Multiaxial Fatigue Damage Parameter and Life Prediction without Any Additional Material Constants

Abstract

:1. Introduction

2. Multiaxial Fatigue Damage Parameters

2.1. Fatemi–Socie Model

2.2. Generalized Strain Energy/Amplitude (GSE/GSA) Damage Parameters

3. Proposed Multiaxial Fatigue Damage Parameter

4. Experimental Validation and Model Comparison

4.1. Materials and Multiaxial Fatigue Data

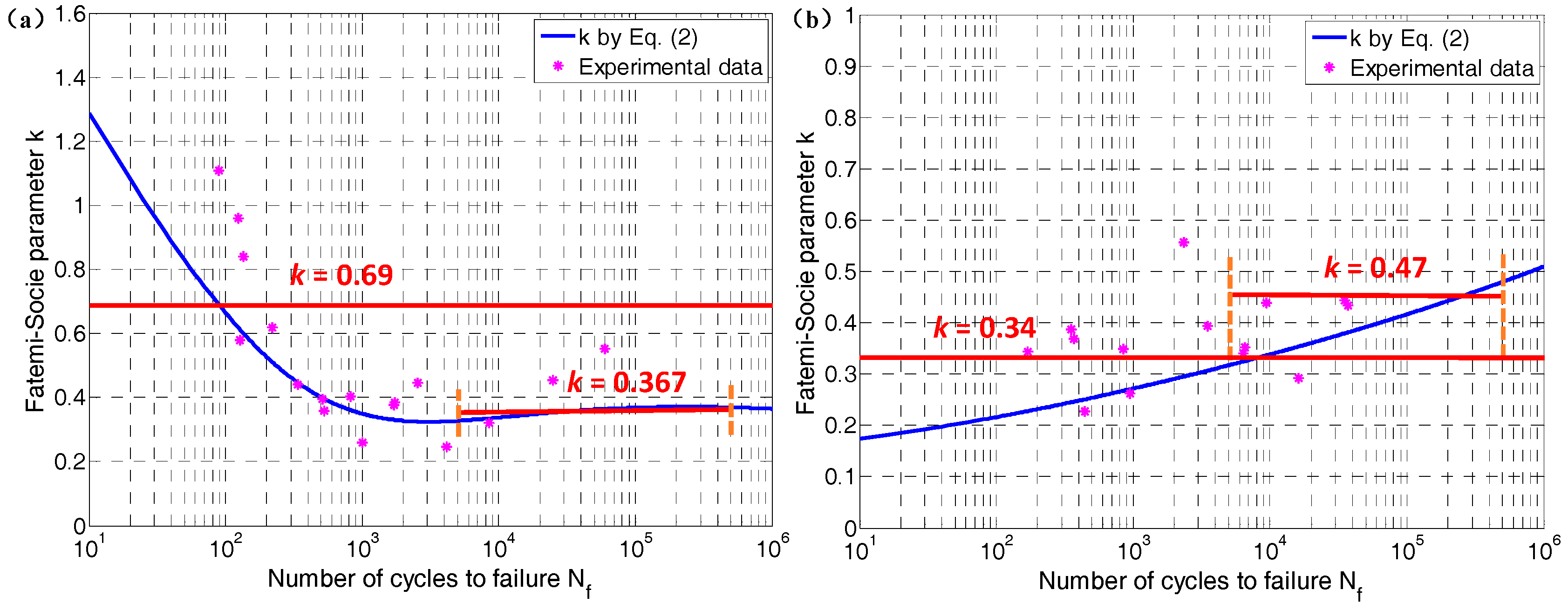

4.2. Discussion on the Additional Material Parameter of the FS Model

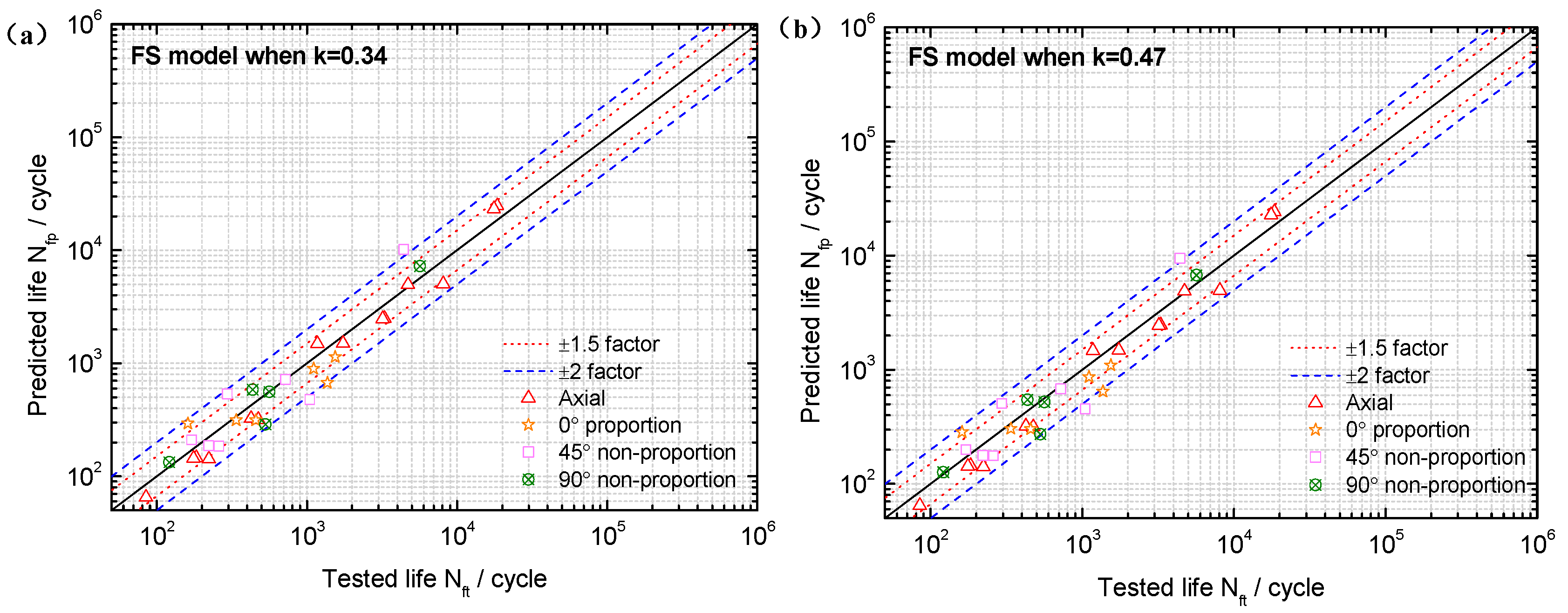

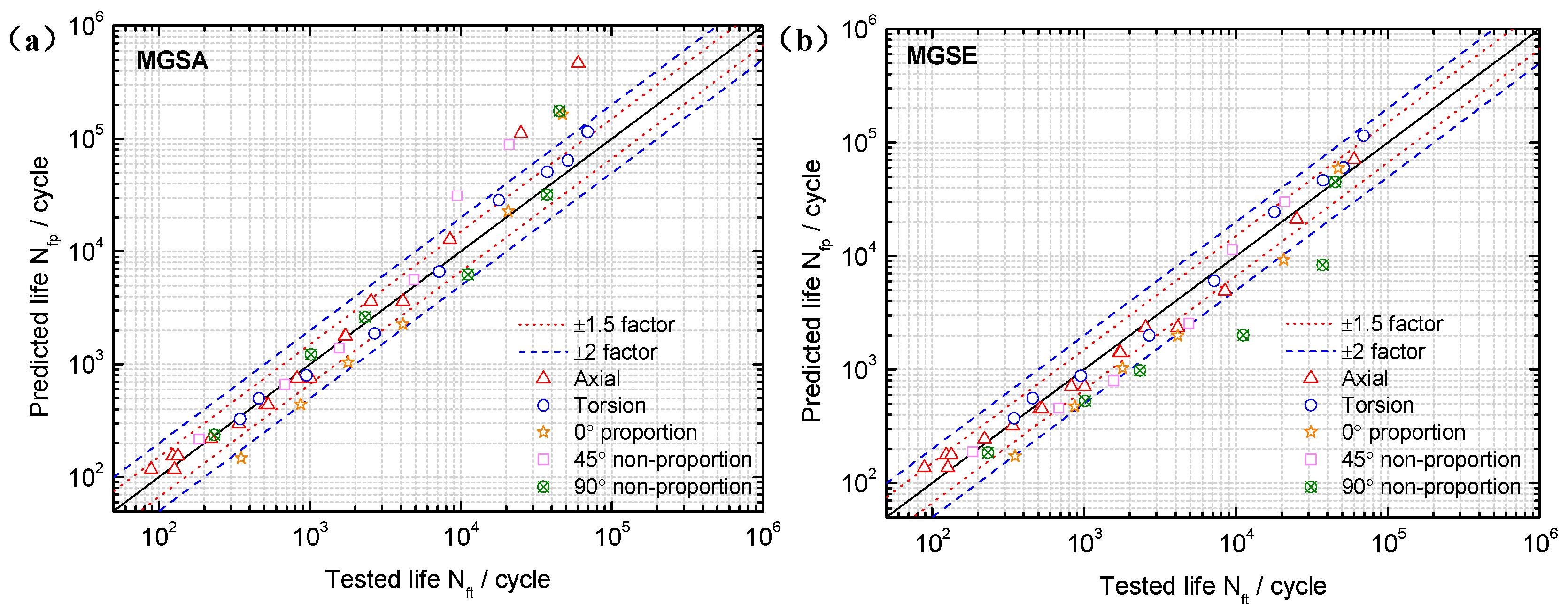

