Hot Deformation and Processing Window Optimization of a 70MnSiCrMo Carbide-Free Bainitic Steel

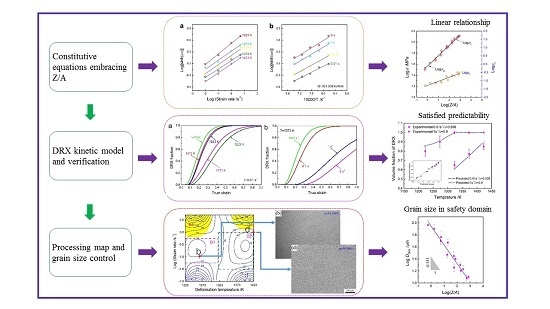

Abstract

:1. Introduction

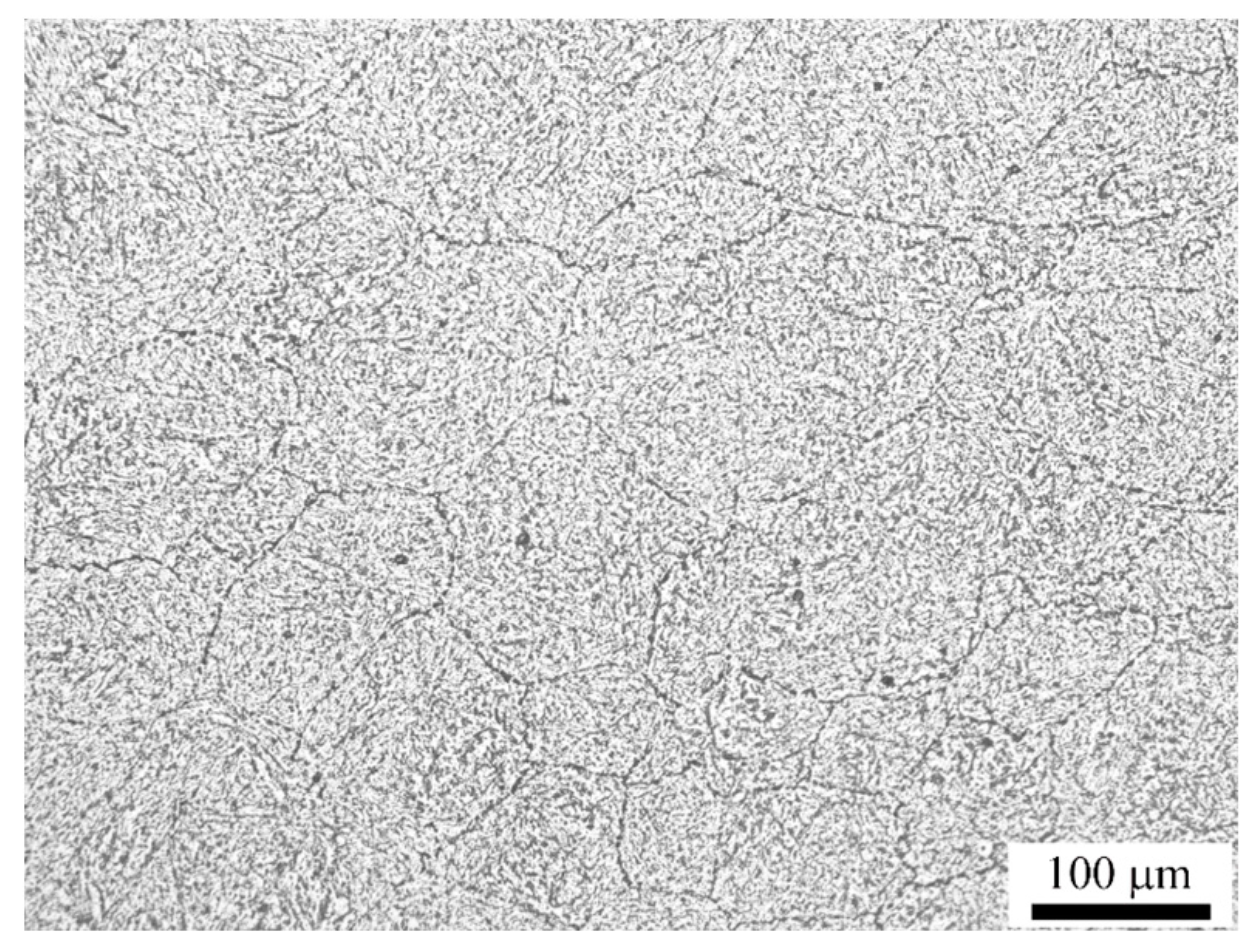

2. Experimental Procedure

