On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel

Abstract

:1. Introduction

2. Methodology

2.1. Manufacturing Conditions

2.2. Material Testing

2.2.1. Composition and Density

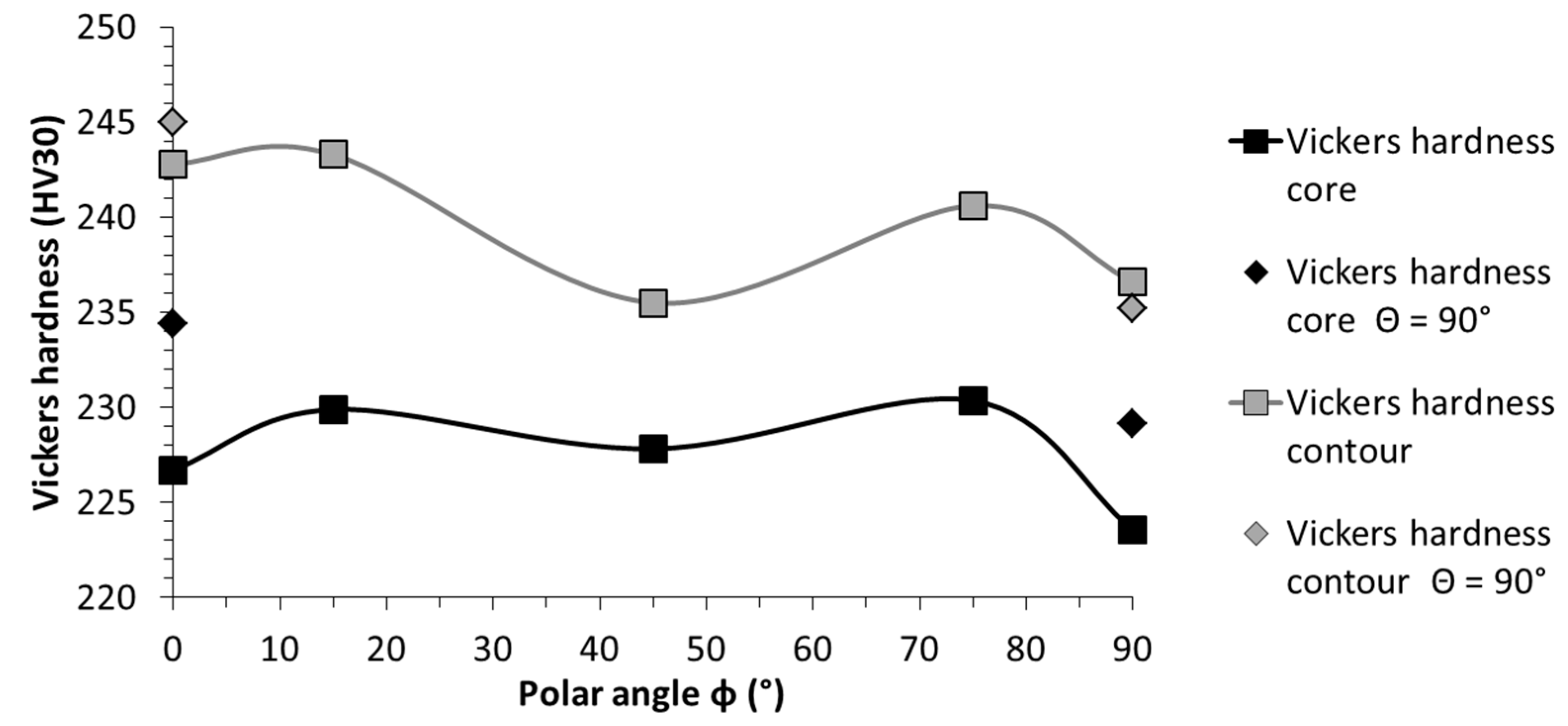

2.2.2. Hardness

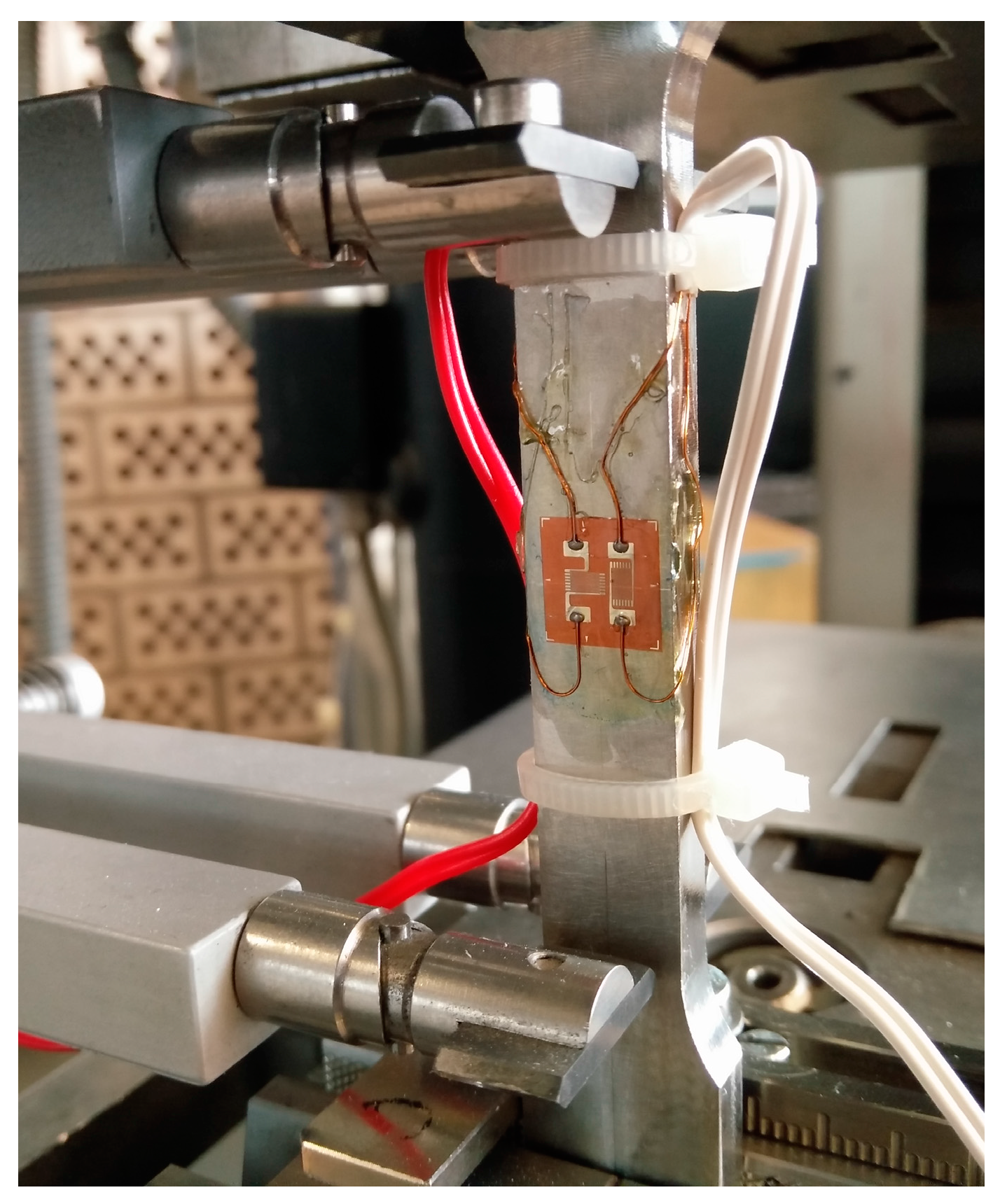

2.2.3. Tensile Testing

2.2.4. Microstructure

3. Results and Discussion

3.1. Density and Composition

3.2. Hardness

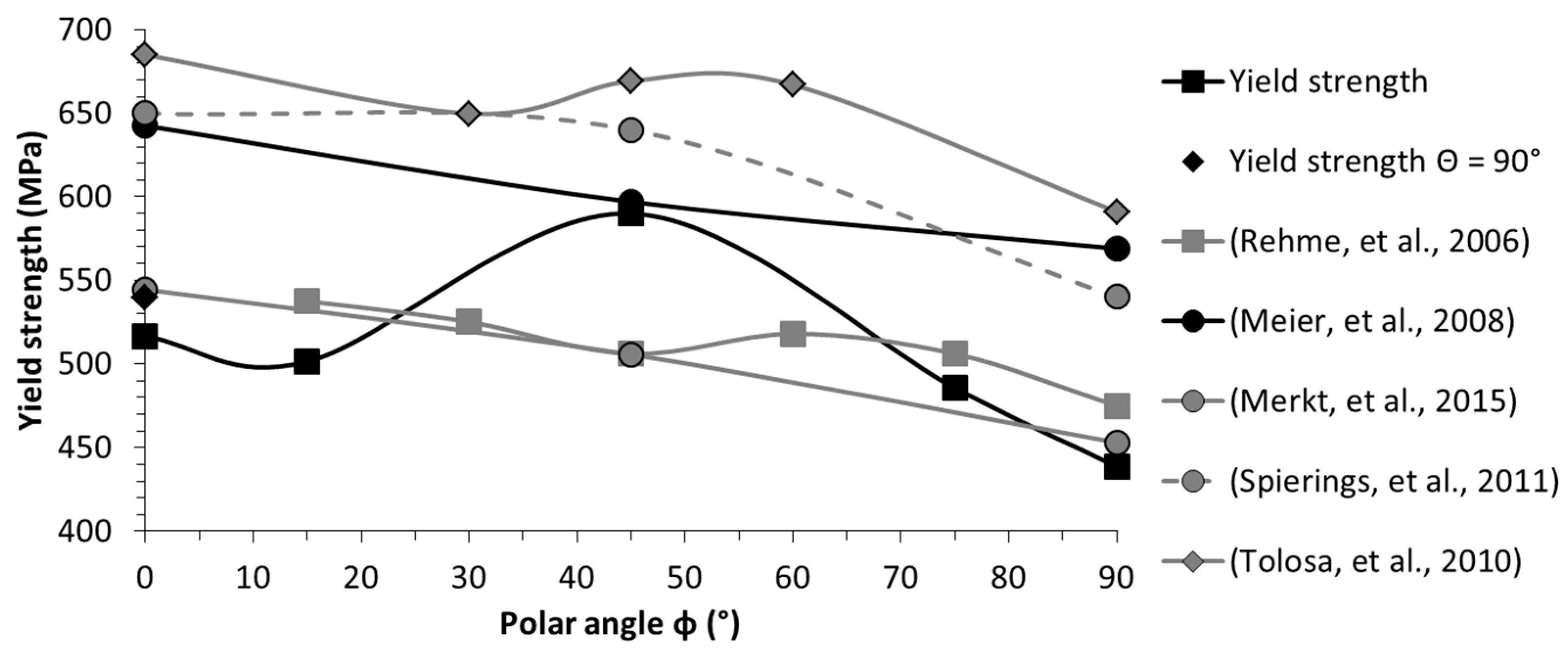

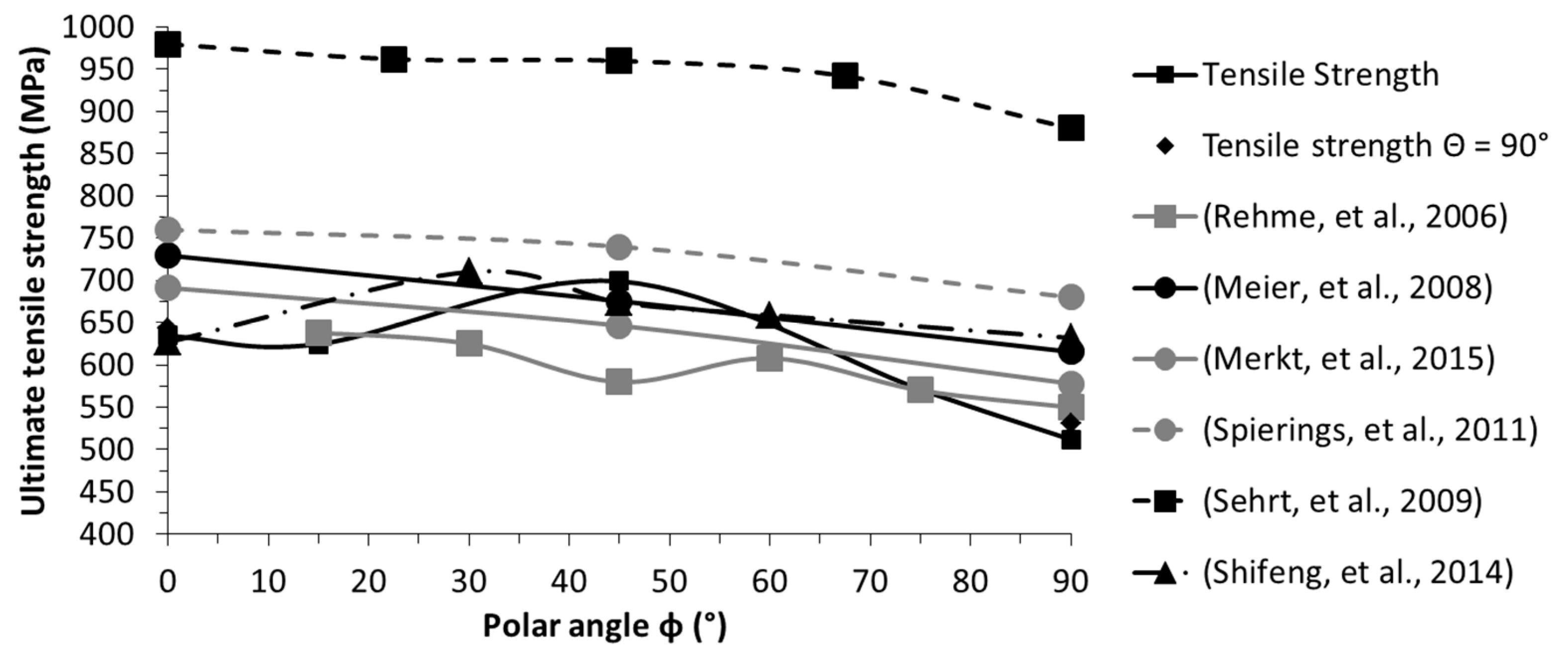

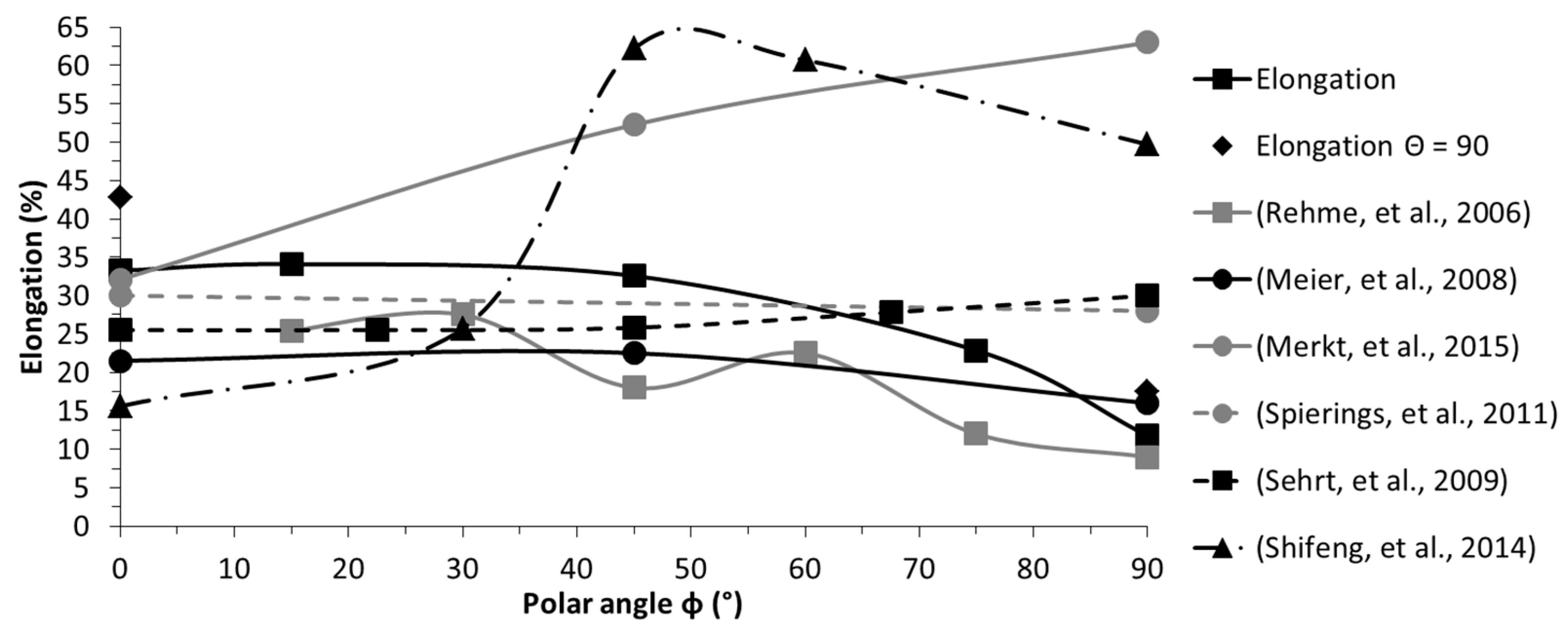

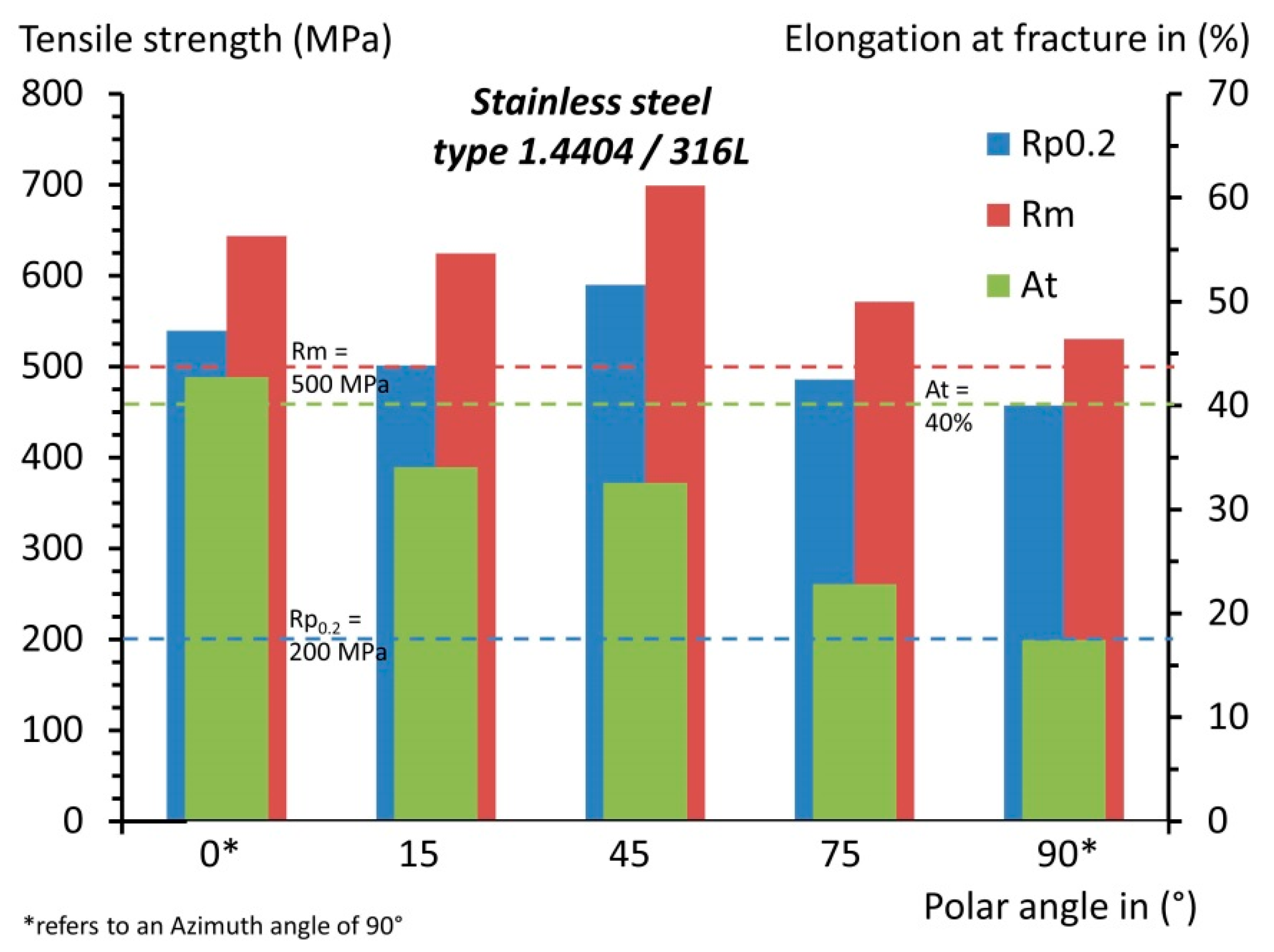

3.3. Tensile Strength

3.4. Comparison AM and Bulk Base Material

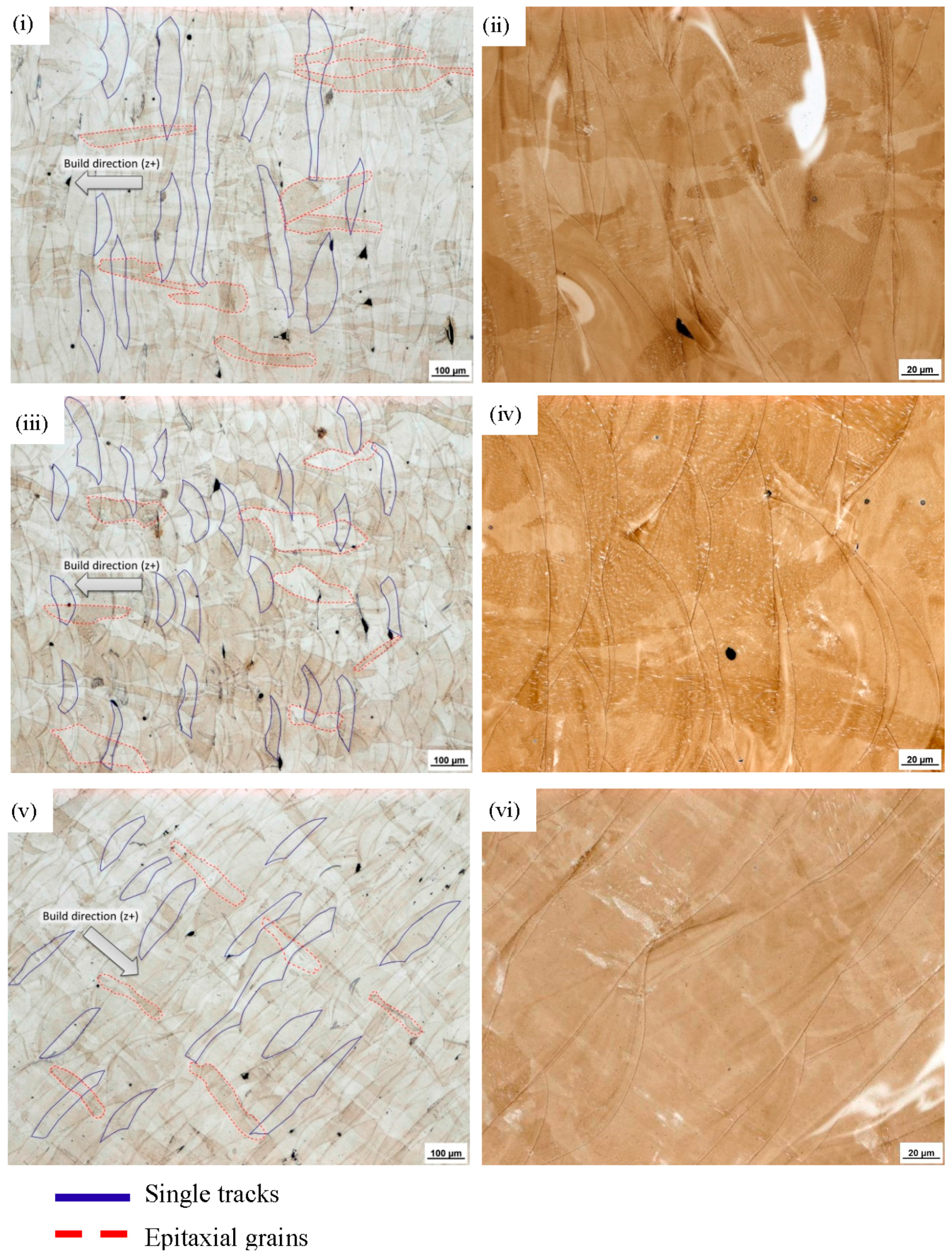

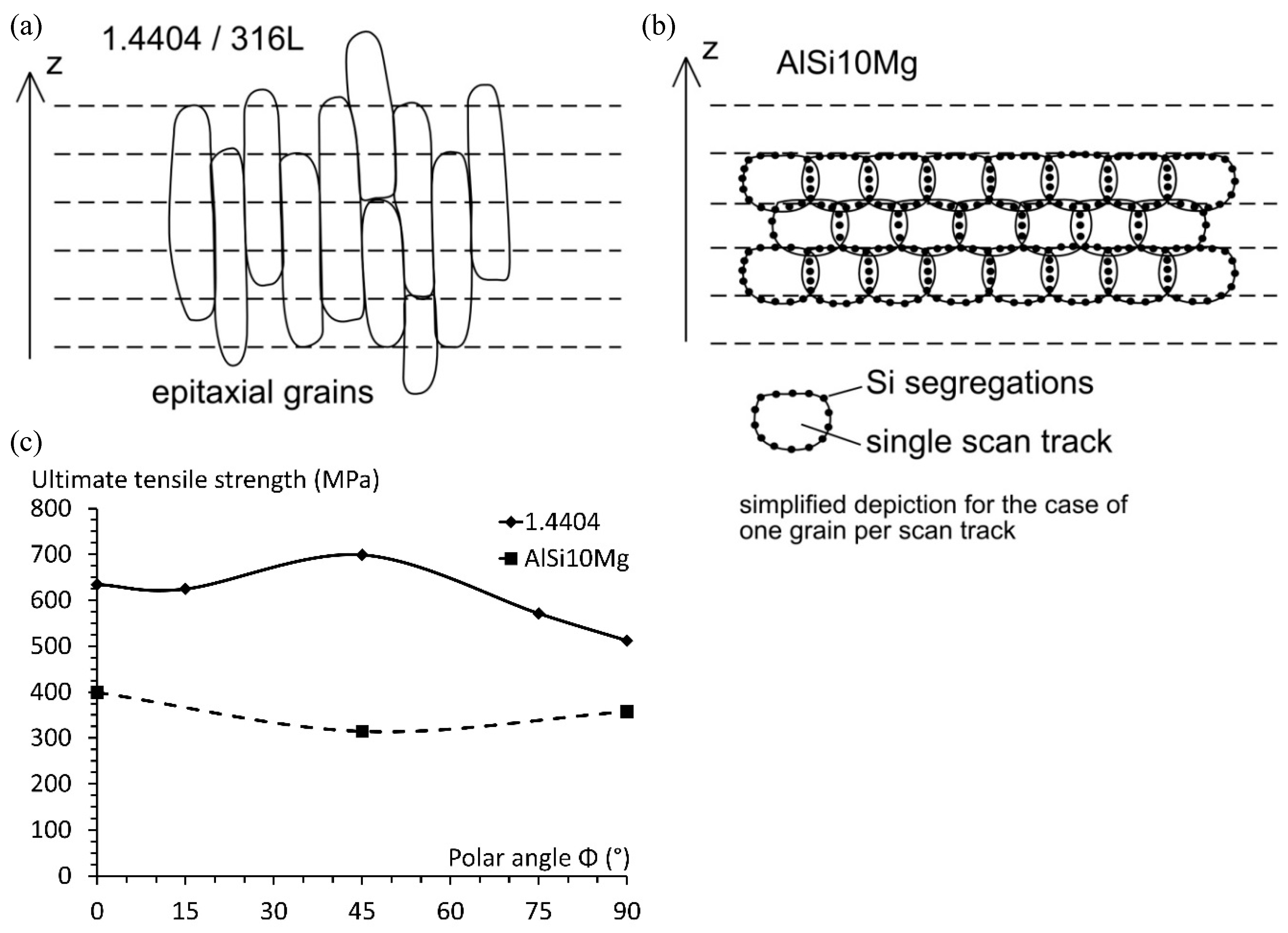

3.5. Comprehensive Analysis of the Directional Dependencies and Their Origin

