Electrochemical Synthesis of Core–Shell-Structured NbC–Fe Composite Powder for Enforcement in Low-Carbon Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Analysis of Sintered Pellet

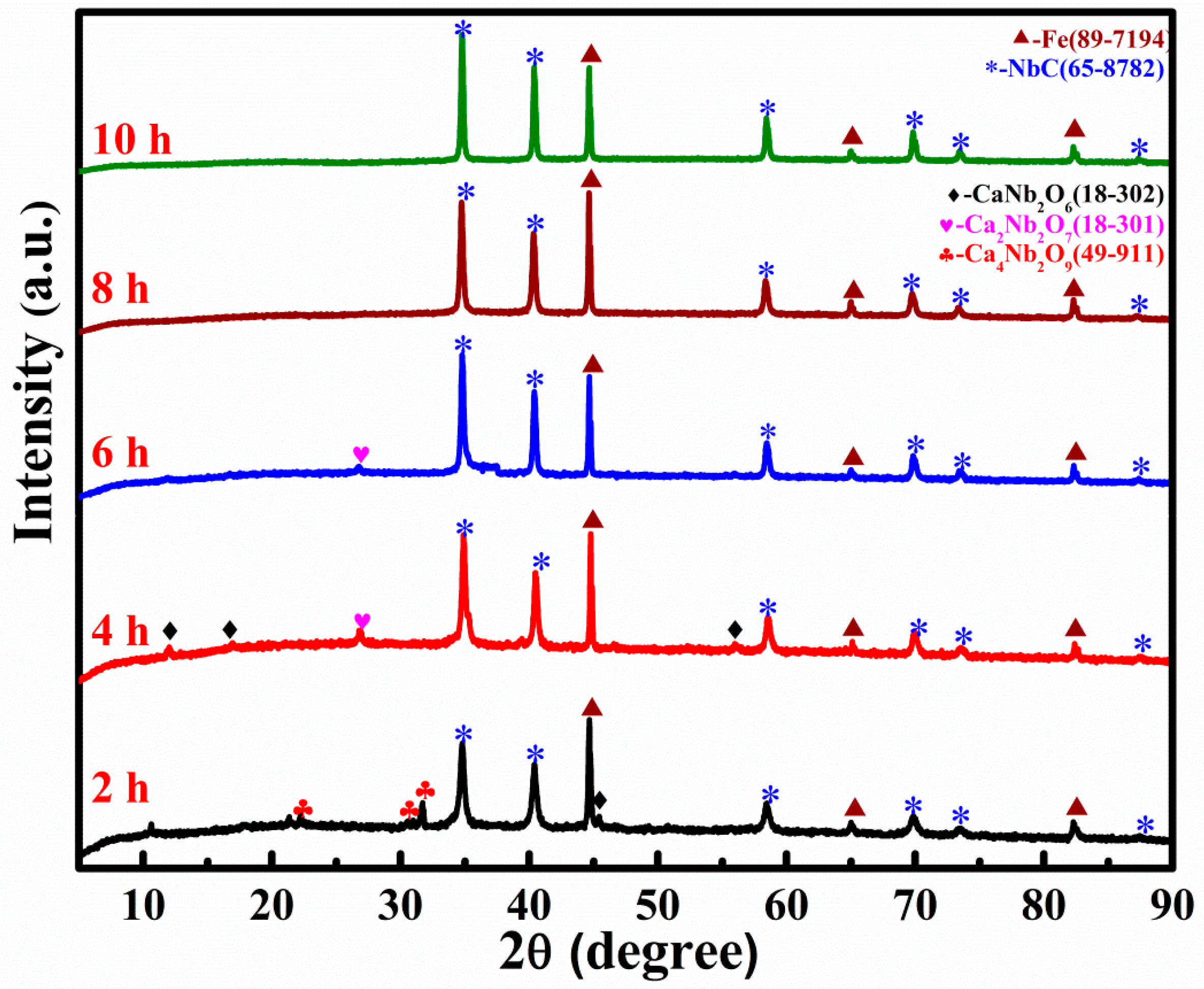

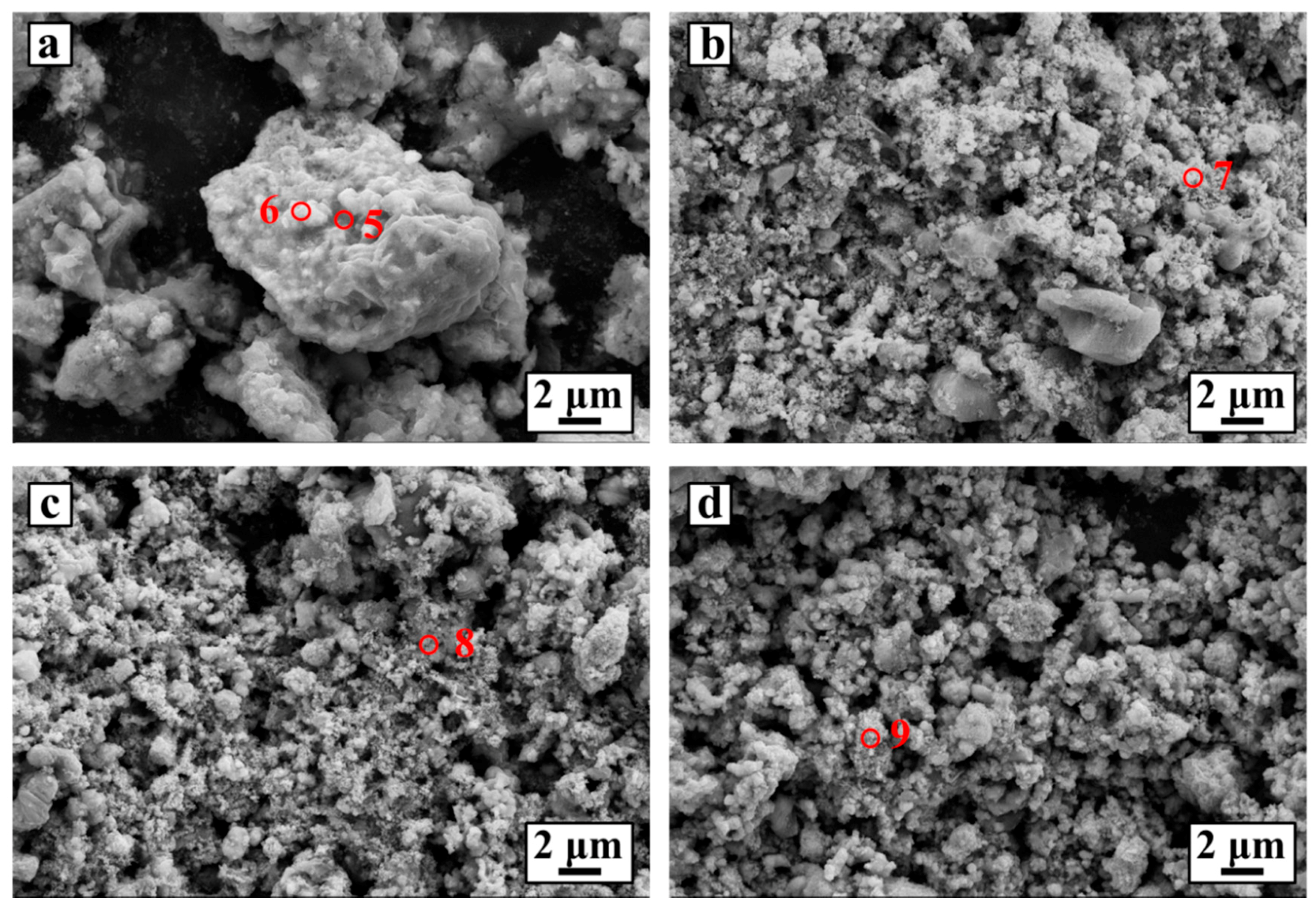

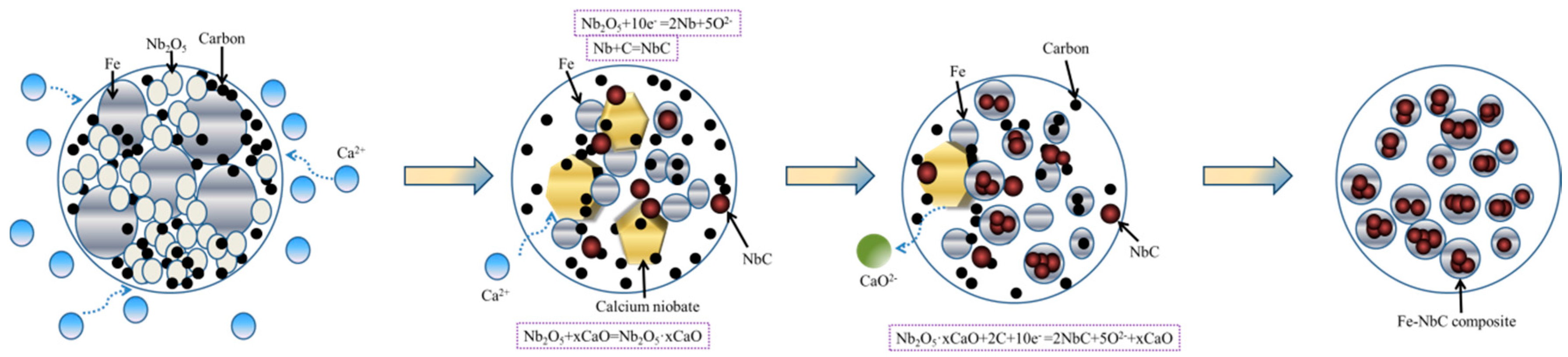