3. Results and Discussion

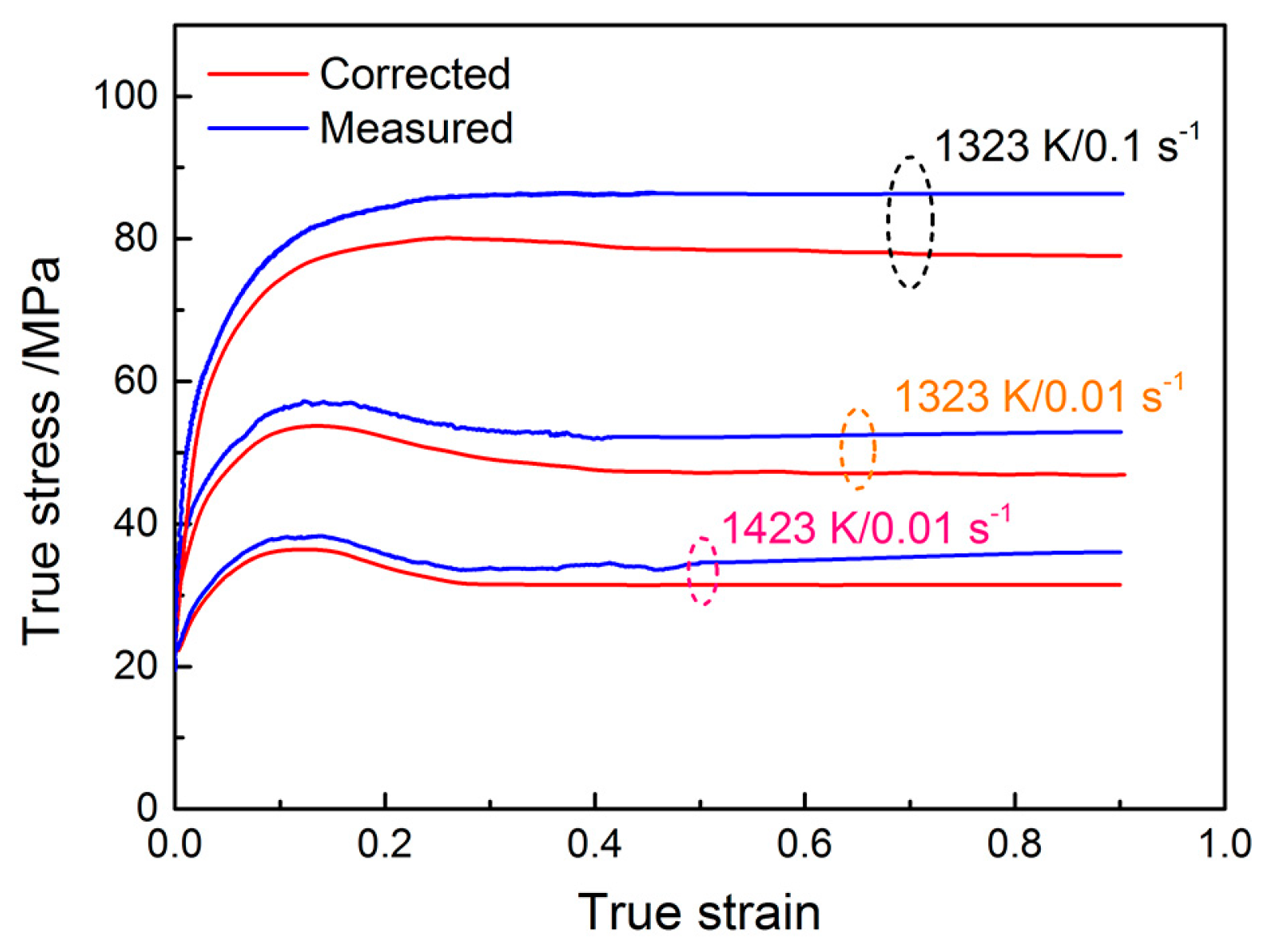

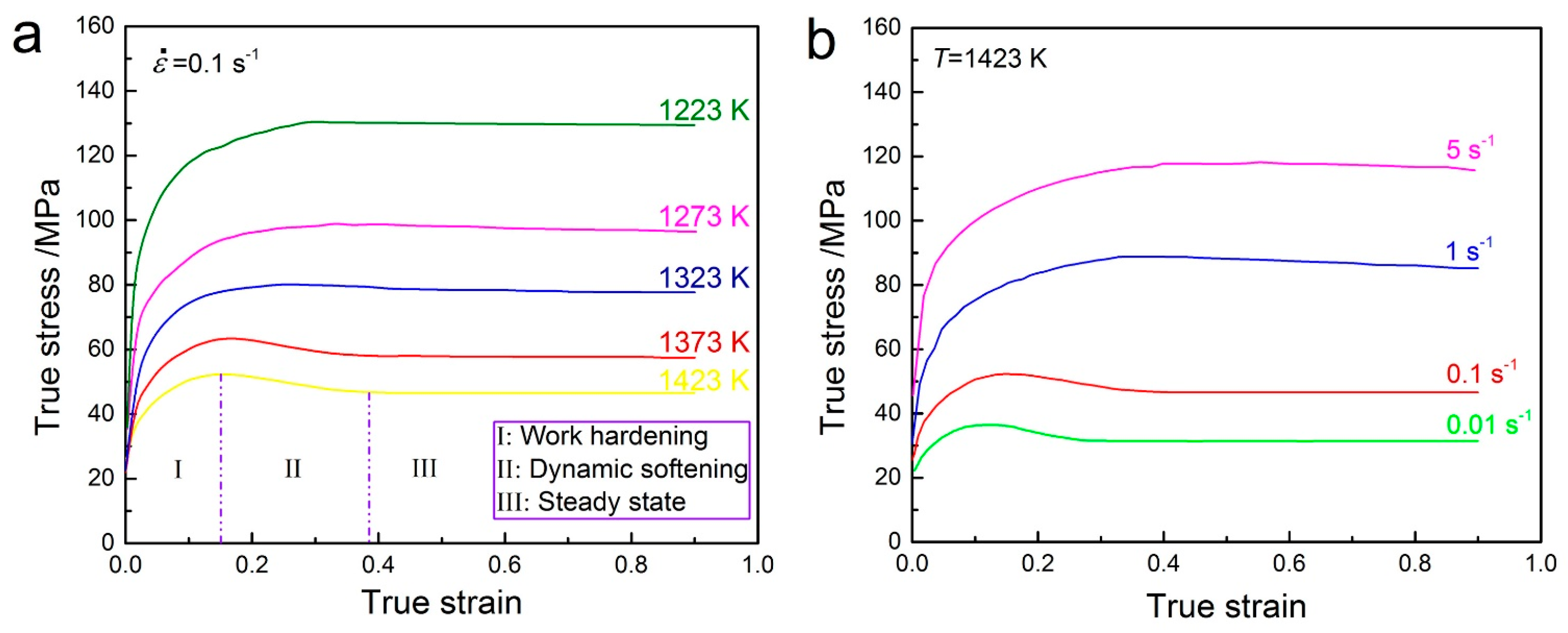

3.1. Flow Behavior

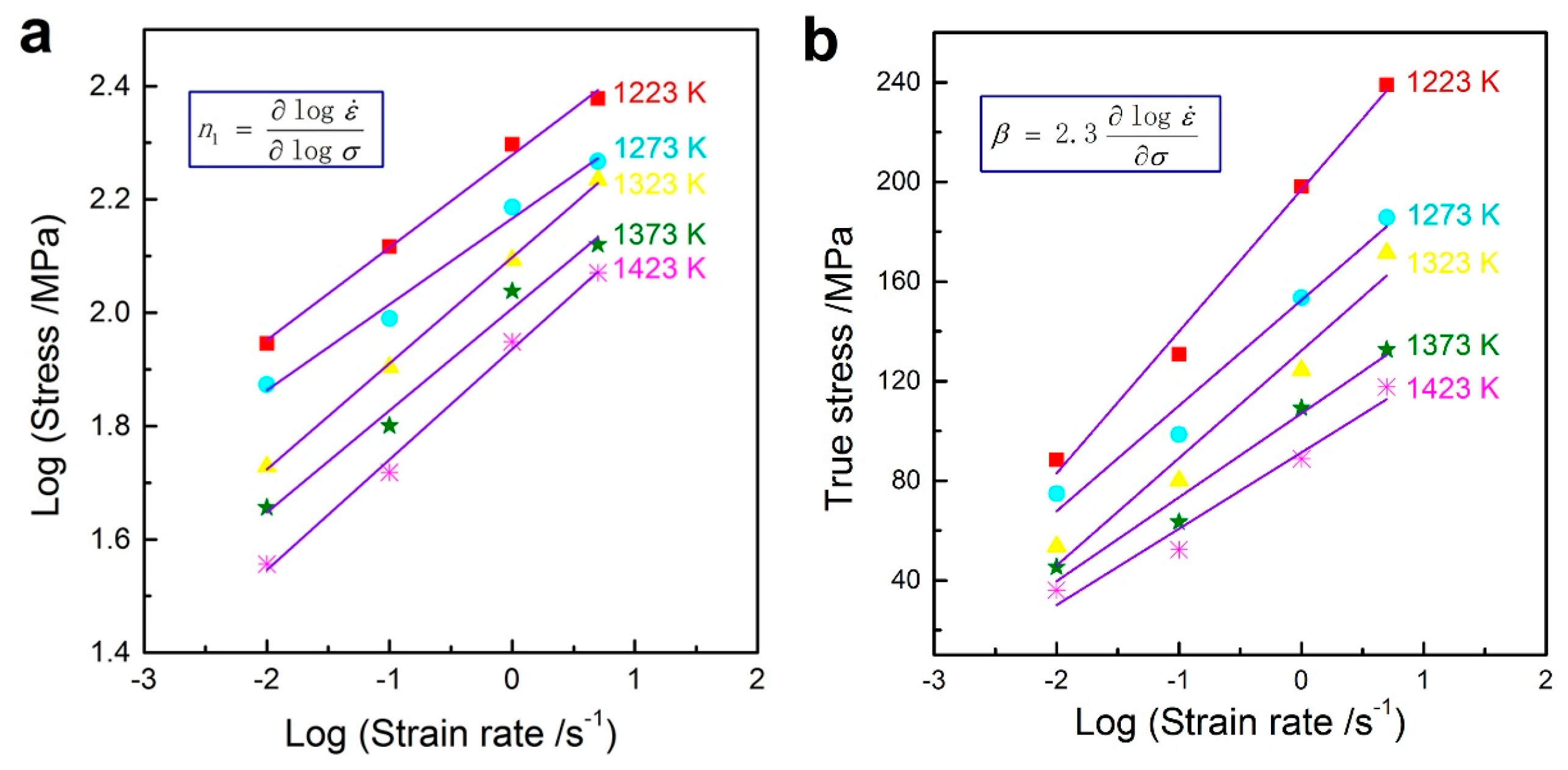

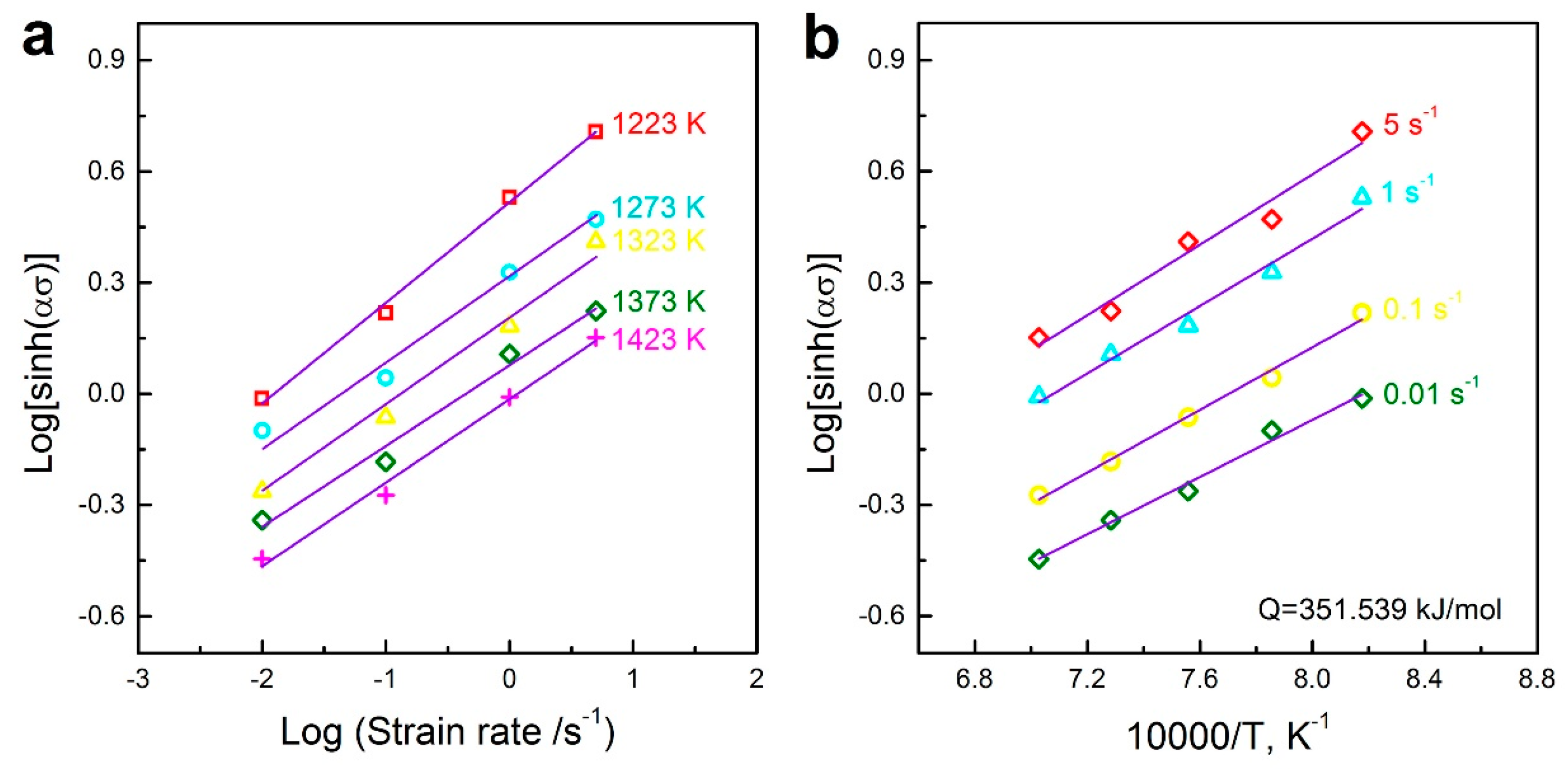

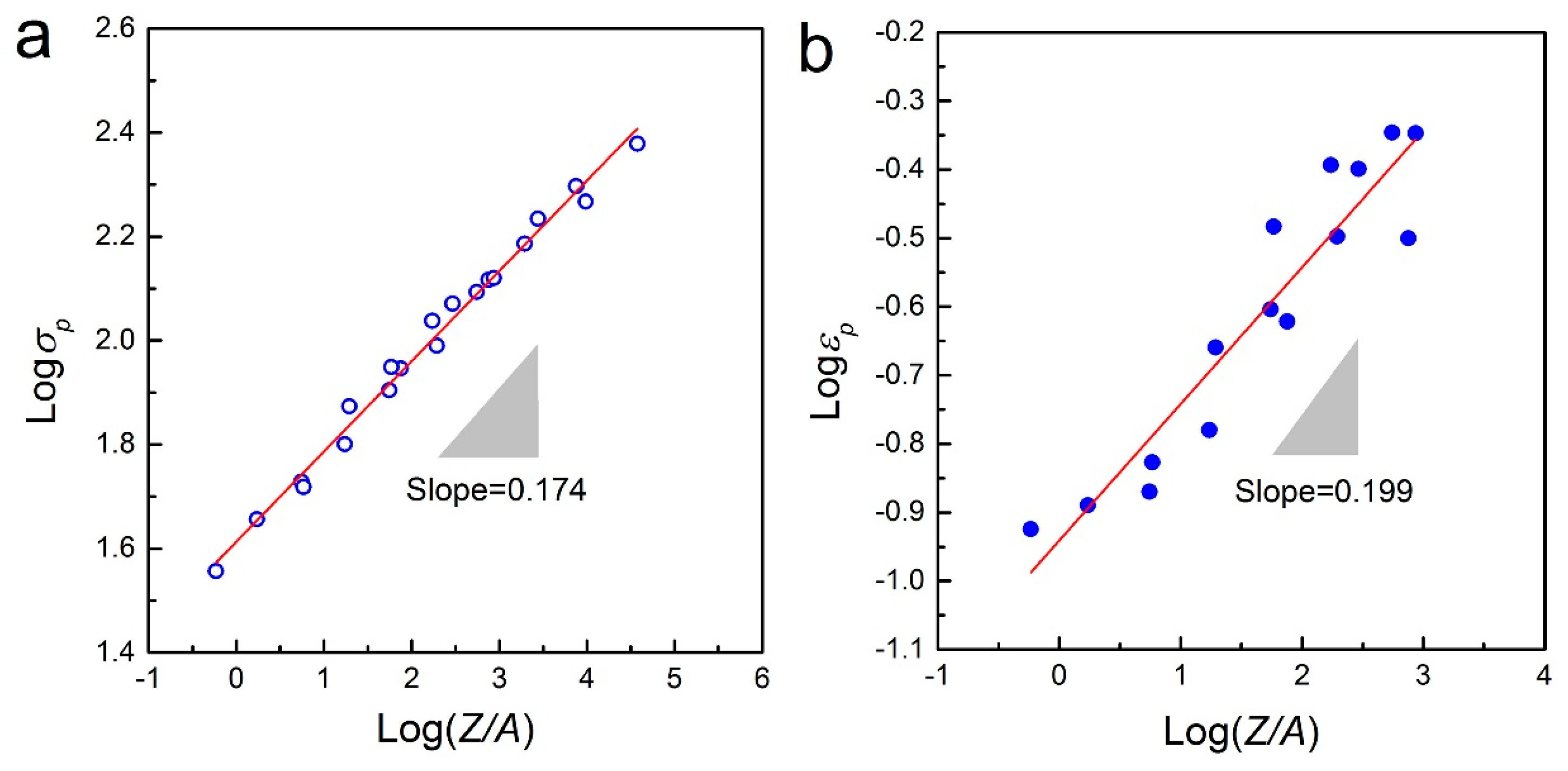

