1. Introduction

The brittleness of geopolymers prevents them from being reliable components in horizontal constructions, such as a cross member for transversal beams and deck flue bricks [

1]. Iron girders and steel concrete are utilized in practical situations, where their usage is often overdesigned. Currently, there is no material which could replace concrete with steel beams in cases of a lower load [

2]. However, in spite of their brittleness, geopolymers are promising materials due to the variability of compositions and the possibility of combining other materials as reinforcement [

3]. Fiber addition has been assessed several times with the publication of the mechanical properties, but no paper was found to have investigated reinforcement under the influence of different proportions of the composite components, while varying the addition of the glass-fiber reinforcement.

Paper [

4] found that reinforcement by short glass fibers does not have any special effect on the increase in the compressive strength results, although it has a significant effect on the increasing flexural strength. The microstructure cracks are the focus of the investigation of the fracture mechanism [

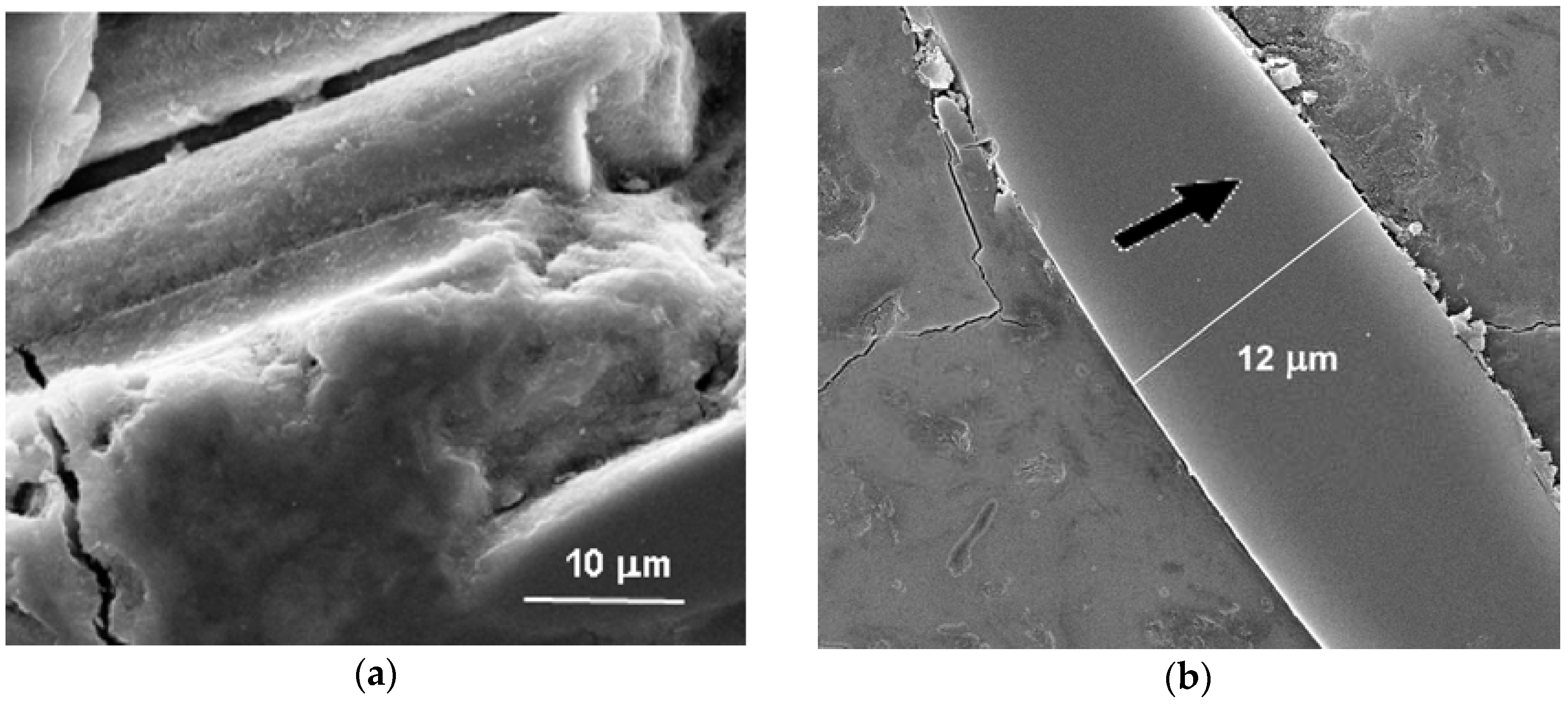

5], where the importance of the presence of glass fibers was shown on glass-fibers overcoming and fixing micro-cracks up to an overload of the fibers. The role of the interfacial transition zone (ITZ) was emphasized in the microstructure [

6]. Whereas plastic fibers are used in Portland cement concrete, they are less suitable for the reinforcement of geopolymers as they do not bind tightly with geopolymers and water transportation takes place on the surface of the fibers during desiccation/polycondensation [

7,

8]. This is because the weakest part of the composite is the ITZ of the fibers, where the matrix has become porous. The resulting compressive and flexural strength do not correspond to the merit of the fibers’ addition. Better adhesion was found using polyvinyl alcohol (PVA) fibers [

9]. Due to the related chemical composition of a geopolymer, glass fibers are more suitable than plastic fibers. Nevertheless, there is a thin alkali-resistant sizing [

10] on the glass fibers, preventing mechanical strain during the fabric’s production. The sizing [

11] is suspected to obstruct the binding of glass fibers to the geopolymer, which can lead to an increase of porosity. This is the reason why the glass fibers’ application was not as efficient as had been supposed.

The contribution of short cut glass fibers to the properties of geopolymer quartz-sand mortars has been investigated in this paper. Mortars have recently been examined [

12], during which the optimal composition was determined, and the grain size and the amount of aggregates were considered. The main goal of this work, however, is to identify the relationship between the geopolymer structure and the short cut glass fibers, to reveal the optimal ratio between the matrix, sand aggregate, and fibers, as well as to find an optimal technique for fabrication and to compare the effect of the aggregate-particle sizes. The fibers may have an influence on water transportation and involve the formation of a tight matrix microstructure in the ITZ by draining water during the polycondensation of the geopolymer gel. In fact, the glass fibers can bridge micro-cracks, which, more or less, are always parts of a geopolymer matrix and so influence the crack sorptivity and the products’ durability [

13,

14]. As has previously been found, the occurrence of fibers has an impact on decreasing the shrinkage [

7]. This can eventually mean a lower number of micro-cracks and thus better mechanical properties. The cut fibers constitute extremely isotropic particles and the impact of the fibers on the brittleness of the geopolymer is examined.

