Transient Numerical Simulation of the Melting and Solidification Behavior of NaNO3 Using a Wire Matrix for Enhancing the Heat Transfer

Abstract

:1. Introduction

2. Mathematical Model of the Heat Exchanger Tube

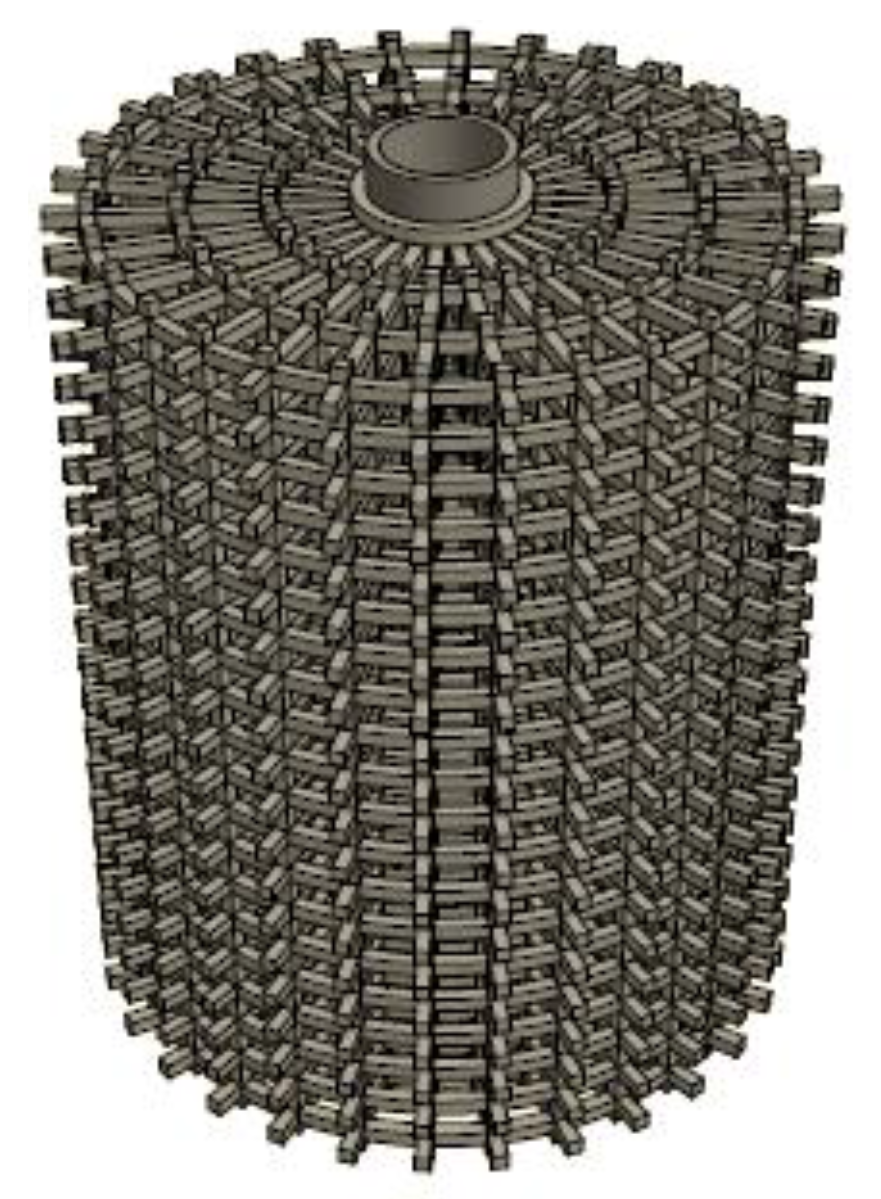

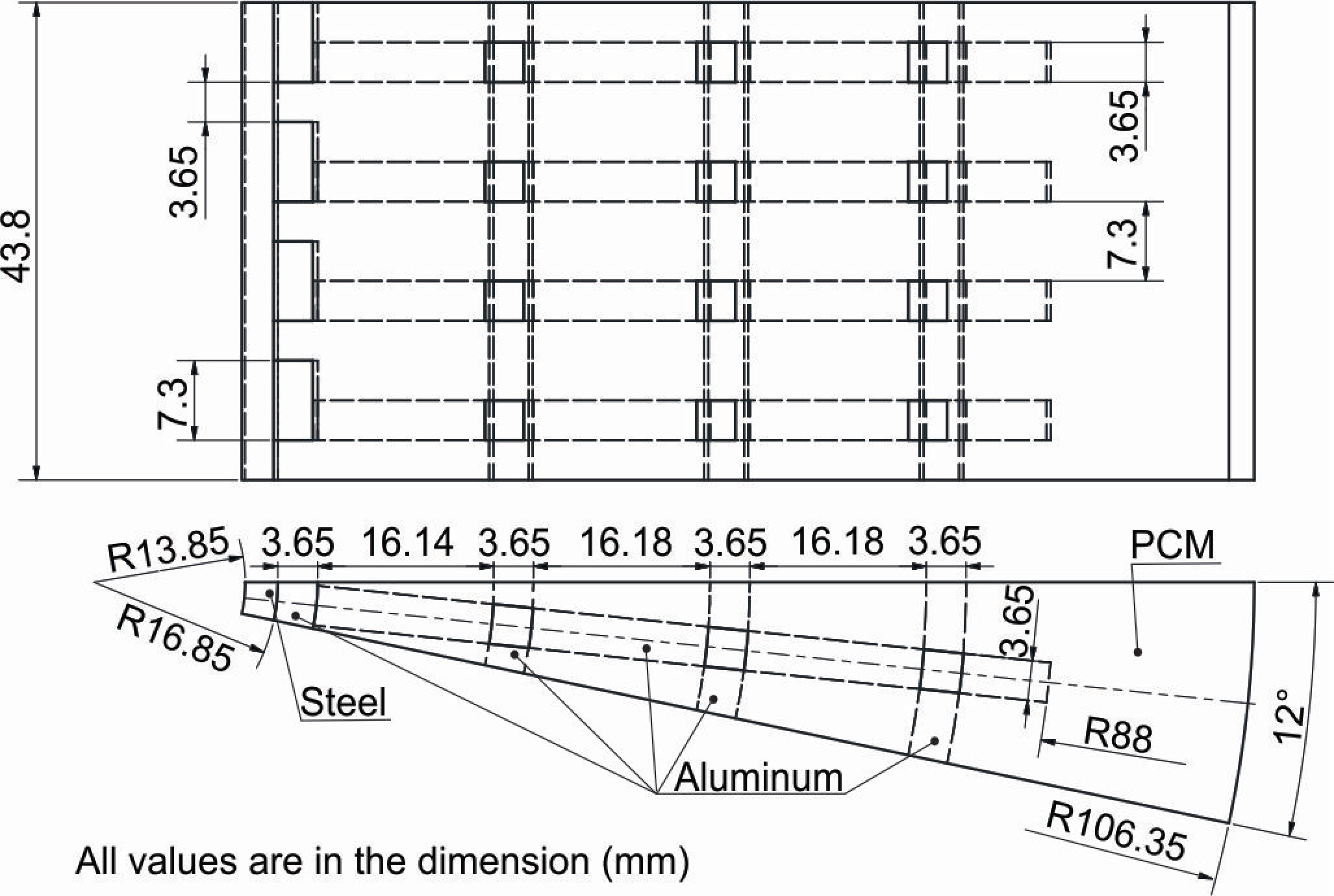

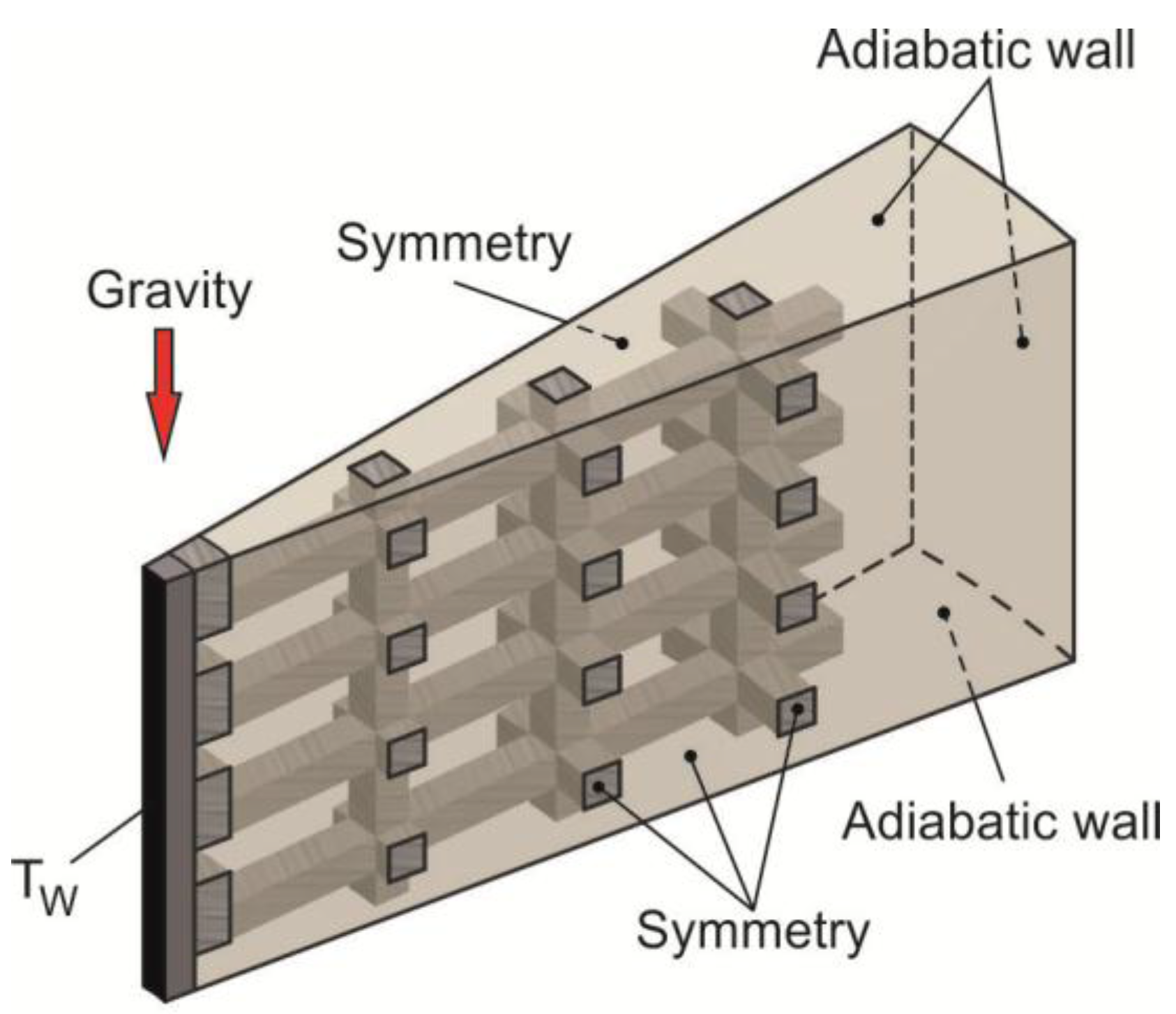

2.1. Physical Model of the Wired Matrix

2.2. Mathematical Model

- Both the solid as well as the liquid phase is homogeneous and isotropic, and the melting process is symmetric within a segment.

- NaNO3 in the liquid phase is considered to be an incompressible and Newtonian fluid.

- The volume change upon phase change is ignored.

- For the molten PCM laminar flow as Newtonian fluid is assumed.

- The solid is homogeneously distributed in the mushy region.

- It is assumed that the PCM has an ideal solidification behavior. Therefore, the subcooling effects are neglected and the solidification temperature is constant.

- A perfect contact between the surfaces of the single wires and also to the steel tube is assumed.