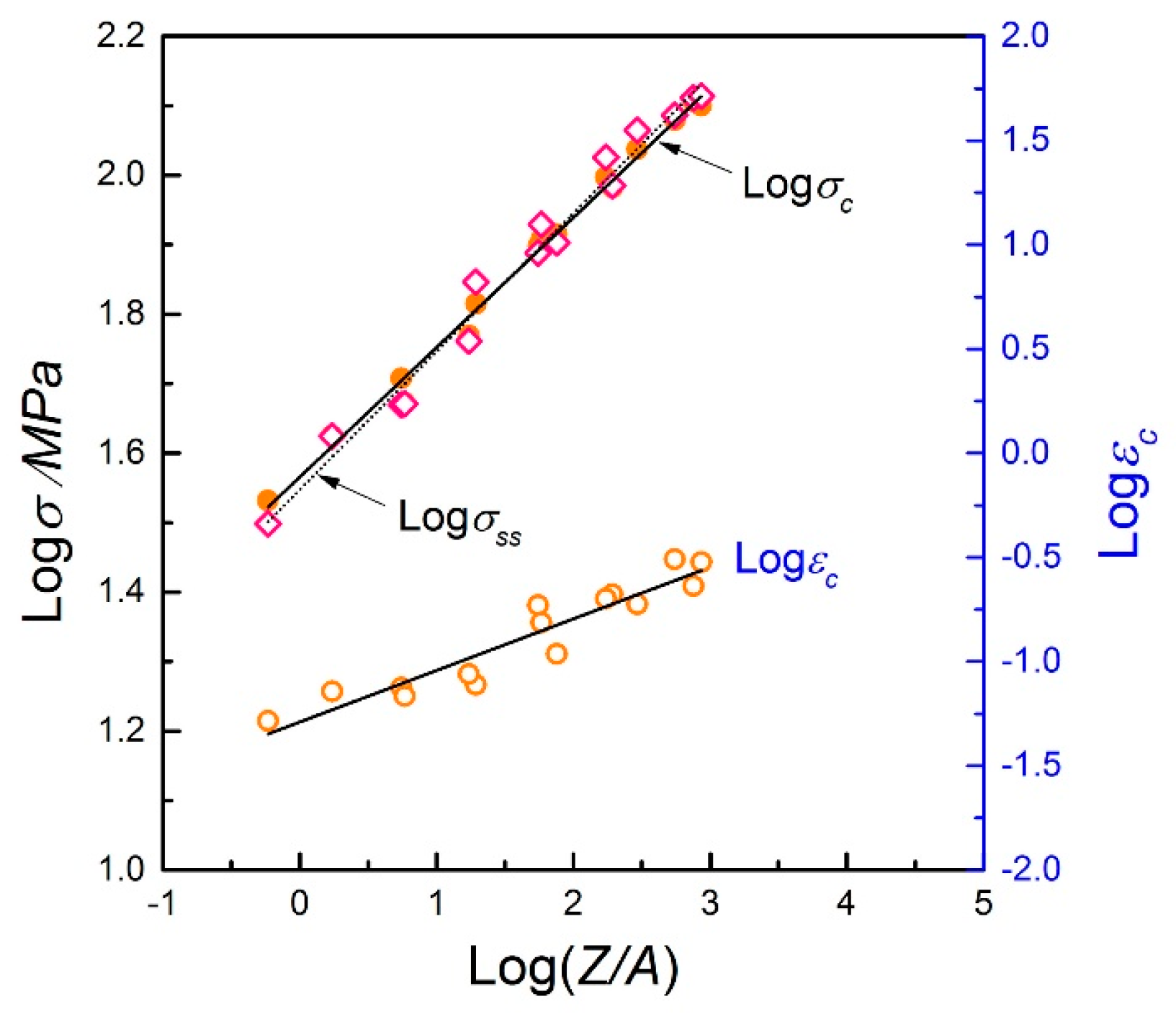

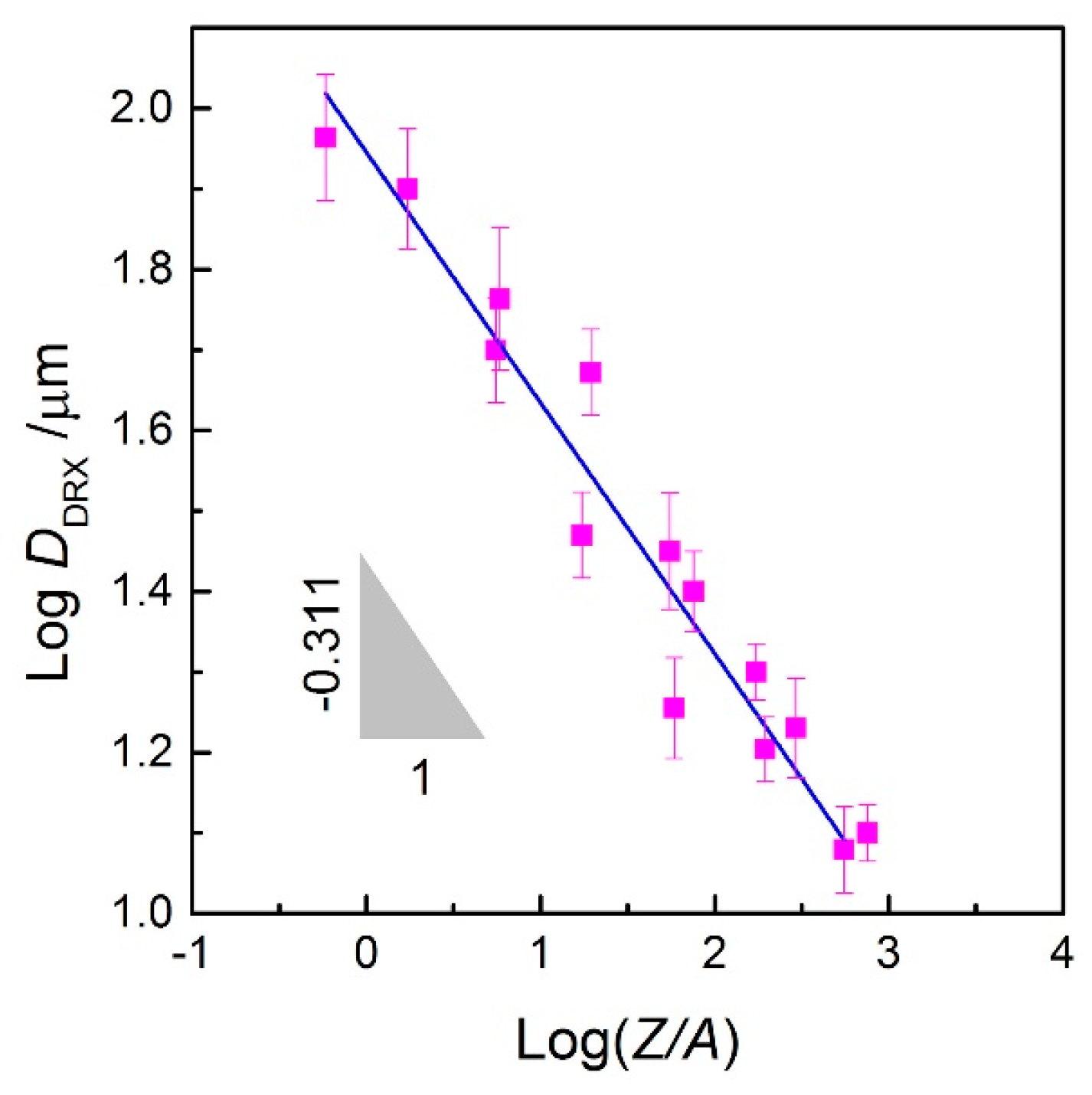

3.2. Z-Parameter and Equations in Flow Softening

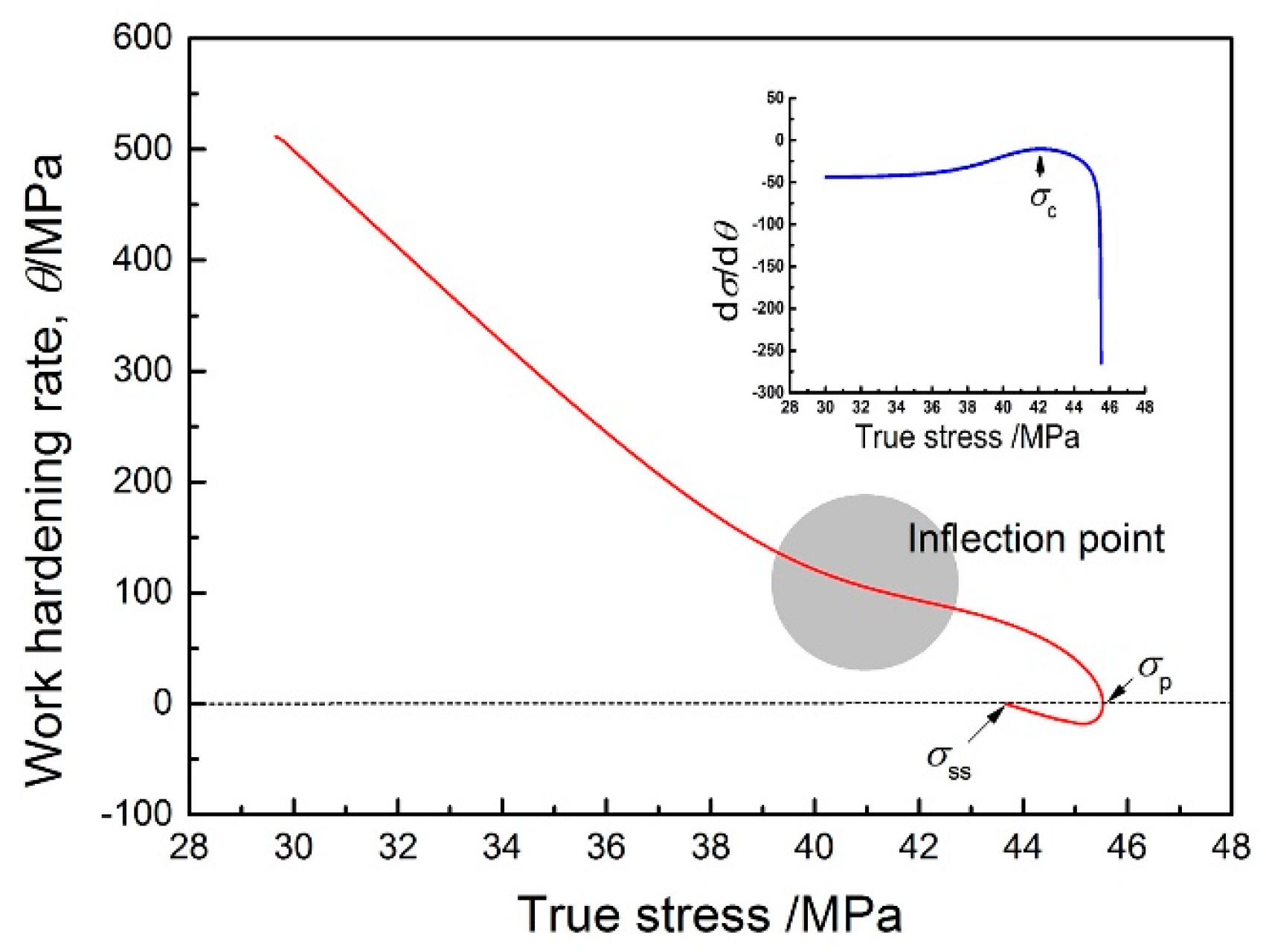

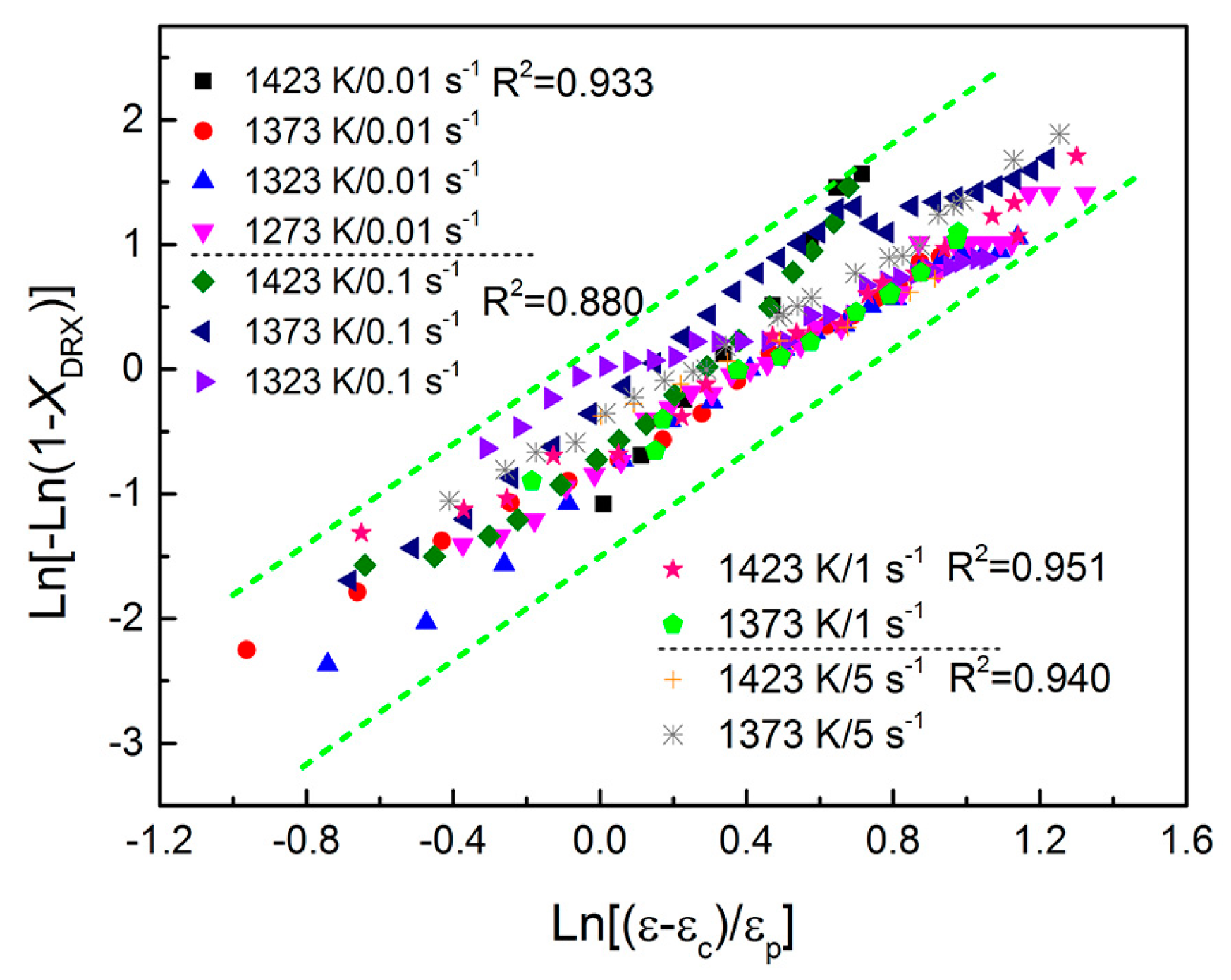

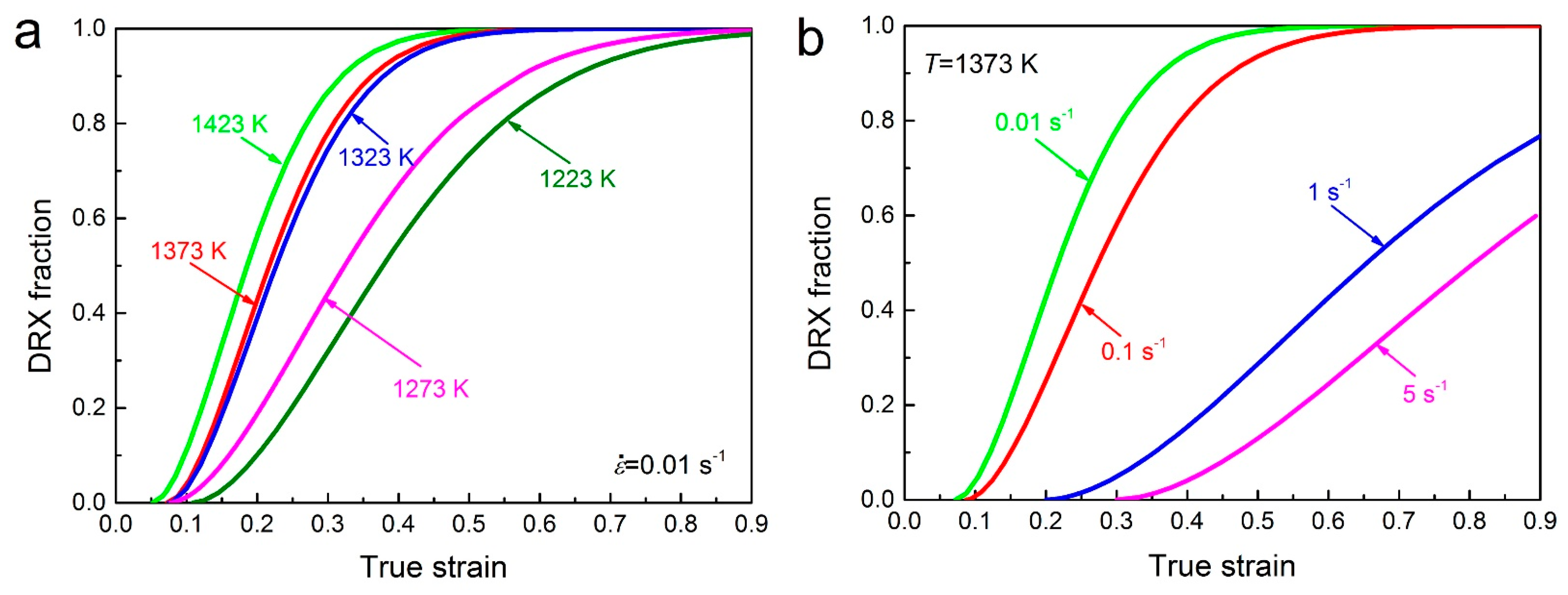