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sehrt, J.T. Möglichkeiten und Grenzen bei der Generativen Herstellung Metallischer Bauteile Durch das Strahlschmelzverfahren. Ph.D. Thesis, University Duisburg-Essen, Duisburg, Germany, 2010. [Google Scholar]

- Campanelli, S.L.; Contuzzi, N.; Angelastro, A.; Ludovico, A.D. Capabilities and performances of the selective laser melting process. In New Trends in Technologies: Devices, Computer, Communication and Industrial Systems; Er, M.J., Ed.; Sciyo: Roosbeek, Belgium, 2010. [Google Scholar]

- Hitzler, L.; Merkel, M.; Freytag, P. Design of a subframe to integrate an electric drivetrain in existing vehicles. Mat.-Wiss. Werkstofftech. 2015, 46, 454–461. [Google Scholar] [CrossRef]

- Merkt, S.J. Qualifizierung von Generativ Gefertigten Gitterstrukturen für maßgeschneiderte Bauteilfunktionen. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2015. [Google Scholar]

- Müller-Lohmeier, K. Stahl- und Aluminiumteile: Praktische Erfahrungen mit generativem Prototyping. In 3. Swiss Rapid Forum; Festo AG & Co. KG: St. Gallen, Switzerland, 2005. [Google Scholar]

- Milovanovic, J.; Stojkovic, M.; Trajanovic, M. Rapid tooling of tyre tread ring mould using direct metal laser sintering. J. Sci. Ind. Res. 2009, 68, 1038–1042. [Google Scholar]

- Buchbinder, D.; Meiners, W.; Brandl, E.; Palm, F.; Müller-Lohmeier, K.; Wolter, M.; Over, C.; Moll, W.; Weber, J.; Skrynecki, N.; et al. Abschlussbericht—Generative Fertigung von Aluminiumbauteilen für die Serienproduktion, 01rio639a-d, BMBF; Fraunhofer ILT: Aachen, Germany, 2010. [Google Scholar]

- Hitzler, L.; Merkel, M.; Hall, W.; Öchsner, A. A review of metal fabricated with powder-bed based additive manufacturing techniques: Process, nomenclature, materials, achievable properties, and its utilization in the medical sector. Adv. Eng. Mater. 2017. under review. [Google Scholar]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett. 2017, 1–5. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316l stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Scipioni Bertoli, U.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Kleszczynski, S.; zur Jacobsmühlen, J.; Sehrt, J.; Witt, G. Mechanical properties of laser beam melting components depending on various process errors. In Digital Product and Process Development Systems; Kovács, G.L., Kochan, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Hu, Z.; Zhu, H.; Zhang, H.; Zeng, X. Experimental investigation on selective laser melting of 17-4PH stainless steel. Opt. Lasers Technol. 2017, 87, 17–25. [Google Scholar] [CrossRef]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42A, 3190–3199. [Google Scholar] [CrossRef]

