Sliding Wear Behavior of UNS R56400 Titanium Alloy Samples Thermally Oxidized by Laser

Abstract

1. Introduction

2. Materials and Methods

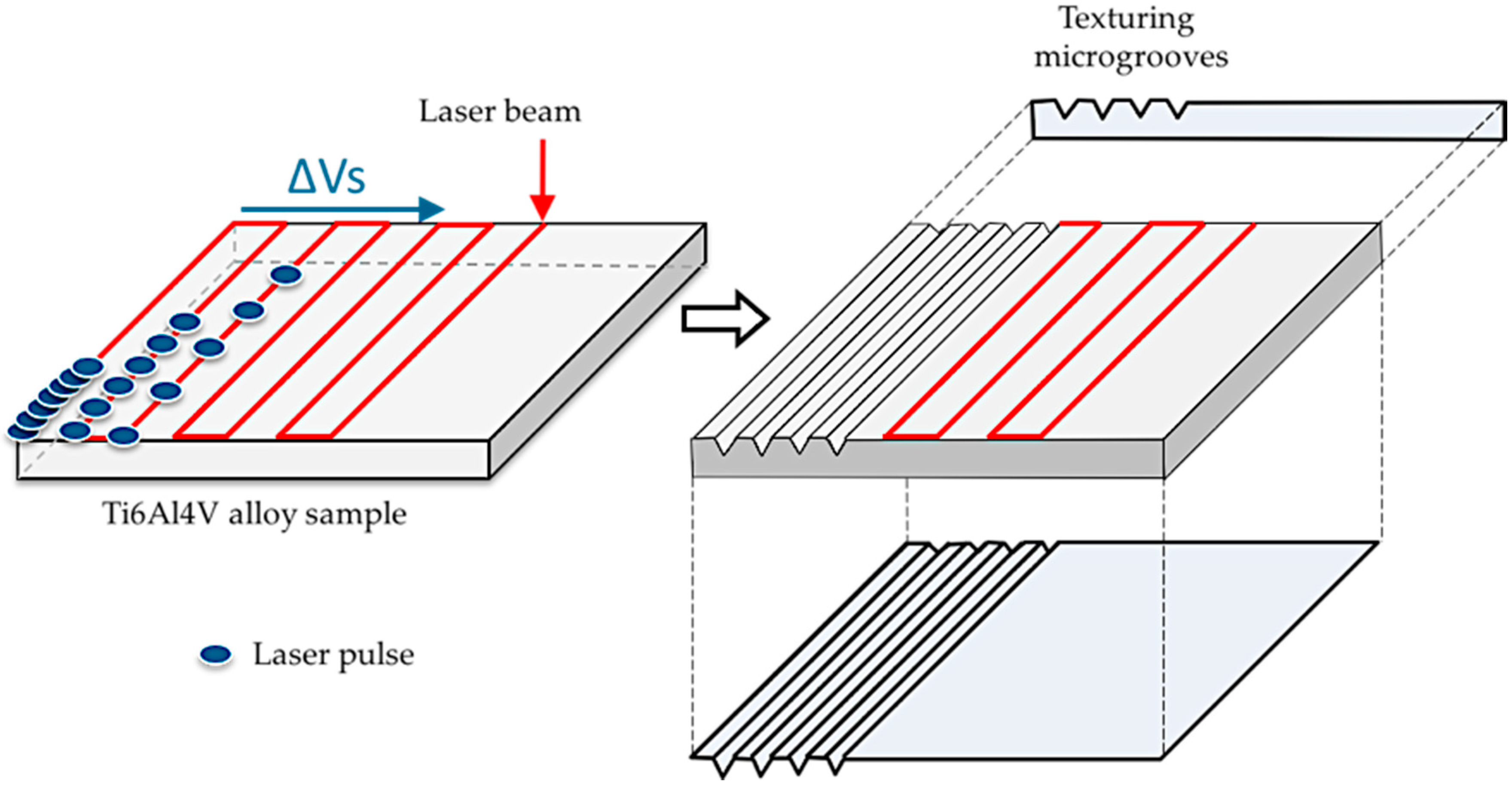

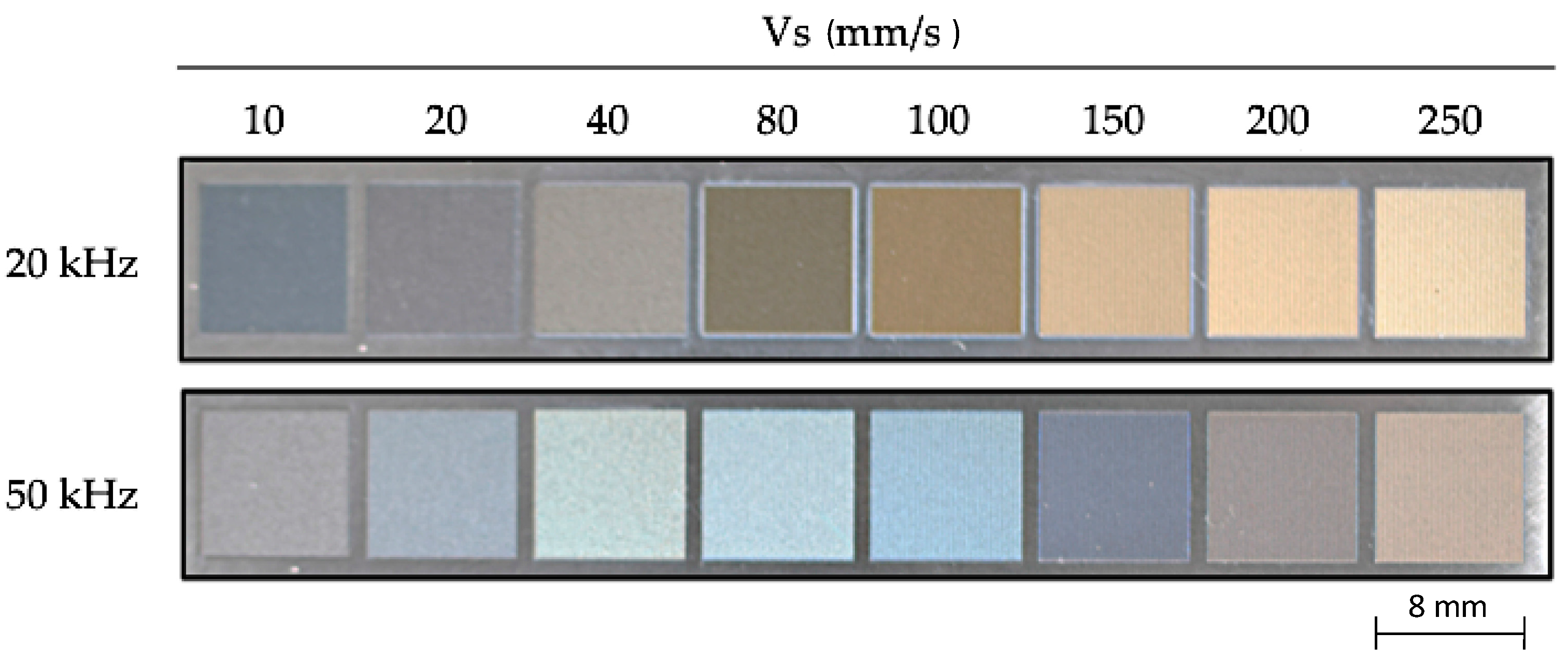

2.1. Laser Texturing Process

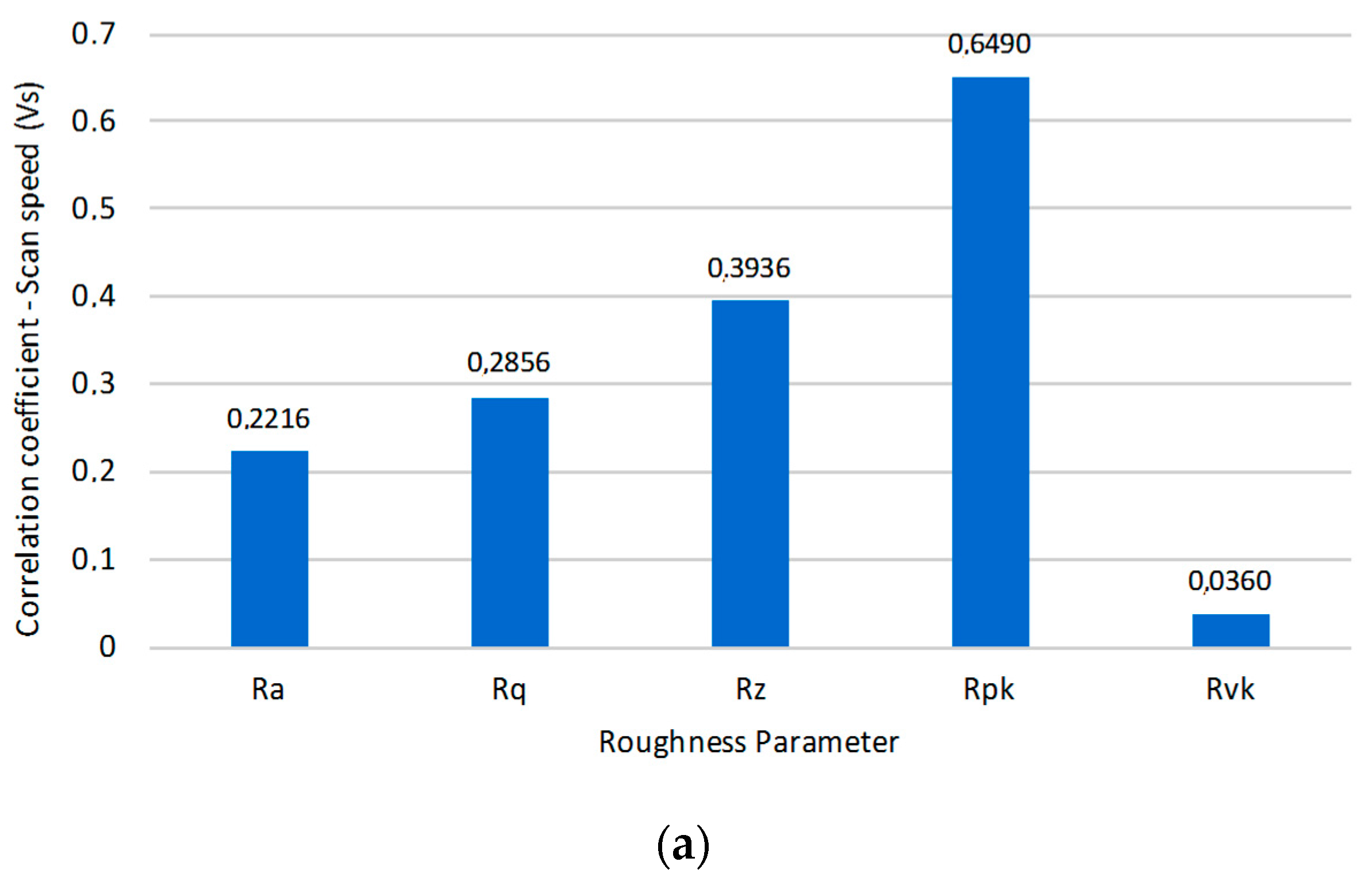

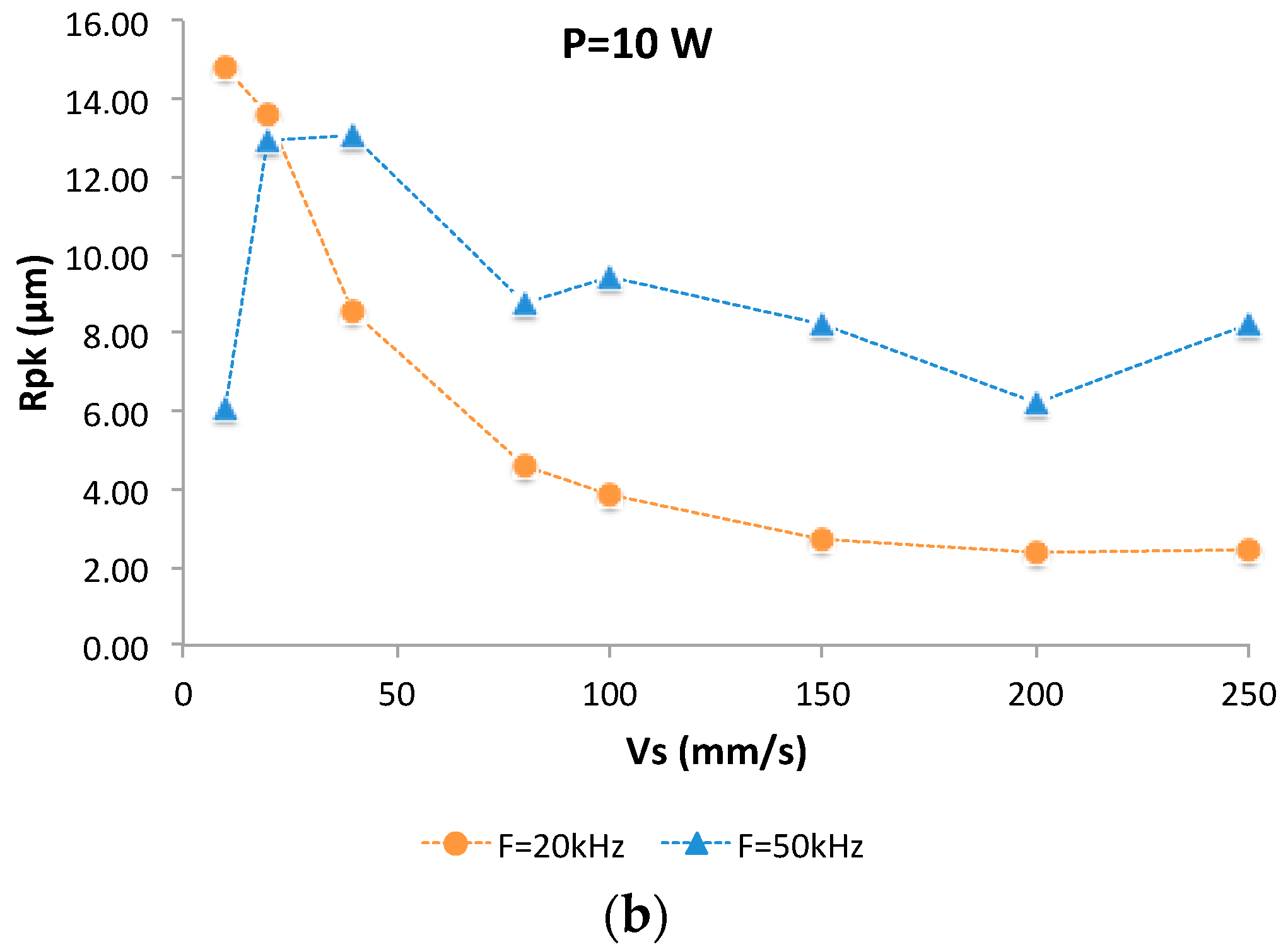

2.2. Textured Layer Characterization

2.3. Pin on Disc Tribological Tests

