1. Introduction

Bioenergy has been regarded as an important alternative energy source that has the potential to help nations alleviate their reliance on petroleum energy, thereby, producing positive impacts on the economy, the environment, and the society [

1]. Diverse studies have concluded that the production of bioenergy is expected to increase in the years to come [

2,

3,

4]. One of the most important obstacles for the bioenergy utilization is related to the high feedstock-logistics costs and the dearth of technologies to convert biomass into useful forms of energy [

5]. “Feedstock logistics” include the necessary operations to harvest the biomass and transport it from the reference site to the pertinent biorefinery. These operations must ensure that the delivered feedstocks meet a set of physical and chemical quality specifications [

1]. To date, most assessments of the biofuel feedstocks availability have focused on quantifying the feasibility of having enough biomass supply to meet the biofuel production goals at minimal cost. However, as the industry grows and matures, concerns related to the quality variability of the feedstock arise and have become critical in the energy conversion process and in the market environment. The inherent variability of the biomass quality is a barrier that restrains the development of reliable bioenergy energy conversion processes. Hence, advanced biomass supply systems and practices are needed to reduce the variability of the biomass quality parameters, such as the ash and the moisture contents [

6].

One of the main challenges of the bioenergy industry consists in quantifying the impacts of the biomass quality across the supply chain (SC). Despite bioenergy being an emerging industry, it inherited concepts and models from the well-established agricultural and logging industries. The primary objective in the traditional biomass feedstock logistics modeling approaches consists in reducing the overall cost of the SC, under the assumption that the biomass quality specifications are consistent and similar to forage and pulpwood [

6]. The single objective of minimizing the total cost (e.g., composed of the feedstock base cost and the logistics and processing operations costs, among others) may produce considerable negative impacts on the biomass quality and, thereby, on the performance of bioenergy SCs. In practice, bioenergy SCs often work with highly variable and/or poor quality biomass characteristics, which in turn impacts the bioenergy conversion process. A recent paper from Idaho National Laboratory [

6] raises the concern that research on feedstock quality still lacks proper theoretical support and that conventional approaches often disregard quality-related issues by focusing solely on decreasing the logistics cost. The emphasis of cost over quality is exemplified by the current pricing structure of the biomass, which is based on the measure “dollar per dry ton” instead of “dollar per clean dry carbohydrate.”

Practitioners who have reached pilot-scale operations, which require large quantities of feedstock, have experienced considerable differences between “pristine” and “field-run” biomass [

7]. The scaling-up process is often accompanied by an undesirable level of risk, which becomes a very important parameter to consider in the bioenergy industry as new technologies with associated quality specifications evolve from the laboratory to the commercial settings [

8]. For example, consider the scenario in which the biorefinery equipment, designed to work with a biomass moisture content of approximately 10%, has to work with a moisture content of 30% continuously throughout an entire year. For this particular case, the biorefinery would incur larger operation and maintenance costs. Equivalently, consider the financial losses if one load of feedstock yields 90 gallons/ton and another load yields 60 gallons/ton. Kenney

et al. [

6] demonstrated through the analysis of the biomass quality characteristics that these scenarios are very likely to occur in practice. The biomass quality is critically dependent upon the moisture, ash and sugar contents, as well as the particle morphology of the feedstock, among other variables. Ignoring the biomass quality variations and, thus, the associated costs when modeling biomass SCs is expected to yield considerable economic losses that will only be discovered after the operations at a biorefinery have begun. The opening of the first commercial-scale cellulosic-ethanol plant to use corn residues as a feedstock, which began operations on 3 September 2014 [

9], highlights the need for creating robust SC models and tailored solution procedures that capture the multiple trade-offs and impacts of the quality level during the SC network design. This biorefinery named Project LIBERTY consumes about 285,000 tons of biomass annually, which are harvested from a 45-mile radius of the plant.