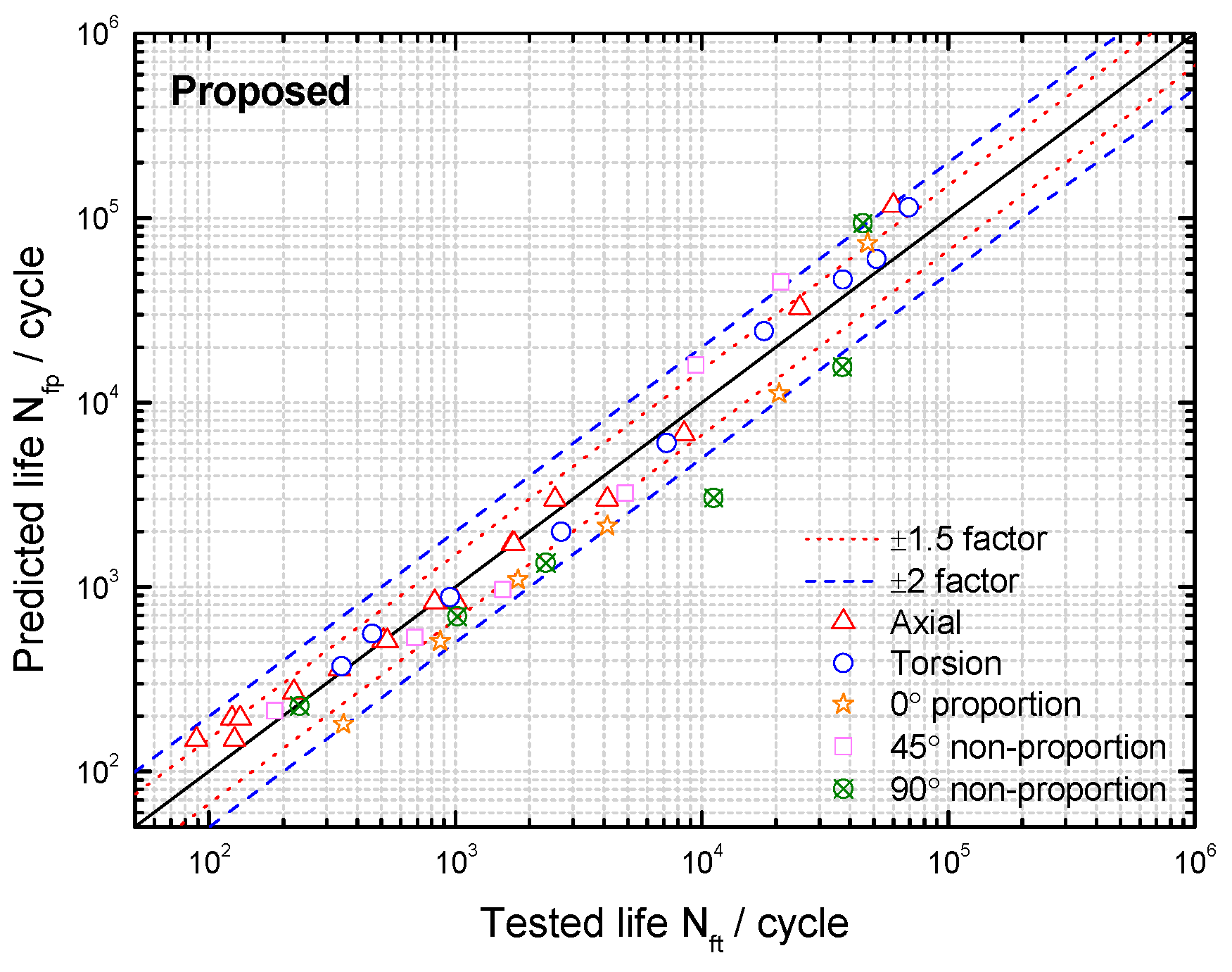

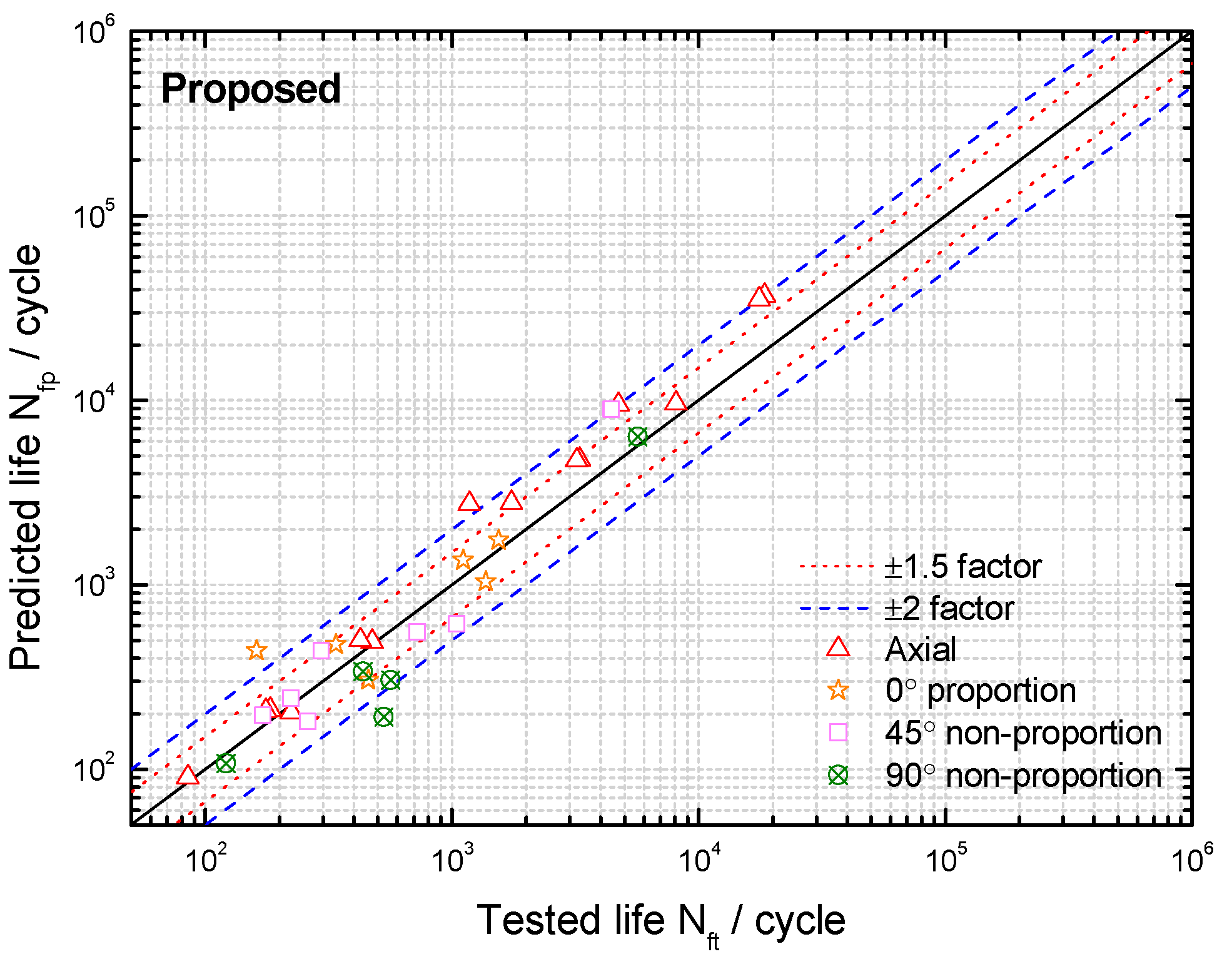

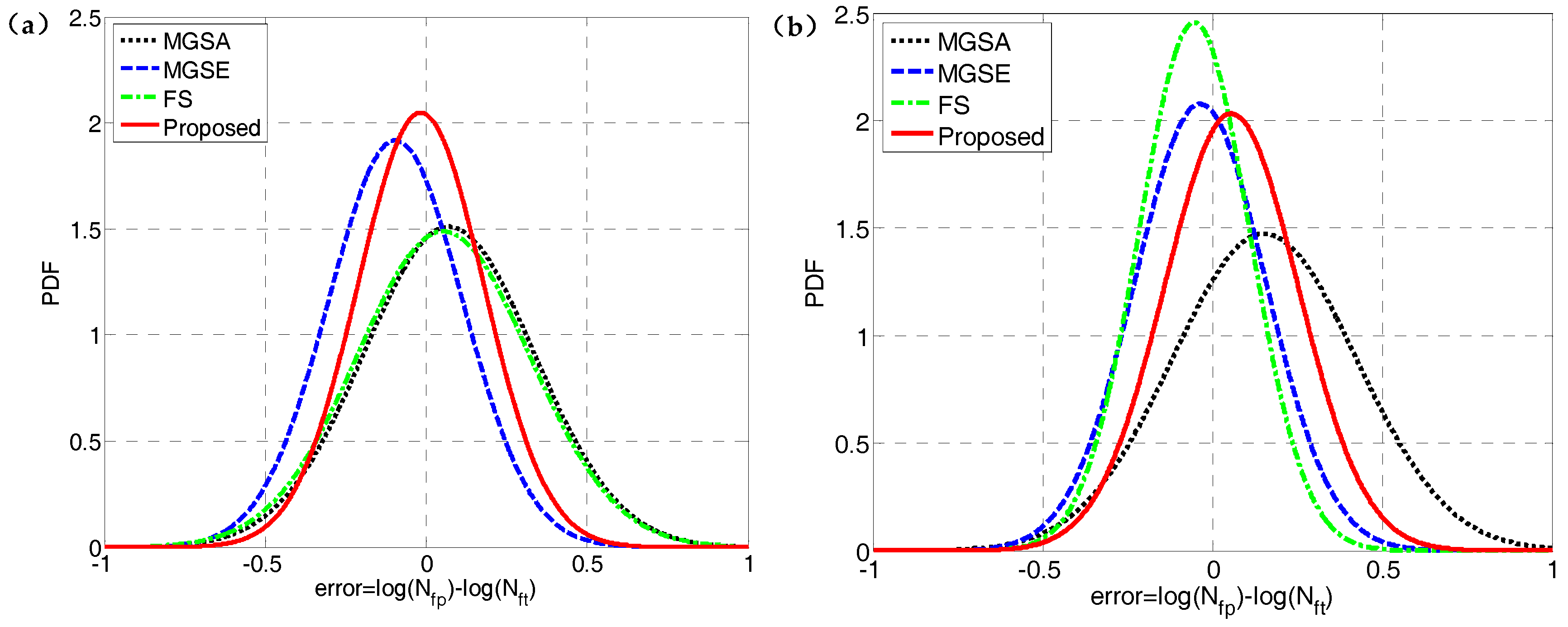

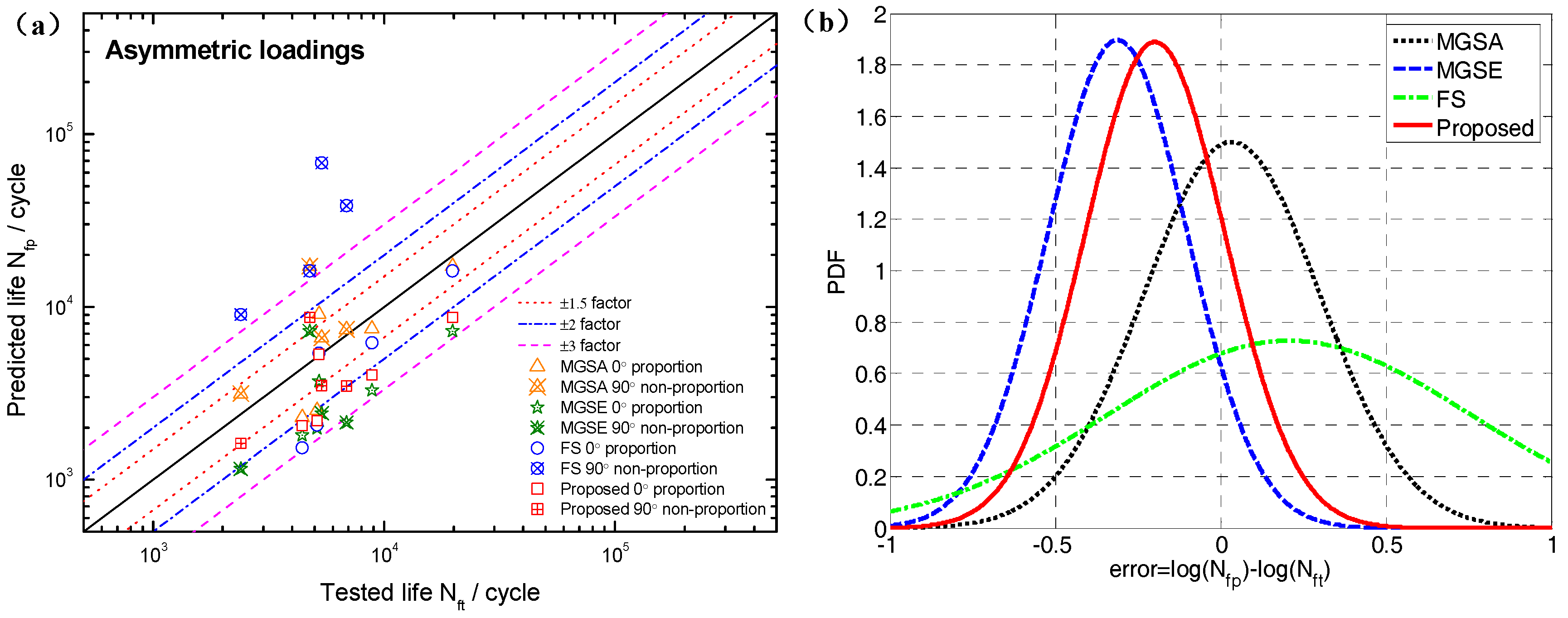

4.3. Model Validation and Comparison

5. Conclusions

- (1)

- The generalized strain amplitude/energy damage parameters are modified and the usage of these two damage parameters is simplified. The MGSA and MGSE damage parameters were elaborated upon by adding correction of normal/shear plastic strain amplitude by normal/shear stress correction factors based on GSA and GSE damage parameters.