2.3. Thermo-Physical Properties

2.4. Numerical Model of the Heat Exchanger Tube

3. Numerical Results and Discussion

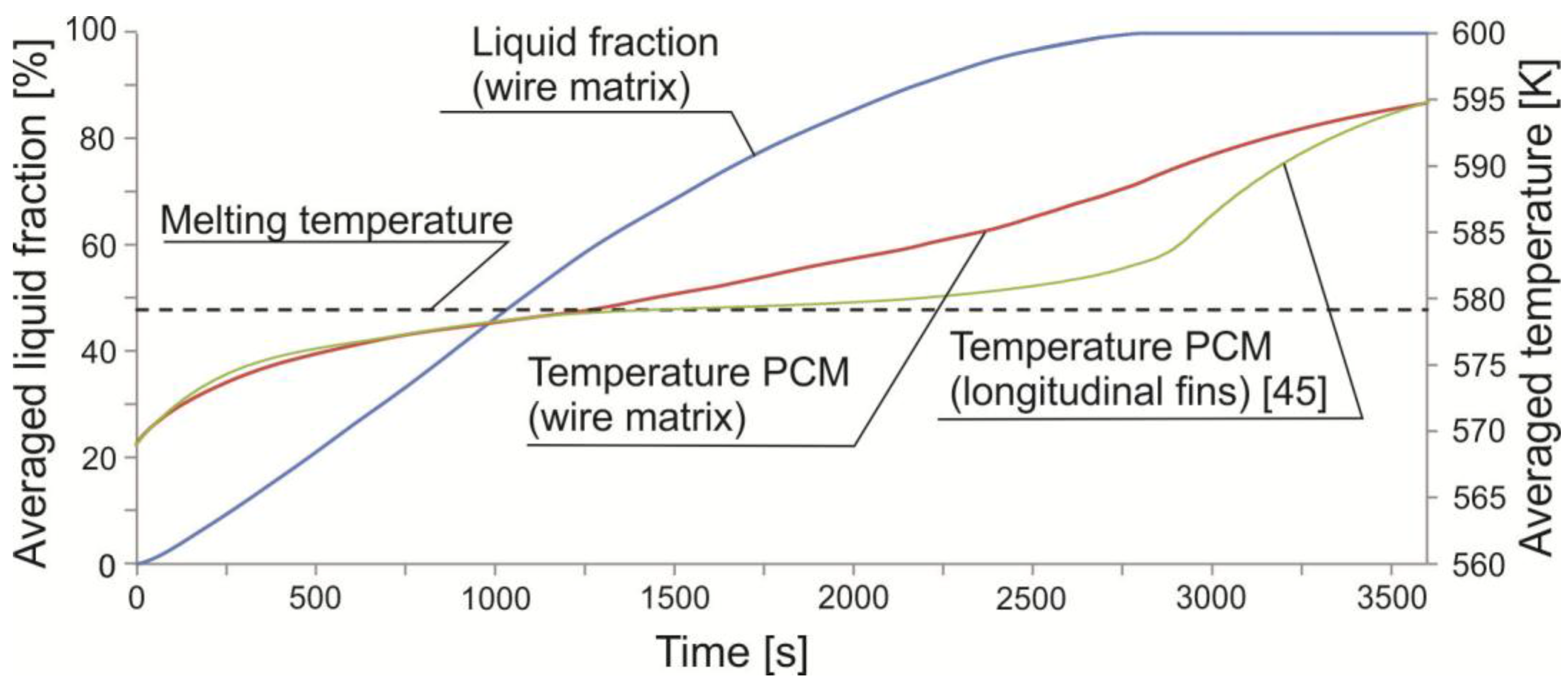

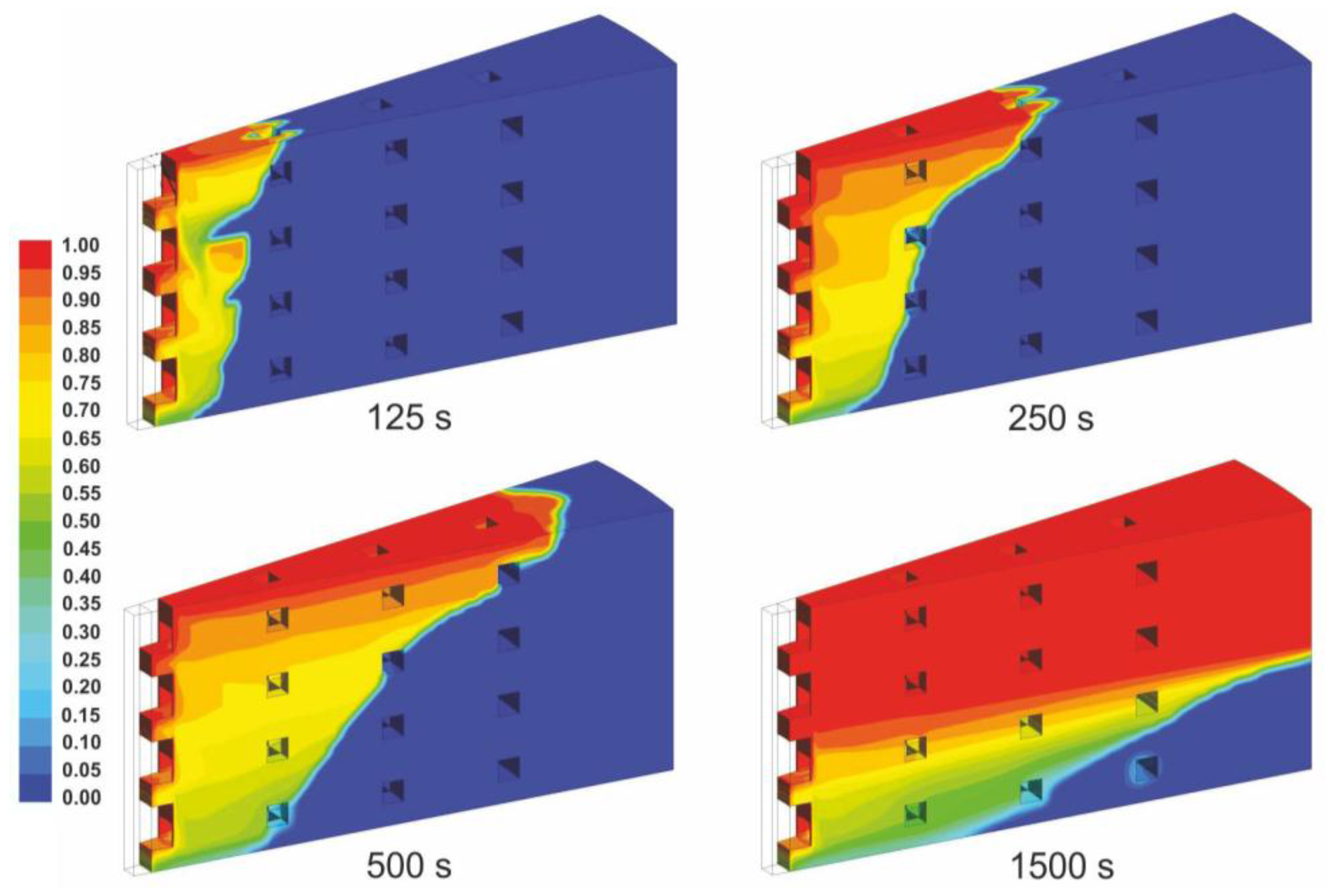

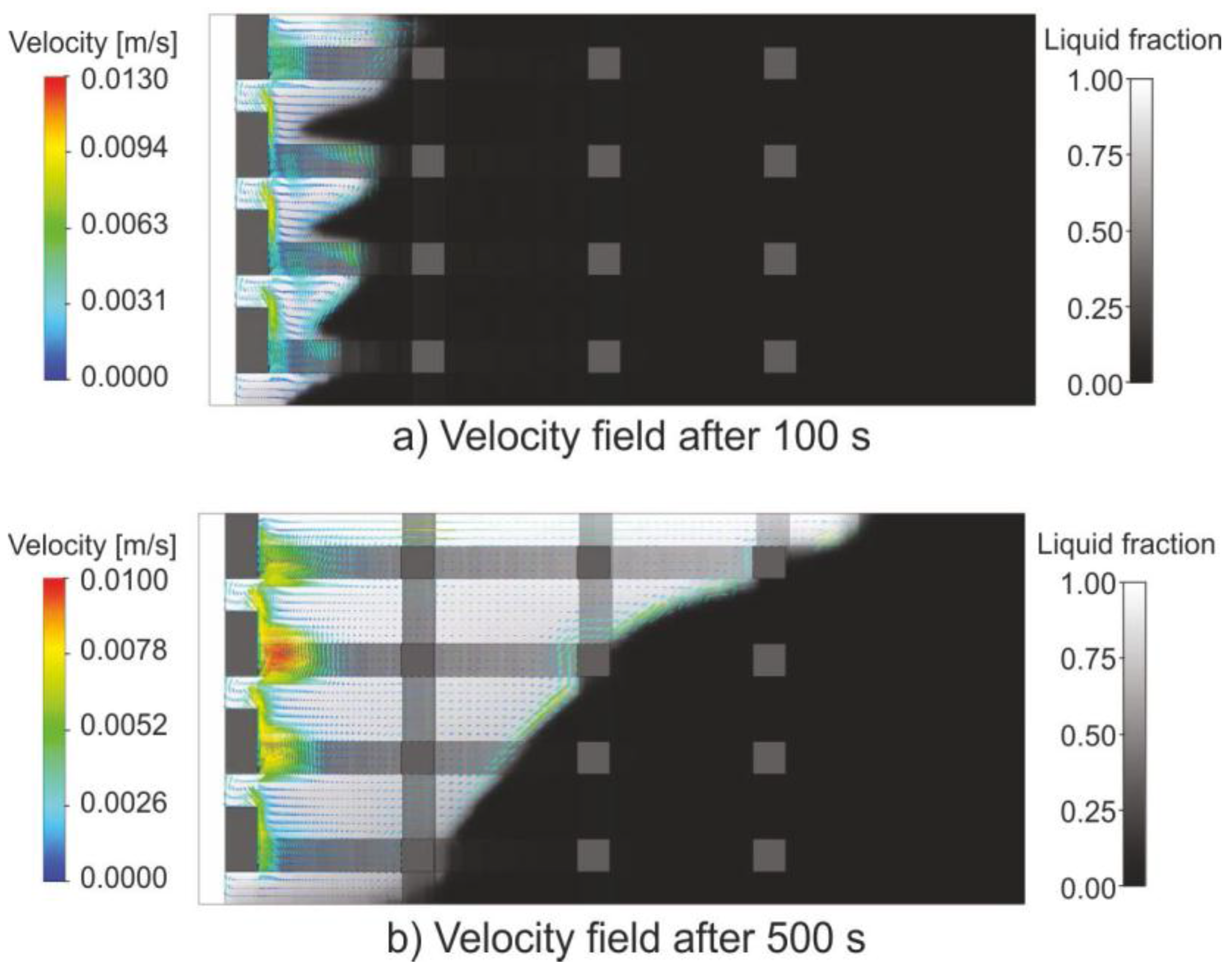

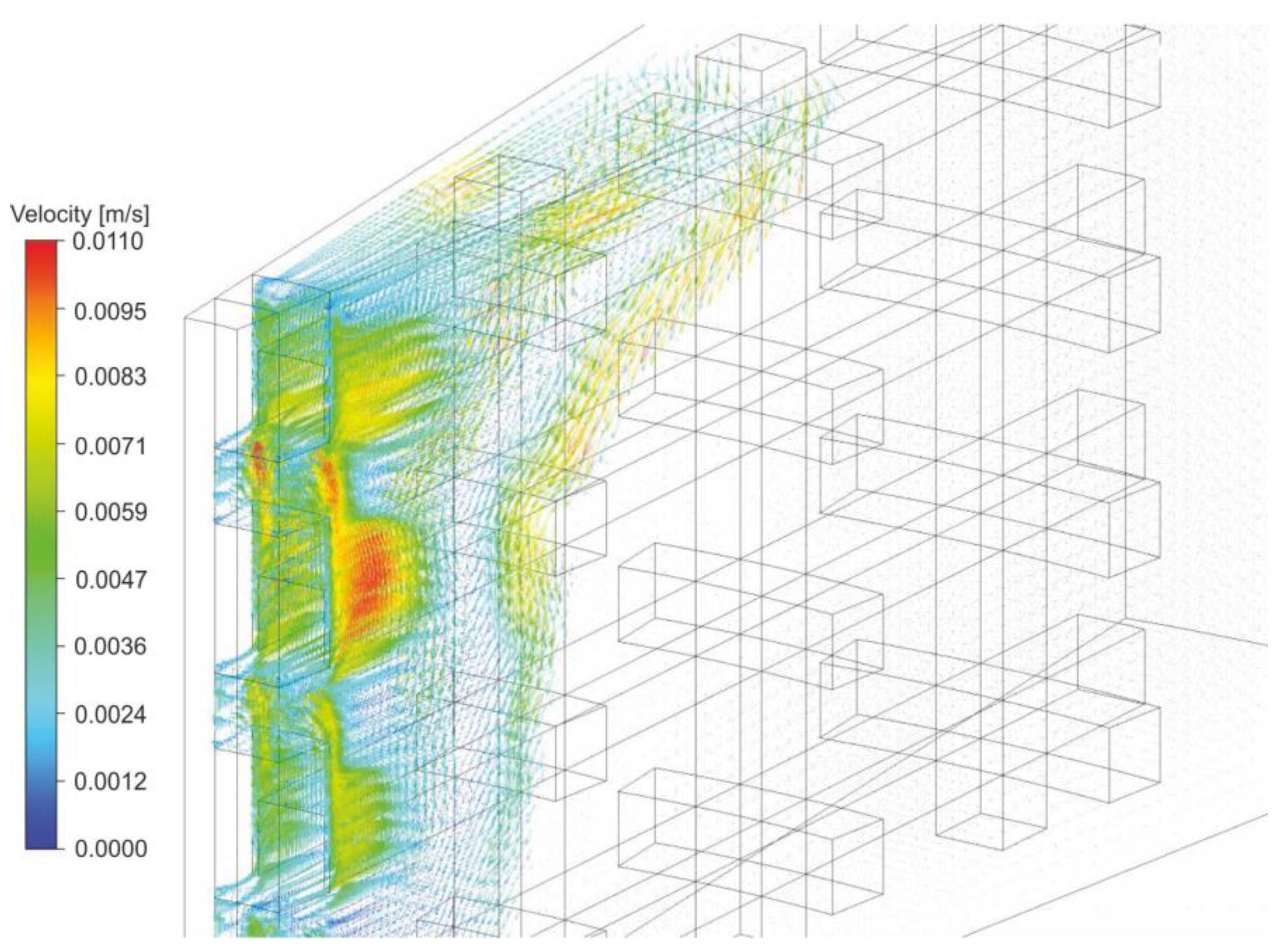

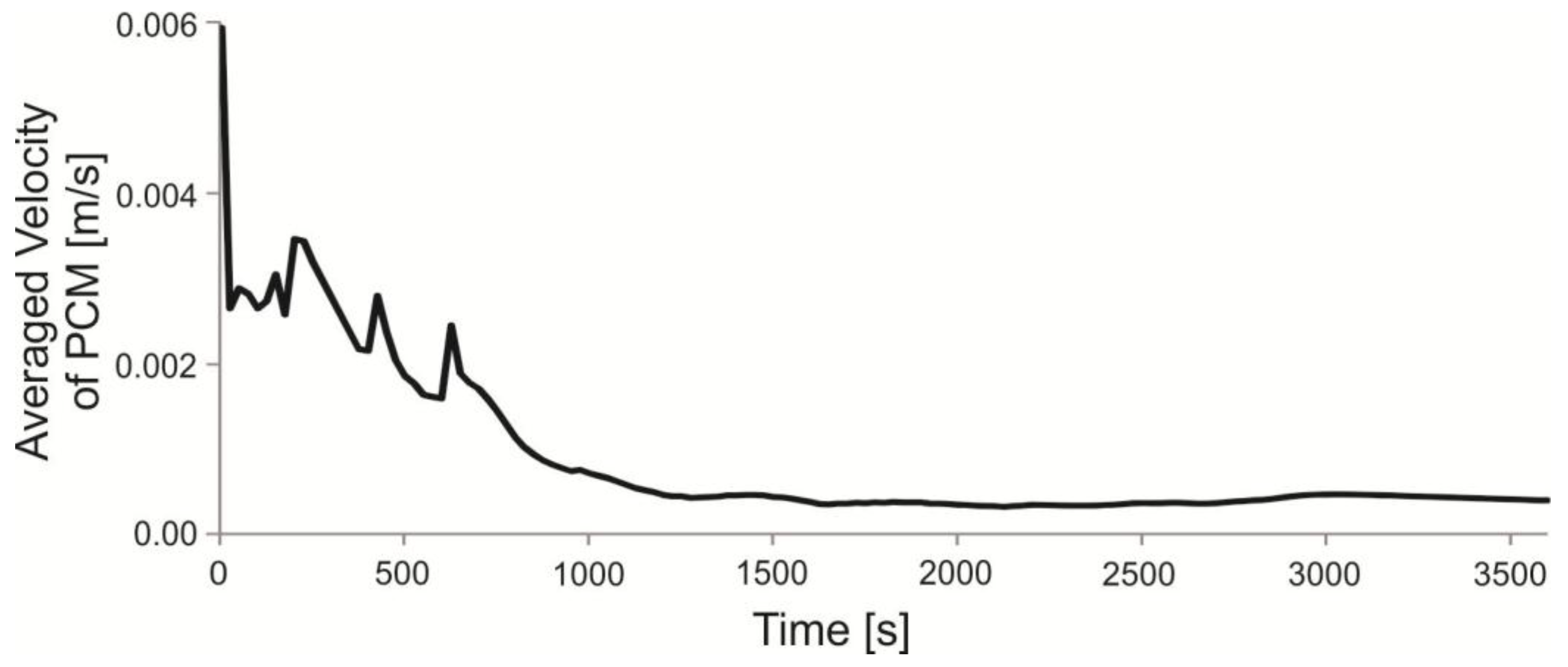

3.1. Results for the Charging Process

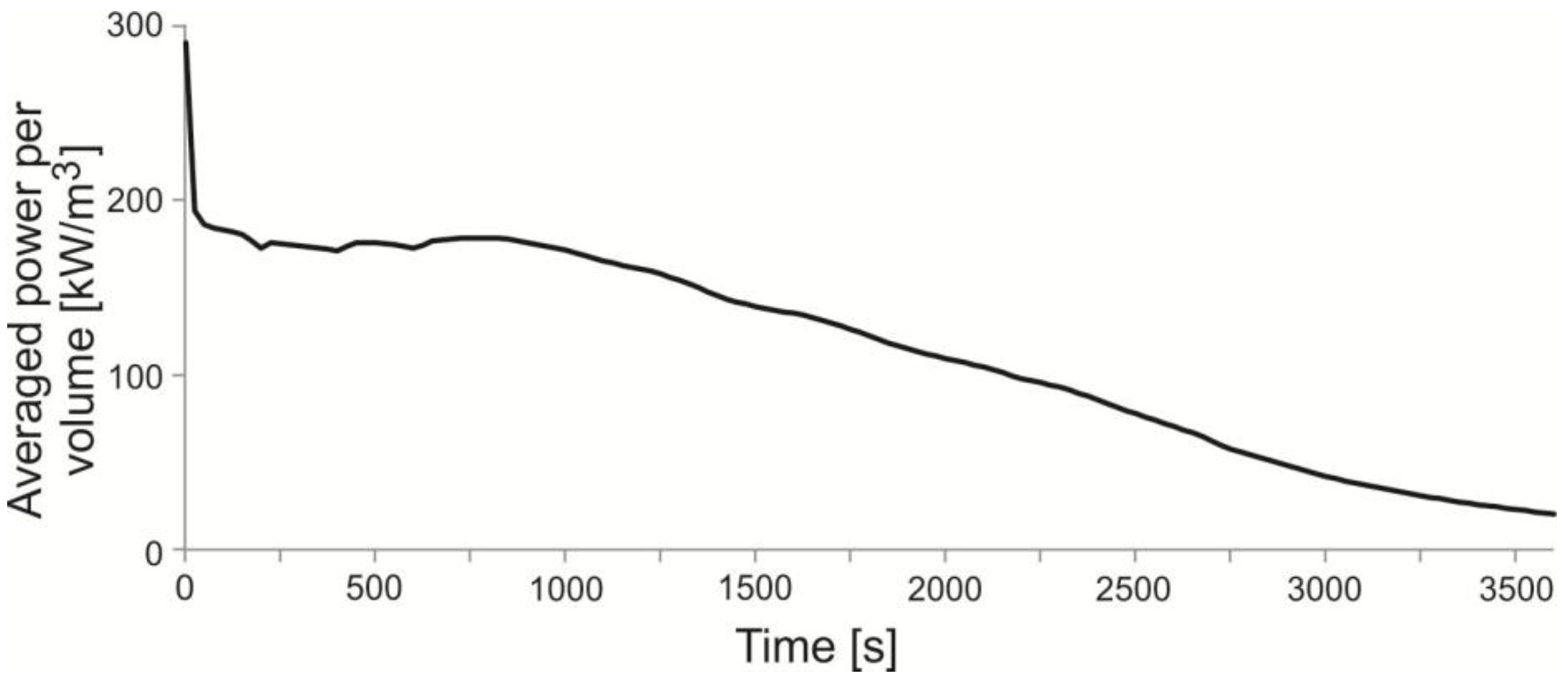

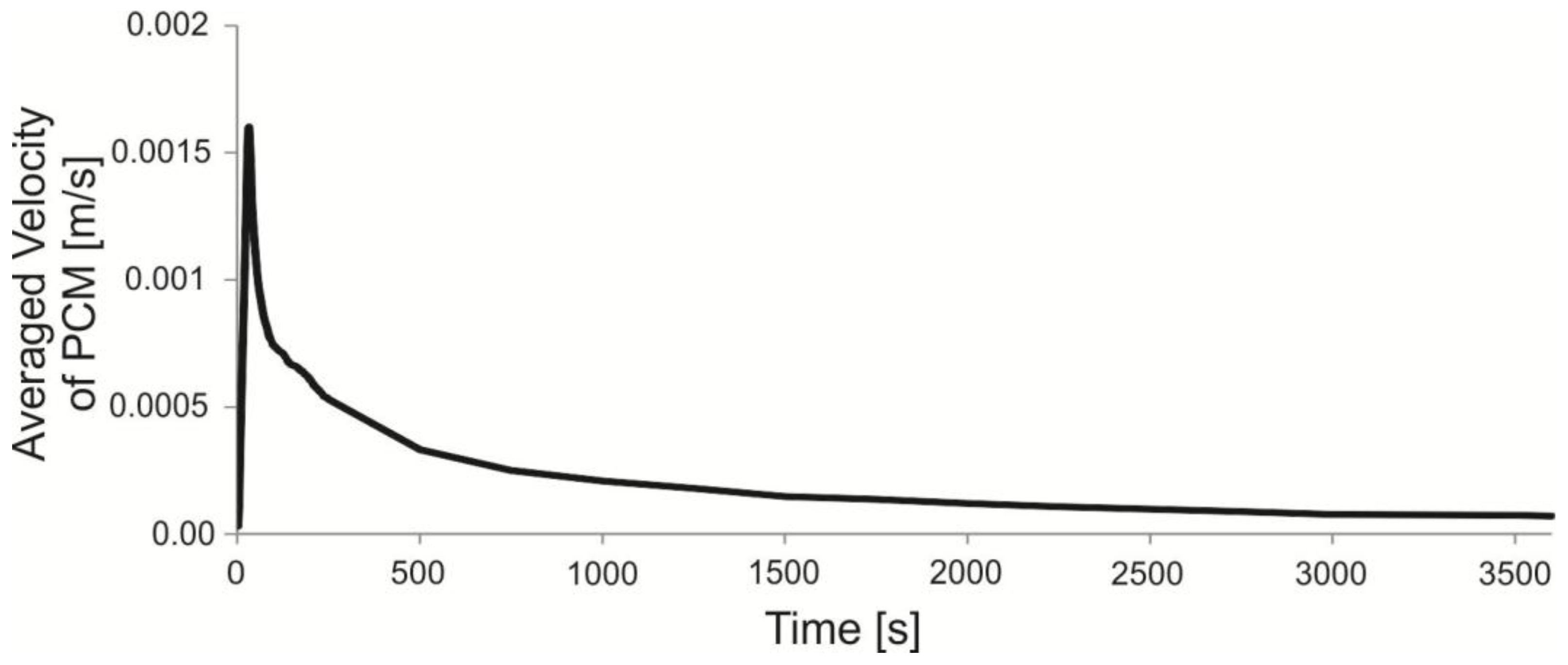

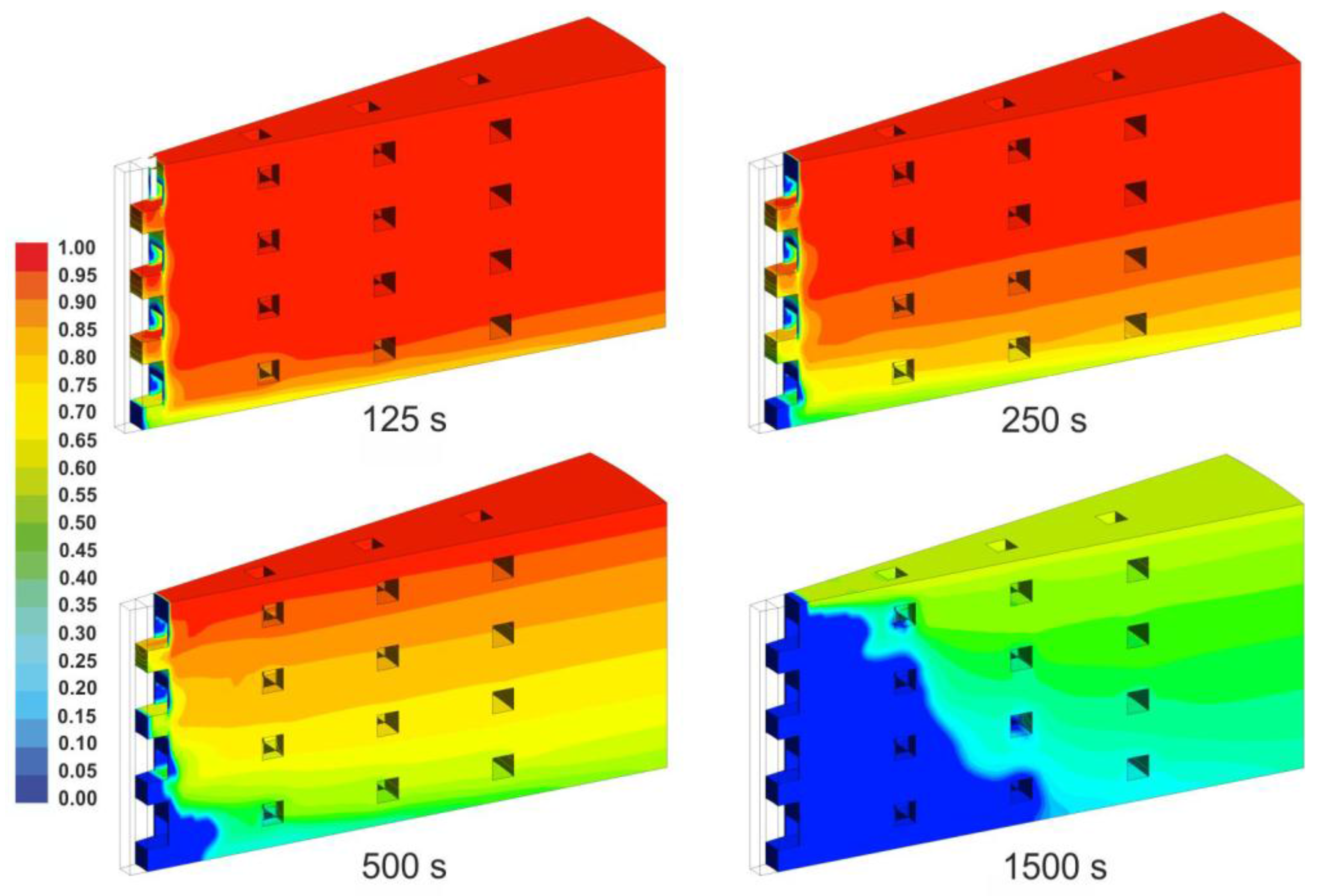

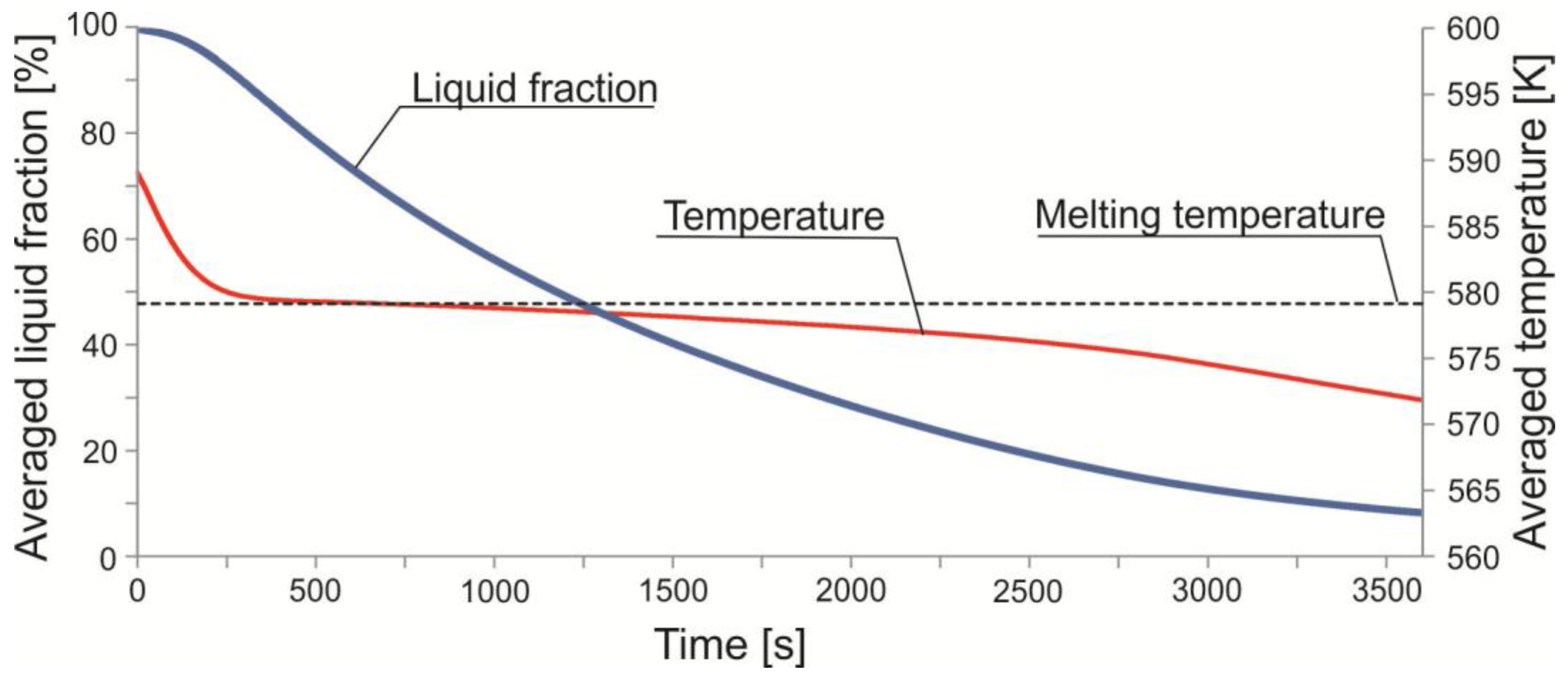

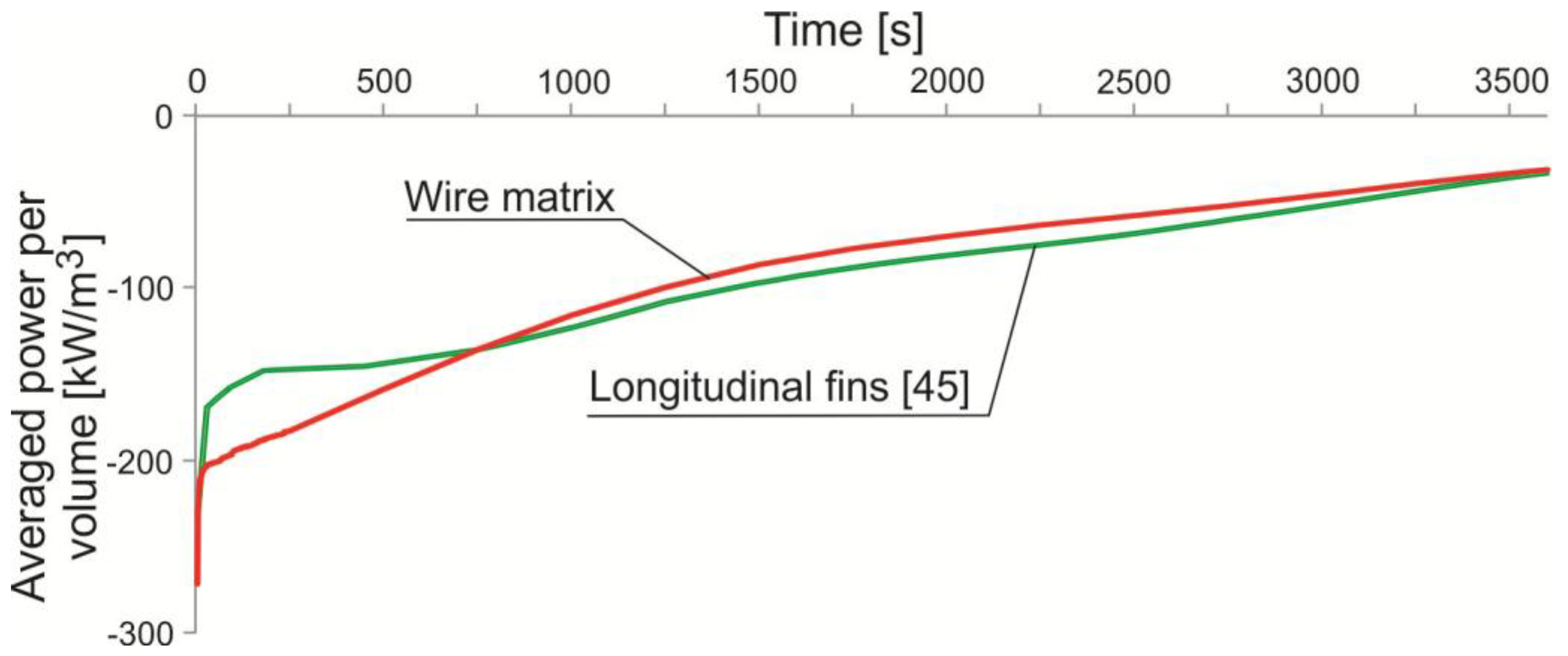

3.2. Results for the Discharging Process

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Ac | Porosity function (kg/m3s) |

| b | Computational constant (-) |

| C | Mushy zone constant (kg/m3s) |

| cp | Specific heat at constant pressure (J/kgK) |

| H | Total enthalpy (J/kg) |

| Hs | Sensible enthalpy (J/kg) |

| Hlat | Latent enthalpy for the phase change in a numerical control volume (J/kg) |

| k | Thermal conductivity (W/mK) |

| L | Latent heat of fusion (J/kg) |

| p | Pressure (N/m2) |

| SM | Source term momentum equation (N/m3) |

| SE | Source term energy equation (J/m3s) |

| t | Time (s) |

| T | Temperature (K) |

| v | Velocity (m/s) |

| Greek letters | |

