A Nature-Inspired Optimization-Based Optimum Fuzzy Logic Photovoltaic Inverter Controller Utilizing an eZdsp F28335 Board

Abstract

:1. Introduction

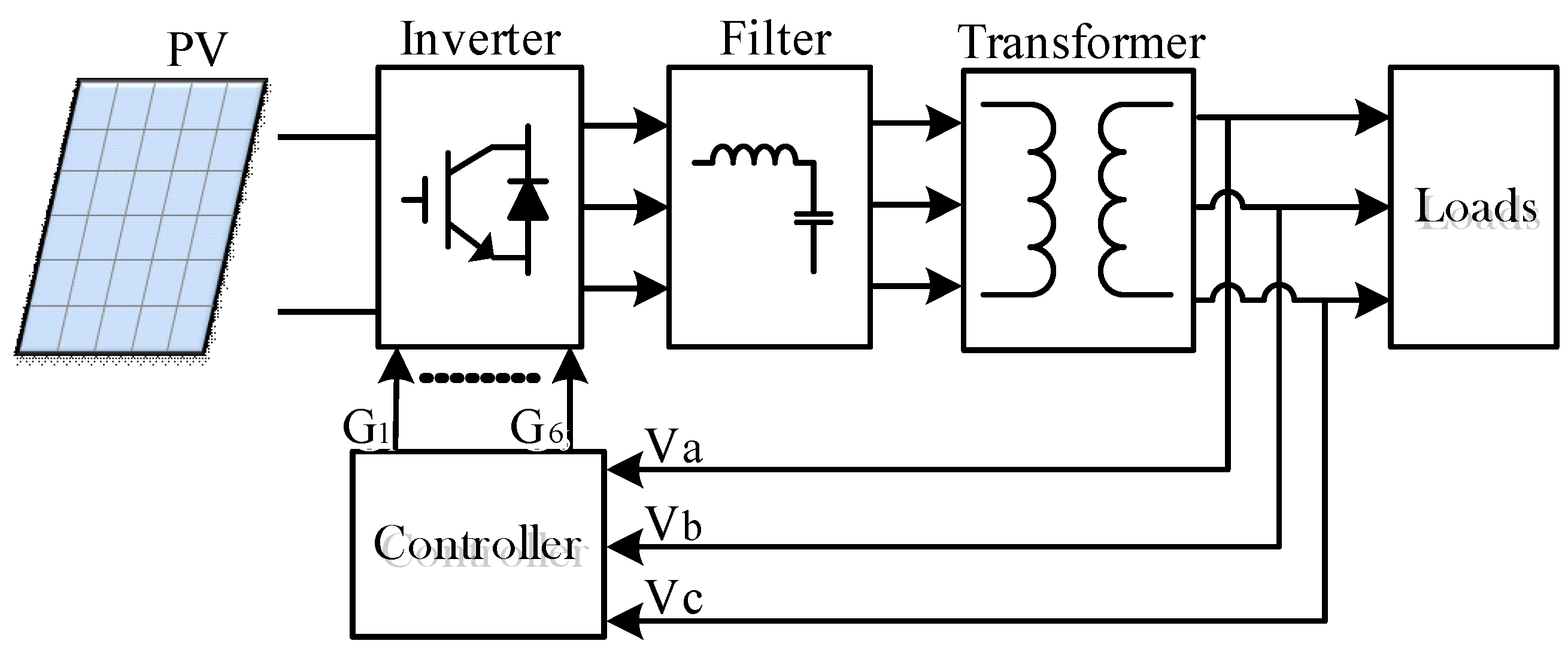

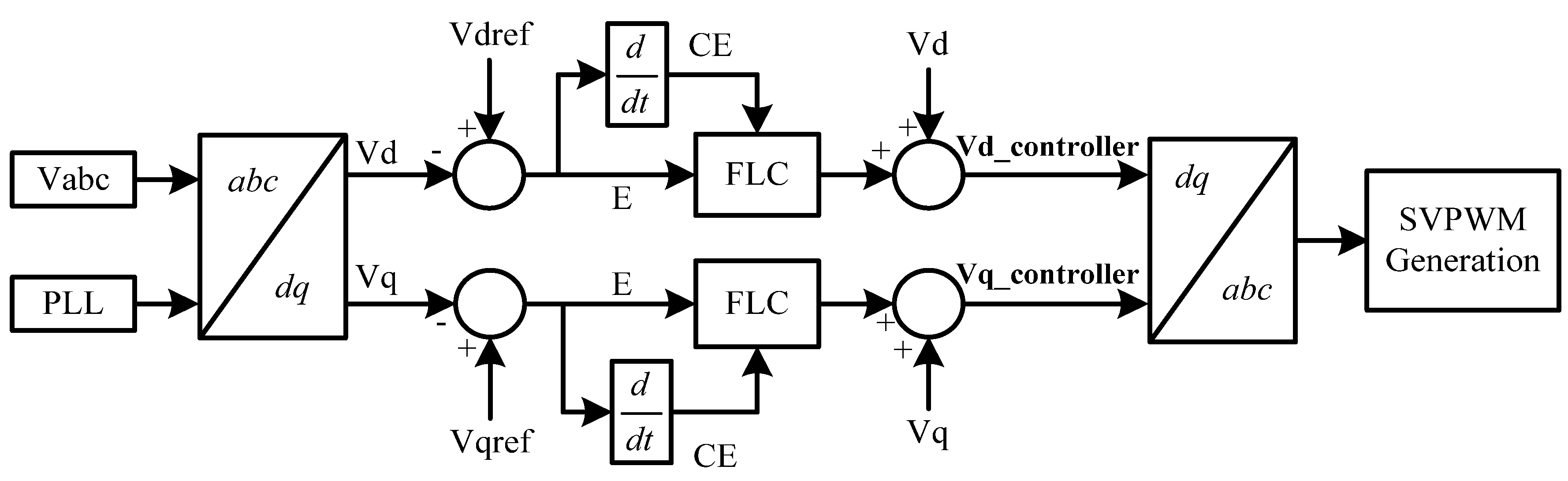

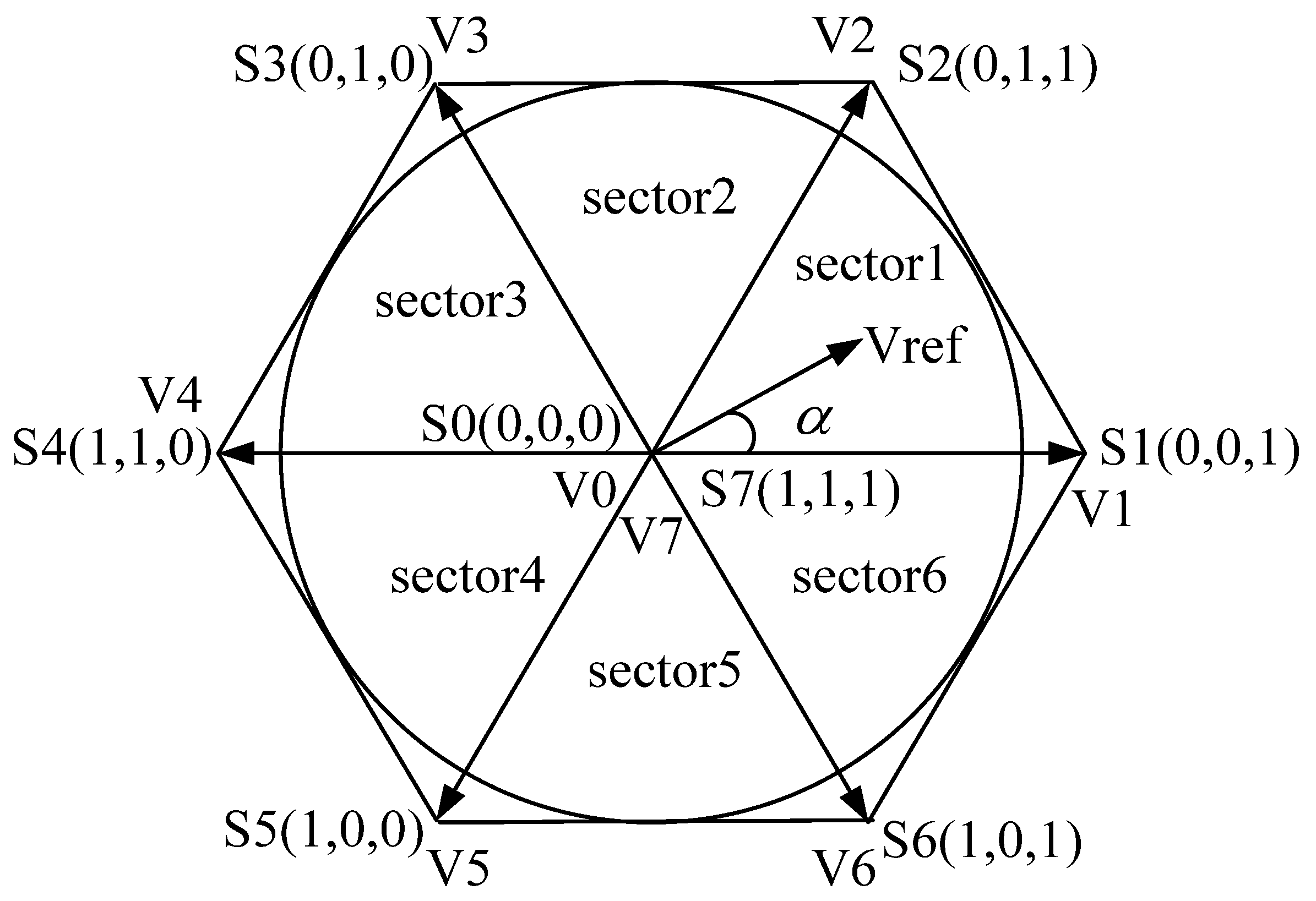

2. Inverter Control Algorithm

3. Inverter Control Using FLC Strategy

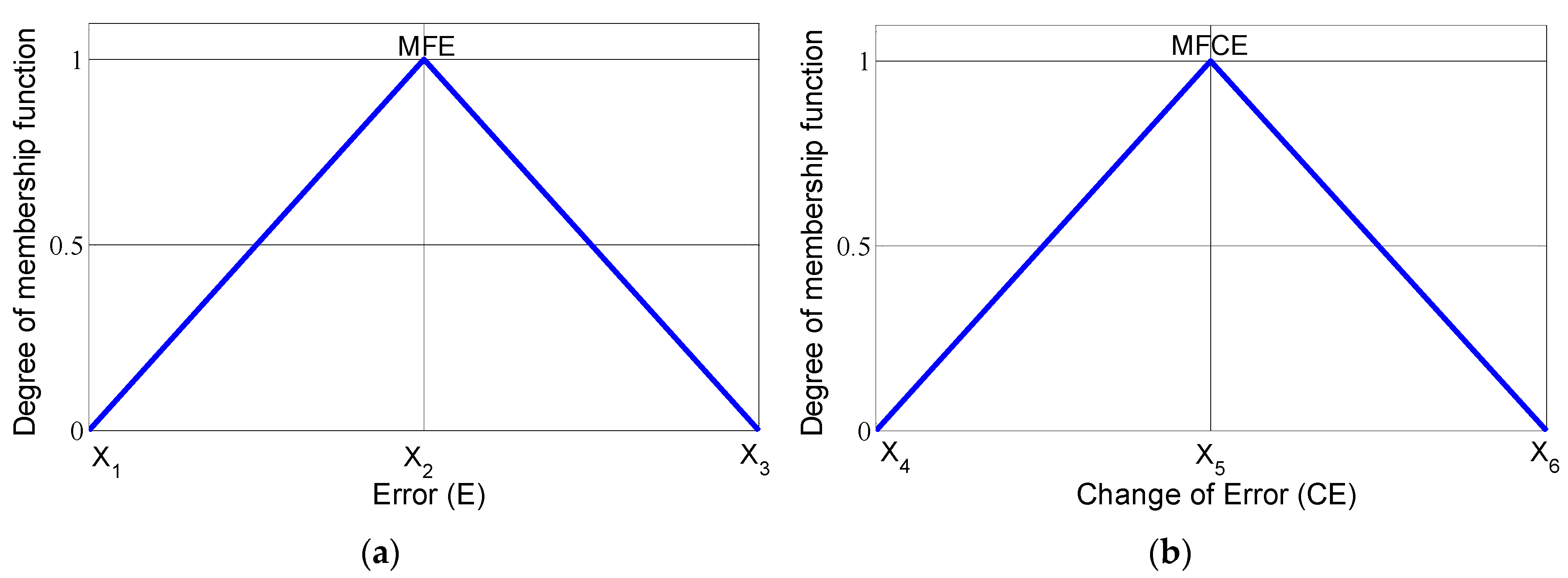

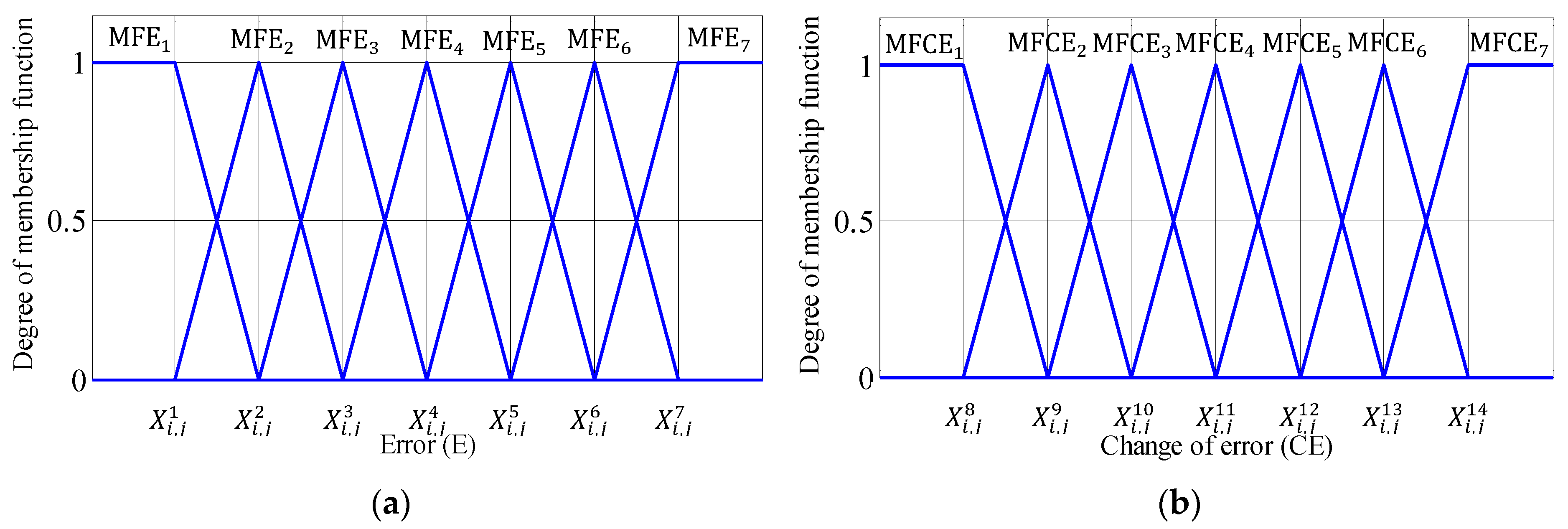

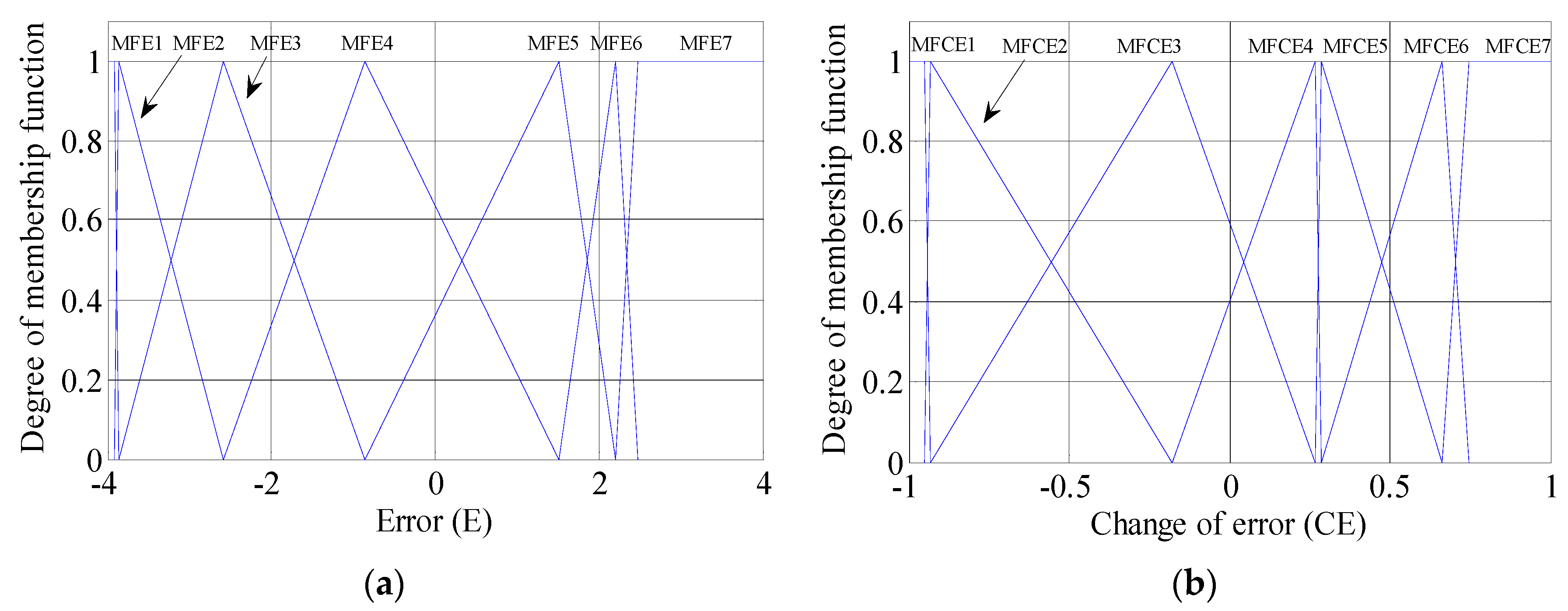

3.1. Fuzzification

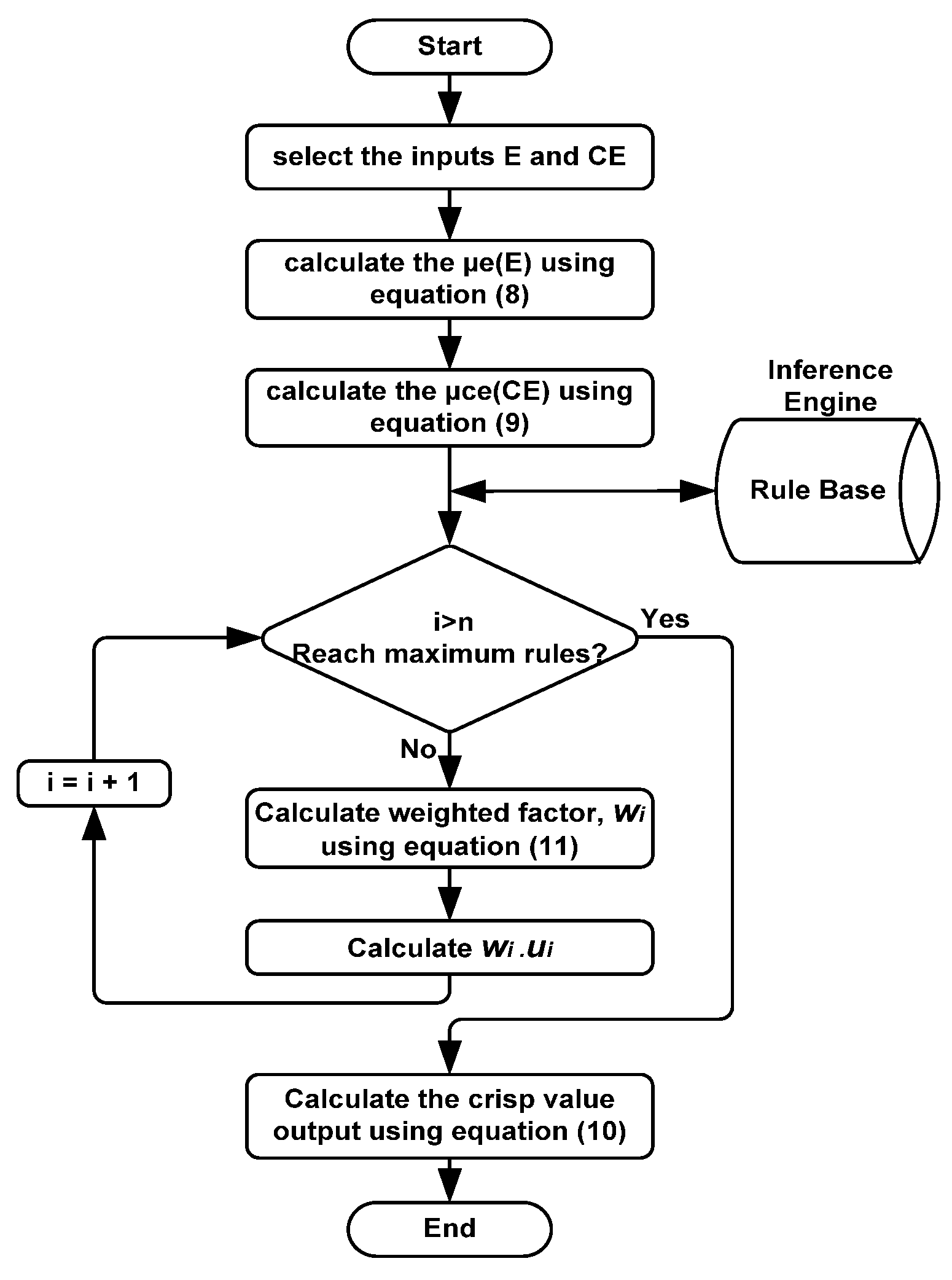

3.2. Inference Engine Design

3.3. Defuzzification

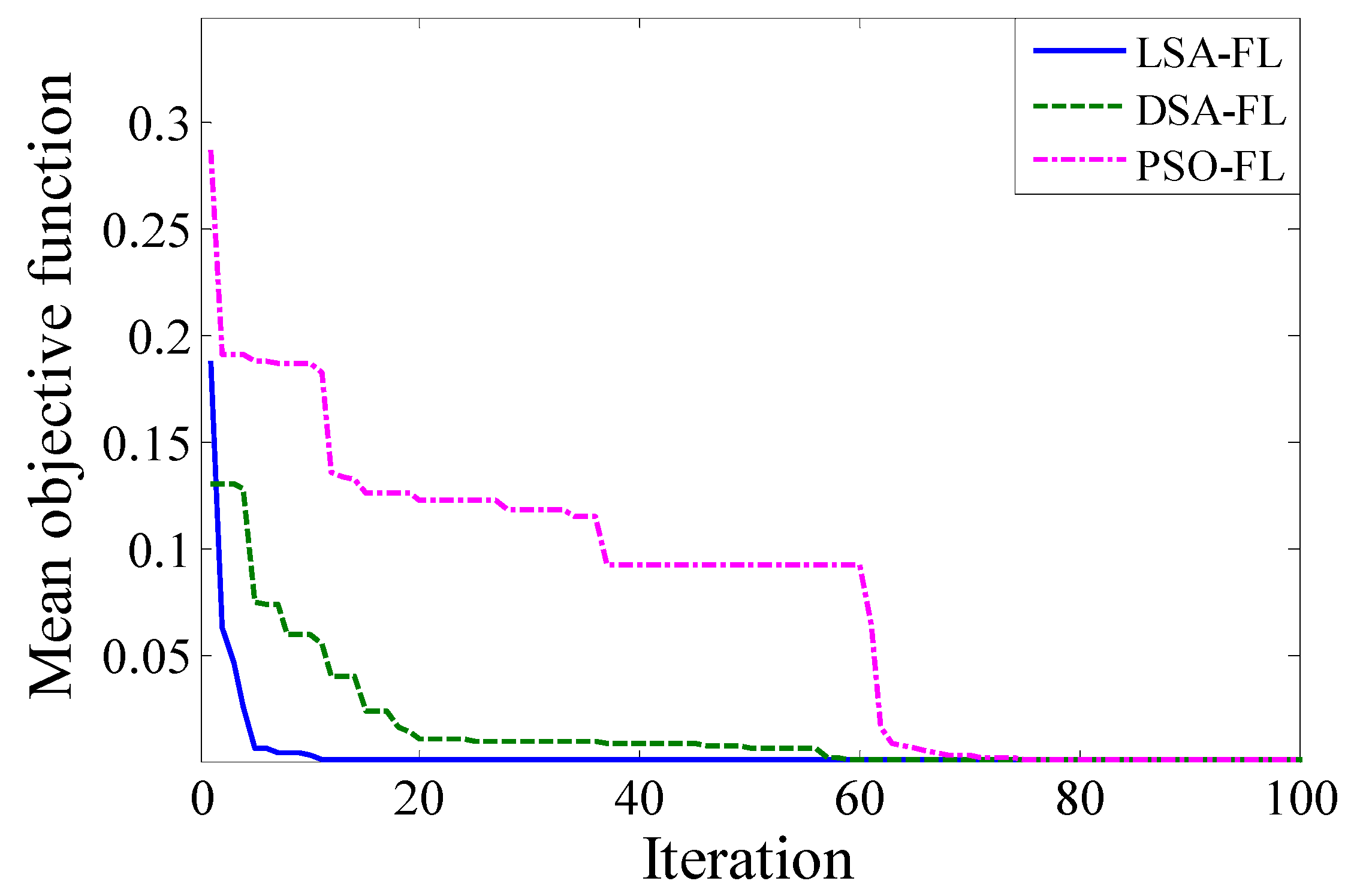

4. Proposed Optimum FLC Design Procedure

4.1. Overview of LSA

4.2. Optimal FLC Problem Formulation

4.2.1. Input Vector

4.2.2. Objective Function

4.2.3. Optimization Constraints

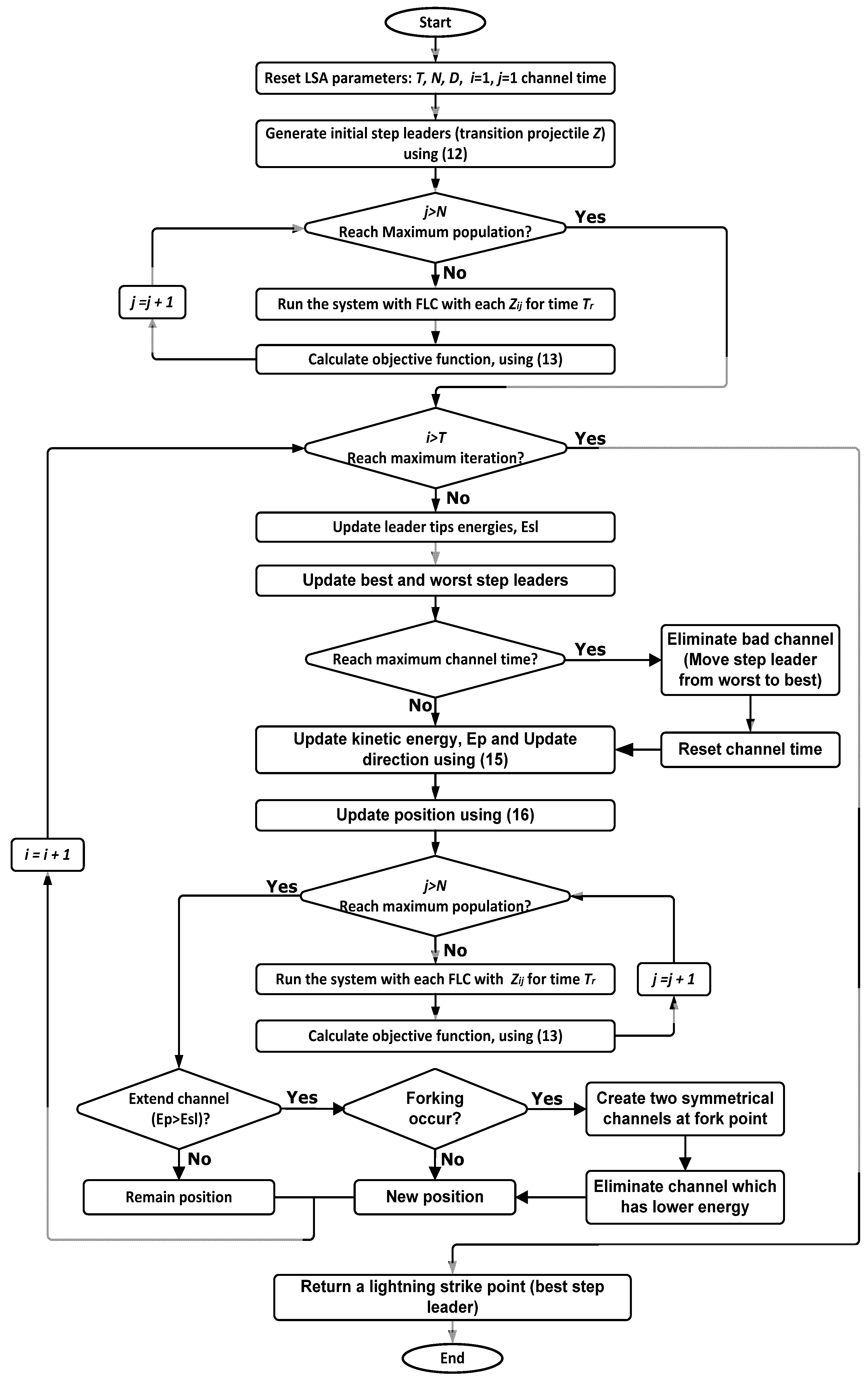

4.3. Implementation Steps of LSA to Obtain the Optimal FLC Design

5. FLC Design for PV Inverter Control Using the Proposed Method

6. Fuzzy Logic PV Inverter Controller Implementation Based eZdsp F28335

6.1. eZdsp F28335 Controller

6.2. Control Algorithm Implementation

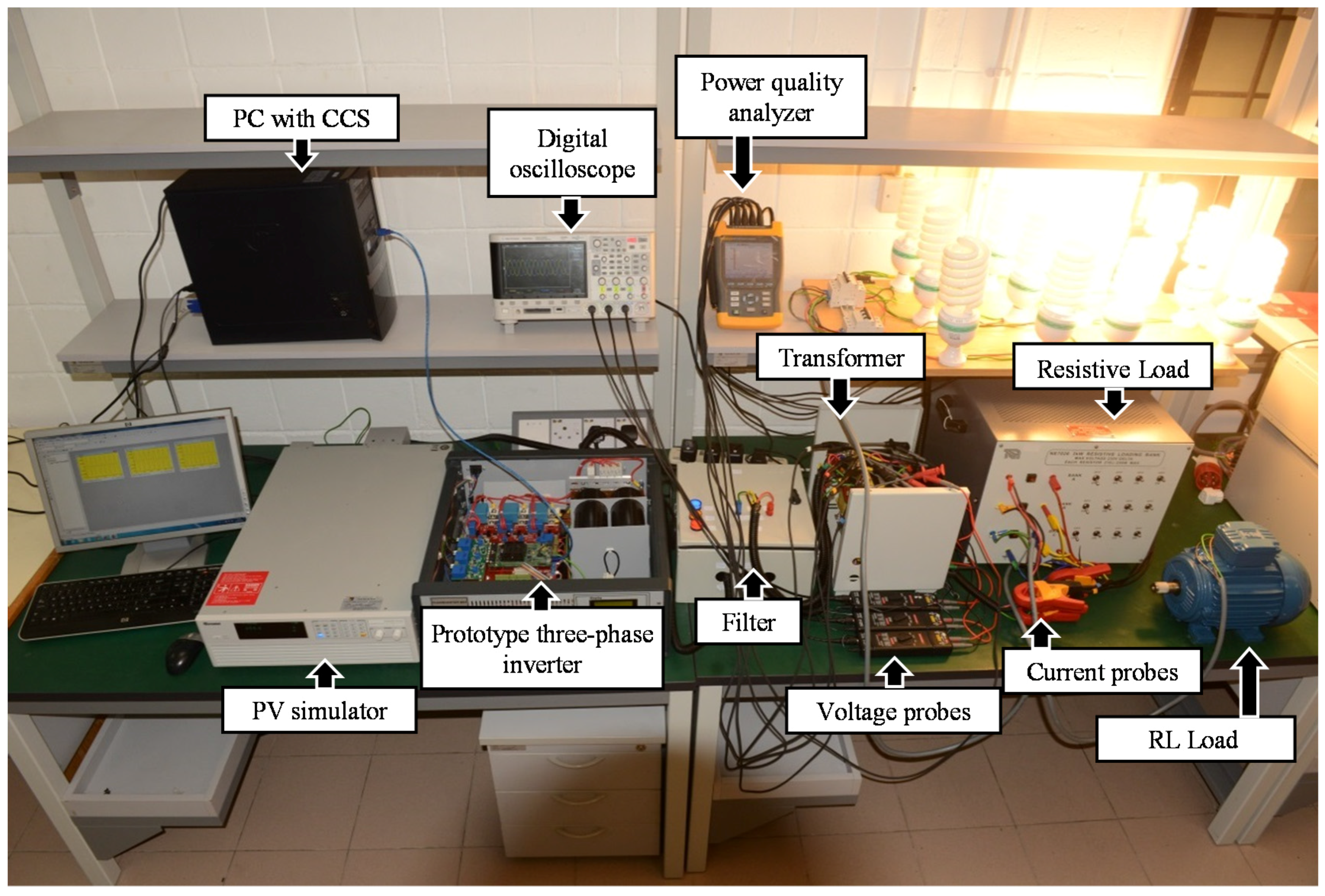

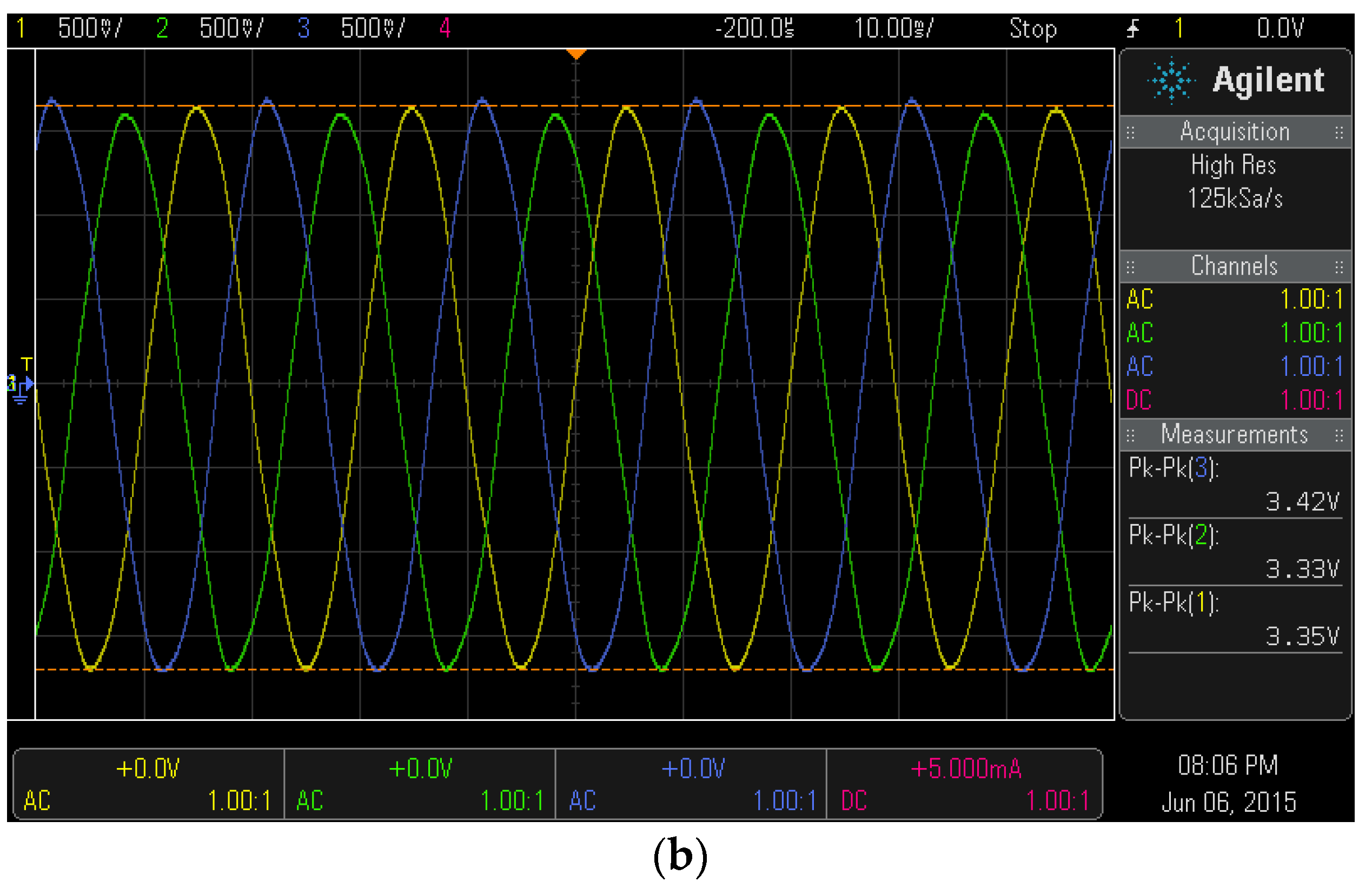

7. Experimental PV Inverter Control System

8. Results and Discussion

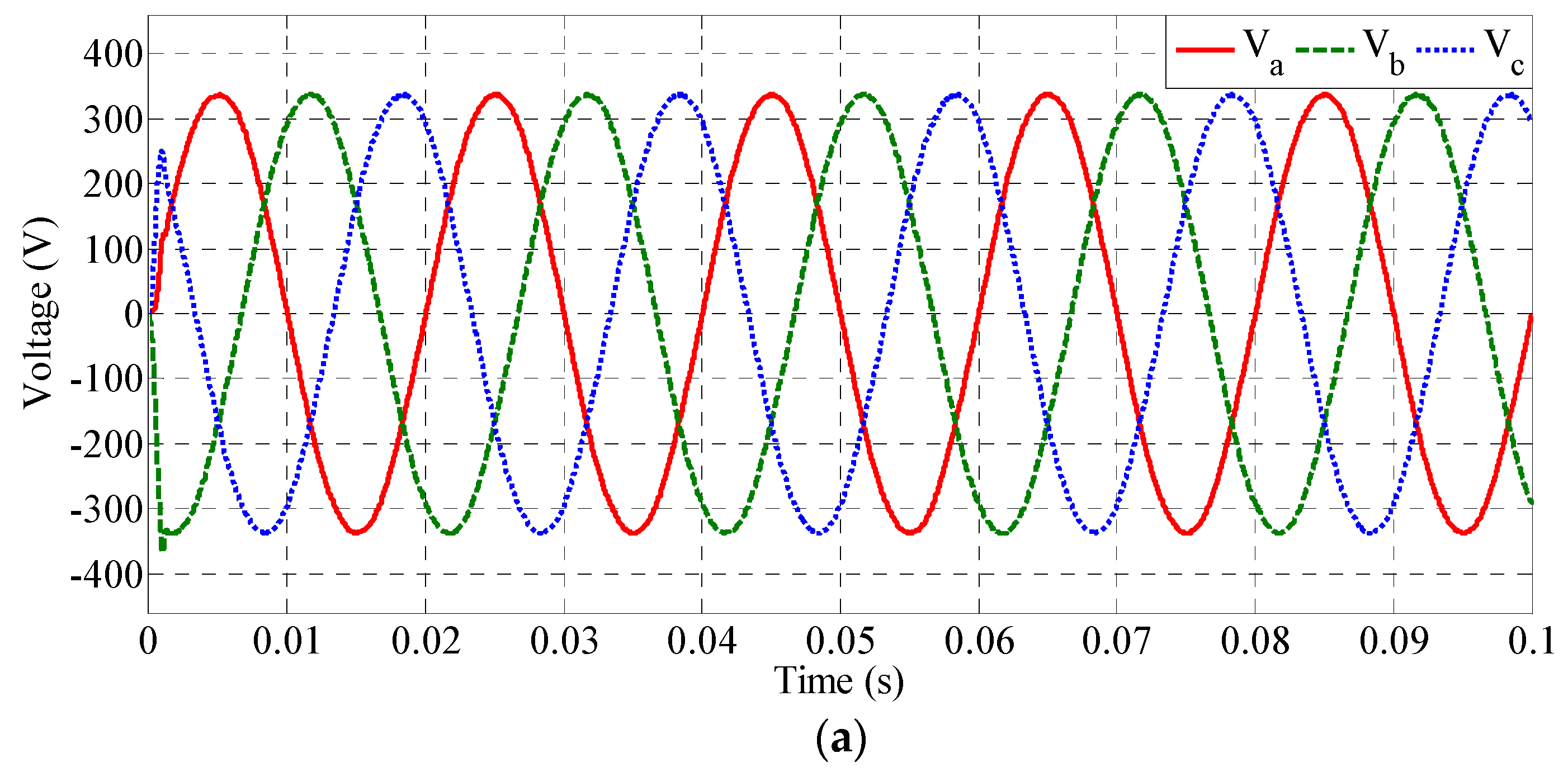

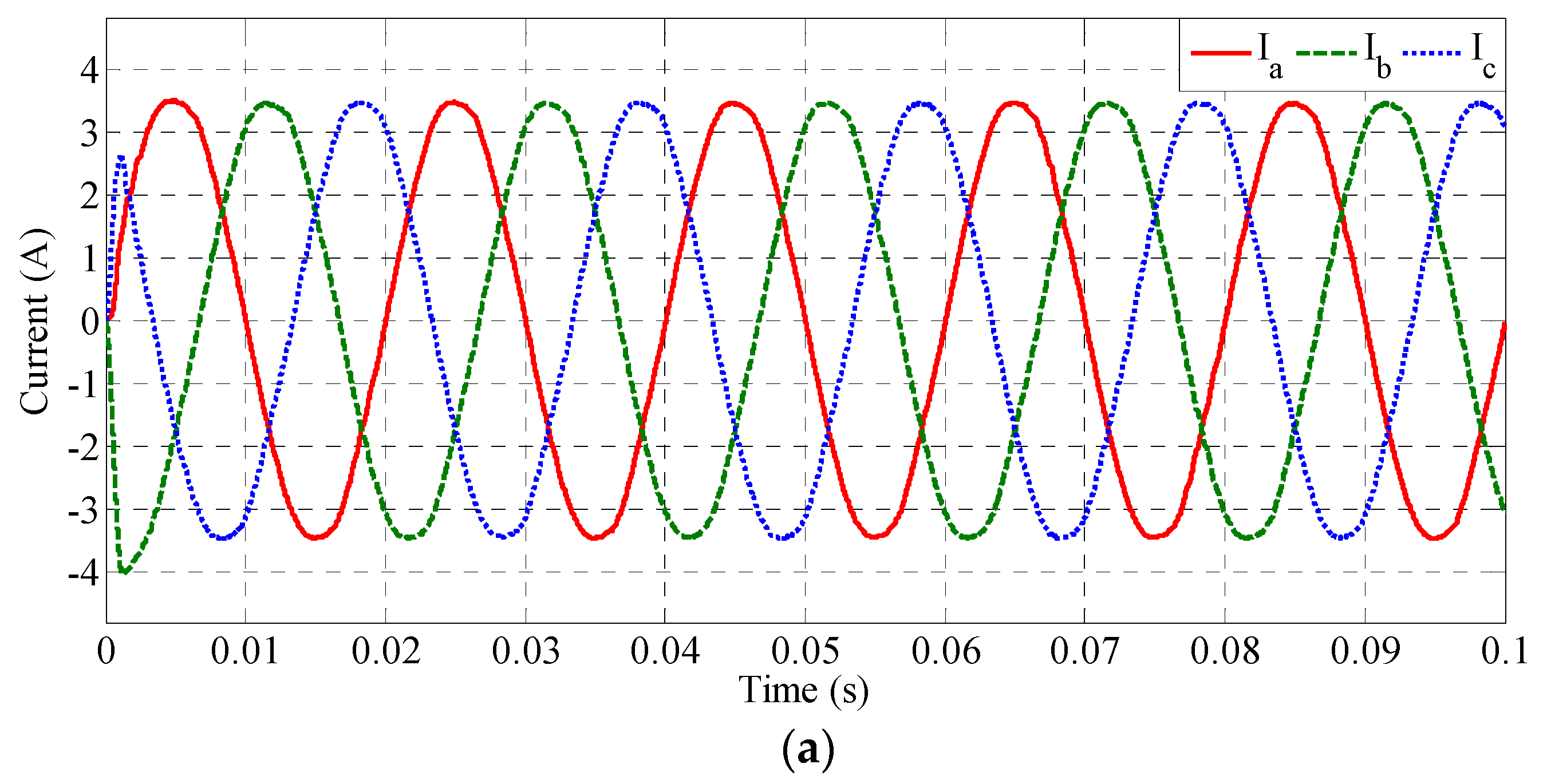

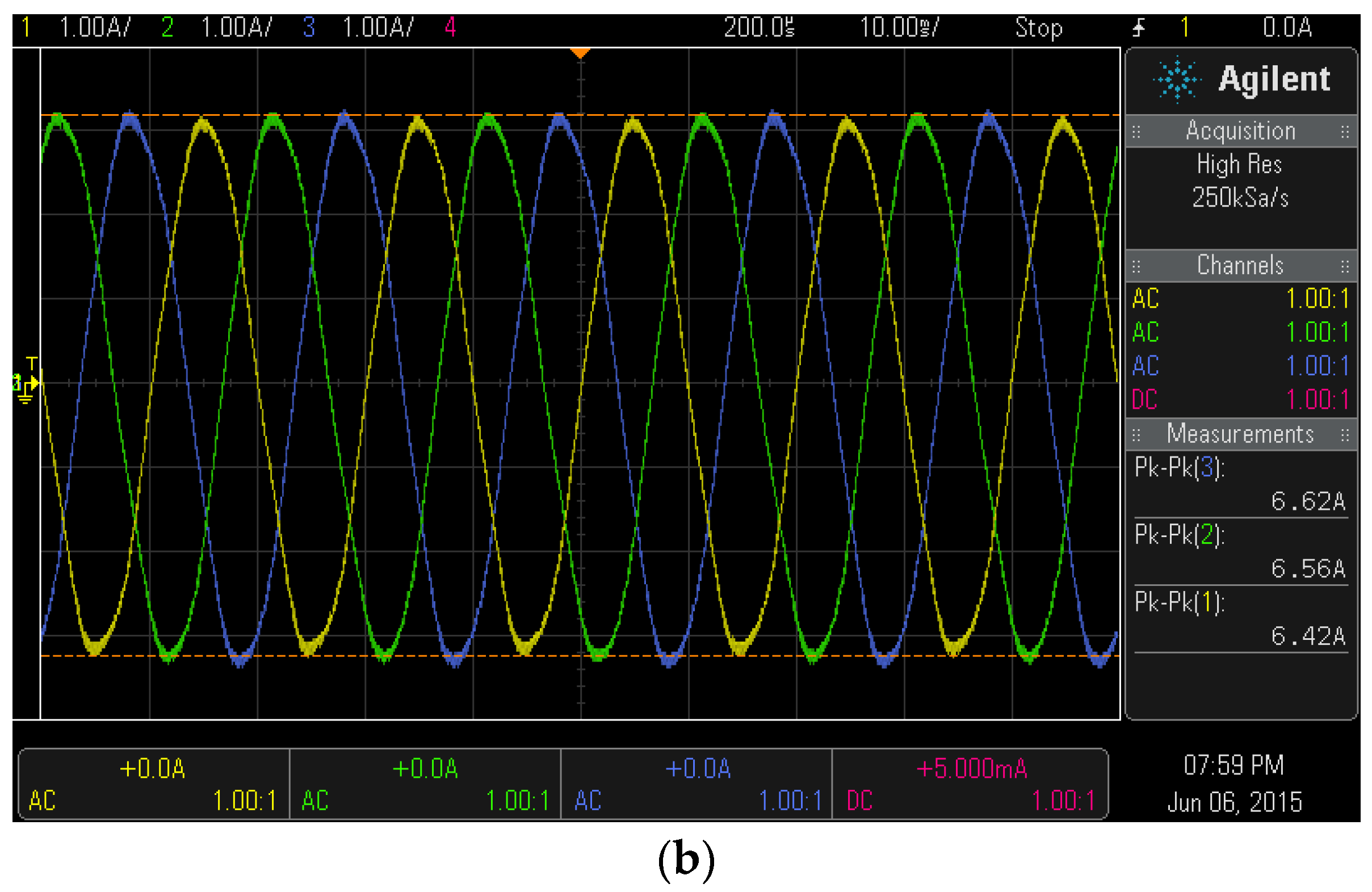

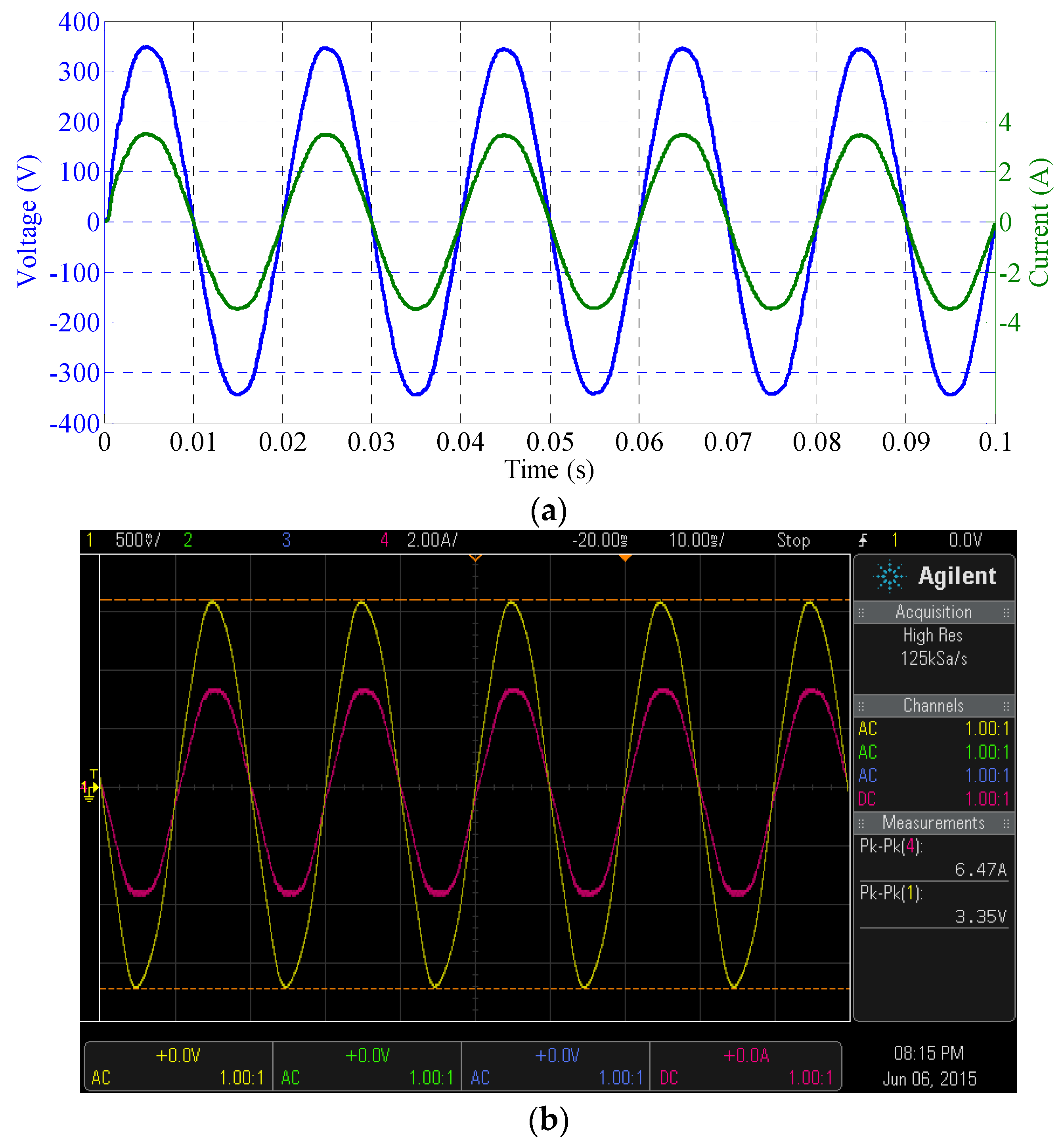

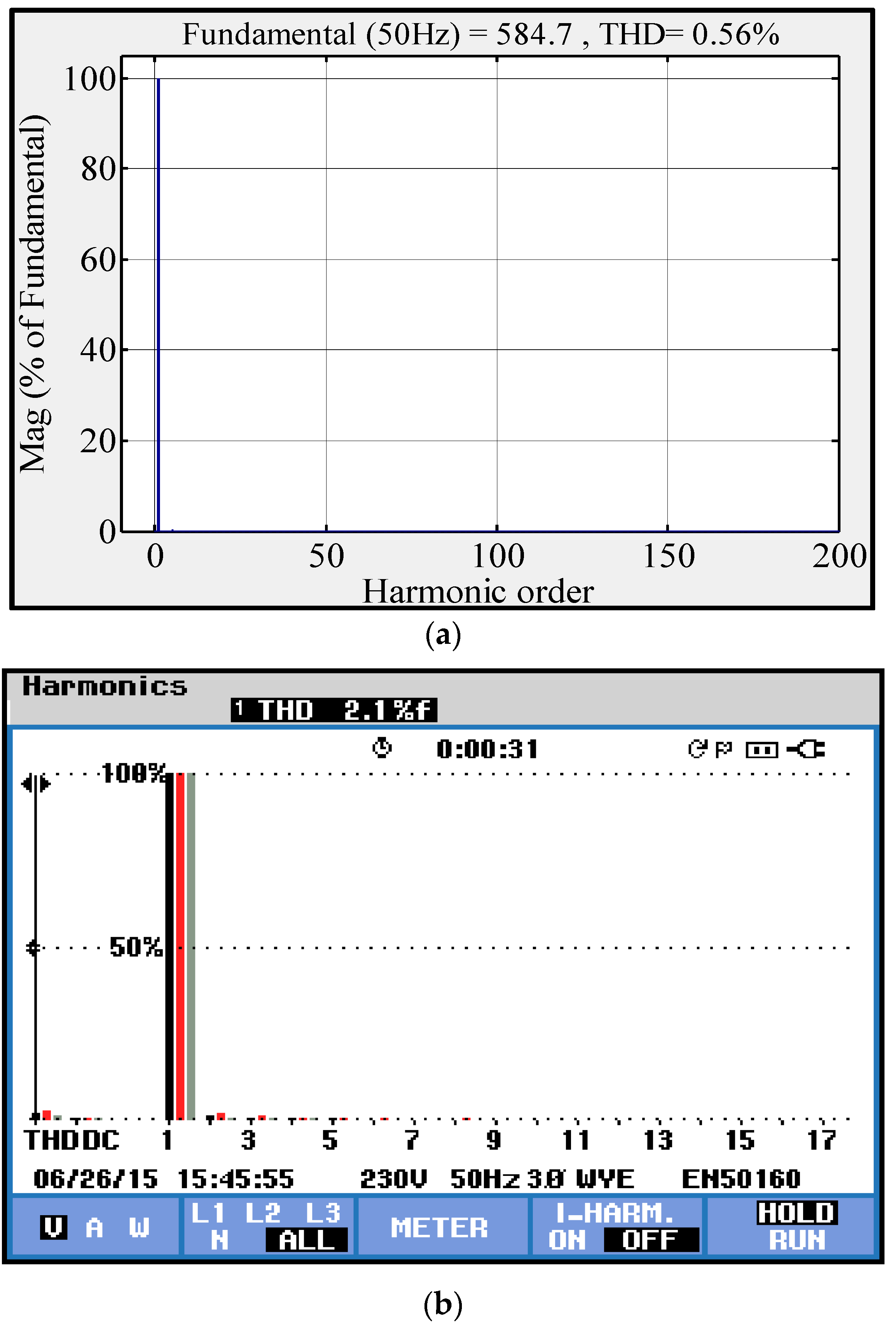

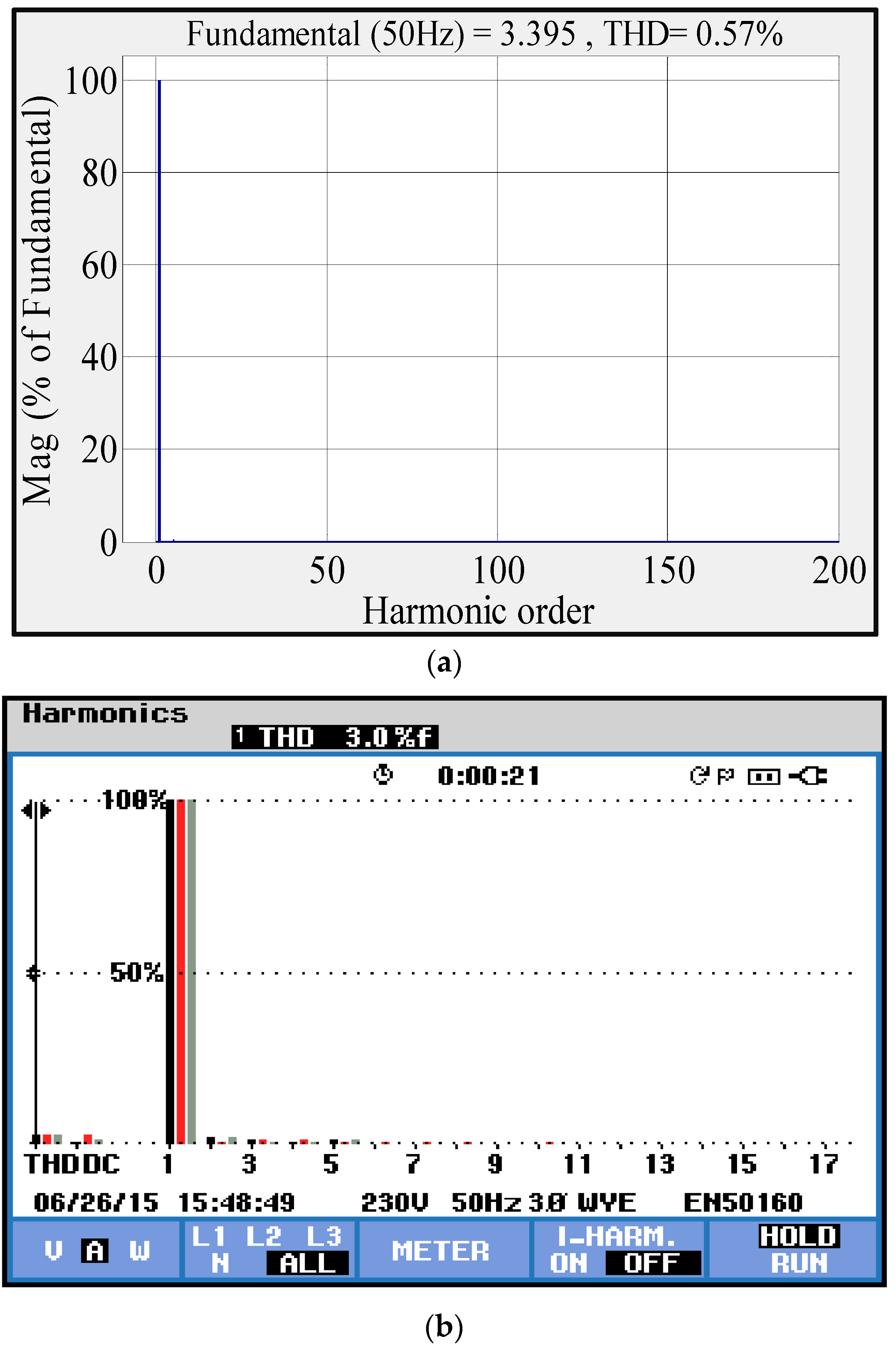