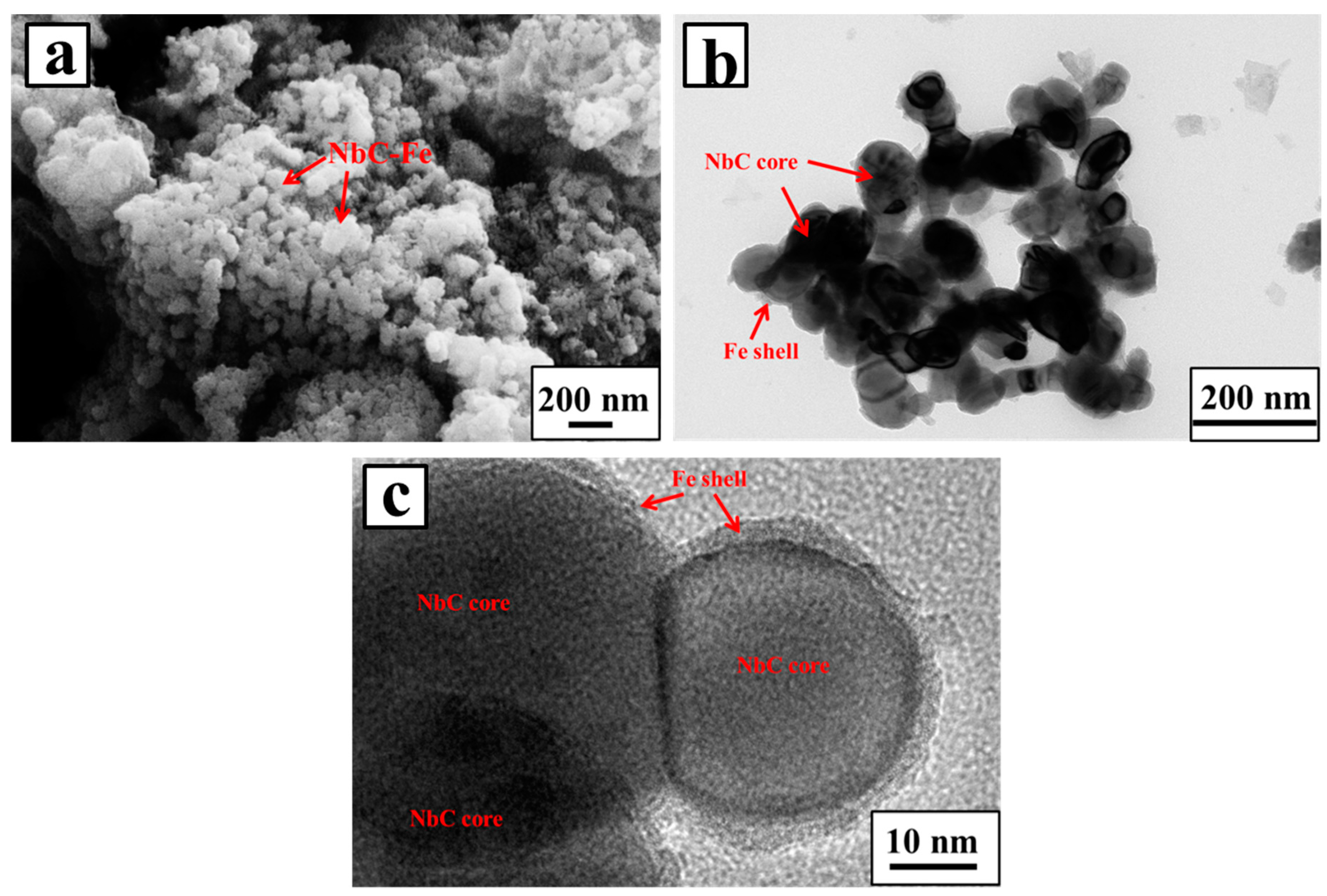

3.2. The Reaction Pathway for Electrochemical Reduction and Carbonization

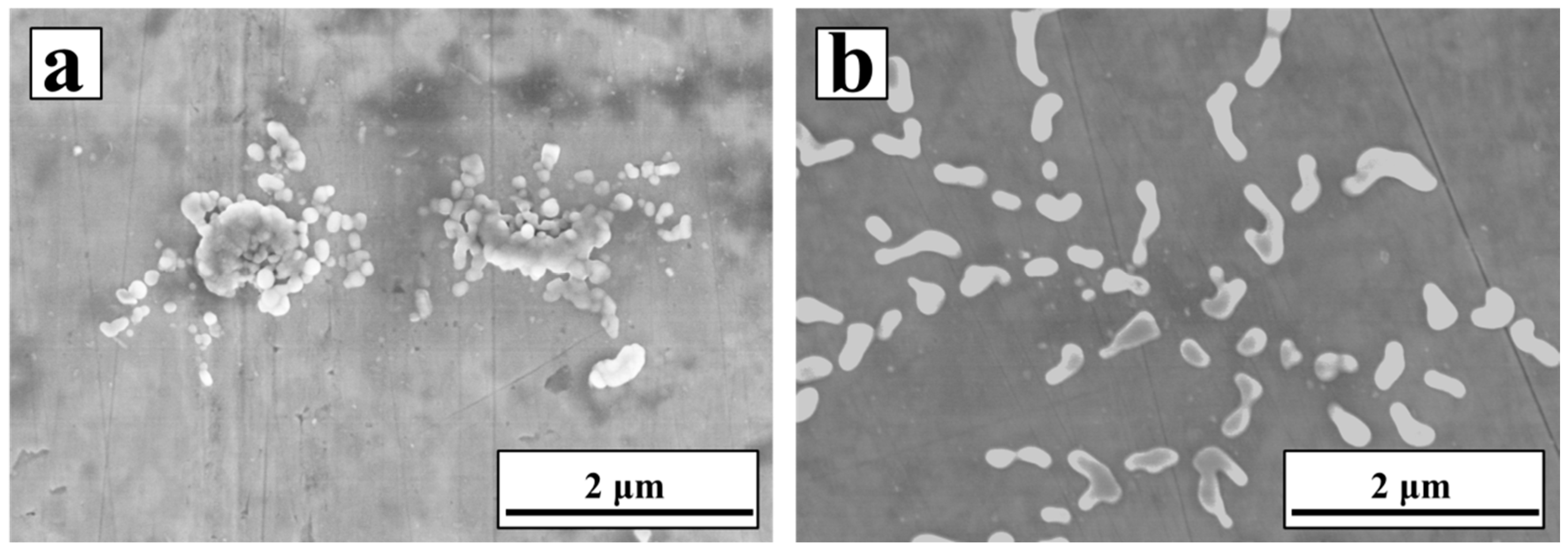

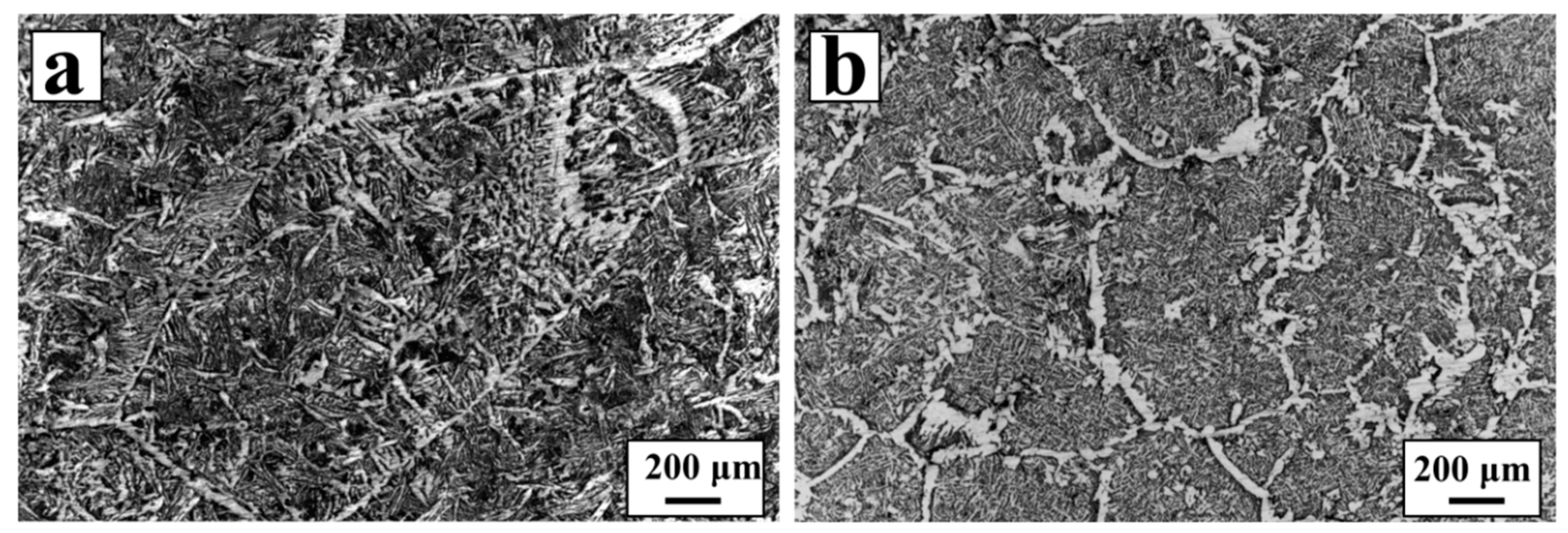

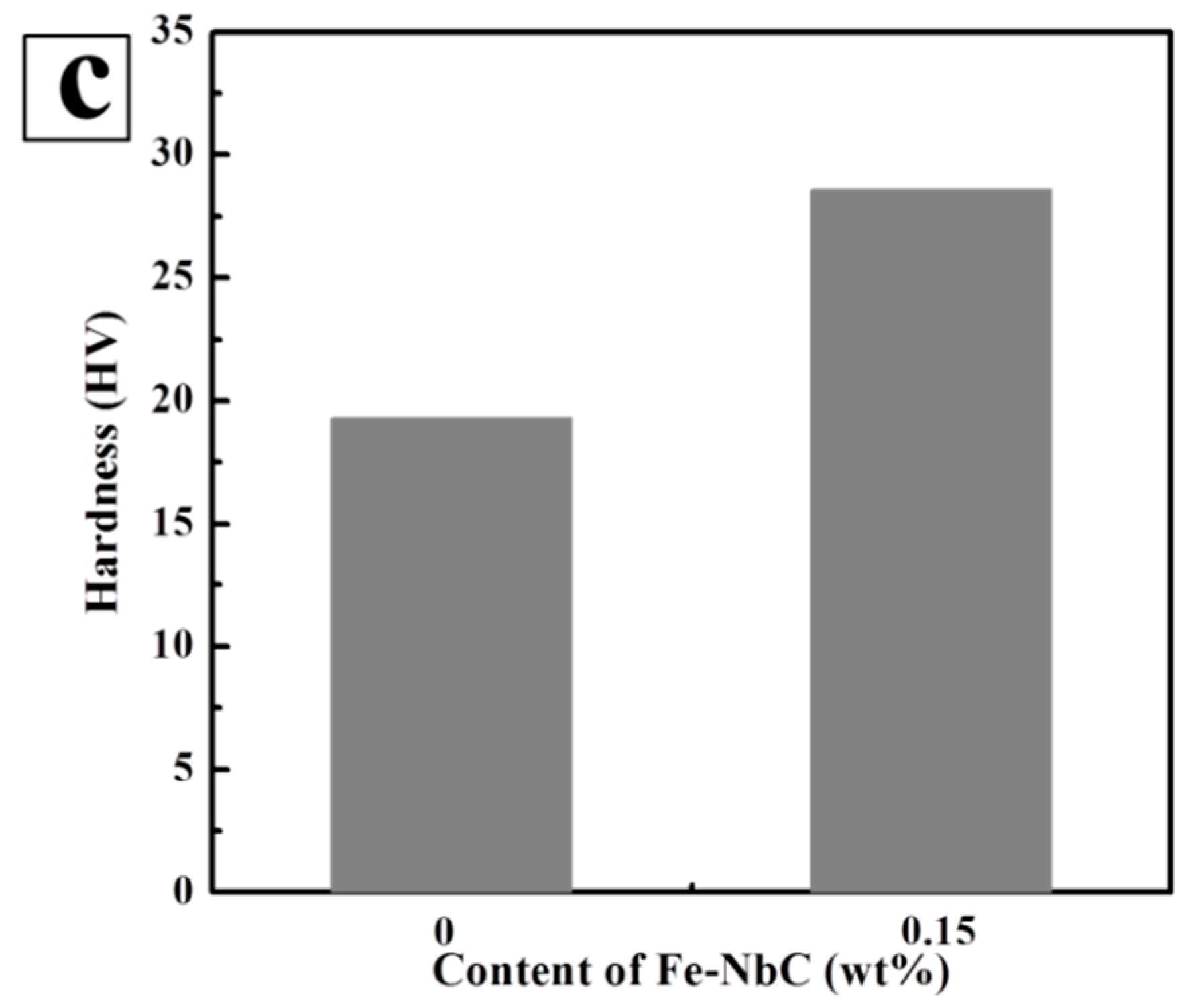

3.3. The Behavior of NbC–Fe in Casted Low-Carbon Steel