| ε | Surface to volume ratio (1/m) |

| γ | Liquid fraction (-) |

| φ | Volume ratio (-) |

| λ | Thermal conductivity (W/mK) |

| ρ | Density (kg/m3) |

| η | Dynamic viscosity (kg/ms) |

| Subscripts | |

| E | Energy balance |

| lat | Latent |

| liq | Liquidus |

| M | Momentum balance |

| ref | Reference |

| s | Sensible |

| sol | Solidus |

| W | Wall |

References

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Laing, D.; Bauer, T.; Breidenbach, N.; Hachmann, B.; Johnson, M. Development of high temperature phase-change-material storages. Appl. Energy 2013, 109, 497–504. [Google Scholar] [CrossRef]

- Gil, A.; Medrano, M.; Martorell, I.; Lazaro, A.; Dolado, P.; Zalba, B.; Cabeza, L.F. State of the art on high temperature thermal energy storage for power generation. Part 1—Concepts, materials and modellization. Renew. Sustain. Energy 2010, 14, 31–55. [Google Scholar] [CrossRef]

- Cárdenas, B.; León, N. High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques. Renew. Sustain. Energy Rev. 2013, 27, 724–737. [Google Scholar] [CrossRef]

- Shatikian, V.; Ziskind, G.; Letan, R. Numerical investigation of a PCM-based heat sink with internal fins: Constant heat flux. Int. J. Heat Mass Transf. 2008, 51, 1488–1493. [Google Scholar] [CrossRef]

