Open-Source Automated Mapping Four-Point Probe

Abstract

:1. Introduction

2. Background

3. Experimental Setup

3.1. Experimental Overview

3.2. Equipment and 3-D Motion Control Description

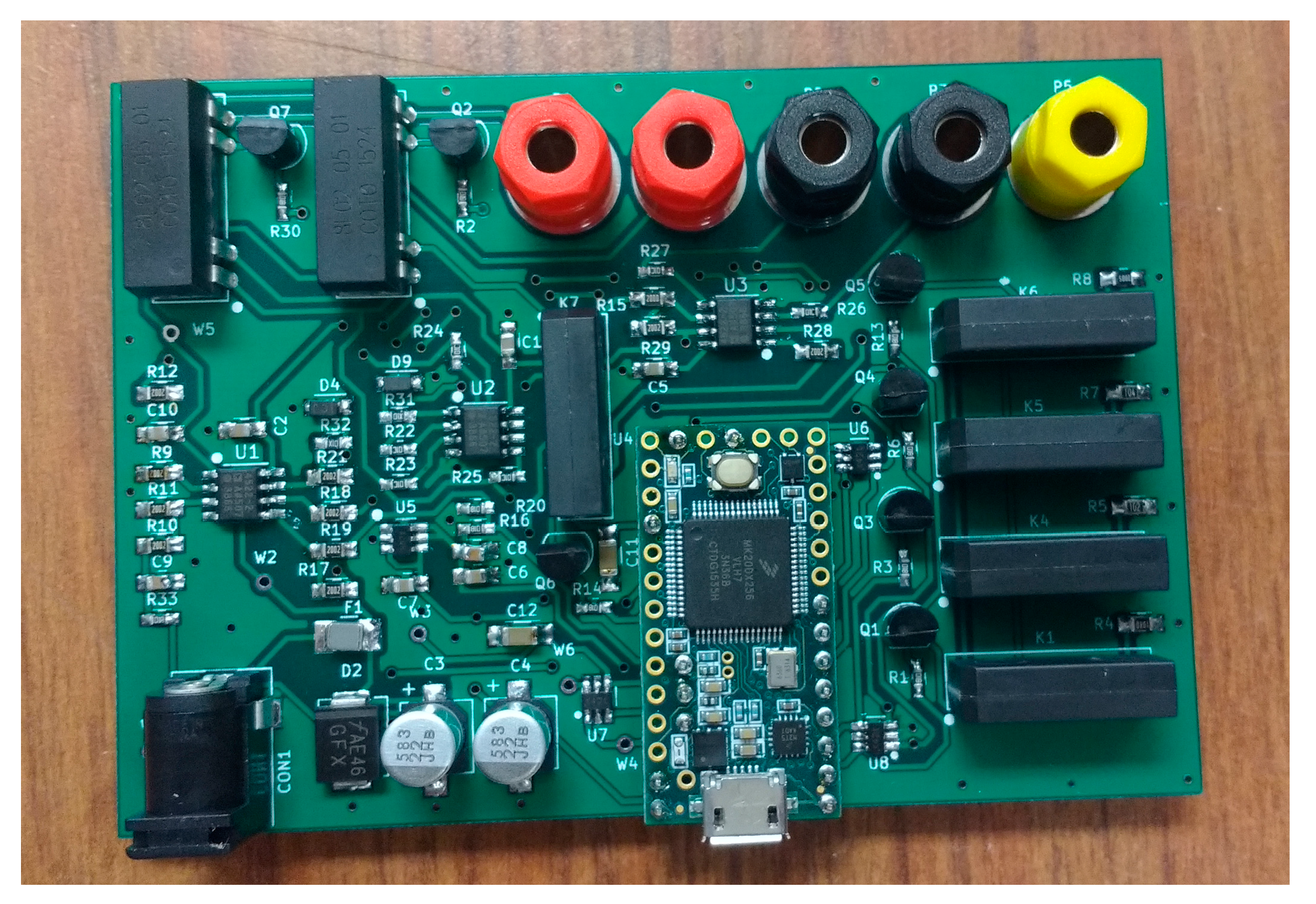

3.3. Open Source Measurement Circuit

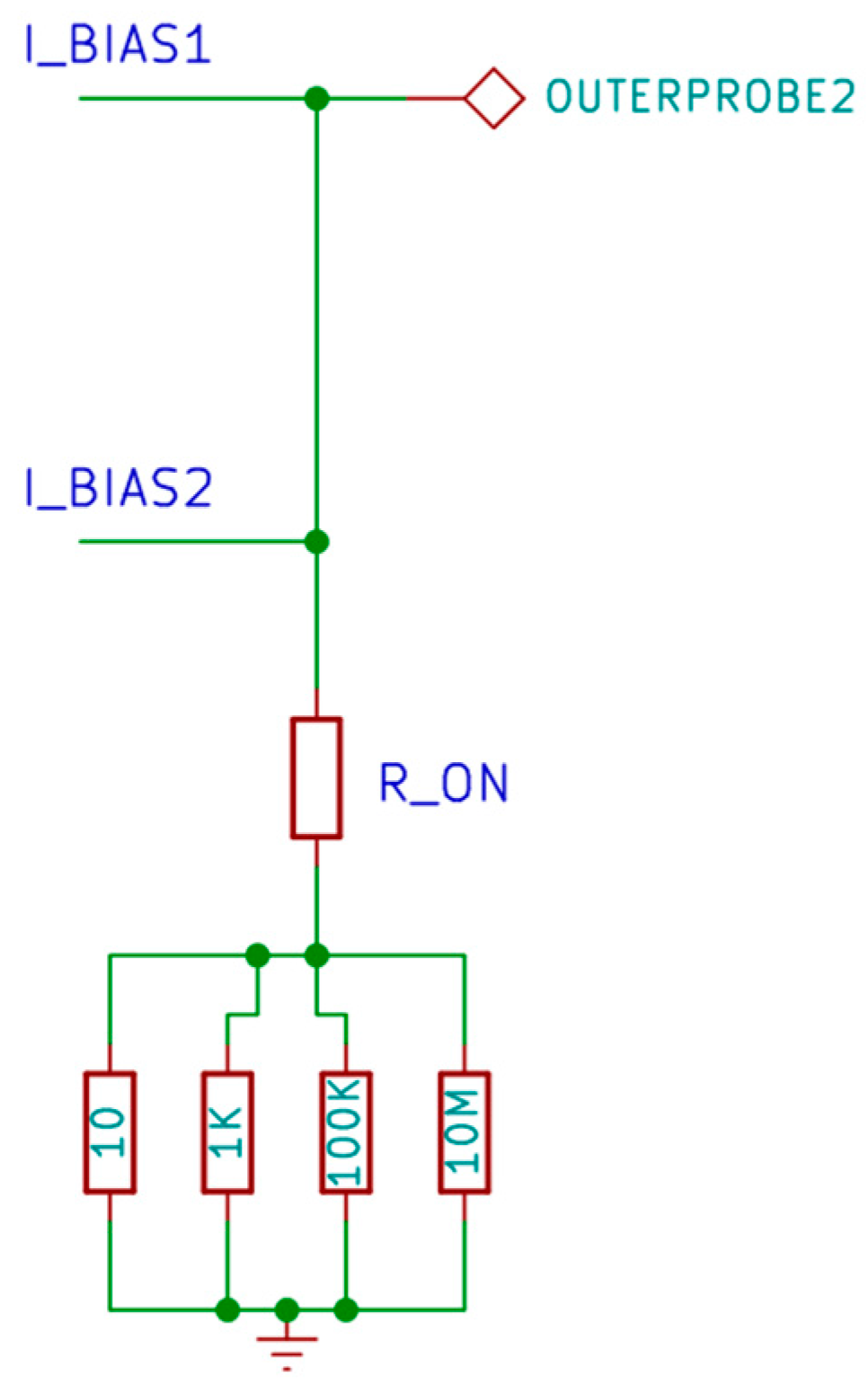

3.3.1. Adjustable Current Source

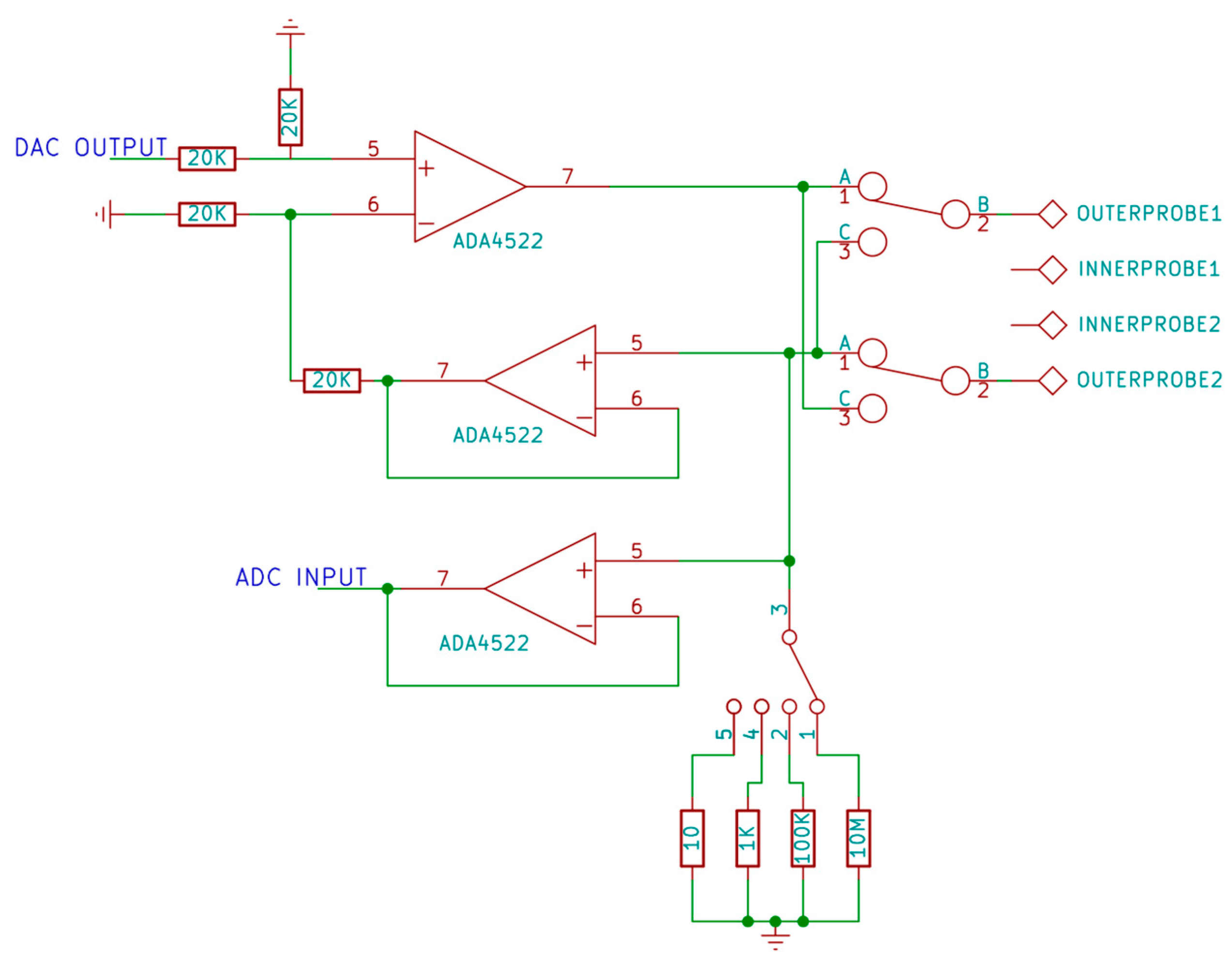

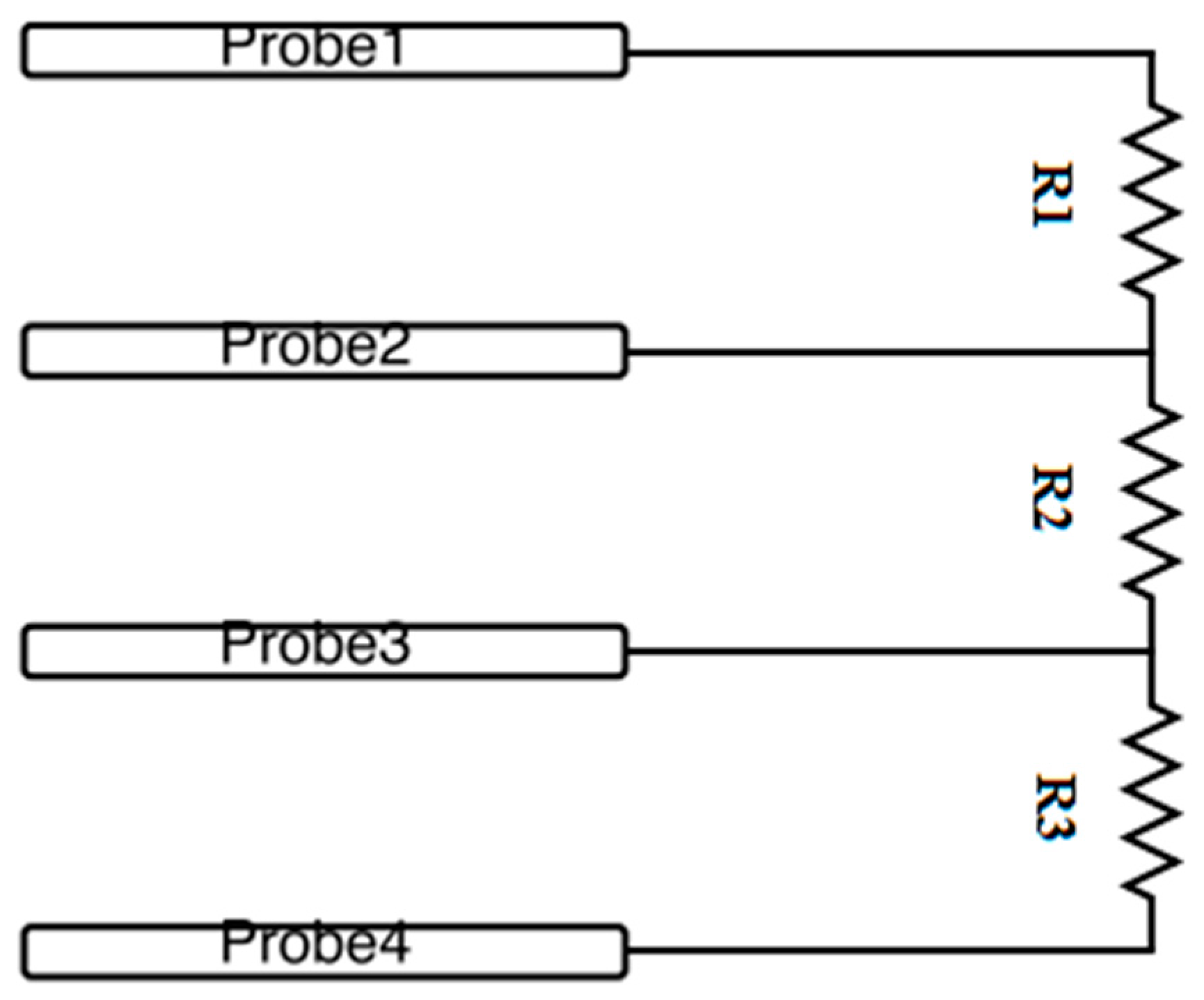

3.3.2. Voltage Measurement Circuit

3.3.3. Main Controller

3.4. Firmware

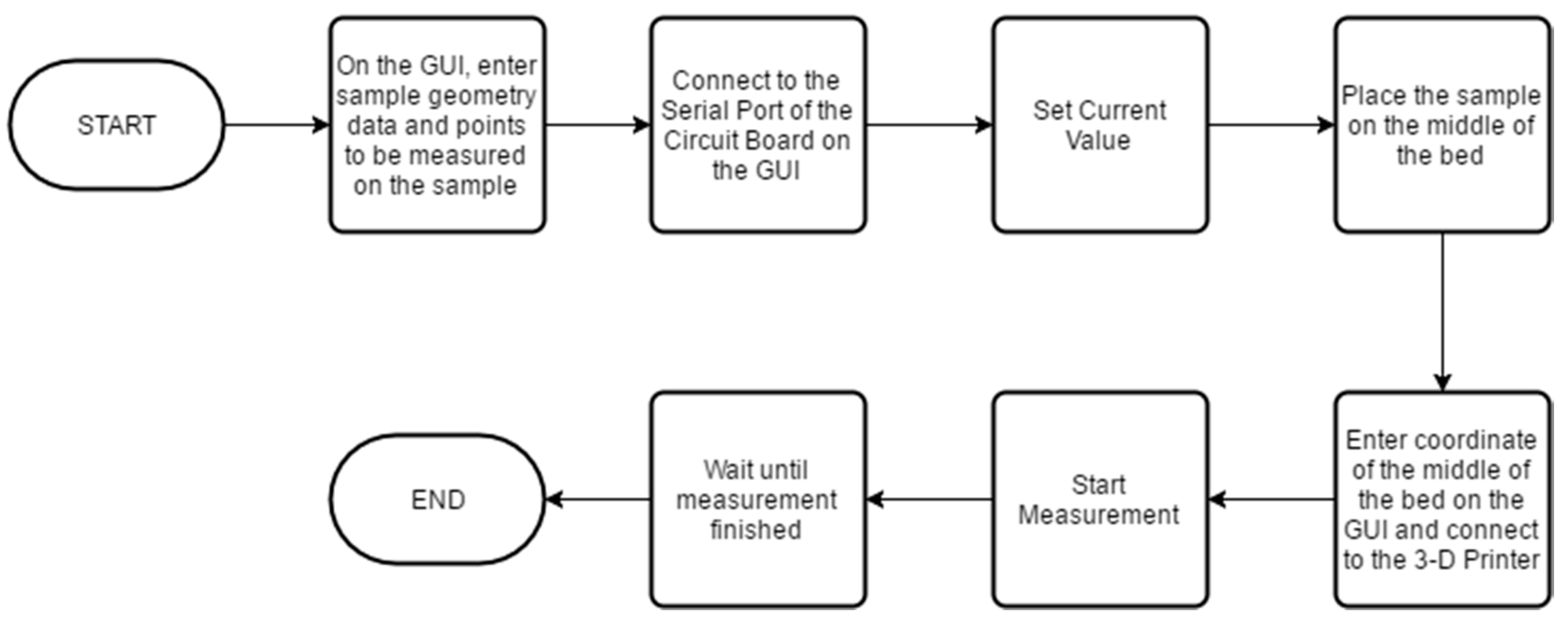

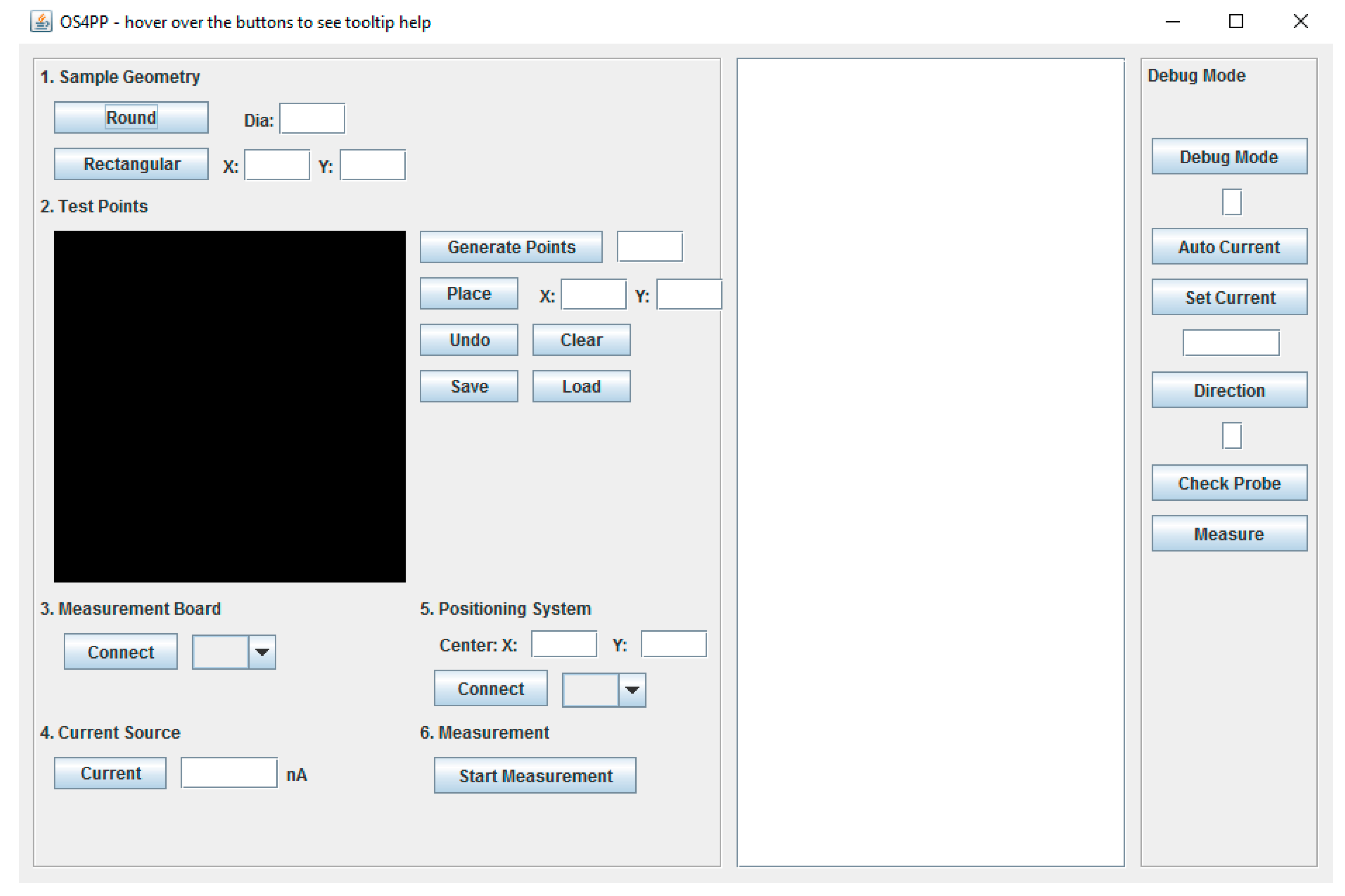

3.5. Software and Graphical User Interface (GUI)

4. Validation

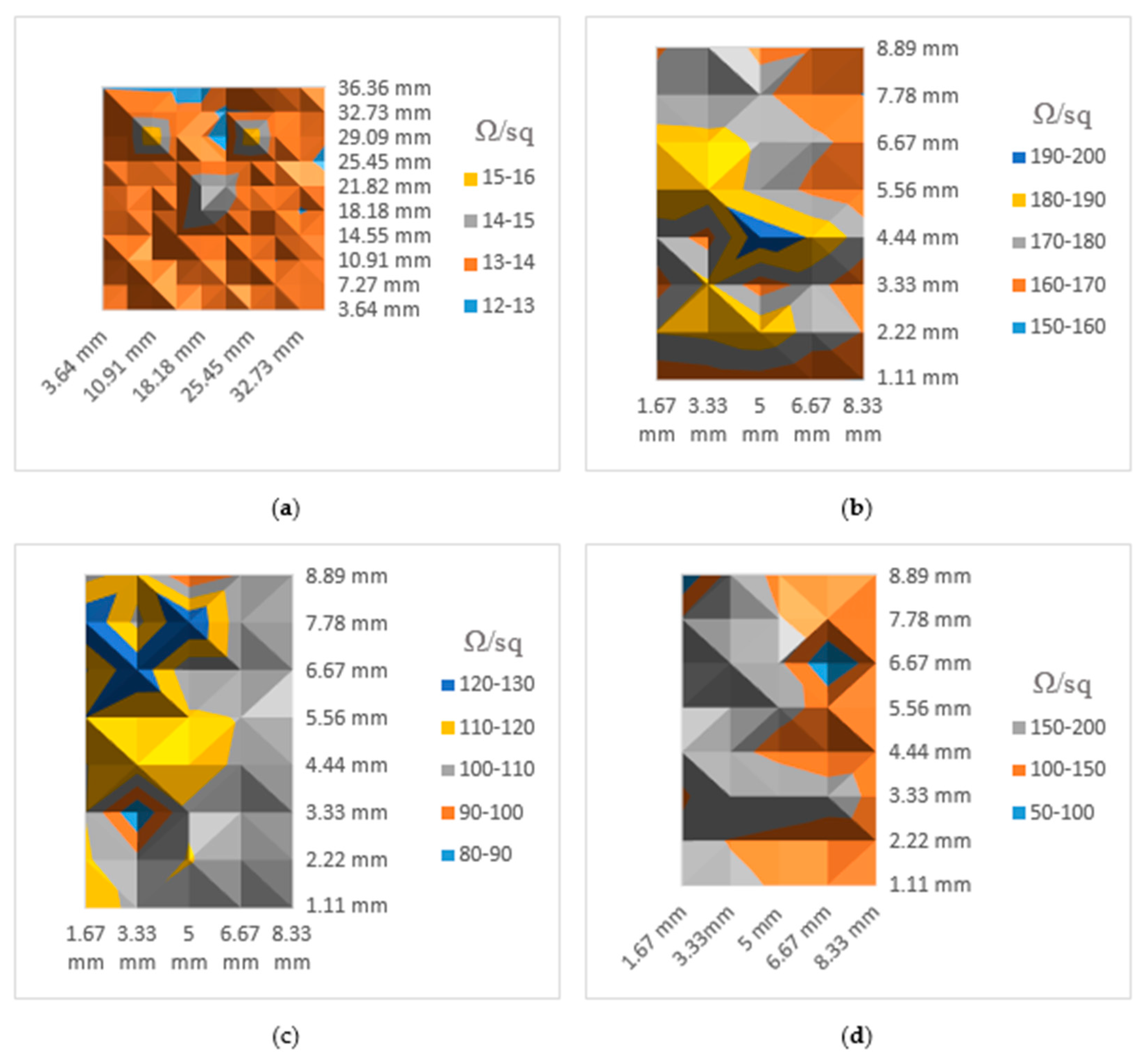

