Evaluating Internal Technological Capabilities in Energy Companies

Abstract

:1. Introduction

2. Literature Review

2.1. Existing Approaches to Evaluate Technological Capabilities

2.1.1. Definition of Technology

2.1.2. Evaluating Technological Capabilities

- (a)

- Explicit/Implicit: Technology can be diversely classified by the purpose of the knowledge. Overall, this is classified as explicit knowledge and implicit knowledge [40]. In the view of efficient selection, some may prioritize the evaluation of technological capability by selecting only one form of the knowledge. However, Archibugi and Coco [41] stated that codified knowledge, such as manuals and patents, are as important as knowledge obtained by implicit learning, and suggested that a partial evaluation can overlook a fundamental part of technological capability. Meanwhile, Nonaka [39] argued that knowledge is created through a conversion process of tacit knowledge and explicit knowledge. This process consists of (1) socialization (e.g., an artisans’ technology transfer), which creates more tacit knowledge from tacit knowledge; (2) externalization (e.g., writing, writing patents), which converts tacit knowledge to implicit knowledge; (3) internalization (e.g., experience), which converts implicit knowledge to tacit knowledge; and (4) combination (e.g., general educational practice of creating knowledge by classifying, combining, and categorizing implicit knowledge), which creates more implicit knowledge from implicit knowledge. In this context, Nonaka [42] emphasized the balanced creation of explicit and implicit knowledge and the continuous interaction based on the knowledge of rationality. Ultimately, the evaluation of technological capability should encompass explicit and implicit knowledge.

- (b)

- Embodied/Dis-embodied: Technological knowledge can be divided into embodied knowledge and dis-embodied knowledge [17]. Embodied technology, as a concept of the embodiment hypothesis, means that technology with a function of “knowledge that is applied to production” becomes embodied into machinery equipment [43]. It can be used as a measurement of production technology. In addition, embodied technology has an important meaning to countries, industries, technological fields, and companies as a “secret of success.” As its level has an impact on the success of technology development in the short term and on potential technology, which comes from technological development results and patents, in the long term [44], the evaluation of technological capability in embodied knowledge is valuable. Meanwhile, if embodied technology expands to the specific knowledge that is dissolved in a series of manufacturing processes and the ideas or knowledge necessary for the improvement of future production and individual technological capability, it can expand to equipment and employee capabilities. This perspective is supported by numerous studies that claim that the knowledge embodied in employees is a core capability of a company, an asset for strategy, and a determinant of competitiveness [45]. Unlike the embodied knowledge of a person or in a form such as equipment, dis-embodied knowledge represents separate efforts to improve technology. At the individual level, dis-embodied knowledge is represented by an exchange between researchers and engineers through individual contact, meeting, and symposia, or an exchange through reading related technological books, papers, and patents. Human mobility [46] and strategic alliance [47] are used as an index for measuring dis-embodied knowledge flows. At an organizational level, dis-embodied knowledge is an element that affects Total Quality Management (TQM), which is employed to achieve business excellence. As shown in a study on the relationship between TQM and a broader field of management theory (see, for example Bauer et al. [48]), the quality of existing products and services, work processes, and the work environment fall under the TQM category of assessment and management. Therefore, the present study aims to measure embodied and dis-embodied knowledge simultaneously.