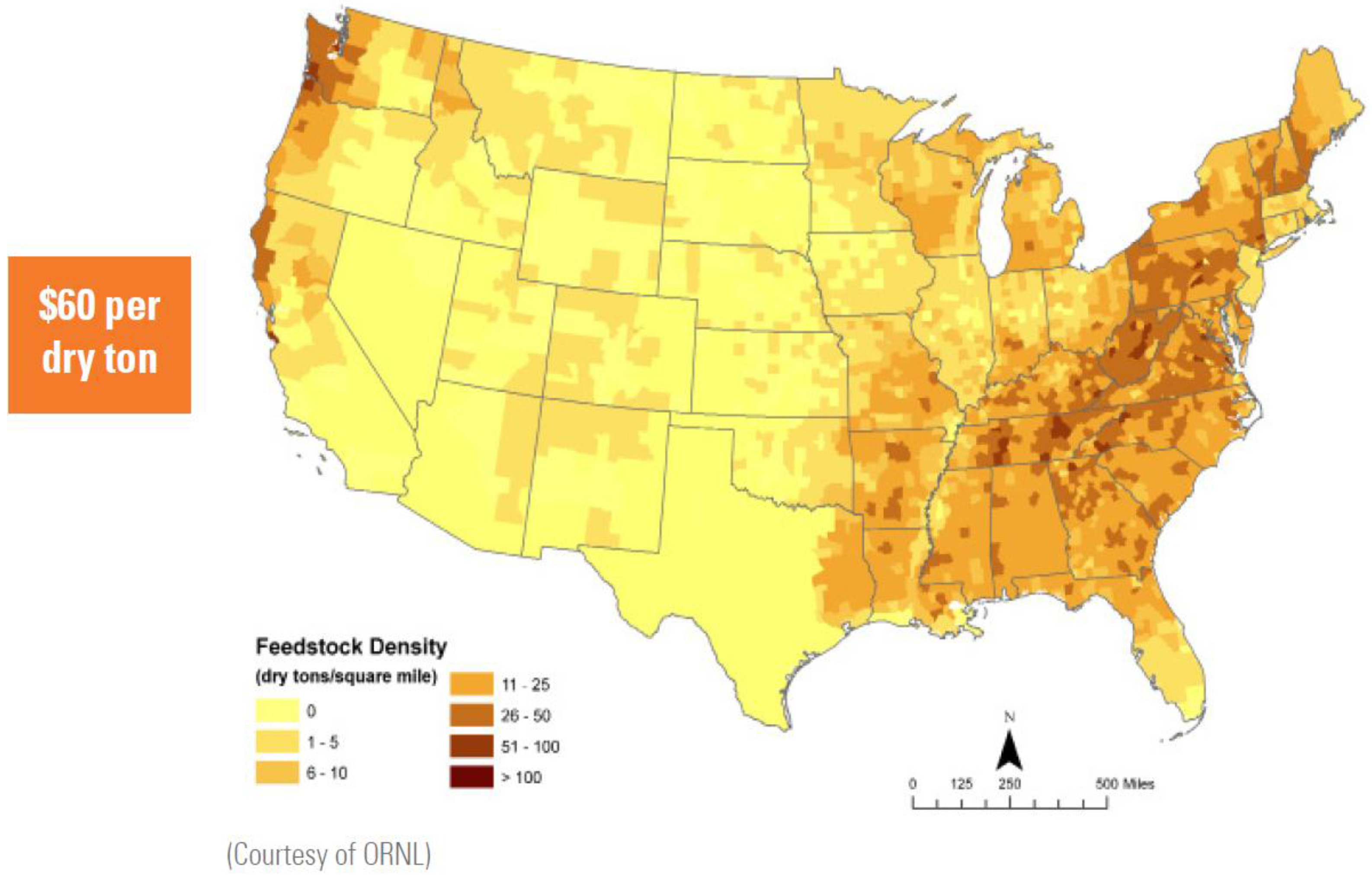

While energy crops (e.g., switchgrass) are expected to constitute the major portion of the biofuel feedstocks in 2022 and beyond, residues from the forest and the agricultural operations are critical feedstocks for the first-type generation of biofuel conversion facilities (e.g., corn-ethanol biorefineries). The report of the U.S. Department of Energy (DOE) “U.S. Billion-Ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry” [

10] projects that nearly 97 million dry tons of logging residues (unused portions of trees cut during logging) are currently available for bioenergy purposes. This makes up 38% of the 258 million dry tons of biomass that are available for new biofuel production. For example, as shown in

Figure 1, logging residues are concentrated in the eastern and north western regions of the United States. In order to take advantage of such energetic potential, the design of efficient large-scale bioenergy SCs is required. Moreover, forest residues are low cost biomass sources; however, they also possess unfavorable quality characteristics, specially, the high ash content [

11].

This paper addresses the problem of designing cost-effective bioenergy SCs by presenting a novel supply chain network design modeling approach that integrates the inherent costs associated to the quality of logging residues. Particularly, this research aims to amend the lack of theoretical background that directly hinders the design of robust biomass-to-biorefinery supply chains. It integrates the logging residues quality specifications needed by the conversion process and the impact of biomass quality characteristics on the supply chain network design. A special characteristic of the proposed computational and theoretical scheme is that it can be straightforwardly transferred to other types of biomass SCs and can also be transferred to other chemical and food industry SCs.

This paper is structured as follows:

Section 2 presents a brief literature review of supply chain design, modeling and optimization; poor quality costing; and biofuel feedstock logistics models.

Section 3 presents the novel modeling approach, named the Bioenergy Supply Chain including Quality (BioSC-Q) model, which is used to quantify the impact of quality control strategies implemented during collection, storage and transportation on the overall cost.

Section 4 presents a realistic case study in the state of Tennessee and the analysis of the results employing the proposed framework.

Section 5 presents a summary of the key insights and the concluding remarks, as well as recommendations for future work.