5. Results and Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Woelfle, M.; Olliaro, P.; Todd, M.H. Open science is a research accelerator. Nat. Chem. 2011, 3, 745–748. [Google Scholar] [CrossRef] [PubMed]

- Hansen, A.; Howard, T.J. The current state of open source hardware: The need for an open source development platform. In Lecture Notes in Mechanical Engineering; Chakrabarti, A., Prakash, R.V., Eds.; Springer: New Delhi, India, 2013; pp. 977–988. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.T.; Khalid, M.; Yang, T.C.K.; Hung, S.T.; Huang, C.M. Physical characterization and pre-assessment of recycled high-density polyethylene as 3D printing material. J. Polym. Environ. 2016, 1–10. [Google Scholar] [CrossRef]

- Pearce, J.M. Building research equipment with free, open-source hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs, 1st ed.; Elsevier Science Publishers B.V.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open labware: 3-D printing your own lab equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef] [PubMed]

- Wijnen, B.; Anzalone, G.C.; Pearce, J.M. Open-source mobile water quality testing platform. J. Water Sanit. Hyg. Dev. 2014, 4, 532–537. [Google Scholar] [CrossRef]

- Kelley, C.D.; Krolick, A.; Brunner, L.; Burklund, A.; Kahn, D.; Ball, W.P.; Weber-Shirk, M. An affordable open-source turbidimeter. Sensors 2014, 14, 7142–7155. [Google Scholar] [CrossRef] [PubMed]