- Seeniraj, R.V.; Lakshmi Narasimhan, N. Performance enhancement of a solar dynamic LHTS module having both fins and multiple PCMs. Sol. Energy 2008, 82, 535–542. [Google Scholar] [CrossRef]

- Sharifi, N.; Bergman, T.L.; Faghri, A. Enhancement of PCM melting in enclosures with horizontally-finned internal surfaces. Int. J. Heat Mass Transf. 2011, 54, 4182–4192. [Google Scholar] [CrossRef]

- Agyenim, F.; Eames, P.; Smyth, M. Heat transfer enhancement in medium temperature thermal energy storage system using a multitube heat transfer array. Renew. Energy 2010, 35, 198–207. [Google Scholar] [CrossRef]

- Beck, A.; Koller, M.; Walter, H.; Hameter, M. Transient numerical analysis of different finned tube designs for the use in latent heat thermal energy storage devices. In Proceedings of the ASME 2015 Power and Energy, San Diego, CA, USA, 28 June–2 July 2015.

- Walter, H.; Beck, A.; Hameter, M. Transient analysis of an improved finned tube heat exchanger for thermal energy storage system. In Proceedings of the ASME 2015 Power and Energy, San Diego, CA, USA, 28 June–2 July 2015.

- Urschitz, G.; Brier, J.; Walter, H.; Mertz, R.; Bleicher, F.; Haider, M. New design of a bimetallic finned tube for the use in a latent heat thermal energy storage units. In Proceedings of the ASME 2015 Power and Energy, San Diego, CA, USA, 28 June–2 July 2015.

