A Re-Evaluation of the Causes of Deformation in 1Cr-1Mo-0.25V Steel for Turbine Rotors and Shafts Based on iso-Thermal Plots of the Wilshire Equation and the Modelling of Batch to Batch Variation

Abstract

:1. Introduction

2. The Data

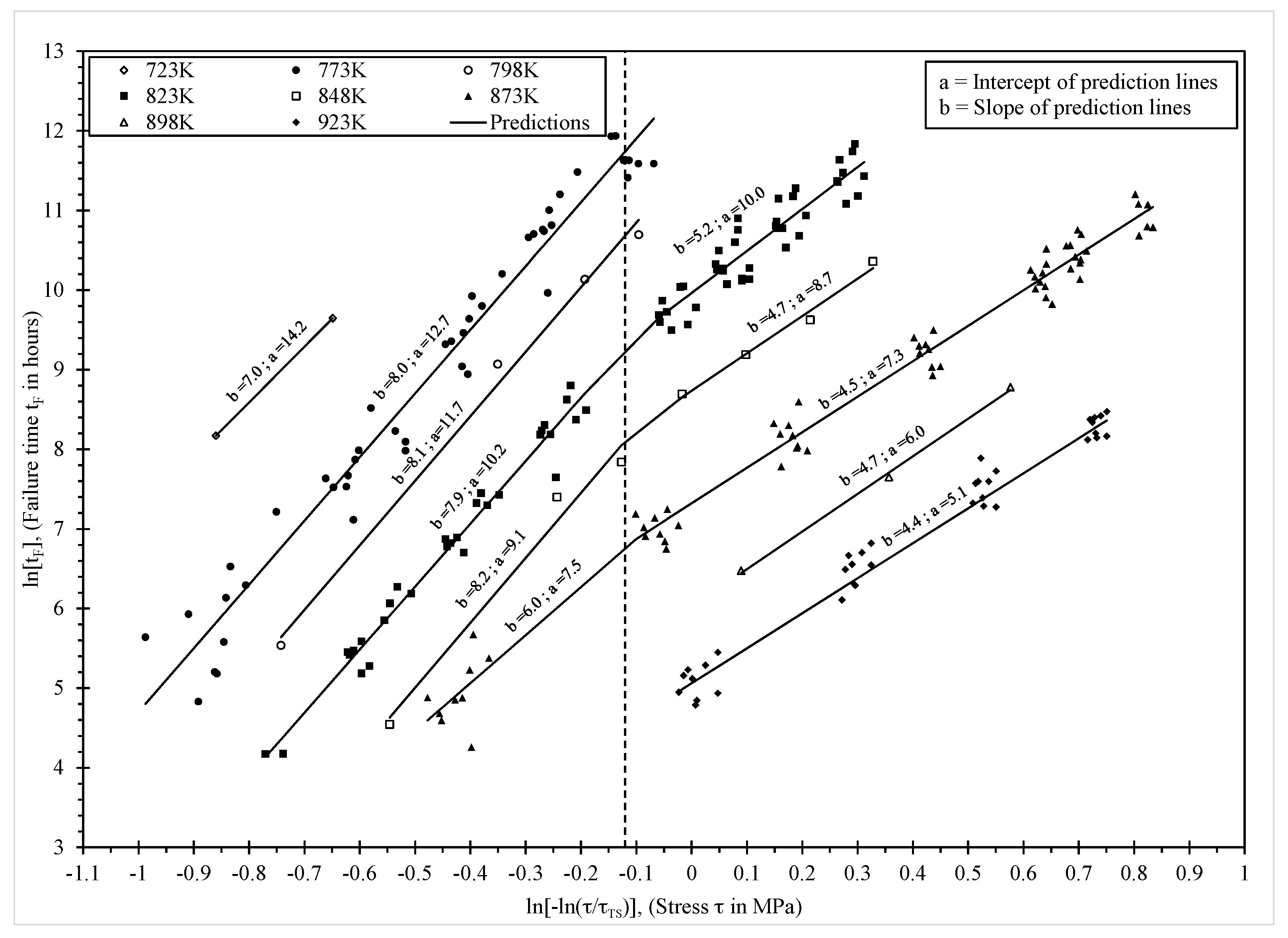

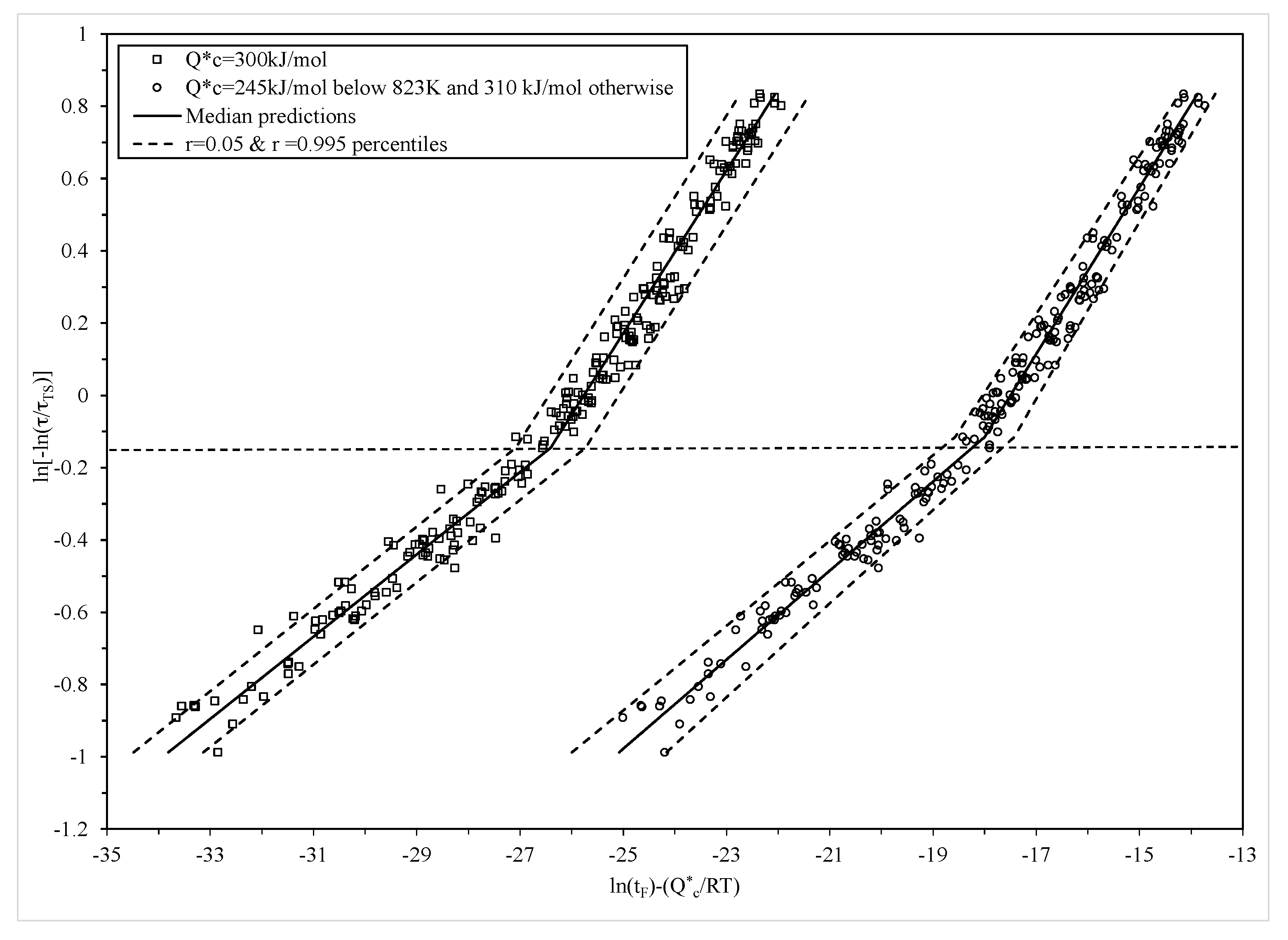