- Laverty, D.M.; Best, R.J.; Brogan, P.; Khatib, I.A.; Vanfretti, L.; Morrow, D.J. The OpenPMU platform for open-source phasor measurements. IEEE Trans. Instrum. Meas. 2013, 62, 701–709. [Google Scholar] [CrossRef]

- Zhang, C.; Anzalone, N.C.; Faria, R.P.; Pearce, J.M. Open-source 3D-printable optics equipment. PLoS ONE 2013, 8, e59840. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, M.C.; Eyre, B.D. A low cost, easy to build, portable, and universal autosampler for liquids. Methods Oceanogr. 2013, 8, 23–32. [Google Scholar] [CrossRef]

- Niezen, G.; Eslambolchilar, P.; Thimbleby, H. Open-source hardware for medical devices. BMJ Innov. 2016, 2, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Costa, E.T.; Mora, M.F.; Willis, P.A.; Lago, C.L.; Jiao, H.; Garcia, C.D. Getting started with open-hardware: Development and control of microfluidic devices. Electrophoresis 2014, 35, 2370–2377. [Google Scholar] [CrossRef] [PubMed]

- Lücking, T.H.; Sambale, F.; Schnaars, B.; Bulnes-Abundis, D.; Beutel, S.; Scheper, T. 3D-printed individual labware in biosciences by rapid prototyping: In vitro biocompatibility and applications for eukaryotic cell cultures. Eng. Life Sci. 2015, 15, 57–64. [Google Scholar] [CrossRef]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences. Anal. Chem. 2014, 86, 3240–3253. [Google Scholar] [CrossRef] [PubMed]