- Elgafy, A.; Lafdi, K. Effect of carbon nanofiber additives on thermal behavior of phase change materials. Carbon 2005, 43, 3067–3074. [Google Scholar] [CrossRef]

- Mettawee, E.; Assassa, G. Thermal conductivity enhancement in a latent heat storage system. Sol. Energy 2007, 81, 839–845. [Google Scholar] [CrossRef]

- Zhang, P.; Song, L.; Lu, H.; Wang, J.; Hu, Y. The influence of expanded graphite on thermal properties for paraffin/high density polyethylene/chlorinated paraffin/antimony trioxide as a flame retardant phase change material. Energy Convers. Manag. 2010, 51, 2733–2737. [Google Scholar] [CrossRef]

- Lopez, J.; Caceres, G.; Palomo Del Barrio, E.; Jomaa, W. Confined melting in deformable porous media: A first attempt to explain the graphite/salt composites behaviour. Int. J. Heat Mass Transf. 2010, 53, 1195–1207. [Google Scholar] [CrossRef]

- Pincemin, S.; Olives, R.; Py, X.; Christ, M. Highly conductive composites made of phase change material sand graphite for thermal storage. Sol. Energy Mater. Sol. Cells 2008, 92, 603–613. [Google Scholar] [CrossRef]

- Salunkhe, P.B.; Shembekar, P.S. A review on effect of phase change material encapsulation on the thermal performance of a system. Renew. Sustain. Energy Rev. 2012, 16, 5603–5616. [Google Scholar] [CrossRef]

