Abstract

This paper investigated the prospects of biodiesel production from macadamia oil as an alternative fuel for diesel engine. The biodiesel was produced using conventional transesterification process using the base catalyst (KOH). A multi-cylinder diesel engine was used to evaluate the performance and emission of 5% (B5) and 20% (B20) macadamia biodiesel fuel at different engine speeds and full load condition. It was found that the characteristics of biodiesel are within the limit of specified standards American Society for Testing and Materials (ASTM D6751) and comparable to diesel fuel. This study also found that the blending of macadamia biodiesel–diesel fuel significantly improves the fuel properties including viscosity, density (D), heating value and oxidation stability (OS). Engine performance results indicated that macadamia biodiesel fuel sample reduces brake power (BP) and increases brake-specific fuel consumption (BSFC) while emission results indicated that it reduces the average carbon monoxide (CO), hydrocarbons (HC) and particulate matter (PM) emissions except nitrogen oxides (NOx) than diesel fuel. Finally, it can be concluded that macadamia oil can be a possible source for biodiesel production and up to 20% macadamia biodiesel can be used as a fuel in diesel engines without modifications.

1. Introduction

The price hiking of petroleum derived fossil fuel and the depletion of the reserve of those fuels have attributed to the necessity of alternative fuel research [1]. Biodiesel is one of the alternative fuels that is produced from vegetable oils, animal fats and waste cooking oil through transesterification process [2,3,4]. Biodiesel is renewable [5], biodegradable [6] and non-toxic, which have the potential to reduce environment pollution and global warming significantly [7,8]. From the last decades, researchers have been trying to find out the biodiesel sources and already there are more than 350 oil-bearing crops that have been introduced to produce biodiesel [9,10]. The conventional biodiesel sources are palm, jatropha, coconut, sunflower, soybean, rapeseed, jojoba, neem, karanja, calophyllum, moringa, cotton, castor oil, and microalgae [11,12,13,14,15]. The feedstocks of biodiesel should be chosen from the sources that are locally available, easily accessible, and economically feasible and technically viable [16].

Australia is increasingly reliant on imported transportation fuel. The increasing demand and dependency on foreign fossil fuel and environmental concerns prompt to the need to explore opportunities to locally produced alternative sources such as biodiesel [17]. The Federal Government and State Governments have developed relevant policies to promote sustainable biodiesel industry to ensure Australian’s long-term energy security. In this context, the research on Macadamia Integrifolia (M. Integrifolia) oil is paramount as this oil has native distribution as well as is available in Australia. macadamia belongs to Proteaceous family and is widely available in New South Wales and central Queensland, which could be considered as a potential alternative source to produce biodiesel [18,19]. The fruits of macadamia are very hard and woody with a pointed apex containing one or two seeds. The seeds are brown in colour, and it is the only part that contains oil. The oil contents of seed are around 70% with golden yellow in colour [20]. Currently, the area under macadamias is almost 18,666 ha and Production for 2014 was estimated at 11,400 t kernel. Nearly 400,000 trees were established in the last five years. There are currently around six million macadamia trees under cultivation; about a third of these are yet to reach full production. By 2020, about 20,000 ha are will be planted to produce more than 16,000 t kernel and it is expected that the export value will be more than $165 million. There are 35% of total production consumes in the local market in which 90% is sold as a kernel. Through the Australian Government’s National Residue Survey, the Australian macadamia industry can demonstrate 15 years of 100% compliance with all relevant standards [21].

Many researchers [22] around the world studied the production of biodiesel from different sources, but a very few researcher [20] studied the production of macadamia biodiesel. Yunus et al. [22] studied the potential of biodiesel production from Ceiba pentandra (C. pentandra) and Nigella sativa (N. sative) oil. They reported that the fuel properties of the C. pentandra biodiesel showed better fuel properties namely flash point (FP), calorific value and viscosity while N. sativa exhibited excellent cold flow properties and oxidation stability (OS). Silitonga et al. [1] studied the potential of biodiesel production from Schleichera oleosa oil. They reported that biodiesel from Schleichera oleosa oil could be used in diesel engine due to its properties. Knothe [20] studied the production of biodiesel from macadamia oil but the details data on macadamia biodiesel–diesel blend is not presented in his study. Similarly, there are many studies [23,24,25,26,27] found on the evaluation of different edible and non-edible oil biodiesel in diesel engines, but there is a lack of research on the on the assessment of macadamia biodiesel performance in diesel engines. Tesfa et al. [27] studied the emission behaviour of different biodiesel from various sources in a multi-cylinder diesel engine. They found that the engine running with biodiesel blends gave up to 20% higher nitrogen oxides (NOx) emission than diesel fuel. Other emissions result using neat biodiesel (B100) indicates that pure biodiesel reduces up to 15% carbon monoxide (CO), 40% CO2 and 30% total hydrocarbon (THC) emissions, respectively than diesel fuel. Yoon et al. [28] studied the performance, emission, and combustion of canola biodiesel in a common rail diesel engine. Their studies indicate that over the entire range of speed, the brake-specific fuel consumption (BSFC) of canola biodiesel was increased while the CO and particulate matter (PM) emissions were significantly decreased. Other emissions like NOx emission increased slightly. The blending ratio had an influence on the engine emissions.

The objective of this study is to investigate the potential of macadamia oil as an alternative source along with the evaluation of the 5% and 20% macadamia biodiesel–diesel blends in a diesel engine. The fuel properties of produced biodiesel and its blend with diesel fuel were also analysed according to ASTM standards. The effect of macadamia biodiesel–diesel blending on fuel properties has been reported too.

2. Materials and Method

2.1. Materials

Crude macadamia oil was purchased from Coles, North Rockhampton, Australia. All other reagents, methanol, filter paper 150 mm were available in our chemical laboratory, Central Queensland University (North Rockhampton, Australia).