- Su, C.-K.; Hsia, S.-C.; Sun, Y.-C. Three-dimensional printed sample load/inject valves enabling online monitoring of extracellular calcium and zinc ions in living rat brains. Anal. Chim. Acta 2014, 838, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Maldonado-Torres, M.; López-Hernández, J.F.; Jiménez-Sandoval, P.; Winkler, R. “Plug and Play” assembly of a low-temperature plasma ionization mass spectrometry imaging (LTP-MSI) system. J. Proteom. 2014, 102, 60–65. [Google Scholar] [CrossRef] [PubMed]

- Wittbrodt, J.N.; Liebel, U.; Gehrig, J. Generation of orientation tools for automated zebrafish screening assays using desktop 3D printing. BMC Biotechnol. 2014, 14. [Google Scholar] [CrossRef] [PubMed]

- Damase, T.R.; Stephens, D.; Spencer, A.; Allen, P.B. Open source and DIY hardware for DNA nanotechnology labs. J. Biol. Methods 2015, 2. [Google Scholar] [CrossRef] [PubMed]

- Herrmann, K.-H.; Gärtner, C.; Güllmar, D.; Krämer, M.; Reichenbach, J.R. 3D printing of MRI compatible components: Why every MRI research group should have a low-budget 3D printer. Med. Eng. Phys. 2014, 36, 1373–1380. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Laboratory equipment: Cut costs with open-source hardware. Nature 2014, 505, 618. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Quantifying the value of open source hard-ware development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2015, 34, 192–195. [Google Scholar] [CrossRef]

- Zhang, C.; Wijnen, B.; Pearce, J.M. Open-source 3-D platform for low-cost scientific instrument ecosystem. J. Lab. Autom. 2016, 21, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Wijnen, B.; Petersen, E.E.; Hunt, E.J.; Pearce, J.M. Free and open-source automated 3-D microscope. J. Microsc. 2016, 264, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Kurz, J. Global PV’s 5 Year Outlook—Strong Continued Growth; Apricum—The Cleantech Advisory: Berlin, Germany, 2015. [Google Scholar]

- The 2016 Global PV Outlook: US, Asian Markets Strengthened by Policies to Reduce CO2. Available online: http://www.renewableenergyworld.com/articles/2016/01/the-2016-global-pv-outlook-u-s-and-asian-markets-strengthened-by-policies-to-reduce-co2.html (accessed on 29 August 2016).

- Pearce, J.M. Photovoltaics—A path to sustainable futures. Futures 2002, 34, 663–674. [Google Scholar] [CrossRef]

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energy Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef]

- Smalley, R.E. Future global energy prosperity: The terawatt challenge. MRS Bull. 2005, 30, 412–417. [Google Scholar] [CrossRef]

- Vora, A.; Gwamuri, J.; Pala, N.; Kulkarni, A.; Pearce, J.M.; Güney, D.Ö. Exchanging ohmic losses in metamaterial absorbers with useful optical absorption for photovoltaics. Sci. Rep. 2014, 4. [Google Scholar] [CrossRef] [PubMed]

- Vora, A.; Gwamuri, J.; Pearce, J.M.; Bergstrom, P.L.; Güney, D.Ö. Multi-resonant silver nano-disk patterned thin film hydrogenated amorphous silicon solar cells for Staebler-Wronski effect compensation. J. Appl. Phys. 2014, 116. [Google Scholar] [CrossRef]

- Tamang, A.; Sai, H.; Jovanov, V.; Bali, S.I.H.; Matsubara, K.; Knipp, D. On the interplay of interface morphology and microstructure of high-efficiency microcrystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2016, 151, 81–88. [Google Scholar] [CrossRef]

- Onwudinanti, C.; Vismara, R.; Isabella, O.; Grenet, L.; Emieux, F.; Zeman, M. Advanced light management based on periodic textures for Cu(In,Ga)Se2 thin-film solar cells. Opt Express 2016, 24, A693–A707. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.; Furlan, A.; Li, W.; Arapov, K.; Santbergen, R.; Wienk, M.M.; Zeman, M.; Smets, A.H.M.; Janssen, R.A.J. Highly efficient hybrid polymer and amorphous silicon multijunction solar cells with effective optical management. Adv. Mater. Weinh. 2016, 28, 2170–2177. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Guney, D.O.; Pearce, J.M. Plasmonic enhancement of amorphous silicon solar photovoltaic cells with hexagonal silver arrays made with nanosphere lithography. Mater. Express 2016, 3, 105034. [Google Scholar] [CrossRef]

- Conibeer, G.; Green, M.; Corkish, R.; Cho, Y.; Cho, E.C.; Jiang, C.W.; Fangsuwannarak, T.; Pink, E.; Huang, Y.; Puzzer, T.; et al. Silicon nanostructures for third generation photovoltaic solar cells. Thin Solid Films 2006, 511, 654–662. [Google Scholar] [CrossRef]

- Gwamuri, J.; Vora, A.; Khanal, R.R.; Phillips, A.B.; Heben, M.J.; Guney, D.O.; Bergstrom, P.; Kulkarni, A.; Pearce, J.M. Limitations of ultra-thin transparent conducting oxides for integration into plasmonic-enhanced thin-film solar photovoltaic devices. Mater. Renew. Sustain. Energy 2015, 4. [Google Scholar] [CrossRef]

- Hanaei, H.; Assadi, M.K.; Saidur, R. Highly efficient antireflective and self-cleaning coatings that incorporate carbon nanotubes (CNTs) into solar cells: A review. Renew. Sustain. Energy Rev. 2016, 59, 620–635. [Google Scholar] [CrossRef]

- Sun, H. Recent progress in anti-reflection layer fabrication for solar cells. J. Nanoelectron. Optoelectron. 2016, 11, 257–264. [Google Scholar] [CrossRef]

- Tomasi, A.; Sahli, F.; Seif, J.P.; Fanni, L.; de Nicolas Agut, S.M.; Geissbühler, J.; Paviet-Salomon, B.; Nicolay, S.; Barraud, L.; Niesen, B.; et al. Transparent electrodes in silicon heterojunction solar cells: Influence on contact passivation. IEEE J. Photovolt. 2016, 6, 17–27. [Google Scholar] [CrossRef]