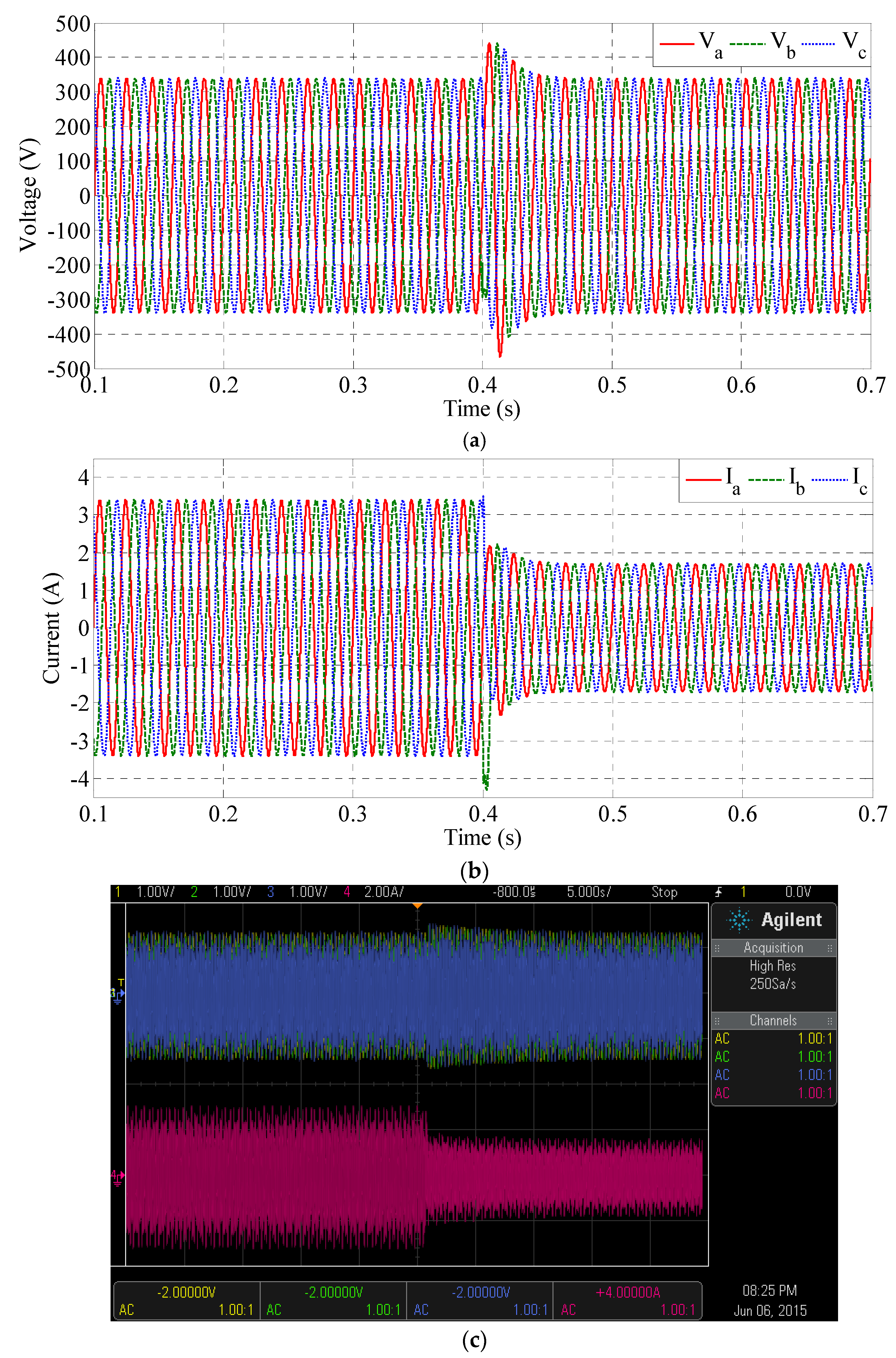

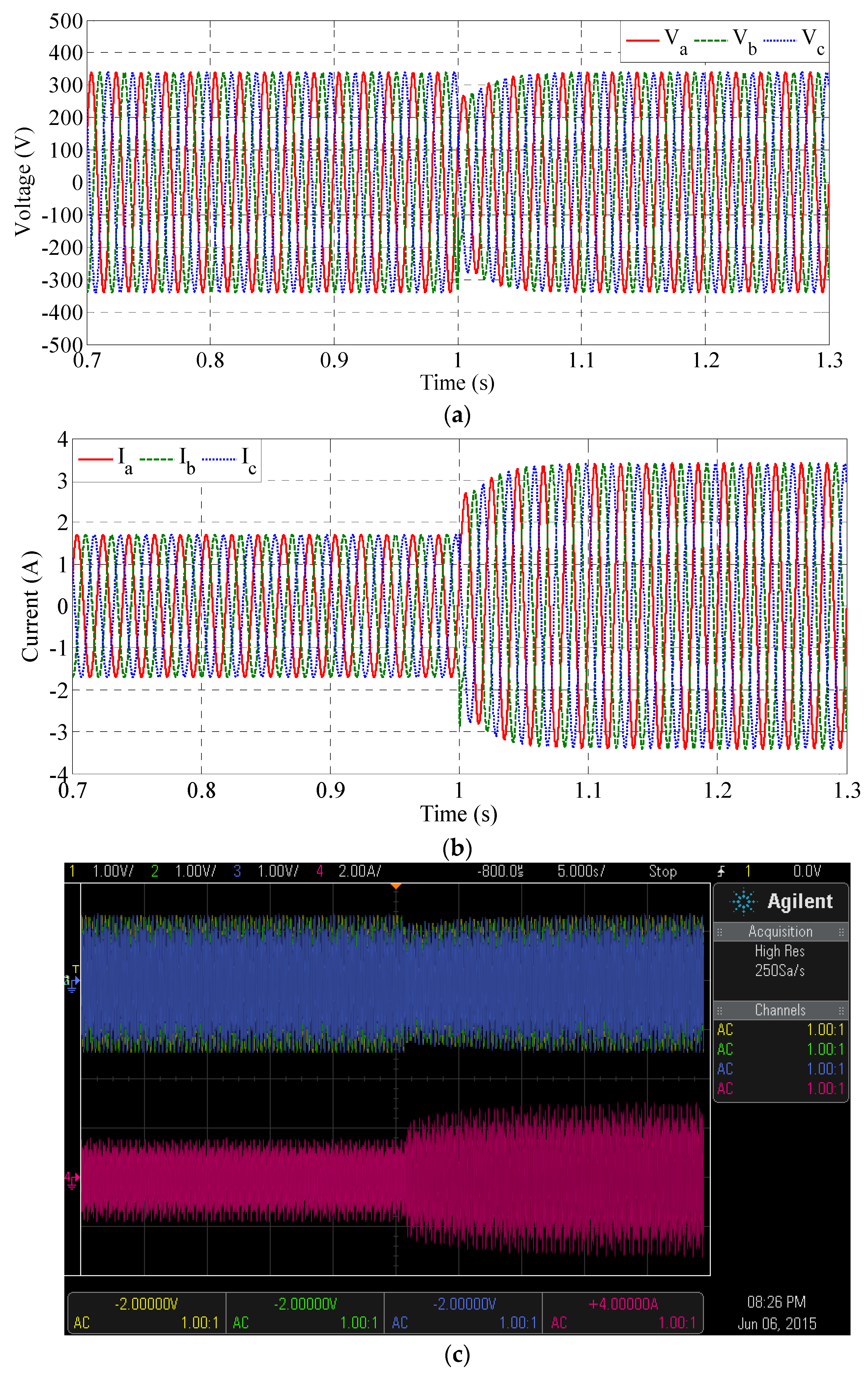

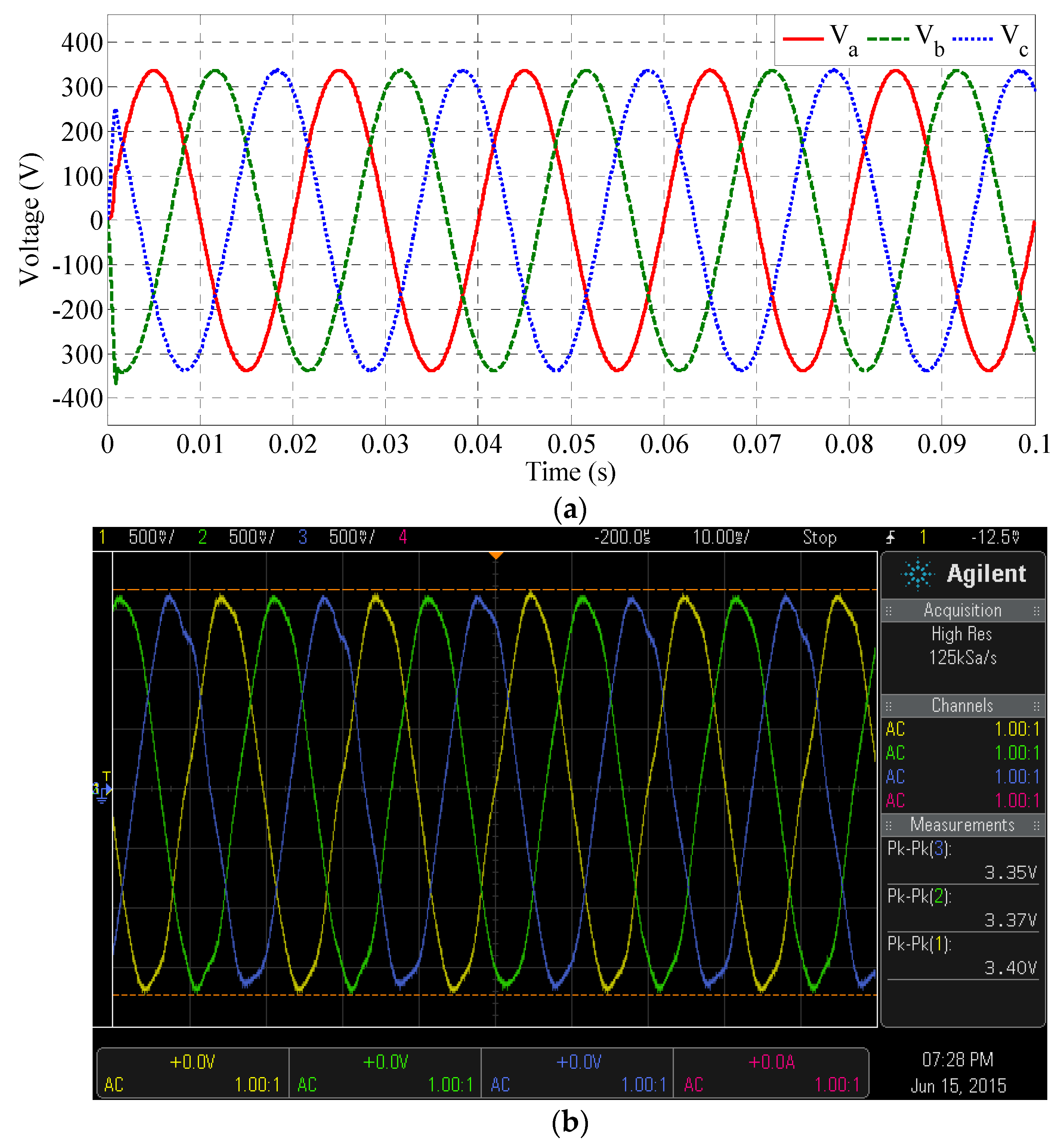

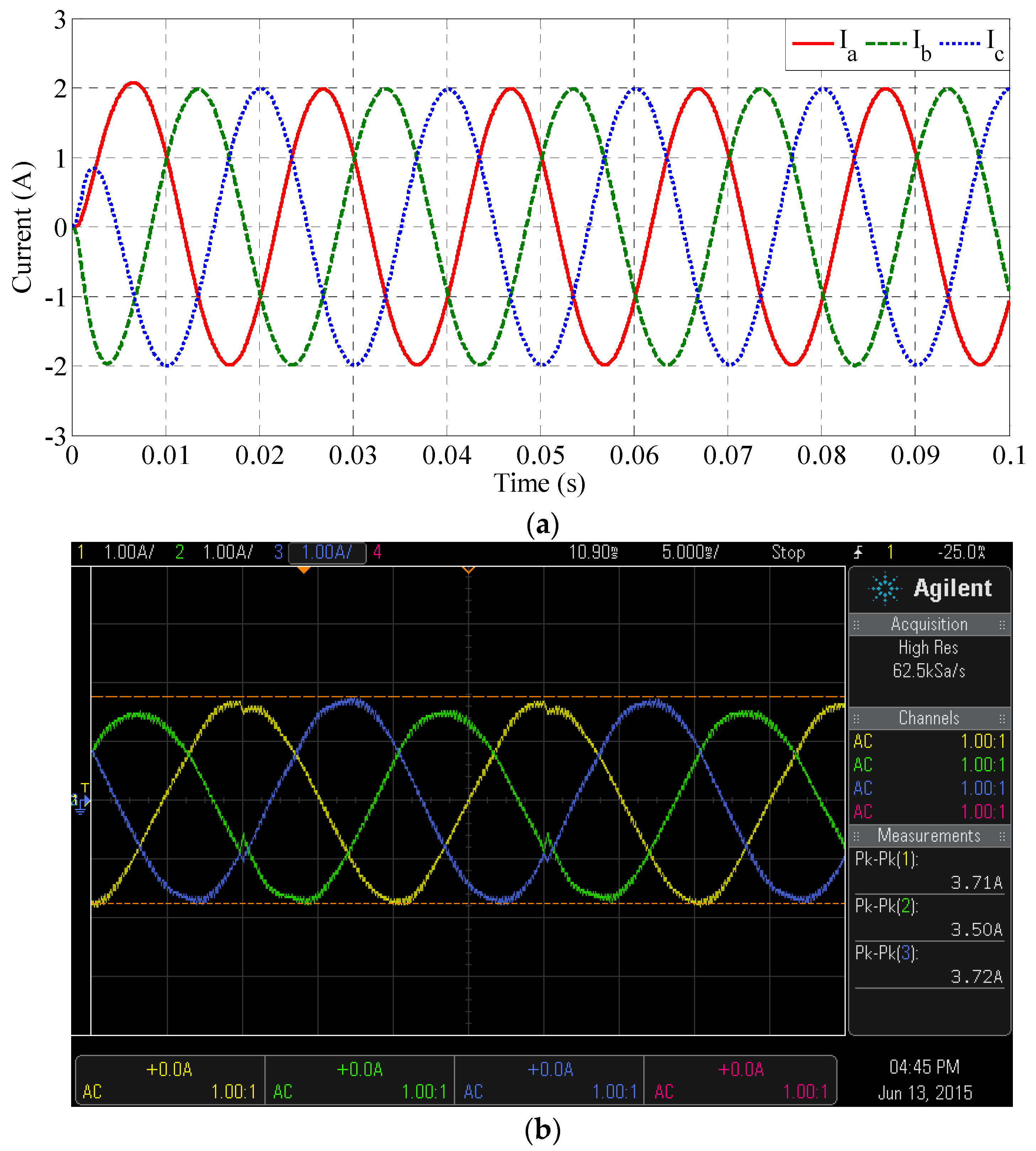

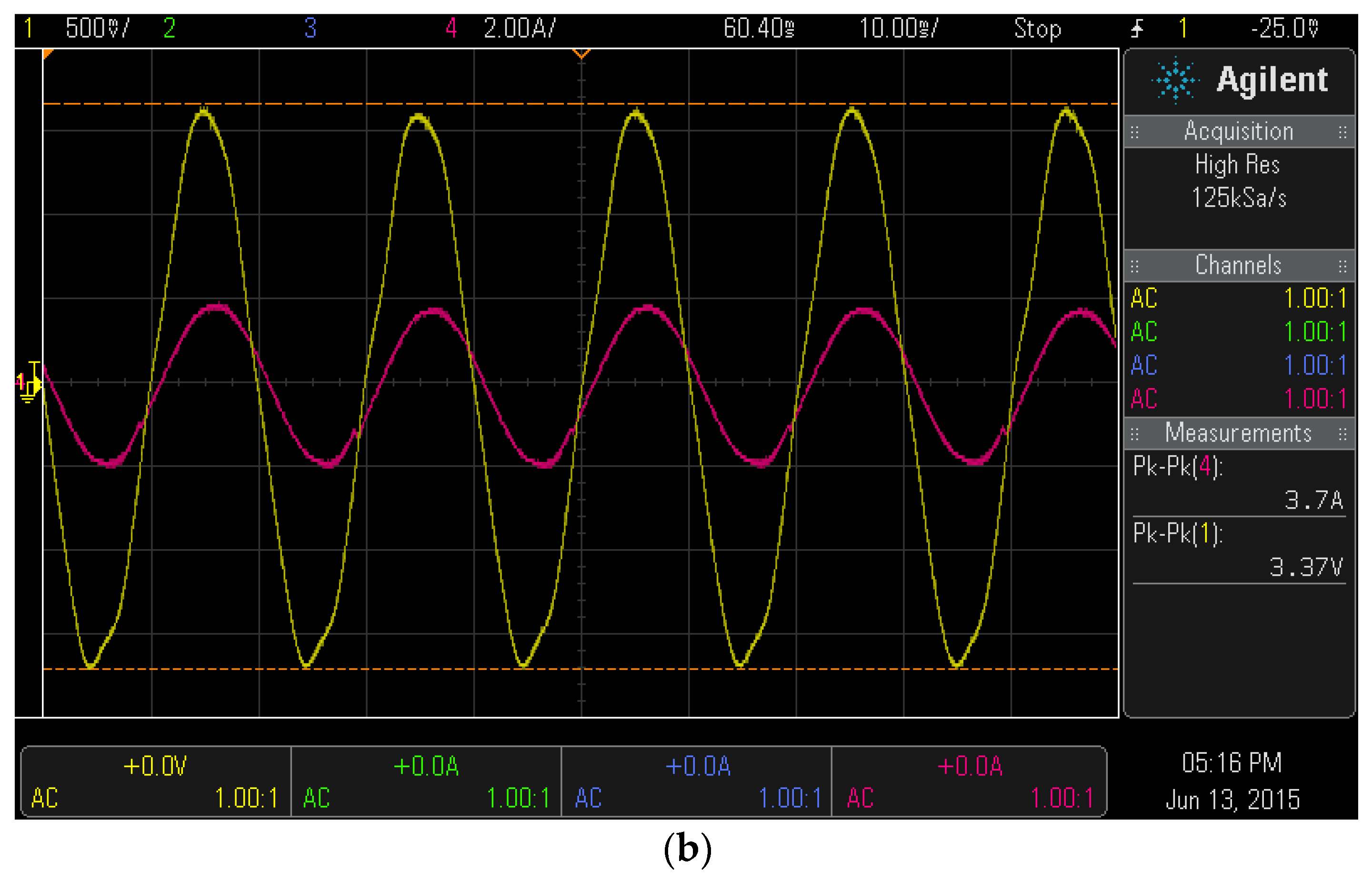

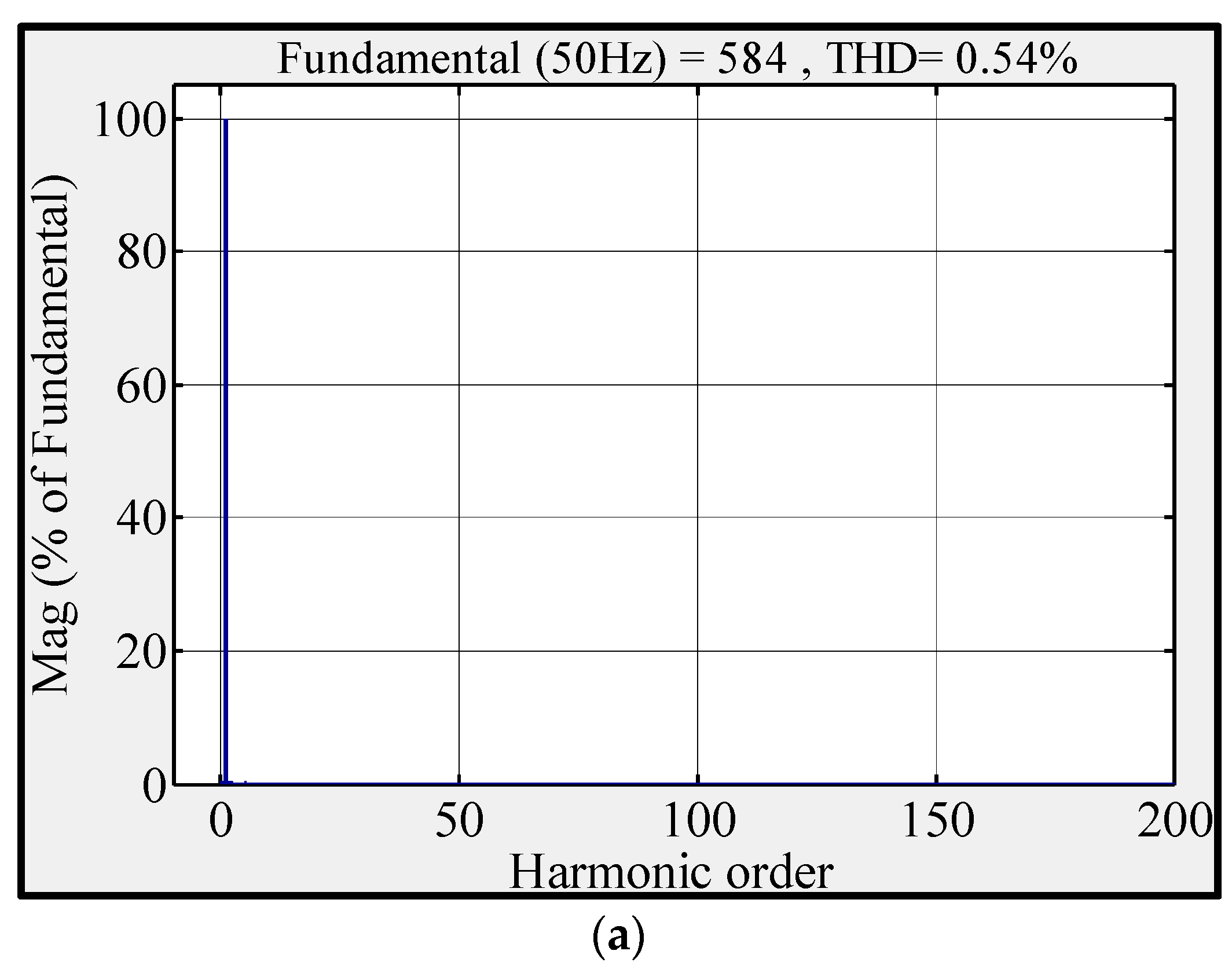

8.1. Results with Resistive Load (R)

8.1.1. Step Change in R Load

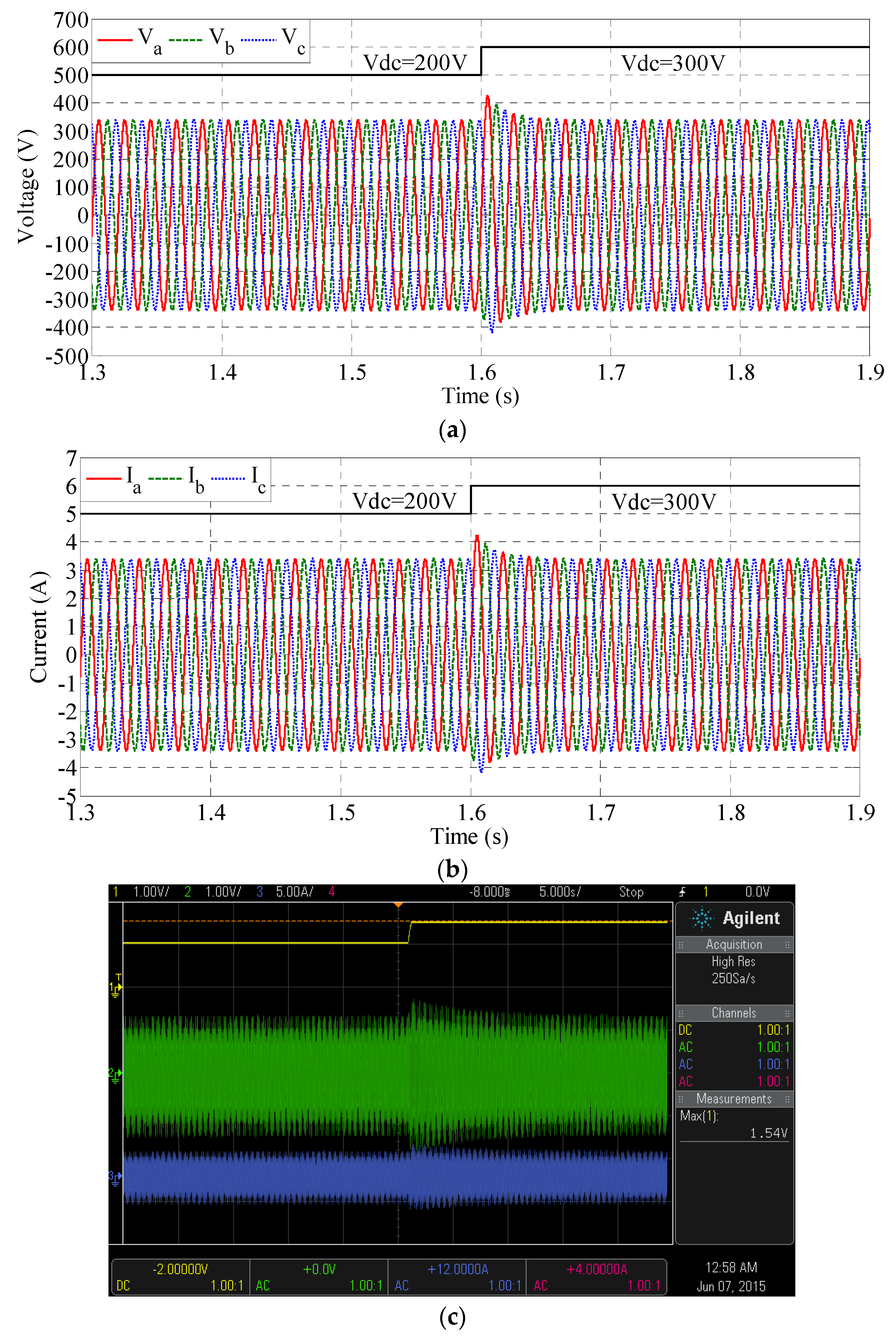

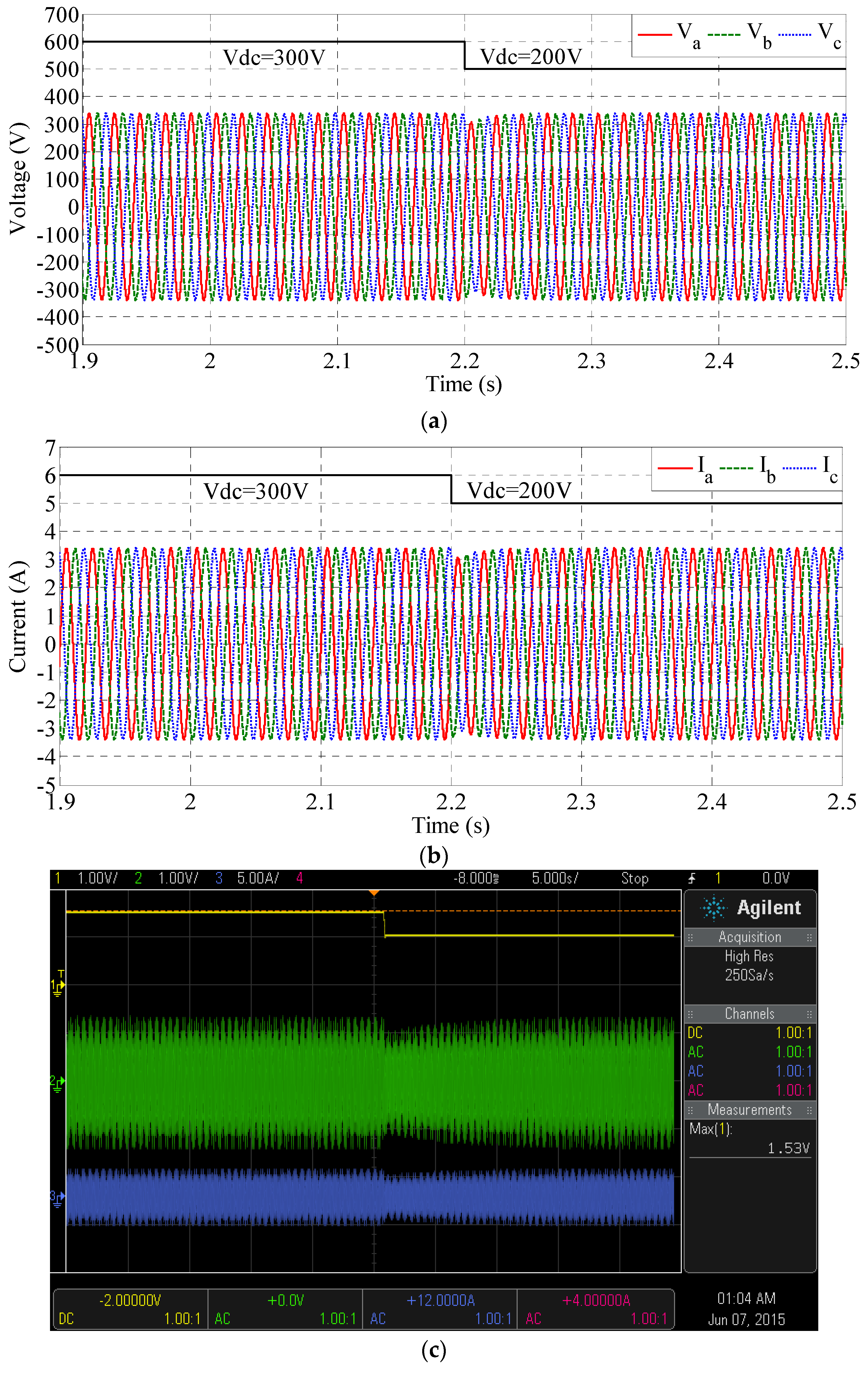

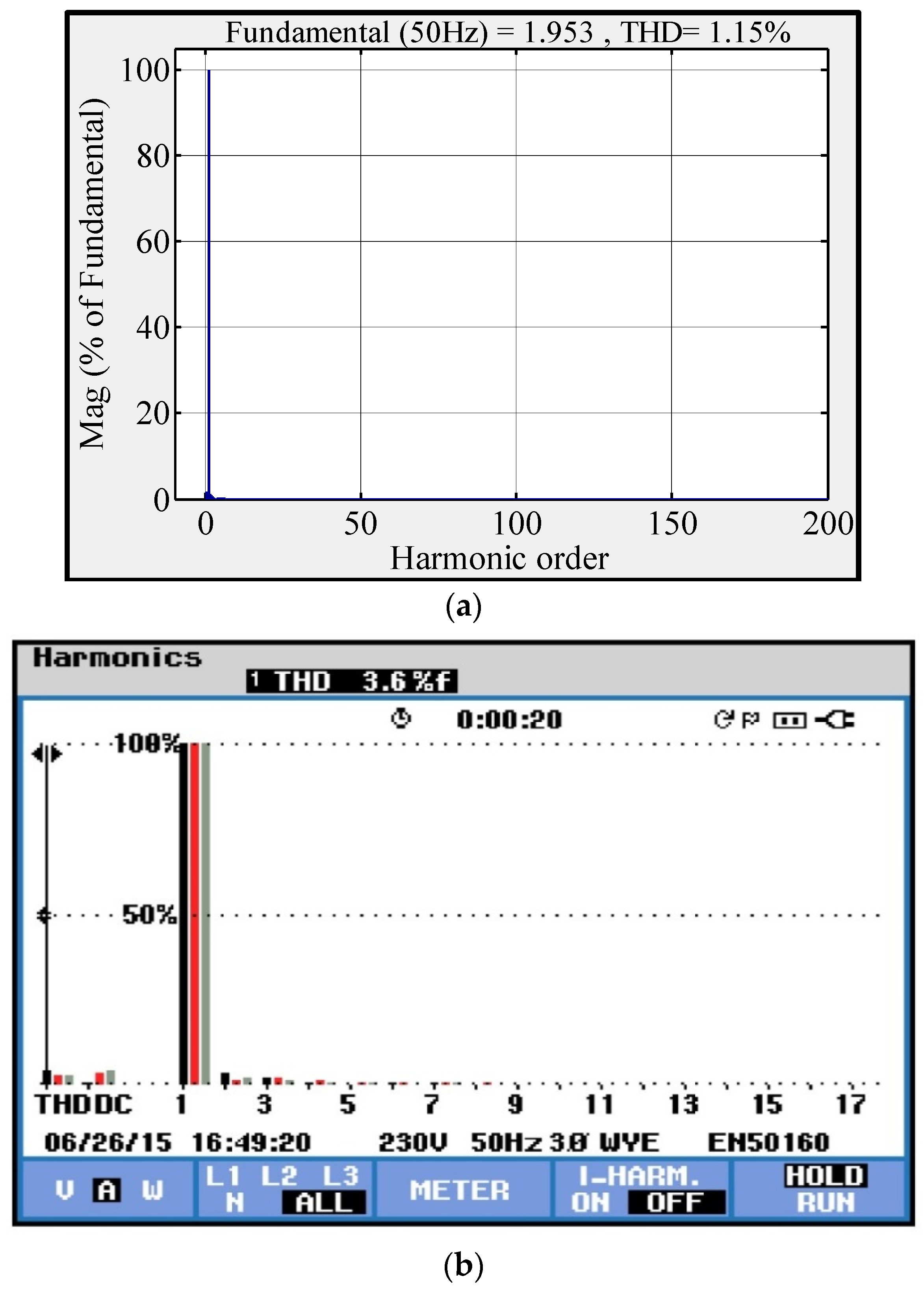

8.1.2. Step Change in Vdc

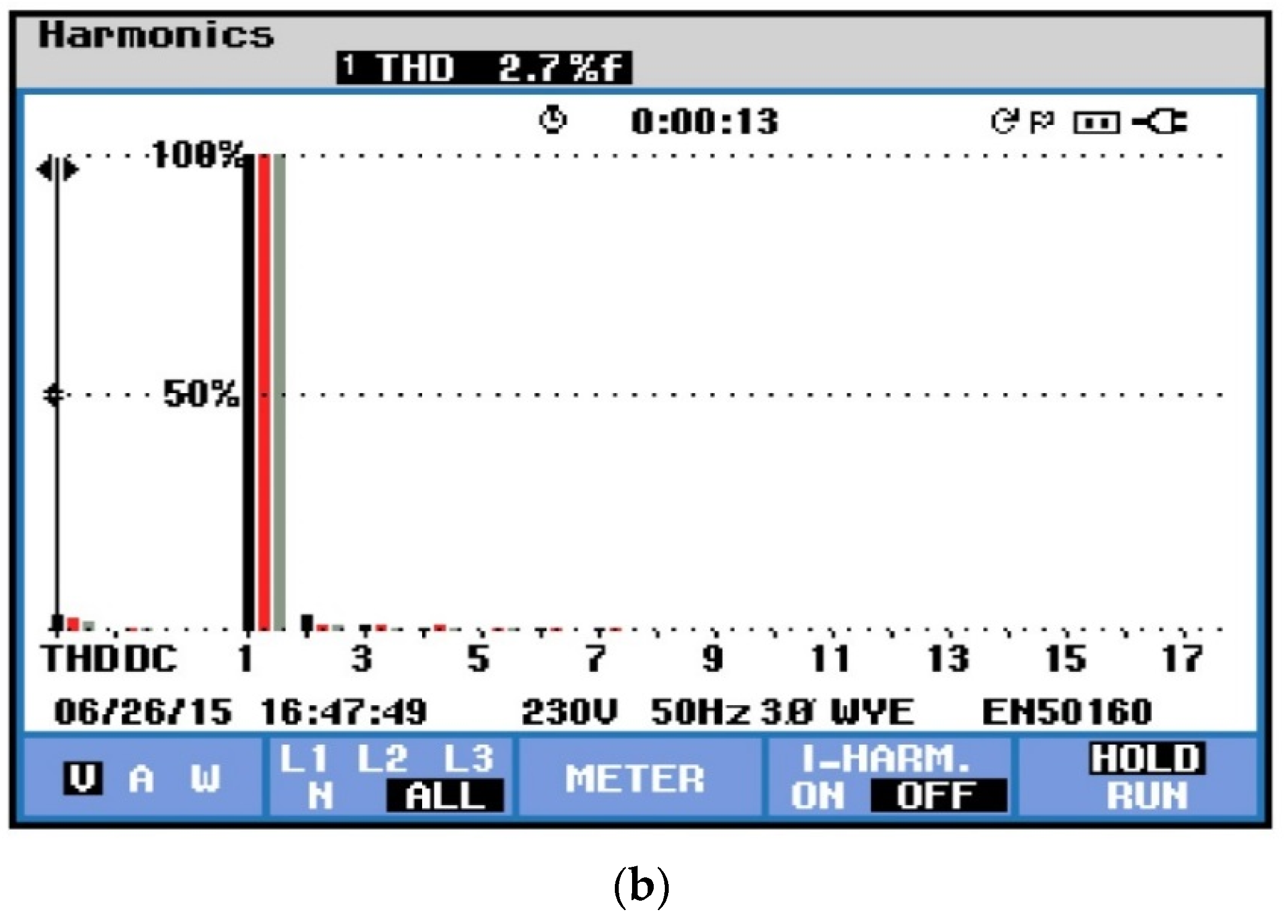

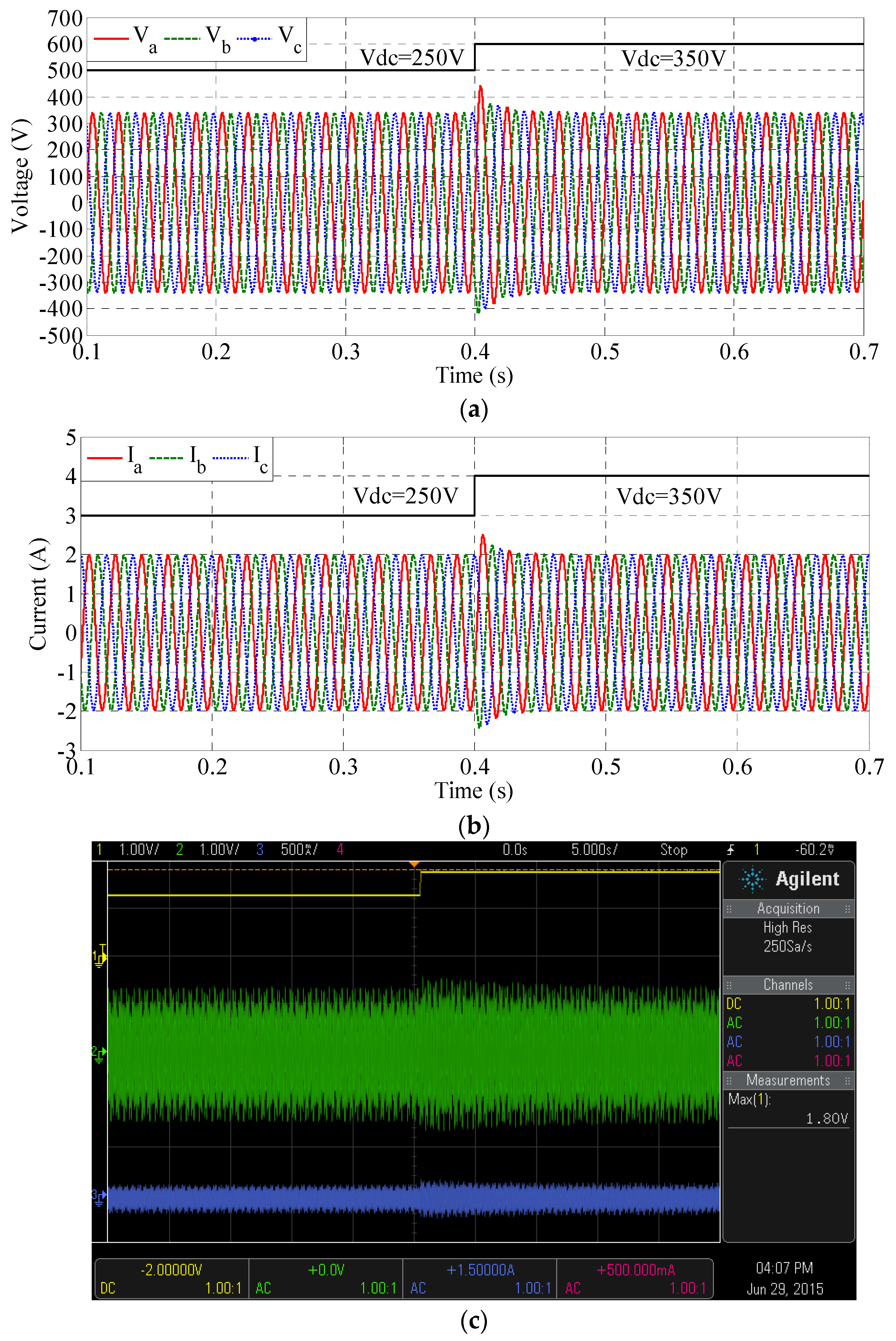

8.2. Results with Resistive and Inductive Load (RL)

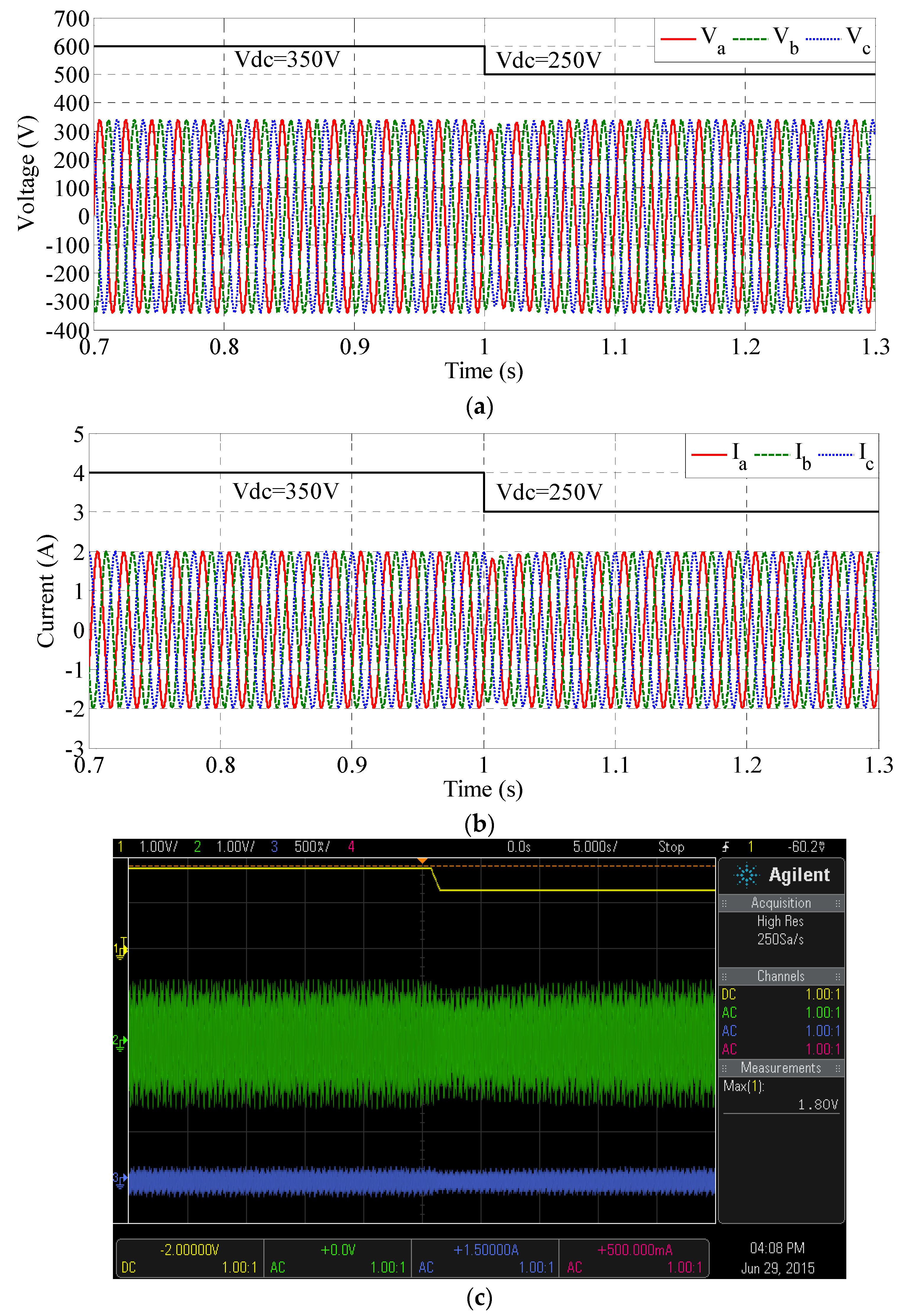

Step Change Vdc

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sperati, S.; Alessandrini, S.; Pinson, P.; Kariniotakis, G. The Weather Intelligence for Renewable Energies Benchmarking Exercise on Short-Term Forecasting of Wind and Solar Power Generation. Energies 2015, 8, 9594–9619. [Google Scholar] [CrossRef]

- Chel, A.; Tiwari, G.N.; Chandra, A. Simplified method of sizing and life cycle cost assessment of building integrated photovoltaic system. Energy Build. 2009, 41, 1172–1180. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Chen, Z.; Kjaer, S. Power electronics as efficient interface in dispersed power generation systems. IEEE Trans. Power Electron. 2004, 19, 1184–1194. [Google Scholar] [CrossRef]

- Ortega, R.; Figueres, E.; Garcerá, G.; Trujillo, C.L.; Velasco, D. Control techniques for reduction of the total harmonic distortion in voltage applied to a single-phase inverter with nonlinear loads: Review. Renew. Sust. Energ. Rev. 2012, 16, 1754–1761. [Google Scholar] [CrossRef]