- Lenert, A.; Nam, Y.; Yilbas, B.S.; Wang, E.N. Focusing of phase change microparticles for local heat transfer enhancement in laminar flows. Int. J. Heat Mass Transf. 2013, 56, 380–389. [Google Scholar] [CrossRef]

- Seyf, H.R.; Zhou, Z.; Ma, H.B.; Zhang, Y. Three dimensional numerical study of heat-transfer enhancement by nano-encapsulated phase change material slurry in microtube heat sinks with tangential impingement. Int. J. Heat Mass Transf. 2013, 56, 561–573. [Google Scholar] [CrossRef]

- Yang, J.; Du, X.; Yang, L.; Yang, Y. Numerical analysis on the thermal behavior of high temperature latent heat thermal storage system. Sol. Energy 2013, 98, 543–552. [Google Scholar] [CrossRef]

- Ermis, K.; Erek, A.; Dincer, I. Heat transfer analysis of phase change process in a finned-tube thermal energy storage system using artificial neural network. Int. J. Heat Mass Transf. 2007, 50, 3163–3175. [Google Scholar] [CrossRef]

- Chen, W.Z.; Yang, Q.S.; Dai, M.Q.; Cheng, M. An analytical solution of the heat transfer process during contact melting of phase change material inside a horizontal elliptical tube. Int. J. Energy Res. 1998, 22, 131–140. [Google Scholar] [CrossRef]