- Gwamuri, J.; Marikkannan, M.; Mayandi, J.; Bowen, P.K.; Pearce, J.M. Influence of oxygen concentration on the performance of ultra-thin RF magnetron sputter deposited indium tin oxide films as a top electrode for photovoltaic devices. Materials 2016, 9. [Google Scholar] [CrossRef]

- Gwamuri, J.; Vora, A.; Mayandi, J.; Güney, D.Ö.; Bergstrom, P.L.; Pearce, J.M. A new method of preparing highly conductive ultra-thin indium tin oxide for plasmonic-enhanced thin film solar photovoltaic devices. Sol. Energy Mater. Sol. Cells 2016, 149, 250–257. [Google Scholar] [CrossRef]

- Duong, T.; Lal, N.; Grant, D.; Jacobs, D.; Zheng, P.; Rahman, S.; Shen, H.; Stocks, M.; Blakers, A.; Weber, K.; et al. Semitransparent perovskite solar cell with sputtered front and rear electrodes for a four-terminal tandem. IEEE J. Photovolt. 2016, 6, 679–687. [Google Scholar] [CrossRef]

- Valdes, L.B. Resistivity measurements on germanium for transistors. Proc. IRE 1954, 42, 420–427. [Google Scholar] [CrossRef]

- Smits, F.M. Measurement of sheet resistivities with the four-point probe. Bell Syst. Techn. J. 1958, 37, 711–718. [Google Scholar] [CrossRef]

- Keywell, F.; Dorosheski, G. Measurement of the sheet resistivity of a square wafer with a square four-point probe. Rev. Sci. Instrum. 1960, 31, 833–837. [Google Scholar] [CrossRef]

- Logan, M.A. An AC bridge for semiconductor resistivity measurements using a four-point probe. Bell Syst. Tech. J. 1961, 40, 885–919. [Google Scholar] [CrossRef]

- Vaughan, D.E. Four-probe resistivity measurements on small circular specimens. Br. J. Appl. Phys. 1961, 12, 414–416. [Google Scholar] [CrossRef]

- Swartzendruber, L.J. Four-point probe measurement of non-uniformities in semiconductor sheet resistivity. Solid-State Electron. 1964, 7, 413–422. [Google Scholar] [CrossRef]

- Yoshimoto, S.; Murata, Y.; Kubo, K.; Tomita, K.; Motoyoshi, K.; Kimura, T.; Okino, H.; Hobara, R.; Matsuda, I.; Honda, S.; Katayama, M.; Hasegawa, S. Four-point probe resistance measurements using PtIr-coated carbon nanotube tips. Nano Lett. 2007, 7, 956–959. [Google Scholar] [CrossRef] [PubMed]

- Thorsteinsson, S.; Wang, F.; Petersen, D.H.; Hansen, T.M.; Kjær, D.; Lin, R.; Kim, J.-Y.; Nielsen, P.F.; Hansen, O. Accurate microfour-point probe sheet resistance measurements on small samples. Rev. Sci. Instrum. 2009, 80. [Google Scholar] [CrossRef] [PubMed]

- Ekawita, R.; Rahmawati, E.; Abdullah, M.; Khairurrijal. Four point probe method based on LOG112 and C8051F006 SoCs for resistivity measurement. In Proceedings of the 2009 International Conference on Instrumentation, Communications, Information Technology, and Biomedical Engineering (ICICI-BME), Bandung, Indonesia, 23–25 November 2009; pp. 1–3.

- Haibin, P.; Jianning, D.; Xiaofei, W.; Boquan, L. Design, implementation, and assessment of a high-precision and automation measurement system for thin film resistivity. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering (MACE), Wuhan, China, 26–28 June 2010; pp. 2235–2238.

- Miccoli, I.; Edler, F.; Pfnür, H.; Tegenkamp, C. The 100th anniversary of the four-point probe technique: The role of probe geometries in isotropic and anisotropic systems. J. Phys. Condens. Matter 2015, 27. [Google Scholar] [CrossRef] [PubMed]

- Zimney, E.J.; Dommett, G.H.B.; Ruoff, R.S.; Dikin, D.A. Correction factors for 4-probe electrical measurements with finite size electrodes and material anisotropy: A finite element study. Meas. Sci. Technol. 2007, 18, 2067–2073. [Google Scholar] [CrossRef]

- Uhlir, A. The potentials of infinite systems of sources and numerical solutions of problems in semiconductor engineering. Bell Syst. Tech. J. 1955, 34, 105–128. [Google Scholar] [CrossRef]

- Perloff, D.S. Four-point probe correction factors for use in measuring large diameter doped semiconductor wafers. J. Electrochem. Soc. 1976, 123, 1745–1750. [Google Scholar] [CrossRef]

- Yamashita, M.; Agu, M. Geometrical correction factor for semiconductor resistivity measurements by four-point probe method. Jpn. J. Appl. Phys. 1984, 23, 1499–1504. [Google Scholar] [CrossRef]

- Rymaszewski, R. Empirical method of calibrating a 4-point microarray for measuring thin-film-sheet resistance. Electron. Lett. 1967, 3, 57–58. [Google Scholar] [CrossRef]

- Rymaszewski, R. Relationship between the correction factor of the four-point probe value and the selection of potential and current electrodes. J. Phys. E Sci. Instrum. 1969, 2, 170–174. [Google Scholar] [CrossRef]

- Schroder, D.K. Semiconductor Material and Device Characterization, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1998. [Google Scholar]

- Algahtani, F.; Thulasiram, K.B.; Nasir, N.M.; Holland, A.S. Four point probe geometry modified correction factor for determining resistivity. In Proceedings of the 2013 Micro/Nano Materials, Devices, and Systems, Melbourne, Victoria, Australia, 8–11 December 2013.

- Jandel Four Point Probes. Available online: http://www.jandel.co.uk/products/four-point-probes.html (accessed on 7 September 2016).