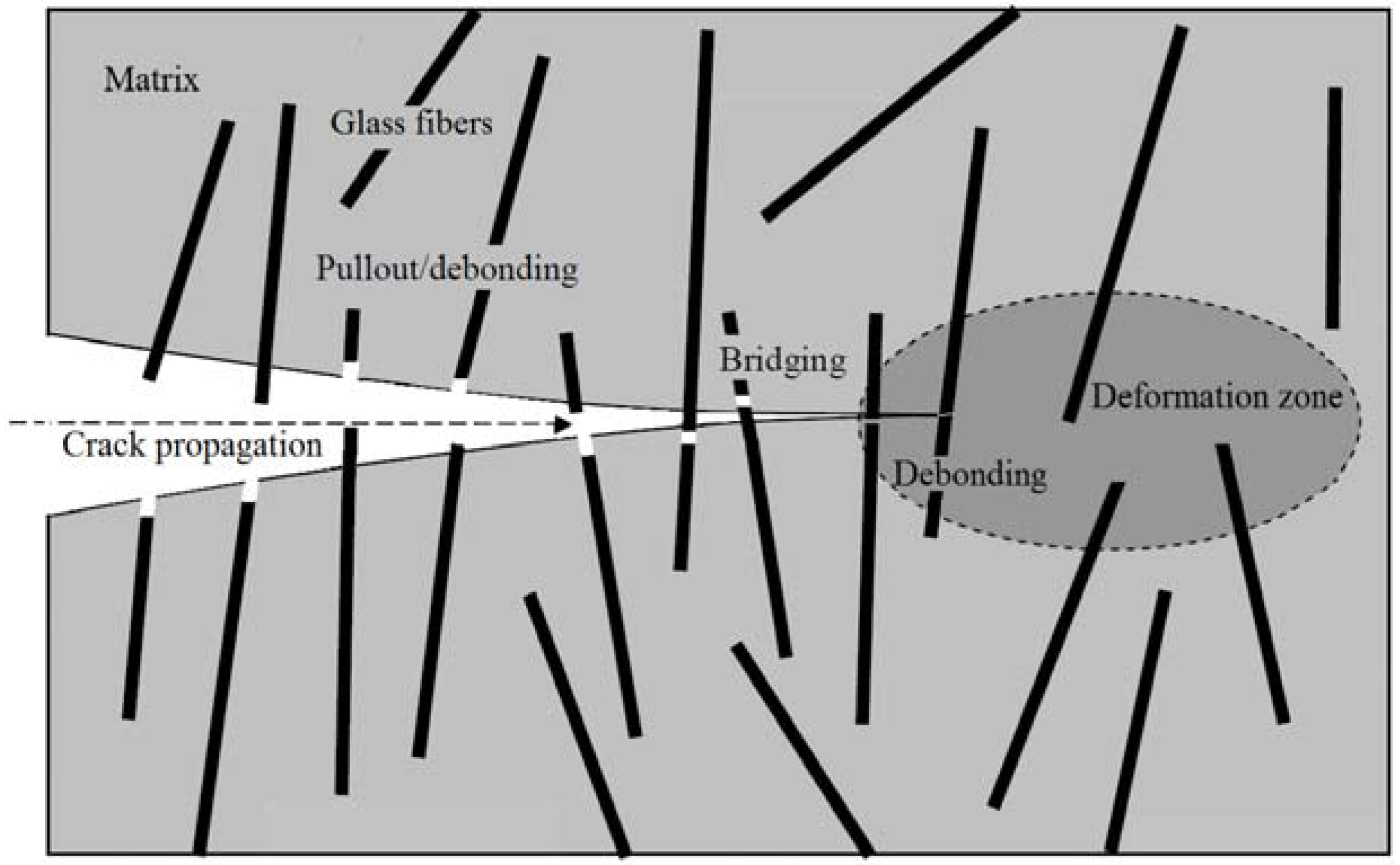

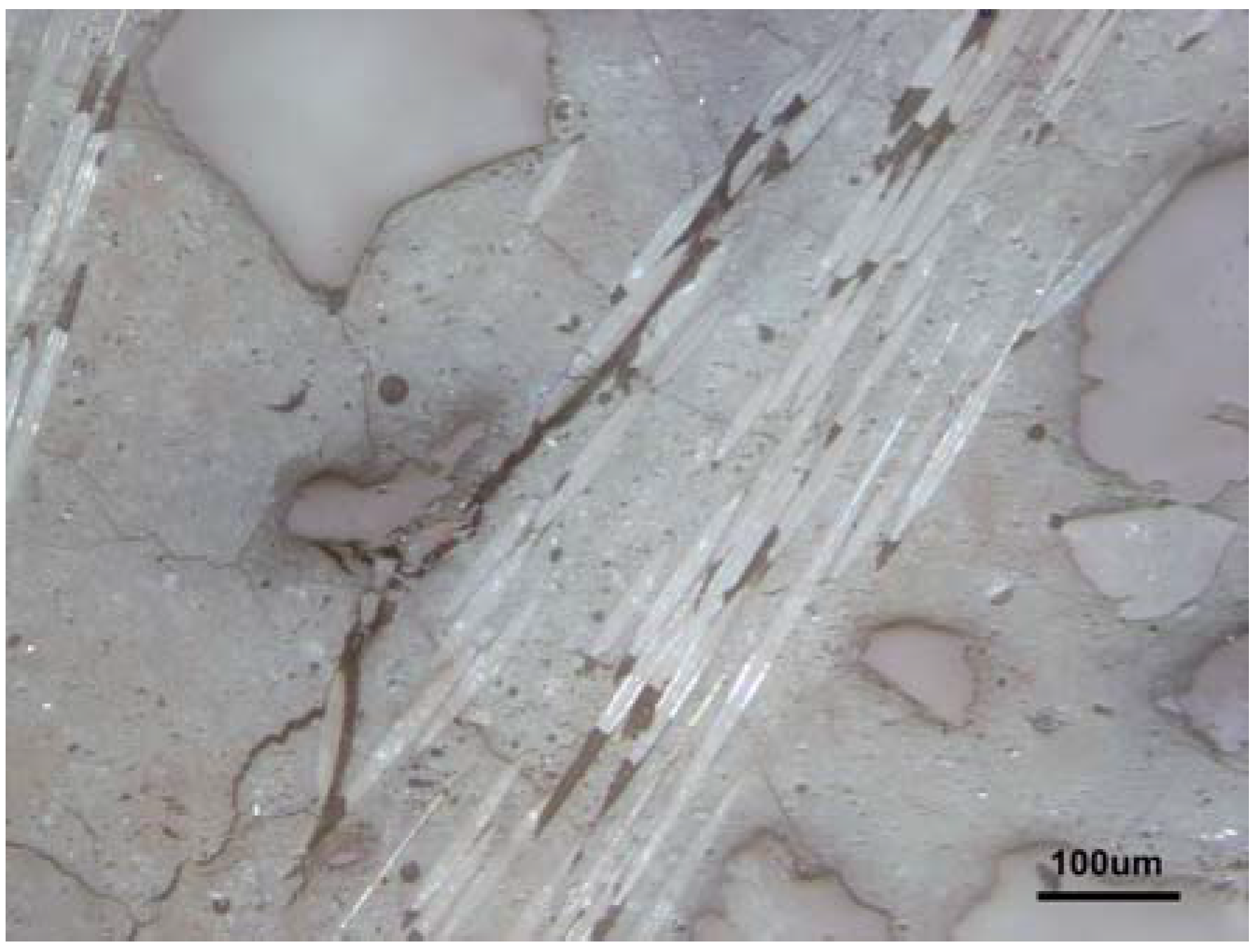

Figure 1 exemplifies the supposed behavior of the glass-fiber reinforcement in the geopolymer matrix, where the fibers are severed during the fracture while pulling them partly out of the matrix [

15,

16]. This grid is able to efficiently hinder the brittle fracture, in addition to improving the toughness of the composite structure, as is proven in our measurement. The combination of the varying ratios of the aggregate and fibers in the geopolymer was investigated by means of compressive strength, flexural strength, elastic modulus, and impact strength, using the Charpy method. The fiber addition suspected to be responsible for the increased capillarity was investigated in detail with the help of the resistance to acid waters and changes in the porous-structural parameters. The chemical stability and durability of reinforced composites was compared with a mortar without reinforcement. The intention was to demonstrate the acid resistance limited by certain structure parameters. We know that not all geopolymers are acid resistant, and at present, we are dealing with that issue in subsequent research focused on selected optimized compositions. The acid resistance in this paper is considered in order to compare the various mixtures with and without glass fibers.

2. Materials and Methods

2.1. Materials

As the initial materials, metakaolin, sodium silicate solution, and sodium hydroxide, were used to prepare the geopolymer binder. In this experiment, the molar ratio selected was Si/Al = 1.8, Na/Al = 1.0, and H2O/SiO2 = 0.7. Metakaolin was prepared from pulverized kaolin Sedlec Ia calcined at 750 °C for 6 h. The chemical composition of this kaolin is the following (wt %): SiO2 (47.3), Al2O3 (36.9), Fe2O3 (0.90), TiO2 (0.20), CaO (0.25), MgO (0.27), K2O (0.95), Na2O (0.02), and Loss by ignition (12.9). The particle size of metakaolin was 0.1–25 µm, with D50 = 15 µm.

The binder dispersion was stirred for 5 min under an intensive regime and successively under the vacuum removal of the air bubbles created by stirring. The quartz sand provided by Sklopisek Strelec, a.s. (Ujezd pod Troskami, Czech Republic), was added as the aggregate. The source was selected in three different types of sand, varying in grain-size distribution, and therefore, in the specific surface as a contact and reactive area (resulting into interfacial transition zone-ITZ), calculated from the grain-size measurement with the CILAS 940 and CILAS 2000 laser-dispersive granulometry equipment (Colas, Orleans, France). The sizes and specific surfaces are summarized below in

Table 1.

Cut glass fibers of 4.5 mm in length (provided by Skolil-Kompozit s.r.o., Prague, Czech Republic) were added to the sand composite mixtures in two different portions, computed to the amount of geopolymer binder as a concentration of 5.0 and 2.5 wt % in relation to the mixture viscosity.

2.2. Sample Preparation

The usual ultimate addition of 5 wt % was due to the difficulty of the incorporation of the fibers into the paste, with the exception of the paste with coarse sand, which allowed an addition of 6.9 wt % through the diminished surface area of the coarse grains. Conversely, if the same amount of coarse sand was replaced with fine sand, the ultimate amount of the fibers was only 2.5 wt %, and the highest amount of 78 wt % of sand also allowed only 1.7 wt % of fibers, similar to the medium grain-sized mortar. For the thorough homogenization of the aggregates, the sand was mixed with glass fibers in a dry state. The prepared geopolymer binder was then added to the sand-fibers mix and kneaded well, in order to thoroughly shred the fiber bunches. Air bubbles and gaps were avoided by vibration. For a comparison of the fibers’ effect on the properties of geopolymers, three series of mixtures were manufactured according to

Table 2,

Table 3 and

Table 4: composites with two different concentrations of fibers in the matrix and mortars without glass fiber addition. The addition of fibers without sand was not planned because of the sedimentation of the fibers and because the reinforcement was based on the various shapes of the aggregate, on the combination of spherical and isotropic particles. The prepared composites, M7-2.5* and M7-5*, exhibited a segregation of the glass fibers on the bottom of the specimens. Furthermore, it was ineffective to homogenize the reinforcement of mortars with less than 34 wt % of sand. Therefore, the process was continued with the addition of sand aggregate until the homogenization was reliable. Conversely, the mortar with 82 wt % of sand was not able to accept the glass fiber reinforcement.

The maximum glass fibers addition to the ultimate amount of fine and medium grain-sized sand was only possible at a value of 1.7 wt %. To simplify the figure captions, the results are shown in the columns assigned to 2.5 wt % in all of the diagrams, yet the discrepancy is only highlighted in the first graph legend.

Three different dimensions of prism-shaped samples were manufactured into molds according to the given methods of the mechanical-property measurements described in

Table 5. According to the standards used, three samples were produced from each mixture.