2.2. Biodiesel Fuel Production Procedure

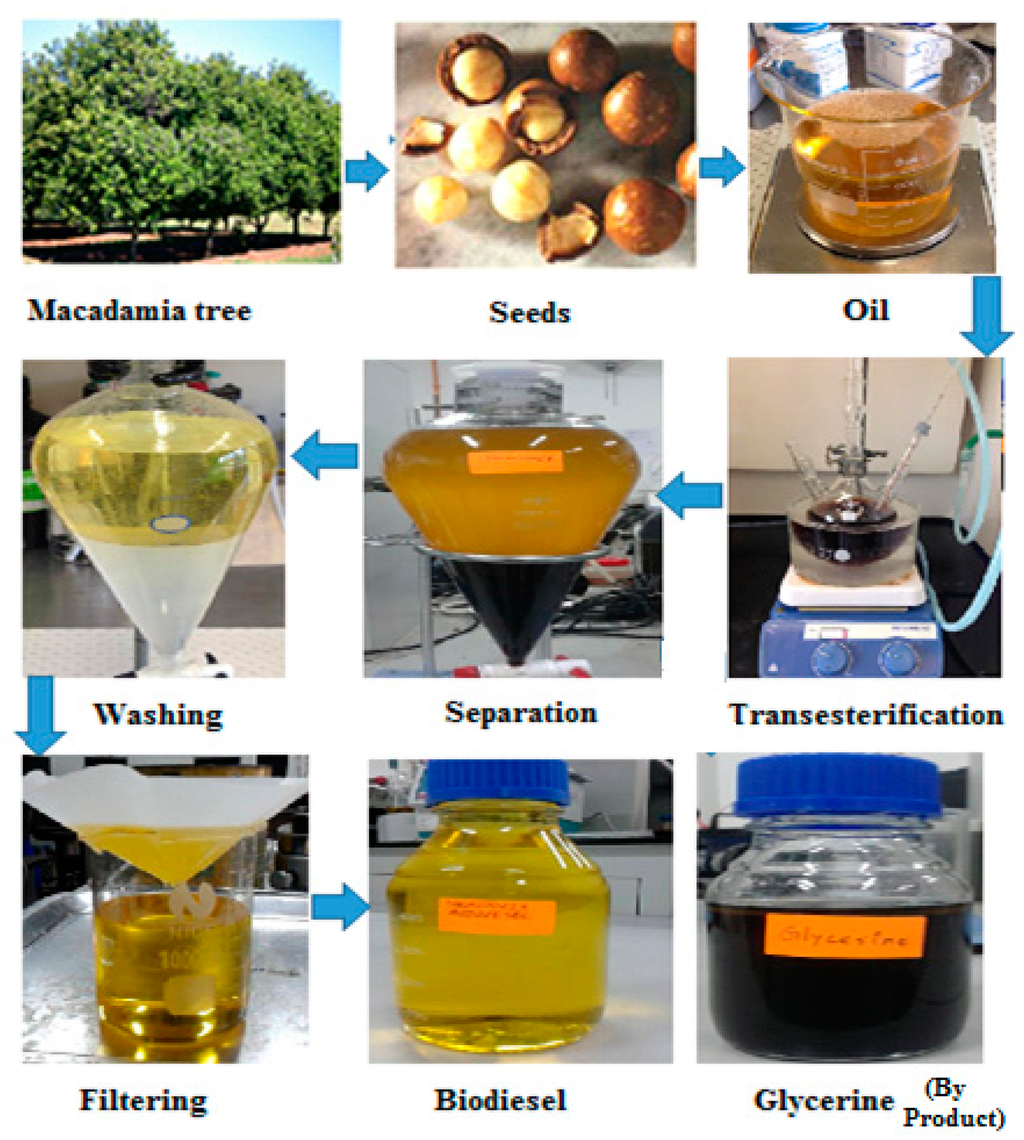

In this study, a small-scale three-neck laboratory reactor 1 L in size equipped with reflux condenser, thermometer, and magnetic stirrer was used to produce biodiesel from crude macadamia oil. The free fatty acid of crude oil was found around two, which indicate that esterification is not necessary to produce biodiesel. For this reason, biodiesel was produced through only the transesterification process. Figure 1 shows the production process of macadamia biodiesel. In this process, 1 L of preheated crude macadamia oil was reacted with 6:1 molar ratio of methanol to oil in the presence of 1% (w/w) of KOH catalyst. The reaction was maintained at 60 °C for 2 h at 800 rpm. After completion of the reaction, the mixture was poured into a separation funnel for 14 h to be cooled, settled and separated glycerol from biodiesel. The upper part of the funnel contains biodiesel, and the bottom was glycerine, which contains excess methanol and impurities. The biodiesel was collected, and the glycerine was drawn off. The produced biodiesel was then heated at 65 °C to remove any remaining methanol. Then, the biodiesel was washed using warm distilled water to remove all impurities. Finally, the washed biodiesel was dried using Na2SO4 and filtered through a filter paper. Then the final product was collected and stored for characterization. The biodiesel yield was more than 90%, which was calculated using following Equation:

Figure 1.

Production of macadamia biodiesel.

2.3. Biodiesel–Diesel Blending

The produced biodiesel was then blended with diesel fuel in a beaker glass through magnetic stirrer with maintaining speed at 2000 rpm for 30 min. In this study, biodiesel was blended with diesel fuel at a ratio of 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80% and 90% by volume to examine the blending effect on fuel properties.