- Determining the Best Choice of Probe Tip Specifications for a Given Material. Available online: http://four-point-probes.com/determining-the-best-choice-of-probe-tip-specifications-for-a-given-material/ (accessed on 7 September 2016).

- Four Point Probe Tip Specifications & Applications Chart. Available online: http://four-point-probes.com/four-point-probe-tip-specifications-applications-chart/ (accessed on 7 September 2016).

- Hasegawa, S.; Shiraki, I.; Tanikawa, T.; Petersen, C.L.; Hansen, T.M.; Boggild, P.; Grey, F. Direct measurement of surface-state conductance by microscopic four-point probe method. J. Phys. Condens. Matter 2002, 14, 8379–8392. [Google Scholar] [CrossRef]

- ANALOG DEVICES—ADA4522-2 Datasheet. Available online: http://www.analog.com/en/products/amplifiers/operational-amplifiers/ada4522-2.html#product-overview (accessed on 7 September 2016).

- Wong, V.; Kusuda, V. Zero-drift amplifiers: Now easy to use in high precision circuits. Analog Dialog. 2015, 49, 44–47. [Google Scholar]

- Difference Amplifier Forms Heart of Precision Current Source: Analog Dialogue: Analog Devices. Available online: http://www.analog.com/library/analogDialogue/archives/43-09/current_source.html (accessed on 7 September 2016).

- 9007 Series/Spartan SIP Reed Relays. Available online: http://cotorelay.com/product/9007-series-spartan-sip-reed-relays/ (accessed on 7 September 2016).

- Resistivity Measurements of Semiconductor Materials using the 4200A-SCS Parameter Analyzer and a Four-Point Collinear Probe. Available online: http://www.tek.com/dl/1KW-60640-0_FourPointCollinear_4200A-SCS_AN.pdf (accessed on 30 October 2016).

- Nash, E. Common Mode and Instrumentation Amplifiers; Analog Devices: Cambridge, MA, USA, 1998. [Google Scholar]

- Arduino Home. Available online: https://www.arduino.cc/ (accessed on 7 September 2016).

- KiCad EDA. Available online: http://kicad-pcb.org/ (accessed on 7 September 2016).

- Open Science Framework—Open Source 4 Point Probe. Available online: https://osf.io/kcbmq/ (accessed on 10 November 2016).

- Four Point Probe GUI and Software. Available online: https://github.com/mtu-most/fourpointprobe (accessed on 10 November 2016).

- Java SE at a Glance. Available online: http://www.oracle.com/technetwork/java/javase/overview/index.html (accessed on 16 October 2016).

- WindowBuilder—Is a Powerful and Easy to Use Bi-Directional Java GUI Designer. Available online: https://eclipse.org/windowbuilder/ (accessed on 16 October 2016).

- Bárdoš, L.; Libra, M. Effect of the oxygen absorption on properties of ITO layers. Vacuum 1989, 39, 33–36. [Google Scholar] [CrossRef]

- Zhou, Y.; Shim, J.W.; Fuentes-Hernandez, C.; Sharma, A.; Knauer, K.A.; Giordano, A.J.; Marder, S.R.; Kippelen, B. Direct correlation between work function of indium-tin-oxide electrodes and solar cell performance influenced by ultraviolet irradiation and air exposure. Phys. Chem. Chem. Phys. 2012, 14, 12014–12021. [Google Scholar] [CrossRef] [PubMed]

| Sample | OS4PP | Jandel | Keithley | |||

|---|---|---|---|---|---|---|

| Rsh (Ω/sq) | Std Dev | Rsh (Ω/sq) | Std Dev | Rsh (Ω/sq) | Std Dev | |

| R. Reference Sample | 13.308 | 0.49 | 13.09 | 0.85 | 13.304 | 0.27 |

| A. 50 nm ITO annealed 10 min | 171.86 | 11.79 | 182.36 | 15.21 | 176.08 | 8.4 |

| B. 50 nm ITO annealed 20 min | 110.76 | 7.33 | 113.42 | 9.18 | 111.8 | 5.83 |

| C. 50 nm ITO annealed 30 min | 142.84 | 27.76 | 177.52 | 42.79 | 159.07 | 15.9 |

| Component | Commercial Machine | Open-Source OS4PP |

|---|---|---|

| Probe | Jandel macor probe head | Jandel cylindrical four-point probe head |

| Measurement Unit | RM3 test unit | Custom measurement circuit |

| Mounting Stand | Lucas labs S–302−4 | RepRap Prusa Mendel i1 with custom probe holder |

| Source | Closed source | Reprap project + osf.io |

| Cost | $1600 probe head + $3200 RM3 + $2500 S–302−4 = $7300 | $1600 probe head + $130 circuit + $250 RepRap = $1980 |

| Maximum Wafer Size | 4” circular | 8” × 8” square |

| Accuracy | 0.3% (high sensitivity mode) | 1% (<1 MΩ sheet resistances) |

| Positioning Resolution | Manual sample placement by hand | 100 microns X-Y accuracy |

| Multiple Measurement | Manual | Automatic |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chandra, H.; Allen, S.W.; Oberloier, S.W.; Bihari, N.; Gwamuri, J.; Pearce, J.M. Open-Source Automated Mapping Four-Point Probe. Materials 2017, 10, 110. https://doi.org/10.3390/ma10020110

Chandra H, Allen SW, Oberloier SW, Bihari N, Gwamuri J, Pearce JM. Open-Source Automated Mapping Four-Point Probe. Materials. 2017; 10(2):110. https://doi.org/10.3390/ma10020110

Chicago/Turabian StyleChandra, Handy, Spencer W. Allen, Shane W. Oberloier, Nupur Bihari, Jephias Gwamuri, and Joshua M. Pearce. 2017. "Open-Source Automated Mapping Four-Point Probe" Materials 10, no. 2: 110. https://doi.org/10.3390/ma10020110

APA StyleChandra, H., Allen, S. W., Oberloier, S. W., Bihari, N., Gwamuri, J., & Pearce, J. M. (2017). Open-Source Automated Mapping Four-Point Probe. Materials, 10(2), 110. https://doi.org/10.3390/ma10020110