- Mosaffa, A.H.; Talati, F.; Basirat Tabrizi, H.; Rosen, M.A. Analytical modelling of PCM solidification in a shell and tube finned thermal storage for air conditioning systems. Energy Build. 2012, 49, 356–361. [Google Scholar] [CrossRef]

- Tay, N.H.S.; Belusko, M.; Bruno, F. An effectiveness-NTU technique for characterising tube-in-tank phase change thermal energy storage systems. Appl. Energy 2012, 91, 309–319. [Google Scholar] [CrossRef]

- Tay, N.H.S.; Bruno, F.; Belusko, M. Experimental validation of a CFD and an ε-NTU model for a large tube-in-tank PCM system. Int. J. Heat Mass Transf. 2012, 55, 5931–5940. [Google Scholar] [CrossRef]

- Belhamadia, Y.; Kane, A.S.; Fortin, A. An enhanced mathematical model for phase change problems with natural convection. Numer. Anal. Model. 2012, 3, 192–206. [Google Scholar]

- Bellan, S.; Gonzalez-Aguilar, J.; Romero, M.; Rahman, M.M.; Goswami, Y.D.; Stefanakos, E.K.; Couling, D. Numerical analysis of charging and discharging performance of a thermal energy storage system with encapsulated phase change material. Appl. Therm. Eng. 2014, 71, 481–500. [Google Scholar] [CrossRef]

- Gupta, S.C. A moving grid numerical scheme for multi-dimensional solidification with transition temperature range. Comput. Methods Appl. Mech. Eng. 2000, 189, 525–544. [Google Scholar] [CrossRef]

- Lamberg, P.; Siren, K. Analytical model for solidification in a finite PCM storage with internal fins. Heat Mass Transf. 2003, 39, 167–176. [Google Scholar] [CrossRef]

- Florez, W.F.; Power, H.; Chejne, F. Numerical solution of thermal convection problems using the multidomain boundary element method. Numer. Methods Partial Differ. Equ. 2002, 18, 469–489. [Google Scholar] [CrossRef]

- Laing, D.; Bauer, T.; Steinmann, W.-D.; Lehmann, D. Advanced high temperature latent heat storage system—Design and test results. In Proceedings of the 11th International Conference on Thermal Energy Storage, Stockholm, Sweden, 14–17 June 2009.

- Koller, M.; Walter, H.; Hameter, M. Transient numerical simulation of the melting behavior of NaNO3 in a latent thermal energy storage device using a wire matrix for enhancing the heat transfer. In Proceedings of the 11th International Conference on Heat and Mass Transfer, Budapest, Hungary, 12–14 December 2015.

- Voller, V.R.; Cross, M.; Markatos, N.C. An enthalpy method for convection/diffusion phase change. Int. J. Numer. Methods Eng. 1987, 24, 271–284. [Google Scholar] [CrossRef]

- Voller, V.R.; Prakash, A. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- FLUENT Manual, Chapter 21: Modeling Solidification and Melting; ANSYS, Inc.: Canonsburg, PA, USA, 2001.

- Hameter, M.; Walter, H. Influence of the mushy parameter on the numerical simulation of the melting and solidification process of phase change materials. In Proceedings of the 26th European Symposium on Computer Aided Process Engineering, Portorož, Slovenia, 12–15 June 2016.

- Bauer, T.; Laing, D.; Tamme, R. Characterization of sodium nitrate as a phase change material. Int. J. Thermophys. 2012, 33, 91–104. [Google Scholar] [CrossRef]

- Jriri, T.; Rogez, J.; Bergman, C.; Mathieu, J.C. Thermodynamic study of the condensed phases of NaNO3, KNO3, CsNO3 and their transitions. Thermochim. Acta 1995, 266, 147–161. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew. Sustain. Energy Rev. 2012, 16, 2118–2132. [Google Scholar] [CrossRef]

- Polyakov, V.D.; Beruli, S.H. Specific weight of alloys from nitrate and nitrite systems of potassium and sodium. Izvest. Siktora Fiz.-Khim. Anal. 1955, 26, 164–172. (In Russian) [Google Scholar]

- Janz, G.J.; Krebs, U.; Siegenthaler, H.F.; Tomkins, R.P.T. Molten salts: Volume 3 nitrates, nitrites, and mixtures: electrical conductance, density, viscosity, and surface tension data. J. Phys. Chem. Ref. Data 1972, 1, 581–746. [Google Scholar] [CrossRef]

- Bloom, H.; Knaggs, I.W.; Molloy, J.J.; Welch, D. Molten salt mixtures. Part 1: Electrical conductivities, activation energies of ionic migration and molar volumes of molten binary halide mixtures. Trans. Faraday Soc. 1953, 49, 1458–1465. [Google Scholar] [CrossRef]

- Janz, G.J.; Allen, C.B.; Bansal, N.P.; Murphy, R.M.; Tomkins, R.P.T. Physical Properties Data Compilations Relevant to Energy Storage, Part II: Molten Salts: Data on Single and Multi-Component Salt Systems; National Bureau of Standards: New York, NY, USA, 1979. [Google Scholar]

- Kitade, S.; Kobayashi, Y.; Nagasaka, Y.; Nagashima, A. Measurement of the thermal conductivity of molten KNO3 and NaNO3 by the transient hot-wire method with ceramic coated probes. High Temp. High Press. 1989, 21, 219–224. [Google Scholar]

- Koller, M. Numerical Simulation of the Melting and Solidification Process of a Latent Thermal Energy Storage System with Different Methods to Improve the Heat Transfer Surface. Master’s Thesis, Vienna University of Technology, Vienna, Austria, 2015. [Google Scholar]

- Urschitz, G.; Walter, H.; Hameter, M. Experimental investigation of a finned mono tube—Latent heat thermal energy storage (LHTES). In Proceedings of the ASME 2014 8th International Conference on Energy Sustainability, Boston, MA, USA, 30 June–2 July 2014. ASME Paper No. ES-FuelCell2014-6338.

- Urschitz, G.; Walter, H.; Hameter, M. Laboratory test rig of a LHTES (Latent Heat Thermal Energy Storage): Construction and first experimental results. J. Energy Power Eng. 2014, 8, 1838–1847. [Google Scholar]

- Sciacovelli, A.; Verda, V.; Colella, F. Numerical investigation on the thermal performance enhancement in a latent heat thermal storage unit, Nantes, France. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012.

- Walter, H.; Beck, A.; Hameter, M. Influence of the fin design on the melting and solidification process of NaNO3 in a thermal energy storage system. J. Energy Power Eng. 2015, 9, 913–928. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koller, M.; Walter, H.; Hameter, M. Transient Numerical Simulation of the Melting and Solidification Behavior of NaNO3 Using a Wire Matrix for Enhancing the Heat Transfer. Energies 2016, 9, 205. https://doi.org/10.3390/en9030205

Koller M, Walter H, Hameter M. Transient Numerical Simulation of the Melting and Solidification Behavior of NaNO3 Using a Wire Matrix for Enhancing the Heat Transfer. Energies. 2016; 9(3):205. https://doi.org/10.3390/en9030205

Chicago/Turabian StyleKoller, Martin, Heimo Walter, and Michael Hameter. 2016. "Transient Numerical Simulation of the Melting and Solidification Behavior of NaNO3 Using a Wire Matrix for Enhancing the Heat Transfer" Energies 9, no. 3: 205. https://doi.org/10.3390/en9030205

APA StyleKoller, M., Walter, H., & Hameter, M. (2016). Transient Numerical Simulation of the Melting and Solidification Behavior of NaNO3 Using a Wire Matrix for Enhancing the Heat Transfer. Energies, 9(3), 205. https://doi.org/10.3390/en9030205