3. The Original Wilshire Study

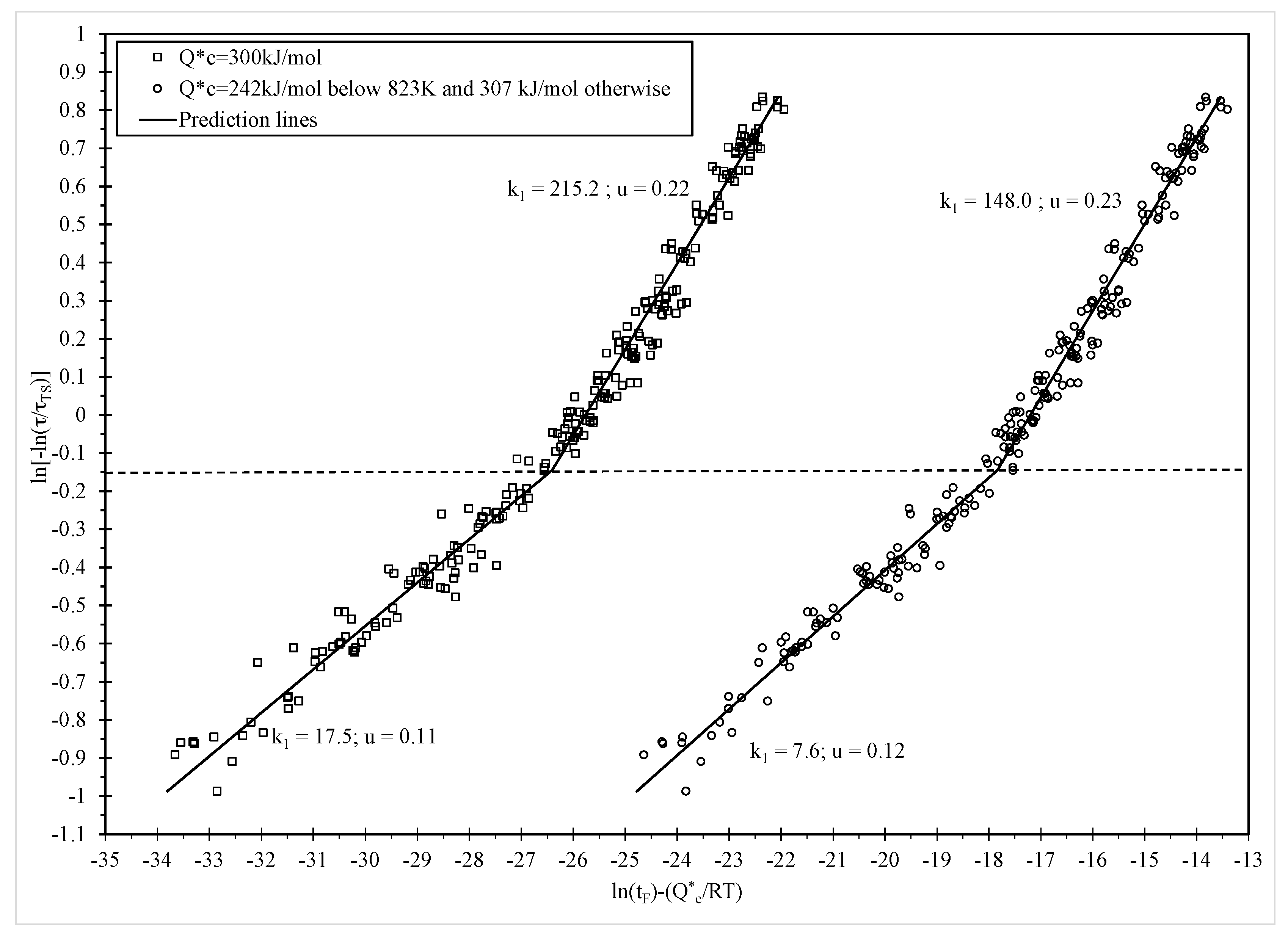

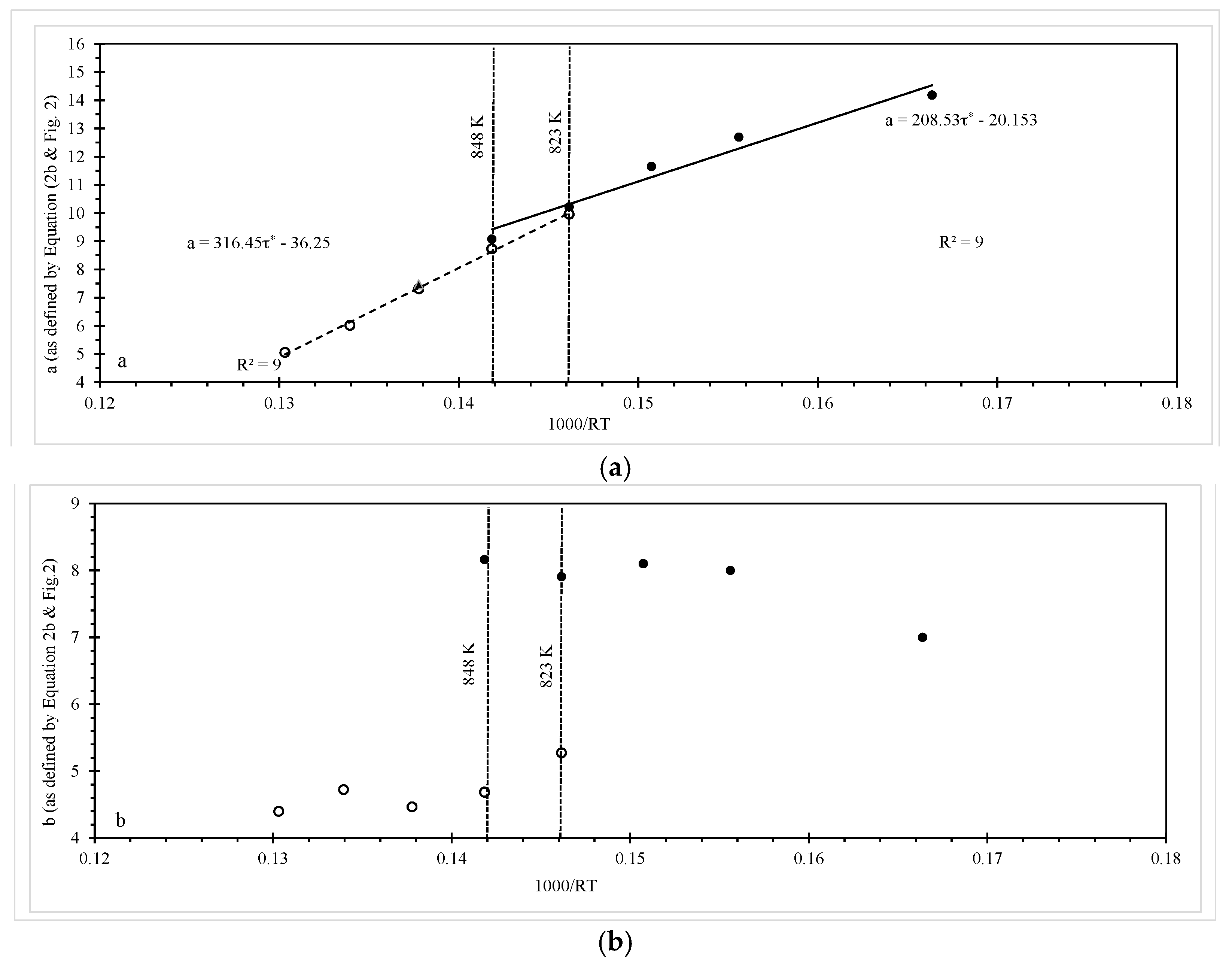

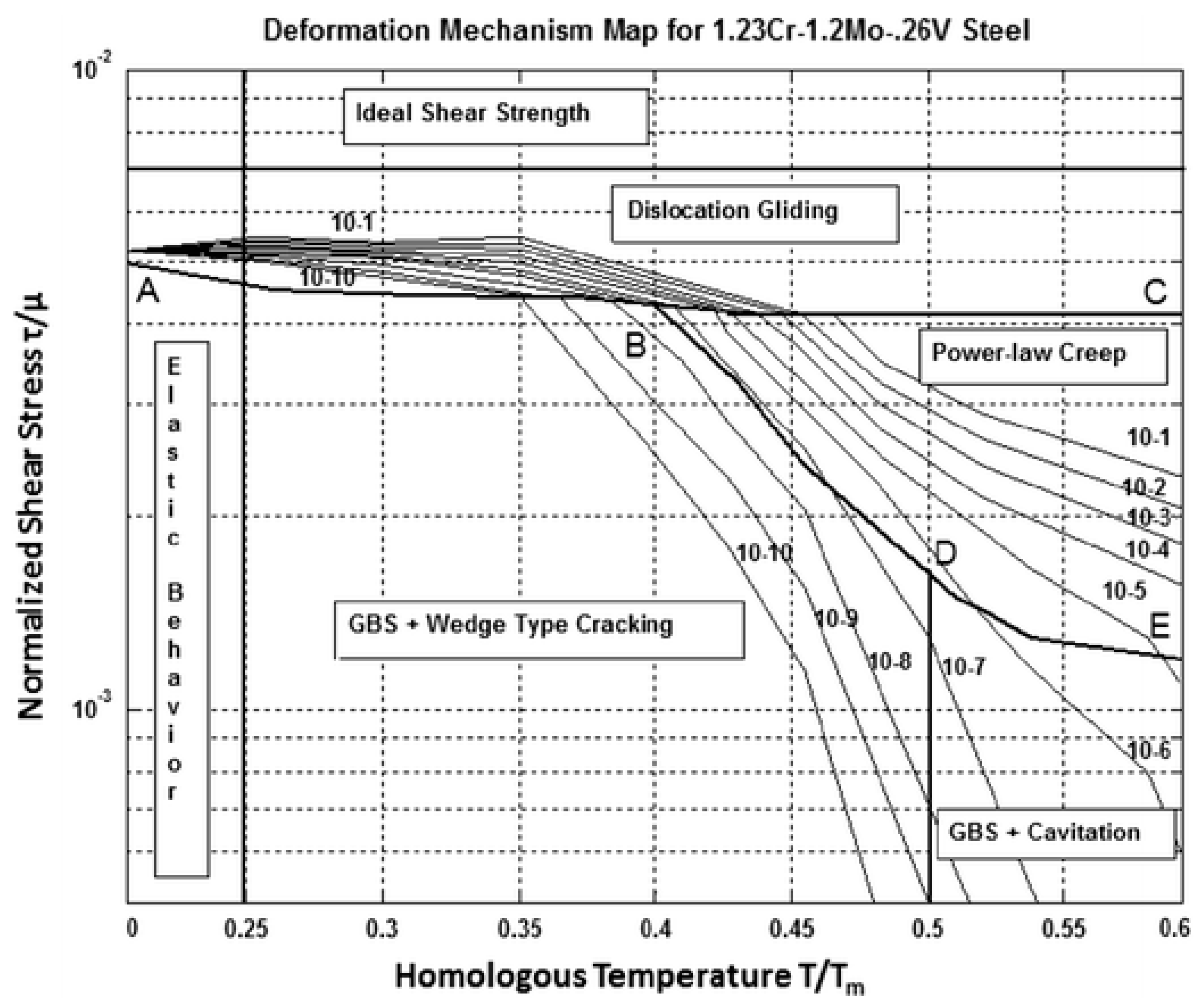

4. Re-Analysis of the Original Wilshire Study

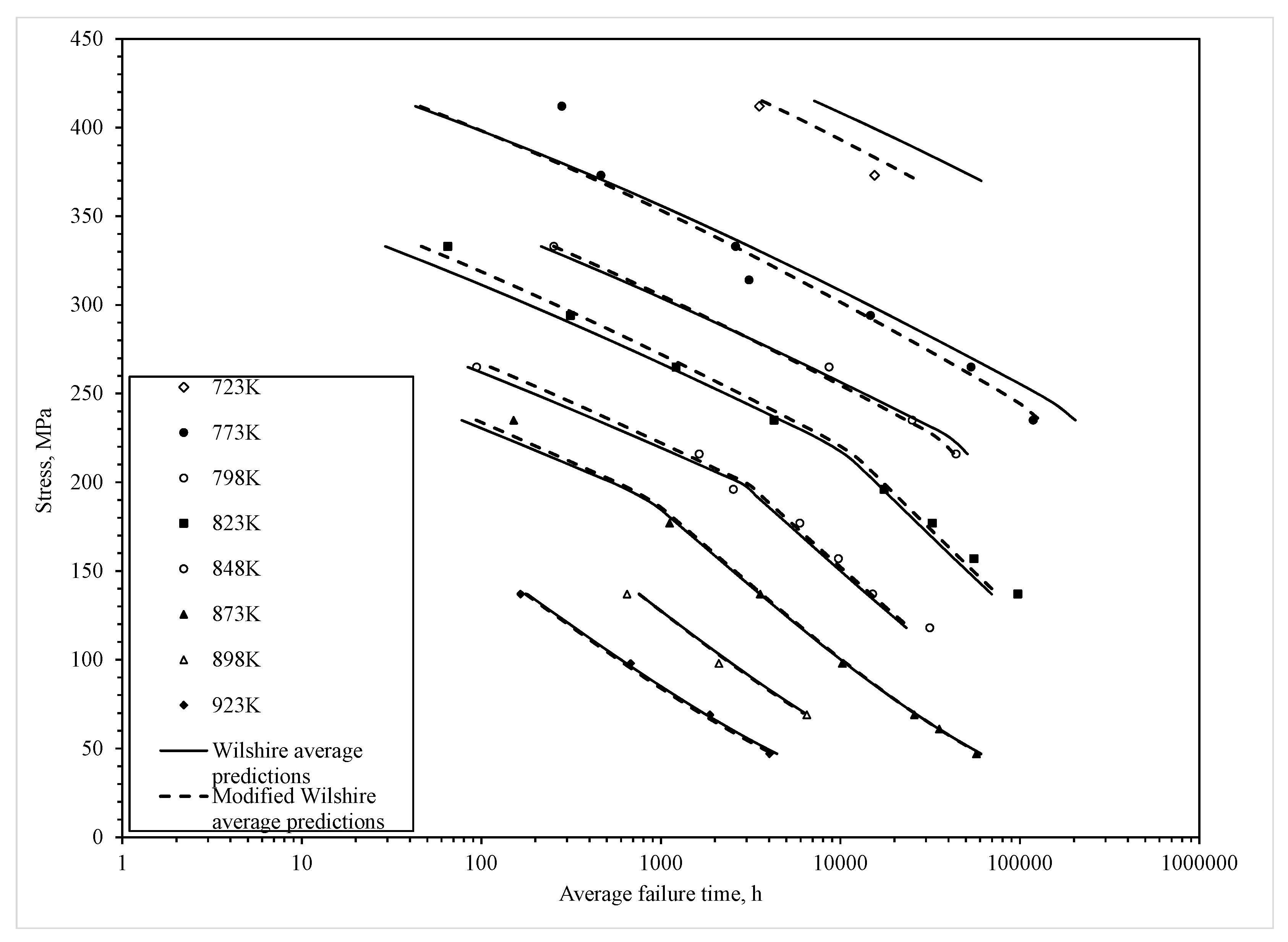

5. A Comparison of the Original and Modified Wilshire Equations