- (2)

- By considering the effects of normal strain and shear strain on the damage of the critical plane, the normal/shear strain is corrected by different forms of normal and shear stress correction factors. A simple and efficient multiaxial fatigue damage parameter is proposed based on the normal stress correction factor including cyclic yield stress.

- (3)

- The material constant k of the FS model is discussed in this paper. It is found that the FS model using the fitted k provides less accurate fatigue life predictions for TC4, and a good performance of fatigue life prediction for GH4169 at 650 °C. However, when corresponding to the high cycle life regime, the mean value of k can enhance the fatigue life prediction ability of the FS model for the two materials. This indicates that fatigue life prediction results are more sensitive to the k in the low cycle life regime, and less sensitive to k in the high cycle life regime.

- (4)

- The proposed MGSA and MGSE models provide acceptable fatigue life predictions for TC4 and GH4169 under various loadings. However, the MGSA model has shown poor performance in the high cycle life regime, and the MGSE model gives a conservative prediction for low-cycle non-proportional multiaxial loadings. The proposed damage parameter overcomes the shortcomings of the MGSA and MGSE models, and nearly all of its prediction results fall within a factor of . It provides a better analysis for multiaxial fatigue life prediction under asymmetric loadings than others, while considering normal/shear mean stress effects. Also, further comprehensive assessment of the proposed damage parameter needs to be addressed for different materials under different loading paths.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Maximum shear strain amplitude on the critical plane | |

| Maximum normal stress on the critical plane | |

| Cyclic yield stress | |

| Shear fatigue strength coefficient | |

| Shear fatigue ductility coefficient | |

| Number of cycles to failure | |

| Shear modulus | |

| Shear fatigue strength exponent | |

| Shear fatigue ductility exponent | |

| Fatemi–Socie parameter | |

| Elastic Poisson’s ratio | |

| Plastic Poisson’s ratio | |

| Fatigue strength exponent | |

| Fatigue ductility exponent | |

| Fatigue strength coefficient | |

| Fatigue ductility coefficient | |

| Elastic shear strain range on the critical plane | |

| Plastic shear strain range on the critical plane | |

| Maximum shear stress on the critical plane | |

| Normal strain range acting on the critical plane | |

| Elastic normal strain range on the critical plane | |

| E | Young modulus |

| Effective Poisson’s ratio | |

| Experimental life | |

| Model predicted life | |

| FS | Fatemi–Socie |

| GSA | Generalized strain amplitude |

| GSE | Generalized strain energy |

| MGSA | Modified generalized strain amplitude |

| MGSE | Modified generalized strain energy |

References

- Maktouf, W.; Sai, K. An investigation of premature fatigue failures of gas turbine blade. Eng. Fail. Anal. 2015, 47, 89–101. [Google Scholar] [CrossRef]

- Hu, D.Y.; Wang, R.Q. Combined fatigue experiments on full scale turbine components. Aircr. Eng. Aerosp. Technol. 2013, 85, 4–9. [Google Scholar] [CrossRef]

- Hu, D.Y.; Wang, R.Q.; Fan, J.; Shen, X. Probabilistic damage tolerance analysis on turbine disk through experimental data. Eng. Fract. Mech. 2012, 87, 73–82. [Google Scholar] [CrossRef]

- Zhu, S.P.; Huang, H.Z.; Peng, W.; Wang, H.K.; Mahadevan, S. Probabilistic Physics of Failure-based framework for fatigue life prediction of aircraft gas turbine discs under uncertainty. Reliab. Eng. Syst. Saf. 2016, 146, 1–12. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhang, X.C.; Tu, S.T.; Zhu, S.P.; Zhang, C.C. A modified strain energy density exhaustion model for creep-fatigue life prediction. Int. J. Fatigue 2016, 90, 12–22. [Google Scholar] [CrossRef]

- Wang, R.Z.; Zhang, X.C.; Gong, J.G.; Zhu, X.M.; Tu, S.T.; Zhang, C.C. Creep-fatigue life prediction and interaction diagram in nickel-based GH4169 superalloy at 650 °C based on cycle-by-cycle concept. Int. J. Fatigue 2017, 97, 114–123. [Google Scholar] [CrossRef]

- Hu, D.Y.; Ma, Q.; Shang, L.; Gao, Y.; Wang, R.Q. Creep-fatigue behavior of turbine disc of superalloy GH720Li at 650 °C and probabilistic creep-fatigue modeling. Mater. Sci. Eng. A 2016, 670, 17–25. [Google Scholar] [CrossRef]

- Hu, D.Y.; Meng, F.; Liu, H.; Song, J.; Wang, R. Experimental investigation of fatigue crack growth behavior of GH2036 under combined high and low cycle fatigue. Int. J. Fatigue 2016, 85, 1–10. [Google Scholar] [CrossRef]

- Zhu, S.P.; Yang, Y.J.; Huang, H.Z.; Lv, Z.; Wang, H.K. A unified criterion for fatigue-creep life prediction of high temperature components. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2017, 231, 677–688. [Google Scholar] [CrossRef]

- Zhu, S.P.; Huang, H.Z.; He, L.P.; Liu, Y.; Wang, Z. A generalized energy-based fatigue-creep damage parameter for life prediction of turbine disk alloys. Eng. Fract. Mech. 2012, 90, 89–100. [Google Scholar] [CrossRef]