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grove, D.E.; Gupta, U.; Castleman, A., Jr. Effect of Hydrocarbons on the Morphology of Synthesized Niobium Carbide Nanoparticles. Langmuir 2010, 26, 16517–16521. [Google Scholar] [CrossRef] [PubMed]

- Kwon, H.; Kim, W.; Kim, J. Stability Domains of NbC and Nb(CN) During Carbothermal Reduction of Niobium Oxide. J. Am. Ceram. Soc. 2015, 98, 315–319. [Google Scholar] [CrossRef]

- Song, Q.S.; Xu, Q.; Meng, J.C.; Lou, T.P.; Ning, Z.Q.; Qi, Y.; Yu, K. Preparation of niobium carbide powder by electrochemical reduction in molten salt. J. Alloys Compd. 2015, 647, 245–251. [Google Scholar] [CrossRef]

- Li, Y.Y.; Xiao, Z.Y.; Ngai, T.L.; Xia, W.; Chen, W.P. Warm compacted NbC particulate reinforced iron-base composite(II)-Microstructure and properties. Trans. Nonferr. Met. Soc. China 2002, 12, 664–668. [Google Scholar]

- Speer, J.; Hansen, S. Austenite Recrystallization and Carbonitride Precipitation in Niobium Microalloyed Steels. Metall. Mater. Trans. A 1989, 20, 25–38. [Google Scholar] [CrossRef]

- Rainforth, W.M.; Black, M.P.; Higginson, R.L.; Palmiere, E.J.; Sellars, C.M.; Prabst, I.; Warbichler, P.; Hofer, F. Precipitation of NbC in a model austenitic steel. Acta Mater. 2002, 50, 735–747. [Google Scholar] [CrossRef]