2.4. Characterization of Biodiesel Fuel

The physico-chemical properties of the crude oil, biodiesel and biodiesel–diesel blend were tested according to the ASTM D6751 standards. Table 1 shows the list of the equipment used in this study to characterise the biodiesel. Fatty acid composition was tested using gas chromatography (Agilent 6890 model, Wilmington, DE 19808-1610 USA). Fourier transform infrared (FT-IR) was done using a Perkin Elmer biodiesel FAME analyser equipped with the MIR TGS detector in the range of 4000–400 cm−1. Cetane number (CN), iodine value (IV), saponification value (SV), degree of unsaturation (DU) and long chain saturated factor (LCSF) was determined using the following Equations [29]:

where Ai is the percentage of each component, D is the number of double bond and Mw is the molecular mass of each component.

CN = 46.3 + (5458/SV) − (0.225 × IV)

SV = ∑(560 × Ai)/Mwi

IV = ∑(254 × Ai × D)/Mwi

LCSF = 0.1 × (C16:0, wt %) + 0.5 × (C18:0 wt %) +1 × (C20:0 wt %) + 1.5 × (C22:0 wt %) + 2.0 × (C24:0 wt %)

DU = ∑(MUFA + 2 × PUFA)

Table 1.

List of equipment used in this study. OS: oxidation stability; KV: kinematic viscosity; D: density; FP: flash point.

2.5. Engine Test

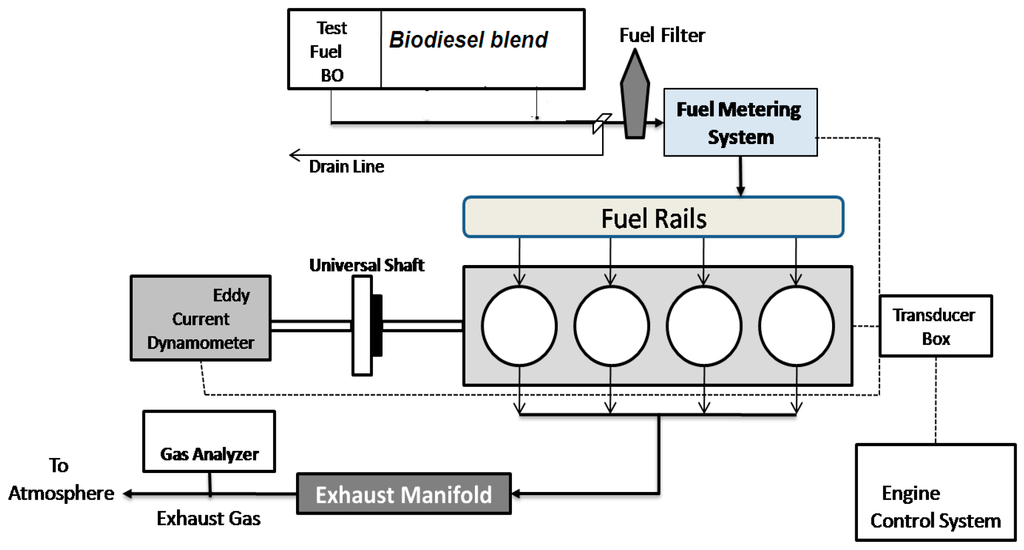

A multi-cylinder diesel engine (model V3300, Kubota Tractor Australia PTY Ltd., Victoria, Australia) was used to perform the performance and emission test. In the performance and emission study, B5 and B20 fuels have been used based on the suggestion from the literature [30,31] that up to 20% biodiesel can be used in a diesel engine with no modifications. Engine performance data were collected at full load condition and at different speeds ranging from 1200 rpm to 2400 rpm at an interval of 100 rpm, whereas emission data were collected only at idle speed (800 rpm) and the speed at which maximum torque was found (1400 rpm). First, the engine was run using diesel fuel for a few minutes to warm up before switching to the biodiesel blend. Furthermore, the engine was run with diesel fuel before it was shut down. Figure 2 shows the engine test bed and Figure 3 shows the schematic diagram of the engine test bed. Table 2 shows the specifications of the engine used in this study. A CODA 5 exhaust gas analyser (Coda Products Pty Ltd., Hamilton, Asutralia) was used to measure the NOx, hydrocarbons (HC), and CO emissions from the engine and A MPM-4M particulate monitor (Pacific Data System, Queensland, Australia) was used to measure the PM emission.

Figure 2.

Engine test bed used in this study.

Figure 3.

Schematic diagram of the engine test bed.

Table 2.

The specifications of the engine used in this study.

3. Results and Discussion

3.1. Crude Oil Properties

The crude oil from macadamia was characterised by viscosity, density, FP, acid value, and higher heating value (HHV). The properties of macadamia oil are presented in Table 3. The viscosity of crude oil was found 39.22 mm2/s, which is 11–12 times greater than conventional diesel fuel. The FP, pour point, and cold filter plugging point was 167.5 °C, 8 °C, and 9 °C, respectively. The acid value was determined as 4 mg·KOH/g, which is similar to other conventional biodiesel feedstocks.

Table 3.

Properties of crude macadamia oil.

3.2. Characteristics of Macadamia Biodiesel Fuel

The fuel properties of macadamia biodiesel were analysed and compared with diesel and ASTM D6751 standards. Table 4 shows the fuel properties of macadamia biodiesel. It was found that the kinematic viscosity (KV) of macadamia is 4.46 mm2/s and the acid value lowered to 0.07 mg·KOH/g. However, all these results are within the specified limit ASTM D6751 standards (1.9–6 mm2/s). The FP was found 178.5 °C, which is much higher than diesel fuel (68.5 °C) that indicates macadamia biodiesel fuel is safer to handle and storage. The OS and HHV of macadamia biodiesel were found 3.35 h and 39.90 MJ/kg, respectively.

Table 4.

Properties of macadamia biodiesel compared to other fuels.

3.2.1. Fatty Acid Composition

Fatty acids are categorised into saturated and unsaturated fatty acid. A fatty acid that does not contain double bond is known as saturated fatty acid, and that contains double bond is known as unsaturated fatty acid. Table 5 shows the fatty acid composition of macadamia oil. It can be seen that macadamia biodiesel has 15.80% saturated and 82.60% unsaturated fatty acids. Oleic acid (18:1) was the predominant fatty acid (61.3%) in macadamia biodiesel sample. The degree of unsaturation and long chain saturated factor was found 84.50 and 7.24, respectively.