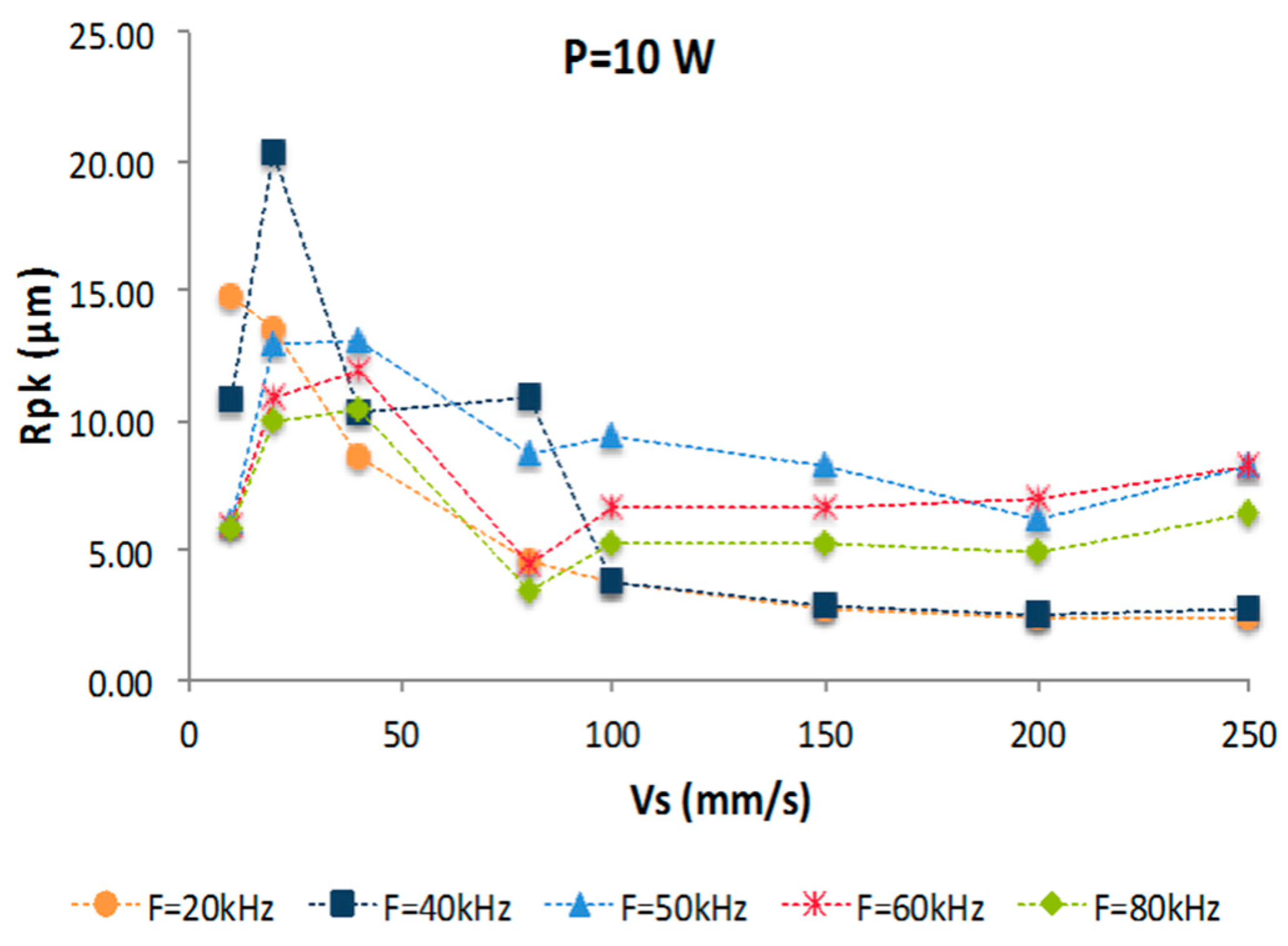

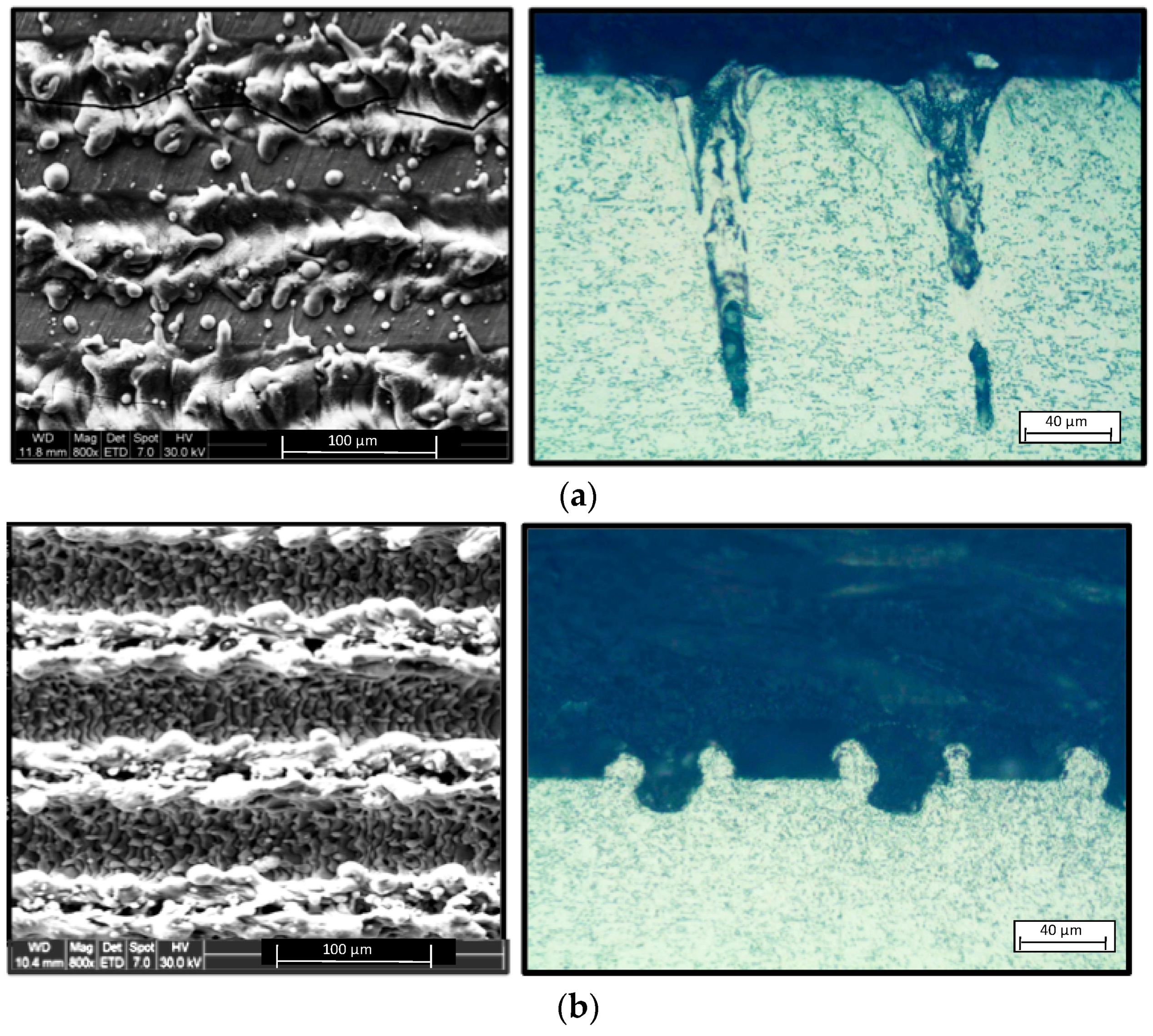

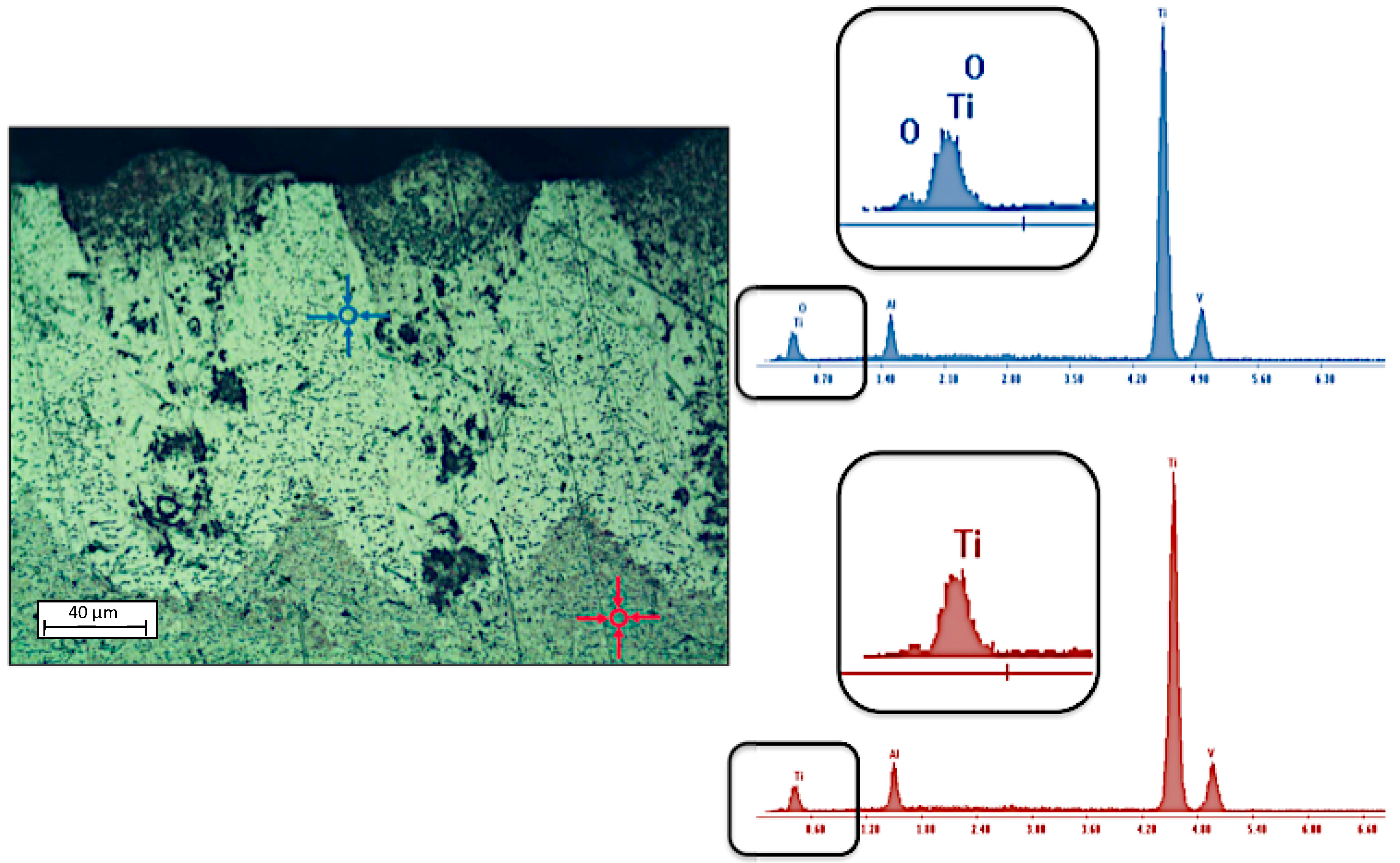

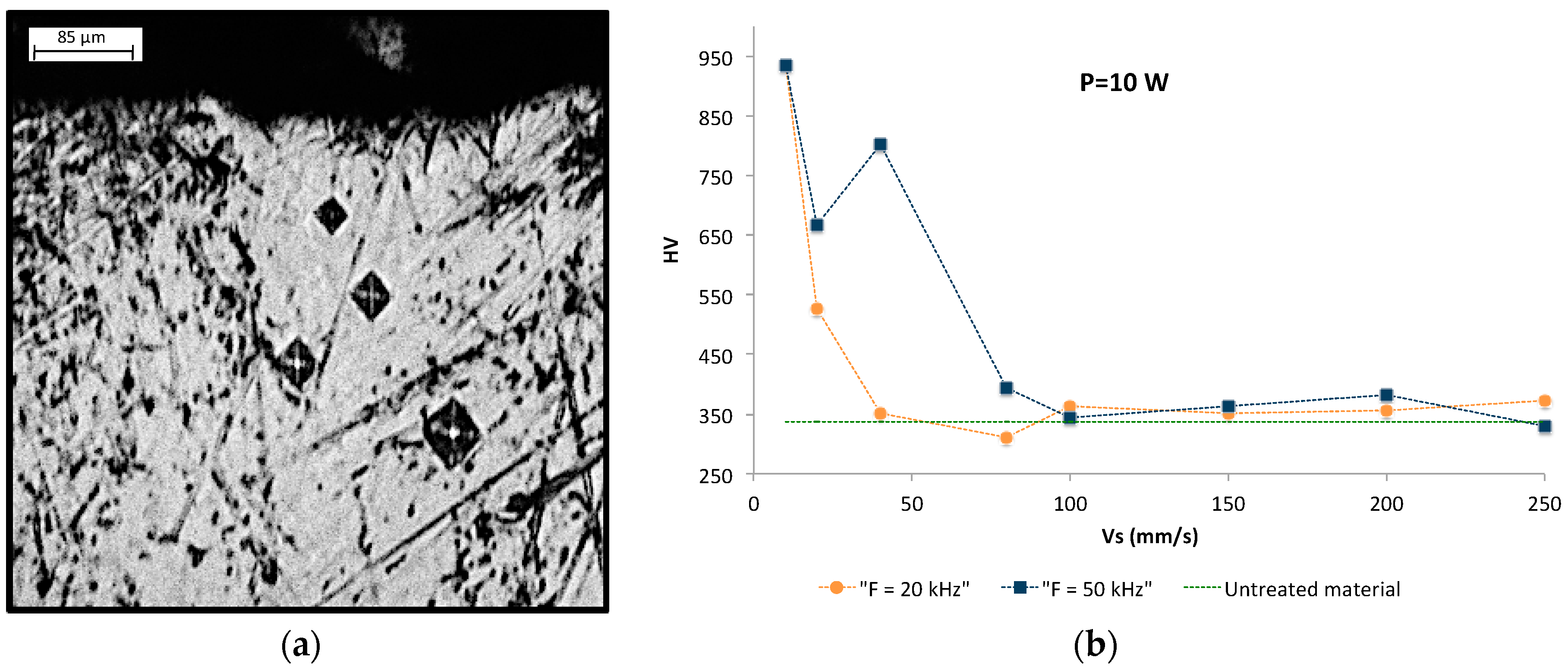

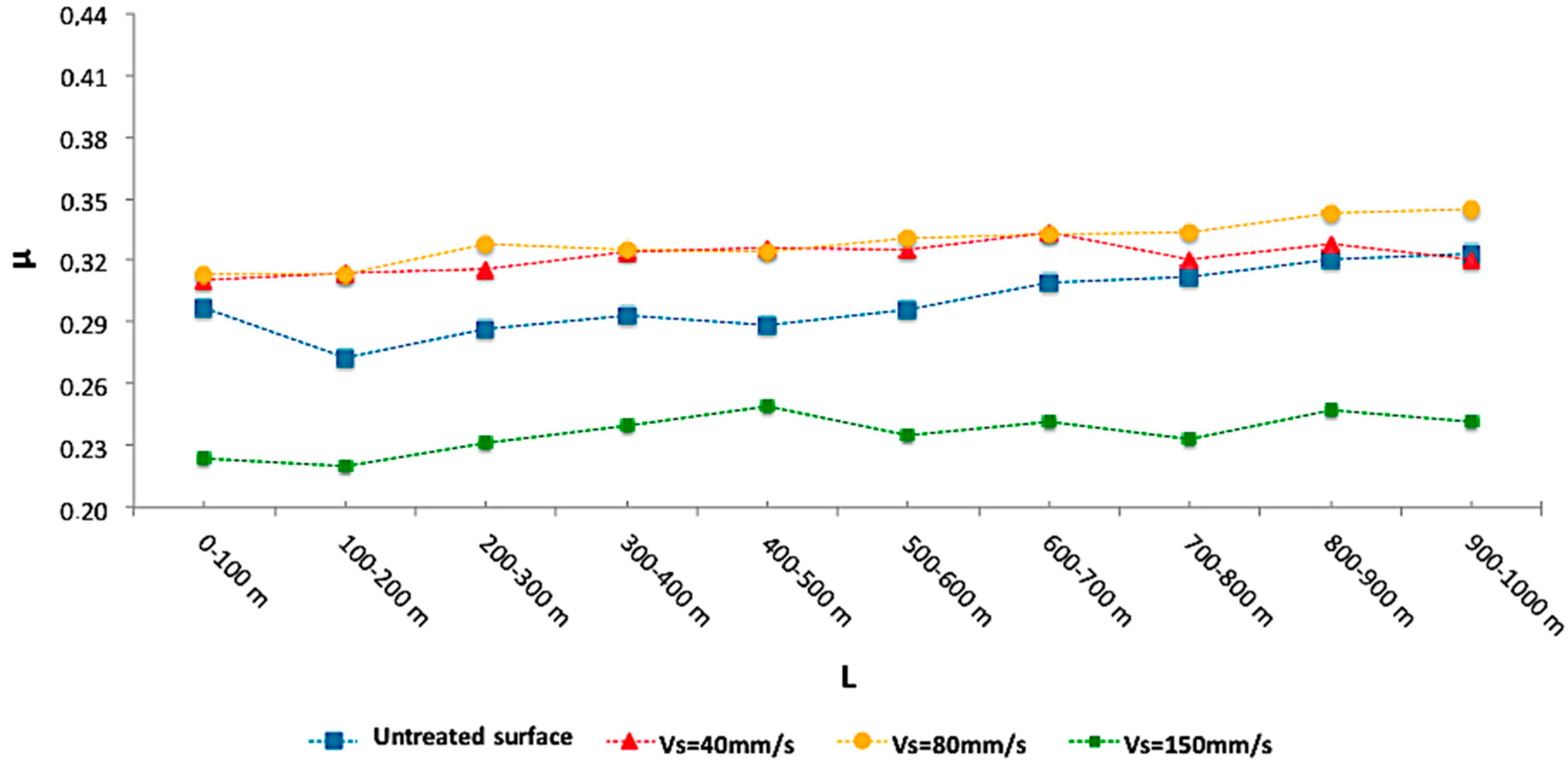

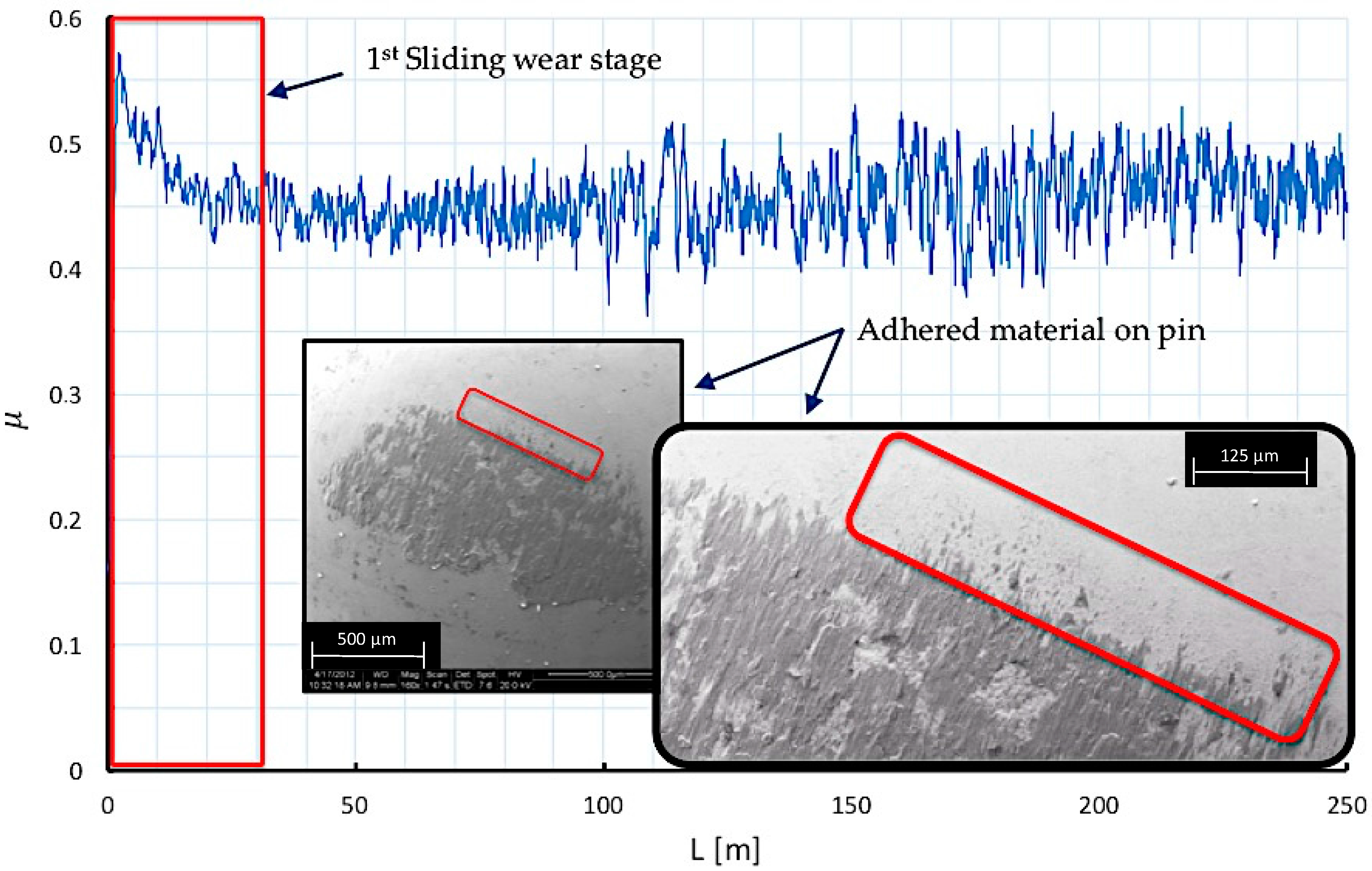

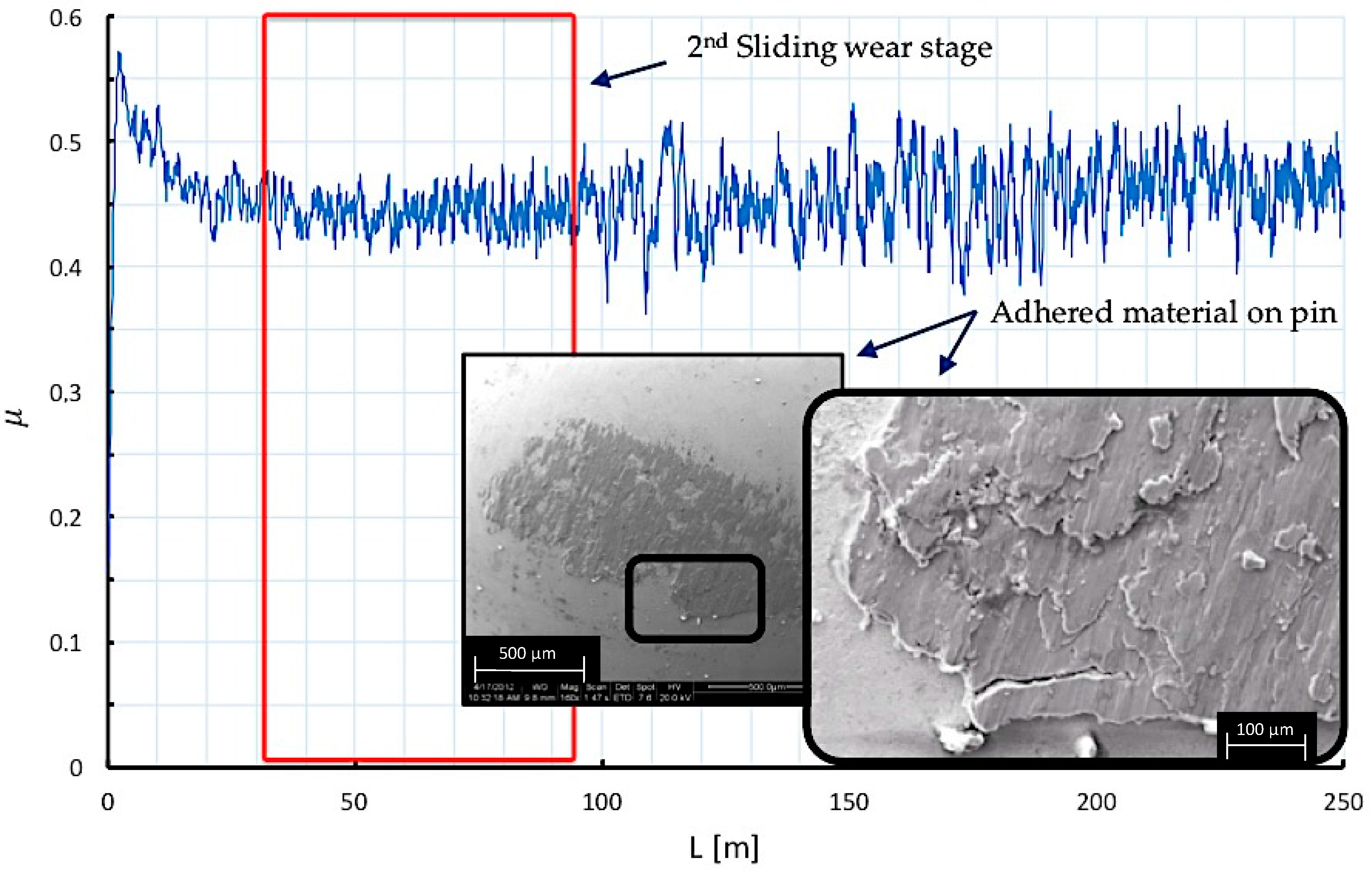

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Veiga, C.; Davim, J.P.; Loureiro, A.J.R. Properties and applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 