- Ryu, T. Development of Power Conditioner Using Digital Controls for Generating Solar Power. Oki Tech. Rev. 2009, 76, 40–43. [Google Scholar]

- Selvaraj, J.; Rahim, N.A. Multilevel Inverter for Grid-Connected PV System Employing Digital PI Controller. IEEE Trans. Ind. Electron. 2009, 56, 149–158. [Google Scholar] [CrossRef]

- Sanchis, P.; Ursaea, A.; Gubia, E.; Marroyo, L. Boost DC-AC Inverter: A New Control Strategy. IEEE Trans. Power Electron. 2005, 20, 343–353. [Google Scholar] [CrossRef]

- Ghani, Z.A.; Hannan, M.A.; Mohamed, A. Simulation model linked PV inverter implementation utilizing dSPACE DS1104 controller. Energy Build. 2013, 57, 65–73. [Google Scholar] [CrossRef]

- Daud, M.Z.; Mohamed, A.; Hannan, M.A. An Optimal Control Strategy for DC Bus Voltage Regulation in Photovoltaic System with Battery Energy Storage. Sci. World J. 2014, 2014, 271087. [Google Scholar] [CrossRef] [PubMed]

- Liserre, M.; Dell’Aquila, A.; Blaabjerg, F. Genetic Algorithm-Based Design of the Active Damping for an LCL-Filter Three-Phase Active Rectifier. IEEE Trans. Power Electron. 2004, 19, 76–86. [Google Scholar] [CrossRef]

- Li, W.; Man, Y.; Li, G. Optimal parameter design of input filters for general purpose inverter based on genetic algorithm. Appl. Math. Comput. 2008, 205, 697–705. [Google Scholar] [CrossRef]

- Sundareswaran, K.; Jayant, K.; Shanavas, T.N. Inverter Harmonic Elimination through a Colony of Continuously Exploring Ants. IEEE Trans. Ind. Electron. 2007, 54, 2558–2565. [Google Scholar] [CrossRef]

