Experimental and Computational Study of Ductile Fracture in Small Punch Tests

Abstract

:1. Introduction

- Further exploit multiaxial SP testing for numerical model validation,

- Consolidate the parameter identification through application of the model to a wide range of disk thicknesses,

- Elucidate the effects of shear and initial porosity on damage progression and failure,

- Derive robust predictions for the yield stress (YS) and ultimate tensile stress (UTS) for future applications.

2. Theory

2.1. A Word on Notation

2.2. Fundamental Kinematical Assumptions and Hypoelastic Plasticity

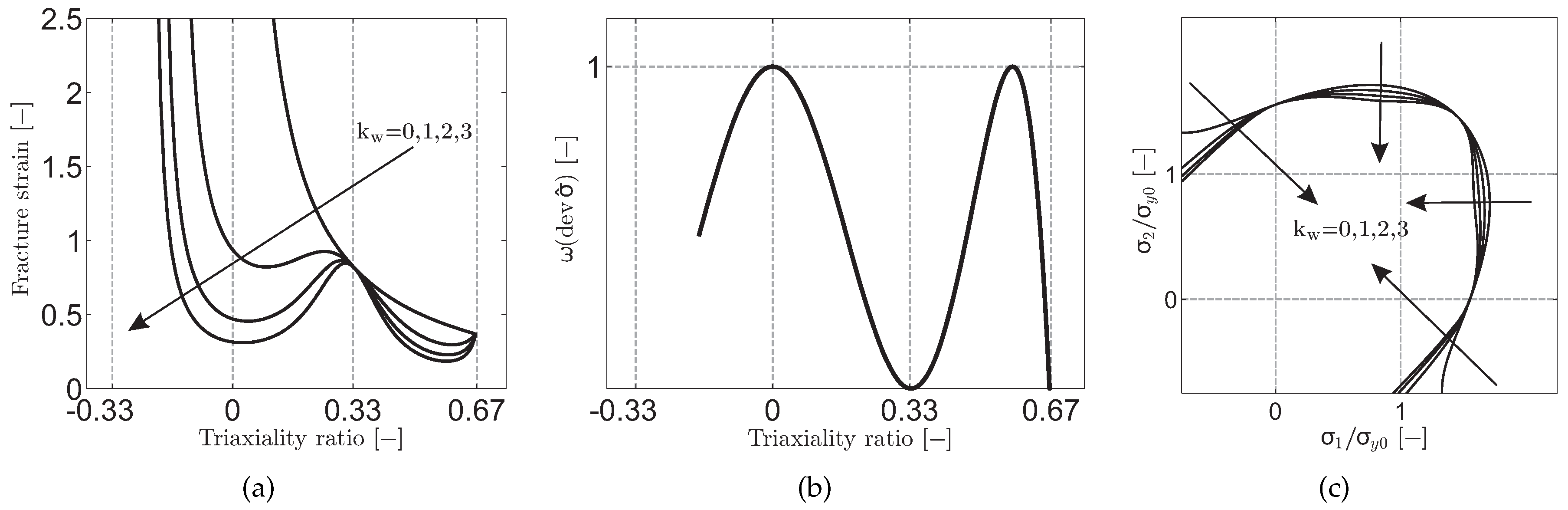

2.3. Shear Modified GTN Porous Plasticity—Local Formulation

Integral-Type Nonlocal Extension

3. Experiments

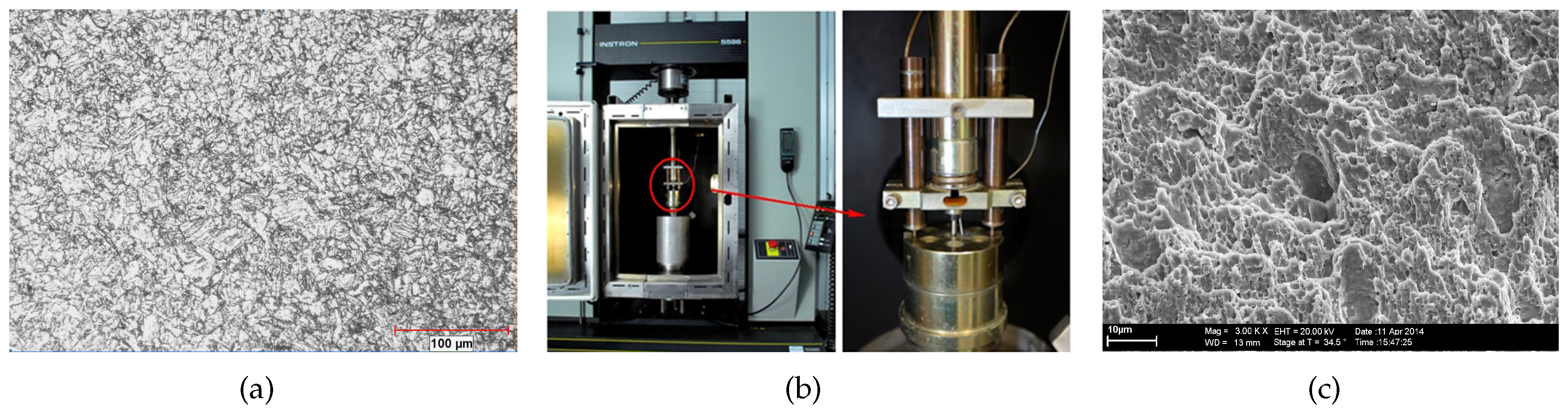