Table 5.

Fatty acid composition of macadamia biodiesel. DU: degree of unsaturation; LCSF: long chain saturated factor.

3.2.2. Fourier Transform Infrared Analysis

Macadamia biodiesel was also characterised using FT-IR to identify the characteristics peaks. The resolution was 4 cm-1 and eight scans. Figure 4 shows the FT-IR spectrum of the macadamia biodiesel. FT-IR spectra shows the characteristics peaks of biodiesel at 2925–2854 cm−1 due to C–H stretching vibration and CH2 asymmetric and symmetric vibration, respectively; 1742 cm−1 equivalent to C=O stretching vibration; 1459 cm−1 equivalent to CH2 shear vibration; 1357 cm−1 equal to CH3 bending vibration; 1168 cm−1 equivalent to C–O–C symmetric stretching vibration; and 1019 cm−1 equivalent to C–O–C antisymmetric stretching vibration. This result reflects the conversion of triglycerides to the methyl ester.

Figure 4.

Fourier transform infrared (FT-IR) Spectrum of macadamia biodiesel.

3.2.3. Properties of Biodiesel–Diesel Blending

The blending of fossil diesel fuel with biodiesel is an important idea to improve the properties of biodiesel fuel as it is reported that diesel fuel contains zero oxygen [33]. Macadamia has poor OS, which could be improved by blending with diesel fuel. In Table 6, it can be seen that stability performance of all the blends increased with the addition of diesel fuel with biodiesel and all values are within the specified limits of both ASTM D6751 (3 h) and EN14112 (6 h). The properties result of macadamia biodiesel–diesel blends is given in Table 6. All results indicate that by blending biodiesel with diesel fuel offers a significant improvement of biodiesel fuel properties. All the results were found within the ASTM D6751 standards.

Table 6.

Properties of macadamia biodiesel–diesel blends. M. Integrifolia: Macadamia Integrifolia.

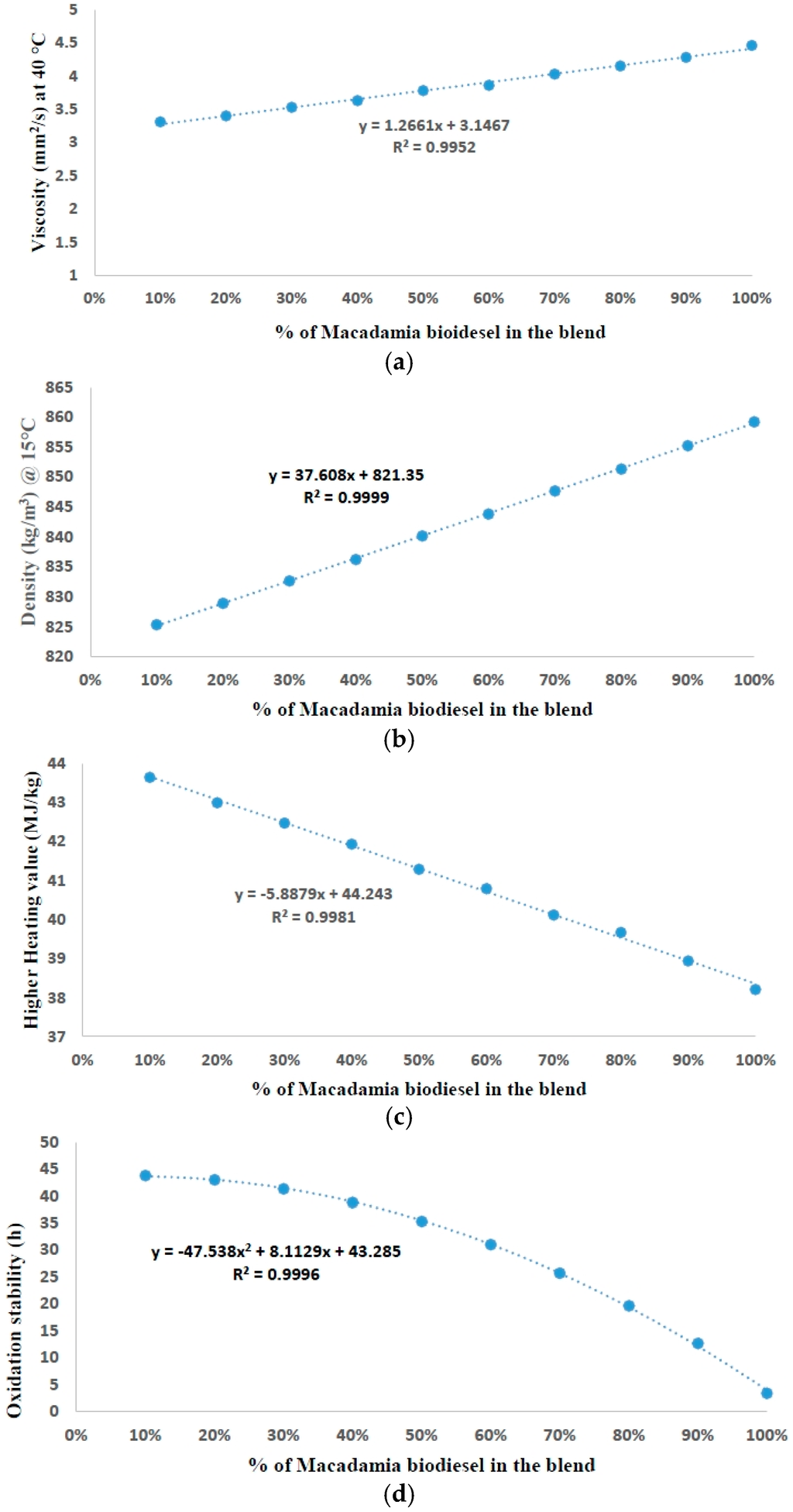

The following empirical equations have been developed from Figure 5a–d to predict the KV, D, HHV and OS of any macadamia–diesel blend (where x denotes % of macadamia biodiesel in the blend).

