Customized a Ti6Al4V Bone Plate for Complex Pelvic Fracture by Selective Laser Melting

Abstract

:1. Introduction

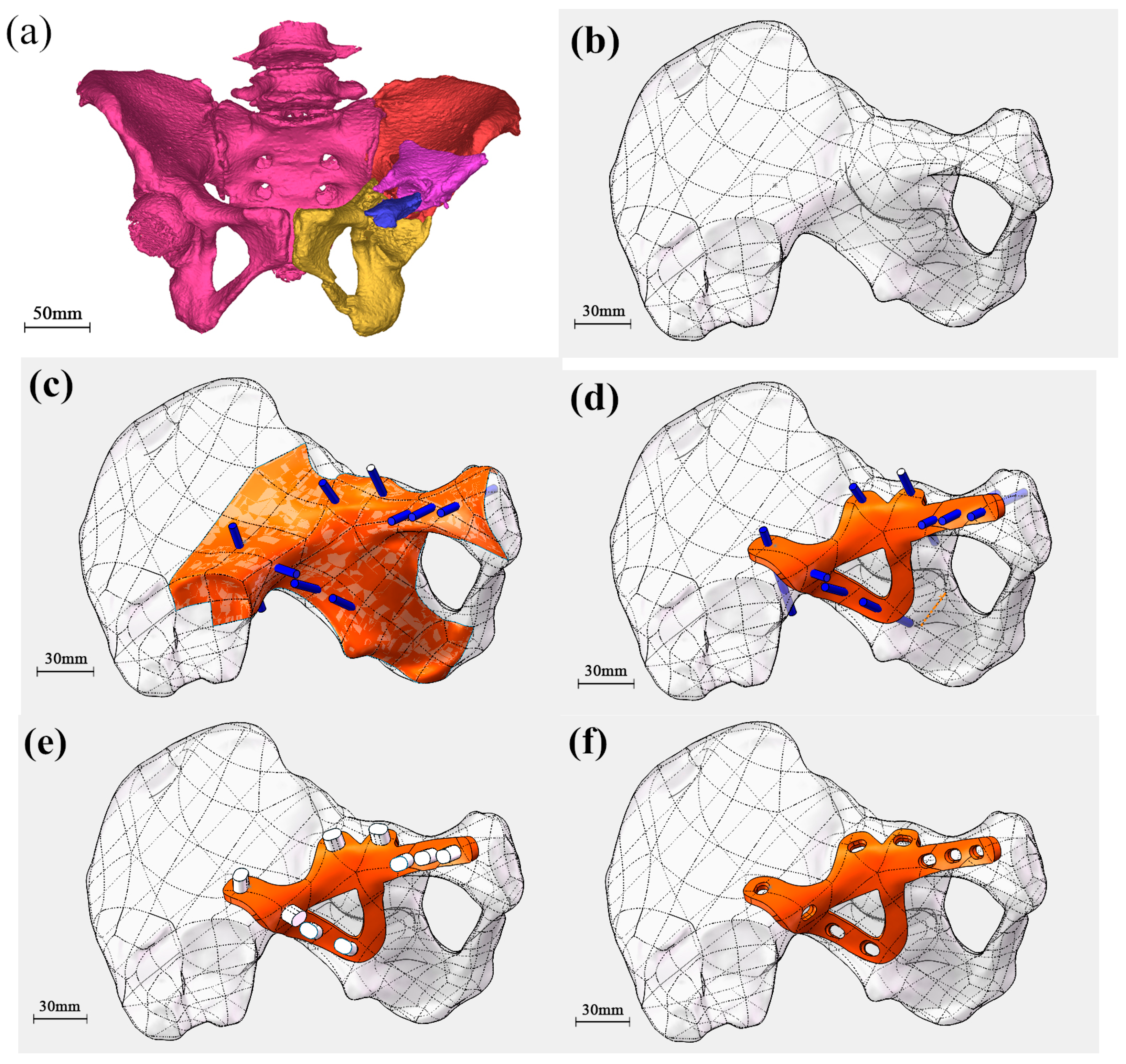

2. Customized Design of Bone Plate for Pelvic Fracture

2.1. Procedure A: Extraction of Computed Tomography (CT) Data of the Target Pelvis

2.2. Procedure B: Generation of the Pelvis Model

2.3. Procedure C: Fabrication of the Original Shape of the Customized Bone Plate

2.4. Procedure D: Determination of the Shape and Thickness of the Customized Bone Plate

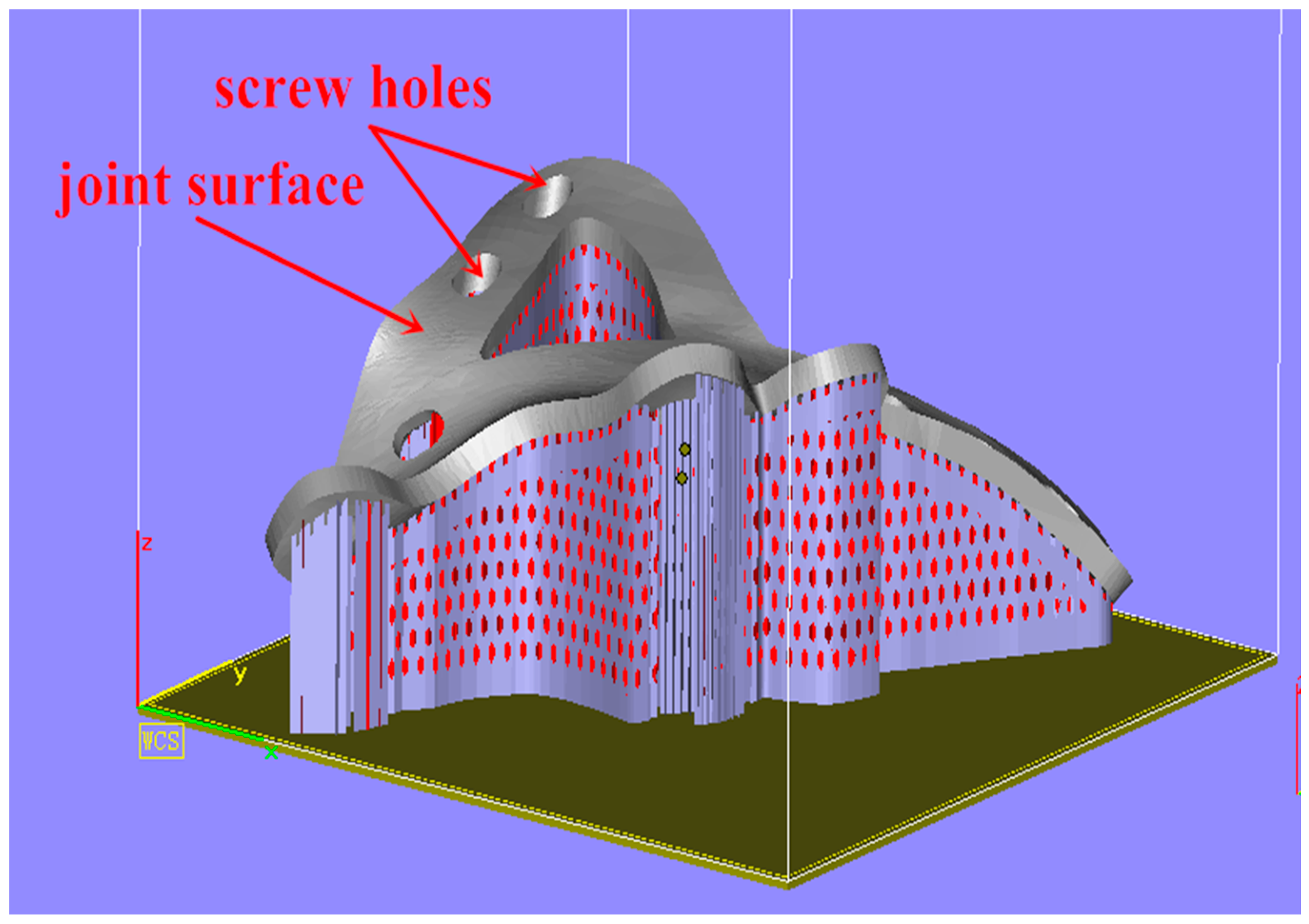

2.5. Procedure E: Fabrication of Screw Holes of the Customized Bone Plate

2.6. Procedure F: Finishing of the Edge of Customized Bone Plate

3. Experimental Methods

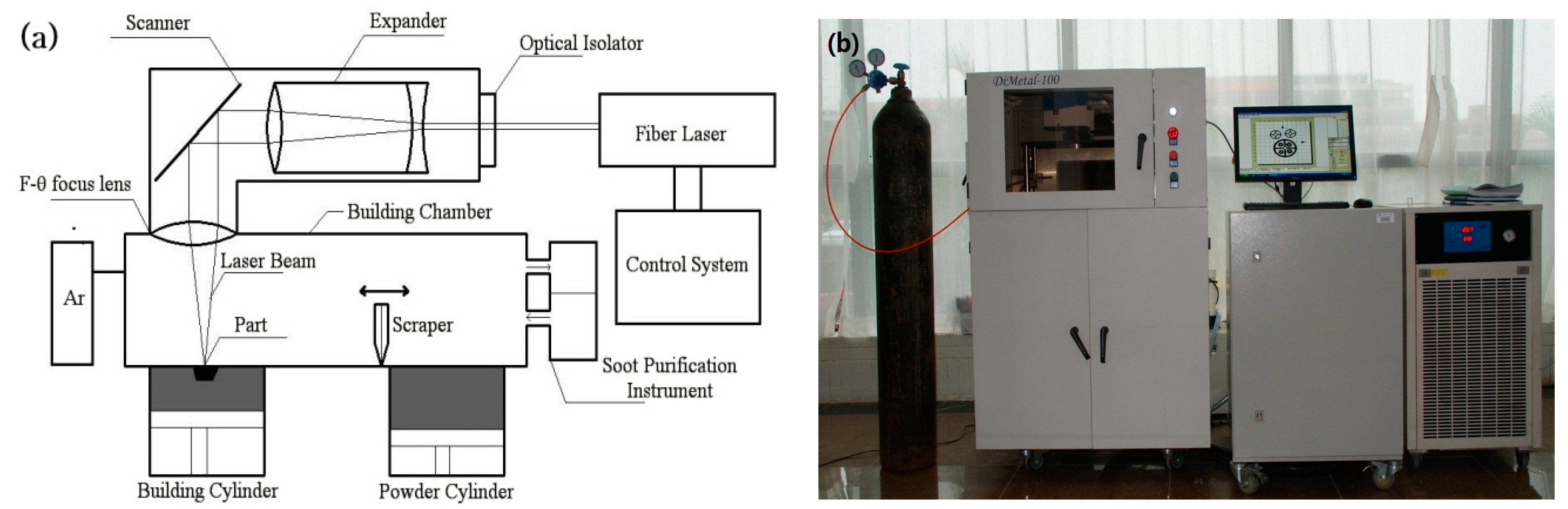

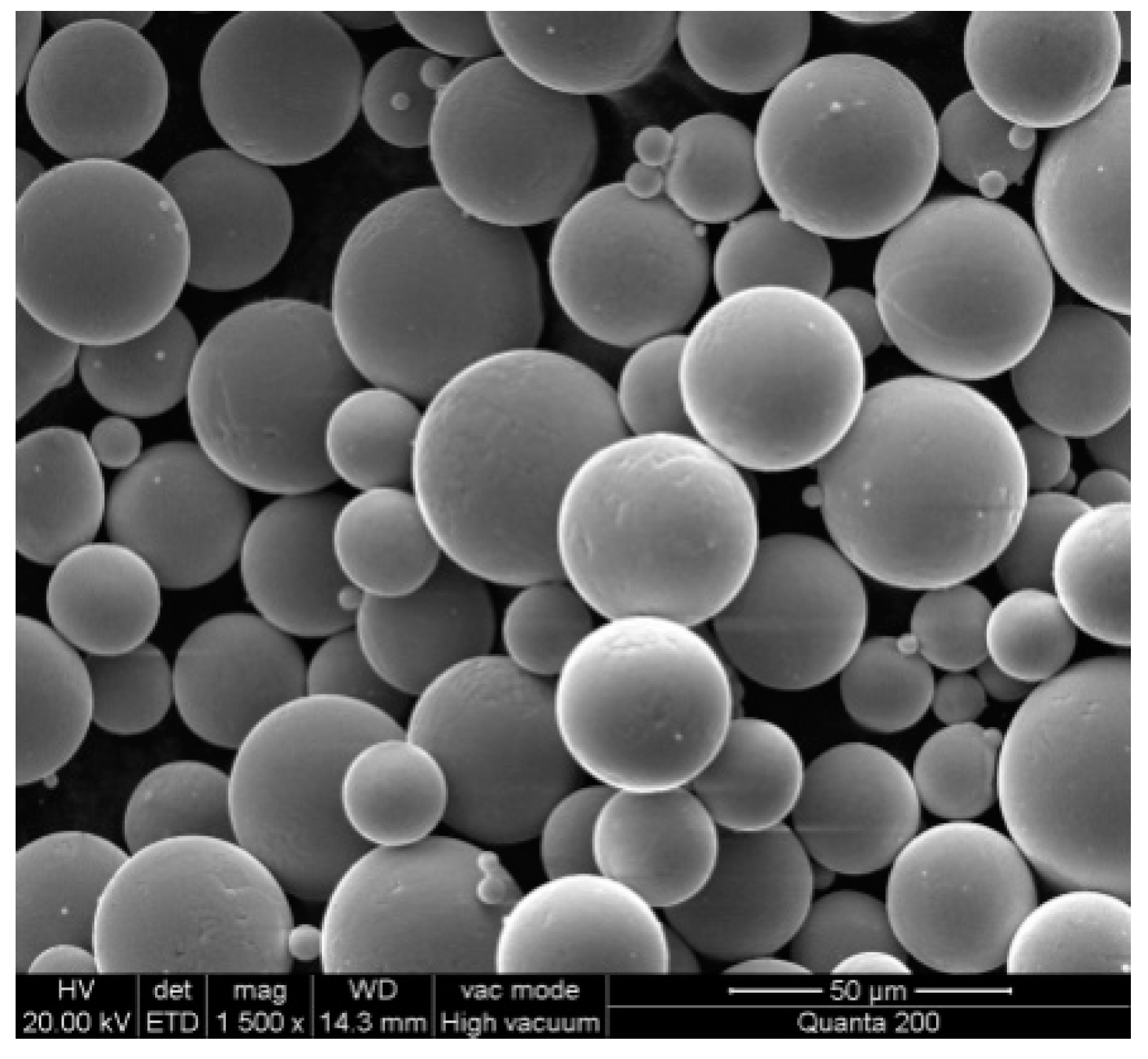

