Coaxial Electrospinning and Characterization of Core-Shell Structured Cellulose Nanocrystal Reinforced PMMA/PAN Composite Fibers

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Preparation of Cellulose Nanocrystals

2.3. Preparation of the Spinning Solution

- Dissolve the PAN powder in DMF under vigorous magnetic stirring at 50 °C for 24 h to obtain a 16 w/v % concentrated PAN solution.

- Dissolve PMMA particles in DMF under vigorous magnetic stirring at 50 °C for 24 h to obtain a 22 wt % concentrated PMMA solution.

- Add the CNCs, obtained as described above, to the PMMA solution and agitate for 12 h followed by ultrasonic dispersion for 20 min before electrospinning. The CNCs loading levels in respect to the PMMA weight were chosen at 0, 5, 10, 15, 20 wt %. For the simplicity of discussion, we use PMMA + x CNCs to designate the samples, where x (wt %) is the CNCs loading level.

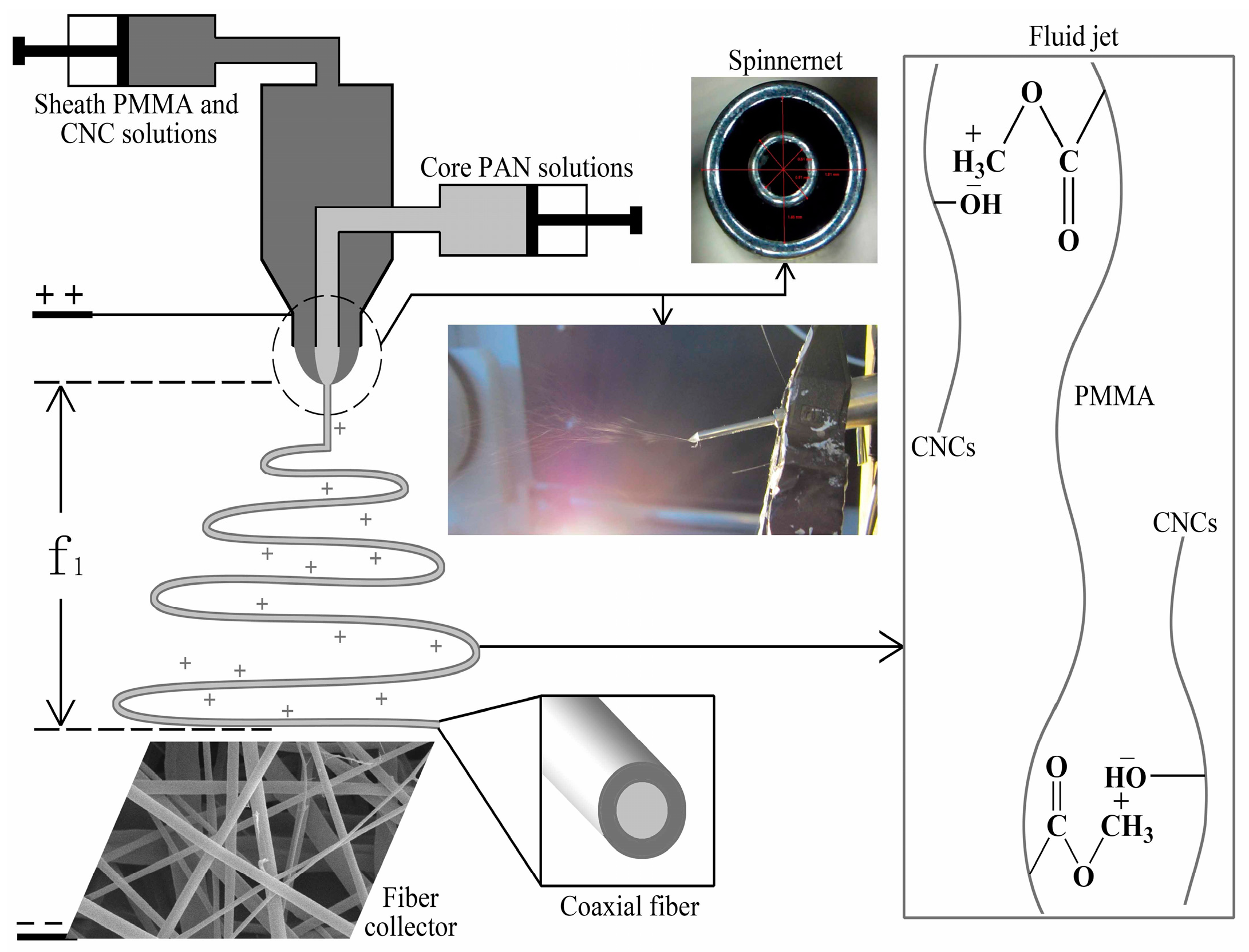

2.4. Coaxial Electrospinning Set-Up