Figure 5.

Effect of macadamia biodiesel–diesel blending on (a) KV; (b) D; (c) higher heating value (HHV); and (d) OS.

It is seen that the blending has a significant effect on both KV, D, HHV, and OS. For example, the addition of 10% diesel with biodiesel reduced viscosity from 4.45 mm2/s to 4.28 mm2/s. The value of D and KV increases as the percentages of biodiesel in the blends increases, whereas HHV and OS decrease as the percentages of biodiesel increases in the blends as expected. The KV, D and HHV of blends showed a linear relationship with the significant regression (R2) value 0.9952, 0.9999 and 0.9981, respectively, whereas the only OS of blends showed a polynomial relationship with the R2 value of 0.9996. It is evident that macadamia biodiesel–diesel blend significantly improves the KV, D, HHV and OS of biodiesel.

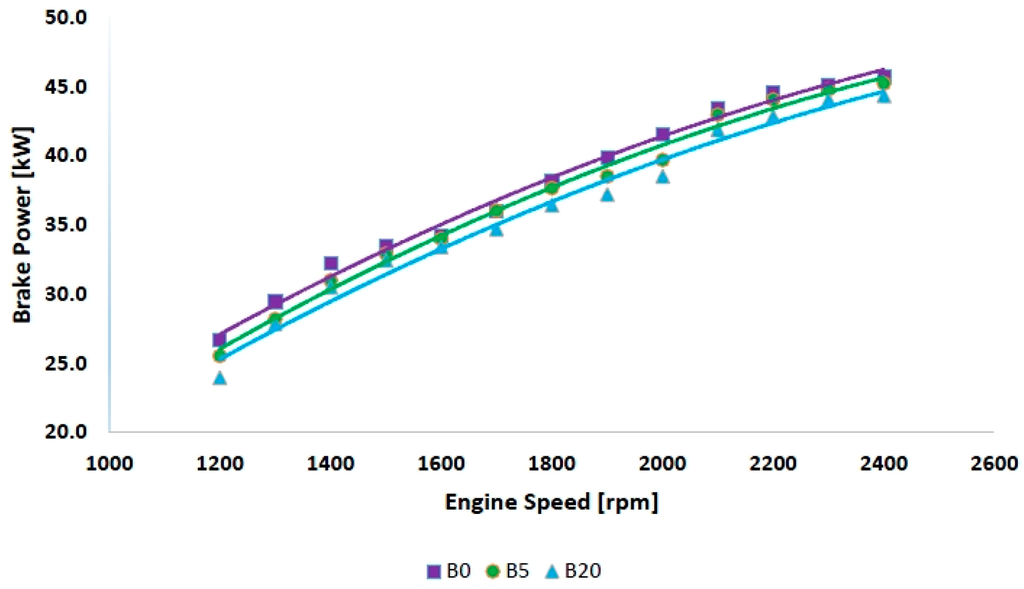

3.3. Brake Power

Figure 6 shows the engine brake power (BP) output of B5 (5% macadamia biodiesel and 95% diesel fuel), B20 (20% macadamia biodiesel and 80% diesel fuel) and B0 (pure diesel fuel) at different engine speeds. Figure 6 clearly shows that brake power for diesel fuel is higher than biodiesel blended fuel, which is also supported by other researchers [23,34]. On average, the highest brake power was found for diesel fuel followed by B5 and B20, 37.7, 37 and 36 kW, respectively. At all test speeds, B5 and B20 fuels reduce the brake power by 2% and 4.56%, respectively. The reduction of BP for biodiesel–diesel blended fuel can be attributed to the HHV of biodiesel fuel [35]. The HHV of macadamia biodiesel is lower than diesel fuel (Table 4).

Figure 6.

Variation of brake power with speeds.

3.4. Brake Specific Fuel Consumption

The properties of fuel such as the calorific value, density, and viscosity play a primary role in engine fuel consumption [25]. Figure 7 shows the BSFC of B5, B20, and B0 at different engine speeds. Figure 7 clearly demonstrates that over the entire range of speed, the macadamia biodiesel–diesel blended fuel gives a higher BSFC than diesel fuel, which is supported by the literature [36]. On average, BSFC of B0, B5 and B20 fuel are 203 g/kWh, 216 g/kWh and 285.2 g/kWh, respectively, and BSFC of B5 and B20 fuels are, respectively, 6% and 28.8% higher than diesel fuel. Higher fuel consumption is the result of higher density and lower calorific value of biodiesel, which causes the higher mass injection for the same volume [37]. The density of macadamia biodiesel is higher and the heating value is lower than the diesel fuel.

Figure 7.

Variation of brake specific fuel consumption with speeds.

3.5. Carbon Monoxide Emission

Figure 8 compares the CO emission of B5, B20, and B0 at different engine speeds. Figure 8 clearly shows that, over the entire range of speed, the macadamia biodiesel fuels provide lower CO emission than diesel fuel, which is supported by other studies [38]. Fuel sample B0 produces 1100 ppm and 2200 ppm CO emissions while B5 produces 1010 ppm and 1950 ppm and B20 produces 600 ppm and 1000 ppm at 800 rpm and 1400 rpm, respectively. At 800 rpm, B5 and B20 reduce CO emission by 8.2% and 45.45%, respectively, whereas they reduce CO emission by 11.3% and 54.54%, respectively, at 1400 rpm compared with diesel fuel. The reason of lowering CO emission for biodiesel-diesel blended fuel can be attributed to the higher oxygen contents and higher cetane number of biodiesel fuel. Biodiesel fuel contains 12% higher oxygen, which allows more carbon molecules to burn and combustion becomes completed [39].

