1. Introduction

Over the years, it has been established that thermal energy storage systems (TESSs) with phase change materials (PCMs) can efficiently reduce the excessive usage of fossil fuels and subsequent global warming [

1,

2]. Thermal energy storage (TES) is found to play a vital role in a broad range of industrial and residential applications. The use of TESSs with PCMs in buildings enhances the human comfort by reducing the internal air temperature fluctuation. Consequently, the indoor air temperature remains near the required temperature over an extended time period [

3]. Sensible heat TES, which stores heat in fluid or solid form, latent heat TES, which uses latent heat during the phase change process, and thermoelectric devices are the common examples of different types of TES technologies. TESSs can rapidly discharge or store huge amounts of heat with solar energy and heat as alternating sources [

4]. Recent research reveals the advancements of extensive building architecture and management based on TES with PCMs. TES is attractive due to its absolute suitability to reduce the gap between energy demand and supply [

5].

Several commercial PCMs have been developed with varying melting temperatures. Considering the cost of various PCMs, Rezaei

et al. [

6] examined their influence on energy and exergy efficiencies. Based on the lumped-parameter method, Li

et al. [

7] established an analytical temperature model. They calculated the enthalpy difference of inorganic salts derived from two types of composite materials. It is shown that the melting point and the enthalpy difference of the binary eutectics (LiNO

3-NaNO

3, LiCL-NaCL and Li

2CO

3-Na

2CO

3) are consistent with the ones obtained from standard methods. Meanwhile, many efforts are made to produce high performance PCM integration in building walls. Romero-Sanchez

et al. [

8] evaluated the thermal performance of PCMs by incorporating in natural stone. Experiments and numerical simulation are carried out to improve the thermal properties of natural stone, where concrete pilot houses are constructed. These pilot houses are covered with trans-ventilated facade designs via Spanish Bateigazul natural stone. An improvement in human comfort with the reduction in energy consumption is evidenced upon implementing PCMs.

Izquierdo-Barrientos

et al. [

9] inspected the effects of PCMs on external building walls with various configurations by altering the PCMs’ layer position, ambient conditions, wall orientation and phase transition temperature. A 1D transient heat transfer numerical model is developed and solved using a finite difference method. Results revealed no significant reduction in the total heat lost during winter irrespective of the variation of the PCM wall orientation or the transition temperature. Moreover, during the summer time, a significant difference in the heat gain is evidenced, which is attributed to the elevated solar radiation fluxes.

The thermal performances of a PCM based co-polymer composite wallboard were experimentally assessed by Kuznik and Virgone [

10], where two identical enclosures, called Test Cells 1 and 2, were constructed. The volume of each test cell is (3.10 m × 3.10 m × 2.50 m) and is bounded on five sides by a fixed temperature regulated air mass. The sixth side is a glazed face that separates the test cell from a climate compartment. The air temperature in the room containing PCM is found to decrease up to 4.2 °C without any thermal stratification as compared to the room without PCM composite.

Employing PCM in a representative Mediterranean building, De Gracia

et al. [

11] evaluated its environmental impact in terms of warming. Three scenarios, such as different temperature control systems, different PCM types or different weather conditions, are emphasized based on the life cycle assessment (LCA) process. It is shown that the presence of PCM in the building envelope decreased the energy consumption without considerable reduction of the global impact. The LCA for the real rooms exhibited an impact reduction of 37% upon incorporating polyurethane (PU) into the reference room (REF). Kuznik

et al. [

12] optimized the PCM wallboard thickness in lightweight buildings with reduced air temperature fluctuations inside the room, where the in-house numerical code CODYMUR is used to calculate the optimal thickness.

In another experiment, Navarro

et al. [

13] evaluated the PCM performance in terms of internal thermal gains. Three different rooms with the same internal dimensions (2.4 m × 2.4 m × 2.4 m) are considered. These rooms are labelled as (1) the REF (built using traditional two-layered brick with an air gap and without insulation), (2) the PU (constructed by a traditional brick with of spray foam thickness of 5 cm (walls) and 3 cm (roof)) and (3) the PCM (made with a PCM layer in the southern and western walls and on the roof). It is found that during the summer season the PCM room stored the heat produced by the internal loads, thus limiting the heat dissipation to the outer environment. The REF is found to possess higher temperature fluctuations in its envelope (27.5–24 °C) than other rooms with insulation (28–26 °C).