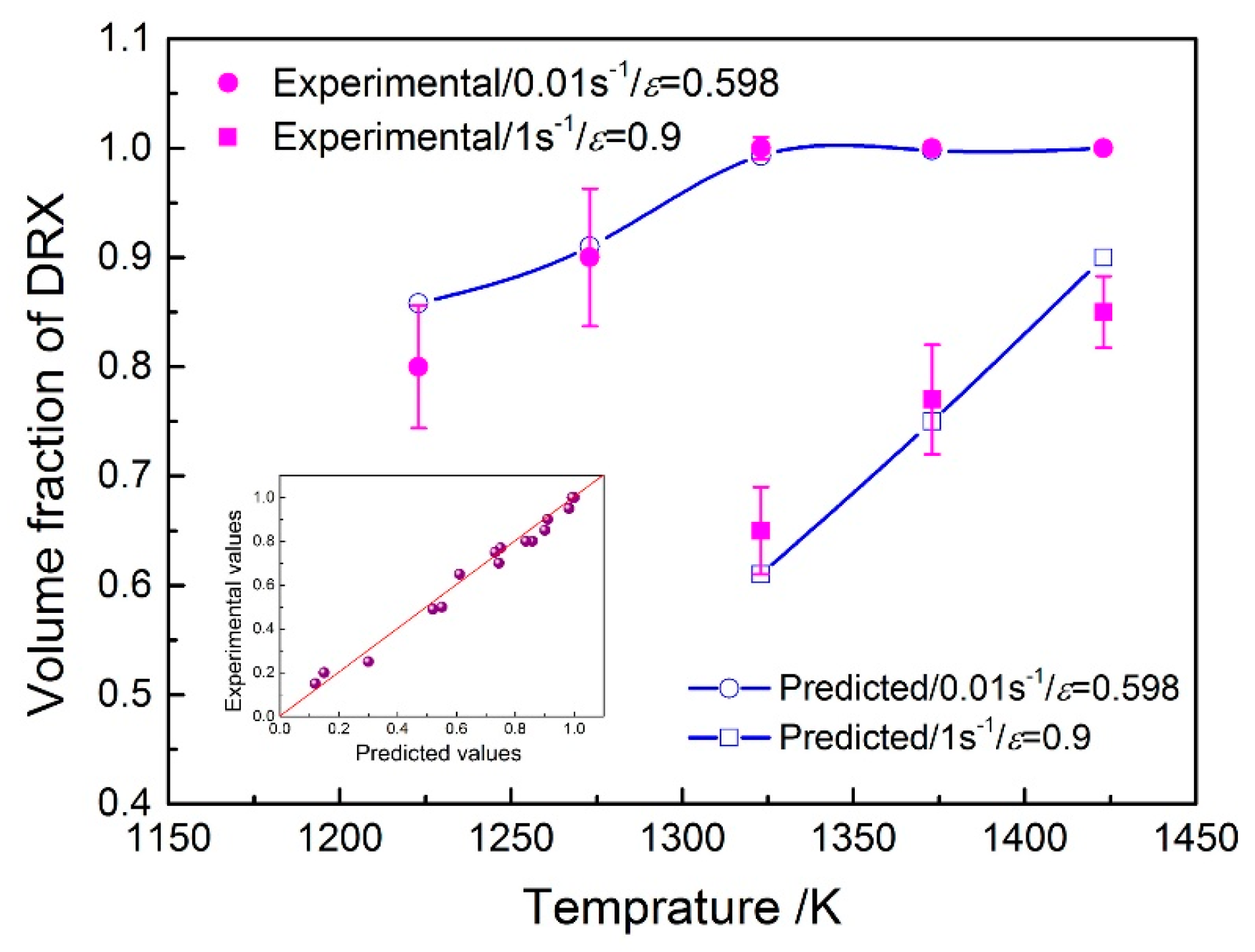

3.3. DRX Kinetic Model

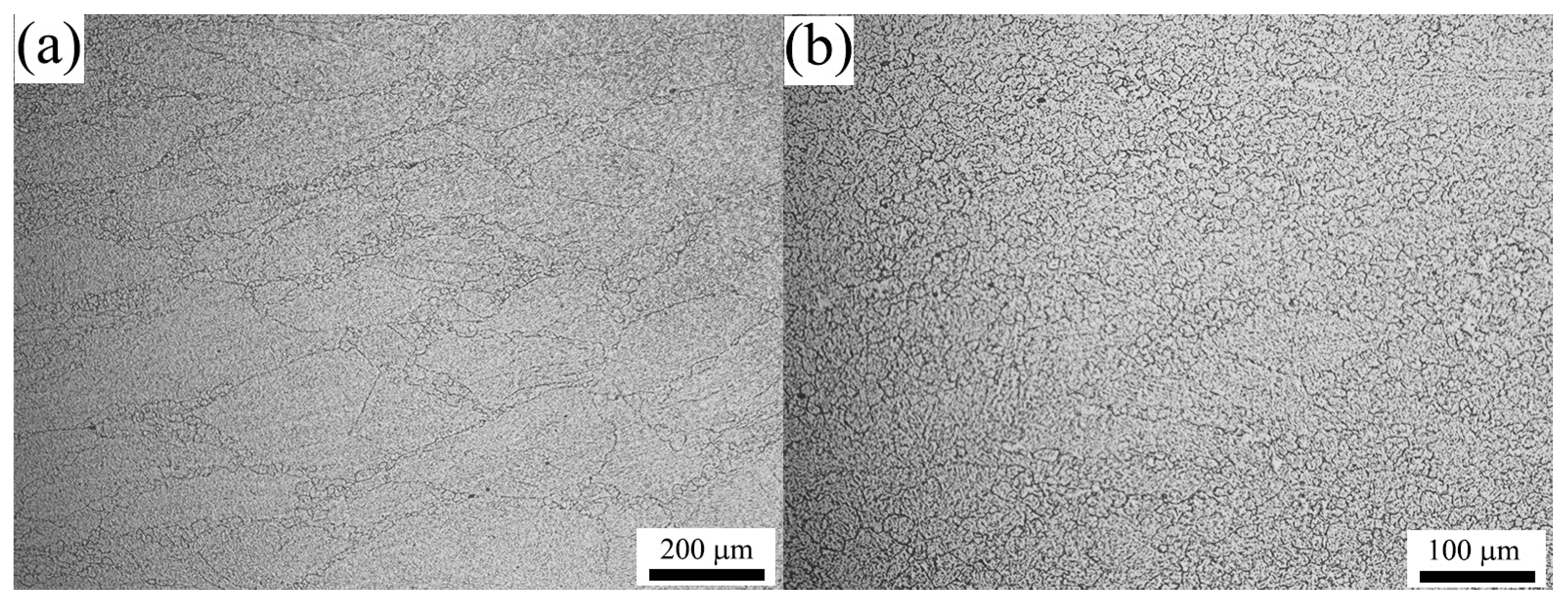

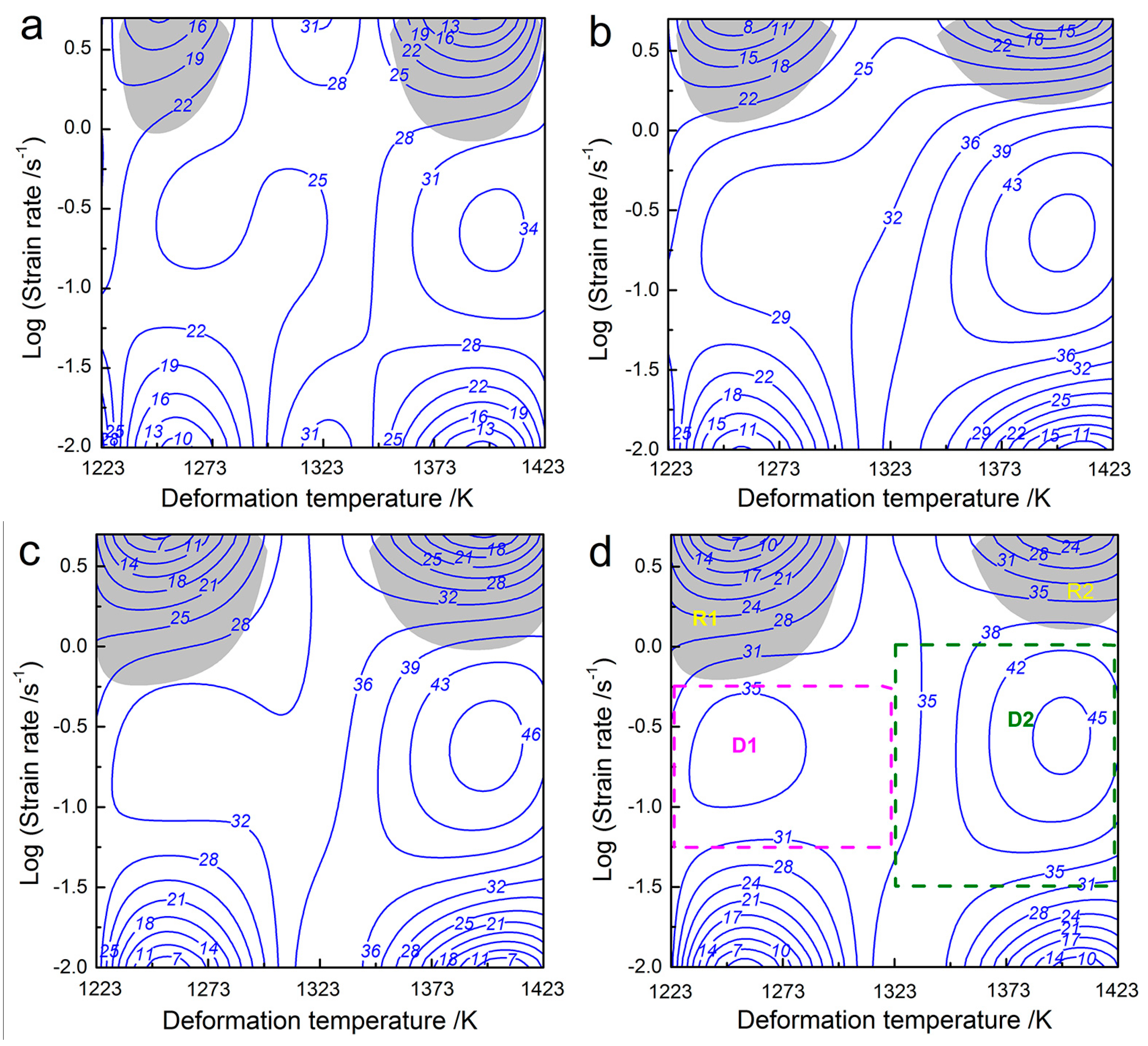

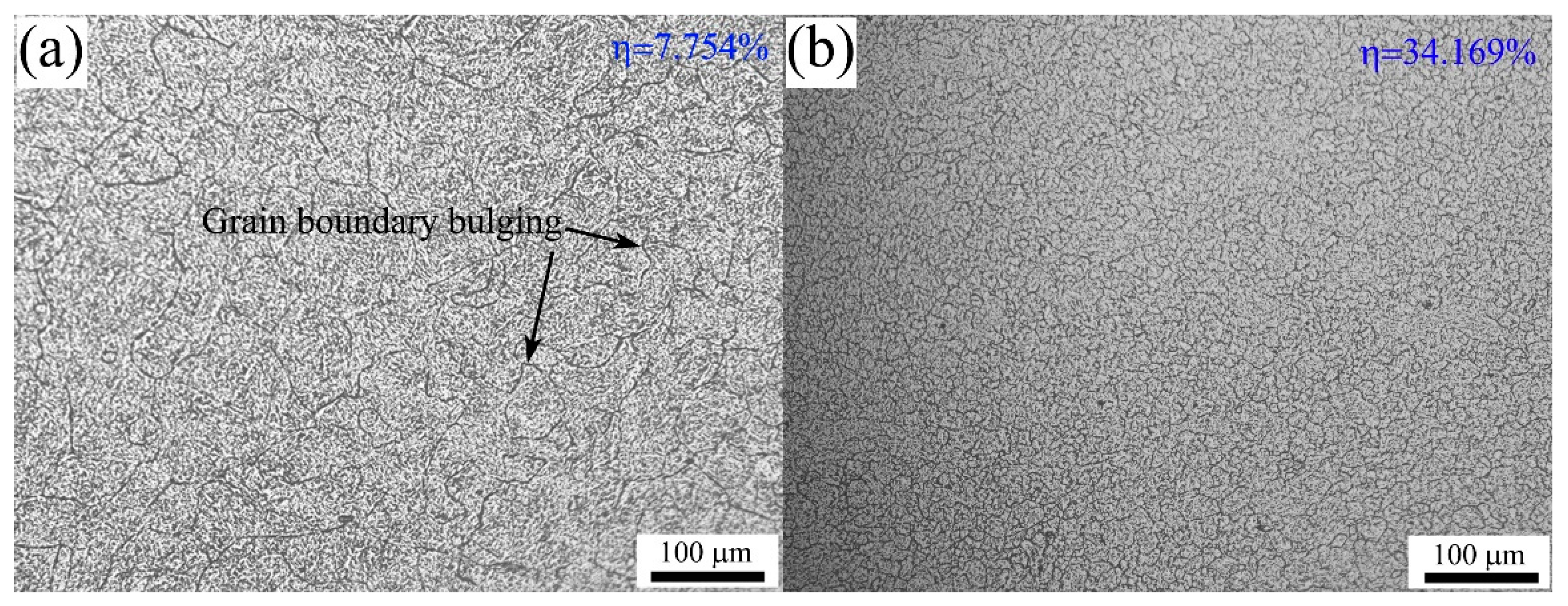

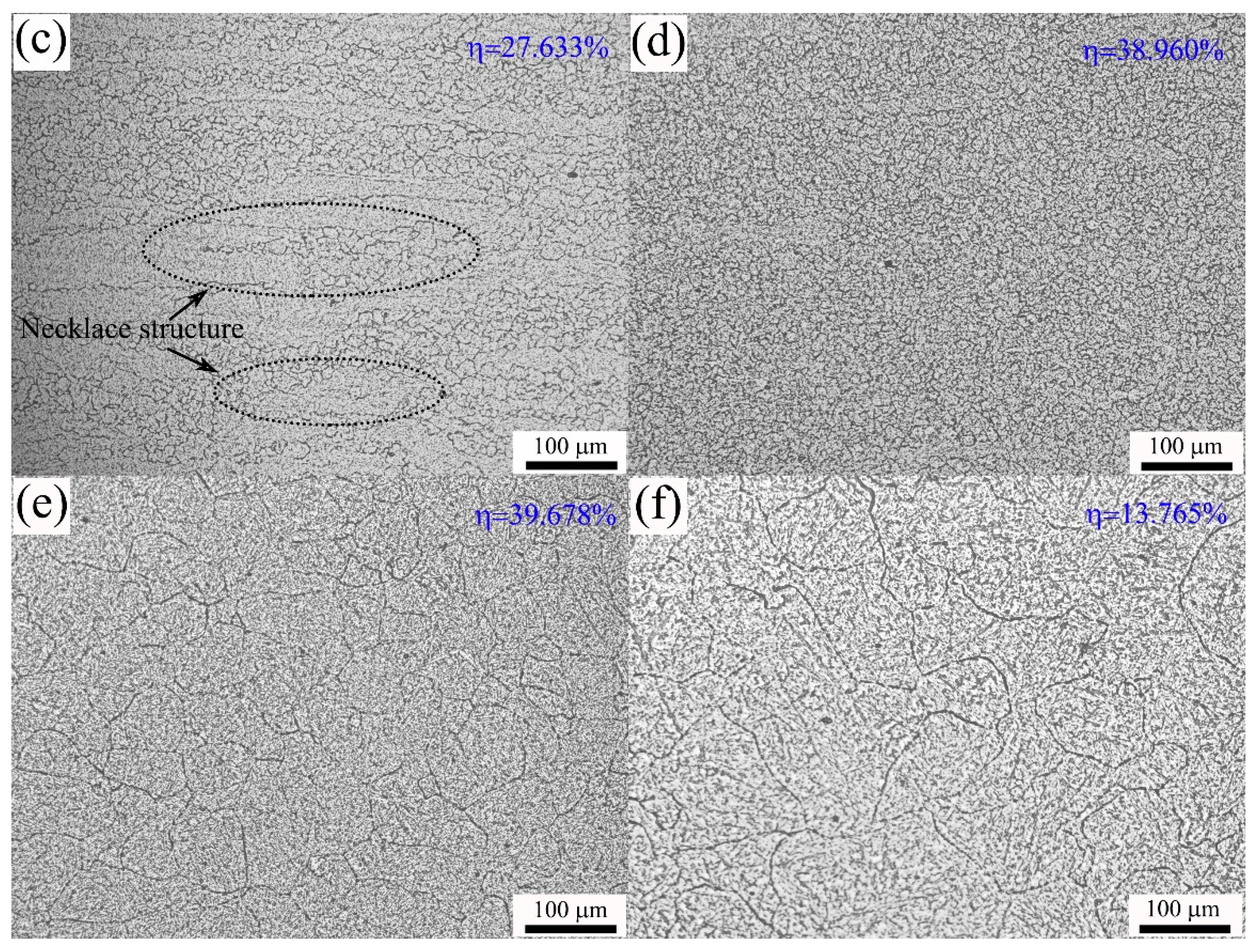

3.4. Processing Map and Microstructures

4. Conclusions

- (1)

- The flow stress is strongly dependent on the deformation temperature and strain rate during hot compression, and it increases with increasing the strain rate, and decreases with the increase in temperature. The single peak stress can be easily found on the flow curves obtained at high temperatures and/or low strain rates, which implies that the DRX is responsible for the dynamic softening under these conditions.