Figure 8.

Variation of carbon monoxides emission with speeds.

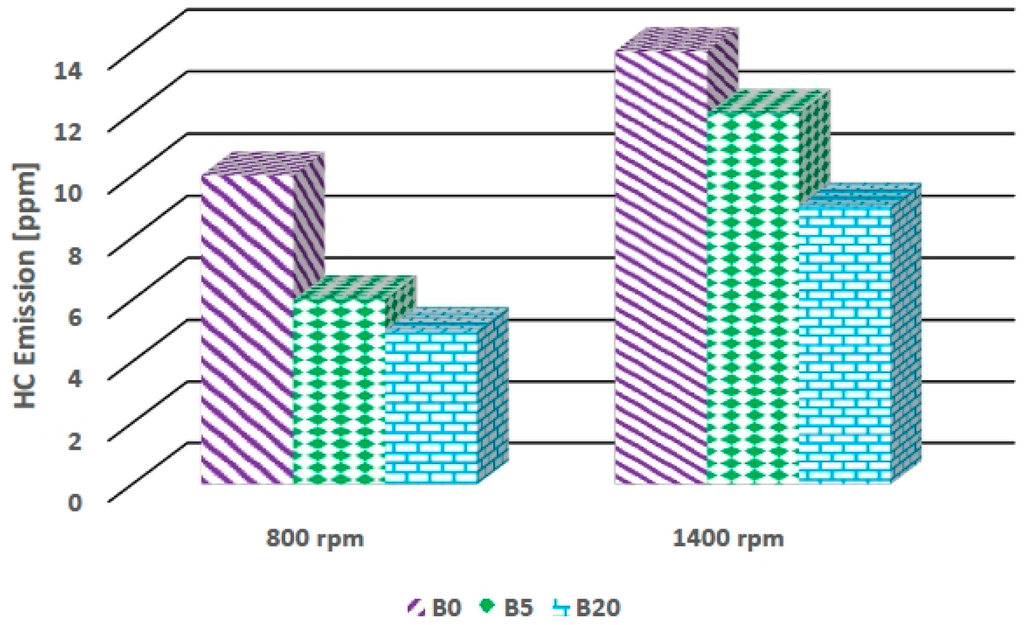

3.6. Hydrocarbon Emission

Figure 9 compares the HC emission of B5, B20, and B0 at different engine speeds. Figure 9 clearly shows that, at all engine speeds, the macadamia biodiesel fuel reduces HC emission significantly than diesel fuel, and this result is in agreement with the results reported by [40]. Fuel sample B0 produces 10 ppm and 14 ppm HC emissions while B5 produces 6 ppm and 12 ppm and B20 produces 5 ppm and 9 ppm at 800 rpm and 1400 rpm respectively. At 800 rpm, B5 and B20 reduce HC emission by 40% and 50%, respectively, whereas they reduce HC emission by 14% and 36%, respectively, at higher engine speed compared with diesel fuel. Lowering HC emission for biodiesel fuel can be explained by the higher oxygen contents and higher cetane number of biodiesel fuel as explained for CO emission [35].

Figure 9.

Variation of hydrocarbon emission with speeds.

3.7. Nitrogen Oxides Emission

Figure 10 compares the NOx emission of B5, B20, and B0 at different engine speeds. It is seen that, over both speed conditions, biodiesel blended fuels increase NOx emission compared to diesel fuel. Özçelik et al. [41] also reported a similar result for NOx emission when they tested camellia biodiesel blend in a diesel engine. Fuel sample B0 produces 111 ppm and 301 ppm NOx emissions while B5 produces 155 ppm and 324 ppm and B20 provides 177 ppm and 336 ppm at 800 rpm and 1400 rpm, respectively. At 800 rpm, B5 and B20 increase NOx emission by 28% and 37%, respectively, whereas they also increase NOx emission by 7% and 10%, respectively, at higher engine speed compared with diesel fuel. Increase in NOx emission for biodiesel fuel can be explained by the advance in combustion and higher oxygen contents of biodiesel fuel [42]. Biodiesel fuel has higher cetane number, which shortens the ignition delay, thereby improving combustion [35].

Figure 10.

Variation of nitrogen oxides emission with speeds.

3.8. Particulate Matter Emission

Figure 11 compares the PM emission of B5, B20, and B0 at different engine speeds. It clearly shows that, at both 800 rpm and 1400 rpm speed, the macadamia biodiesel fuel reduces PM emission significantly compared to diesel fuel, and this result is in agreement with the results reported by Qi et al. [43]. Fuel sample B0 produces 312.2 mg/m3 and 482.1 mg/m3 PM emissions, while B5 produces 285.4 mg/m3 and 447.5 mg/m3 and B20 provides 86.1 mg/m3 and 218 mg/m3 at 800 rpm and 1400 rpm, respectively. At 800 rpm, B5 and B20 reduce PM emission by 8.6% and 72.4%, respectively, whereas they reduce PM emission by 7.2% and 54.8%, respectively, at 1400 rpm compared with diesel fuel. Lowering PM emission for biodiesel fuel can be explained by the higher oxygen contents which help to complete combustion [35] and higher cetane number of biodiesel fuel [44].

Figure 11.

Variation of particulate matter emission with speeds.

4. Error Analysis

Experimental error and uncertainty can be arisen from different ways such as instrument selection, condition, calibration, environment, observation, reading, and test planning. Therefore, uncertainty analysis is required to prove the accuracy of the experiments. Table 7 presents the summary of measurement accuracy and the relative uncertainty of the different measured parameters.

Table 7.

Relative uncertainty for parameters brake power (BP), brake-specific fuel consumption (BSFC), carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx) and particulate matter (PM) emission.