- Zhu, S.P.; Yue, P.; Yu, Z.Y.; Wang, Q.Y. A combined high and low cycle fatigue model for life prediction of turbine blades. Materials 2017, 10, 698. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.P.; Huang, H.Z.; Liu, Y.; Yuan, R.; He, L. An efficient life prediction methodology for low cycle fatigue-creep based on ductility exhaustion theory. Int. J. Damage Mech. 2013, 22, 556–571. [Google Scholar] [CrossRef]

- Correia, J.; Apetre, N.l.; Arcari, A.; De Jesus, A.; Muñiz-Calvente, M.; Calçada, R.; Berto, F.; Fernández-Canteli, A. Generalized probabilistic model allowing for various fatigue damage variables. Int. J. Fatigue 2017, 100, 187–194. [Google Scholar] [CrossRef]

- Blasón, S.; Muniz-Calvente, M.; Koller, R.; Przybilla, C.; Fernández-Canteli, A. Probabilistic assessment of fatigue data from shape homologous but different scale specimens. Application to an experimental program. Eng. Fract. Mech. 2017, in press. [Google Scholar] [CrossRef]

- Zhu, S.P.; Huang, H.Z.; Li, Y.; Liu, Y.; Yang, Y. Probabilistic modeling of damage accumulation for time-dependent fatigue reliability analysis of railway axle steels. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2015, 229, 23–33. [Google Scholar] [CrossRef]

- Muniz-Calvente, M.; De Jesus, A.M.P.; Correia, J.; Fernández-Canteli, A. A methodology for probabilistic prediction of fatigue crack initiation taking into account the scale effect. Eng. Fract. Mech. 2017, in press. [Google Scholar] [CrossRef]

- Calvente, M.M.; Blasón, S.; Canteli, A.F.; de Jesús, A.; Correia, J.A.F.O. A probabilistic approach for multiaxial fatigue criteria. Frattura ed Integrita Strutturale 2017, 11, 160–165. [Google Scholar]

- Stephanov, S. A curvilinear integral method for multiaxial fatigue life computing under non-proportional, arbitrary or random stressing. Int. J. Fatigue 1993, 15, 467–472. [Google Scholar] [CrossRef]

- Brighenti, R.; Carpinteri, A. A notch multiaxial-fatigue approach based on damage mechanics. Int. J. Fatigue 2012, 39, 122–133. [Google Scholar] [CrossRef]

- Brighenti, R.; Carpinteri, A.; Corbari, N. Damage mechanics and Paris regime in fatigue life assessment of metals. Int. J. Press. Vessel. Pip. 2013, 104, 57–68. [Google Scholar] [CrossRef]

- Stefanov, S.H.; Hanselka, H.; Sonsino, C.M. Application of IDD (Integration of Damage Differentials) for Fatigue Life Assessment/LBF Report No. FB-236; Fraunhofer Institute LBF: Darmstadt, Germany, 2009. [Google Scholar]

- Ellyin, F. A Strain Energy Based Criterion for Multiaxial Fatigue Failure. 2014. Available online: https://scholar.google.co.uk/scholar?q=A+strain+energy+based+criterion+for+multiaxial+fatigue+failure&btnG=&hl=en&as_sdt=0%2C5 (accessed on 3 August 2017).

- Wu, Z.R.; Hu, X.T.; Song, Y.D. Multiaxial fatigue life prediction for titanium alloy TC4 under proportional and nonproportional loading. Int. J. Fatigue 2014, 59, 170–175. [Google Scholar] [CrossRef]

- Socie, D.; Marquis, G. Multiaxial Fatigue; Society of Automotive Engineers: Warrendale, PA, USA, 1999. [Google Scholar]

- Fatemi, A.; Socie, D.F. A Critical plane to multiaxial fatigue damage including out-of-phase loading. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 149–165. [Google Scholar] [CrossRef]

- Wang, C.H.; Brown, M.W. A path-independent parameter for fatigue under proportional and non-proportional loading. Fatigue Fract. Eng. Mater. Struct. 1993, 16, 1285–1298. [Google Scholar] [CrossRef]

- Wang, C.H.; Brown, M.W. Multiaxial random load fatigue: Life prediction techniques and experiments. In Multiaxial Fatigue and Design, ESIS 21; Pineau, A., Cailletaud, G., Lindley, T.C., Eds.; Mechanical Engineering: London, UK, 1996; pp. 513–527. [Google Scholar]

- Findley, W.N. A Theory for the Effect of Mean Stress on Fatigue of Metals under Combined Torsion and Axial Load or Bending; Engineering Materials Research Laboratory, Division of Engineering, Brown University: Providence, RI, USA, 1958. [Google Scholar]

- Smith, R.N.; Watson, P.; Topper, T.H. A stress-strain function for the fatigue of metals. J. Mater. 1970, 5, 767–778. [Google Scholar]

- Liu, K.C. A method based on virtual strain-energy parameters for multiaxial fatigue life prediction. In Advances in Multiaxial Fatigue; McDowell, D.L., Ellis, R., Eds.; ASTM International: West Conshohocken, PA, USA, 1993. [Google Scholar]

- Chu, C.C.; Conle, F.A.; Bonnen, J.J.F. Multiaxial stress-strain modeling and fatigue life prediction of SAE Axle Shafts. In Advances in Multiaxial Fatigue; McDowell, D.L., Ellis, R., Eds.; ASTM International: West Conshohocken, PA, USA, 1993. [Google Scholar]

- Ma, S.; Markert, B.; Yuan, H. Multiaxial fatigue life assessment of sintered porous iron under proportional and non-proportional loadings. Int. J. Fatigue 2017, 97, 214–226. [Google Scholar] [CrossRef]

- Ince, A. Development of Computational Multiaxial Fatigue Modelling for Notched Components. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, May 2012. [Google Scholar]

- Shamsaei, N.; Gladskyi, M.; Panasovskyi, K.; Shukaev, S.; Fatemi, A. Multiaxial fatigue of titanium including step loading and load path alteration and sequence effects. Int. J. Fatigue 2010, 32, 1862–1874. [Google Scholar] [CrossRef]