3. The BioSC-COQ Model Formulation

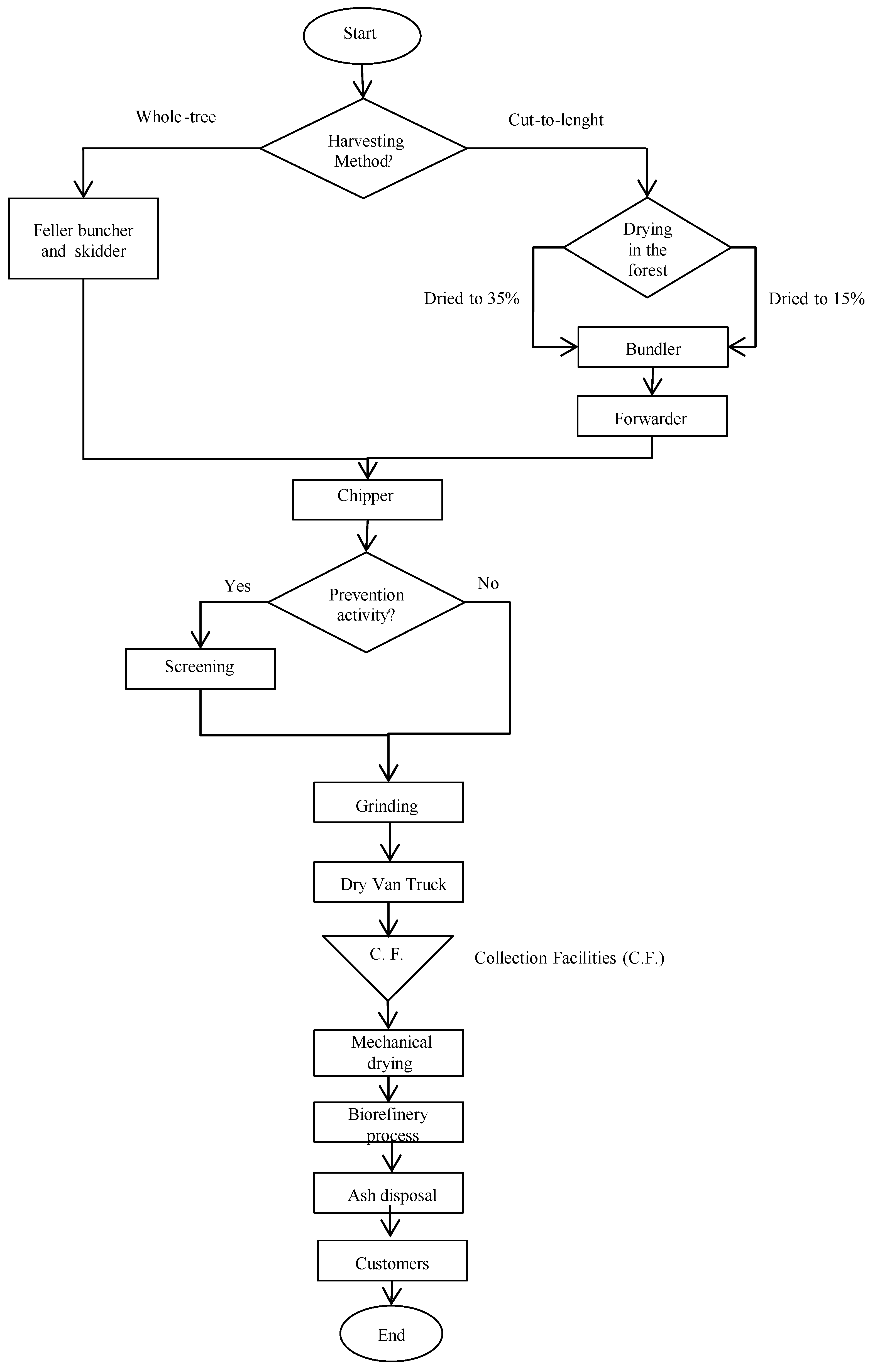

3.1. Harvesting Methods

Two collection strategies for logging residues are considered, as depicted in

Figure 3;

the whole-tree and

cut-to-length harvesting methods. The whole-tree (WT) harvesting system uses a feller-buncher to fall and stack trees in the forest. A skidder collects the stacks of trees and hauls them to the landing. At the landing, a delimber removes the tops and branches from the trunk of the tree, which are to be sold for logs or pulpwood. The residues can be chipped for transportation to a biorefinery.

The cut-to-length (CTL) system consists of a specialized harvester that cuts the tree at the base. Then, it rotates the tree to a position parallel with the ground and pulls it through rollers that delimb the tree as it cuts the logs into customized lengths. The residues are typically left in the forest. If these residues are to be used for bioenergy production purposes, they can be left in the forest for several weeks or months to allow them to dry naturally as part of a moisture management strategy. After being allowed to dry, they are collected and transported to the landing for chipping and transport. Collecting and transporting loose residues can be a time-consuming and costly operation.

As with all woody biomass, the moisture and the ash contents are critical parameters while determining the efficiency of the conversion technologies (e.g., the yields and the feasibility to use as-is biomass). Woody biomass is best suited for thermo-chemical conversion processes, which require that feedstocks have moisture contents of 10% or less and ash contents of 1% or less (i.e., these represent the target values). Biomass with moisture and ash concentrations above these target values will incur additional costs within the SC.

Woody biomass entering a thermochemical conversion facility will undergo a process of

mechanical drying (e.g., using a rotary drum dryer). The time spent in the dryer and the energy used by the dryer will depend on the initial moisture content. Allowing residues to dry in the forest (e.g., the CTL system) prior to the transportation to the biorefinery will reduce the energy required and, thus, the costs to dry the biomass. For the purposes of this study, it is assumed that the moisture content of the useful residues at the time a tree is cut is 50% (this corresponds to the WT system). After the residues are allowed to dry in the forest, the moisture content can be expected to be lower [

28]. For this study, the CTL system can reach a 35 or 15% moisture content depending on the time the biomass is allowed to naturally dry in the forest.

On the other hand, if the biomass contains more ash than the target content, the remaining ash will be left in the reactor; thus, it will require proper disposal. As expected, the cost associated with the ash disposal increases with increasing initial ash content. This study considers the beneficial effects of passing the biomass through a

screener following grinding, as described by Dukes

et al. [

29], to separate ash from the woody biomass chips, as shown in

Figure 3.

Table 1 shows the harvesting methods that are considered in this work, indicating the different moisture contents and which scenarios employ biomass screening as a prevention activity.