- (2)

- The constitutive equation embraced by the parameter of Z/A is developed, where the hot deformation activation energy is 351.539 kJ/mol. In addition, the critical conditions for the occurrence of DRX are identified throughout the hot working range and the ratio between the critical strain and peak strain is about 0.779.

- (3)

- The process of DRX can be accelerated remarkably by increasing the deformation temperature or decreasing the strain rate. The model of the DRX volume fraction during hot compression is developed based on the Avrami equation as follows: . The comparative evaluation indicates that the model has good capability to describe and predict the kinetic behavior of DRX.

- (4)

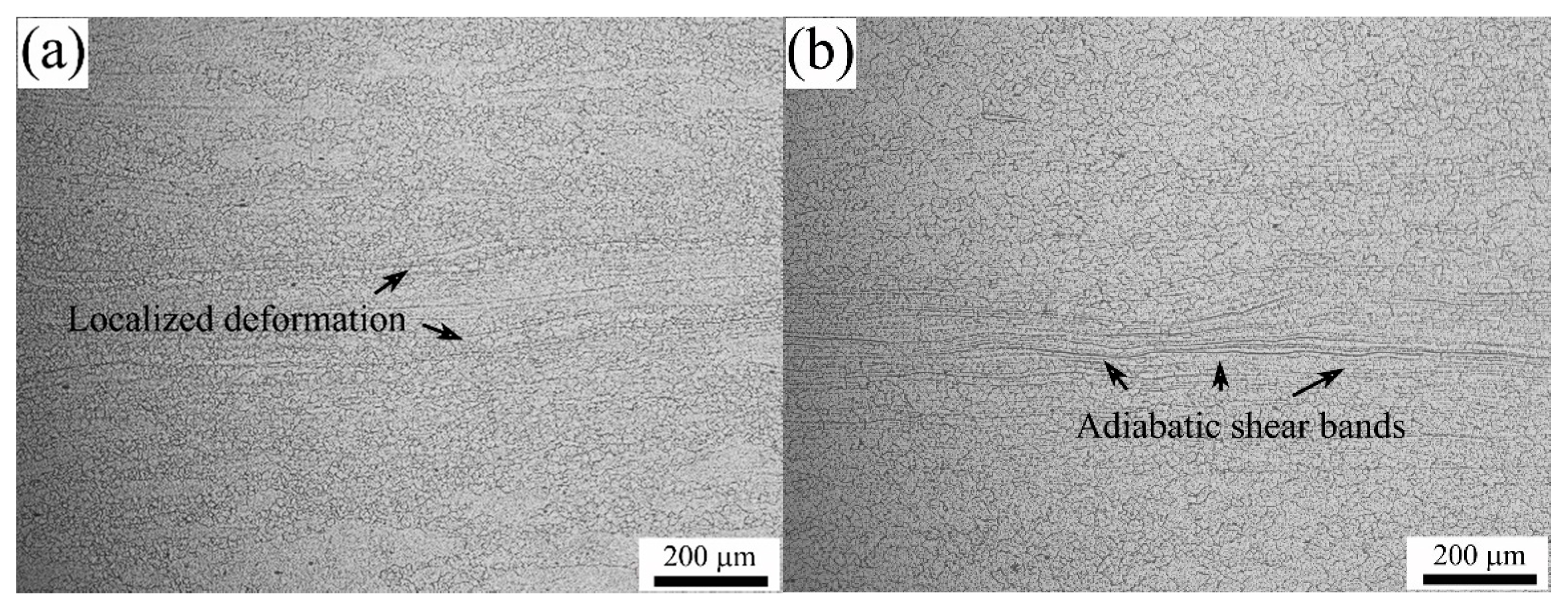

- The processing map at different true strains was established based on DMM. The strain has obvious impacts on the efficiency of the power dissipation and the instability parameter. To obtain a reasonable DRX and good hot workability, the optimum hot working parameters are the temperature range from 1323–1423 K and strain rate range from 0.06–1 s−1 with a peak power dissipation efficiency of 45%. The instability regions caused by localized deformation and adiabatic shear are located at high strain rates, which should be avoided during hot processing.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yoozbashi, M.N.; Yazdani, S.; Wang, T.S. Design of a new nanostructured, high-Si bainitic steel with lower cost production. Mater. Des. 2011, 32, 3248–3253. [Google Scholar] [CrossRef]

- Caballero, F.G.; Miller, M.K.; Garcia-Mateo, C. Carbon supersaturation of ferrite in a nanocrystalline bainitic steel. Acta Mater. 2010, 58, 2338–2343. [Google Scholar] [CrossRef]

- Huang, H.; Sherif, M.Y.; Rivera-Diaz-Castillo, P.E.J. Combinatorial optimization of carbide-free bainitic nanostructures. Acta Mater. 2013, 61, 1639–1647. [Google Scholar] [CrossRef]

- Misra, A.; Sharma, S.; Sangal, S.; Upadhyaya, A.; Mondal, K. Critical isothermal temperature and optimum mechanical behaviour of high Si-containing bainitic steels. Mater. Sci. Eng. A 2012, 558, 725–729. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels; IOM Commercial Ltd.: London, UK, 2001. [Google Scholar]

- Caballero, F.G.; Miller, M.K.; Babu, S.S.; Garcia-Mateo, C. Atomic scale observations of bainite transformation in a high carbon high silicon steel. Acta Mater. 2007, 55, 381–390. [Google Scholar] [CrossRef]

- Long, X.Y.; Zhang, F.C.; Kang, J.; Lv, B.; Shi, B. Low-temperature bainite in low-carbon steel. Mater. Sci. Eng. A 2014, 594, 344–351. [Google Scholar] [CrossRef]

- Kazum, O.; Bobby Kannan, M.; Beladi, H.; Timokhina, I.B.; Hodgson, P.D.; Khoddam, S. Aqueous corrosion performance of nanostructured bainitic steel. Mater. Des. 2014, 54, 67–71. [Google Scholar] [CrossRef]

- Pointner, P. High strength rail steels-the importance of material properties in contact mechanics problems. Wear 2008, 265, 1373–1379. [Google Scholar] [CrossRef]

- Qian, L.; Zhou, Q.; Zhang, F.C.; Meng, J.Y.; Zhang, M.; Tian, Y. Microstructure and mechanical properties of a low carbon carbide-free bainitic steel Co-alloyed with Al and Si. Mater. Des. 2012, 39, 264–268. [Google Scholar] [CrossRef]

- Han, Y.; Wu, H.; Liu, C.; Liu, Y.X. Microstructures and mechanical characteristics of a medium carbon super-bainitic steel after isothermal transformation. JMEPEG 2014, 23, 4230–4236. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Development of hard bainite. ISIJ Int. 2003, 43, 1238–1243. [Google Scholar] [CrossRef]

- Hu, F.; Hodgson, P.D.; Wu, K.M. Acceleration of the super bainite transformation through a coarse austenite grain size. Mater. Lett. 2014, 122, 240–243. [Google Scholar] [CrossRef]

- Xu, G.; liu, F.; Wang, L.; Hu, H.J. A new approach to quantitative analysis of bainitic transformation in a superbainite steel. Scr. Mater. 2013, 68, 833–836. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.-S.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Han, Y.; Liu, G.W.; Zou, D.N.; Liu, R.; Qiao, G.J. Deformation behavior and microstructural evolution of as-cast 904L austenitic stainless steel during hot compression. Mater. Sci. Eng. A 2013, 565, 342–350. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wen, D.X.; Deng, J.; Liu, G.; Chen, J. Constitutive models for high temperature flow behaviors of a Ni-based superalloy. Mater. Des. 2014, 59, 115–123. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.W.; Shen, W.F.; Liu, C.R.; Xia, Y.N.; Li, R.Q. Study on constitutive modeling and processing maps for hot deformation of medium carbon Cr-Ni-Mo alloyed steel. Mater. Des. 2016, 90, 804–814. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.W.; Xu, Q.H.; Xia, Y.N.; Shen, W.F. The kinetics and cellular automaton modeling of dynamic recrystallization behavior of a medium carbon Cr-Ni-Mo alloyed steel in hot working process. Mater. Sci. Eng. A 2016, 678, 33–43. [Google Scholar] [CrossRef]