3.1. Processing Optimization of Metal 3D Printing Devices and Materials

3.2. Experimental Procedure

3.3. Test Methods

4. Results and Discussion

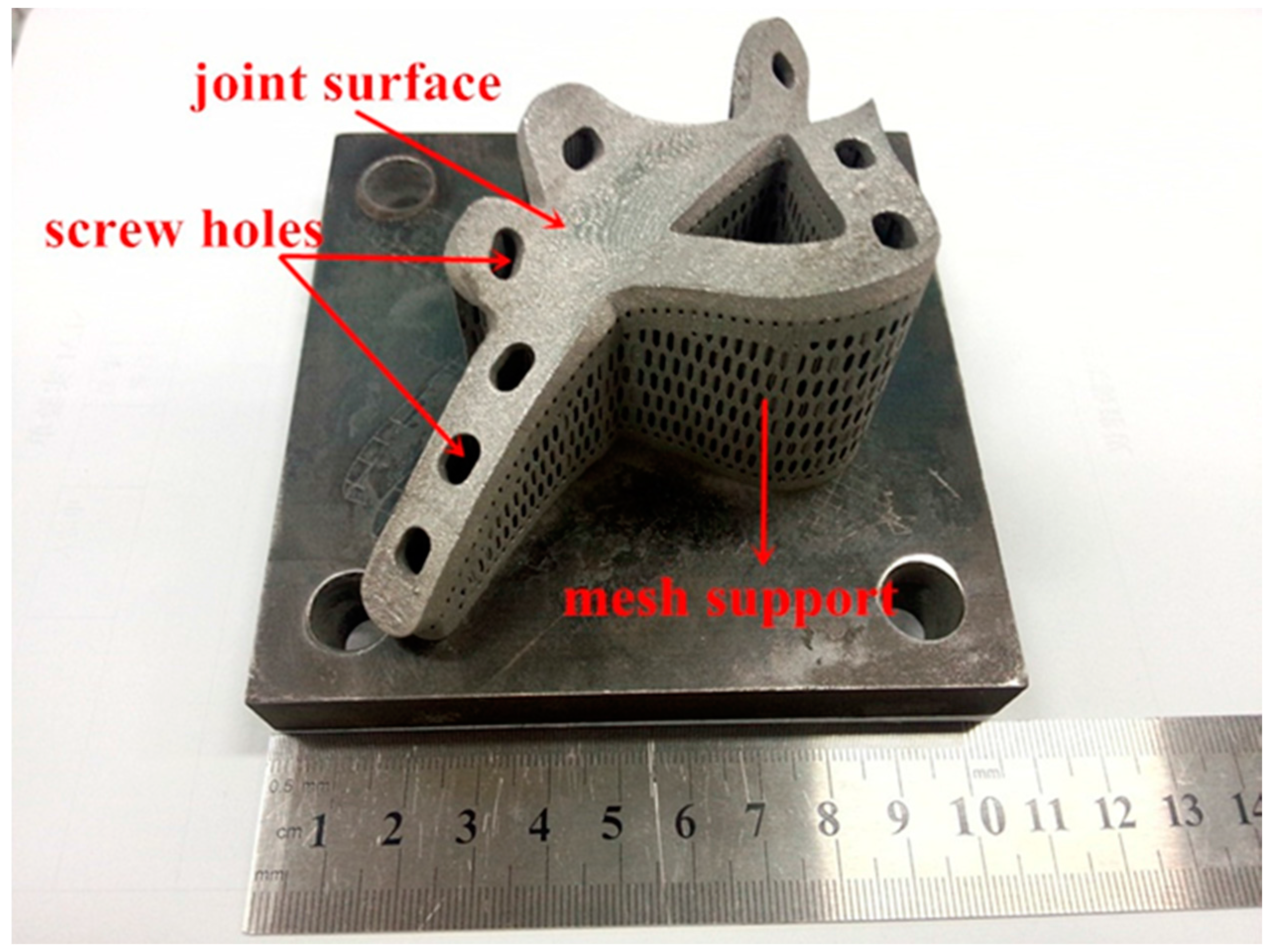

4.1. SLM Processing and Heat Treatment of Customized Bone Plate

4.2. Measurement of Mechanical Properties of Customized Bone Plate

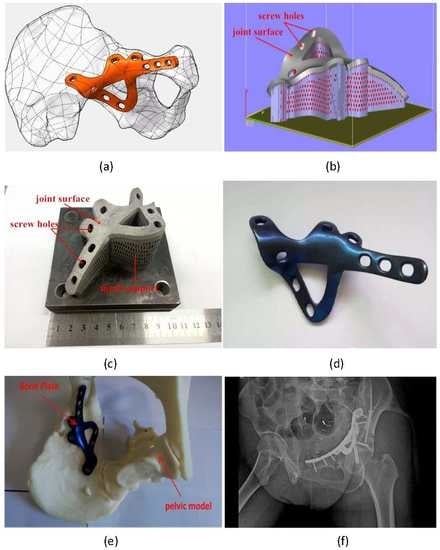

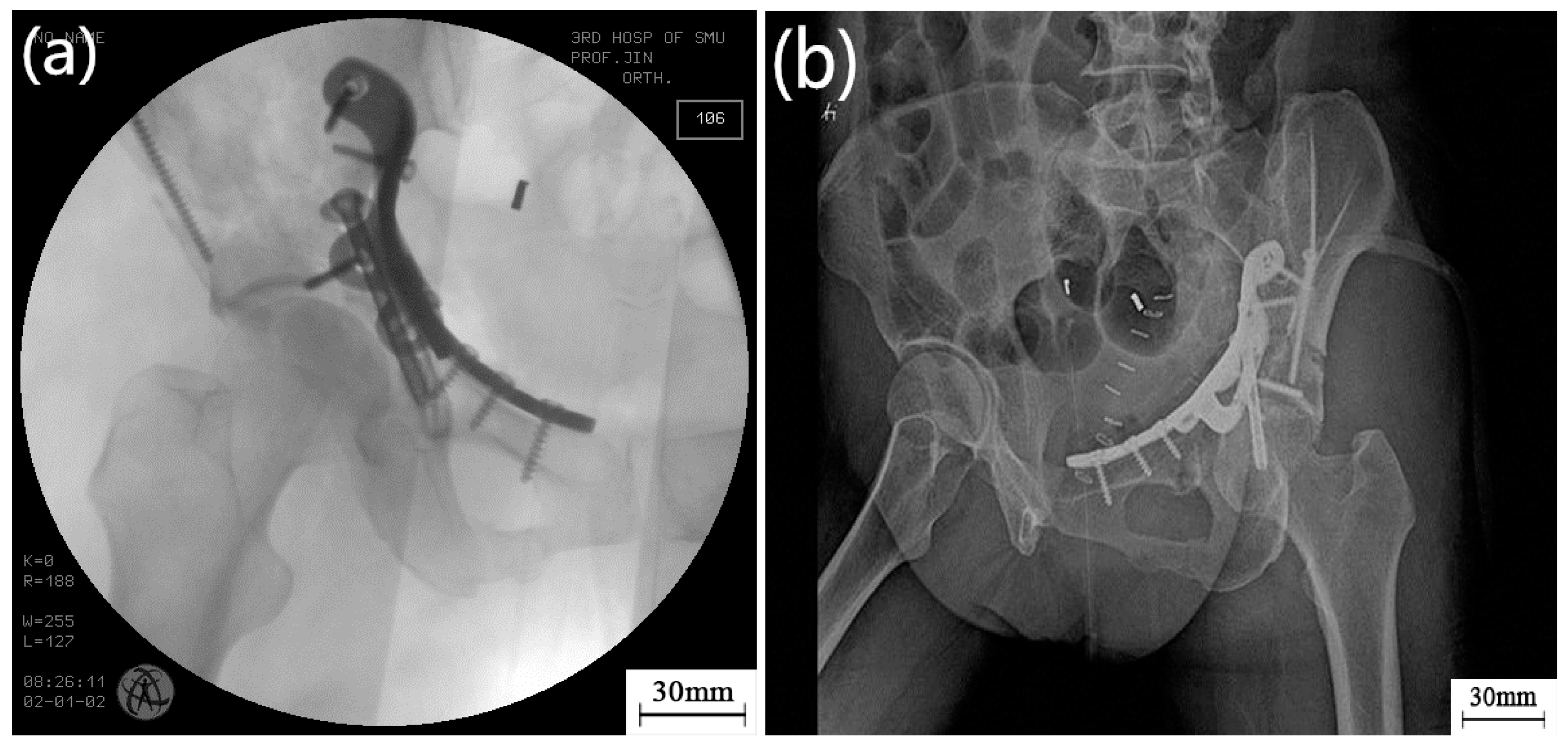

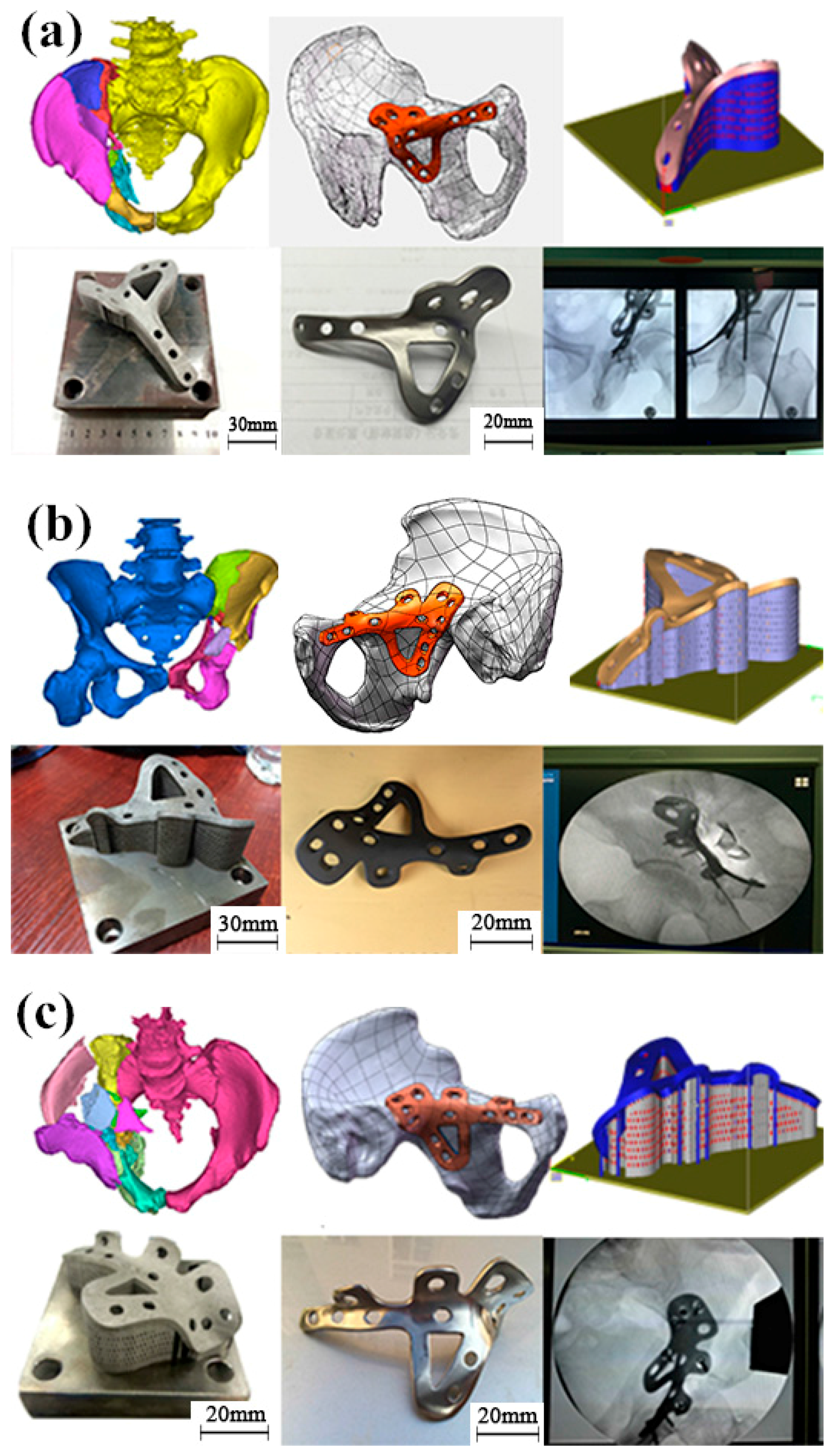

4.3. Pre-Operative Simulation and Clinical Application

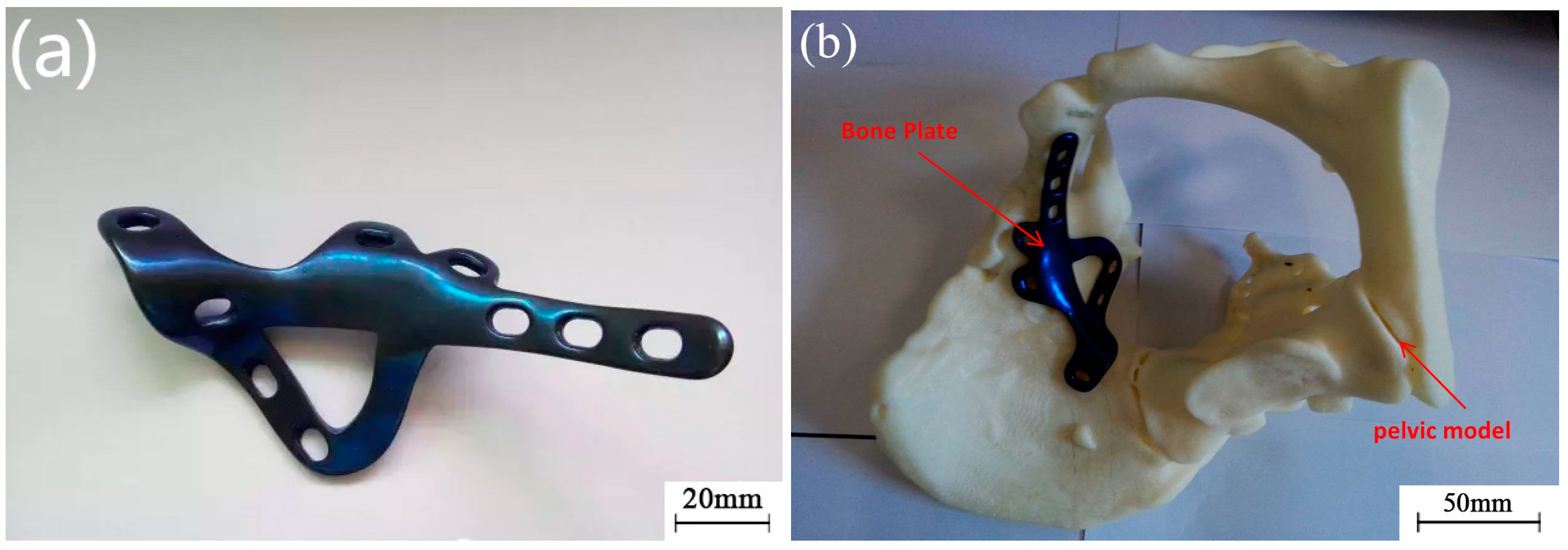

4.3.1. Surface Treatment and Pre-Operative Simulation

4.3.2. Clinical Application of Customized Bone Plate

4.4. Discussion

4.4.1. Improved Design of Customized Bone Plate

4.4.2. Improvement of SLM Fabrication Processing of a Customized Bone Plate

4.4.3. Clinical Applications of the Customized Bone Plate after Improvement