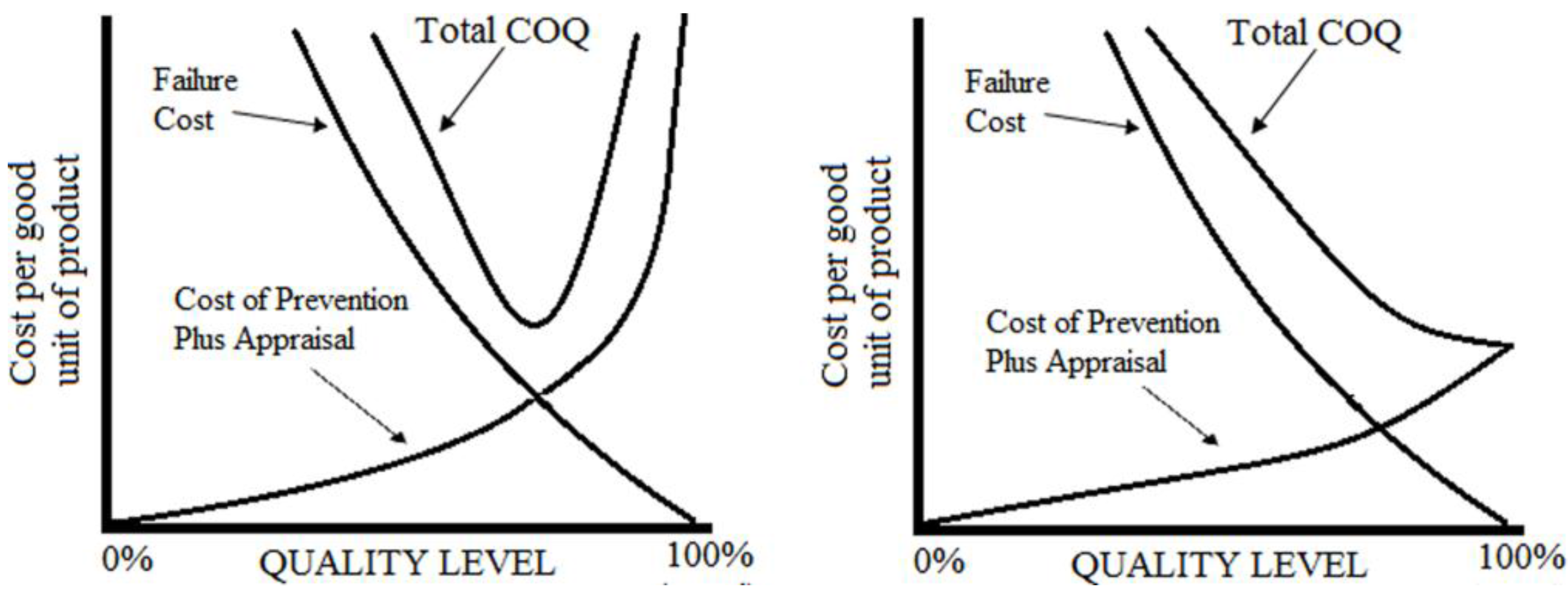

3.2. Quality Costing Model for the Logging Residues Supply Chain

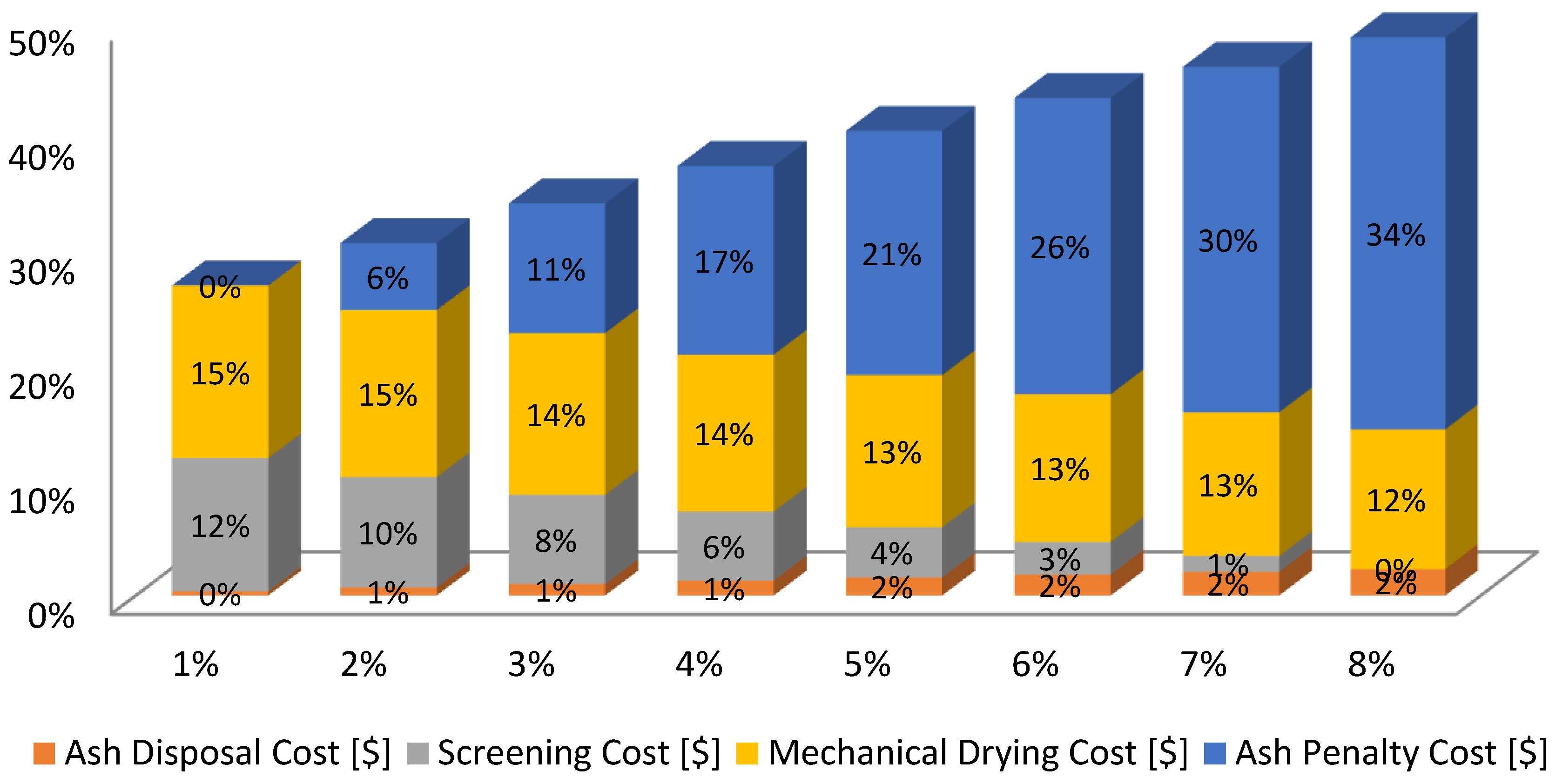

This section presents a formal methodology to compute the cost incurred by quality and operational affairs within the SC. The BioSC-COQ model defines as critical-to-quality characteristics the moisture and the ash contents. The costs include the fixed equivalent annual investment costs required to open collection facilities, the fixed equivalent annual investment costs required to open the bio-refineries, the mechanical drying, grinding, screening, ash disposal, ash penalty and the transportation costs. As mentioned in the background section, the total cost of poor quality can be broken into the conformance costs (prevention and appraisal categories) and the nonconformance costs (internal and external failure as well as opportunity costs). The definitions of these costs within the logging BioSC-COQ model are described as follows.

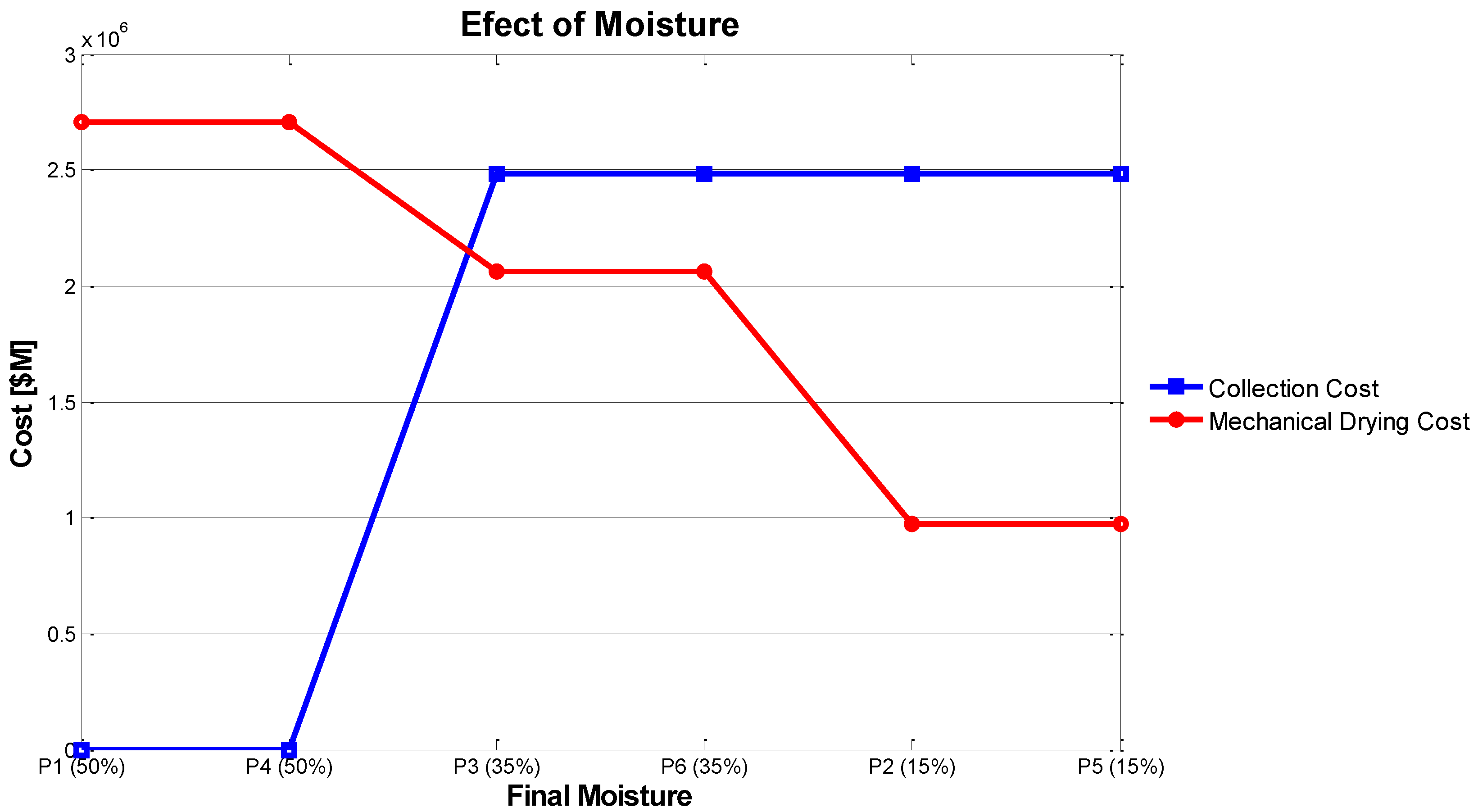

The

conformance costs are linked to two prevention costs. The first prevention cost is related to the moisture content and consists of the

collection cost after drying the useful residues. A benefit of implementing the CTL harvest strategy is the opportunity to naturally dry the biomass in the forest to reduce, to some extent (e.g., 35% or 15%), the initial moisture content (e.g., ~50%). Reducing the moisture content decreases the transportation cost as moist biomass is bulky and reduces the energy required during the mechanical drying process at the biorefinery. However, the additional costs of collecting the residues and transporting them to the landing are incurred. In the baseline WT system, the collection cost is null as all the collection costs are only attributed to conventional products (logs or pulpwood). The second prevention cost is related to the ash content and consists of the

screening cost incurred in order to reduce the initial ash concentration. Passing the wood chips through a screener after grinding is considered in some harvesting methods (e.g., P1 and P4 in

Table 1). It is worth noting that no inspection-related techniques (appraisal costs) are considered for this BioSC-COQ model because inspecting the quality of the biomass is not a common practice and inspection

per se does improve the biomass quality.