- Wei, H.-L.; Liu, G.-Q.; Zhao, H.-T.; Zhang, M.-H. Effect of carbon content on hot deformation behaviors of vanadium microalloyed steels. Mater. Sci. Eng. A 2014, 596, 112–120. [Google Scholar] [CrossRef]

- Wei, H.-L.; Liu, G.-Q.; Xiao, X.; Zhang, M.-H. Dynamic recrystallization behavior of a medium carbon vanadium microalloyed steel. Mater. Sci. Eng. A 2013, 573, 215–221. [Google Scholar] [CrossRef]

- Yang, Z.N.; Zhang, F.C.; Zhang, C.L.; Zhang, M.; Lv, B.; Qu, L. Study on hot deformation behaviour and processing maps of low carbon bainitic steel. Mater. Des. 2015, 66, 258–266. [Google Scholar] [CrossRef]

- Saadatkia, S.; Mirzadeh, H.; Cabrera, J.-M. Hot deformation behavior, dynamic recrystallization, and physically-based constitutive modeling of plain carbon steels. Mater. Sci. Eng. A 2015, 636, 196–202. [Google Scholar] [CrossRef]

- Zhu, S.L.; Cao, H.Z.; Ye, J.S.; Hu, W.H.; Zheng, G.Q. Dynamic recrystallization behavior of medium carbon Cr-Ni-Mo-Nb steel during hot deformation. J. Iron Steel Res. Int. 2015, 22, 264–271. [Google Scholar] [CrossRef]

- Hui, W.J.; Chen, S.L.; Shao, C.W.; Zhang, Y.J.; Dong, H. Hot deformation behavior of Vanadium-microalloyed medium-carbon steel for fracture splitting connecting rod. J. Iron Steel Res. Int. 2015, 22, 615–621. [Google Scholar] [CrossRef]

- Rajput, S.K.; Chaudhari, G.P.; Nath, S.K. Characterization of hot deformation behavior of a low carbon steel using processing maps, constitutive equations and Zener-Hollomon parameter. J. Mater. Process. Technol. 2016, 237, 113–125. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; Garcia-Mateo, C.; Sourmail, T.; Kuntz, M.; Rementeria, R.; Caballero, F.G. Ductility of nanostructured bainite. Metals 2016, 6, 302. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Sourmail, T.; Caballero, F.G.; Smanio, V.; Kuntz, M.; Ziegler, C.; Leiro, A.; Vuorinen, E.; Elvira, R.; Teeri, T. Nanostructured steel industrialization: Plausible reality. Mater. Sci. Technol. 2014, 30, 1071–1078. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Jimenez, J.A.; Yen, H.W.; Miller, M.K.; Morales-Rivas, L.; Kuntz, M.; Ringer, S.P.; Yang, J.R.; Caballero, F.G. Low temperature bainitic ferrite: Evidence of carbon super-saturation and tetragonality. Acta Mater. 2015, 91, 162–173. [Google Scholar] [CrossRef]

- Sourmail, T.; Caballero, F.G.; Garcia-Mateo, C.; Smanio, V.; Ziegler, C.; Kuntz, M.; Elvira, R.; Leiro, A.; Vuorinen, E.; Teeri, T. Evaluation of potential of high Si high C steel nanostructured bainite for wear and fatigue applications. Mater. Sci. Technol. 2013, 29, 1166–1173. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; Yen, H.W.; Huang, B.M.; Kuntz, M.; Caballero, F.G.; Yang, J.R.; Garcia-Mateo, C. Tensile response of two nanoscale bainite composite-like structures. JOM 2015, 67, 2223–2235. [Google Scholar] [CrossRef]

- Evans, R.W.; Scharning, P.J. Axisymmetric compression test and hot working properties of alloys. Mater. Sci. Technol. 2001, 17, 995–1004. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, G.J.; Sun, J.P.; Zou, D.N. A comparative study on constitutive relationship of as-cast 904L austenitic stainless steel during hot deformation based on Arrhenius-type and artificial neural network models. Comput. Mater. Sci. 2013, 67, 93–103. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. Characterization of deformation instability in modified 9Cr-1Mo steel during thermo-mechanical processing. Mater. Des. 2011, 32, 716–722. [Google Scholar] [CrossRef]

- Shi, C.; Lai, J.; Chen, X.-G. Microstructural evolution and dynamic softening mechanisms of Al-Zn-Mg-Cu alloy during hot compressive deformation. Materials 2014, 7, 244–264. [Google Scholar] [CrossRef]

- Liu, G.W.; Han, Y.; Shi, Z.Q.; Sun, J.P.; Zou, D.N.; Qiao, G.J. Hot deformation and optimization of process parameters of an as-cast 6Mo superaustenitic stainless steel: A study with processing map. Mater. Des. 2014, 53, 662–672. [Google Scholar] [CrossRef]

- Han, Y.; Wua, H.; Zhang, W.; Zou, D.N.; Liu, G.W.; Qiao, G.J. Constitutive equation and dynamic recrystallization behavior of as-cast 254SMO super-austenitic stainless steel. Mater. Des. 2015, 69, 230–240. [Google Scholar] [CrossRef]

- Sellars, C.M.; Mc Tegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Xi, T.; Yang, C.G.; Babar Shahzad, M.; Yang, K. Study of the processing map and hot deformation behavior of a Cu-bearing 317LN austenitic stainless steel. Mater. Des. 2015, 87, 303–312. [Google Scholar] [CrossRef]

- El Wahabi, M.; Cabrera, J.M.; Prado, J.M. Hot working of two AISI 304 steels: A comparative study. Mater. Sci. Eng. A 2003, 343, 116–125. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 1996, 44, 127–136. [Google Scholar] [CrossRef]

- Cai, Z.W.; Chen, F.X.; Ma, F.J.; Guo, J.Q. Dynamic recrystallization behavior and hot workability of AZ41M magnesium alloy during hot deformation. J. Alloys Compd. 2016, 670, 55–63. [Google Scholar] [CrossRef]

- Jonas, J.J.; Quelennec, X.; Lan, J.; Martin, E. The Avrami kinetics of dynamic recrystallization. Acta Mater. 2009, 57, 2748–2756. [Google Scholar] [CrossRef]

- Zou, D.N.; Liu, R.; Han, Y.; Zhang, W.; Wu, K.; Liu, X.H. On dynamic recrystallization under hot working of superaustenitic stainless steel. Mater. Sci. Technol. 2014, 30, 411–417. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps; ASM: Materials Park, OH, USA, 1997. [Google Scholar]

- Sun, Y.; Wan, Z.P.; Hu, L.X.; Ren, J.S. Characterization of hot processing parameters of powder metallurgy TiAl-based alloy based on the activation energy map and processing map. Mater. Des. 2015, 86, 922–932. [Google Scholar] [CrossRef]

- Jiang, H.; Dong, J.X.; Zhang, M.C.; Zheng, L.; Yao, Z.H. Hot deformation characteristics of Alloy 617B nickel-based superalloy: A study using processing map. J. Alloys Compd. 2015, 647, 338–350. [Google Scholar] [CrossRef]

- Sarebanzadeh, M.; Mahmudi, R.; Roumina, R. Constitutive analysis and processing map of an extruded Mg-3Gd-1Zn alloy under hot shear deformation. Mater. Sci. Eng. A 2015, 637, 155–161. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Gao, K.Y.; Wu, X.L.; Wang, W.; Nie, Z.R. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy. J. Alloys Compd. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K. Recent advances in the science of mechanical processing. Indian J. Technol. 1990, 28, 435–451. [Google Scholar]

- Fan, Q.C.; Jiang, X.Q.; Zhou, Z.H.; Ji, W.; Cao, H.Q. Constitutive relationship and hot deformation behavior of Armco-type pure iron for a wide range of temperature. Mater. Des. 2015, 65, 193–203. [Google Scholar] [CrossRef]

- Mehtonen, S.V.; Palmiere, E.J.; Misra, R.D.K.; Karjalainen, L.P.; Porter, D.A. Dynamic restoration mechanisms in a Ti–Nb stabilized ferritic stainless steel during hot deformation. Mater. Sci. Eng. A 2014, 601, 7–19. [Google Scholar] [CrossRef]

- Liu, L.; Hou, L.G.; Cui, H.; Huang, J.F.; Zhang, Y.A.; Zhang, J.S. Hot deformation behavior and processing map of spray formed M3:2 high speed steel. J. Iron Steel Res. Int. 2016, 23, 501–508. [Google Scholar] [CrossRef]

- Han, Y.; Liu, G.W.; Zou, D.N.; Sun, J.P.; Qiao, G.J. Investigation on hot deformation of 20Cr-25Ni superaustenitic stainless steel with starting columnar dendritic microstructure based on kinetic analysis and processing map. Mater. Sci. Technol. 2013, 29, 300–308. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Sun, Y.; Zhang, W.; Chen, H. Hot Deformation and Processing Window Optimization of a 70MnSiCrMo Carbide-Free Bainitic Steel. Materials 2017, 10, 318. https://doi.org/10.3390/ma10030318

Han Y, Sun Y, Zhang W, Chen H. Hot Deformation and Processing Window Optimization of a 70MnSiCrMo Carbide-Free Bainitic Steel. Materials. 2017; 10(3):318. https://doi.org/10.3390/ma10030318

Chicago/Turabian StyleHan, Ying, Yu Sun, Wei Zhang, and Hua Chen. 2017. "Hot Deformation and Processing Window Optimization of a 70MnSiCrMo Carbide-Free Bainitic Steel" Materials 10, no. 3: 318. https://doi.org/10.3390/ma10030318

APA StyleHan, Y., Sun, Y., Zhang, W., & Chen, H. (2017). Hot Deformation and Processing Window Optimization of a 70MnSiCrMo Carbide-Free Bainitic Steel. Materials, 10(3), 318. https://doi.org/10.3390/ma10030318