3.1. Material Employed

3.2. Experimental Setup

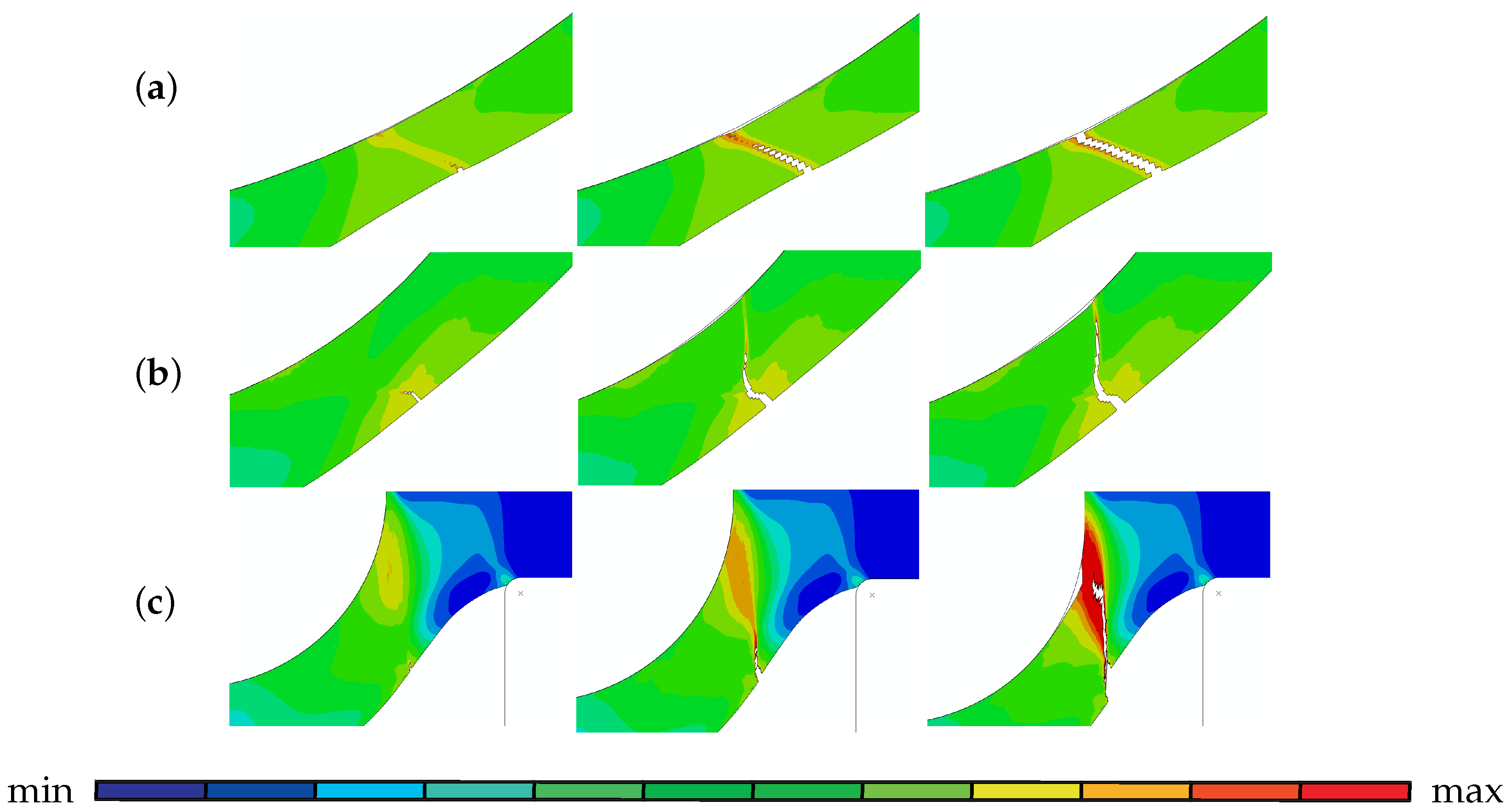

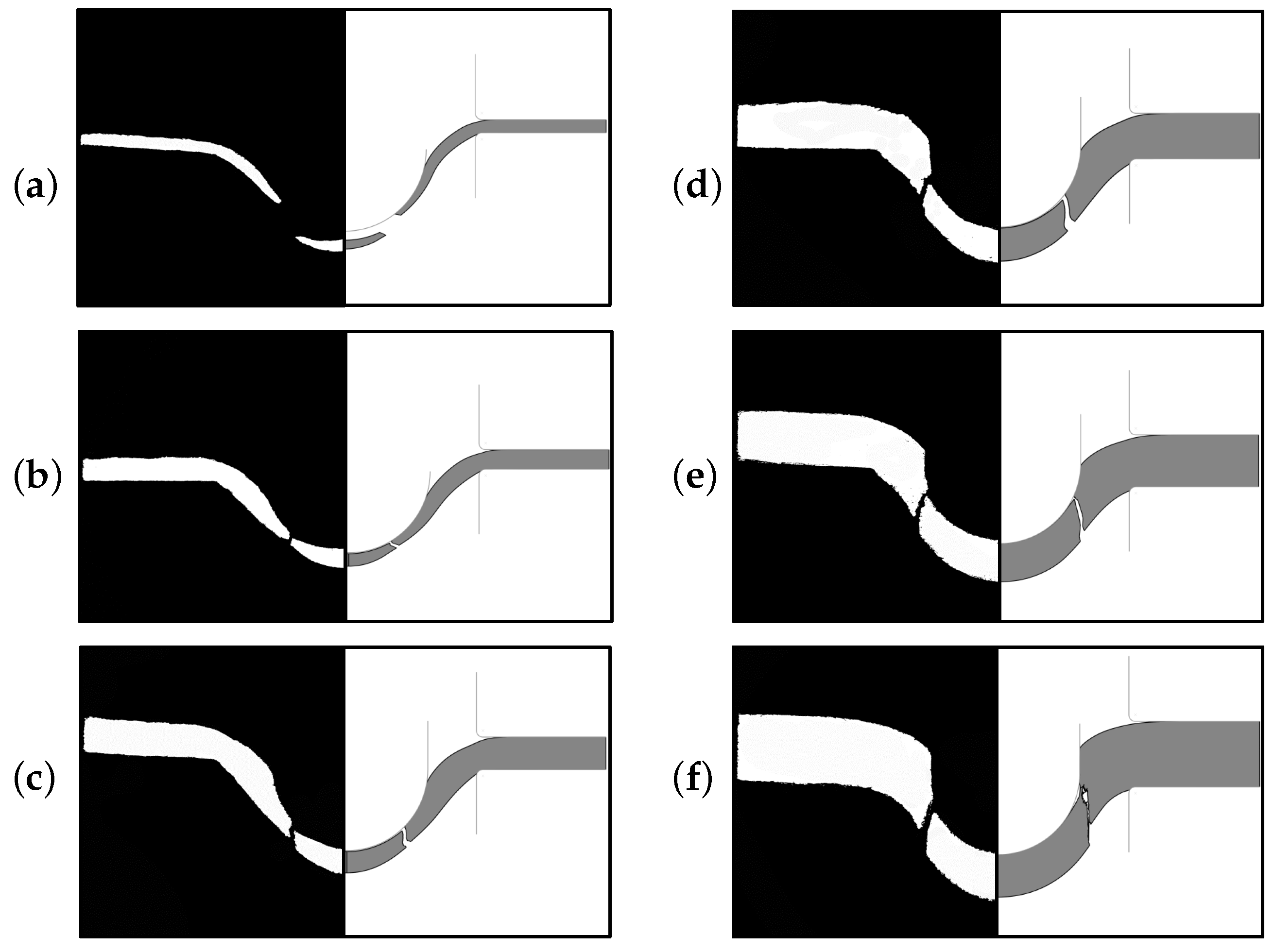

3.3. Crack Propagation and Fracture Surfaces

4. Material Parameters for P91 Steel

5. Small Punch Test Simulations

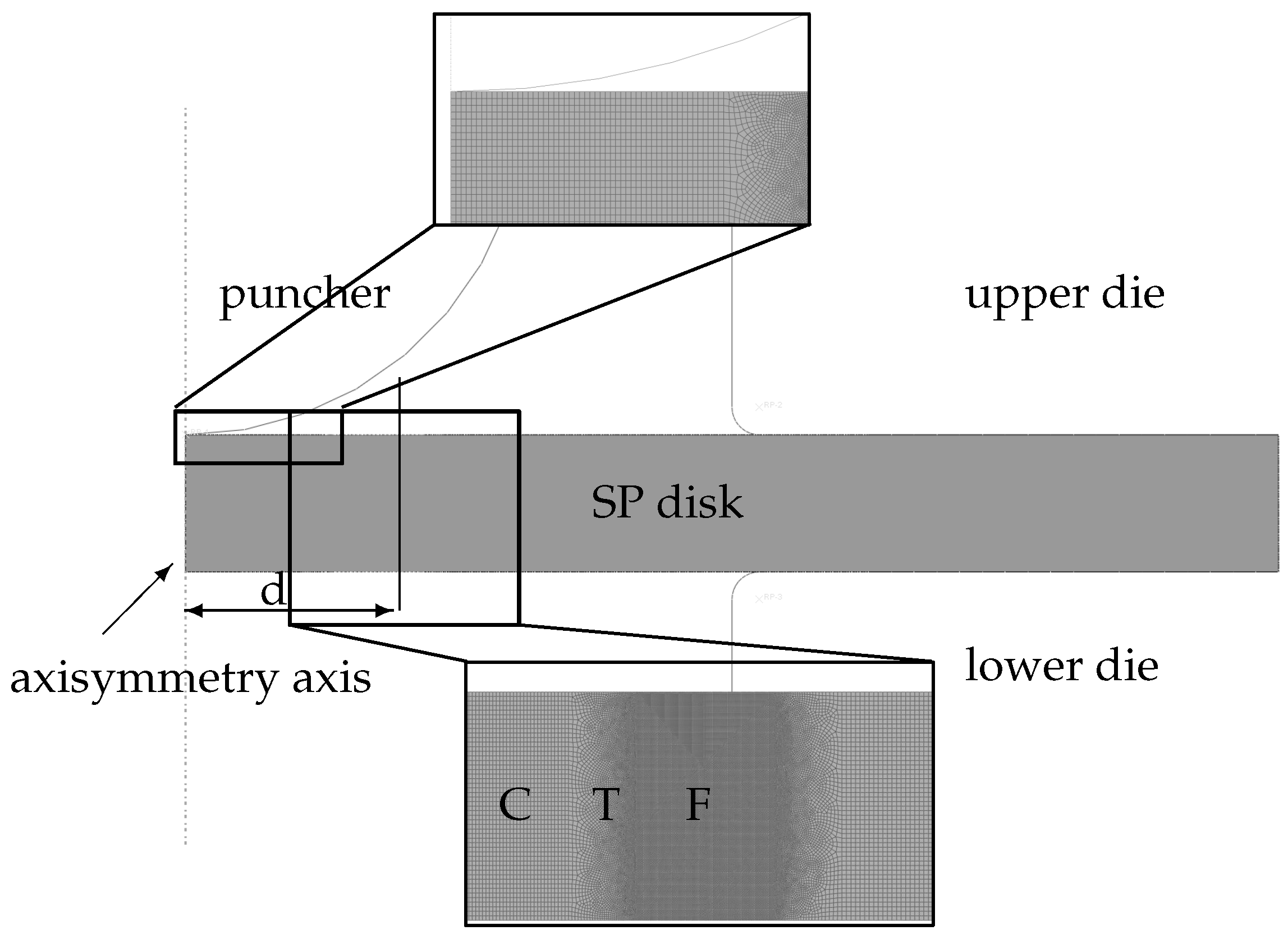

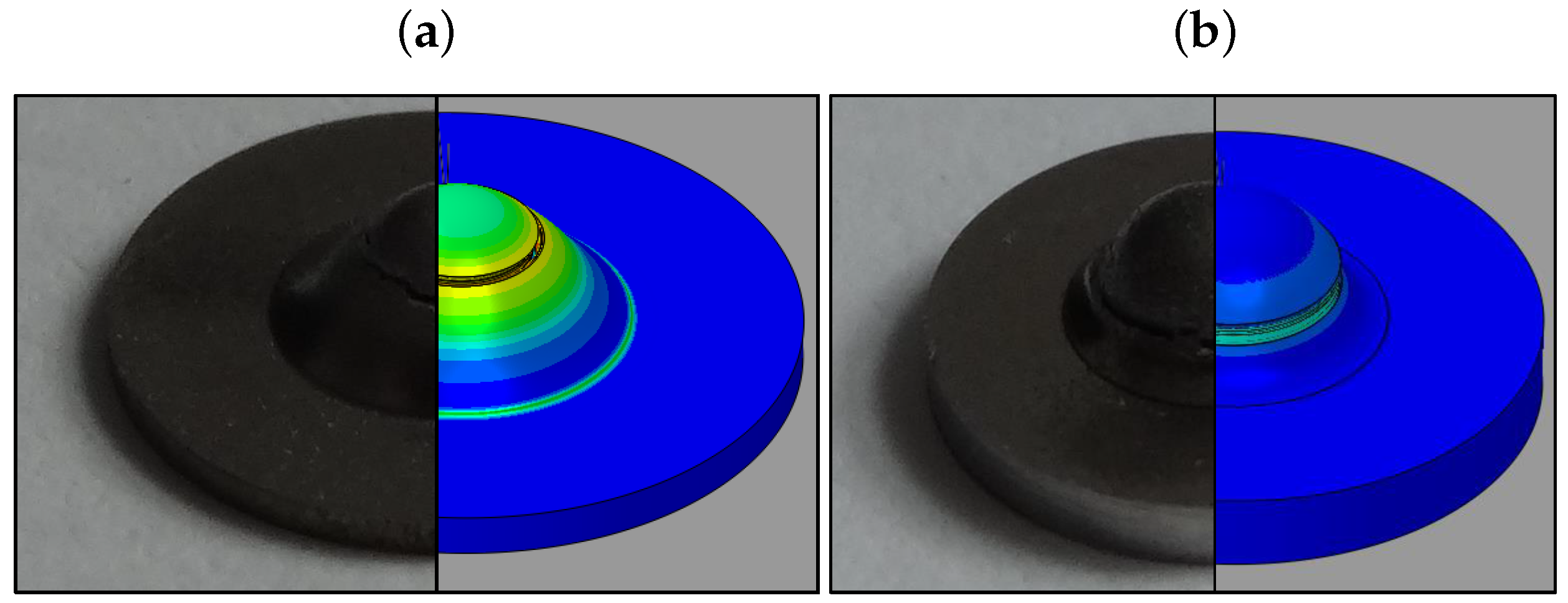

5.1. Finite Element Model

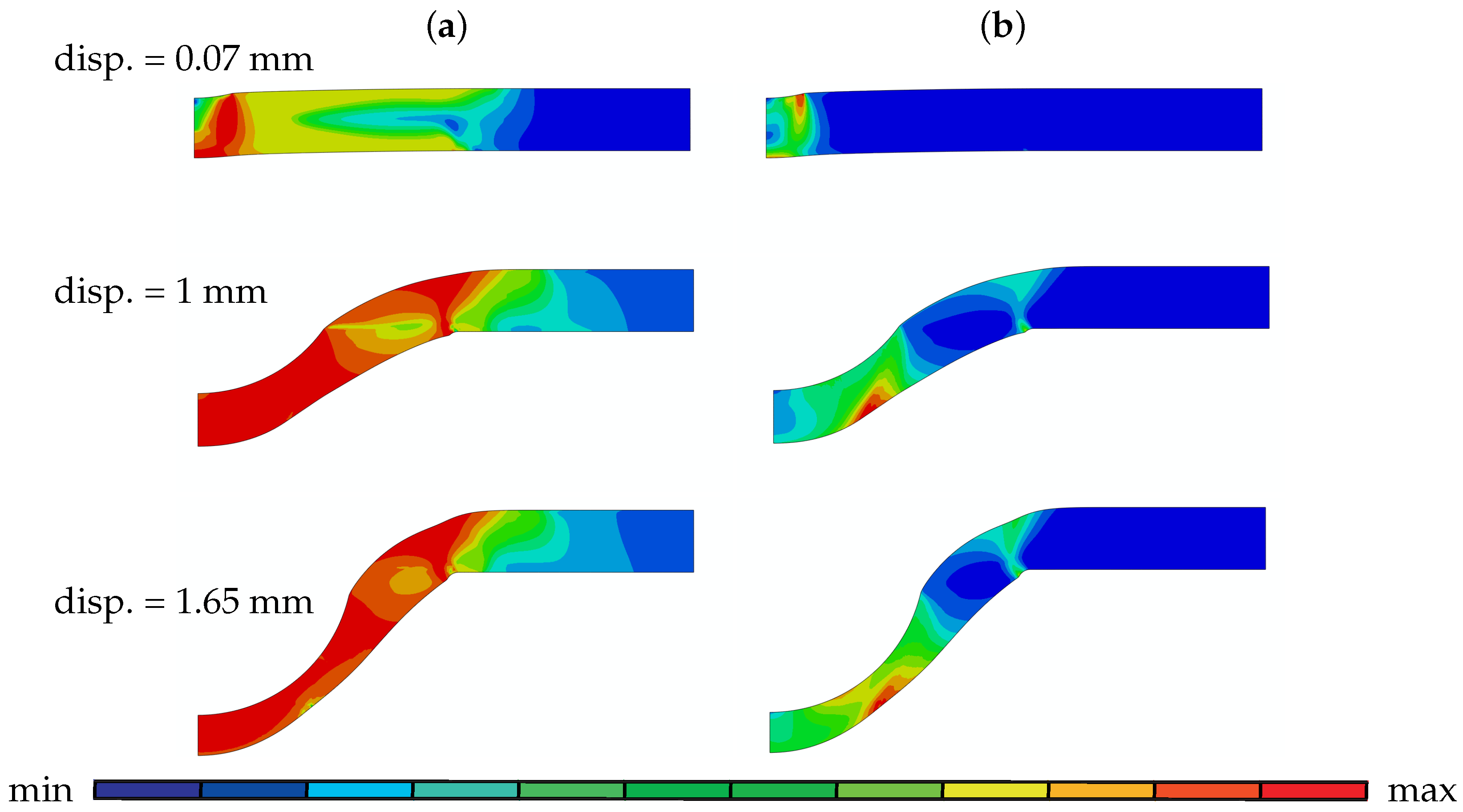