- Hitzler, L.; Janousch, C.; Schanz, J.; Merkel, M.; Heine, B.; Mack, F.; Hall, W.; Öchsner, A. Direction and location dependency of selective laser melted AlSi10Mg specimens. J. Mater. Process. Technol. 2017, 243, 48–61. [Google Scholar] [CrossRef]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Brandt, M. Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by selective laser melting (SLM). J. Mater. Process. Technol. 2017, 249, 502–511. [Google Scholar] [CrossRef]

- Meier, H.; Haberland, C. Experimental studies on selective laser melting of metallic parts. Mat.-Wiss. Werkstofftech. 2008, 39, 665–670. [Google Scholar] [CrossRef]

- Sehrt, J.; Witt, G. Auswirkung des anisotropen Gefüges strahlgeschmolzener Bauteile auf mechanische Eigenschaftswerte. In RTejournal; Forum für Rapid Technologie: Duisburg, Germany, 2009; Volume 6. [Google Scholar]

- Rehme, O.; Emmelmann, C. Rapid Manufacturing of Lattice Structures with Selective Laser Melting; Laser-Based Micropackaging: San Jose, CA, USA, 2006; p. 61070K. [Google Scholar]

- Tolosa, I.; Garciandia, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. 2013, 50, 581–586. [Google Scholar] [CrossRef]

- Niendorf, T.; Brenne, F.; Schaper, M. Lattice structures manufactured by SLM: On the effect of geometrical dimensions on microstructure evolution during processing. Metall. Mater. Trans. B 2014, 45, 1181–1185. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly anisotropic steel processed by selective laser melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Elwany, A.; Yadollahi, A.; Thompson, S.M.; Bian, L.; Shamsaei, N. Mechanical properties and microstructural characterization of selective laser melted 17-4 PH stainless steel. Rapid Prototyp. J. 2017, 23, 280–294. [Google Scholar] [CrossRef]

- Zhang, D. Entwicklung des Selective Laser Melting (SLM) für Aluminumwerkstoffe. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2004. [Google Scholar]

- Alrbaey, K.; Wimpenny, D.; Tosi, R.; Manning, W.; Moroz, A. On optimization of surface roughness of selective laser melted stainless steel parts: A statistical study. J. Mater. Eng. Perform. 2014, 23, 2139–2148. [Google Scholar] [CrossRef]

- Schanz, J.; Hofele, M.; Hitzler, L.; Merkel, M.; Riegel, H. Laser polishing of additive manufactured AlSi10Mg parts with an oscillating laser beam. In Machining, Joining and Modifications of Advanced Materials; Springer: Singapore, 2016; pp. 159–169. [Google Scholar]

- Schanz, J.; Hofele, M.; Ruck, S.; Schubert, T.; Hitzler, L.; Schneider, G.; Merkel, M.; Riegel, H. Metallurgical investigations of laser remelted additively manufactured AlSi10Mg parts. Mat.-Wiss. Werkstofftech. 2017, 48, 463–476. [Google Scholar] [CrossRef]

- Martínez, S.; Lamikiz, A.; Ukar, E.; Calleja, A.; Arrizubieta, J.A.; Lopez de Lacalle, L.N. Analysis of the regimes in the scanner-based laser hardening process. Opt. Lasers Eng. 2017, 90, 72–80. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.-M. Improving the surface quality and mechanical properties by shot-peening of 17-4 stainless steel fabricated by additive manufacturing. Mater. Des. 2016, 110, 914–924. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Antonenkova, G.; Grigoriev, S.; Smurov, I. Use of track/layer morphology to develop functional parts by selective laser melting. J. Laser Appl. 2013, 25, 052003. [Google Scholar] [CrossRef]

- Figliuzzi, M.; Mangano, F.; Mangano, C. A novel root analogue dental implant using CT scan and CAD/CAM: Selective laser melting technology. Int. J. Oral. Maxillofac. Surg. 2012, 41, 858–862. [Google Scholar] [CrossRef] [PubMed]

- Abd-Elghany, K.; Bourell, D.L. Property evaluation of 304L stainless steel fabricated by selective laser melting. Rapid Prototyp. J. 2012, 18, 420–428. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Jenn, M. Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: Influence of starting tic particle size and volume content. Mater. Des. 2016, 104, 141–151. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. In-situ formation of novel TiC-particle-reinforced 316L stainless steel bulk-form composites by selective laser melting. J. Alloys Compd. 2017, 706, 409–418. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. Rapid fabrication of bulk-form TiB2/316L stainless steel nanocomposites with novel reinforcement architecture and improved performance by selective laser melting. J. Alloys Compd. 2016, 680, 480–493. [Google Scholar] [CrossRef]

- Hitzler, L.; Janousch, C.; Schanz, J.; Merkel, M.; Mack, F.; Öchsner, A. Non-destructive evaluation of AlSi10Mg prismatic samples generated by selective laser melting: Influence of manufacturing conditions. Mat.-Wiss. Werkstofftech. 2016, 47, 564–581. [Google Scholar] [CrossRef]

- Hitzler, L.; Hirsch, J.; Merkel, M.; Hall, W.; Öchsner, A. Position dependent surface quality in selective laser melting. Mat.-Wiss. Werkstofftech. 2017, 48, 327–334. [Google Scholar] [CrossRef]

- Prüfung Metallischer Werkstoffe—Zugproben; DIN 50125; Deutsches Institut für Normung e.V.: Berlin, Germany, 2009.

- Krahmer, D.M.; Polvorosa, R.; López de Lacalle, L.N.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Hitzler, L.; Hirsch, J.; Merkel, M.; Öchsner, A. Thermal environment and inclination angle dependencies on the surface quality of selective laser melted 316L steel. Defect Diffus. Forum 2017, 372, 202–207. [Google Scholar] [CrossRef]

- Metallic Materials—Vickers Hardness Test—Part 2: Verification and Calibration of Testing Machines; DIN EN ISO 6507-2; Deutsches Institut für Normung e.V.: Berlin, Germany, 2016.

- Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; DIN EN ISO 6892-1; Deutsches Institut für Normung e.V.: Berlin, Germany, 2016.

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsava, I.; Fredriksson, G.; Yadroitsev, I. Microstructural and thermal stability of selective laser melted 316L stainless steel single tracks. S. Afr. J. Ind. Eng. 2017, 28. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Gäumann, M.; Bezençon, C.; Canalis, P.; Kurz, W. Single-crystal laser deposition of superalloys: Processing-microstructure maps. Acta Mater. 2001, 49, 1051–1062. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.-M. Understanding the deformation behavior of 17-4 precipitate hardenable stainless steel produced by direct metal laser sintering using micropillar compression and tem. Int. J. Adv. Manuf. Technol. 2016, 90, 119–126. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Montani, M.; Demir, A.G.; Mostaed, E.; Vedani, M.; Previtali, B. Processability of pure Zn and pure Fe by SLM for biodegradable metallic implant manufacturing. Rapid Prototyp. J. 2017, 23, 514–523. [Google Scholar] [CrossRef]

- Woite, M. Edelstahl 1.4404. Available online: http://www.woite-edelstahl.info/14404de.html (accessed on 14 June 2017).

- AZO Materials. Stainless Steel—Grade 316L—Properties, Fabrication and Applications (UNS S31603). Available online: http://www.azom.com/article.aspx?ArticleID=2382# (accessed on 14 June 2017).

- Atlas Steels. Grade Data Sheet, 316 316L 316H. Available online: http://www.atlassteels.com.au/documents/Atlas_Grade_datasheet_316_rev_Jan_2011.pdf (accessed on 14 June 2017).

- Hibbeler, R.C. Mechanics of Materials, 8th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2011; ISBN1 10: 0136022308. ISBN2 13: 9780136022305. [Google Scholar]

- Daggett, S.S. A Simplified Approach to Determining “Effective” Elastic Mechanical Properties of Fiber-Polymer Composite Systems. Ph.D. Thesis, Wichita State University, Wichita, KS, USA, 1997. [Google Scholar]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. Scanning strategies for texture and anisotropy tailoring during selective laser melting of TiC/316L stainless steel nanocomposites. J. Alloys Compd. 2017, 728, 424–435. [Google Scholar] [CrossRef]

- Metallic Materials—Conversion of Hardness Values; DIN EN ISO 18265:2014-02; Deutsches Institut für Normung e.V.: Berlin, Germany, 2014.