- Mohamed, Y.A.I.; El Saadany, E.F. Hybrid Variable-Structure Control with Evolutionary Optimum-Tuning Algorithm for Fast Grid-Voltage Regulation Using Inverter-Based Distributed Generation. IEEE Trans. Power Electron. 2008, 23, 1334–1341. [Google Scholar] [CrossRef]

- Rai, A.K.; Kaushika, N.D.; Singh, B.; Agarwal, N. Simulation model of ANN based maximum power point tracking controller for solar PV system. Sol. Energy Mater. Sol. Cells 2011, 95, 773–778. [Google Scholar] [CrossRef]

- Ali, J.A.; Hannan, M.A.; Mohamed, A. A Novel Quantum-Behaved Lightning Search Algorithm Approach to Improve the Fuzzy Logic Speed Controller for an Induction Motor Drive. Energies 2015, 8, 13112–13136. [Google Scholar] [CrossRef]

- Sakhar, A.; Davari, A.; Feliachi, A. Fuzzy logic control of fuel cell for stand-alone and grid connection. J. Power Sources 2004, 135, 165–176. [Google Scholar] [CrossRef]

- Thiagarajan, Y.; Sivakumaran, T.S.; Sanjeevikumar, P. Design and Simulation of FUZZY Controller for a Grid connected Stand Alone PV System. In Proceedings of the EEE Conference on Computing, Communication and Networking (ICCCn’08), St. Thomas, VI, USA, 18–20 December 2008; pp. 1–6.

- Hong, Y.-Y.; Hsieh, Y.-L. Interval Type-II Fuzzy Rule-Based STATCOM for Voltage Regulation in the Power System. Energies 2015, 8, 8908–8923. [Google Scholar] [CrossRef]

- Altin, N.; Sefa, I. dSPACE based adaptive neuro-fuzzy controller of grid interactive inverter. Energy Conv. Manag. 2012, 56, 130–139. [Google Scholar] [CrossRef]