5.2. Results and Discussion

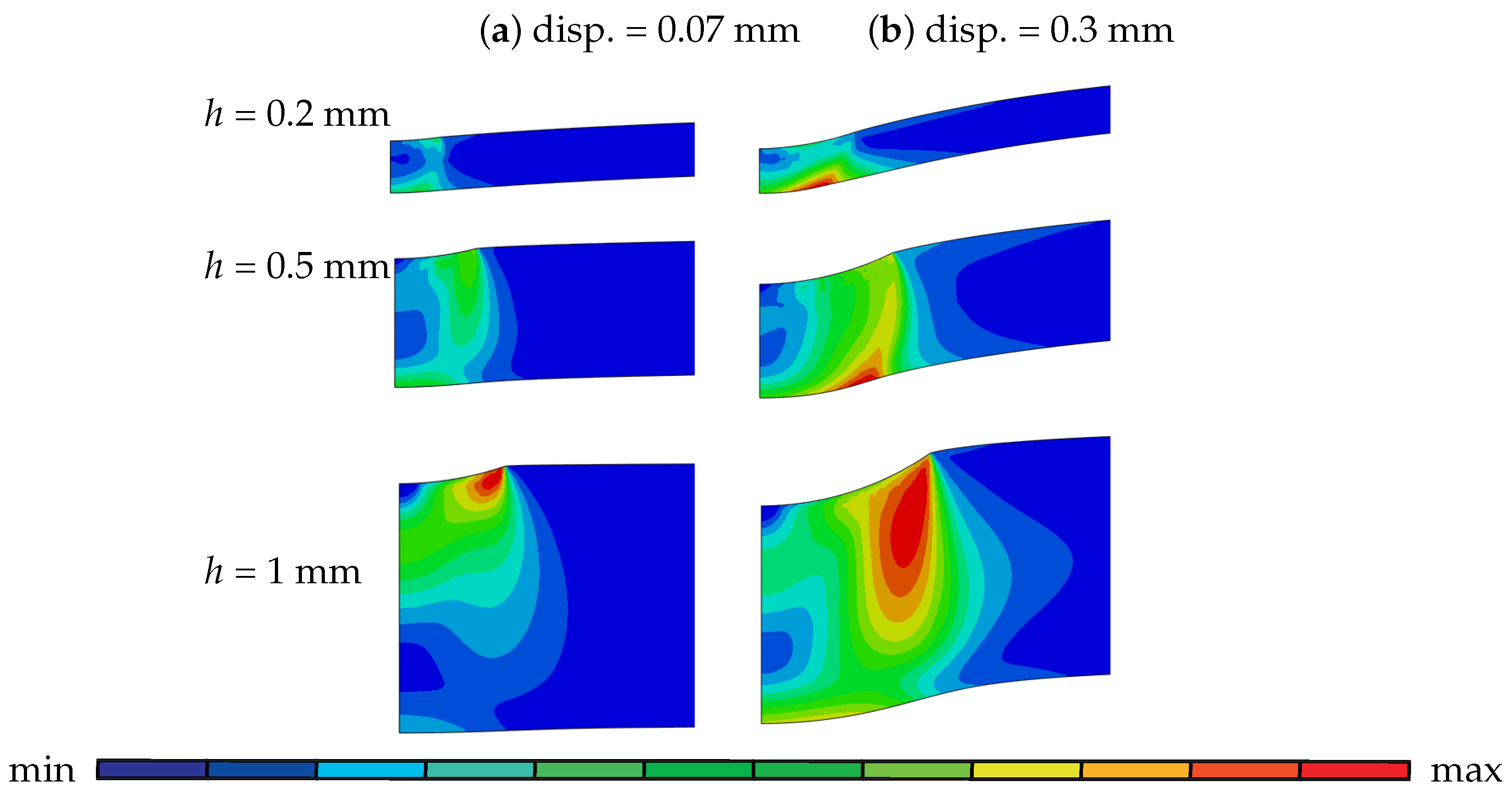

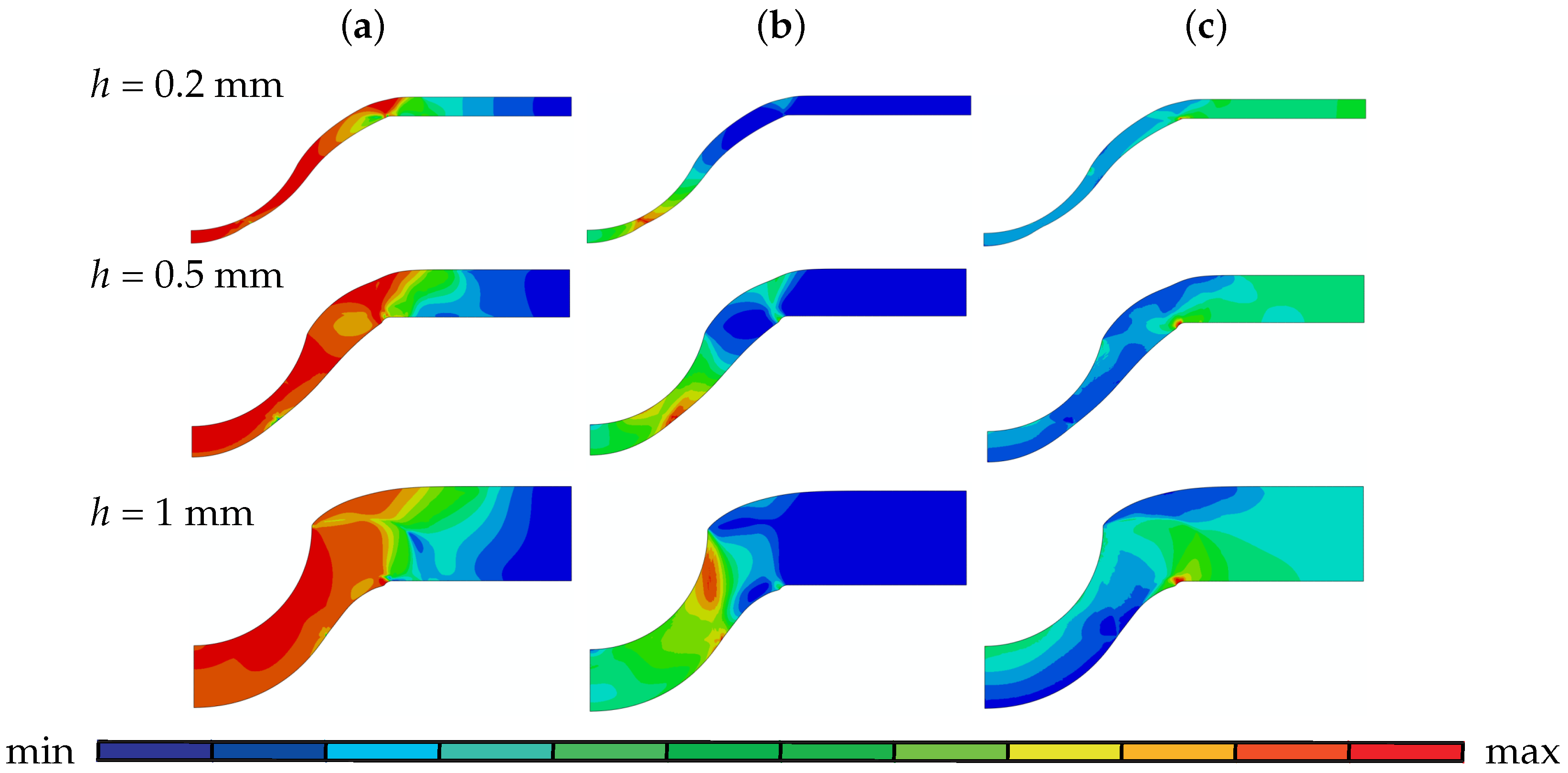

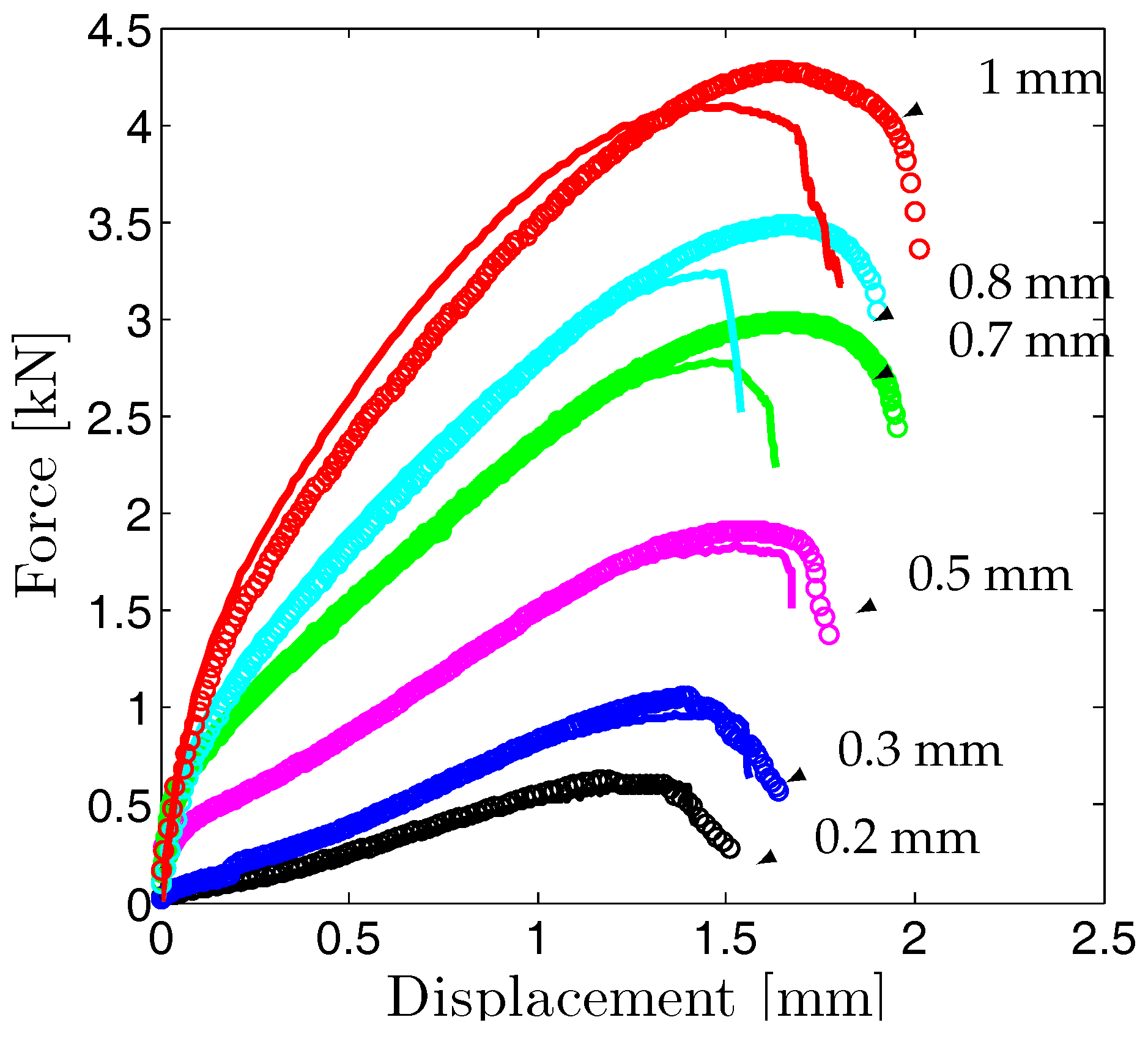

5.2.1. The Influence of Geometrical Parameters: Thickness

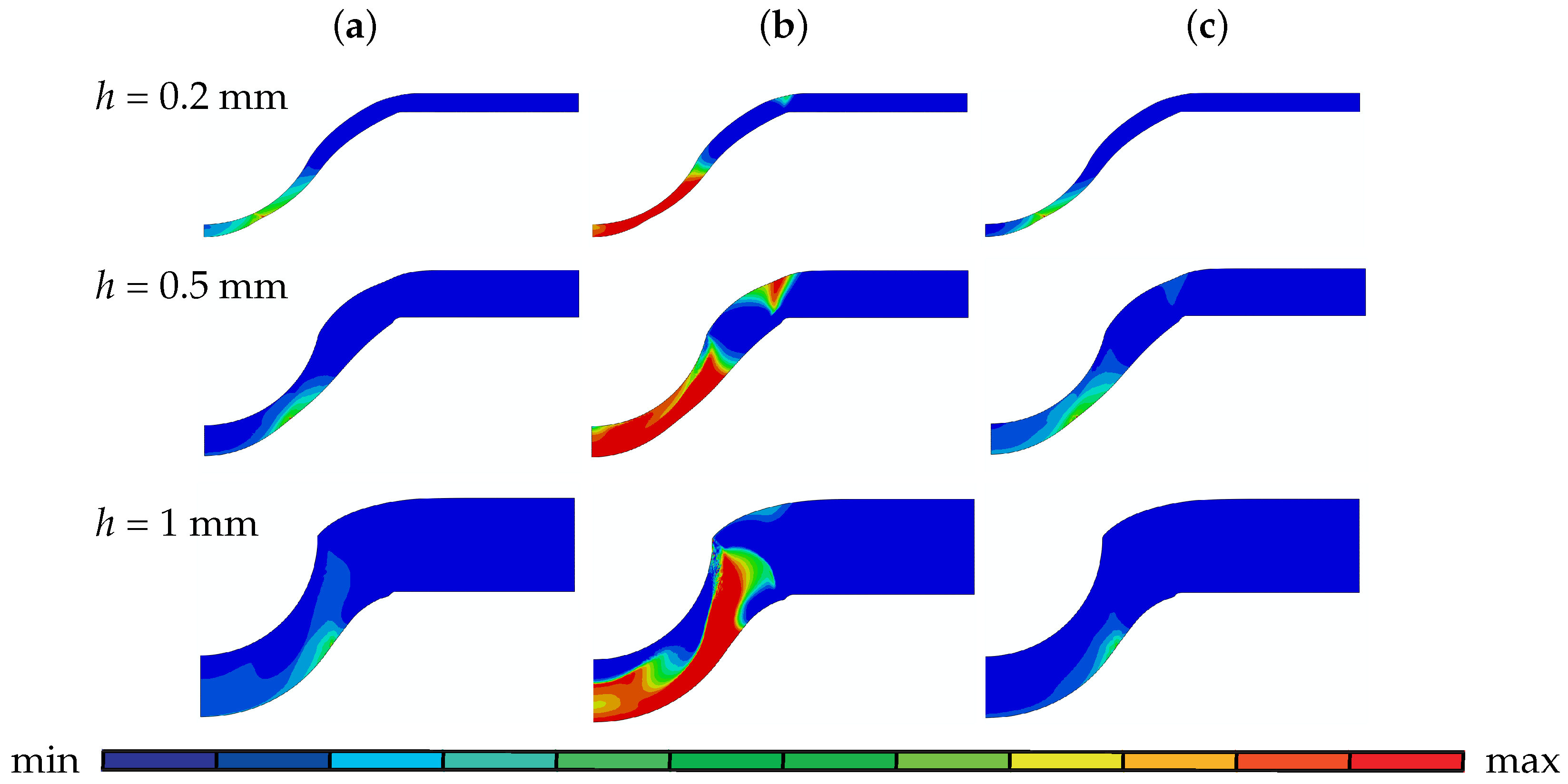

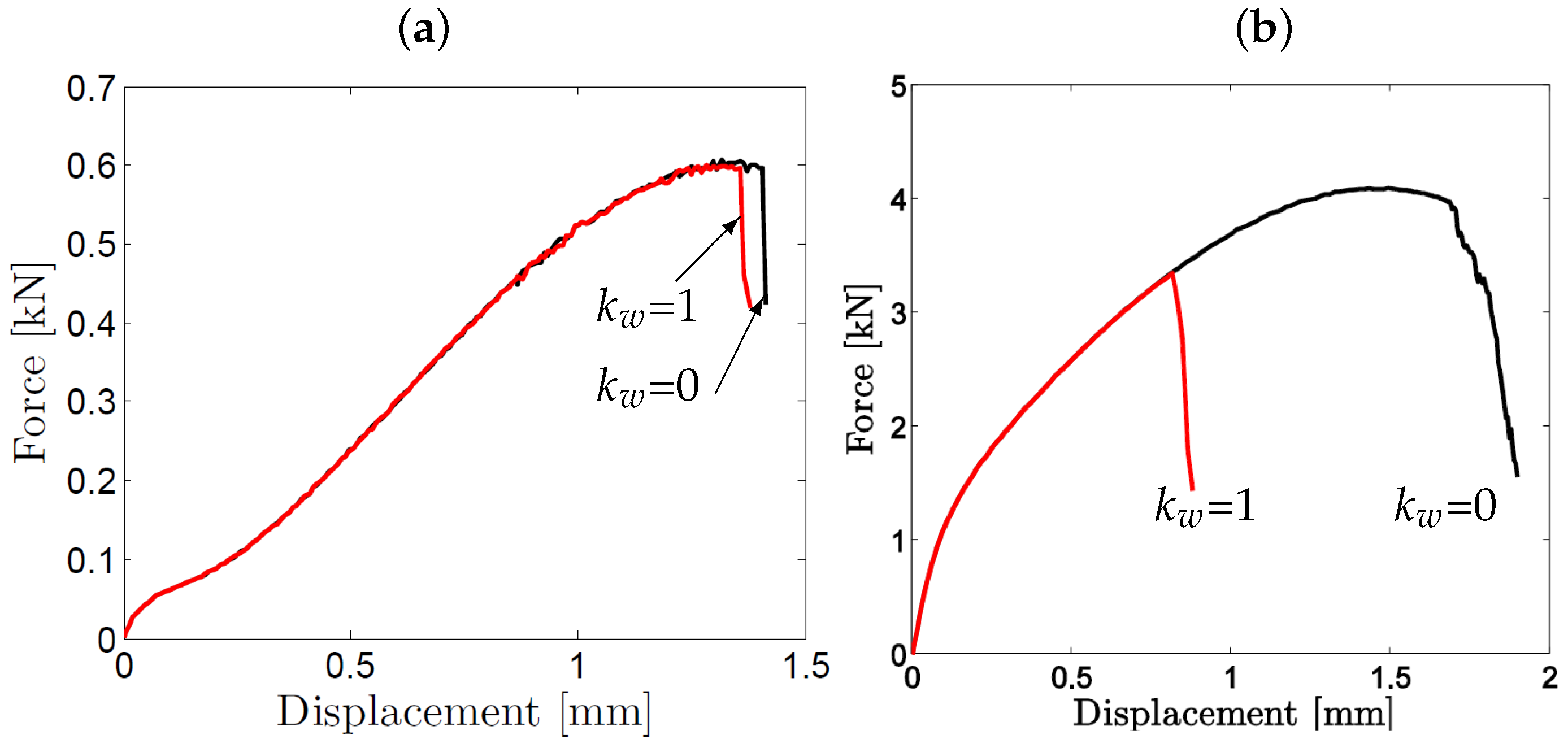

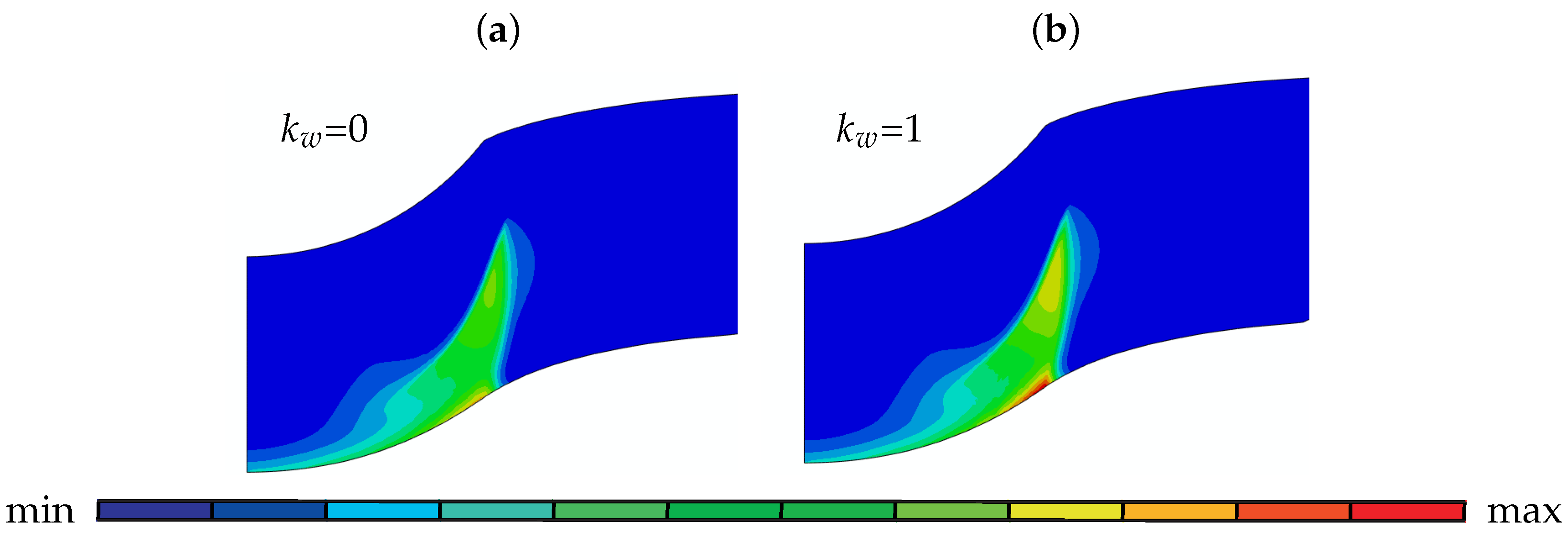

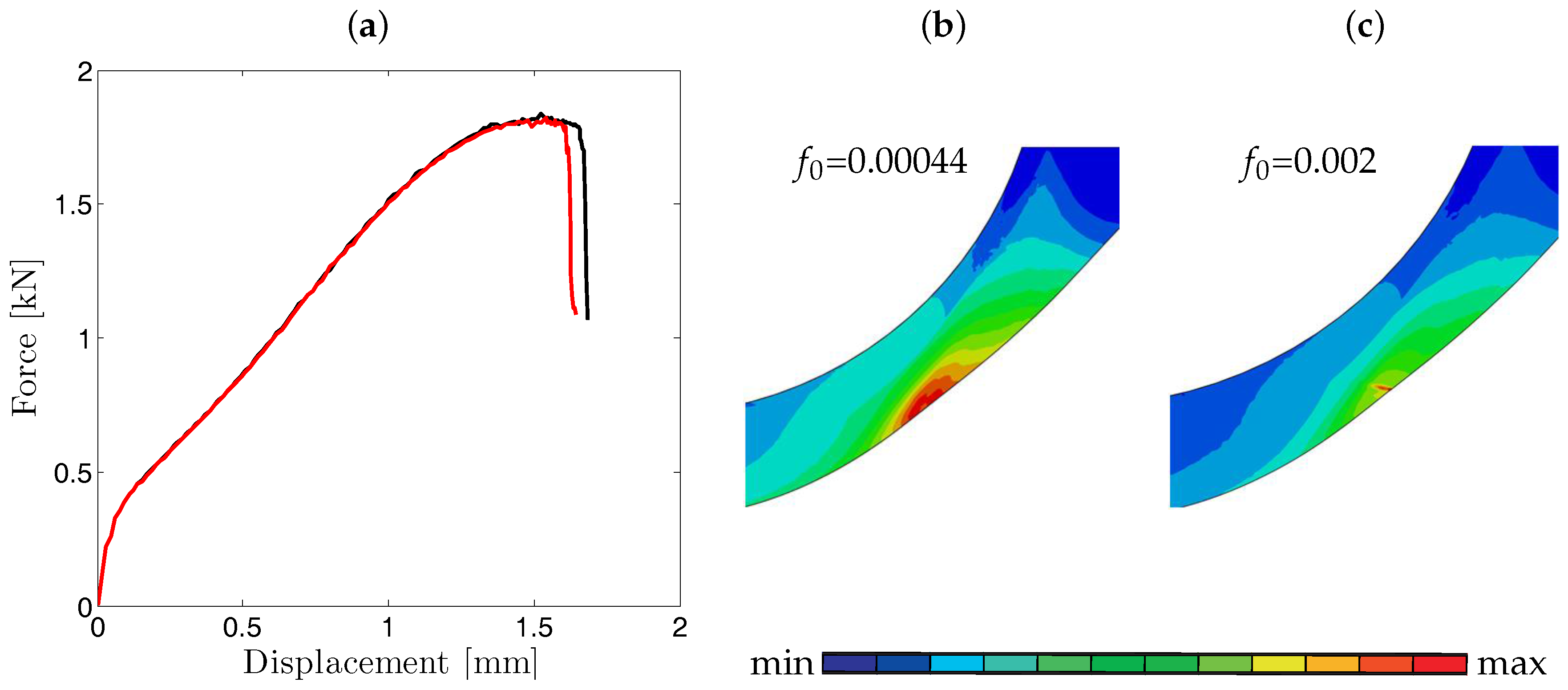