- Mertens, R.; Vrancken, B.; Holmstock, N.; Kinds, Y.; Kruth, J.P.; Van Humbeeck, J. Influence of powder bed preheating on microstructure and mechanical properties of H13 tool steel SLM parts. Phys. Procedia 2016, 83, 882–890. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, Y.; Li, R.; Wei, Q.; Liu, J. Manufacturing AISI316L components via selective laser melting coupled with hot isostatic pressing. In Advanced Material Science and Technology, Pts 1 and 2; Tan, Y., Ju, D.Y., Eds.; Trans Tech Publications Ltd.: Zurich, Switzerland, 2011; Volume 675–677, pp. 853–856. [Google Scholar]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. Selective laser melting of TiB2/316L stainless steel composites: The roles of powder preparation and hot isostatic pressing post-treatment. Powder Technol. 2017, 309, 37–48. [Google Scholar] [CrossRef]

- Leuders, S.; Lieneke, T.; Lammers, S.; Tröster, T.; Niendorf, T. On the fatigue properties of metals manufactured by selective laser melting—The role of ductility. J. Mater. Res. 2014, 29, 1911–1919. [Google Scholar] [CrossRef]

- Yadroitsava, I.; Yadroitsev, I. Residual stress in metal specimens produced by direct metal laser sintering. In Proceedings of the SFF Symposium, Austin, TX, USA, 10–12 August 2015. [Google Scholar]

- Yadroitsava, I.; Yadroitsev, I. Evaluation of Residual Stress in Selective Laser Melting of 316L Steel. In Proceedings of the 1st International Conference on Progress in Additive Manufacturing (Pro-AM 2014), Nanyang Executive Centre NTU, Singapore, 26–28 May 2014; pp. 278–283. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I.; Smurov, I. Strategy of Fabrication of Complex Shape Parts Based on the Stability of Single Laser Melted Track; Pfleging, W., Lu, Y., Washio, K., Eds.; SPIE: San Francisco, CA, USA, 2011; p. 79210C. [Google Scholar]

- Wen, S.; Li, S.; Wei, Q.; Yan, C.; Zhang, S.; Shi, Y. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 2014, 214, 2660–2667. [Google Scholar] [CrossRef]

- ThyssenKrupp. Nichtrostender Austenitischer Stahl TK 1.4404. Available online: http://www.thyssenkrupp.at/files/rohre/Werkstoffdatenblaetter/1.4404.pdf (accessed on 21 August 2017).

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N.M. On the precipitation hardening of selective laser melted AlSi10Mg. Metall. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Anisotropic mechanical behavior of AlSi10Mg parts produced by selective laser melting. JOM 2017, 69, 516–522. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Brenne, F.; Tröster, T.; Richard, H.A.; Schwarze, D. Functionally graded alloys obtained by additive manufacturing. Adv. Eng. Mater. 2014, 16, 857–861. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. Manuf. Technol. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Hirsch, J. Anisotropes Materialverhalten von Edelstahl 316L beim selektiven Laserstrahlschmelzen. Master’s Thesis, Aalen University, Aalen, Germany, 2017. [Google Scholar]

- David, S.A.; Vitek, J.M. Correlation between solidification parameters and weld microstructures. Int. Mater. Rev. 1989, 34, 213–245. [Google Scholar] [CrossRef]

- Trapp, J.; Rubenchik, A.M.; Guss, G.; Matthews, M.J. In situ absorptivity measurements of metallic powders during laser powder-bed fusion additive manufacturing. Appl. Mater. Today 2017, 9, 341–349. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Fernández, A.; Celaya, A.; Lamikiz, A.; López de Lacalle, L.N. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Lasers Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