5. Conclusions

In this study, macadamia biodiesel was obtained through transesterification process using the base catalyst (KOH) with the superb conversion efficiency (more than 90% of biodiesel was obtained). It was found that all the physical and chemical properties meet the ASTM D6751 standards. Moreover, the blending of macadamia biodiesel with diesel fuel improves the fuel properties significantly, in particular, the OS. Engine performance study shows that the average brake power for macadamia biodiesel blended fuels are up to 4.6% lower and BSFC values are 28.8% higher than diesel fuel due to the lower calorific value of macadamia biodiesel. Blended fuel also reduces CO emissions up to 54.54%, HC emissions up to 50% and PM emissions by 72.4%, but increases NOx emission (10%) at higher engine speed compared to diesel fuel. The reason could be attributed to the higher oxygen contents and higher cetane number of biodiesel fuel.

Finally, it can be suggested that macadamia oil can be a potential source for biodiesel production and up to 20% macadamia biodiesel can be used as a fuel for diesel engines as a mixture of diesel fuel without any modification.

Acknowledgments

This work was conducted under the International Postgraduate Research Award (IPRA) Scholarship funded by the Central Queensland University, Australia.

Author Contributions

The contributions of each author are as follows: Md Mofijur Rahman produced biodiesel, collected experimental data, analysed the numerical results, drafted and revised the manuscript; Mohammad Rasul contributed to the experimental design and thoroughly revised the paper; Nur Md Sayeed Hassan helped to revise the paper according to the reviewer comments; and Justin Hyde checked the revised manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Kusumo, F.; Aditiya, H.B.; Ghazali, N.N.N. Schleichera oleosa L oil as feedstock for biodiesel production. Fuel 2015, 156, 63–70. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.G.; Hyde, J.; Azad, A.K.; Mamat, R.; Bhuiya, M.M.K. Role of biofuel and their binary (diesel-biodiesel) and ternary (ethanol-biodiesel-diesel) blends on internal combustion engines emission reduction. Renew. Sustain. Energy Rev. 2016, 53, 265–278. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Rizwanul Fattah, I.M. Evaluation of n-butanol as an oxygenated additive to improve combustion-emission-performance characteristics of a diesel engine fuelled with a diesel-calophyllum inophyllum biodiesel blend. RSC Adv. 2015, 5, 17160–17170. [Google Scholar] [CrossRef]

- Atabani, A.E.; Mofijur, M.; Masjuki, H.H.; Badruddin, I.A.; Kalam, M.A.; Chong, W.T. Effect of croton megalocarpus, calophyllum inophyllum, moringa oleifera, palm and coconut biodiesel-diesel blending on their physico-chemical properties. Ind. Crops Prod. 2014, 60, 130–137. [Google Scholar] [CrossRef]

- Ganjehkaviri, A.; Mohd Jaafar, M.N.; Hosseini, S.; Musthafa, A. Performance evaluation of palm oil-based biodiesel combustion in an oil burner. Energies 2016, 9. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Sanjid, A.; Rahman, M.M. Assessing idling effects on a compression ignition engine fueled with jatropha and palm biodiesel blends. Renew. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Chong, W.T. Characterization and production of ceiba pentandra biodiesel and its blends. Fuel 2013, 108, 855–858. [Google Scholar] [CrossRef]

- Mofijur, M.; Hazrat, M.A.; Rasul, M.G.; Mahmudul, H.M. Comparative evaluation of edible and non-edible oil methyl ester performance in a vehicular engine. Energy Procedia 2015, 75, 37–43. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E. Evaluation of biodiesel blending, engine performance and emissions characteristics of jatropha curcas methyl ester: Malaysian perspective. Energy 2013, 55, 879–887. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of moringa oleifera and palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Tüccar, G.; Aydın, K. Evaluation of methyl ester of microalgae oil as fuel in a diesel engine. Fuel 2013, 112, 203–207. [Google Scholar] [CrossRef]

- Islam, M.A.; Rahman, M.M.; Heimann, K.; Nabi, M.N.; Ristovski, Z.D.; Dowell, A.; Thomas, G.; Feng, B.; Von Alvensleben, N.; Brown, R.J. Combustion analysis of microalgae methyl ester in a common rail direct injection diesel engine. Fuel 2015, 143, 351–360. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Engine performance and emission analysis using oxidatively stabilized jatropha curcas biodiesel. Fuel 2013, 106, 152–156. [Google Scholar] [CrossRef]

- Islam, M.; Magnusson, M.; Brown, R.; Ayoko, G.; Nabi, M.; Heimann, K. Microalgal species selection for biodiesel production based on fuel properties derived from fatty acid profiles. Energies 2013, 6, 5676–5702. [Google Scholar] [CrossRef]

- Ali, O.; Mamat, R.; Najafi, G.; Yusaf, T.; Safieddin Ardebili, S.M. Optimization of biodiesel-diesel blended fuel properties and engine performance with ether additive using statistical analysis and response surface methods. Energies 2015, 8, 14136–14150. [Google Scholar] [CrossRef]

- Lim, S.; Teong, L.K. Recent trends, opportunities and challenges of biodiesel in malaysia: An overview. Renew. Sustain. Energy Rev. 2010, 14, 938–954. [Google Scholar] [CrossRef]

- Hassan, N.M.S.; Rasul, M.G.; Harch, C.A. Modelling and experimental investigation of engine performance and emissions fuelled with biodiesel produced from australian beauty leaf tree. Fuel 2015, 150, 625–635. [Google Scholar] [CrossRef]

- The bopple nut. Mount Bauple & District Historical Society Inc. Available online: http://www.Bauplemuseum.Com/bopple%20nut%20pub.Pdf (assessed on 30 December 2015).

- Macadamia%. Available online: https://www.anbg.gov.au/apni/ (assessed on 30 December 2015).