Pasupathy and Velraj [

14] analyzed (theoretically and experimentally) the thermal performance of an inorganic eutectic PCM-based thermal storage system (TSS) for energy conservation in buildings. In the design, one room contained PCM on the roof, and the other room is devoid of the PCM panel. The inner walls, except the ceiling of the rooms, are insulated by a 6 mm-thick plywood on all sides to determine the sole influence of the PCM panel on the roof. The PCM panel is made of (2 m × 2 m) stainless steel having a thickness of 2.54 cm. The stainless steel accommodated an inorganic salt hydrate (48% CaCl

2 + 4.3% NaCl + 0.4% KCl + 47.3% H

2O) as the PCM. The measured room temperatures are observed to vary ~27 ± 3 °C during the experiment. Despite many dedicated efforts, a comprehensive understanding of the PCM-mediated reduction in heat flux inside the building is far from being achieved.

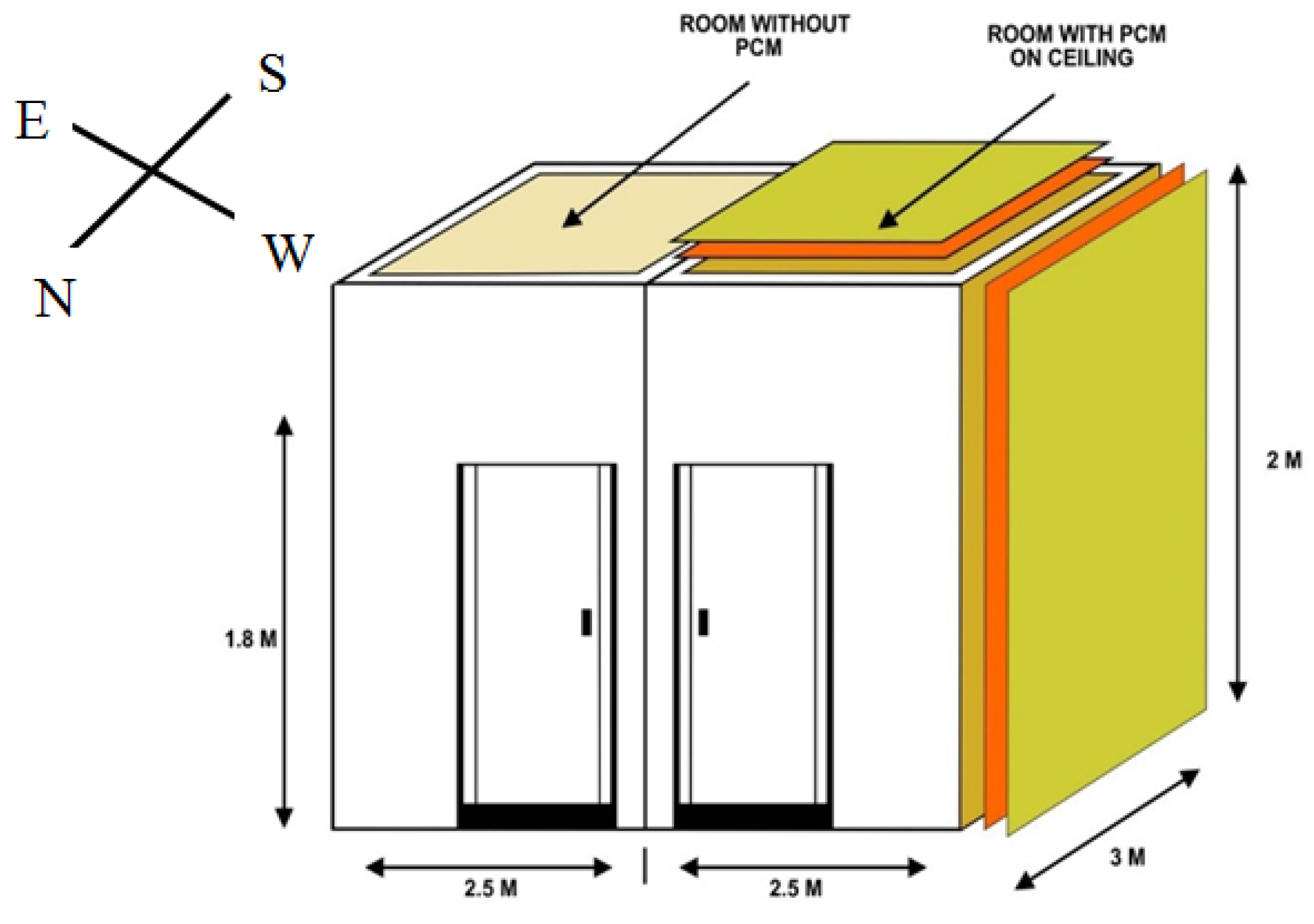

In this paper, experimental and numerical investigations were performed using PCMs in building architecture to determine their impact on lowering the heat flux inside the building. Two identical rooms, one without and the other with PCM, were considered for experiments. Numerical simulation was done based on the transient heat transfer model. The heat flux inside the room is determined to assess the thermal performance of such PCMs. Results are discussed, analyzed, compared and validated.

2. Numerical Scheme

The boundary condition on the inner surface of the aluminum frame follows natural convection. Most of the previous researchers considered the bottom wall as insulated, because the temperature difference between the room and the wall was very small. The heat transfer coefficient (

h) inside the room is calculated (FORTRAN programming).