2.2. Internal Technological Capabilities in Energy Generation and Supply Firms

3. Development of an Evaluation Model

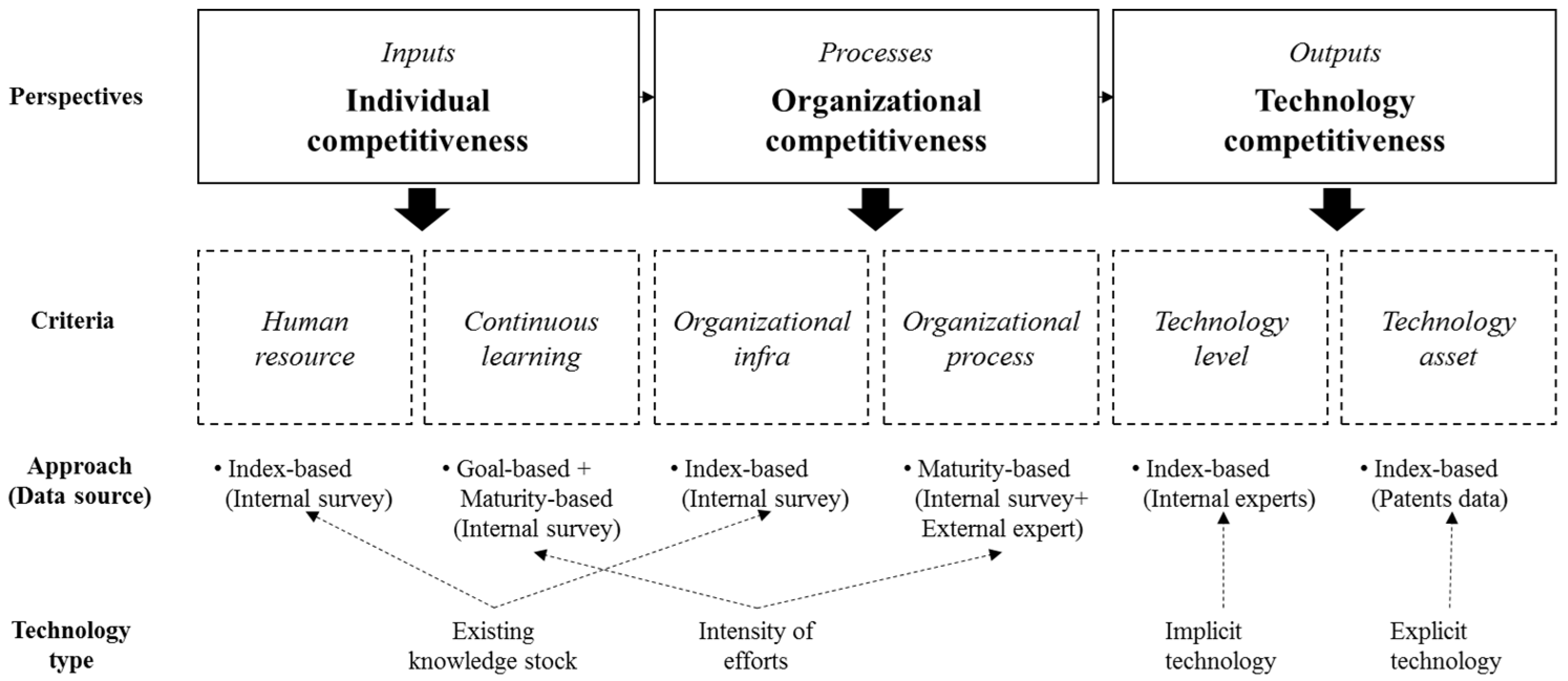

3.1. A Conceptual Framework to Evaluate Internal Technological Capabilities

3.2. Evaluation Areas and Criteria

3.2.1. Individual Competitiveness

3.2.2. Organizational Competitiveness

3.2.3. Technology Competitiveness

3.3. Evaluation Methods

3.3.1. Area-Wise Evaluation

3.3.2. Overall Evaluation

4. Application of the Suggested Model

4.1. Background

4.2. Preliminary Activities

4.3. Area-Wise Evaluation Results

4.4. Overall Evaluation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix

| Division | Section | Survey Item | Average | Standard Deviation | Assessment | Level |

|---|---|---|---|---|---|---|

| Human resource | Quantity | 1 item | 3.54 | 1.08 | Less than 4 | 3.0 |

| Superiority * | 139 tasks | 4.16 | 0.57 | Less than 5 | 4.0 | |

| Capacity building willingness | Self-development * | 3 items | 3.18 | 1.04 | Less than 4 | 3.0 |

| Cooperation * | 7 items | 1.98 | 1.08 | Less than 2 | 1.0 | |

| Knowledge management | Level 2(a) | 4.14 | 0.78 | Fully achieved | 5.0 | |

| Level 2(b) | 4.14 | 0.84 | ||||

| Level 3(a) | 4.15 | 0.78 | Fully achieved | |||

| Level 3(b) | 4.05 | 0.88 | ||||

| Level 3(c) | 4.01 | 0.89 | ||||

| Level 4 | 4.01 | 0.87 | Fully achieved | |||

| Level 5 | 4.04 | 0.91 | Fully achieved |

| Division | Section | Survey Item | Average | Standard Deviation | Assessment | Level |

|---|---|---|---|---|---|---|

| Infrastructure | Quantity * | 2 items | 4.50 | 0.98 | Less than 5 | 4 |

| Superiority * | 13 items | 4.05 | 0.87 | |||

| Process capability | Standardization | Level 2(a) | 4.33 | 0.68 | Fully achieved | 5 |