2.5. Characterization of Spinning Solutions

2.6. Evaluation of Coaxial Electrospun Composite Nanofibers

3. Results and Discussion

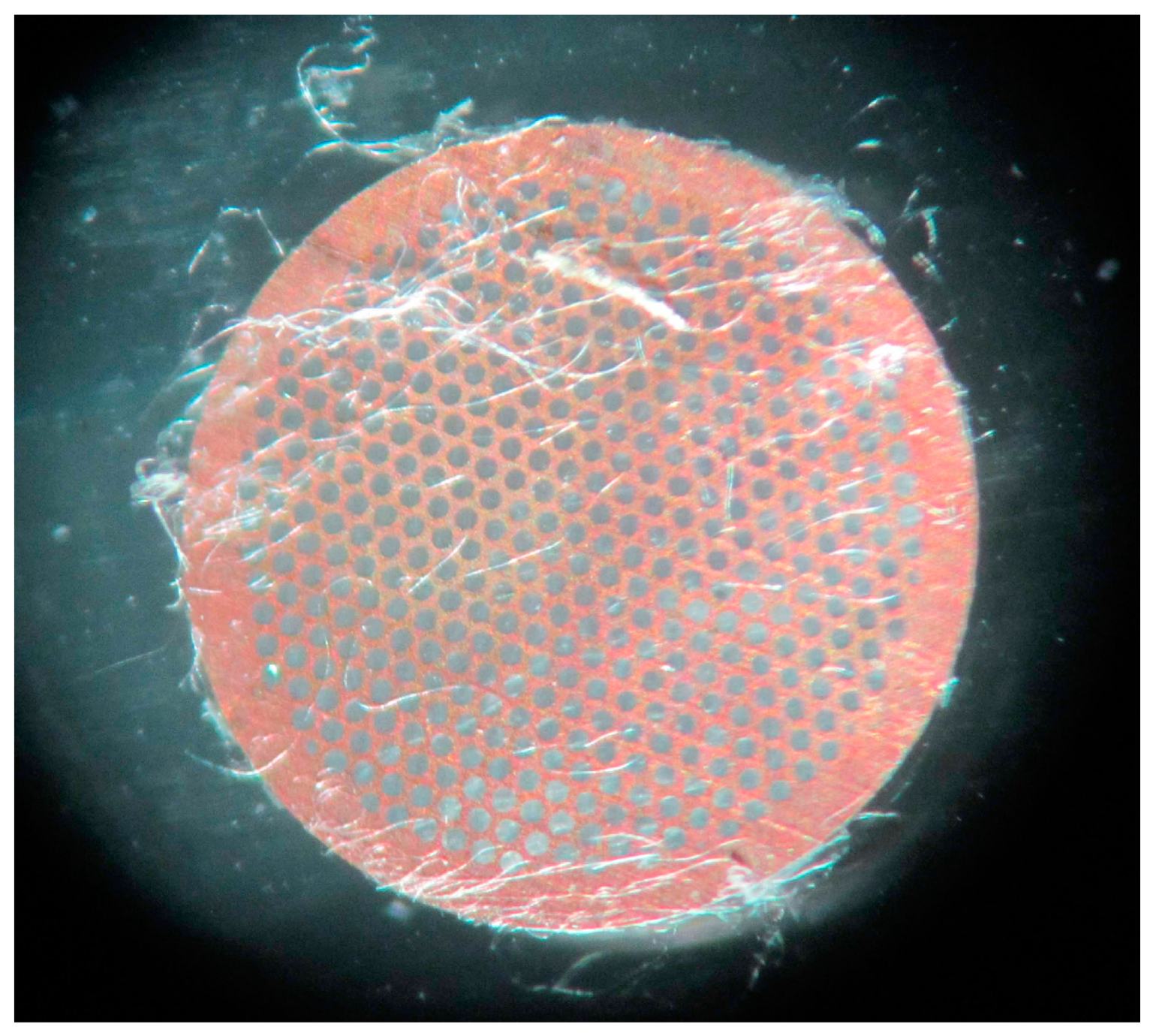

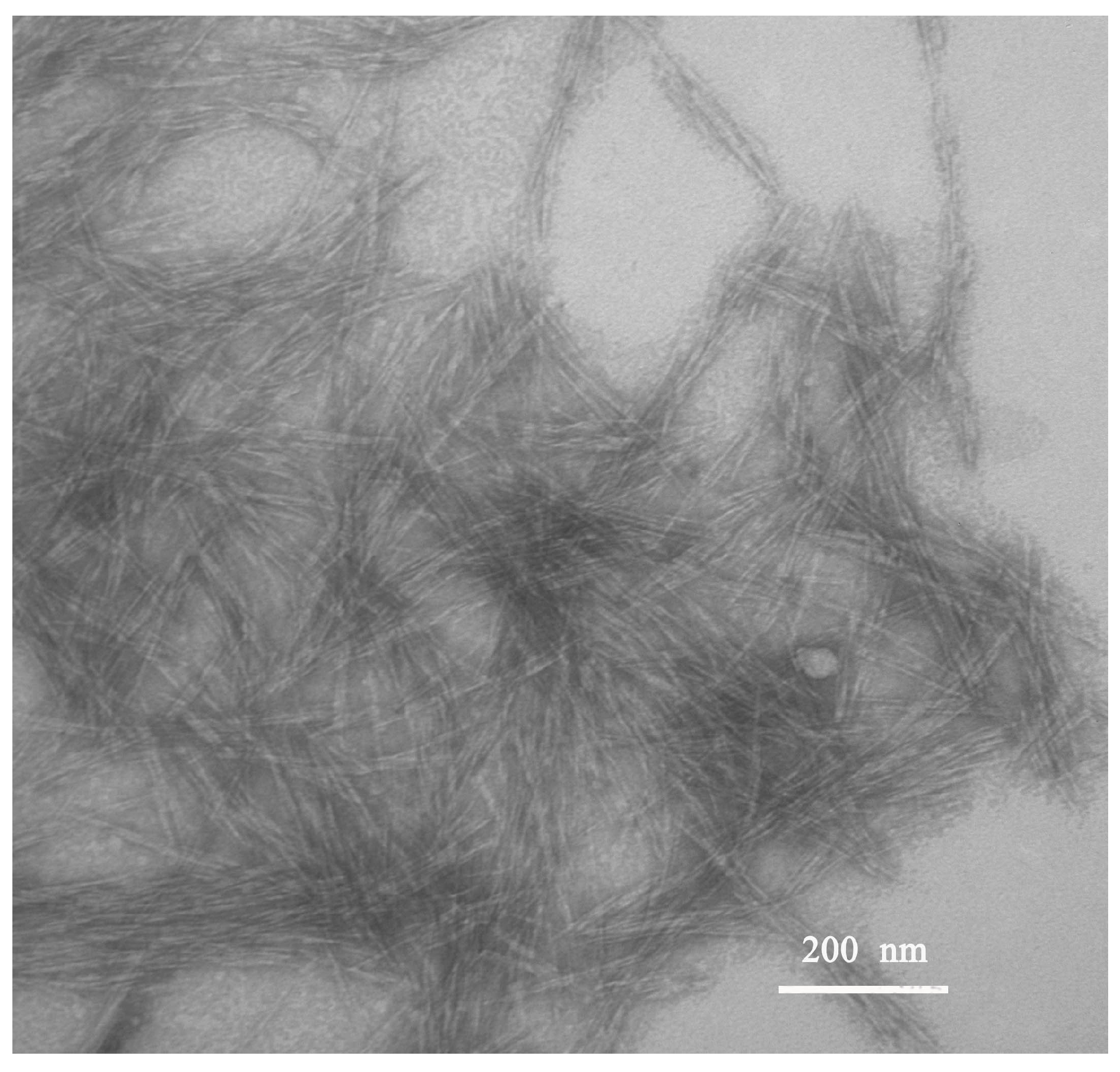

3.1. The Morphology of CNCs

3.2. Properties of Spinning Solution

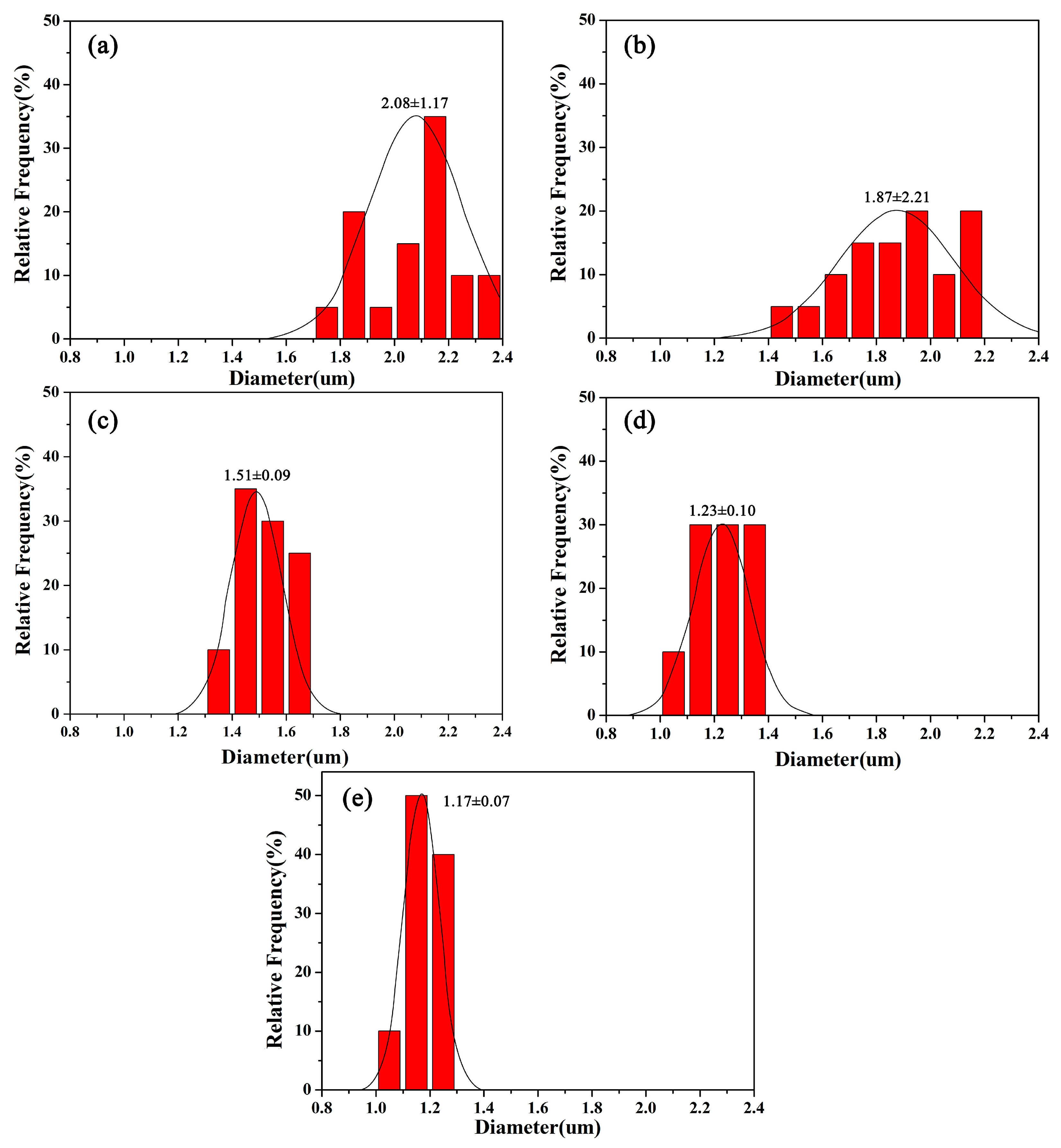