2.3. Measurement Methods

The compressive strength was measured by the standard CSN EN 196-1 [

17] method on the EU40 testing machine provided by VEB Werkstoffprüfmachinen (Leipzig, German Democratic Republic). The flexural strength was carried out according to the same standard by three-point bending with the FPZ100 machine provided by VEG TIW Rauenstein Thüringer (Rauenstein, German Democratic Republic). The declarative measurement of the differences between the mix compositions was provided by the standard method on the specimens with a size of 40 mm × 40 mm × 160 mm, carried out by the accredited Experimental laboratory of Czech Technical University in Prague (FCE CTU, Prague, Czech Republic).

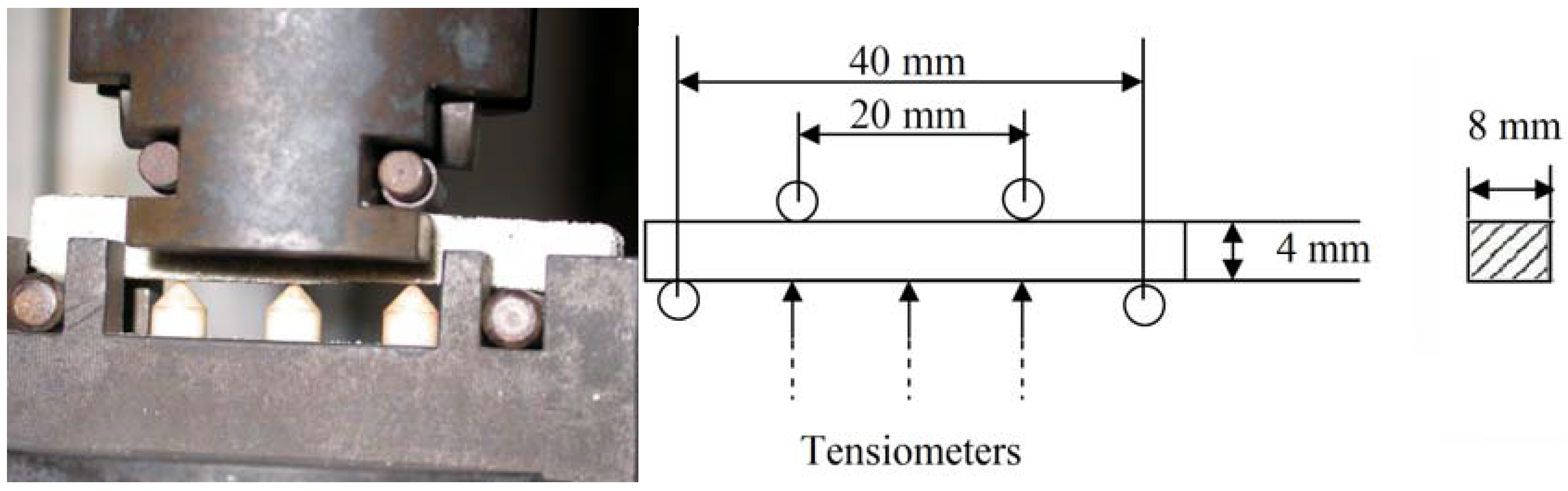

The elastic modulus was measured during four-point bending on the INSPEKT equipment by Hegewald & Peschke Meß- und Prüftechnik GmbH (Nossen, Germany), according to the intrinsic rules (

Figure 2.). The sample size and shape were determined by the principal of the measurement of the four-point elastic modulus on this equipment. This methodology is based on the measurement of the glass-reinforced plastic of laminated shape, with a rule that the length of the sample must be at least twenty-times larger than the thickness. Under this ratio, the E-modulus depends on the ratio of length to thickness and the measurement is unstable.

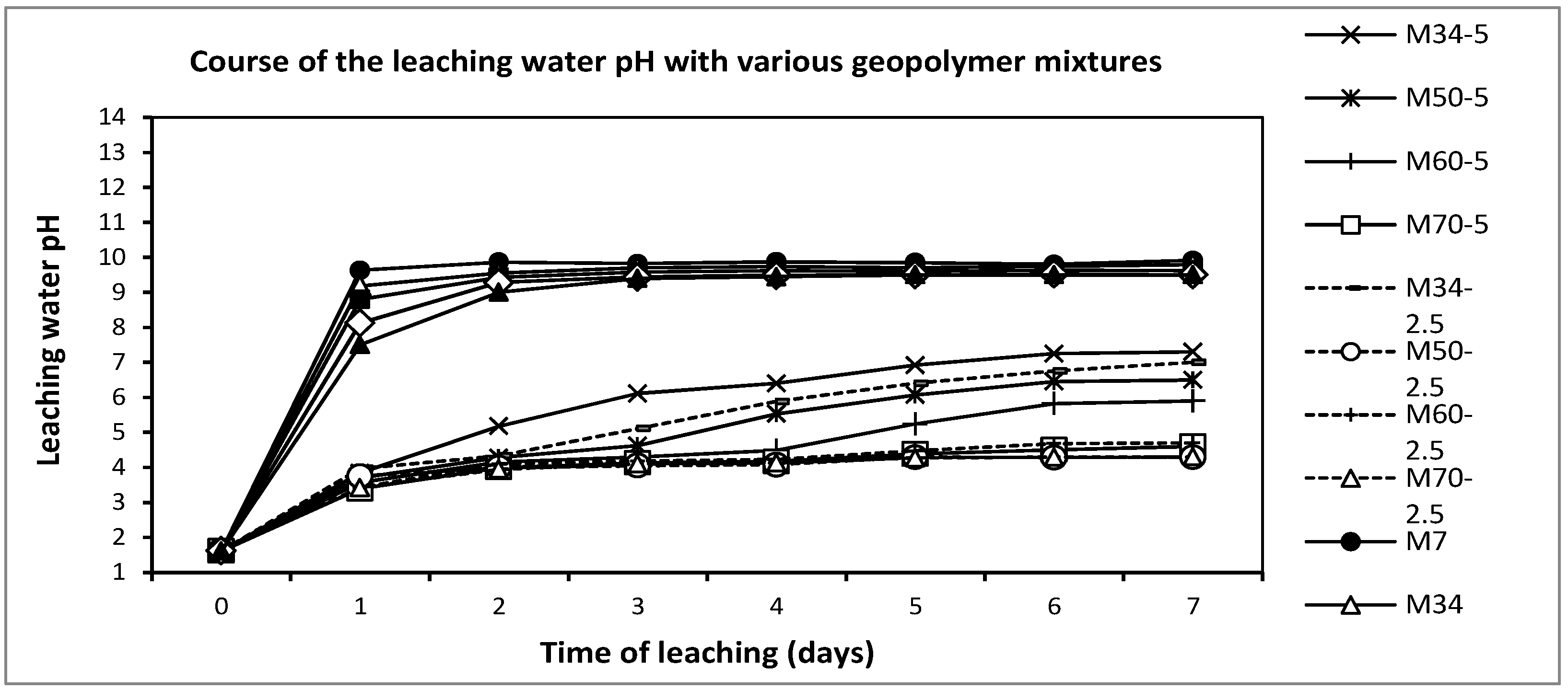

The chemical stability of the composites was accomplished with the help of leaching in 0.2% HCl for one week at room temperature. The excess leaching solution was the same in all cases, denoting three samples of composites (10 g totally) in 50 mL of the acid solution. Leaching in acid water was undertaken to determine whether some of the composites from the prepared series endure the procedure and whether the structure records a measurable deterioration that would result in changes in the mechanical-strength and structural properties. In this experiment, the flexural strength and elastic modulus were measured after leaching and compared with the results measured on samples without leaching. A decrease was evaluated as structural decay. The measurement was carried out on 8 mm × 4 mm × 65 mm samples (according to

Figure 2). In this case, the predominant orientation of fibers caused by shaping influenced the results of three-point bending if compared with the results reached for the 40 mm × 40 mm × 160 mm samples, but the measurement of the acid leaching impact conducted on the small samples is fully comparable and the results are reproducible. The immediate leaching of all samples occurred under the same conditions in the whole specimen volume and affected the small samples more intensively. Therefore, the experiment was relatively fast and the low deterioration had a huge influence on the changes of the structural properties and the bending strength, as well as on the E-modulus. The leaching waters left at the end of the test were compared in terms of their pH, using the Mettler-Toledo SevenCompact pH meter (Mettler-Toledo International Inc., Columbus, OH, USA).