| Level 2(b) | 4.23 | 0.66 | ||||

| Level 3(a) | 4.28 | 0.73 | Fully achieved | |||

| Level 3(b) | 4.19 | 0.73 | ||||

| Level 4 | 4.18 | 0.77 | Fully achieved | |||

| Level 5(a) | 4.18 | 0.79 | Fully achieved | |||

| Level 5(b) | 4.07 | 0.81 | ||||

| Quality management | Level 2(a) | 4.38 | 0.67 | Fully achieved | 5 | |

| Level 2(b) | 4.48 | 0.63 | ||||

| Level 3(a) | 4.52 | 0.58 | Fully achieved | |||

| Level 3(b) | 4.50 | 0.60 | ||||

| Level 3(c) | 4.39 | 0.73 | ||||

| Level 4(a) | 4.43 | 0.72 | Fully achieved | |||

| Level 4(b) | 4.45 | 0.64 | ||||

| Level 5 | 4.49 | 0.59 | Fully achieved | |||

| Issue management | Level 2(a) | 4.48 | 0.61 | Fully achieved | 5 | |

| Level 2(b) | 4.53 | 0.59 | ||||

| Level 3(a) | 4.36 | 0.67 | Fully achieved | |||

| Level 3(b) | 4.50 | 0.62 | ||||

| Level 4(a) | 4.44 | 0.62 | Fully achieved | |||

| Level 4(b) | 4.43 | 0.64 | ||||

| Level 5 | 4.46 | 0.61 | Fully achieved |

References

- Figueiredo, P.N. Beyond technological catch-up: An empirical investigation of further innovative capability accumulation outcomes in latecomer firms with evidence from Brazil. J. Eng. Technol. Manag. 2014, 31, 73–102. [Google Scholar] [CrossRef]

- Zahra, S.A. Technology strategy and new venture performance: A study of corporate-sponsored and independent biotechnology ventures. J. Bus. Ventur. 1996, 11, 289–321. [Google Scholar] [CrossRef]

- Ford, D. Develop your technology strategy. Long Range Plan. 1988, 21, 85–95. [Google Scholar] [CrossRef]

- Lowe, A.; Ridgway, K.; Atkinson, H. QFD in new production technology evaluation. Int. J. Prod. Econ. 2000, 67, 103–112. [Google Scholar] [CrossRef]

- Panda, H.; Ramanathan, K. Technological capability assessment of a firm in the electricity sector. Technovation 1996, 16, 561–588. [Google Scholar] [CrossRef]

- Moghaddam, N.B.; Mousavi, S.M.; Moallemi, E.A.; Yousefdehi, H. Wind energy status of Iran: Evaluating Iran’s technological capability in manufacturing wind turbines. Renew. Sustain. Energy Rev. 2011, 15, 4200–4211. [Google Scholar] [CrossRef]

- Costa-Campi, M.T.; García-Quevedo, J.; Trujillo-Baute, E. Challenges for R&D and innovation in energy. Energy Policy 2015, 83, 193–196. [Google Scholar]

- Margolis, R.M.; Kammen, D.M. Underinvestment: the energy technology and R&D policy challenge. Science 1999, 285, 690–692. [Google Scholar] [PubMed]

- Jaffe, A.B. Characterizing the “technological position” of firms, with application to quantifying technological opportunity and research spillovers. Res. Policy 1989, 18, 87–97. [Google Scholar] [CrossRef]

- Chiu, Y.J.; Chen, Y.W. Using AHP in patent valuation. Math. Comput. Modell. 2007, 46, 1054–1062. [Google Scholar] [CrossRef]

- Steele, L.W. Managing Technology—The Strategic View; McGraw-Hill: New York, NY, USA, 1989. [Google Scholar]

- Phaal, R.; Farrukh, C.J.; Probert, D.R. Technology roadmapping—A planning framework for evolution and revolution. Technol. Forecst. Soc. 2004, 71, 5–26. [Google Scholar] [CrossRef]

- Dosi, G. Technological paradigms and technological trajectories: A suggested interpretation of the determinants and directions of technical change. Res. Policy 1982, 11, 147–162. [Google Scholar] [CrossRef]

- Mansfield, E.; Romeo, A. Technology transfer to overseas subsidiaries by US-based firms. Q. J. Econ. 1980, 737–750. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, U.; Persaud, A. Building technological capability through importing technology: The case of Indonesian manufacturing industry. J. Technol. Transf. 1999, 24, 81–96. [Google Scholar] [CrossRef]

- Kim, L. Building technological capability for industrialization: Analytical frameworks and Korea’s eperience. Ind. Corp. Chang. 1999, 8, 111–136. [Google Scholar] [CrossRef]

- Knowledge-Based Economy; OECD (Organisation for Economic Cooperation and Development): Paris, France, 1996.