5. Conclusions

- Key procedures in designing customized bone plates included: (1) extraction of the CT data of the pelvis; (2) generation of a pelvic model; (3) fabrication of the initial shape of the bone plate; (4) determination of the shape and thickness of the bone plate; (5) generating of the screw holes; and (6) printing of the final bone plate model.

- In order to guarantee the surface quality of the attaching face between bone plate and bone, the attaching surface of the plate was oriented upwards and a cone-type support added to the lower surface to improve heat conductivity during the SLM fabricating process. Heat treatment in vacuum was employed to eliminate residual stress to prevent the bone plate from deforming after fabrication. Following heat treatment the plate had a hardness of HV1 360–390, an ultimate tensile strength of 1000–1100 MPa, yield strength of 900–950 MPa, and an elongation of 8%–10%, thus satisfying operating requirements.

- The customized bone plate was used in a clinical operation. Matching of the customized bone plate and broken pelvis was confirmed by intra operative C-arm and X-ray imaging following surgery, which not only fixed the broken bone blocks, but also guided pelvis restoration. Operating time was reduced to about 2 h.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lund, T.; Laine, T.; Österman, H.; Yrjönen, T.; Schlenzka, D. Accuracy of computer assisted pedicle screw insertion: The evidence. J. Bone Jt. Surg. Br. 2012, 21, 247–255. [Google Scholar]

- Ryken, T.C.; Owen, B.D.; Christensen, G.E.; Reinhardt, J.M. Image-based drill templates for cervical pedicle screw placement. J. Neurosurg. Spine 2009, 10, 21–26. [Google Scholar] [CrossRef] [PubMed]