133–148. [Google Scholar]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. 2006, C26, 1269–1277. [Google Scholar] [CrossRef]

- Vinicius, A.R.H. Titanium production for aerospace applications. J. Aerosp. Technol. Manag. 2009, 1, 7–17. [Google Scholar]

- Mouritz, A.P. Introduction to Aerospace Materials; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 202–223. [Google Scholar]

- James, A.S.; Thomas, K.; Mann, P.; Wall, R. The role and impacts of surface engineering in environmental design. Mater. Des. 2005, 26, 594–601. [Google Scholar] [CrossRef]

- Tian, Y.S.; Chen, C.Z.; Li, S.T.; Huo, Q.H. Research progress on laser surface modification of titanium alloys. Appl. Surf. Sci. 2005, 242, 177–184. [Google Scholar] [CrossRef]

- Mohammed, M.T.; Khan, Z.A.; Siddiquee, A.N. Surface modification of titanium materials for developing corrosion behavior in human body environment: A review. Procedia Mater. Sci. 2014, 6, 1610–1618. [Google Scholar] [CrossRef]

- Biswas, A.; Chatterjee, U.K.; Li, L.; Manna, I.; Majumdar, J.D. Laser assisted surface modification of Ti-6Al-4V for bioimplant application. Surf. Rev. Lett. 2007, 14, 531–534. [Google Scholar] [CrossRef]

- Chi-Wai, C.; Seunghwan, L.; Graham, S.; Gianluca, S.; Chi-Ho, N.; Ahmed, S.; Hau-Chung, M. Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl. Surf. Sci. 2016, 367, 80–90. [Google Scholar]

- Ehteman Haghighi, S.; Lu, H.B.; Jian, G.Y.; Cao, G.H.; Habibi, D.; Zhang, L.C. Effect of α” martensite on the microstructure and mechanical properties of beta-type Ti-Fe-Ta alloys. Mater. Des. 2015, 76, 47–54. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Attar, H.; Ehthemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bönisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Ehthemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Vazquez-Martinez, J.M.; Salguero, J.; Botana, F.J.; Gomez-Parra, A.; Fernandez-Vidal, S.R.; Marcos, M. Tribological wear analysis of laser surface treated Ti6Al4V based on volume lost evaluation. Key Eng. Mater. 2014, 615, 82–87. [Google Scholar] [CrossRef]