- Kim, L. From Imitation to Innovation: Dynamics of Korea’s Technological Learning; Harvard University Press: Boston, MA, USA, 1997. [Google Scholar]

- Camison, C.; Villar-Lopez, A. Organizational innovation as an enabler of technological innovation capabilities and firm performance. J. Bus. Res. 2014, 67, 2891–2902. [Google Scholar] [CrossRef]

- Zahra, S.A.; Ireland, R.D.; Hitt, M.A. International expansion by new venture firms: International diversity, mode of market entry, technological learning, and performance. Acad. Manag. J. 2000, 43, 925–950. [Google Scholar] [CrossRef]

- Cortes de Castro, E.; Figueiredo, P.N. Does technological learning pay off? Inter-firm differences in technological capability-accumulation paths and operational performance improvement. Res. Policy 2005, 31, 73–94. [Google Scholar]

- Dutrénit, G. Building technological capabilities in latercomer firms: A review essay. Sci. Technol. Soc. 2004, 9, 209–214. [Google Scholar] [CrossRef]

- Figueiredo, P.N. Industrial policy changes and firm-level technological capability development: Evidence from Northern Brazil. World Dev. 2007, 36, 55–88. [Google Scholar] [CrossRef]

- Jonker, M.; Romijn, H.; Szirmai, A. Technological effort, technological capabilities and economic performance: A case study of the paper manufacturing sector in West Java. Technovation 2006, 26, 121–134. [Google Scholar] [CrossRef]

- Romijn, H.; Albaladejo, M. Determinants of innovation capability in small electronics and software firms in South East England. Res. Policy 2002, 31, 1053–1067. [Google Scholar] [CrossRef]

- Leonard-Barton, D. Wellsprings of Knowledge; Harvard University Press: Boston, MA, USA, 1995. [Google Scholar]

- Dosi, G. Sources, procedures and microeconomic effects of innovation. J. Econ. Lit. 1988, 26, 1120–1171. [Google Scholar]

- Cohen, W.M.; Levinthal, D.A. Absorptive capacity: A new perspective on learning and innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Camison, C.; Forés, B. Knowledge absorptive capacity: New Insights for its conceptualization and measurement. J. Bus. Res. 2010, 63, 707–715. [Google Scholar] [CrossRef]

- Cepeda-Carrión, G.; Cegarra-Navarro, J.G.; Jimenez, D. The effect of absorptive capacity on innovativeness: Context and information systems capability as catalysts. Brit. J. Manag. 2012, 23, 110–129. [Google Scholar] [CrossRef]

- Kocoglu, I.; Akgun, A.E.; Keskin, H. The differential relationship between absorptive capacity and product innovativeness: A theoretically derived framework. Int. Bus. Res. 2015, 8, 108–120. [Google Scholar] [CrossRef]

- Chiesa, V.; Frattini, F.; Gilardoni, E.; Manzini, R.; Pizzurno, E. Searching for factors influencing technological asset value. Eur. J. Inn. Manag. 2007, 10, 467–488. [Google Scholar] [CrossRef]

- Motohashi, K. Assessment of technological capability in science industry linkage in China by patent database. World Pat. Inf. 2008, 30, 225–232. [Google Scholar] [CrossRef]

- Golec, A.; Kahya, E. A fuzzy model for competency-based employee evaluation and selection. Comput. Ind. Eng. 2007, 52, 143–161. [Google Scholar] [CrossRef]

- Bharadwaj, A.S. A resource-based perspective on information technology capability and firm performance: An empirical investigation. MIS Q. 2000, 24, 169–196. [Google Scholar] [CrossRef]

- Park, J.; Lee, H.; Park, Y. Disembodied knowledge flows among industrial clusters: A patent analysis of the Korean manufacturing sector. Technol. Soc. 2009, 31, 73–84. [Google Scholar] [CrossRef]