3.3. The Morphology of Coaxial Electrospun Composite Nanofibers

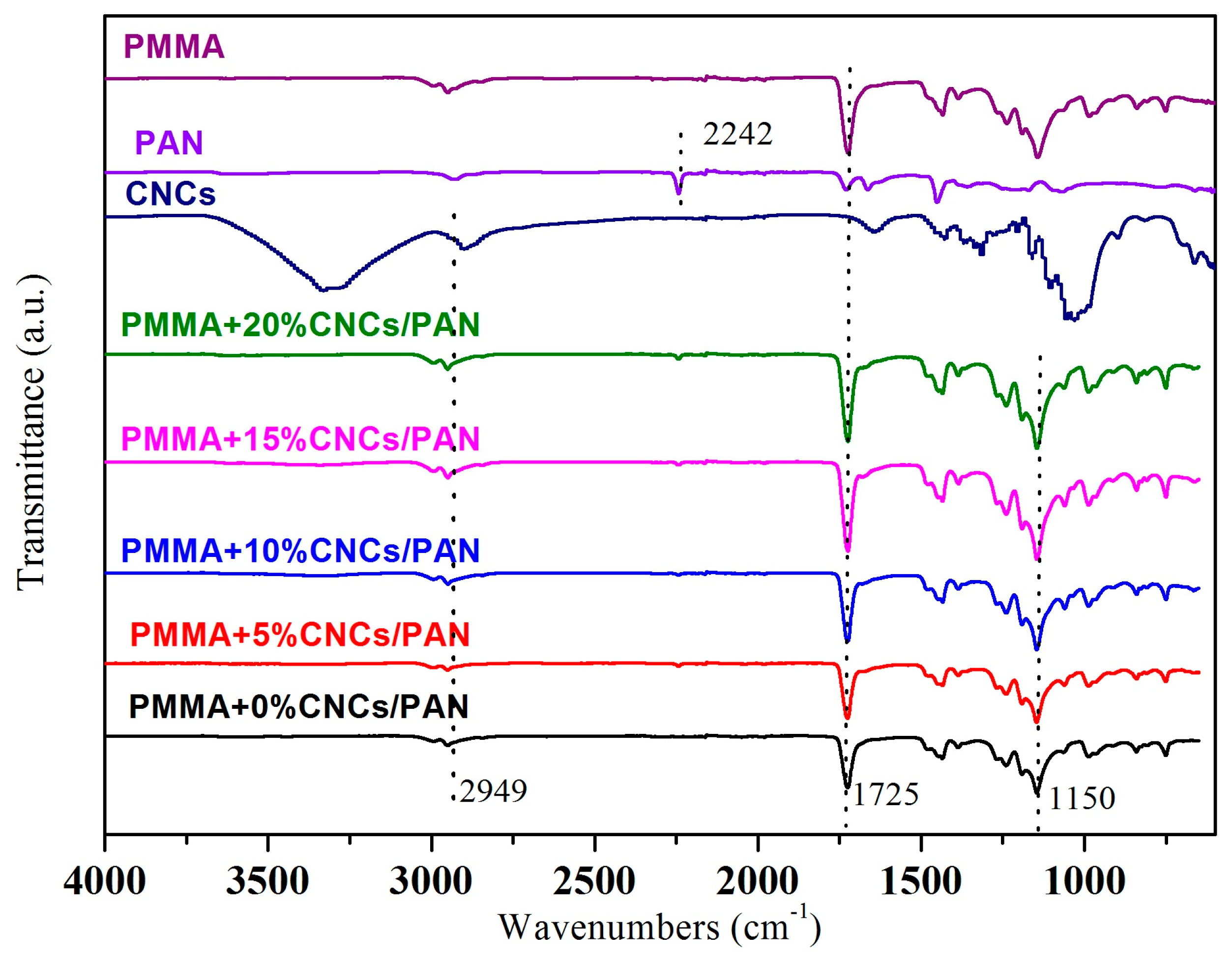

3.4. FTIR of Coaxial Electrospun Composite Nanofibers

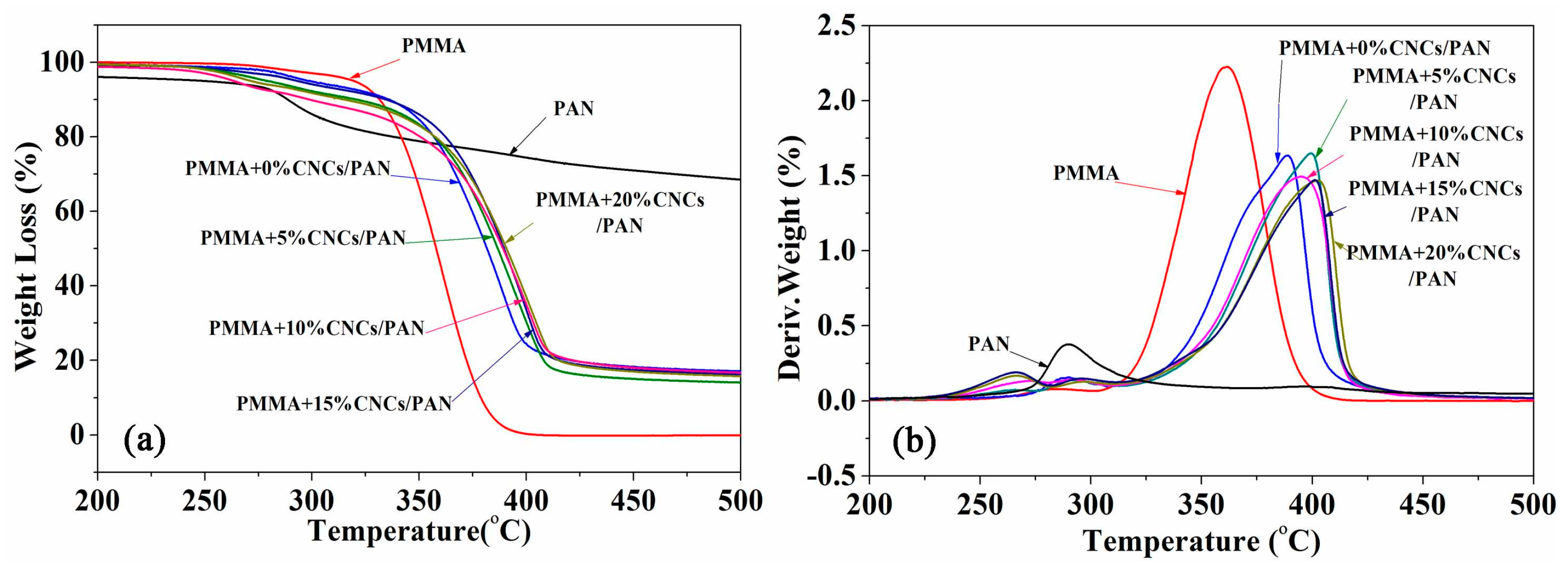

3.5. Thermal Behavior of Coaxial Composite Nanofibers

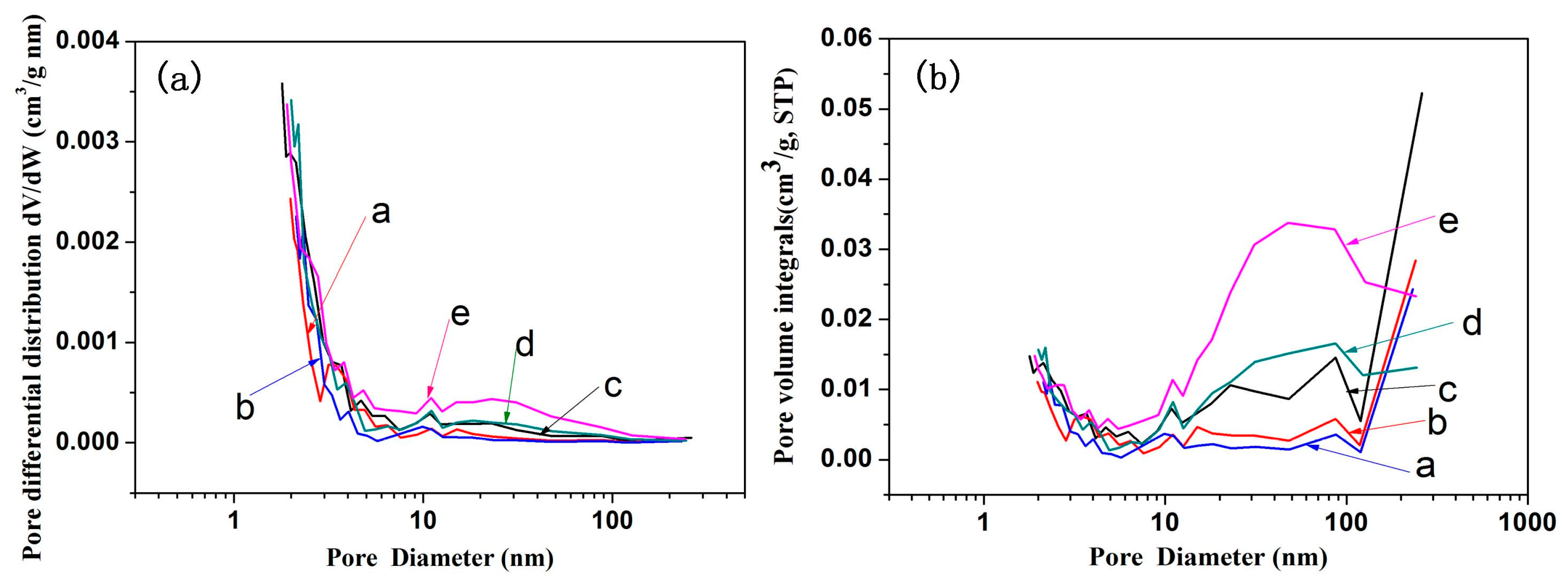

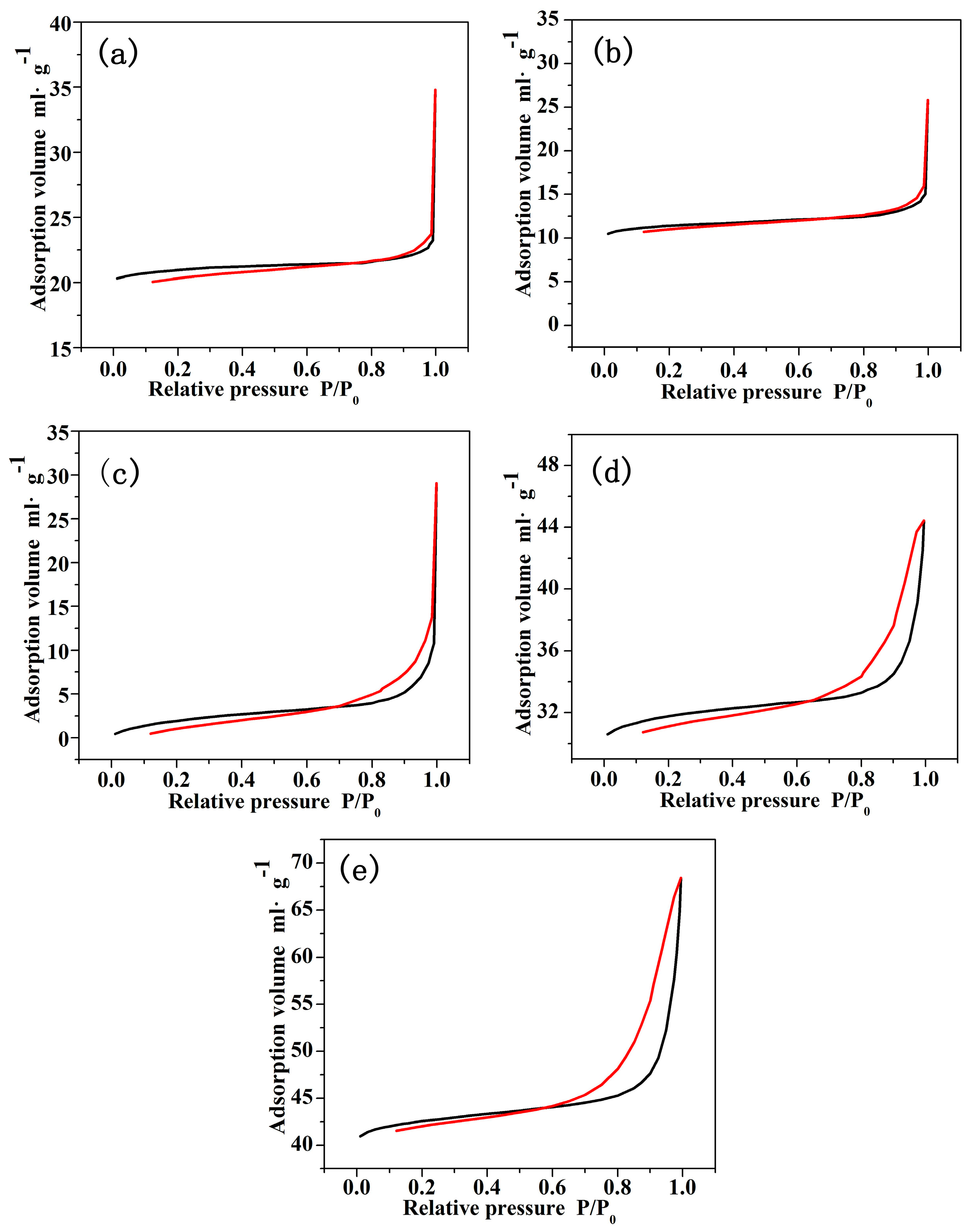