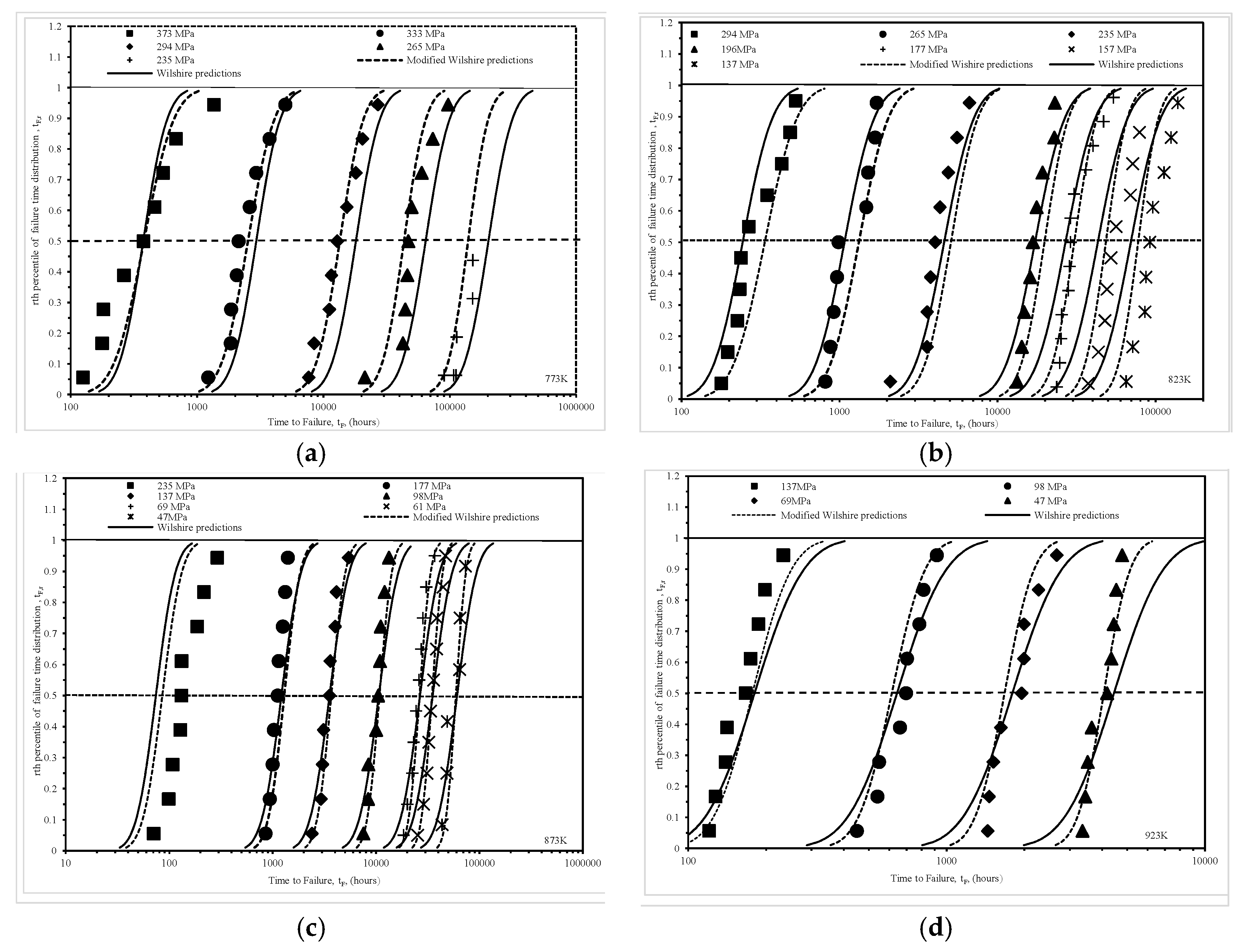

6. Predicted Time to Failure

7. Batch to Batch Variation and the Wilshire Equation

7.1. A Generalised Failure Time Distribution

7.2. Parameter Estimation

7.3. Findings

8. Conclusions

Acknowledgments

Conflicts of Interest

References

- Allen, D.; Garwood, S. Report 1: Energy materials. Available