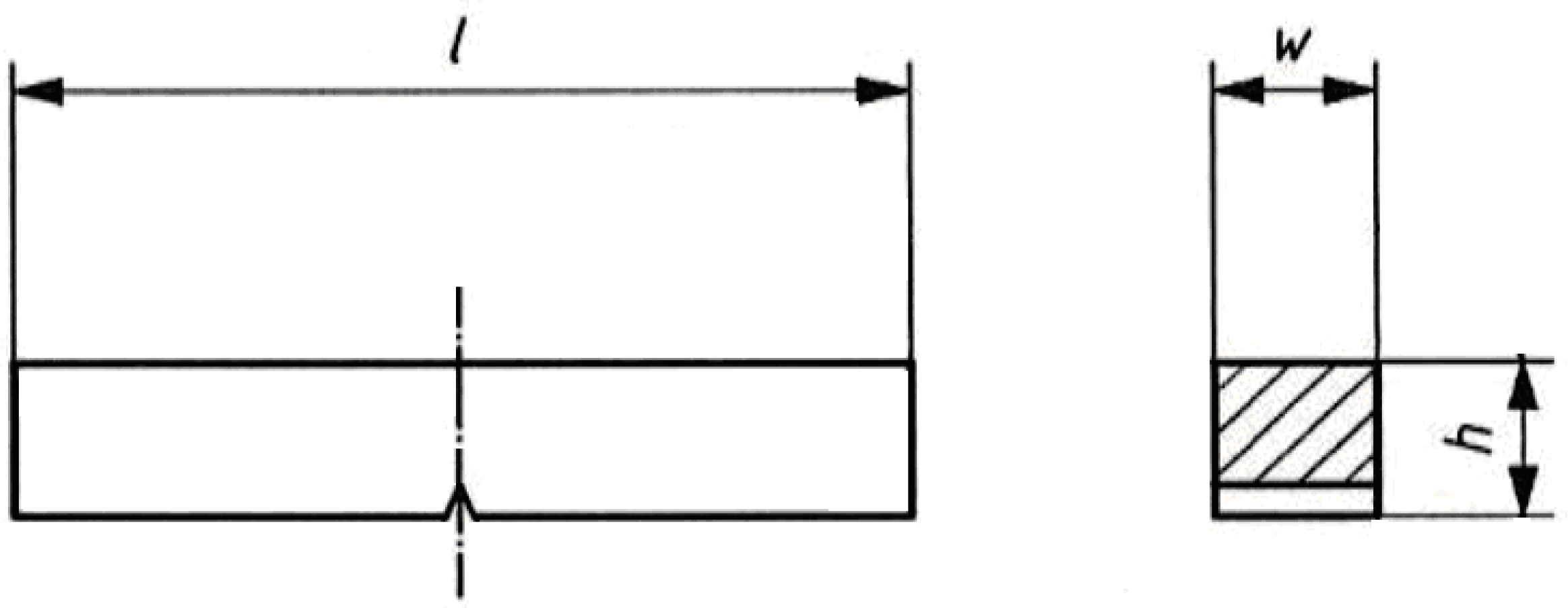

Notch toughness was measured on Charpy equipment; for the sample sizes, see

Figure 3.

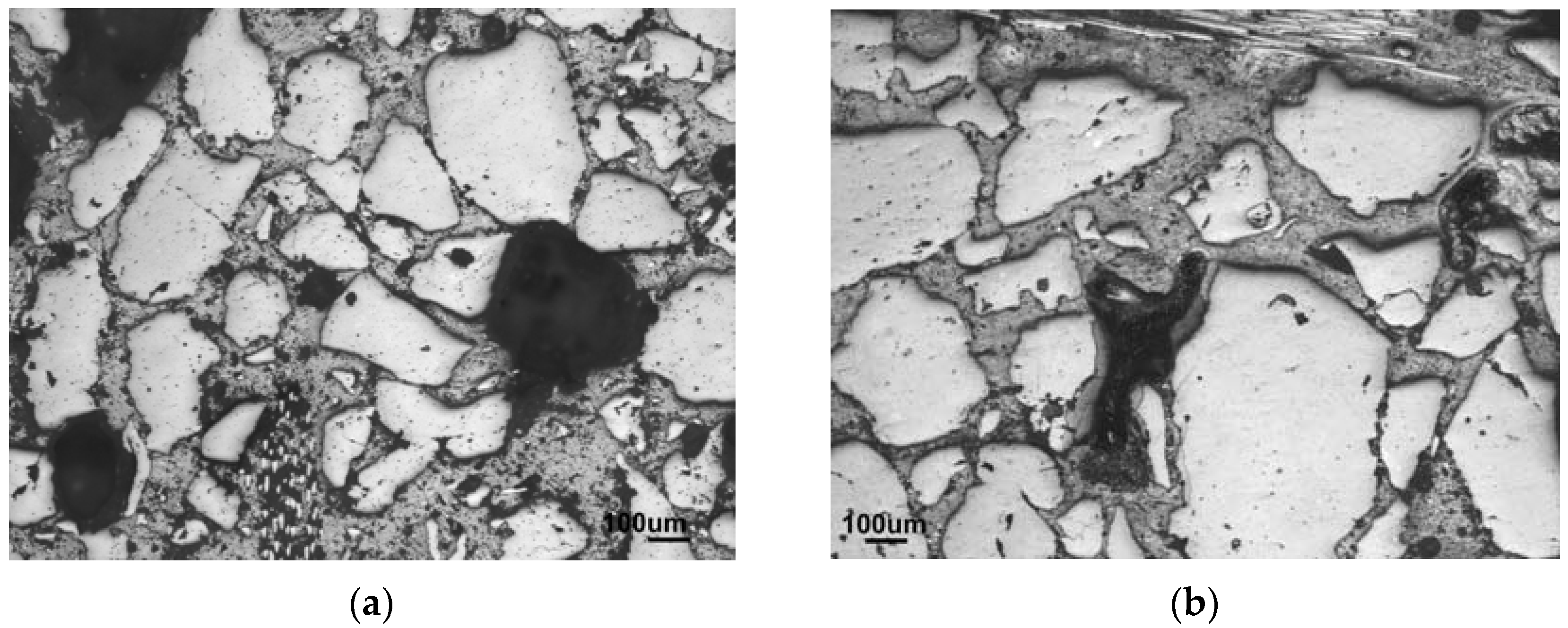

2.4. Microscopy Observation

A scanning electron microscope (SEM) documented the microstructure by the Quanta 450 equipment from FEI company (Hillsboro, OR, USA). The heterogeneous matter was determined on polished cross-sections, which were vacuum coated with gold to prevent localized charging of the specimen and the consequent distortion of the electron beam, as geopolymers are poor conductors of electrons.