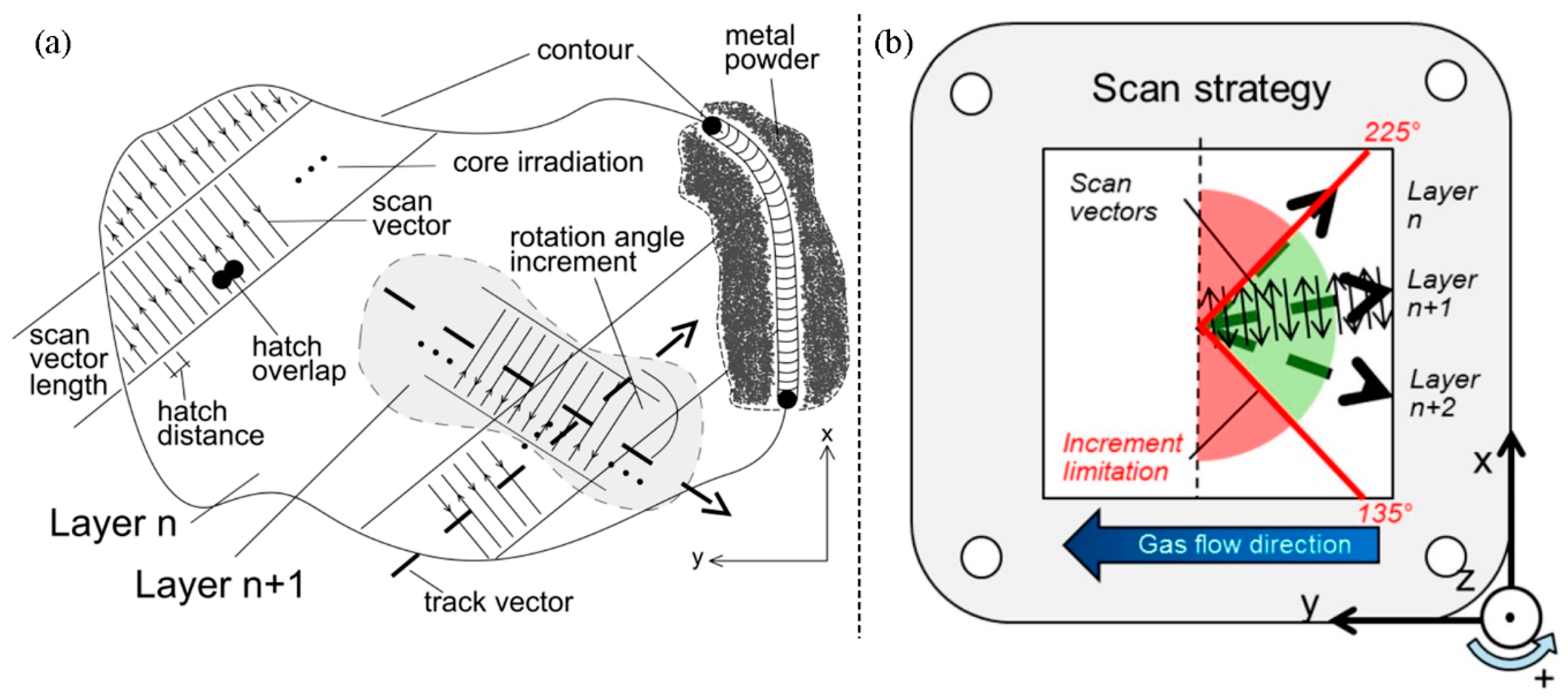

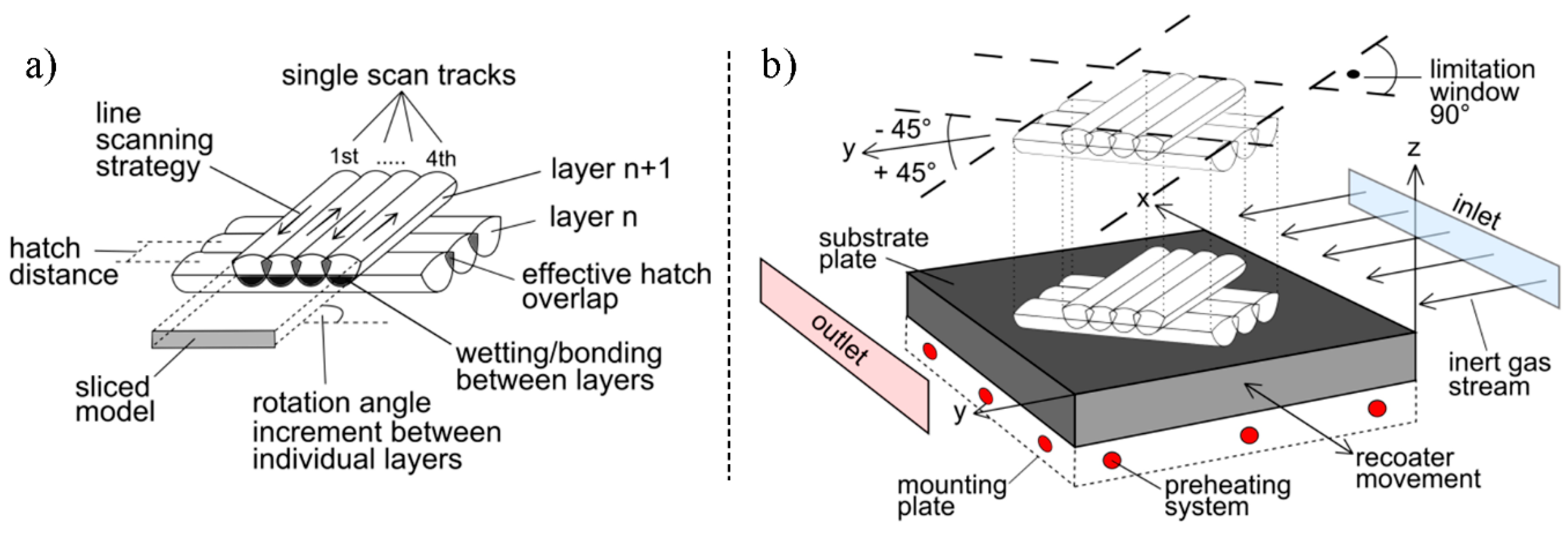

| Parameter Set | Scan Speed (mm/s) | Laser Power (W) | Hatch Distance (mm) | Rotation Angle Increment (°) | Energy Density (J/mm3) |

|---|---|---|---|---|---|

| Contour | 400 | 100 | 0.09 | - | 92.6 |

| Core | 800 | 200 | 0.12 | 33 | 69.4 |

| Final layer | 400 | 300 | 0.1 | - | 250.0 |

| Support | 875 | 200 | - | - | - |

| Common | Layer thickness of 30 μm | ||||

| Mounting plate temperature of 200 °C | |||||

| Nitrogen is employed as the inert gas | |||||

| Contour is irradiated first, followed by the core, utilising the line scanning strategy with a scan vector length of 10 mm | |||||

| Limitation window of 90°, respectively ±45° to the y-axis | |||||

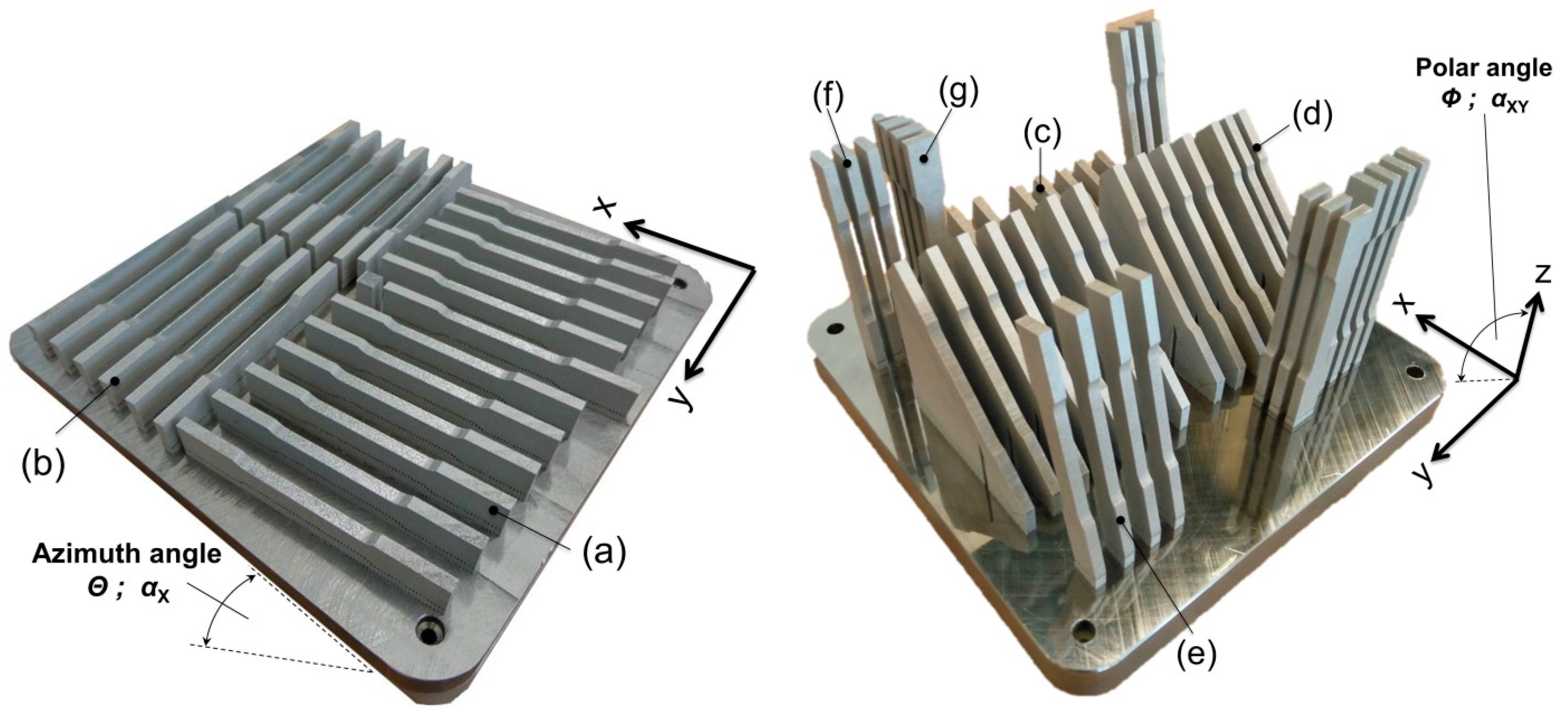

| Config. | Polar Angle Φ; αXY (°) | Azimuth Angle Θ; αX (°) | Total Runtime (h) |

|---|---|---|---|

| (a) | 0 | 0 | 39.5 |

| (b) | 0 | 90 | |

| (c) | 15 | 0 | 86.5 |

| (d) | 45 | 0 | |

| (e) | 75 | 0 | |

| (f) | 90 | 0 | |

| (g) | 90 | 90 |

| Config. | Fe | C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|---|---|

| (a)–(b) | Bal | 0.031 | 0.564 | 1.044 | <0.005 | 0.007 | 16.837 | 11.691 | 2.371 | - |

| (c)–(g) | Bal | 0.0235 | 0.585 | 1.051 | <0.005 | <0.005 | 16.994 | 11.257 | 2.390 | - |

| DIN EN 10088-3 | Bal | <0.03 | <1 | <2 | <0.045 | <0.03 | 16.5–18.5 | 10–13 | 2–2.5 | <0.1 |

| Config. | Vickers Hardness Core (HV30) | Standard Deviation Core (HV30) | Vickers Hardness Contour (HV30) | Standard Deviation Contour (HV30) |