- Takahashi, K.; Yamane, Y.; Hamada, K.; Morikawa, K.; Bahagia, S.; Diawati, L.; Cakravastia, A. Quantifying the technology level of production system for technology transfer. Ind. Eng. Manag. Syst. 2011, 10, 97–103. [Google Scholar]

- Creswell, J.W. Research Design: Qualitative, Quantitative, and Mixed Approaches, 4th ed.; SAGE: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Nonaka, I. The knowledge-creating company. Harv. Bus. Rev. 1991, 69, 96–104. [Google Scholar]

- Chen, C.J. The effects of knowledge attribute, alliance characteristics, and absorptive capacity on knowledge transfer performance. R&D Manag. 2004, 34, 311–321. [Google Scholar]

- Archibugi, D.; Coco, A. Measuring technological capabilities at the country level: A survey and a menu for choice. Res. Policy 2005, 34, 175–194. [Google Scholar] [CrossRef]

- Nonaka, I. A dynamic theory of organizational knowledge creation. Organ. Sci. 1994, 5, 14–37. [Google Scholar] [CrossRef]

- Jorgenson, D.W. The embodiment hypothesis. J. Political Econ. 1966, 74, 1–17. [Google Scholar] [CrossRef]

- Rubenstein, A.H. Managing Technology in the Decentralized Firm; John Wiley and Sons: New York, NY, USA, 1989. [Google Scholar]

- Hall, R. The strategic analysis of intangible resources. Strateg. Manag. J. 1992, 13, 135–144. [Google Scholar] [CrossRef]

- Criscuolo, P. On the road again: Researcher mobility inside the R&D network. Res. Policy 2005, 34, 1350–1365. [Google Scholar]

- Gay, B.; Dousset, B. Innovation and network structural dynamics: Study of the alliance network for a major sector of the biotechnology industry. Res. Policy 2005, 34, 1457–1475. [Google Scholar] [CrossRef]

- Bauer, J.; Falshaw, R.; Oakland, J.S. Implementing business excellence. Total Qual. Manag. Bus. Excell. 2005, 16, 543–553. [Google Scholar] [CrossRef]

- Larger, T. A new conceptual model for the development of process technology in process industry: A point of departure for the transformation of the “Process Development Process” into a formal work process? Int. J. Inn. Manag. 2000, 4, 319–346. [Google Scholar]

- Freeman, C. Technical innovation in the world chemical industry and changes of techno-economic paradigm. In New Explorations in the Economics of Technical Change; Freeman, C., Soete, L., Eds.; Frances Printer: London, UK, 1990. [Google Scholar]

- Kallrath, J. Planning and scheduling in the process industry. OR Spectr. 2002, 24, 219–250. [Google Scholar] [CrossRef]

- Griliches, Z. Patent statistics as economic indicators: A survey. J. Econ. Lit. 1990, 28, 1661–1707. [Google Scholar]

- Acs, Z.J.; Anselin, L.; Varga, A. Patents and innovation counts as measures of regional production of new knowledge. Res. Policy 2002, 31, 1069–1085. [Google Scholar] [CrossRef]

- Prud’homme, D. Dulling the Cutting Edge: How Patent-Related Policies and Practices Hamper Innovation in China. Available online: http://ssrn.com/abstract=2190293 (accessed on 23 February 2016).

- Acs, Z.J.; Audretsch, D.B. Patents as a measure of innovative activity. Kyklos 1989, 42, 171–180. [Google Scholar] [CrossRef]

- Pavitt, K. Sectoral patterns of technical change: Towards a taxonomy and a theory. Res. Policy 1984, 13, 343–373. [Google Scholar] [CrossRef]

- Shah, N. Process industry supply chains: Advances and challenges. Comput. Chem. Eng. 2005, 29, 1225–1235. [Google Scholar] [CrossRef]

- Holsapple, C.W.; Joshi, K.D. Organizational knowledge resources. Decis. Support. Syst. 2001, 31, 39–54. [Google Scholar] [CrossRef]

- MacDuffie, J.P. Human resource bundles and manufacturing performance: Organizational logic and flexible production systems in the World Auto Industry. ILR Rev. 1995, 48, 197–221. [Google Scholar] [CrossRef]

- Orvis, K.A.; Ratwani, K.L. Leader self-development: A contemporary context for leader development evaluation. Leadersh. Q. 2010, 21, 657–674. [Google Scholar] [CrossRef]