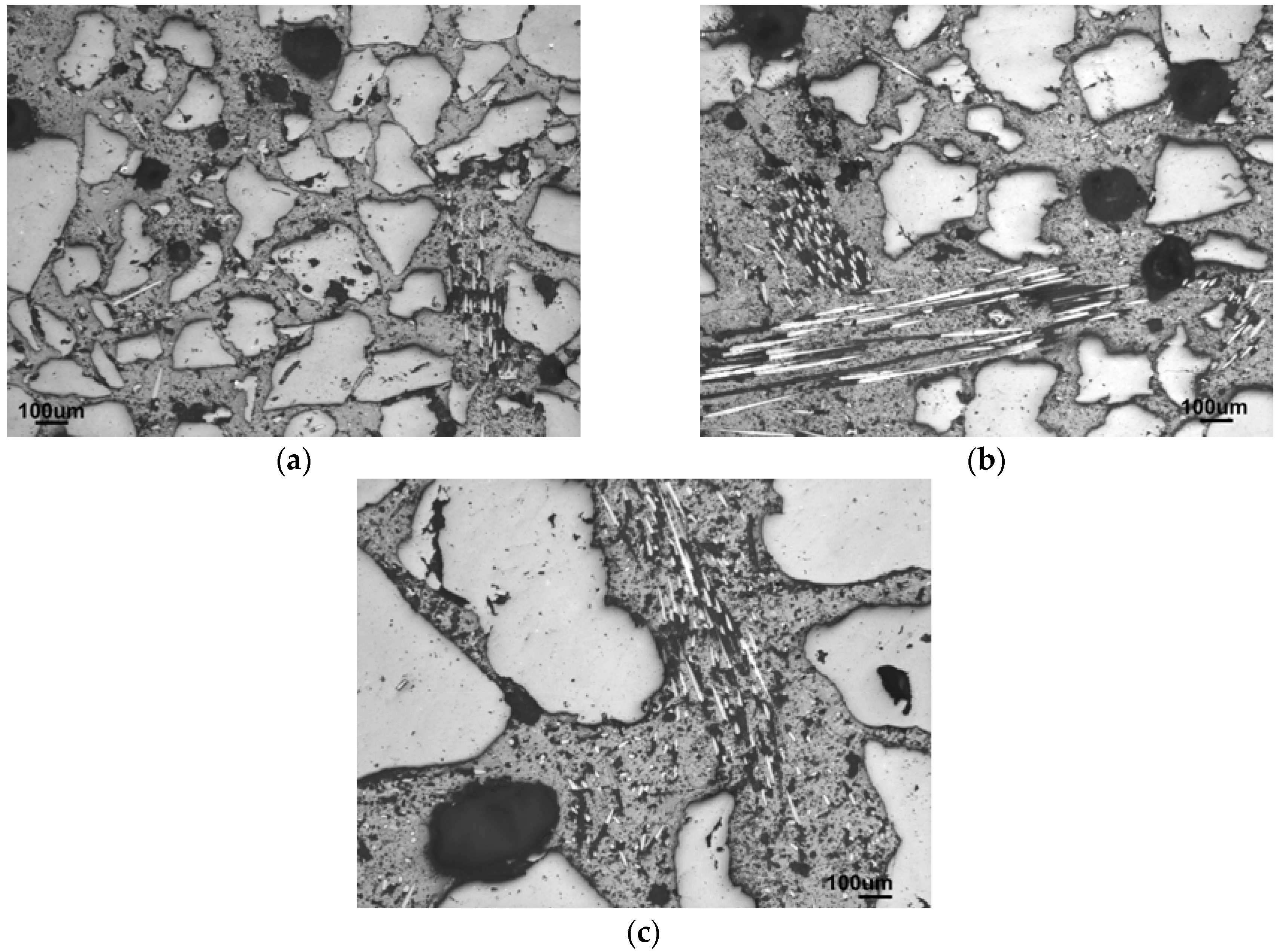

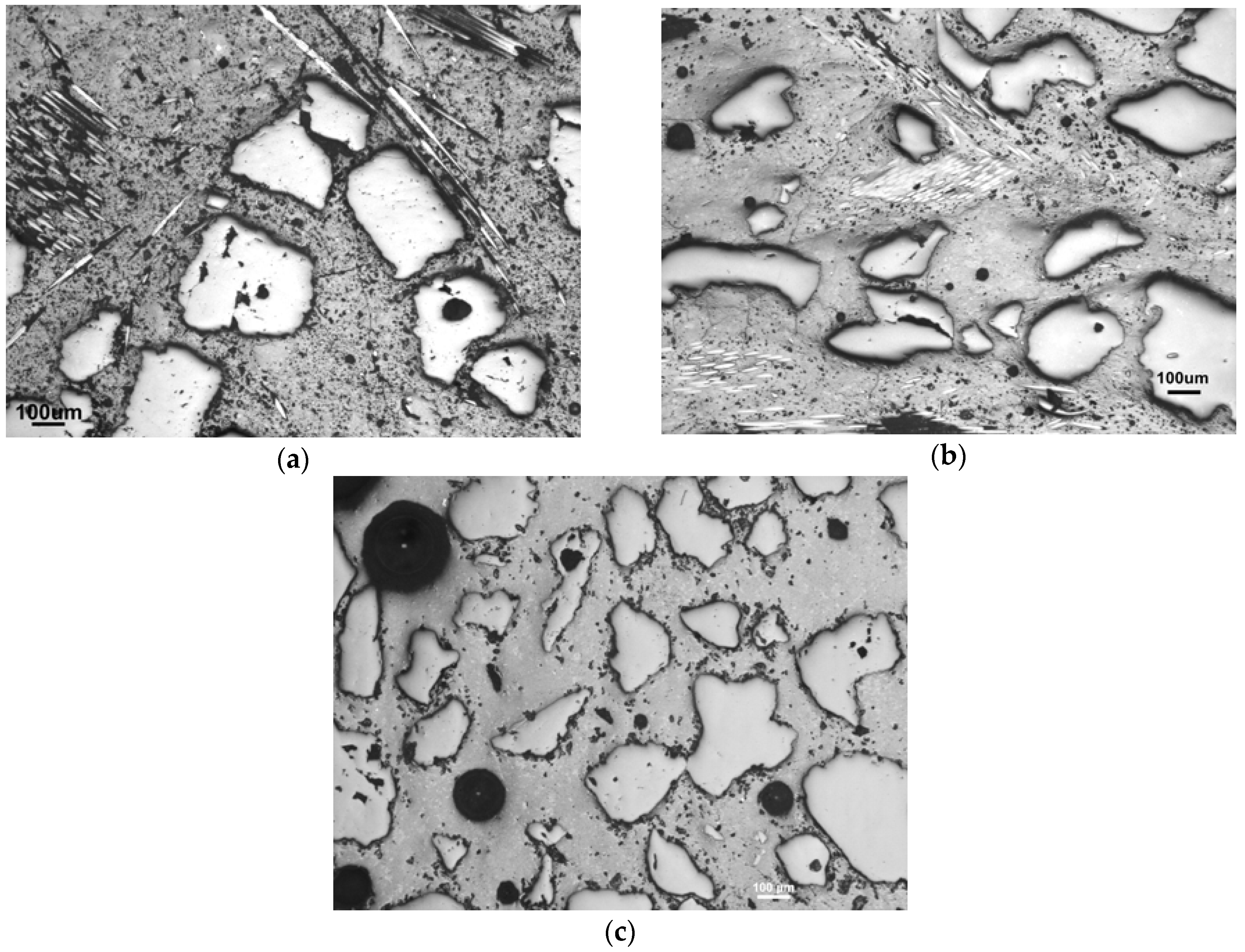

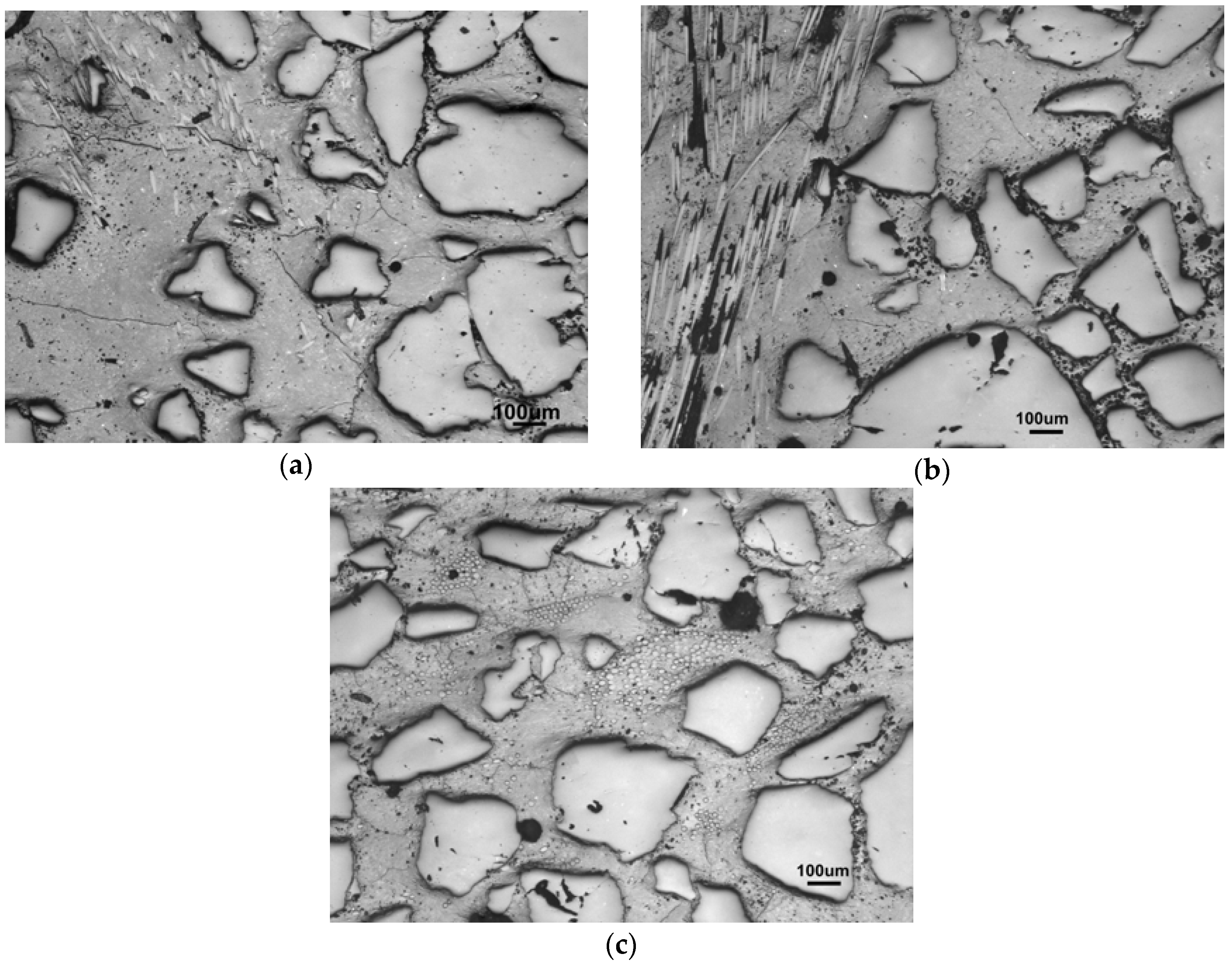

Optical microscopy of the composites determined the apparent texture of each composition with NIKON OPTIPHOT-100 microscopy (Nikon Corporation, Tokyo, Japan) in reflected light with a magnification of 50×. The images were shot by a JENOPTIK color digital camera (Jenoptik AG, Jena, Germany)and edited by the NIS-Elements AR system provided by Laboratory Imaging, s.r.o. (Prague, Czech Republic), for image analysis. As the representation in SEM produced less of an overview, the images were mostly collected by optical microscopy. The structures of the composites presented synoptic maps of all the composition objects, such as pores, aggregates, and microcracks in the contrast outlines.