- Aniolek, K.; Kupka, M.; Barylski, A. Sliding wear resistance of oxide layers formed on a titanium surface during thermal oxidation. Wear 2016, 356–357, 23–29. [Google Scholar] [CrossRef]

- Vazquez-Martinez, J.M.; Salguero, J.; Botana, F.J.; Contreras, J.P.; Fernandez-Vidal, S.R.; Marcos, M. Metrological evaluation of the tribological behavior of laser surface treated Ti6Al4V alloy. Procedia Eng. 2013, 63, 752–760. [Google Scholar] [CrossRef]

- Vazquez-Martinez, J.M.; Botana, M.; Botana, F.J.; Del Sol, I.; Salguero, J.; Marcos, M. Thermal laser oxidation based texturing as finishing treatment for improving surface properties of UNS R56400. In Proceedings of the 7th Manufacturing Engineering Society International Conference, Vigo, Spain, 28–30 July 2017. [Google Scholar]

- Tahseen, J.; Sunan, D.; Haider, B.; Dimov, S. Laser induced single spot oxidation of titanium. Appl. Surf. Sci. 2016, 387, 617–624. [Google Scholar]

- Antonczak, A.J.; Skoronski, L.; Trzcinski, M.; Kinzhybalo, V.V.; Lazarek, L.K.; Abramski, K.M. Laser induced oxidation of titanium substrate: Analysis of the physicochemical structure of the surface and sub-surface layers. Appl. Surf. Sci. 2015, 325, 217–226. [Google Scholar] [CrossRef]

- Ali, N.; Bashir, S.; Kalsoom, U.; Akram, M.; Mahmood, K. Effect of dry and wet ambient environment on the pulsed laser ablation of titanium. Appl. Surf. Sci. 2013, 270, 49–57. [Google Scholar] [CrossRef]

- Fusi, M.; Russo, V.; Casari, C.S.; Bassi, A.L.; Bottani, C.E. Titanium oxide nanostructure films by reactive pulsed laser deposition. Appl. Surf. Sci. 2009, 255, 5334–5337. [Google Scholar] [CrossRef]

- Yue, L.; Wang, Z.; Li, L. Material morphological characteristics in laser ablation of alpha case from titanium alloy. Appl. Surf. Sci. 2012, 258, 8065–8071. [Google Scholar] [CrossRef]

- Seol, J.; Chester, J.V.T.; Heesoo, L. Degradation of TiAlN coatings by the accelerate life test using pulsed laser ablation. Ceram. Int. 2014, 40, 8677–8685. [Google Scholar]

- Leuders, S.; Thone, M.; Riemer, A.; Niendorf, T.; Troster, T.; Richard, H.A.; Maier, H.J. On the mechanical behavior of titanium alloy Ti6Al4V manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Zhang, S. Green Tribology: Fundamentals and future development. Friction 2013, 1, 186–194. [Google Scholar] [CrossRef]

- Kennedy, D.M.; Hashmi, M.S.J. Methods of wear testing for advanced surface coatings and bulk materials. J. Mater. Process. Technol. 1998, 77, 246–253. [Google Scholar] [CrossRef]

- Holmberg, K.; Ronkainen, H.; Matthews, A. Tribology of thin coatings. Ceram. Int. 2000, 1, 787–795. [Google Scholar] [CrossRef]

- Mang, T.; Bobzin, K.; Bartels, T. Industrial Tribology. Tribosystems, Friction, Wear and Surface Engineering, Lubrication; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve; International Organization Standardization (ISO): Geneva, Switzerland, 1996.

- Oh, J.M.; Lee, B.G.; Cho, S.W.; Choi, G.S.; Lim, J.W. Oxygen effects on the mechanical properties and lattice strain of Ti and Ti-6Al-4V. Met. Mater. Int. 2011, 17, 733–736. [Google Scholar] [CrossRef]

- Pérez del Pino, A.; Fernández-Pradas, J.M.; Serra, P.; Morenza, J.L. Coloring of titanium through laser oxidation: Comparative study with anodizing. Surf. Coat. Technol. 2004, 187, 106–112. [Google Scholar] [CrossRef]

- Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture; International Organization Standardization (ISO): Geneva, Switzerland, 1997.

| Al | V | Fe | C | O | N | H | Ti |

|---|---|---|---|---|---|---|---|

| 6.26 | 3.91 | 0.18 | 0.011 | <0.10 | <0.10 | <0.10 | Rest |

| P (W) | F (kHz) | Vs (mm/s) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 10 | 20 | 40 | 80 | 100 | 150 | 200 | 250 |

| 50 | |||||||||

| 8 | 70 | 40 | 80 | 150 | |||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez, J.M.V.; Pedemonte, F.J.B.; Galvin, M.B.; Gomez, J.S.; Barcena, M.M. Sliding Wear Behavior of UNS R56400 Titanium Alloy Samples Thermally Oxidized by Laser. Materials 2017, 10, 830. https://doi.org/10.3390/ma10070830

Martinez JMV, Pedemonte FJB, Galvin MB, Gomez JS, Barcena MM. Sliding Wear Behavior of UNS R56400 Titanium Alloy Samples Thermally Oxidized by Laser. Materials. 2017; 10(7):830. https://doi.org/10.3390/ma10070830

Chicago/Turabian StyleMartinez, Juan Manuel Vazquez, Francisco J. Botana Pedemonte, Marta Botana Galvin, Jorge Salguero Gomez, and Mariano Marcos Barcena. 2017. "Sliding Wear Behavior of UNS R56400 Titanium Alloy Samples Thermally Oxidized by Laser" Materials 10, no. 7: 830. https://doi.org/10.3390/ma10070830

APA StyleMartinez, J. M. V., Pedemonte, F. J. B., Galvin, M. B., Gomez, J. S., & Barcena, M. M. (2017). Sliding Wear Behavior of UNS R56400 Titanium Alloy Samples Thermally Oxidized by Laser. Materials, 10(7), 830. https://doi.org/10.3390/ma10070830