 1987. [Google Scholar]

- Wesemann, I.; Hoffmann, A.; Mrotzek, T.; Martin, U. Investigation of solid solution hardening in molybdenum alloys. Int. J. Refract. Met. Hard Mater. 2010, 28, 709–715. [Google Scholar] [CrossRef]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Chang, C.T.; Shiue, R.K. Infrared brazing Ti–6Al–4V and Mo using the Ti–15Cu–15Ni braze alloy. Int. J. Refract. Met. Hard Mater. 2005, 23, 161–170. [Google Scholar] [CrossRef]

- Casalino, G.; Guglielmi, P.; Lorusso, V.D.; Mortello, M.; Peyre, P.; Sorgente, D. Laser offset welding of AZ31B magnesium alloy to 316 stainless steel. J. Mater. Process. Technol. 2017, 242, 49–59. [Google Scholar] [CrossRef]

- Tan, C.; Liu, F.; Sun, Y.; Chen, B.; Song, X.; Li, L.; Zhao, H.; Feng, J. Laser Brazing Characteristics of Al to Brass with Zn-Based Filler. J. Mater. Eng. Perform. 2018, 27, 3521–3531. [Google Scholar] [CrossRef]

- Tan, C.; Yang, J.; Zhao, X.; Zhang, K.; Song, X.; Chen, B.; Li, L.; Feng, J. Influence of Ni coating on interfacial reactions and mechanical properties in laser welding-brazing of Mg/Ti butted joint. J. Alloys Compd. 2018, 764, 186–201. [Google Scholar] [CrossRef]

- Du, C.; Wang, X.; Hu, L. Microstructure, mechanical properties and residual stress of a 2205DSS/Q235 rapidly formed LBW joint. J. Mater. Process. Technol. 2018, 256, 78–86. [Google Scholar] [CrossRef]

- Fellinger, J.; Citarella, R.; Giannella, V.; Lepore, M.; Sepe, R.; Czerwinski, M.; Herold, F.; Stadler, R.; the W7-X team. Overview of fatigue life assessment of baffles in Wendelstein 7-X. Fusion Eng. Des. 2018. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Zhang, B.; Zhang, B.; Wang, Y.; Feng, J. Microstructure Evolution and Embrittlement of Electron Beam Welded TZM Alloy Joint. Mater. Sci. Eng. A 2017, 700, 512–518. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, G.; Zhou, Y.; Li, S. Direct observation of keyhole characteristics in deep penetration laser welding with a 10 kW fiber laser. Opt. Express 2013, 21, 19997–20004. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-J.; Bai, Q.-L.; Ning, J.; Wang, A.; Yang, J.-N.; Yin, X.-Q.; Zhang, J.-X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 110, 35–50. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Shao, X.; Gong, S.; Xiao, J. Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: Local evaporation, plume swing and gas entrapment into porosity. Opt. Lasers Eng. 2016, 82, 28–40. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.Y.; Song, X.G.; Tan, C.W.; He, Z.Z.; Huang, Y.X.; Feng, J.C. Influence of laser offset on laser welding-brazing of Al/brass dissimilar alloys. J. Alloys Compd. 2017, 717, 78–92. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Li, W.; Shao, X.; Gong, S. Efficient multiple time scale method for modeling compressible vapor plume dynamics inside transient keyhole during fiber laser welding. Opt. Laser Technol. 2016, 77, 203–214. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Campanelli, S.L. Ytterbium fiber laser welding of Ti6Al4V alloy. J. Manuf. Process. 2015, 20, 250–256. [Google Scholar] [CrossRef]

- Boccarusso, L.; Arleo, G.; Astarita, A.; Bernardo, F.; De Fazio, P.; Durante, M.; Memola Capece Minutolo, F.; Sepe, R.; Squillace, A. A new approach to study the influence of the weld bead morphology on the fatigue behaviour of Ti–6Al–4V laser beam-welded butt joints. Int. J. Adv. Manuf. Technol. 2017, 88, 75–88. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, Y.; Hao, K.; Chen, Y. Cracking in dissimilar laser welding of tantalum to molybdenum. Opt. Laser Technol. 2018, 102, 54–59. [Google Scholar] [CrossRef]

- Sun, J.; Yan, Q.; Gao, W.; Huang, J. Investigation of laser welding on butt joints of Al/steel dissimilar materials. Mater. Des. 2015, 83, 120–128. [Google Scholar] [CrossRef]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J. Interfacial microstructure and mechanical property of Ti6Al4V/A6061 dissimilar joint by direct laser brazing without filler metal and groove. Mater. Sci. Eng. A 2013, 560, 111–120. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Peyre, P. Yb–YAG laser offset welding of AA5754 and T40 butt joint. J. Mater. Process. Technol. 2015, 223, 139–149. [Google Scholar] [CrossRef]

| Specimen | Power (W) | Welding Speed (m/min) | Defocusing Amount (mm) | Laser Offset (mm) |

|---|---|---|---|---|

| 1 | 4000 | 1.5 | 4 | −0.25 |

| 2 | 4000 | 1.5 | 4 | 0 |

| 3 | 4000 | 1.5 | 4 | +0.25 |

| 4 | 4000 | 1.5 | 4 | +0.5 |

| 5 | 4000 | 1.5 | 4 | +0.75 |

| Specimen | Yield Stress (Mpa) | Ultimate Stress (Mpa) | Elongation (%) |

|---|---|---|---|

| −0.25 mm | - | 59.58 | - |

| 0 mm | 112.59 | 156.48 | - |

| +0.25 mm | 136.17 | 189.33 | - |

| +0.5 mm | 308.84 | 346.58 | - |

| +0.75 mm | - | 50.22 | - |

| Ti-BM | 260.66 | 500.40 | 15 |

| Mo-BM | 625.55 | 780.64 | 4.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Lu, G.; Ning, J.; Zhang, L.; Long, J.; Zhang, G. Influence of Beam Offset on Dissimilar Laser Welding of Molybdenum to Titanium. Materials 2018, 11, 1852. https://doi.org/10.3390/ma11101852

Zhang L, Lu G, Ning J, Zhang L, Long J, Zhang G. Influence of Beam Offset on Dissimilar Laser Welding of Molybdenum to Titanium. Materials. 2018; 11(10):1852. https://doi.org/10.3390/ma11101852

Chicago/Turabian StyleZhang, Linjie, Guangfeng Lu, Jie Ning, Liangliang Zhang, Jian Long, and Guifeng Zhang. 2018. "Influence of Beam Offset on Dissimilar Laser Welding of Molybdenum to Titanium" Materials 11, no. 10: 1852. https://doi.org/10.3390/ma11101852

APA StyleZhang, L., Lu, G., Ning, J., Zhang, L., Long, J., & Zhang, G. (2018). Influence of Beam Offset on Dissimilar Laser Welding of Molybdenum to Titanium. Materials, 11(10), 1852. https://doi.org/10.3390/ma11101852