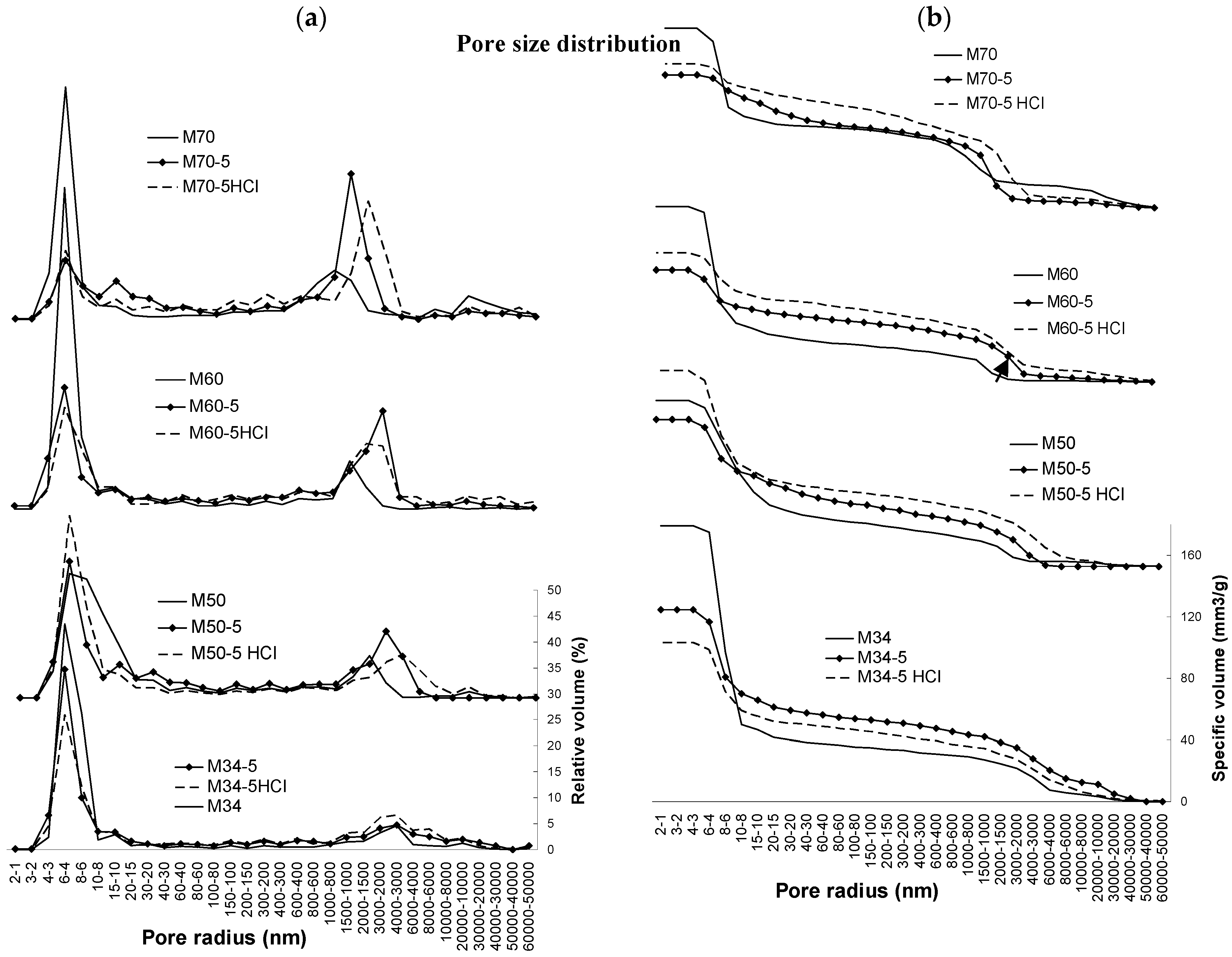

2.5. Structure Determination

The structure was determined by high-pressure mercury porosimetry performed on a Pascal 240 device from POROTEC Vertrieb von wissenschaftlichen Geräten GmbH (Hofheim am Taunus, Germany). To determine the pore sizes, the ink-bottle computation model of pore shape was applied for adjoining the measured pressure of mercury to the appropriate size of the pores. The pore size distribution was recorded, to determine the influence of the reinforcement and aggregate addition on the structure parameters. The porosimetry was further recorded to detect deterioration after acid leaching.

2.6. Collection of FTIR Spectra

The changes in the structure of the sample were determined by Protégé 460 E.S.P. (Thermo Nicolet Corporation, Madison, WI, USA). Infrared Spectroscopy at an extension of 4000–400 cm−1, a resolution of 4 cm−1, and an average of 128 scans for the ATR mode with a diamond crystal.