3.6. The Specific Surface Area and Pore Size Distribution of Coaxial Composite Nanofibers

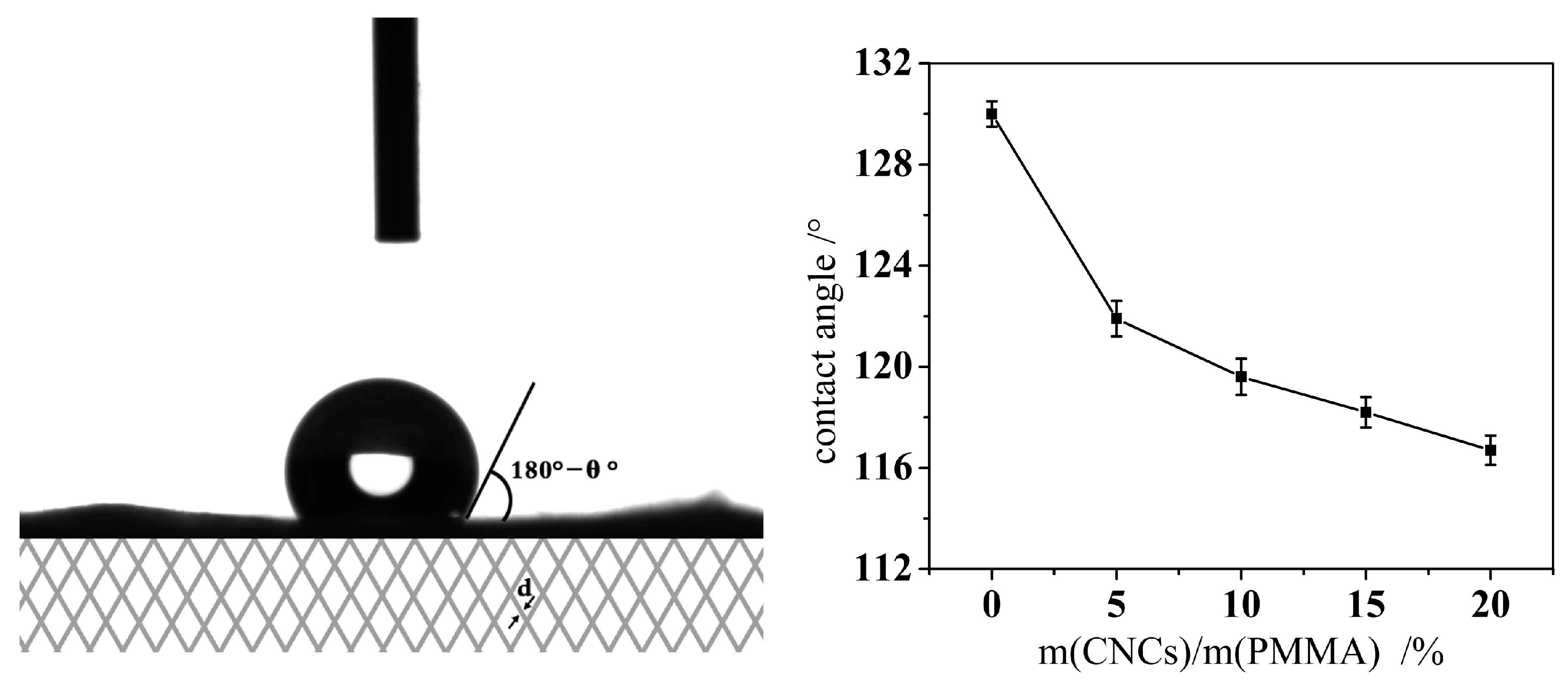

3.7. Wettability of Coaxial Electrospun Composite Membrane

4. Conclusions

- The fiber diameter decreased from 2 μm to 1.17 μm when the CNCs level increased from 0% to 20%, while its distribution narrowed.