- Lopez-Crespo, P.; Moreno, B.; Lopez-Moreno, A.; Zapatero, J. Study of crack orientation and fatigue life prediction in biaxial fatigue with critical plane models. Eng. Fract. Mech. 2015, 136, 115–130. [Google Scholar] [CrossRef]

- Ince, A.; Glinka, G. A generalized fatigue damage parameter for multiaxial fatigue life prediction under proportional and non-proportional loadings. Int. J. Fatigue 2014, 62, 34–41. [Google Scholar] [CrossRef]

- Banvillet, A.; Łagoda, T.; Macha, E.; Niesłony, A.D.A.M.; Palin-Luc, T.; Vittori, J.F. Fatigue life under non-Gaussian random loading from various models. Int. J. Fatigue 2004, 26, 349–363. [Google Scholar] [CrossRef]

- Fatemi, A.; Shamsaei, N. Multiaxial fatigue: An overview and some approximation models for life estimation. Int. J. Fatigue 2011, 33, 948–958. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Sharifimehr, S.; Phan, N.; Shamsaei, N. Multiaxial fatigue behavior of wrought and additive manufactured Ti-6Al-4V including surface finish effect. Int. J. Fatigue 2017, 100, 347–366. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Zhu, S.P.; Liu, Q.; Liu, Y. A new energy-critical plane damage parameter for multiaxial fatigue life prediction of turbine blades. Materials 2017, 10, 513. [Google Scholar]

- Jiang, Y. A fatigue criterion for general multiaxial loading. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 19–32. [Google Scholar] [CrossRef]

- Chu, C.C. Fatigue damage calculation using the critical plane approach. J. Eng. Mater. Technol. 1995, 117, 41. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Wang, D. Determination of the plastic properties of materials treated by ultrasonic surface rolling process through instrumented indentation. Mater. Sci. Eng. A 2014, 600, 21–31. [Google Scholar] [CrossRef]

- Sun, G.Q.; Shang, D.G.; Bao, M. Multiaxial fatigue damage parameter and life prediction under low cycle loading for GH4169 alloy and other structural materials. Int. J. Fatigue 2010, 32, 1108–1115. [Google Scholar] [CrossRef]

- Zhao, G.P.; Zhao, B.K. Aeronautical Materials Handbook; China Standard Press: Beijing, China, 2002. [Google Scholar]

- Li, J.; Li, C.W.; Qiao, Y.J.; Zhang, Z.P. Fatigue life prediction for some metallic materials under constant amplitude multiaxial loading. Int. J. Fatigue 2014, 68, 10–23. [Google Scholar] [CrossRef]

- Reis, L.; Li, B.; De Freitas, M. Crack initiation and growth path under multiaxial fatigue loading in structural steels. Int. J. Fatigue 2009, 31, 1660–1668. [Google Scholar] [CrossRef]

- Abazadeh, B.; Chakherlou, T.N.; Farrahi, G.H.; Alderliesten, R.C. Fatigue life estimation of bolt clamped and interference fitted-bolt clamped double shear lap joints using multiaxial fatigue criteria. Mater. Des. 2013, 43, 327–336. [Google Scholar] [CrossRef]

- Shamsaei, N.; Fatemi, A. Effect of hardness on multiaxial fatigue behaviour and some simple approximations for steels. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 631–646. [Google Scholar] [CrossRef]

- Zhu, S.P.; Foletti, S.; Beretta, S. Probabilistic framework for multiaxial LCF assessment under material variability. Int. J. Fatigue 2017, 103, 371–385. [Google Scholar] [CrossRef]

- Ince, A. A mean stress correction model for tensile and compressive mean stress fatigue loadings. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 939–948. [Google Scholar] [CrossRef]

- Zhu, S.P.; Lei, Q.; Huang, H.Z.; Yang, Y.J.; Peng, W. Mean stress effect correction in strain energy-based fatigue life prediction of metals. Int. J. Damage Mech. 2016. [Google Scholar] [CrossRef]

- Zhu, S.P.; Lei, Q.; Wang, Q.Y. Mean stress and ratcheting corrections in fatigue life prediction of metals. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1343–1354. [Google Scholar] [CrossRef]