4. Conclusions

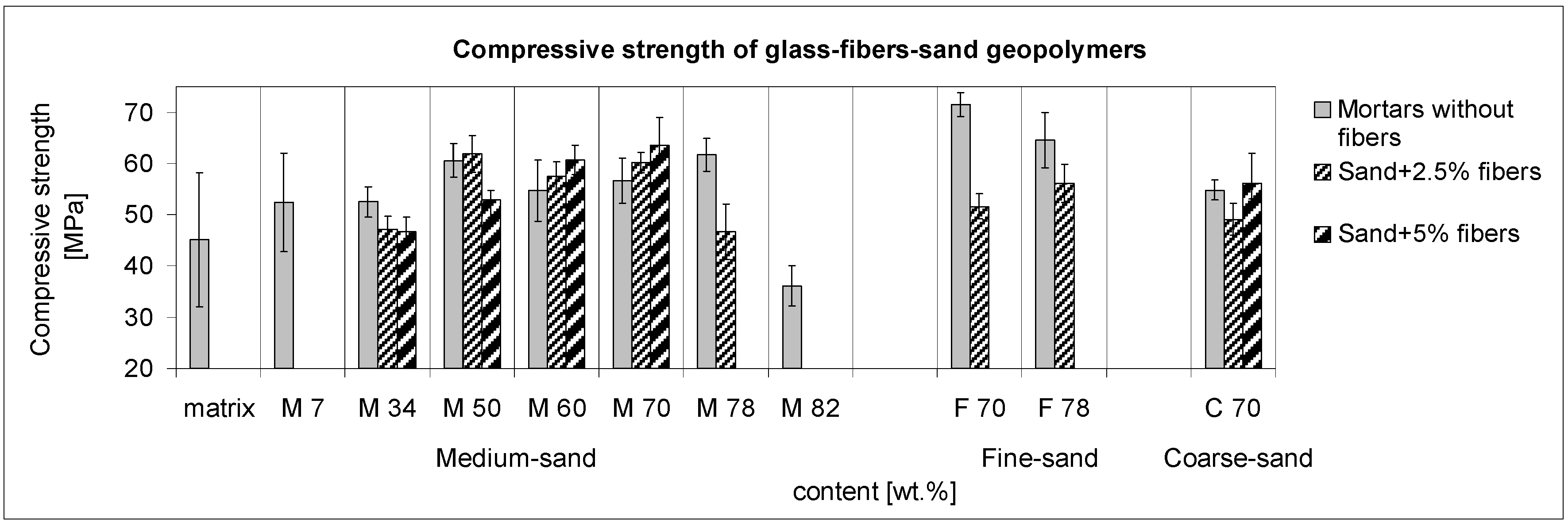

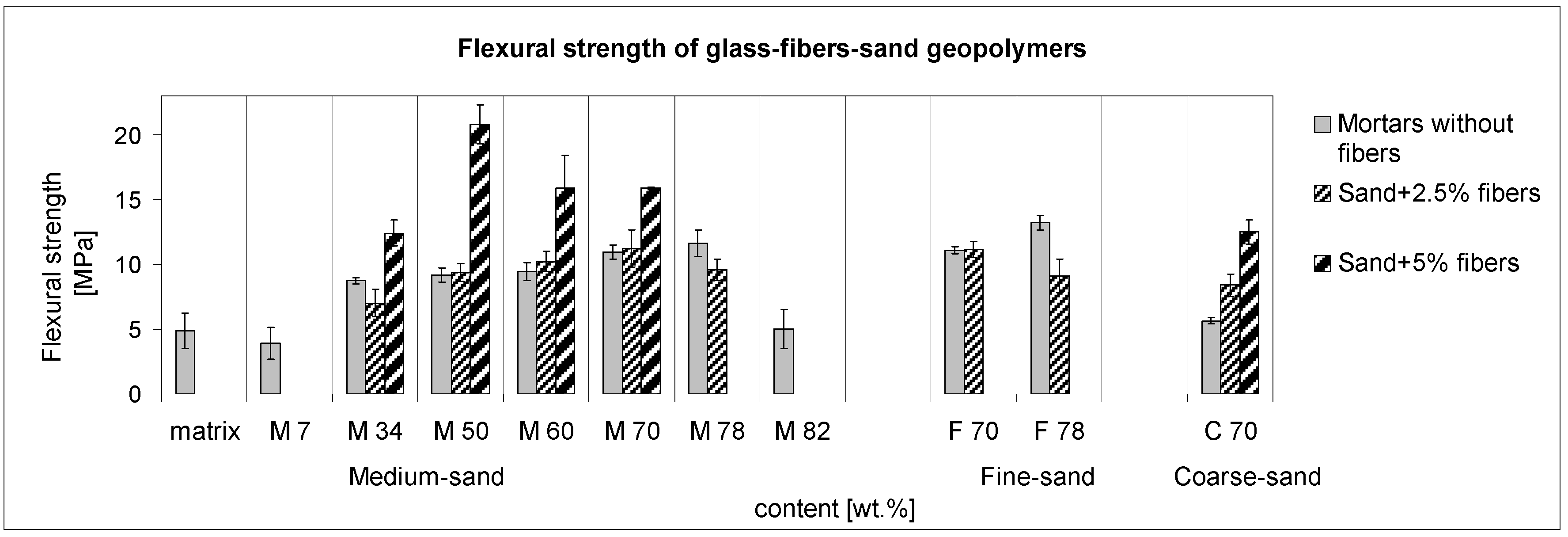

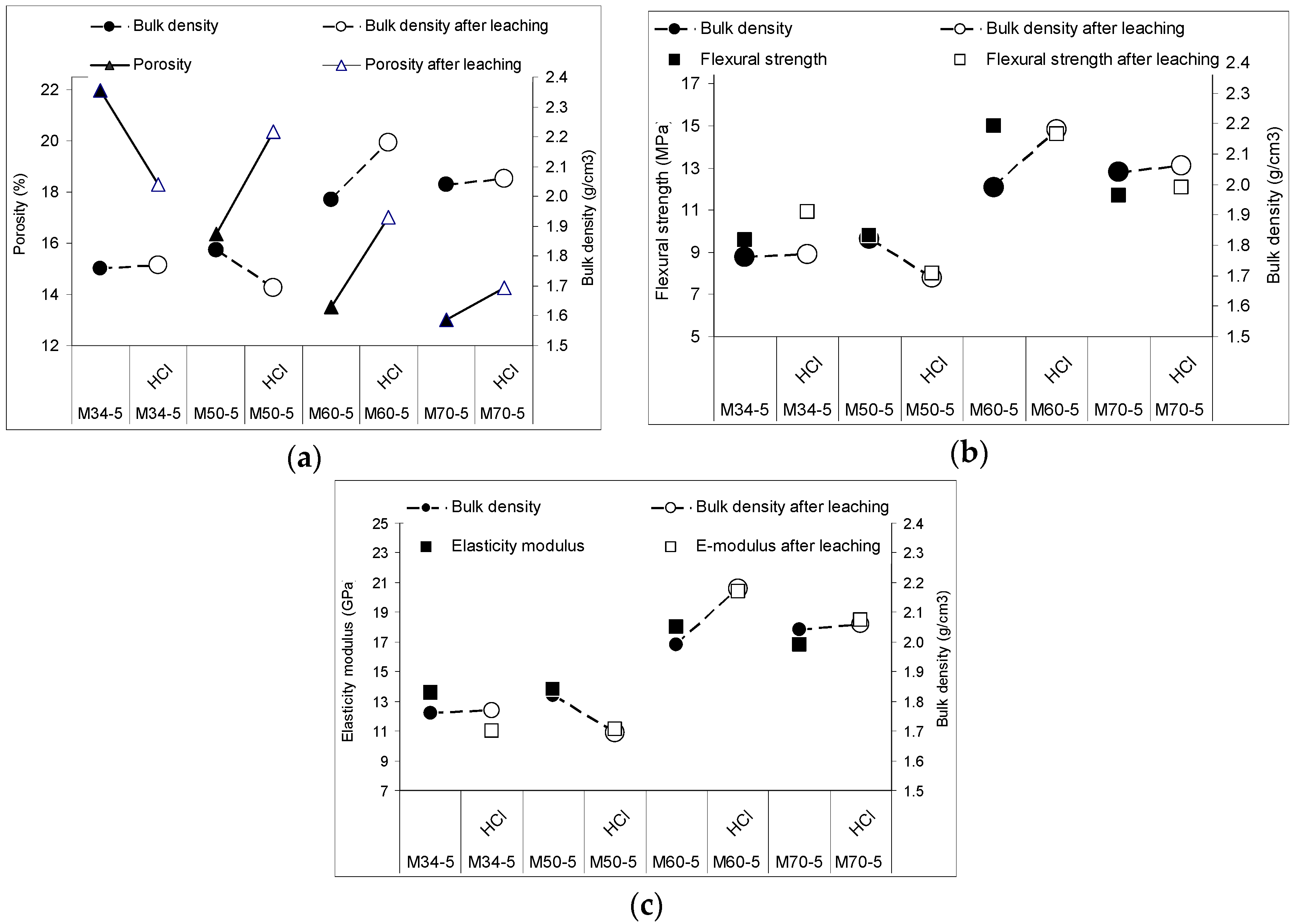

The study presented the results of the mechanical properties and acid water resistance observations of geopolymer (GP) mortars reinforced with 2.5 and 5 wt % of glass fibers calculated as the concentration in the GP matrix in comparison with a series of mortars without fibers of the increasing amount of aggregate. The aggregate was quartz sand of varying grain sizes in an amount of 34 up to 82 wt % in the compositions.

As the results of mechanical properties showed, the structure after the addition of fibers was strengthened if the composition was optimally designed. The optimized addition was 5 wt % of glass fibers, the constant calculated as a part of the matrix, and the amount of the sand aggregates was optimal in the 50–70 wt % range.