- Collotta, M.; Messineo, A.; Nicolosi, G.; Pau, G. A Dynamic Fuzzy Controller to Meet Thermal Comfort by Using Neural Network Forecasted Parameters as the Input. Energies 2014, 7, 4727–4756. [Google Scholar] [CrossRef]

- Cheng, P.C.; Peng, B.R.; Liu, Y.H.; Cheng, Y.S.; Huang, J.W. Optimization of a Fuzzy-Logic-Control-Based MPPT Algorithm Using the Particle Swarm Optimization Technique. Energies 2015, 8, 8534–8561. [Google Scholar] [CrossRef]

- Shareef, H.; Mutlag, A.H.; Mohamed, A. A novel approach for fuzzy logic PV inverter controller optimization using lightning search algorithm. Neurocomputing 2015, 168, 435–453. [Google Scholar] [CrossRef]

- Nasiri, R.; Radan, A. Pole-placement control strategy for 4 leg voltage source inverters. In Proceedings of the IEEE Conference on Power Electronic & Drive Systems & Technologies (PEDSTC‘10), Tehran, Iran, 17–18 February 2010; pp. 74–82.

- Thandi, G.S.; Zhang, R.; Zhing, K.; Lee, F.C.; Boroyevich, D. Modeling, control and stability analysis of a PEBB based DC DPS. IEEE Trans. Power Deliv. 1999, 14, 497–505. [Google Scholar] [CrossRef]

- Mohan, N.; Undeland, T.M.; Robbins, W.P. Power Electronics: Converters, Applications, and Design, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Altin, N.; Ozdemir, S. Three-phase three-level grid interactive inverter with fuzzy logic based maximum power point tracking controller. Energy Conv. Manag. 2013, 69, 17–26. [Google Scholar] [CrossRef]