5.2.2. The Influence of Material Parameters

5.2.3. Comparison to Experimentally Determined Results

6. Conclusions and Outlook

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SP | small punch |

| GTN | Gurson-Tvergaard-Needleman |

| RKR | Ritchie-Rice-Knott |

| YS | yield stress |

| UTS | ultimate tensile strength |

| SEM | scanning electrone microscope |

References

- Gülçimen, B.; Durmuṣ, A.; Ülkü, S.; Hurst, R.; Turba, K.; Hähner, P. Mechanical characterisation of a P91 weldment by means of small punch fracture testing. Int. J. Press. Vessel. Pip. 2013, 105, 28–35. [Google Scholar] [CrossRef]

- Gülçimen, B.; Hähner, P. Determination of creep properties of a P91 weldment by small punch testing and a new evaluation approach. Mater. Sci. Eng. A 2013, 588, 125–131. [Google Scholar] [CrossRef]

- Cheon, J.; Kim, I. Initial Deformation During Small Punch Testing. J. Test. Eval. 1996, 24, 255–262. [Google Scholar]

- Soyarslan, C.; Gülçimen, B.; Bargmann, S.; Hähner, P. Modeling of fracture in small punch tests for small- and large-scale yielding conditions at various temperatures. Int. J. Mech. Sci. 2016, 106, 266–285. [Google Scholar] [CrossRef]