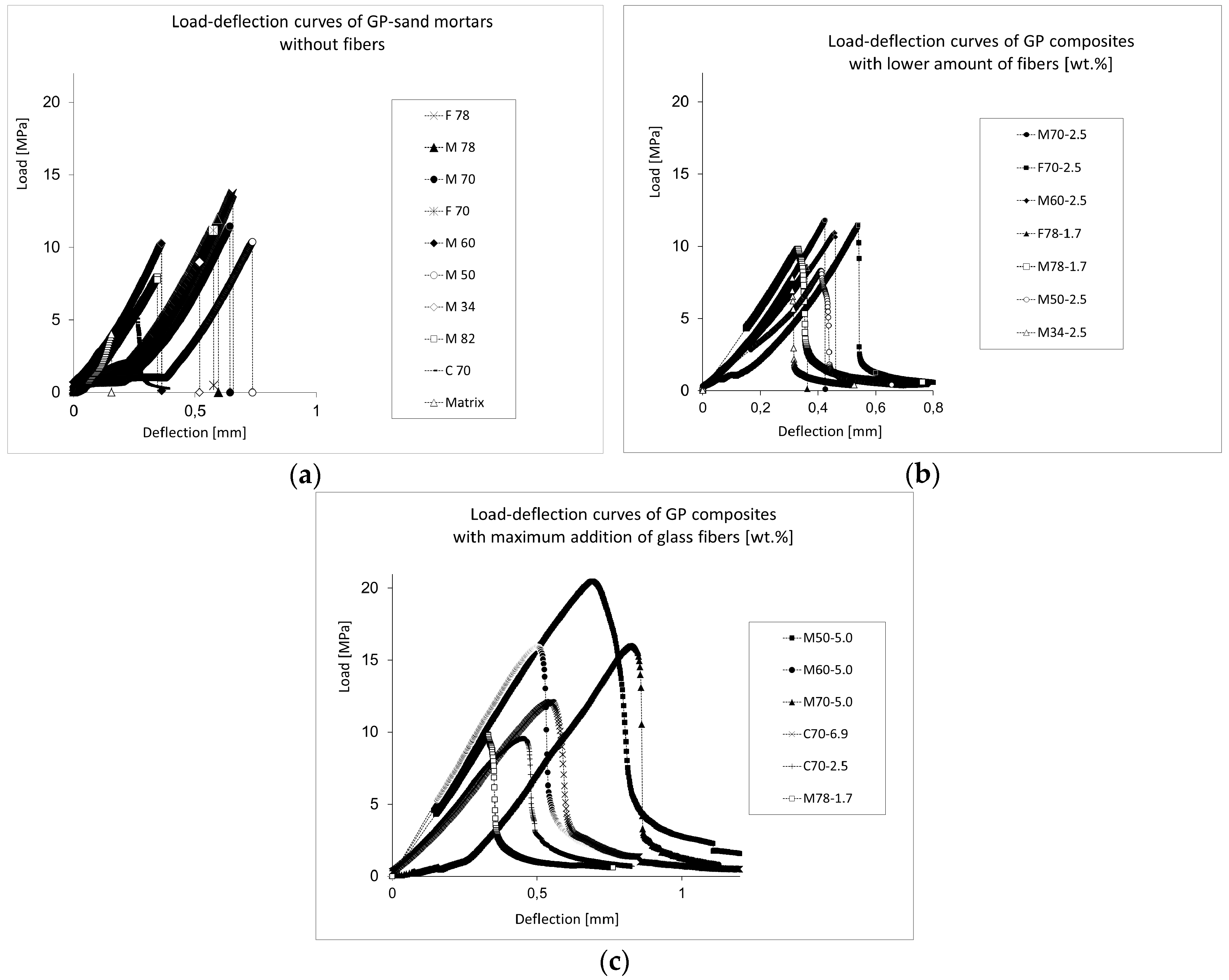

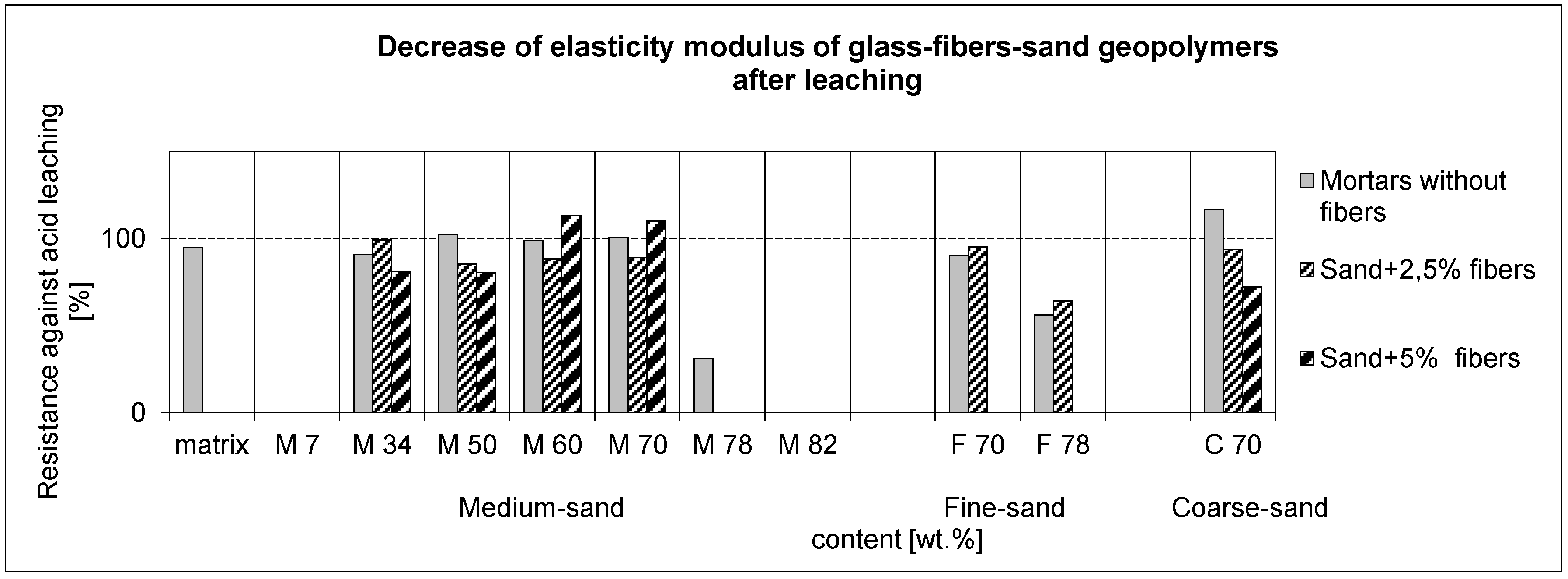

The study showed the importance of the complex balanced ratios between compounds when a new additive is used. Beside that, the effect of the aggregate-particle size distribution was evaluated. The reinforcement was beneficial for the compressive strength and hugely so for the flexural strength, for effectively diminished brittleness confirmed by the load-deflection curves and also for the chemical stability in acid waters. Moreover, the composition, which satisfied the conditions, was only a part of all the possible mixtures. It was found that simply adding glass fibers into the GP mortar could worsen the composite mechanical properties and its acid water resistance. Another condition of the effective addition of glass fibers is the sufficient shredding of the fiber bunches, and when enough matrix thoroughly coated the surfaces of aggregate, the reinforcement fibers and the space between all the particles.

In terms of the compressive strength, the maximum of 64 MPa was reached with an amount of 70 wt % of the sand medium fractioned with matrix reinforced by 5 wt % of fiber. The best reinforcement reached an improvement of 8.5% in comparison to the mortar without fibers. However, the samples of finer sand (D50 = 0.28 mm) reached the absolute maximum of a compressive strength of 65 MPa containing 70 wt % of sand without fibers.

Focusing on flexural strength, the maximum of 21 MPa was reached. The composite of 5 wt % of fibers in the matrix contained 60 wt % of sand (medium fractioned grain-size D50 = 0.71 mm). The reinforcement oversized for 100% of the maximal flexural strength without fibers.

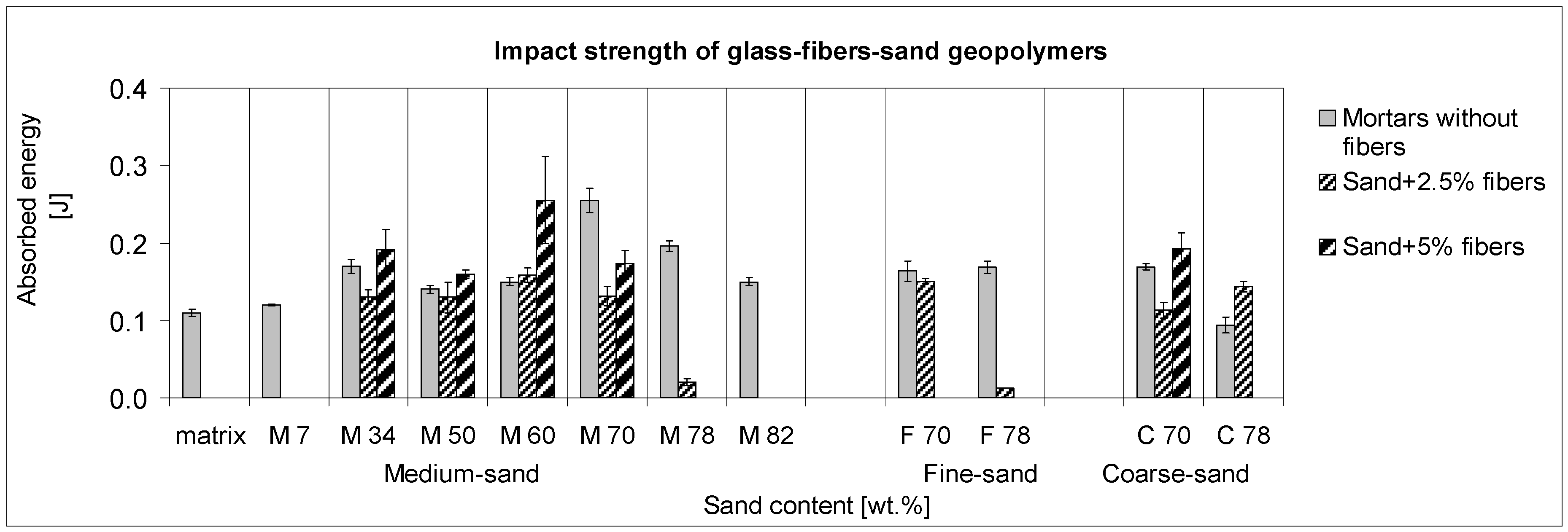

The presence of glass fibers is active in the fracture mechanism; above all, it is obvious in the strain-stress curves, in which the failure slowed down after the ultimate load. The best performance of fibers arose in the case of the fiber-reinforced composite of 50 wt % of sand medium fractioned. However, the maximum impact strength was reached at 60 wt % of the same sand with 5 wt % of fibers in matrix. Compared with the best value reached without glass fibers, the improvement of impact strength was small, of about 10%, reached at 70 wt % of sand. It implies that the courses of the stress-strain curve and impact strength were controlled by different plots acting under different destructive conditions. Whereas the three-point bending pulls the fibers out, the impact strength is more affected by the fiber-glass’ brittleness.

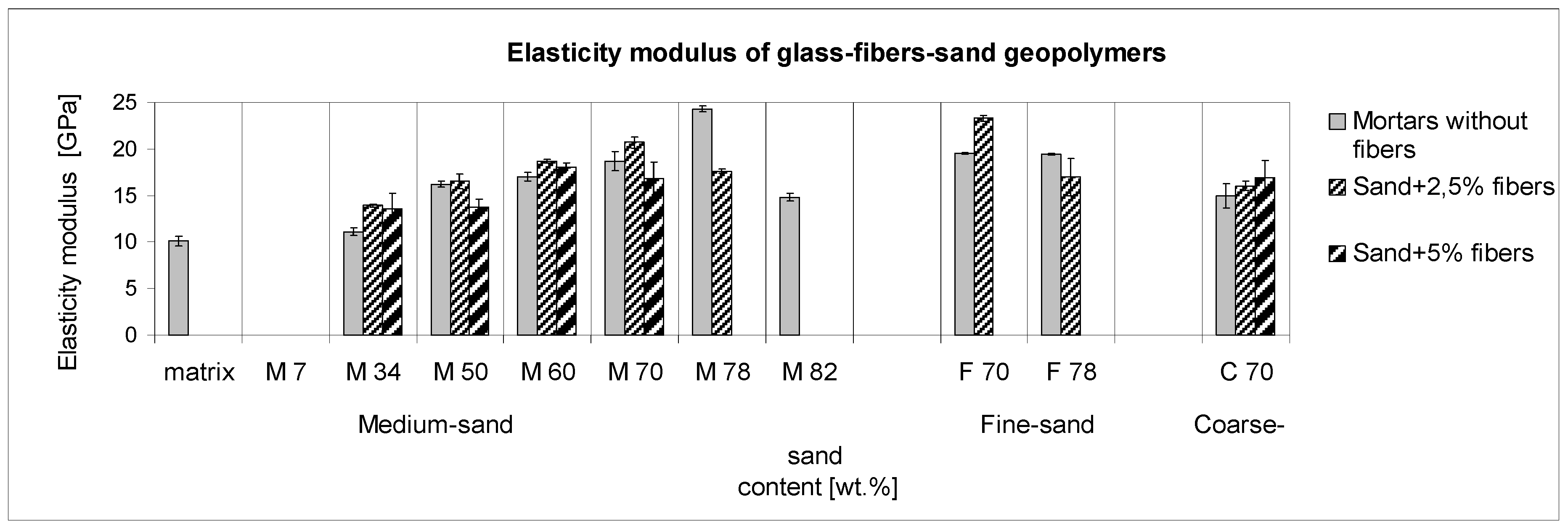

The trend of the elastic modulus as a non-destructive method showed completely different relations. The highest stiffness pointed to the lower reinforcement by 2.5 wt % of fibers in the matrix. The reason for this lies in the intrinsic modulus of the fiber glass.

Although the glass fibers contributed to a significant porosity increase in the size range of over 10 nm in the radius of mesopores and above all in the range of macropores, the bulk porosity decreased with regard to the mortars. This is because macropores arose as the fiber ITZ at the expense of the GP matrix mesopores, which comprise the main part of the bulk porosity. The lowered porosity by fibers as a non-porous material is the minority.

It is apparent that the ITZ between the matrix, sand grains, and fibers is an important part of composites, affecting the mechanical properties and the acid water resistance. Through microscopy, the porous structure and the pH of the leaching waters revealed that fibers induced macropores, but bridged and reduced the microcracks, and thus improved the resistance of composites in acid waters. Despite the expected decomposition after leaching, as the macropores increased the porosity, the optimized fiber composite withstood the leaching, and even improved the mechanical properties and reduced open porosity. The likely reason for this might be the continuing polycondensation and amorphous SiO2 released by acid leaching, which could precipitate back into the interstitial space, in cracks, in mesopores, and probably partially blocked the macropores. This result can reveal a prospective use for geopolymers in the mining industry and for the fabrication of tunnel segments.