- Katz, J.S.; Martin, B.R. What is research collaboration? Res. Policy 1997, 26, 1–18. [Google Scholar] [CrossRef]

- Tyler, B.B. The complementarity of cooperative and technological competencies: A resource-based perspective. J. Eng. Technol. Manag. 2001, 18, 1–27. [Google Scholar] [CrossRef]

- Chuang, S.H. A resource-based perspective on knowledge management capability and competitive advantage: An empirical investigation. Expert Syst. Appl. 2004, 27, 459–465. [Google Scholar] [CrossRef]

- Kulkarni, U.; Freeze, R. Development and validation of a knowledge management capability assessment model. In Proceedings of the 25th International Conference on Information System, Washington, DC, USA, 12–15 December 2004.

- Byrd, T.A.; Turner, D.E. An exploratory examination of the relationship between flexible IT infrastructure and competitive advantage. Inf. Manag. 2001, 39, 41–52. [Google Scholar] [CrossRef]

- Rai, A.; Patnayakuni, R.; Seth, N. Firm performance impacts of digitally enabled supply chain integration capabilities. MIS Q. 2006, 30, 225–246. [Google Scholar]

- Münstermann, B.; Weitzel, T. What is process standardization? In Proceedings of the 2008 International Conference on Information Resources Management (Conf-IRM), Niagara Falls, ON, Canada, 18–20 May 2008.

- Lobo, S.R.; Matawie, K.M.; Samaranayake, P. Assessment and improvement of quality management capabilities for manufacturing industries in Australia. Total Qual. Manag. Bus. Excell. 2012, 23, 103–121. [Google Scholar] [CrossRef]

- Vergidis, K.; Turner, C.J.; Tiwari, A. Business process perspectives: Theoretical developments vs. real-world practice. Int. J. Prod. Econ. 2008, 114, 91–104. [Google Scholar] [CrossRef]

- Guglielmi, M.; Williams, E.; Groepper, P.; Lascar, S. The technology management process at the European space agency. Acta. Astronaut. 2010, 66, 883–889. [Google Scholar] [CrossRef]

- Ernst, H. Evaluation of Dynamic Technological Developments by Means of Patent Data; Springer: Berlin, Germany, 1999; pp. 103–132. [Google Scholar]

- Michel, J.; Bettels, B. Patent citation analysis. A closer look at the basic input data from patent search reports. Scientometrics 2001, 51, 185–201. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chang, K.C. Exploring the nonlinear effects of patent citations, patent share and relative patent position on market value in the US pharmaceutical industry. Technol. Anal. Strateg. Manag. 2010, 22, 153–169. [Google Scholar] [CrossRef]

- Lall, S. Building Industrial Competitiveness in Developing Countries; OECD (Organisation for Economic Cooperation and Development): Paris, France, 1990. [Google Scholar]

- Rousseva, R. Classifying organisational capabilities by their nature and role for technological capability. In Proceedings of the British Academy of Management Conference, Brighton, UK, 15–17 September 2009.

- Vera, D.; Crossan, M.; Apaydin, M. A Framework for Integrating Organizational Learning, Knowledge, Capabilities, and Absorptive Capacity. In Handbook of Organizational Learning and Knowledge Management; Easterby-Smith, M., Lyles, M., Eds.; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Saaty, T.L. The Analytical Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

| Perspectives | Criteria | Indexes | Description | References |

|---|---|---|---|---|

| Individual competitiveness | Human resource | Quantity | Provision of necessary human resources | [58,59] |

| Superiority | Professionalism of staff | |||

| Continuous learning | Self-development | Conducting self-development activities | [60] | |

| Cooperation | Participation in exchange and cooperation activities | [61,62] | ||

| Knowledge management | DB operation and data management | [63,64] | ||

| Organizational competitiveness | Organizational infrastructure | Quantity | Ensuring the necessary infrastructure | [65,66] |

| Superiority | Excellence of owned infrastructure | |||

| Organizational process | Standardization | Standardization of operation processes | [67] | |

| Quality management | Excellence of process quality management | [68] | ||

| Issue management | Ability to prevent and manage irregular work | [69] | ||

| Technology competitiveness | Technology level | Technology leadership | Level of R&D leadership | [70] |

| Technology asset | Patent activity | The number of patent applications | [71] | |

| Patent effect | The average number of patent citations | [72] | ||

| Patent competitiveness | Patent share and growth rate of patents | [73] | ||

| Patent profitability | The average size of the patent family | [74] |

| Level | Description—Conceptual Criteria |

| 5 | (Optimizing) Optimal stage at which a standard process is continuously improved. |