- Melkent, T.; Foley, K.T.; Estes, B.T.; Chaudoin, J. Image Guided Spinal Surgery Guide, System, and Method for Use Thereof. U.S. Patent 6,348,058, 19 February 2002. [Google Scholar]

- Malik, H.H.; Darwood, A.R.; Shaunak, S.; Kulatilake, P.; El-Hilly, A.A.; Mulki, O.; Baskaradas, A. Three-dimensional printing in surgery: A review of current surgical applications. J. Surg. Res. 2015, 199, 512–522. [Google Scholar] [CrossRef] [PubMed]

- Martelli, N.; Serrano, C.; van den Brink, H.; Pineau, J.; Prognon, P.; Borget, I.; El Batti, S. Advantages and disadvantages of 3-dimensional printing in surgery: A systematic review. Surgery 2016, 159, 1485–1500. [Google Scholar] [CrossRef] [PubMed]

- Condino, S.; Carbone, M.; Ferrari, V.; Faggioni, L.; Peri, A.; Ferrari, M.; Mosca, F. How to build patient-specific synthetic abdominal anatomies. An innovative approach from physical toward hybrid surgical simulators. Int. J. Med. Robot. Comput. Assist. Surg. 2011, 7, 202–213. [Google Scholar] [CrossRef] [PubMed]

- Tam, M.D.; Laycock, S.D.; Bell, D.; Chojnowski, A. 3-D printout of a DICOM file to aid surgical planning in a 6 year old patient with a large scapular osteochondroma complicating congenital diaphysealaclasia. J. Radiol. Case Rep. 2012, 6, 31–37. [Google Scholar] [PubMed]

- Birnbaum, K.; Schkommodau, E.; Decker, N.; Prescher, A.; Klapper, U.; Radermacher, K. Computer-assisted orthopedic surgery with individual templates and comparison to conventional operation method. Spine 2001, 26, 365–370. [Google Scholar] [CrossRef] [PubMed]

- Engel, M.; Bodem, J.P.; Hoffmann, J.; Freudlsperger, C. Reconstruction of a near-total nasal defect using a precontoured titanium mesh with a converse scalping flap. J. Craniofac. Surg. 2012, 23, e410–e412. [Google Scholar]

- Sugimoto, M.; Lee, S.Y.; Sakai, Y.; Nishida, K.; Kuroda, R.; Kurosaka, M. Tactile surgical navigation system for complex acetabular fracture surgery. Orthopedics 2014, 37, 237–242. [Google Scholar]

- Harrysson, O.L.A.; Marcellin-Little, D.J.; Horn, T.J. Applications of metal additive manufacturing in veterinary orthopedic surgery. JOM 2015, 67, 647–654. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Bartolo, P.; Kruth, J.P.; Silva, J.; Levy, G.; Malshe, A.; Rajurkar, K.; Leu, M. Biomedical production of implants by additive electro-chemical and physical processes. CIRP Ann.-Manuf. Technol. 2012, 61, 635–655. [Google Scholar] [CrossRef]