- Knothe, G. Biodiesel derived from a model oil enriched in palmitoleic acid, macadamia nut oil. Energy Fuels 2010, 24, 2098–2103. [Google Scholar] [CrossRef]

- Macadamias. Available online: http://nutindustry.Org.Au/anic/industry-snapshots/australian-macadamias.Asp (assessed on 21 March 2016).

- Khan, T.Y.; Atabani, A.E.; Badruddin, I.A.; Ankalgi, R.F.; Khan, T.M.; Badarudin, A. Ceiba pentandra, nigella sativa and their blend as prospective feedstocks for biodiesel. Ind. Crops Prod. 2015, 65, 367–373. [Google Scholar] [CrossRef]

- Ali, O.M.; Mamat, R.; Abdullah, N.R.; Abdullah, A.A. Analysis of blended fuel properties and engine performance with palm biodiesel-diesel blended fuel. Renew. Energy 2016, 86, 59–67. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Q.; Chang, F.; Pan, H.; Liu, X.-F.; Li, H.; Hu, D.-Y.; Yang, S. Production and fuel properties of biodiesel from firmiana platanifolia l.F. As a potential non-food oil source. Ind. Crops Prod. 2015, 76, 768–771. [Google Scholar] [CrossRef]

- Palash, S.M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.R.; Sanjid, A. Biodiesel production, characterization, diesel engine performance, and emission characteristics of methyl esters from aphanamixis polystachya oil of bangladesh. Energy Convers. Manag. 2015, 91, 149–157. [Google Scholar] [CrossRef]

- Mattarelli, E.; Rinaldini, C.; Savioli, T. Combustion analysis of a diesel engine running on different biodiesel blends. Energies 2015, 8, 3047–3057. [Google Scholar] [CrossRef]

- Tesfa, B.; Gu, F.; Mishra, R.; Ball, A. Emission characteristics of a ci engine running with a range of biodiesel feedstocks. Energies 2014, 7, 334–350. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, M.; Kim, H.; Choi, N. Effects of canola oil biodiesel fuel blends on combustion, performance, and emissions reduction in a common rail diesel engine. Energies 2014, 7, 8132–8149. [Google Scholar] [CrossRef]

- Islam, M.A.; Brown, R.J.; Brooks, P.R.; Jahirul, M.I.; Bockhorn, H.; Heimann, K. Investigation of the effects of the fatty acid profile on fuel properties using a multi-criteria decision analysis. Energy Convers. Manag. 2015, 98, 340–347. [Google Scholar] [CrossRef]

- Bari, S. Performance, combustion and emission tests of a metro-bus running on biodiesel-ulsd blended (b20) fuel. Appl. Energy 2014, 124, 35–43. [Google Scholar] [CrossRef]

- Ge, J.; Kim, M.; Yoon, S.; Choi, N. Effects of pilot injection timing and egr on combustion, performance and exhaust emissions in a common rail diesel engine fueled with a canola oil biodiesel-diesel blend. Energies 2015, 8, 7312–7325. [Google Scholar] [CrossRef]

- Atabani, A.E.; César, A.D.S. Calophyllum inophyllum l.—A prospective non-edible biodiesel feedstock. Study of biodiesel production, properties, fatty acid composition, blending and engine performance. Renew. Sustain. Energy Rev. 2014, 37, 644–655. [Google Scholar] [CrossRef]

- Wakil, M.A.; Kalam, M.A.; Masjuki, H.H.; Fattah, I.R.; Masum, B.M. Evaluation of rice bran, sesame and moringa oils as feasible sources of biodiesel and the effect of blending on their physicochemical properties. RSC Adv. 2014, 4, 56984–56991. [Google Scholar] [CrossRef]

- Altaie, M.A.H.; Janius, R.B.; Rashid, U.; Taufiq-Yap, Y.H.; Yunus, R.; Zakaria, R.; Adam, N.M. Performance and exhaust emission characteristics of direct-injection diesel engine fueled with enriched biodiesel. Energy Convers. Manag. 2015, 106, 365–372. [Google Scholar] [CrossRef]

- Xue, J.; Grift, T.E.; Hansen, A.C. Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 2011, 15, 1098–1116. [Google Scholar] [CrossRef]

- Öztürk, E. Performance, emissions, combustion and injection characteristics of a diesel engine fuelled with canola oil–hazelnut soapstock biodiesel mixture. Fuel Process. Technol. 2015, 129, 183–191. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z. Experimental studies on the combustion characteristics and performance of a direct injection engine fueled with biodiesel/diesel blends. Energy Convers. Manag. 2010, 51, 2985–2992. [Google Scholar] [CrossRef]

- Pali, H.S.; Kumar, N.; Alhassan, Y. Performance and emission characteristics of an agricultural diesel engine fueled with blends of sal methyl esters and diesel. Energy Convers. Manag. 2015, 90, 146–153. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M.; Turkcan, A.; Sayin, C. Performance and combustion characteristics of a di diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009, 88, 629–636. [Google Scholar] [CrossRef]

- Özçelik, A.E.; Aydoğan, H.; Acaroğlu, M. Determining the performance, emission and combustion properties of camelina biodiesel blends. Energy Convers. Manag. 2015, 96, 47–57. [Google Scholar] [CrossRef]

- Meng, X.; Chen, G.; Wang, Y. Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Process. Technol. 2008, 89, 851–857. [Google Scholar] [CrossRef]

- Qi, D.H.; Geng, L.M.; Chen, H.; Bian, Y.Z.; Liu, J.; Ren, X.C. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil. Renew. Energy 2009, 34, 2706–2713. [Google Scholar] [CrossRef]

- Korres, D.M.; Karonis, D.; Lois, E.; Linck, M.B.; Gupta, A.K. Aviation fuel jp-5 and biodiesel on a diesel engine. Fuel 2008, 87, 70–78. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).