|---|---|---|---|---|

| (a) | 226.7 | 6.1 | 242.8 | 18.4 |

| (b) | 234.4 | 8.0 | 245.0 | 12.2 |

| (c) | 229.9 | 5.6 | 243.3 | 26.9 |

| (d) | 227.8 | 7.2 | 235.5 | 11.0 |

| (e) | 230.4 | 6.2 | 240.6 | 14.3 |

| (f) | 223.6 | 7.9 | 236.6 | 13.7 |

| (g) | 229.2 | 8.3 | 235.2 | 9.3 |

| Reference | Vickers Hardness | Machine | Max. Laser Power [W] |

|---|---|---|---|

| This work | 223–245 HV30 | SLM 280HL | 400 |

| Cherry, et al. [10] | 220–225 HV | Renishaw AM250 | 200 |

| Tolosa, et al. [21] | 215–255 HV mean of 235 HV | SLM 250 Realizer | - |

| Kruth, et al. [50] | 220–250 HV0.1 | - | - |

| Montani, et al. [51] | 245 HV | Prototype, not further specified | 1000 |

| Sheet metal, typical value [52,53,54] | ~220 HV(212–217 HB) | - | - |

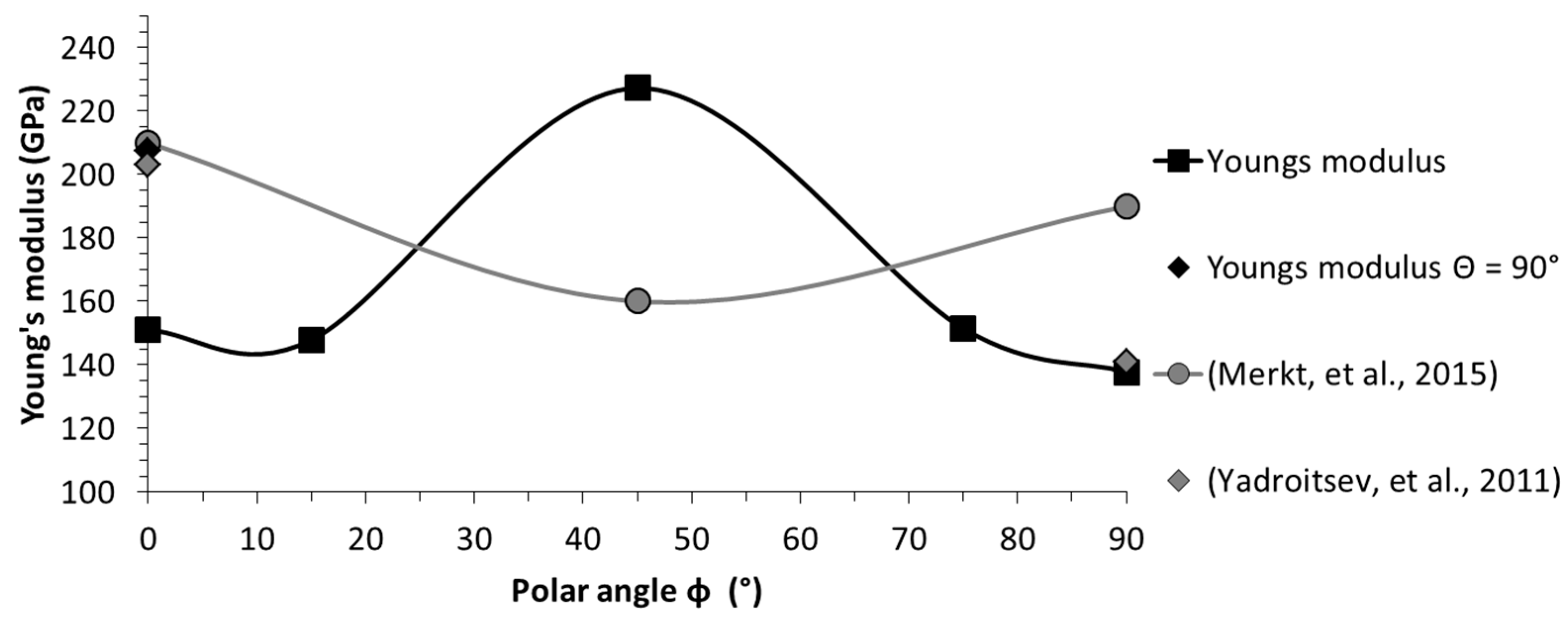

| Config. | Young’s Modulus E (GPa) | Yield Strength Rp0.2 (MPa) | Ultimate Tensile Strength Rm (MPa) | Elongation at Failure At (%) | Poisson’s Ratio ν (-) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Average | STDEV | Average | STDEV | Average | STDEV | Average | STDEV | Average | STDEV | |

| (a) | 151.01 | 25.56 | 516.51 | 7.16 | 634.43 | 7.39 | 33.24 | 0.57 | 0.444 | 0.031 |

| (b) | 207.57 | 24.22 | 539.47 | 3.29 | 643.67 | 3.25 | 42.74 | 0.82 | 0.155 | 0.014 |

| (c) | 147.87 | 23.59 | 501.32 | 7.70 | 624.65 | 4.36 | 34.09 | 1.12 | 0.479 | 0.058 |

| (d) | 227.35 | 25.12 | 589.89 | 11.86 | 698.98 | 23.65 | 32.56 | 10.17 | 0.203 | 0.024 |

| (e) | 151.43 | 18.80 | 485.65 | 11.93 | 571.23 | 18.63 | 22.84 | 7.27 | 0.558 | 0.020 |

| (f) | 137.78 | 14.25 | 438.60 | 9.69 | 511.99 | 17.95 | 11.76 | 5.38 | 0.453 | 0.005 |

| (g) | 137.83 | 16.25 | 457.21 | 17.29 | 530.22 | 8.09 | 17.46 | 4.42 | 0.170 | 0.085 |

| Reference | Configurations | Range Re/Rm (-) | Averaged * Ratio Re/Rm (-) |

|---|---|---|---|

| this work | 7 | 0.8026–0.8623 | 0.8383 |

| Meier and Haberland [18] | 5 | 0.8621–0.9261 | 0.8889 |

| Merkt [4] | 3 | 0.7819–0.7877 | 0.7844 |

| Rehme and Emmelmann [20] | 150 | 0.8400–0.8877 ** | 0.8597 ** |

| Riemer, et al. [47] | 1 | 0.8177 | - |

| heat treated 2 h, 650 °C | 0.7445 | - | |

| Spierings, et al. [14] | 3 | 0.7941–0.8648 | 0.8380 |

| Tolosa, et al. [21] | 15 | 0.9163–0.9967 | 0.9565 |

| bulk base 1.4404 [67] | - | 0.4 | - |

| Layer | Track Vector Angle | Scan Vector Angle |

|---|---|---|

| 1 | (bottom increment limitation border) = 135° | (track vector angle) ± 90° = 45°; 225° |

| 2 | (previous track vector angle) + (rotation angle increment) = 135° + 33° = 168° | (track vector angle) ± 90° = 78°; 258° |

| 3 | (previous track vector angle) + (rotation angle increment) = 168° + 33° = 201° | (track vector angle) ± 90° = 111°; 291° |

| 4 | would be outside the limitation window!, thus: (previous track vector angle) + (rotation angle increment)—(top Increment limitation border) + (bottom Increment limitation border) = 201° + 33° − 225° + 135° = 144° | (track vector angle) ± 90° = 54°; 234° |

| 5 | (previous track vector angle) + (rotation angle increment) = 144° + 33° = 177° | (track vector angle) ± 90° = 87°; 267° |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hitzler, L.; Hirsch, J.; Heine, B.; Merkel, M.; Hall, W.; Öchsner, A. On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel. Materials 2017, 10, 1136. https://doi.org/10.3390/ma10101136

Hitzler L, Hirsch J, Heine B, Merkel M, Hall W, Öchsner A. On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel. Materials. 2017; 10(10):1136. https://doi.org/10.3390/ma10101136

Chicago/Turabian StyleHitzler, Leonhard, Johann Hirsch, Burkhard Heine, Markus Merkel, Wayne Hall, and Andreas Öchsner. 2017. "On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel" Materials 10, no. 10: 1136. https://doi.org/10.3390/ma10101136

APA StyleHitzler, L., Hirsch, J., Heine, B., Merkel, M., Hall, W., & Öchsner, A. (2017). On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel. Materials, 10(10), 1136. https://doi.org/10.3390/ma10101136