The non-conformance costs are linked to the failure costs associated to biomass that does not meet the moisture and the ash contents specifications for the energy conversion process. Although the CTL harvest strategy incurs an additional cost for collecting residues as a separate operation, it reduces the energy required to dry woody biomass from a 35% or 15% to 10% moisture content (i.e., the target value required by the conversion process). The cost of the mechanical drying process is considered a nonconformance cost and it is directly related to the moisture content. Similarly, the cost to dispose the ash that remains in the reactor, after the conversion process takes place, is also a nonconformance cost that is directly associated to not having the target ash content before the biomass is left at the throat of the reactor.

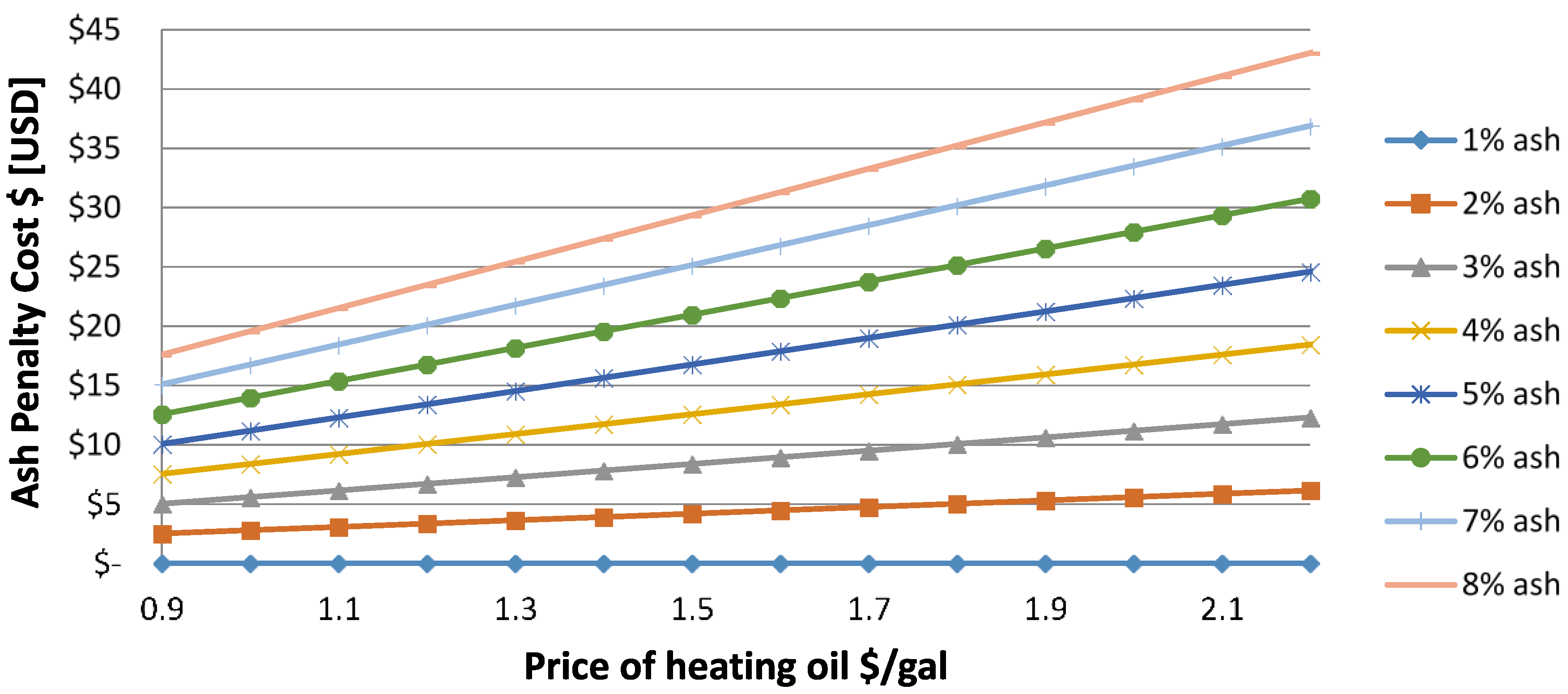

Moreover, the opportunity cost is modeled as the ash penalty cost for reduced oil yield. The difference between the profit that would have been generated when meeting the target ash content versus the yield obtained with a high ash content is computed.

All these quality-related costs are expressed in analytical expressions and integrated into the mathematical model presented in

Section 3.3.

3.3. Mathematical Formulation

The bioenergy supply chain network modeled is depicted in

Figure 4.

Indices/Sets | Set of parcels. |

| Set of potential sites for collection facilities. |

| Set of potential sites for bio-refineries. |

| Set of customers. |

| Set of harvesting methods. |

Decision Variables | Amount of biomass [ton] harvested via method p, shipped from parcel i to the collection facility j, in period t, where , and |

| Amount of biomass [ton] harvested via method p, shipped from the collection facility j to the bio-refinery k, in period t, where , and |

| Amount of biofuel [liters] shipped from bio-refinery k to customer l in period t, where and |

| Binary variable that is equal to 1 if parcel i connected to the collection facility j that uses the harvesting method p is active in period t, and equal to 0 otherwise. |

| Binary variable that is equal to 1 if collection facility j is open, and equal to 0 otherwise. |

| Binary variable that is equal to 1 if bio-refinery k is operating, and equal to 0 otherwise. |