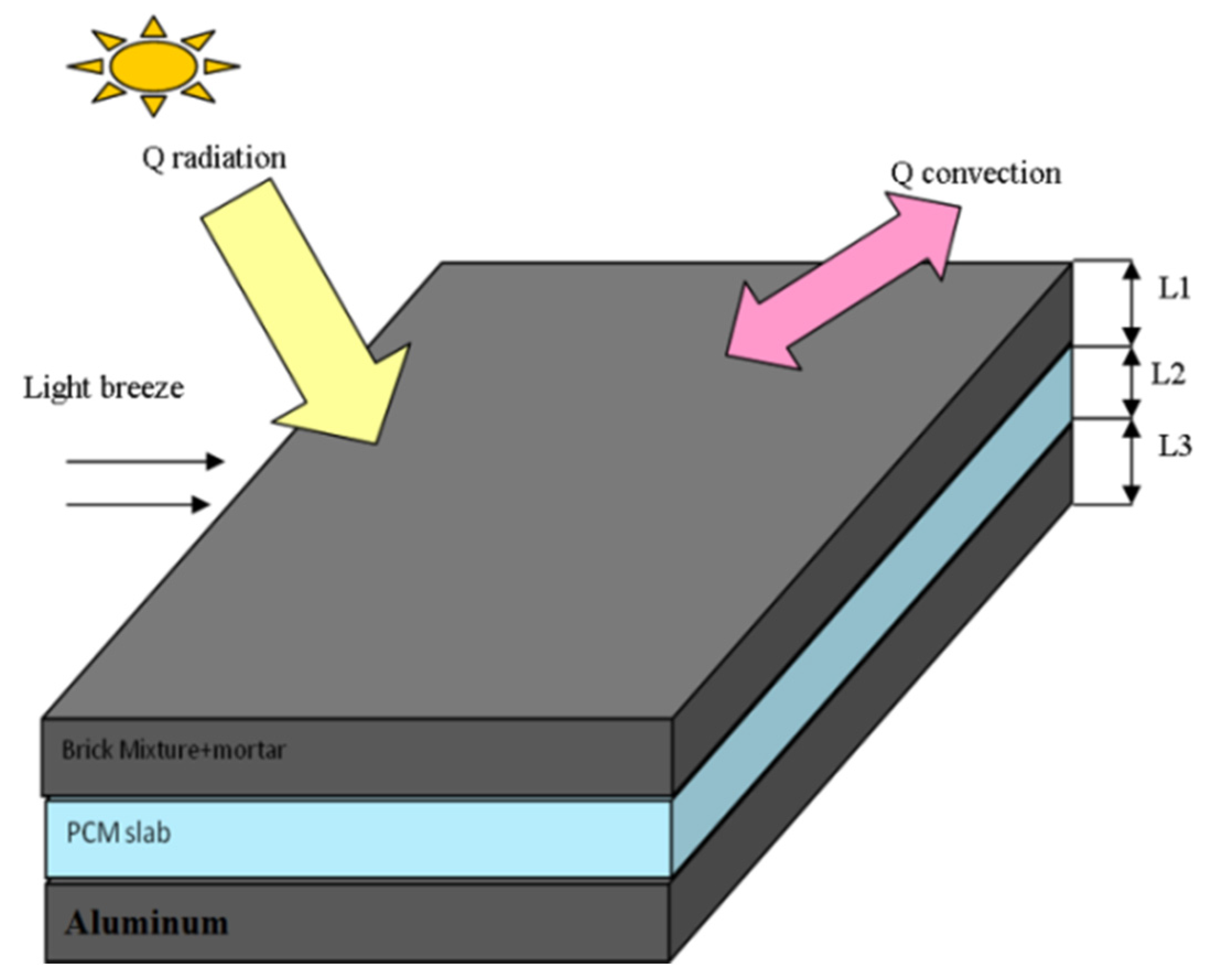

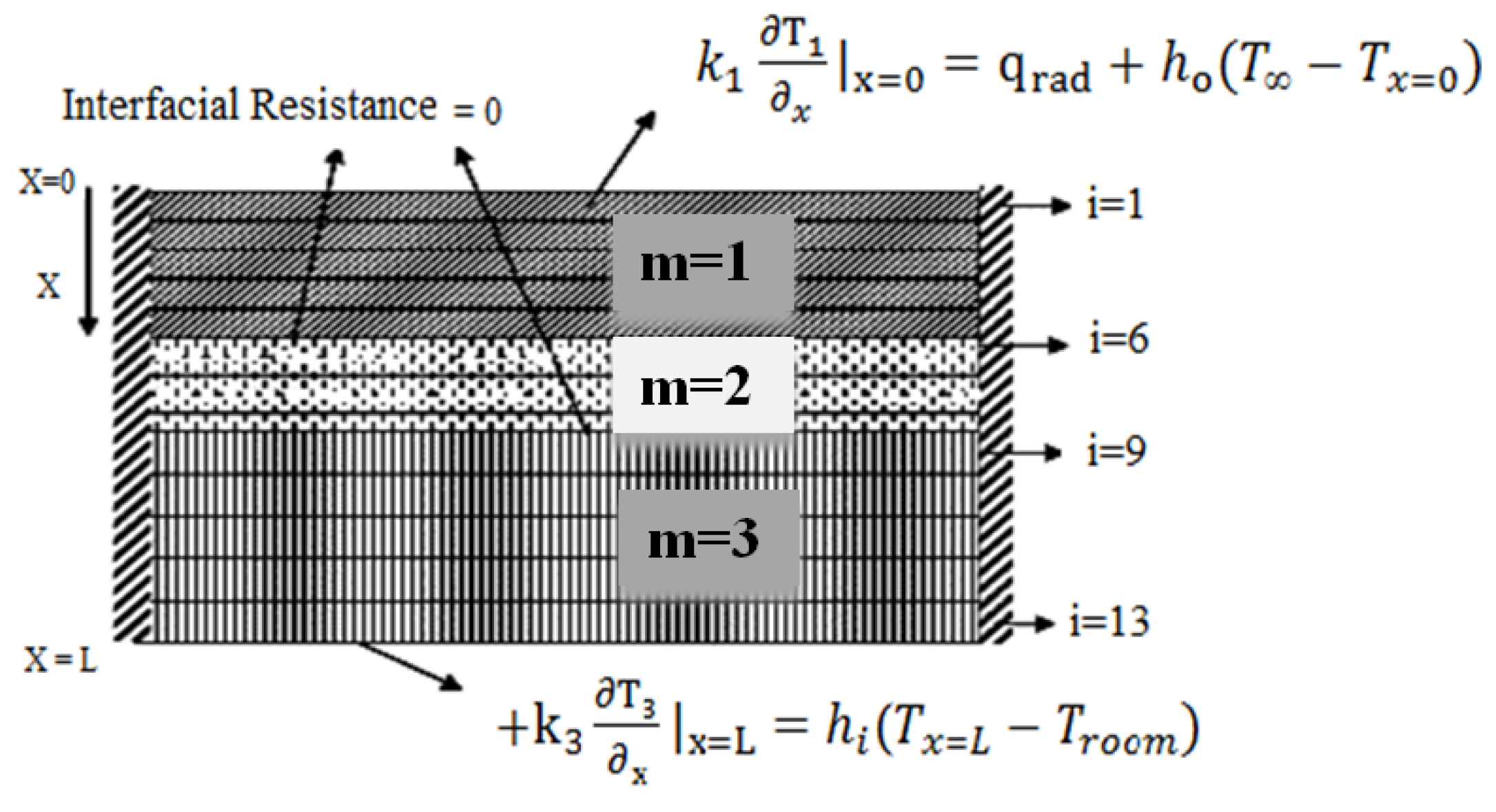

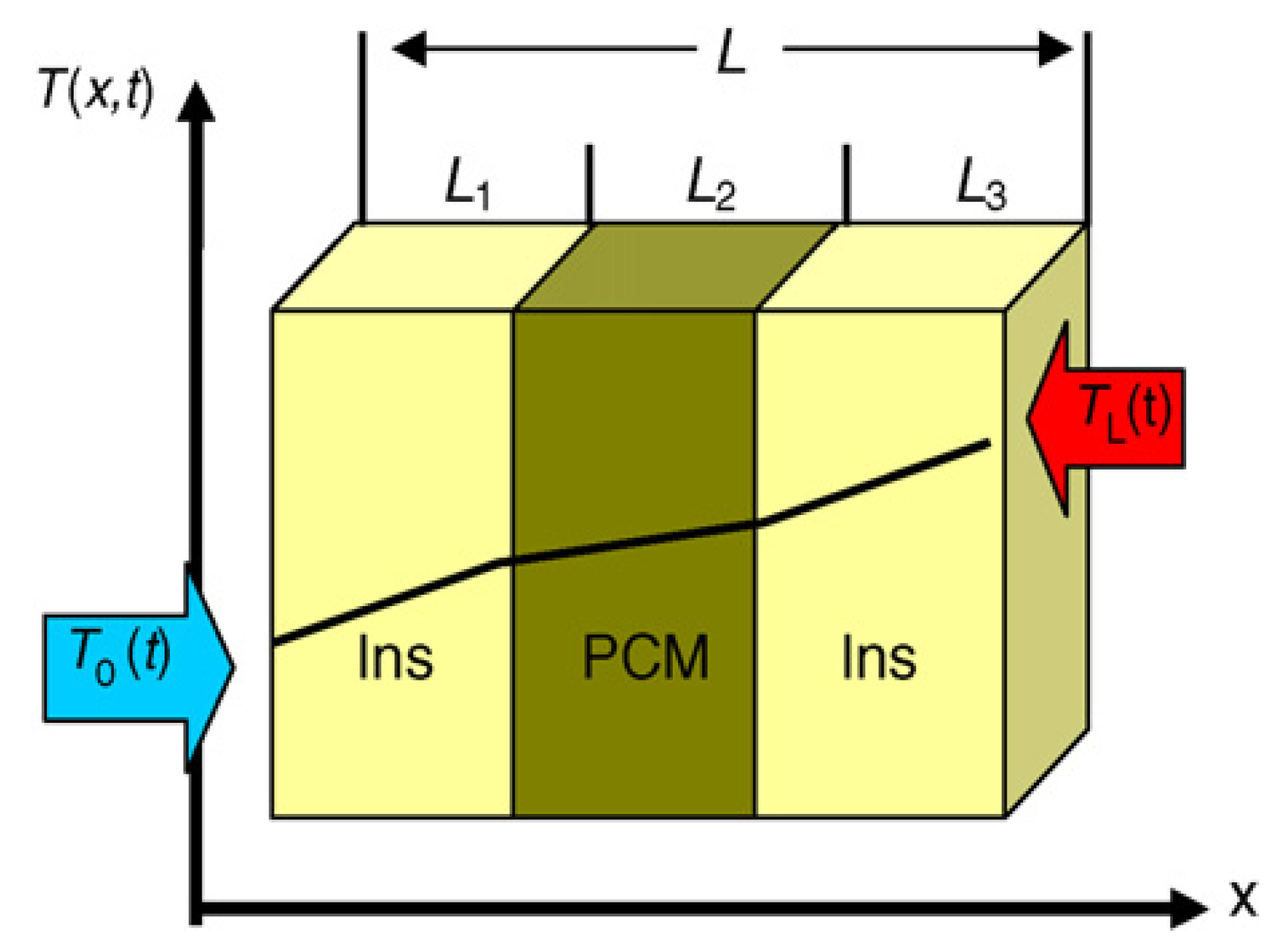

Figure 1 and

Figure 2 display the schematics for the numerical model formulation, which assumes the following:

- (i)

One dimensional heat conduction in the composite wall is considered, and the end impacts are not taken into account.

- (ii)

The thermal conductivity of the aluminum frame and the roof top slab are constant irrespective of temperature variation.

- (iii)

The PCM is uniform and isotropic.

- (iv)

The convection impact in the molten PCM is not considered.

- (v)

The interfacial resistances are negligible.

- (vi)

The value of

Cp for the PCM panel is considered as follows:

where

is the specific heat capacity,

hsl is the enthalpy change of solid-liquid, Δ

T is half of the temperature range over which the phase change occurs and

Tm is the phase transition temperature.

- (vii)

The latent heat being highly sensitive to the phase transition process of the PCM is modeled over a range of temperatures, where is considered to be uniform during the phase conversion. Although, in reality, varies with temperature.

Figure 1.

Schematic diagram of phase change material (PCM) incorporated ceiling.

Figure 1.

Schematic diagram of phase change material (PCM) incorporated ceiling.

Figure 2.

Finite volume grid for the analysis.

Figure 2.

Finite volume grid for the analysis.

Following these assumptions, the governing equation and the boundary conditions are written as:

where

m = 1 for the roof top slab,

m = 2 for the PCM panel and

m = 3 for the bottom aluminum frame. The same equation holds for all three material regions and takes different values of

k,

and

.

In the outer walls (

x = 0), where the floor is exposed to solar radiation, the boundary condition is expressed as:

The radiation effect is considered only during the sunshine hours. The boundary condition (

x =

L) in the bottom layer of the aluminum frame is:

The instantaneous continuity of heat flux and temperature at the interfaces x = and is preserved.

The equation for the top volume cell is written as:

The equation for the volume cells located in between the top and bottom volume cells yields:

The above-mentioned discretized equations are applicable to volume cells for 2–4, 7 and for 10–12 of the roof top slab, PCM panel and aluminum frame, respectively, with: = 1, = 2, 3, 4; = 2, = 7; and = 3, =10, 11, 12.

The equation for the interface volume cell 5 is written as:

where

and

are the cell thickness of the roof top slab and PCM panel, respectively. Similarly, the equation can be written for volume cell 6. A similar process is extended to control Volumes 8 and 9, which involve cell thicknesses

and

corresponding to the PCM panel and the bottom aluminum frame, respectively.