| Monotonic properties | (GPa) | (GPa) | (MPa) | (MPa) | n | |

| 108.4 | 43.2 | 942.5 | 0.25 | 1054 | 0.0195 | |

| Uniaxial properties | (MPa) | b | c | (MPa) | ||

| 1116.9 | − 0.049 | 0.579 | − 0.679 | 1031 | 0.0478 | |

| Torsional properties | (MPa) | (MPa) | ||||

| 716.9 | − 0.06 | 2.24 | − 0.8 | 446.7 | 0.016 | |

| 716.9 | − 0.06 | 2.24 | − 0.8 | 446.7 | 0.016 |

| T (°C) | E (GPa) | (MPa) | (MPa) | b | c | (MPa) | ||

|---|---|---|---|---|---|---|---|---|

| 650 | 182 | 626.4 | 1476 | 0.162 | − 0.086 | − 0.58 | 1933 | 0.1483 |

| No. | (%) | (%) | (Cycles) | No. | (%) | (%) | (Cycles) | ||

|---|---|---|---|---|---|---|---|---|---|

| 1 | \ | 0.55 | \ | 60,048 | 23 | \ | \ | 1.302 | 2691 |

| 2 | \ | 0.6 | \ | 25,069 | 24 | \ | \ | 1.645 | 951 |

| 3 | \ | 0.7 | \ | 8457 | 25 | \ | \ | 1.942 | 459 |

| 4 | \ | 0.8 | \ | 4135 | 26 | \ | \ | 2.309 | 345 |

| 5 | \ | 0.8 | \ | 2544 | 27 | 0 | 0.345 | 0.648 | 47,195 |

| 6 | \ | 0.9 | \ | 1708 | 28 | 0 | 0.427 | 0.71 | 20,611 |

| 7 | \ | 0.9 | \ | 1730 | 29 | 0 | 0.576 | 0.938 | 4141 |

| 8 | \ | 1.1 | \ | 1007 | 30 | 0 | 0.687 | 1.111 | 1795 |

| 9 | \ | 1.1 | \ | 822 | 31 | 0 | 0.863 | 1.371 | 868 |

| 10 | \ | 1.3 | \ | 510 | 32 | 0 | 1.391 | 2.038 | 351 |

| 11 | \ | 1.3 | \ | 529 | 33 | 45 | 0.391 | 0.643 | 20,953 |

| 12 | \ | 1.5 | \ | 339 | 34 | 45 | 0.418 | 0.702 | 9478 |

| 13 | \ | 1.7 | \ | 221 | 35 | 45 | 0.496 | 0.831 | 4898 |

| 14 | \ | 2 | \ | 124 | 36 | 45 | 0.62 | 1.043 | 1563 |

| 15 | \ | 2 | \ | 134 | 37 | 45 | 0.772 | 1.255 | 683 |

| 16 | \ | 2.3 | \ | 89 | 38 | 45 | 1.224 | 1.756 | 185 |

| 17 | \ | 2.3 | \ | 127 | 39 | 90 | 0.349 | 0.639 | 45,138 |

| 18 | \ | \ | 0.798 | 69,269 | 40 | 90 | 0.418 | 0.704 | 37,273 |

| 19 | \ | \ | 0.833 | 51,146 | 41 | 90 | 0.499 | 0.821 | 11,152 |

| 20 | \ | \ | 0.848 | 37,449 | 42 | 90 | 0.556 | 0.934 | 2332 |

| 21 | \ | \ | 0.889 | 17,887 | 43 | 90 | 0.632 | 1.079 | 1017 |

| 22 | \ | \ | 1.038 | 7218 | 44 | 90 | 1.229 | 1.7 | 233 |

| No. | (%) | (%) | (%) | (%) | (Cycles) | |

|---|---|---|---|---|---|---|

| 1 | 0 | 0.382 | 0.714 | 0 | 1.17 | 19,750 |

| 2 | 0 | 0.556 | 0.889 | 0 | 1.495 | 5126 |

| 3 | 90 | 0.485 | 0.828 | 0 | 1.409 | 4772 |

| 4 | 0 | 0.438 | 0.719 | 0.754 | 0 | 5225 |

| 5 | 0 | 0.565 | 0.911 | 1.042 | 0 | 4422 |

| 6 | 90 | 0.42 | 0.698 | 0.428 | 0 | 6878 |

| 7 | 90 | 0.502 | 0.822 | 0.974 | 0 | 2394 |

| 8 | 0 | 0.466 | 0.726 | 0.978 | 1.386 | 8867 |

| 9 | 90 | 0.423 | 0.705 | 0.826 | 1.253 | 5357 |

| No. | (%) | (%) | (Cycles) | No. | (%) | (%) | (Cycles) | ||

|---|---|---|---|---|---|---|---|---|---|

| 1 | - | 1.4855 | \ | 85 | 17 | 0 | 0.408 | 0.592 | 1544 |

| 2 | \ | 1.1035 | \ | 223 | 18 | 45 | 0.524 | 0.745 | 722 |

| 3 | \ | 1.093 | \ | 183 | 19 | 45 | 0.553 | 0.813 | 295 |

| 4 | \ | 1.0975 | \ | 176 | 20 | 90 | 0.548 | 0.833 | 436 |

| 5 | \ | 0.853 | \ | 475 | 21 | 90 | 0.586 | 0.838 | 563 |

| 6 | \ | 0.848 | \ | 425 | 22 | 0 | 0.546 | 0.884 | 458 |

| 7 | \ | 0.5975 | \ | 1743 | 23 | 45 | 0.704 | 1.09 | 171 |

| 8 | \ | 0.5985 | \ | 1174 | 24 | 45 | 0.701 | 1.16 | 260 |

| 9 | \ | 0.55 | \ | 3290 | 25 | 90 | 0.783 | 1.33 | 121 |

| 10 | \ | 0.5505 | \ | 3204 | 26 * | 0 | 0.54 | 0.896 | 338 |

| 11 | \ | 0.5 | \ | 8097 | 27 * | 0 | 0.536 | 0.945 | 161 |

| 12 | \ | 0.501 | - | 4732 | 28 * | 0 | 0.427 | 0.633 | 1108 |

| 13 | \ | 0.4285 | \ | 18531 | 29 * | 0 | 0.448 | 0.709 | 1370 |

| 14 | \ | 0.4305 | \ | 17633 | 30 * | 45 | 0.478 | 0.749 | 1048 |

| 15 | 45 | 0.354 | 0.42 | 4420 | 31 * | 45 | 0.625 | 1 | 222 |

| 16 | 90 | 0.397 | 0.479 | 5665 | 32 * | 90 | 0.613 | 1.01 | 529 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.-Y.; Zhu, S.-P.; Liu, Q.; Liu, Y. Multiaxial Fatigue Damage Parameter and Life Prediction without Any Additional Material Constants. Materials 2017, 10, 923. https://doi.org/10.3390/ma10080923

Yu Z-Y, Zhu S-P, Liu Q, Liu Y. Multiaxial Fatigue Damage Parameter and Life Prediction without Any Additional Material Constants. Materials. 2017; 10(8):923. https://doi.org/10.3390/ma10080923

Chicago/Turabian StyleYu, Zheng-Yong, Shun-Peng Zhu, Qiang Liu, and Yunhan Liu. 2017. "Multiaxial Fatigue Damage Parameter and Life Prediction without Any Additional Material Constants" Materials 10, no. 8: 923. https://doi.org/10.3390/ma10080923

APA StyleYu, Z.-Y., Zhu, S.-P., Liu, Q., & Liu, Y. (2017). Multiaxial Fatigue Damage Parameter and Life Prediction without Any Additional Material Constants. Materials, 10(8), 923. https://doi.org/10.3390/ma10080923