| Variable that establishes the final ash content, where . |

Parameters

Operational Parameters | Maximum amount [tons] of available biomass in parcel I, where . |

| Capacity of a collection facility [tons] j, where . |

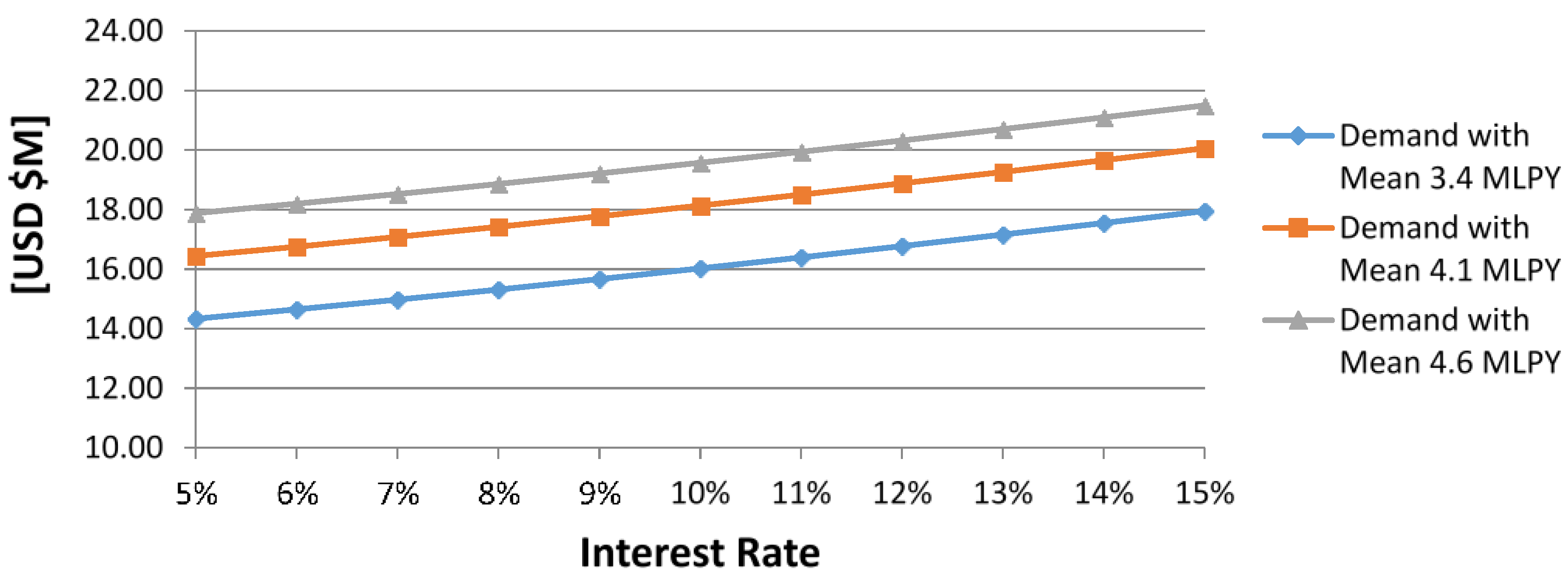

| Capacity of the bio-refinery [MLPY] k, where . |

| Customer demand [MLPY] l, where . |

| Fixed annual equivalent cost [USD $] for opening the collection facility j, where . |

| Fixed annual equivalent fixed cost [USD $] for opening the bio-refinery k, where . |

| Number of bio-refineries k that can operate. |

| Very large positive value. |

| Grinding cost [USD $] employing harvesting method p, where . |

Transportation Parameters | Transportation cost [USD $] per dry ton using harvesting method p from parcel i to collection facility j, where , and . |

| Transportation cost [USD $] per dry ton using harvesting method p from collection facility j to bio-refinery k, where , and . |

| Transportation cost [USD $] per volume from bio-refinery k to the customer l, where and . |

Quality Parameters | Collection cost [USD $] per dry ton of feedstock harvested employing the method p, in parcel i, where and . |

| Parameter that establishes the initial content of ash, where . |

| Mechanical drying cost [USD $] employing harvesting method p, in period t, where . |

| Ash disposal cost [USD $], which is calculated from a linear regression such that , where . |

| Ash penalty cost [USD $], which is calculated from a linear regression such that , where . |

| Screening cost [USD $], which is calculated from a linear regression such that , where is the initial level of ash content, and is the final level of ash content, where with the conditional . |

| Oil yield [liters], which is calculated from a linear regression such that , where . |

Mathematical Model

The BioSC-COQ model aims to minimize overall costs, as follows:

where

[$] is the total cost of transportation,

[$] is the total cost of the harvest processes,

[$] is the fixed annual equivalent cost for opening the collection facilities,

[$] is the fixed annual equivalent cost for opening the bio-refineries,

[$] is the mechanical drying cost,

[$] is the ash disposal cost,

[$] is the screening cost,

[$] is the grinding cost and

[$] is a penalty cost for reduced oil yield due to high ash content. Each cost is modeled as follows:

The BioSC-COQ model is subject to the following constraints:

Constraints Equation (11) impede to exceed the capacity of each parcel

i:

Constraints Equation (12) limit the capacity of each collection facility

j:

Constraints Equation (13) impede to exceed the capacity of each bio-refinery

k:

Constraints Equation (14) ensure demand satisfaction for each customer

l:

Constraints Equation (15) allow the balance of flow between the parcel

i and the facility

j, and between the facility

j and the bio-refinery

k:

Constraints Equation (16) allow the balance of flow between the facility

j and the bio-refinery

k, and between the bio-refinery

k and the customer

l:

Constraints Equation(17) ensure that biomass shipment can only be done through active parcels

:

Constraints Equation (18) ensure that only one harvesting method

p can be employed at each parcel

i:

Constraints Equation (21) establish the maximum number of biorefineries that can operate:

Constraints Equations (20)–(22) define the type of the decision variables in the model.