| 4 | (Quantitatively Managed) Measuring and predicting step for quantitative control of the process. |

| 3 | (Defined) Step at which the activity is planned and managed by standard processes. |

| 2 | (Managed) Step at which the activity plan and planned activities are tracked and managed. |

| 1 | (Initial) Incomplete step at which there is no output that can identify processes. |

| Level | Description—A Case of “Issue Management” |

| 5 | Effort of preventing a problem is continued based on data analysis and a support system. |

| 4 | Data on issue management activity is collected and analysis is conducted. |

| 3 | Manuals on handling issues and the support system are built and managed. |

| 2 | Basic activity for analysis of and addressing causes of an issue is carried out. |

| 1 | An issue was inadequately addressed or it was dependent on an individual worker’s skills. |

| Level | Description—Conceptual Criteria |

| 5 | Achieved more than 85% of target level. |

| 4 | Achieved more than 70% of target level, but less than 85%. |

| 3 | Achieved more than 60% of target level, but less than 70%. |

| 2 | Achieved more than 50% of target level, but less than 60%. |

| 1 | Achieved less than 50% of target level |

| Level | Description—A Case of “Cooperation” |

| 5 | Individual participation for cooperation and achievement of organization’s goals through cooperation is very high. (Planned vs. achieved: greater than and equal to 85%) |

| 4 | Individual participation for cooperation and achievement of organization’s goals through cooperation is relatively high. (Planned vs. achieved: greater than and equal to 70% and less than 85%) |

| 3 | Individual participation for cooperation and achievement of organization’s goals through cooperation is somewhat high. (Planned vs. achieved: greater than and equal to 60% and less than 70%) |

| 2 | Some of Individual participation for cooperation and achievement of organization’s goals through cooperation were made. (Planned vs. achieved: greater than and equal to 50% and less than 60%) |

| 1 | Almost no individual participation for cooperation and achievement of organization’s goals through cooperation were made. (Planned vs. achieved: less than 50%) |

| Category | Description | |

|---|---|---|

| Evaluation of technology level | Own company | Evaluating the level of the element technologies in own company |

| Dominant > Strong > Favorable > Tenable > Weak | ||

| Domestic competitor(s) | Providing information about domestic competitor and evaluating the level of the element technologies in them | |

| Dominant > Strong > Favorable > Tenable > Weak | ||

| Foreign competitor(s) | Providing information about foreign competitor and evaluating the level of the element technologies in them | |

| Dominant > Strong > Favorable > Tenable > Weak | ||

| Matching between division and technology | Assessing the relevance of the organization and the factors described in step 5 | |

| 5 points: high relevance ↔ 1 points: no relevance | ||

| Perspectives | Criteria | Collection Method | Data Source | Collection Period |

|---|---|---|---|---|

| Individual competitiveness | Human resource | Survey | 712 employees | 21–31 July 2014 |

| Continuous learning | ||||

| Organizational competitiveness | Organizational infrastructure | |||

| Organizational process | ||||

| Interview (External expert) | one per department (total of six) | 7–13 August 2014 | ||

| Technology competitiveness | Technology level | Construction of technology tree | Technological expert group | 25 June 2014 |

| Technology asset | Patent collection | Europe (EU), Japan (JP), Korea (KR), United States (US) patent office | 25 June 2014 |

| Category | A | B | C | D | E | F | Total |

|---|---|---|---|---|---|---|---|

| Number of respondents | 133 | 222 | 27 | 24 | 10 | 296 | 712 |

| Response rate | 53.4% | 46.3% | 41.5% | 70.6% | 50.0% | 74.7% | 57.2% |

| Average ranks * | 4.3 | 4.3 | 4.0 | 3.5 | 3.8 | 4.5 | - |

| Year of employments | 13.2 | 13.1 | 11.5 | 13.4 | 15.4 | 14.4 | - |

| Category | Description |

|---|---|

| Processes and labor | Identify key processes and process-specific labor |

| Characteristics of the labor by process | Detailed activities: Listing labor related to the core business |

| Required competencies: Listing core competencies required of personnel for work performed | |

| Systems/SW: Listing core systems, SW, and data required to perform the work | |

| Equipment/facilities (HW): Listing the key facilities and equipment required for the work performed | |