- Simonovski, I.; Holmström, S.; Bruchhausen, M. Small punch tensile testing of curved specimens: Finite element analysis and experiment. Int. J. Mech. Sci. 2017, 120, 204–213. [Google Scholar] [CrossRef]

- Milicka, M.; Dobes, F. Small punch testing of P91 steel. Int. J. Press. Vessel. Pip. 2006, 83, 625–634. [Google Scholar] [CrossRef]

- Gurson, A. Continuum theory of ductile rupture by void nucleation and growth—Part I. Yield criteria and rules for porous ductile media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Tvergaard, V. On localization in ductile materials containing spherical voids. Int. J. Fract. 1982, 18, 237–252. [Google Scholar]

- Tvergaard, V.; Needleman, A. Analysis of the cup-cone fracture in a round tensile bar. Acta Metall. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Nahshon, K.; Hutchinson, J. Modification of the Gurson model to shear failure. Eur. J. Mech. A/Solids 2008, 27, 1–17. [Google Scholar] [CrossRef]

- Needleman, A.; Tvergaard, V. Dynamic crack growth in a nonlocal progressively cavitating solid. Eur. J. Mech. A/Solids 1998, 17, 421–438. [Google Scholar] [CrossRef]

- Chu, C.; Needleman, A. Void nucleation effects in biaxially stretched sheets. J. Eng. Mater. Technol. 1980, 102, 249–256. [Google Scholar] [CrossRef]

- Bao, Y.; Wierzbicki, T. On fracture locus in the equivalent strain and stress triaxiality space. Int. J. Mech. Sci. 2004, 46, 81–98. [Google Scholar] [CrossRef]

- Barsoum, I.; Faleskog, J. Rupture in combined tension and shear: experiments. Int. J. Solids Struct. 2007, 44, 1768–1786. [Google Scholar] [CrossRef]

- Soyarslan, C.; Fassmann, D.P.F.; Plugge, B.; Isik, K.; Kwiatkowski, L.; Schaper, M.; Brosius, A.; Tekkaya, A.E. An Experimental and Numerical Assessment of Sheet-Bulk Formability of Mild Steel DC04. ASME. J. Manuf. Sci. Eng. 2011, 133, 061008. [Google Scholar] [CrossRef]

- Soyarslan, C.; Malekipour Gharbi, M.; Tekkaya, A. A combined experimental-numerical investigation of ductile fracture in bending of a class of a ferritic-martensitic steel. Int. J. Solids Struct. 2012, 49, 1608–1626. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Effects of nonlocal damage in porous plastic solids. Int. J. Solids Struct. 1995, 32, 1063–1077. [Google Scholar] [CrossRef]

- Zbib, H.; Aifantis, E. A gradient-dependent flow theory of plasticity: Application to metal and solid instabilities. Appl. Mech. Rev. 1989, 42, 295–304. [Google Scholar] [CrossRef]

- Pijaudier-Cabot, G.; Bazant, Z. Nonlocal damage theory. J. Eng. Mech. ASCE 1987, 113, 1512–1533. [Google Scholar] [CrossRef]

- Leblond, J.; Perrin, G.; Devaux, J. Bifurcation effects in ductile metals with damage delocalization. J. Appl. Mech. 1994, 61, 236–242. [Google Scholar] [CrossRef]

- CEN Workshop Agreement. Small Punch Test Method for Metallic Materials; Technical Report CWA 15627; CEN: Brussels, Belgium, 2006. [Google Scholar]

- Mao, X.; Takahashi, H. Development of a further-miniaturized specimen of 3 mm diameter for TEM disk (φ 3 mm) small punch tests. J. Nucl. Mater. 1987, 150, 42–52. [Google Scholar] [CrossRef]

- Ha, J.; Fleury, E. Small punch tests to estimate the mechanical properties of steels for steam power plant: II. Fracture Toughness. Int. J. Press. Vessel. Pip. 1998, 75, 707–713. [Google Scholar] [CrossRef]

- Franklin, A. Comparison between a quantitative microscope and chemical methods for assessment of non-metallic inclusions. J. Iron Steel Inst. 1969, 207, 181–186. [Google Scholar]

- Li, Y.Z. New Approach to Determine Fracture Toughness from Small Punch Test, Concept Report, Technical Report. Unpublished work. 2010.

- Abendroth, M.; Kuna, M. Determination of deformation and failure properties of ductile materials by means of the small punch test and neural networks. Comput. Mater. Sci. 2003, 28, 633–644. [Google Scholar] [CrossRef]

- Abenroth, M.; Kuna, M. Identification of ductile damage and fracture parameters from the small punch test using neural networks. Eng. Fract. Mech. 2006, 73, 710–725. [Google Scholar] [CrossRef]

- European Structural Integrity Society (ESIS). Numerical Round Robin on Micro-Mechanical Models, Technical Report Technical Committee; Unpublished work. 1997.

- Lee, J.S.; Jang, J.I.; Lee, B.W.; Choi, Y.; Lee, S.G.; Kwon, D. An instrumented indentation technique for estimating fracture toughness of ductile materials: A critical indentation energy model based on continuum damage mechanics. Acta Mater. 2006, 54, 1101–1109. [Google Scholar] [CrossRef]

- Brown, L.; Embury, J. The initiation and growth of voids at second phase particles. In Proceedings of the Third International Conference on the Strength of Metals and Alloys, Institute of Metals, London, UK, 20–25 August 1973; Volume 25, p. 164. [Google Scholar]

- Xia, L.; Shih, C.F. A computational approach to ductile crack growth under large scale yielding conditions. J. Mech. Phys. Solids 1995, 43, 389–413. [Google Scholar] [CrossRef]

- Xia, L.; Shih, C.F. Ductile crack growth-III. Transition to cleavage fracture incorporating statistics. J. Mech. Phys. Solids 1996, 44, 603–639. [Google Scholar] [CrossRef]

- Xia, L.; Shih, C.F. Ductile Cack Growth-I. A numerical study using computational cells with microstructurally- based length scales. J. Mech. Phys. Solids 1995, 43, 233–259. [Google Scholar] [CrossRef]

| [MPa] | [MPa] | [MPa] | [MPa] | [MPa] | m [-] | n [-] | [-] |

|---|---|---|---|---|---|---|---|

| 520 | 376 | 831 | 123.31 | 75 | 6.14 | 0.541 | 0.006 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gülçimen Çakan, B.; Soyarslan, C.; Bargmann, S.; Hähner, P. Experimental and Computational Study of Ductile Fracture in Small Punch Tests. Materials 2017, 10, 1185. https://doi.org/10.3390/ma10101185

Gülçimen Çakan B, Soyarslan C, Bargmann S, Hähner P. Experimental and Computational Study of Ductile Fracture in Small Punch Tests. Materials. 2017; 10(10):1185. https://doi.org/10.3390/ma10101185

Chicago/Turabian StyleGülçimen Çakan, Betül, Celal Soyarslan, Swantje Bargmann, and Peter Hähner. 2017. "Experimental and Computational Study of Ductile Fracture in Small Punch Tests" Materials 10, no. 10: 1185. https://doi.org/10.3390/ma10101185

APA StyleGülçimen Çakan, B., Soyarslan, C., Bargmann, S., & Hähner, P. (2017). Experimental and Computational Study of Ductile Fracture in Small Punch Tests. Materials, 10(10), 1185. https://doi.org/10.3390/ma10101185