- Hazzab, A.; Bousserhane, I. K.; Zerbo, M.; Sicard, P. Real Time Implementation of Fuzzy Gain Scheduling of PI Controller for Induction Motor Machine Control. Neural Process. Lett. 2006, 24, 203–215. [Google Scholar] [CrossRef]

- Cheng, C.H. Design of output filter for inverters using fuzzy logic. Expert Syst. Appl. 2011, 38, 8639–8647. [Google Scholar] [CrossRef]

- Elmas, C.; Deperlioglu, O.; Sayan, H.H. Adaptive fuzzy logic controller for DC–DC converters. Expert Syst. Appl. 2009, 36, 1540–1548. [Google Scholar] [CrossRef]

- Rajkumar, M.V.; Manoharan, P.S.; Ravi, A. Simulation and an experimental investigation of SVPWM technique on a multilevel voltage source inverter for photovoltaic systems. Int. J. Electr. Power Energy Syst. 2013, 52, 116–131. [Google Scholar] [CrossRef]

- Rajkumar, M.V.; Manoharan, P.S. FPGA based multilevel cascaded inverters with SVPWM algorithm for photovoltaic system. Sol. Energy 2013, 87, 229–245. [Google Scholar] [CrossRef]

- Behera, S.; Das, S.P.; Doradla, S.R. Quasi-resonant inverter-fed direct torque controlled induction motor drive. Electr. Power Syst. Res. 2007, 77, 946–955. [Google Scholar] [CrossRef]

- Durgasukumar, G.; Pathak, M.K. Comparison of adaptive Neuro-Fuzzy-based space-vector modulation for two-level inverter. Int. J. Electr. Power Energy Syst 2012, 38, 9–19. [Google Scholar] [CrossRef]

- Saribulut, L.; Teke, A.; Tumay, M. Vector-based reference location estimating for space vector modulation technique. Electr. Power Syst. Res 2012, 86, 51–60. [Google Scholar] [CrossRef]