online: www.matuk.co.uk/docs/1_StrategicResearchAgenda FINAL.pdf (accessed on 15 December 2007).

- Wilshire, B.; Battenbough, A.J. Creep and Creep Fracture of Polycrystalline Copper. Mater. Sci. Eng. A 2007, 443, 156–166. [Google Scholar] [CrossRef]

- Wilshire, B.; Scharning, P.J. Prediction of Long Term Creep Data for Forged 1Cr-1Mo-0.25V Steel. Mater. Sci. Technol. 2008, 24, 1–9. [Google Scholar] [CrossRef]

- Wilshire, B.; Whittaker, M. Long Term Creep Life Prediction for Grade 22 (2·25Cr-1Mo) Steels. Mater. Sci. Technol. 2011, 27, 642–647. [Google Scholar]

- Wilshire, B.; Scharning, P.J. A New Methodology for Analysis of Creep and Creep Fracture Data for 9–12% Chromium Steels. Int. Mater. Rev. 2008, 53, 91–104. [Google Scholar] [CrossRef]

- Abdallah, A.; Perkins, K.; Williams, S. Advances in the Wilshire Extrapolation Technique—Full Creep Curve Representation for the Aerospace Alloy Titanium 834. Mater. Sci. Eng. A 2012, 550, 176–182. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Evans, M.; Wilshire, B. Long-Term Creep Data Prediction for Type 316H Stainless Steel. Mater. Sci. Eng. A 2012, 552, 145–150. [Google Scholar] [CrossRef]

- NIMS Creep Data Sheet No. 9b, 1990. Available online: http://smds.nims.go.jp/MSDS/en/sheet/Creep.html (accessed on 12 March 2017).