| Major departmental issues | Issues that do not arise in the day-to-day: (1) Task problems that need to be solved; and (2) Suddenly given tasks |

| Individual capability | Required departmental certification: Qualification lists for successful job performance |

| Self-development activities: Types of self-development activities to continually enhance the capabilities |

| Category | Division | Section | Element Technology | R&D Leadership | Relevant Departments | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Own Company | Domestic Competitor | Foreign Competitor | A | B | C | D | E | F | ||||

| Production | Building | Design | T1 | 4 | DC1(4) | FC1(5) | 1 | 1 | 5 | 1 | 1 | 1 |

| … | … | … | … | … | … | … | … | … | … | |||

| … | … | … | … | … | … | … | … | … | … | … | ||

| Operation | … | … | … | … | … | … | … | … | … | … | … | |

| … | … | … | … | … | … | … | … | … | … | |||

| … | … | … | … | … | … | … | … | … | … | … | … | … |

| Criteria | Item | Evaluation Results | Evaluation Methods |

|---|---|---|---|

| Human resource | Quantity | 3.0 | Index-based |

| Superiority | 4.0 | Index-based | |

| Continuous learning | Self-development | 3.0 | Goal-based |

| Cooperation | 1.0 | Goal-based | |

| Knowledge management | 5.0 | Maturity-based | |

| Total evaluation results of individual competitiveness | 3.2 | - | |

| Criteria | Item | Evaluation Results | Evaluation Methods | |

|---|---|---|---|---|

| Organizational infrastructure | Quantity | 4.0 | Index-based | |

| Superiority | 4.0 | Index-based | ||

| Organizational process | Standardization | Survey: 5.0 | 4.5 | Maturity-based |

| Expert: 4.0 | ||||

| Quality management | Survey: 5.0 | 5.0 | Maturity-based | |

| Expert: 5.0 | ||||

| Issue management | Survey: 5.0 | 3.5 | Maturity-based | |

| Expert: 2.0 | ||||

| Total evaluation results of organizational competitiveness | - | 3.9 | - | |

| Criteria | Item | Evaluation Results | Evaluation Methods |

|---|---|---|---|

| Technology level | Integrated level | 3.73 | Index-based |

| Technology asset | Patent activity | 1.90 | Index-based |

| Patent effect | 0.95 | Index-based | |

| Patent competitiveness | 1.14 | Index-based | |

| Patent profitability | 4.73 | Index-based | |

| Total evaluation results of technology competitiveness | 2.49 | - | |

| Category | Criteria | Item | Weight | Area-Wise | Perspective-Wise |

|---|---|---|---|---|---|

| Individual competitiveness | Human resource | Quantity | 2.40% | 3.00 | 3.26 |

| Superiority | 4.75% | 4.00 | |||

| Capacity building willingness | Self-development | 3.20% | 3.00 | ||

| Cooperation | 2.55% | 1.00 | |||

| Knowledge management | 2.10% | 5.00 | |||

| Organizational competitiveness | Infrastructure | Quantity | 9.45% | 4.00 | 4.15 |

| Superiority | 6.40% | 4.00 | |||

| Process capability | Standardization | 6.35% | 4.50 | ||

| Quality management | 5.75% | 5.00 | |||

| Issue management | 7.05% | 3.50 | |||

| Technology competitiveness | Technology level | Integrated level | 25.00% | 3.73 | 3.00 |

| Technology asset | Patent activity | 6.25% | 1.90 | ||

| Patent effect | 6.25% | 0.95 | |||

| Patent competitiveness | 6.25% | 1.14 | |||

| Patent profitability | 6.25% | 4.73 | |||

| Total evaluation results of technology competitiveness | - | - | 3.42 | ||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.; Lee, S. Evaluating Internal Technological Capabilities in Energy Companies. Energies 2016, 9, 145. https://doi.org/10.3390/en9030145

Lee M, Lee S. Evaluating Internal Technological Capabilities in Energy Companies. Energies. 2016; 9(3):145. https://doi.org/10.3390/en9030145

Chicago/Turabian StyleLee, Mingook, and Sungjoo Lee. 2016. "Evaluating Internal Technological Capabilities in Energy Companies" Energies 9, no. 3: 145. https://doi.org/10.3390/en9030145

APA StyleLee, M., & Lee, S. (2016). Evaluating Internal Technological Capabilities in Energy Companies. Energies, 9(3), 145. https://doi.org/10.3390/en9030145