- Yazdani, A.; Fazio, A.R.D.; Ghoddami, H.; Russo, M.; Kazerani, M.; Jatskevich, J.; Strunz, K.; Leva, S.; Martinez, J.A. Modeling guidelines and a benchmark for power system simulation studies of three phase single stage photovoltaic systems. IEEE Trans. Power Deliv. 2011, 26, 1247–1264. [Google Scholar] [CrossRef]

- Lijun, G.; Roger, A.; Shengyi, D.L.; Albena, P.I. Parallel-connected solar PV system to address partial and rapidly fluctuating shadow conditions. IEEE Trans. Ind. Electron. 2012, 56, 1548–1556. [Google Scholar] [CrossRef]

- El Amrani, A.; Mahrane, A.; Moussa, F.Y.; Boukennous, Y. Solar module fabrication. Int. J. Photoenergy 2007, 2007, 27610. [Google Scholar] [CrossRef]

- Young-Hyok, J.; Doo-Yong, J.; Jun-Gu, K.; Jae-Hyung, K.; Tae-Won, L.; Chung-Yuen, W. A real maximum power point tracking method for mismatching compensation in PV array under partially shaded conditions. IEEE Trans. Power Electron. 2011, 26, 1001–1009. [Google Scholar]

- IEEE Std 929-2000. Recommended Practices for Utility Interface of Photovoltaic System. The Institute of Electrical and Electronics Engineers: New York, NY, USA, 2000.

| Error (E) | Change of Error (CE) | ||||||

|---|---|---|---|---|---|---|---|

| MFCE1 | MFCE2 | MFCE3 | MFCE4 | MFCE5 | MFCE6 | MFCE7 | |

| MFE1 | ONB | ONB | ONB | ONB | ONM | ONS | OZ |

| MFE2 | ONB | ONB | ONB | ONM | ONS | OZ | OPS |

| MFE3 | ONB | ONB | ONM | ONS | OZO | OPS | OPM |

| MFE4 | ONB | ONM | ONS | OZ | OPS | OPM | OPB |

| MFE5 | ONM | ONS | OZ | OPS | OPM | OPB | OPB |