6. Conclusions

A cost classification for quality-related costs in bioenergy supply chains using logging residues and a method to quantitatively incorporate the Cost of Quality (COQ) into a holistic supply chain model are presented in this paper. The proposed BioSC-COQ model selects the optimal final moisture and ash contents that minimize the overall cost within the supply chain by balancing the conformance (preventive) and nonconformance (reactive) quality control activities/losses. Furthermore, it includes traditional costs in supply chains such as logistic costs and operational costs of collection centers and bio-refineries while integrating a novel method of quantifying feedstock quality-related costs and selecting cost-effective quality control activities.

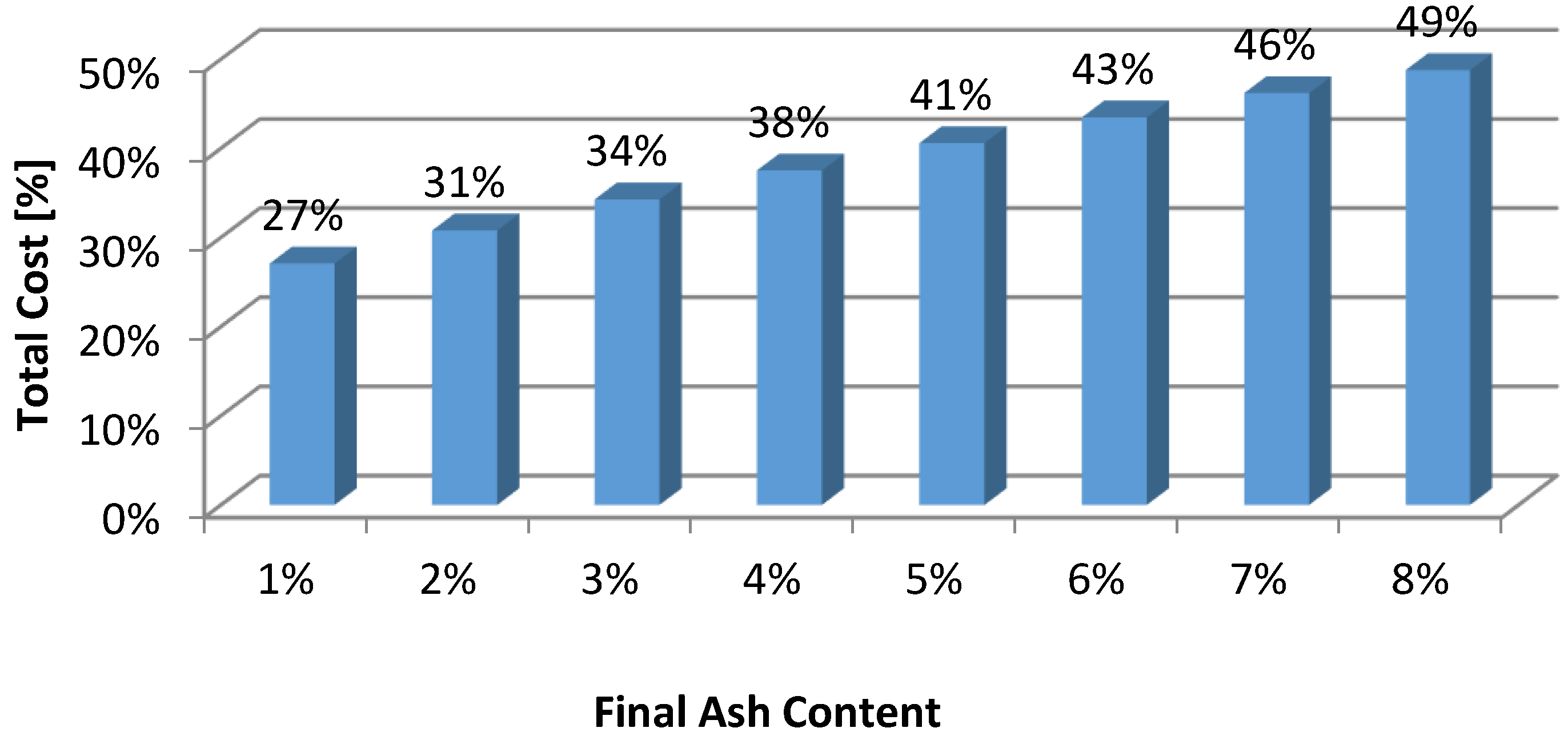

Based on the numeral experimentation, the total supply chain cost increased 7%, for each additional percent in the final ash content. Higher final ash contents result in a lower fuel production; therefore, greater amount of biomass is required to meet the customer demands. With each unit percentage increase of the final ash content from target value, oil yield decreased by 3.8% on average. Moreover, an ash content greater than the target value increases the overall cost by incurring in losses (i.e., ash penalty and ash disposal).

Regarding the impact of moisture content, the model selects the Whole-Tree harvesting method to reach a final moisture content of 50%. The moisture content in the logging residues increases the transportation and mechanical drying costs. However, the cost of collection (incurred when the biomass is left to dry) is higher than the mechanical drying and transportation costs.

In summary, this paper presents a model and solution approach that can be used as a decision support tool for the strategic and tactical planning and management of the logging residues supply chain network. The model takes into consideration aspects related to the biomass quality such as its ash and moisture contents (critical-to-quality characteristics). Previous works have acknowledged the importance of biomass quality in the decision making process but have not incorporated it into an analytical model that can serve as a decision support system. The proposed model closes this gap by building a more comprehensive model that considers and quantifies the feedstock quality implications.