- Zajac, S.; Jansson, B. Thermodynamics of the Fe-Nb-C-N System and the Solubility of Niobium Carbonitrides in Austenite. Metall. Mater. Trans. B 1998, 29, 163–176. [Google Scholar] [CrossRef]

- Kudoh, M.; Tezuka, M.; Matsuura, K. Effect of Niobium on the Formation of Microstructure and Grain Boundary in Fe-Nb and Fe-C-Nb Alloys. ISIJ Int. 2006, 46, 1871–1876. [Google Scholar] [CrossRef]

- Gordo, E.; Gómez, B.; González, R.; Ruiz-Navas, E.M. Study for the Development of Fe-NbC Composites by Advanced PM Techniques. Mater. Sci. Forum 2007, 534–536, 637–640. [Google Scholar] [CrossRef]

- Martinelli, A.E.; Paulo, D.S.A.; Nascimento, R.M.; Távora, M.P.; Gomes, U.U.; Alves, C., Jr. Dilatometric behavior and microstructure of sintered Fe-NbC and Fe-TaC composites. J. Mater. Sci. 2007, 42, 314–319. [Google Scholar] [CrossRef]

- Nelmo, K.A.; Martinelli, A.E.; Maribondo, N.R.; De Araujo Paulo, D.S.; De Freitas Guedes, B.C.; Alves, C. Microstructural Characterization of Conventionally and Plasma-sintered Fe-NbC and Fe-TaC Composites. Int. J. Powder Metall. 2011, 47, 29–37. [Google Scholar]

- Kano, S.; Yang, H.L.; Suzue, R.; Matsukawa, Y.; Satoh, Y.; Sakasegawa, H.; Tanigawa, H.; Abe, H. Precipitation of carbides in F82H steels and its impact on mechanical strength. Nucl. Mater. Energy 2016, 9, 331–337. [Google Scholar] [CrossRef]

- Ni, Z.F.; Sun, Y.S.; Xue, F.; Bai, J.; Lu, Y.J. Microstructure and properties of austenitic stainless steel reinforced with in situ TiC particulate. Mater. Des. 2011, 32, 1462–1467. [Google Scholar] [CrossRef]

- Lazarova, R.; Petrov, R.H.; Gaydarova, V.; Davidkov, A.; Alexeev, A.; Manchev, M.; Manolov, V. Microstructure and mechanical properties of P265GH cast steel after modification with TiCN particles. Mater. Des. 2011, 32, 2734–2741. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, J.J.; Hong, S.M.; Han, B.S.; Lee, M.K.; Rhee, C.K. Fabrication of cast carbon steel with ultrafine TiC particles. Trans. Nonferr. Met. Soc. China 2011, 21, 54–57. [Google Scholar] [CrossRef]

- Razavi, M.; Rahimipour, M.R.; Rajabi-Zamani, A.H. Effect of nanocrystalline TiC powder addition on the hardness and wear resistance of cast iron. Mater. Sci. Eng. A 2007, 454–455, 144–147. [Google Scholar] [CrossRef]

- Chen, L.Y.; Peng, J.Y.; Xu, J.Q.; Choi, H.; Li, X.C. Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing. Scr. Mater. 2013, 69, 634–637. [Google Scholar] [CrossRef]

- Song, Q.S.; Xu, Q.; Xu, L.; Ning, Z.Q.; Lou, T.P.; Xie, H.W.; Qi, Y.; Yu, K. Synthesis of Ni-TiC composite powder electrochemically in molten chlorides. J. Alloys Compd. 2017, 690, 116–121. [Google Scholar] [CrossRef]

- Pagounis, E.; Talvitie, M.; Lindroos, V.K. Microstructure and Mechanical Properties of Hot Work Tool Steel Matrix Composites Produced by Hot Isostatic Pressing. Powder Metall. 1997, 40, 55–61. [Google Scholar] [CrossRef]