| MFE6 | ONS | OZ | OPS | OPM | OPB | OPB | OPB |

| MFE7 | OZ | OPS | OPM | OPB | OPB | OPB | OPB |

| PV Module Type: SolarTIFSTF-120P6 | Values |

|---|---|

| No. of modules in series (NS) | 25 |

| No. of modules in parallel (NP) | 1 |

| Maximum Power (PMPP) | 3 kW |

| Open circuit voltage (Voc) | 537.5 V |

| Short circuit current (Isc) | 7.63 A |

| Voltage at maximum power (VMPP) | 435 V |

| Current At maximum power (IMPP) | 6.89 A |

| Current temperature coefficient (α) | 6.928 mA/°C |

| Voltage temperature coefficient (β) | −0.068 V/°C |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutlag, A.H.; Mohamed, A.; Shareef, H. A Nature-Inspired Optimization-Based Optimum Fuzzy Logic Photovoltaic Inverter Controller Utilizing an eZdsp F28335 Board. Energies 2016, 9, 120. https://doi.org/10.3390/en9030120

Mutlag AH, Mohamed A, Shareef H. A Nature-Inspired Optimization-Based Optimum Fuzzy Logic Photovoltaic Inverter Controller Utilizing an eZdsp F28335 Board. Energies. 2016; 9(3):120. https://doi.org/10.3390/en9030120

Chicago/Turabian StyleMutlag, Ammar Hussein, Azah Mohamed, and Hussain Shareef. 2016. "A Nature-Inspired Optimization-Based Optimum Fuzzy Logic Photovoltaic Inverter Controller Utilizing an eZdsp F28335 Board" Energies 9, no. 3: 120. https://doi.org/10.3390/en9030120

APA StyleMutlag, A. H., Mohamed, A., & Shareef, H. (2016). A Nature-Inspired Optimization-Based Optimum Fuzzy Logic Photovoltaic Inverter Controller Utilizing an eZdsp F28335 Board. Energies, 9(3), 120. https://doi.org/10.3390/en9030120