- Bano, N.; Koul, A.K.; Nganbe, M. A Deformation Mechanism Map for the 1.23Cr-1.2Mo-0.26V Rotor Steel and Its Verification Using Neural Networks. Metall. Mater. Trans. A 2014, 45, 1928–1936. [Google Scholar] [CrossRef]

- Stacy, E.W.; Mihram, G.A. Parameter Estimation for a Generalized Gamma Distribution. Technometrics 1965, 7, 349–358. [Google Scholar] [CrossRef]

- Prentice, R.L. Discrimination amongst Some Parametric Models. Biometrika 1975, 62, 607–614. [Google Scholar] [CrossRef]

- Evans, M. A Generalisation of the Wilshire-Scharning Methodology to Creep Life Prediction with Application to 1Cr-1Mo-0.25V Rotor Steel. J. Mater. Sci. 2008, 43, 6070–6080. [Google Scholar] [CrossRef]

- Lawless, J.F. Inference in the Generalised Gamma and Log Gamma Distributions. Technometrics 1980, 22, 409–419. [Google Scholar] [CrossRef]

- Berndt, B.; Hall, B.; Hall, R.; Hausman, J. Estimation and Inference in Nonlinear Structural Models. Ann. Econ. Soc. Meas. 1974, 3, 653–665. [Google Scholar]

| Parameter | Original Wilshire Equation: Equations (4) and (6) | Modified Wilshire Equation: Equation (5) and (7) | ||

|---|---|---|---|---|

| Estimate | Student t | Estimate | Student t | |

| a1 | −25.135 | −431.03 *** | - | - |

| b1 | 8.786 | 66.19 *** | 8.234 | 64.29 *** |

| Δ1 | −4.343 | −22.30 *** | −3.841 | −21.95 *** |

| a2 | −23.864 | −368.45 *** | - | - |

| b2 | 4.443 | 18.85 *** | 4.392 | 20.25 *** |

| d1 | - | - | −16.646 | −18.63 *** |

| Q*c (kJ/mol) | 300 | - | 242.029 | 39.73 *** |

| Δ2 | - | - | −64.838 | −8.21 *** |

| d2 | - | - | −26.678 | −18.27 *** |

| Q**c | - | - | 306.867 | 30.76 *** |

| τ*crit | −0.145 | - | −0.145 | - |

| Tcrit (K) | - | - | 823 | - |

| R2 (%) | 98.56 | - | 98.02 | - |

| Parameter | Modified Wilshire Equation | |

|---|---|---|

| Estimate | Student t | |

| a1 | - | - |

| b1 | 8.115 | 51.92 *** |

| Δ1 | –3.774 | –19.56 *** |

| b2 | 4.342 | 17.49 *** |

| d1 | –17.067 | –15.17 *** |

| Q*c (kJ/mol) | 244.381 | 31.74 *** |

| Δ2 | –65.175 | –7.13 *** |

| d2 | –27.025 | –15.47 *** |

| Q**c | 309.556 | 25.89 *** |

| β0 | –1.292 | –24.21 *** |

| β1 | –0.538 | –4.55 *** |

| τ*crit | –0.115 | - |

| Tcrit (K) | 823 | - |

| p,q | 0,0 | - |

| Ln L() | –27.778 | - |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evans, M. A Re-Evaluation of the Causes of Deformation in 1Cr-1Mo-0.25V Steel for Turbine Rotors and Shafts Based on iso-Thermal Plots of the Wilshire Equation and the Modelling of Batch to Batch Variation. Materials 2017, 10, 575. https://doi.org/10.3390/ma10060575

Evans M. A Re-Evaluation of the Causes of Deformation in 1Cr-1Mo-0.25V Steel for Turbine Rotors and Shafts Based on iso-Thermal Plots of the Wilshire Equation and the Modelling of Batch to Batch Variation. Materials. 2017; 10(6):575. https://doi.org/10.3390/ma10060575

Chicago/Turabian StyleEvans, Mark. 2017. "A Re-Evaluation of the Causes of Deformation in 1Cr-1Mo-0.25V Steel for Turbine Rotors and Shafts Based on iso-Thermal Plots of the Wilshire Equation and the Modelling of Batch to Batch Variation" Materials 10, no. 6: 575. https://doi.org/10.3390/ma10060575

APA StyleEvans, M. (2017). A Re-Evaluation of the Causes of Deformation in 1Cr-1Mo-0.25V Steel for Turbine Rotors and Shafts Based on iso-Thermal Plots of the Wilshire Equation and the Modelling of Batch to Batch Variation. Materials, 10(6), 575. https://doi.org/10.3390/ma10060575