- Laird, A.; Keating, J.F. Acetabular fractures: A 16-year prospective epidemiological study. J. Bone Jt. Surg. Br. 2005, 87, 969–973. [Google Scholar] [CrossRef] [PubMed]

- Madhu, R.; Kotnis, R.; Al-Mousawi, A.; Barlow, N.; Deo, S.; Worlock, P.; Willett, K. Outcome of surgery for reconstructionof fractures of the acetabulum- the time dependent effect of delay. J. Bone Jt. Surg. Br. 2006, 88, 119–203. [Google Scholar]

- Letournel, E. The treatment of acetabular fractures through the ilioinguinalapproach. Clin. Orthop. Relat. Res. 1993, 292, 62–76. [Google Scholar]

- Matta, J.M. Operative treatment of acetabular fractures through the Ilioinguinal approach a 10-year perspective. Clin. Orthop. Relat. Res. 1994, 305, 10–19. [Google Scholar] [CrossRef]

- Kinik, H.; Armangil, M. Extensile triradiate approach in the management of combined acetabular fractures. Arch. Orthop. Trauma Surg. 2004, 124, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. In Proceedings of the ASME/ISCIE 2012 International Symposium on Flexible Automation, St. Louis, MO, USA, 18–20 June 2012; pp. 507–515.

- Do, D.K.; Li, P. The effect of laser energy input on the microstructure, physical and mechanical properties of Ti-6Al-4V alloys by selective laser melting. Virtual Phys. Prototyp. 2016, 11, 41–47. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion; ASTM F2924-14; ASTM International: West Conshohocken, PA, USA, 2014.

- Vrancken, B.; Thijs, L.; Kruth, J.P.; van Humbeeck, J. Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E. Selective laser melting of titanium alloy with 50 wt % tantalum: Microstructure and mechanical properties. J. Alloys Compd. 2016, 660, 461–470. [Google Scholar] [CrossRef]

- Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications; Standard A. F136; ASTM International: West Conshohocken, PA, USA, 2003.

- Basalah, A.; Shanjani, Y.; Esmaeili, S.; Toyserkani, E. Characterizations of additive manufactured porous titanium implants. J. Biomed. Mater. Res. Part B 2012, 100, 1970–1979. [Google Scholar] [CrossRef] [PubMed]

- Gu, D.; Hagedorn, Y.C.; Meiners, W.; Meng, G.; Batista, R.J.S.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

| Element | Composition (%) | ASTMF2924 (%) [22] | Element | Composition (%) | ASTMF2924 (%) [22] |

|---|---|---|---|---|---|

| Al | 6.0 | 5.50–6.75 | N | 0.012 | <0.05 |

| V | 3.90 | 3.50–4.50 | H | 0.0022 | <0.015 |

| Fe | 0.044 | <0.3 | Y | 0 | <0.005 |

| O | 0.10 | <0.2 | Ti | Balance | Balance |

| C | 0.013 | <0.08 | other | <0.03 | <0.4 |

| Laser Power (W) | Scanning Speed (mm/s) | Scanning Space (µm) | Layer Thickness (µm) | Spot Diameter (µm) |

|---|---|---|---|---|

| 150 | 600 | 80 | 40 | 70 |

| Comparision Items | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV1) |

|---|---|---|---|---|

| 3D printing (before heat treatment) | 1288.70 ± 6.44 | 1063.99 ± 5.32 | 6.43 ± 0.03 | 373 ± 1.9 |

| 3D printing (after heat treatment) | 1081.42 ± 5.41 | 925.26 ± 4.63 | 8.11 ± 0.04 | 367 ± 1.9 |

| standard cast part [22] | >895 | >825 | >6 | 320 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Wang, Y.; Wu, S.; Lin, H.; Yang, Y.; Fan, S.; Gu, C.; Wang, J.; Song, C. Customized a Ti6Al4V Bone Plate for Complex Pelvic Fracture by Selective Laser Melting. Materials 2017, 10, 35. https://doi.org/10.3390/ma10010035

Wang D, Wang Y, Wu S, Lin H, Yang Y, Fan S, Gu C, Wang J, Song C. Customized a Ti6Al4V Bone Plate for Complex Pelvic Fracture by Selective Laser Melting. Materials. 2017; 10(1):35. https://doi.org/10.3390/ma10010035

Chicago/Turabian StyleWang, Di, Yimeng Wang, Shibiao Wu, Hui Lin, Yongqiang Yang, Shicai Fan, Cheng Gu, Jianhua Wang, and Changhui Song. 2017. "Customized a Ti6Al4V Bone Plate for Complex Pelvic Fracture by Selective Laser Melting" Materials 10, no. 1: 35. https://doi.org/10.3390/ma10010035

APA StyleWang, D., Wang, Y., Wu, S., Lin, H., Yang, Y., Fan, S., Gu, C., Wang, J., & Song, C. (2017). Customized a Ti6Al4V Bone Plate for Complex Pelvic Fracture by Selective Laser Melting. Materials, 10(1), 35. https://doi.org/10.3390/ma10010035