- Ren, X.Y.; Peng, Z.J.; Peng, Y.; Fu, Z.Q.; Wang, C.B.; Qi, L.H.; Miao, H.Z. Effect of SiC nano-whisker addition on WC-Ni based cemented carbides fabricated by hot-press sintering. Int. J. Refract. Met. Hard Mater. 2013, 36, 294–299. [Google Scholar] [CrossRef]

- Liu, Z.D.; Tian, J.; Li, B.; Zhao, L.P. Microstructure and mechanical behaviors of in situ TiC particulates reinforced Ni matrix composites. Mater. Sci. Eng. A 2010, 527, 3898–3903. [Google Scholar] [CrossRef]

- Long, B.D.; Umemoto, M.; Todaka, Y.; Othman, R.; Zuhailawati, H. Fabrication of high strength Cu-NbC composite conductor by high pressure torsion. Mater. Sci. Eng. A 2011, 528, 1750–1756. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.L.; Han, W.; Li, M.; Yang, Y.S.; Yan, Y.D.; Zhang, M. Electrochemical Preparation of Mg-Li-Al-Er Alloys by Co-reduction in Molten Chloride. Acta Metall. Sin. Engl. Lett. 2013, 26, 455–460. [Google Scholar] [CrossRef]

- Zou, X.L.; Lu, X.G.; Li, C.H.; Zhao, B.J. Electrochemical extraction of Fe-Ti-Si alloys direct from Ti bearing compound ores. Trans. Inst. Min. Metall. C 2011, 120, 118–124. [Google Scholar] [CrossRef]

- Liu, M.F.; Lu, S.G.; Kan, S.R.; Li, G.X. Effect of electrolysis voltage on electrochemical reduction of titanium oxide to titanium in molten calcium chloride. Rare Met. 2007, 26, 547–551. [Google Scholar]

- Song, Q.S.; Xu, Q.; Tao, R.; Kang, X. Cathodic Phase Transformations During Direct Electrolytic Reduction of Nb2O5 in a CaCl2–NaCl–CaO melt. Int. J. Electrochem. Sci. 2012, 7, 272–281. [Google Scholar]

| Point | Elementary Distribution (at %) | |||

|---|---|---|---|---|

| C | O | Fe | Nb | |

| 1 | 33.02 | 22.13 | 41.67 | 3.18 |

| 2 | 84.31 | 10.10 | 0.69 | 4.90 |

| 3 | 0 | 71.48 | 4.98 | 23.53 |

| Point | Elementary Distribution (at %) | ||||

|---|---|---|---|---|---|

| Ca | Nb | C | O | Fe | |

| 5 | 4.17 | 11.58 | 35.92 | 40.02 | 4.80 |

| 6 | 1.26 | 8.85 | 37.18 | 24.97 | 26.87 |

| 7 | 0.21 | 10.70 | 55.92 | 12.21 | 20.43 |

| 8 | 0.14 | 12.84 | 42.56 | 36.28 | 7.65 |

| 9 | 0.20 | 18.72 | 44.17 | 28.15 | 8.76 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Song, Q.; Xu, Q.; Chen, Y.; Xu, L.; Man, T. Electrochemical Synthesis of Core–Shell-Structured NbC–Fe Composite Powder for Enforcement in Low-Carbon Steel. Materials 2017, 10, 1257. https://doi.org/10.3390/ma10111257

Li H, Song Q, Xu Q, Chen Y, Xu L, Man T. Electrochemical Synthesis of Core–Shell-Structured NbC–Fe Composite Powder for Enforcement in Low-Carbon Steel. Materials. 2017; 10(11):1257. https://doi.org/10.3390/ma10111257

Chicago/Turabian StyleLi, Hongmei, Qiushi Song, Qian Xu, Ying Chen, Liang Xu, and Tiannan Man. 2017. "Electrochemical Synthesis of Core–Shell-Structured NbC–Fe Composite Powder for Enforcement in Low-Carbon Steel" Materials 10, no. 11: 1257. https://doi.org/10.3390/ma10111257

APA StyleLi, H., Song, Q., Xu, Q., Chen, Y., Xu, L., & Man, T. (2017). Electrochemical Synthesis of Core–Shell-Structured NbC–Fe Composite Powder for Enforcement in Low-Carbon Steel. Materials, 10(11), 1257. https://doi.org/10.3390/ma10111257