- The thermal stability of coaxial electrospun composite nanofibers was significantly enhanced.

- CNCs were physically mixed with PMMA and probably distributed on the shell surface of the coaxial composite nanofibers according to the FTIR analysis.

- The specific surface area of the core-shell composite significantly increased with increasing CNCs content.

- The surface structure of the fibers gradually changed from a non-hole to porous surface that contained a higher proportion of mesoporous material.

- The hydrophobic properties of the coaxial electrospun composite membrane reduced due to the presence of –OH hydroxyl groups on the CNCs.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- French, A.D.; Bertoniere, N.R.; Brown, R.M.; Chanzy, H.; Gray, D.; Hattori, K.; Glasser, W. Cellulose. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: New York, NY, USA, 2004; Volume 5, pp. 360–394. [Google Scholar]

- Yue, Y.Y.; Han, J.Q.; Han, G.P. Cellulose fibers isolated from energycane bagasse using alkaline and sodium chlorite treatments: Structural, chemical and thermal properties. Ind. Crop. Prod. 2015, 76, 355–363. [Google Scholar] [CrossRef]

- Lu, P.; Hsieh, Y.L. Preparation and properties of cellulose nanocrystals: Rods, spheres, and network. Carbohydr. Polym. 2010, 82, 329–336. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.L.S.; Nascimento, D.M.; Souza Filho, M.M.; Morais, J.P.S.; Vasconcelos, N.F.; Feitosa, J.P.A. Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohydr. Polym. 2014, 112, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Huan, S.Q.; Bai, L.; Cheng, W.L. Manufacture of electrospun all-aqueous poly (vinyl alcohol)/cellulose nanocrystal composite nanofibrous mats with enhanced properties through controlling fibers arrangement and microstructure. Polymer 2016, 92, 25–35. [Google Scholar] [CrossRef]

- Huan, S.Q.; Bai, L.; Liu, G.X. Electrospun nanofibrous composites of polystyrene and cellulose nanocrystals: Manufacture and characterization. RSC Adv. 2015, 5, 50756–50766. [Google Scholar] [CrossRef]

- Sun, X.; Uyama, H. A poly(vinyl alcohol)/sodium alginate blend monolith with nanoscale porous structure. Nanoscale Res. Lett. 2013, 8. [Google Scholar] [CrossRef] [PubMed]

- Pant, H.R.; Risal, P.; Park, C.H. Core–shell structured electrospun biomimetic composite nanofibers of calcium lactate/nylon-6 for tissue engineering. Chem. Eng. J. 2013, 221, 90–98. [Google Scholar] [CrossRef]

- Han, D.; Steckl, A.J. Triaxial electrospun nanofiber membranes for controlled dual release of functional molecules. ACS Appl. Mater. Interfaces 2013, 5, 8241–8245. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Nyame, V.; MacDiarmid, A.G. Polyaniline/poly(methyl methacrylate) coaxial fibers: The fabrication and effects of the solution properties on the morphology of electrospun core fibers. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 3934–3942. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Electrospinning of nanofibers: Reinventing the wheel. Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Fridrikh, S.V.; Jian, H.Y.; Brenner, M.P. Controlling the fiber diameter during electrospinning. Phys. Rev. Lett. 2003, 90, 144502. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.H.; Inai, R.; Kotaki, M. Systematic parameter study for ultra-fine fiber fabrication via electrospinning process. Polymer 2005, 46, 6128–6134. [Google Scholar] [CrossRef]

- Yu, D.G.; Shen, X.X.; Branford-White, C. Oral fast-dissolving drug delivery membranes prepared from electrospun polyvinylpyrrolidone ultrafine fibers. Nanotechnology 2009, 20, 055104. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Liu, D.; Yao, F. Fabrication and properties of transparent polymethylmethacrylate/cellulose nanocrystals composites. Bioresour. Technol. 2010, 101, 5685–5692. [Google Scholar] [CrossRef] [PubMed]

- Han, G.P.; Huan, S.O.; Han, J.Q. Effect of acid hydrolysis conditions on the properties of cellulose nanoparticle-reinforced polymethylmethacrylate composites. Materials 2013, 7, 16–29. [Google Scholar] [CrossRef]

- Yue, Y.Y.; Zhou, C.J.; French, A.D.; Xia, G.; Han, G.P.; Wang, Q.W.; Wu, Q.L. Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 2012, 19, 1173–1187. [Google Scholar] [CrossRef]

- Greiner, A.; Wendorff, J.H. Electrospinning: A fascinating method for the preparation of ultrathin fibers. Angew. Chem. Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef] [PubMed]

- Ding, B.; Yu, J.Y. Electrospinning and Nanofibers, 1st ed.; Textile & Apparel Press: Beijing, China, 2011; pp. 134–155. ISBN 978-7-5064-7264-8. [Google Scholar]

- Lan, M.B. Nano-Material Testing Technology, 1st ed.; East China University of Science and Technology Press: Shanghai, China, 2009; pp. 182–185. ISBN 978-7-5628-2221-9. [Google Scholar]

- Abe, K.; Iwamoto, S.; Yano, H. Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 2007, 8, 3276–3278. [Google Scholar] [CrossRef] [PubMed]

- Fortunati, E.; Benincasa, P.; Balestra, G.M.; Luzi, F.; Mazzaglia, A.; Del Buono, D.; Puglia, D.; Torre, L. Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA_CH nanocomposites. Ind. Crop. Prod. 2016, 92, 201–217. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, Q.; Zhang, Q. Dynamic rheology studies of in situ polymerization process of polyacrylamide–cellulose nanocrystal composite hydrogels. Colloid Polym. Sci. 2011, 289, 247–255. [Google Scholar] [CrossRef]

- Choi, J.S.; Lee, S.W.; Jeong, L. Effect of organosoluble salts on the nanofibrous structure of electrospun poly (3-hydroxybutyrate-co-3-hydroxyvalerate). Int. J. Biol. Macromol. 2004, 34, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Fong, H.; Chun, I.; Reneker, D.H. Beaded nanofibers formed during electrospinning. Polymer 1999, 40, 4585–4592. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.H.; Yu, D.G. Tunable biphasic drug release from ethyl cellulose nanofibers fabricated using a modified coaxial electrospinning process. Nanoscale Res. Lett. 2014, 9, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.; Wang, H.; Wang, H. The charge effect of cationic surfactants on the elimination of fibre beads in the electrospinning of polystyrene. Nanotechnology 2004, 15, 1375–1381. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Herrera, J.M.; Barrero, A.; Lopez, A. Coaxial jets generated from electrified Taylor cones. Scaling laws. J. Aerosol. Sci. 2003, 34, 535–552. [Google Scholar] [CrossRef]

- Yu, J.H.; Fridrikh, S.V.; Rutledge, G.C. Production of submicrometer diameter fibers by two-fluid electrospinning. Adv. Mater. 2004, 16, 1562–1566. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Ahmad, I.; Abdullah, I. Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 2012, 19, 855–866. [Google Scholar] [CrossRef]

- Kaboorani, A.; Riedl, B.; Blanchet, P. Nanocrystalline cellulose (NCC): A renewable nano-material for polyvinyl acetate (PVA) adhesive. Eur. Polym. J. 2012, 48, 1829–1837. [Google Scholar] [CrossRef]

- Huang, L.; Bui, N.N.; Manickam, S.S. Controlling electrospun nanofiber morphology and mechanical properties using humidity. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1734–1744. [Google Scholar] [CrossRef]

- Zhou, C.J.; Chu, R.; Wu, R.; Wu, Q.L. Electrospun polyethylene oxide/cellulose nanocrystal composite nanofibrous mats with homogeneous and heterogeneous microstructures. Biomacromolecules 2011, 12, 2617–2625. [Google Scholar] [CrossRef] [PubMed]

- Ou, Y.; Wu, Q.; Wan, L. Preparation of porous polyacrylonitrile ultrathin fibers by electrospinning with nonsolvent induced phase separation. Acta Polym. Sin. 2013, 2, 248–254. [Google Scholar]

- Miao, Y.; Liu, T. Recent progress in hierarchically organized polymer nanocomposites based on electrospun nanofibers. Acta Polym. Sin. 2012, 8, 801–811. [Google Scholar] [CrossRef]

| Solution | Conductivity (μS·cm−1) | Viscosity (mPa·s) | Surface Tension (mN·m−1) |

|---|---|---|---|

| PAN | 30.4 ± 2.1 | 500 ± 8 | 29.6 ± 7 |

| PMMA | 2.06 ± 0.11 | 396 ± 5 | 23.4 ± 4 |

| PMMA + 5% CNCs | 7.55 ± 0.33 | 612 ± 6 | 24.9 ± 4 |

| PMMA + 10% CNCs | 15.8 ± 0.71 | 704 ± 9 | 25.8 ± 5 |

| PMMA + 15% CNCs | 29.2 ± 1.29 | 840 ± 11 | 26.2 ± 7 |

| PMMA + 20% CNCs | 33.4 ± 1.33 | 888 ± 12 | 26.6 ± 7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Li, Q.; Ni, X.; Liu, G.; Cheng, W.; Han, G. Coaxial Electrospinning and Characterization of Core-Shell Structured Cellulose Nanocrystal Reinforced PMMA/PAN Composite Fibers. Materials 2017, 10, 572. https://doi.org/10.3390/ma10060572

Li C, Li Q, Ni X, Liu G, Cheng W, Han G. Coaxial Electrospinning and Characterization of Core-Shell Structured Cellulose Nanocrystal Reinforced PMMA/PAN Composite Fibers. Materials. 2017; 10(6):572. https://doi.org/10.3390/ma10060572

Chicago/Turabian StyleLi, Chao, Qingde Li, Xiaohui Ni, Guoxiang Liu, Wanli Cheng, and Guangping Han. 2017. "Coaxial Electrospinning and Characterization of Core-Shell Structured Cellulose Nanocrystal Reinforced PMMA/PAN Composite Fibers" Materials 10, no. 6: 572. https://doi.org/10.3390/ma10060572

APA StyleLi, C., Li, Q., Ni, X., Liu, G., Cheng, W., & Han, G. (2017). Coaxial Electrospinning and Characterization of Core-Shell Structured Cellulose Nanocrystal Reinforced PMMA/PAN Composite Fibers. Materials, 10(6), 572. https://doi.org/10.3390/ma10060572