The equation for the bottom volume cell 13 is given by:

5. Results and Discussion

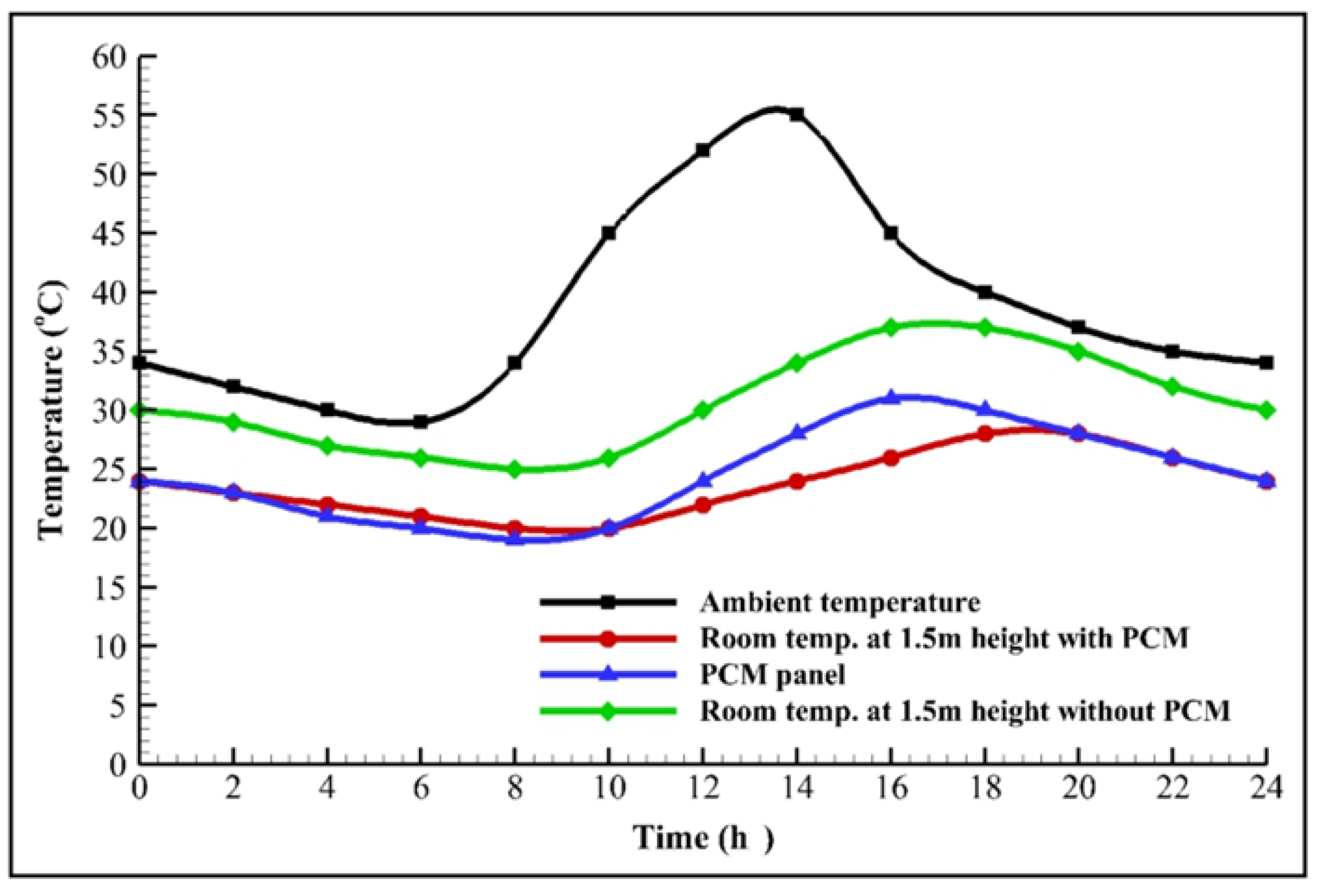

Figure 5 illustrates the average variation of ambient temperature and the temperature inside the test rooms with and without PCM at a 1.5 m height in the month of August. As shown in the figure, the temperature of the room without PCM is found to increase at τ = 12 h, reaches the maximum (35 °C) between 16 h and 17 h and then decreases. This is due to the fact that initially (up to 12 h), the heat is absorbed by the room walls and roof exposed to sun and then slowly released, which caused a greenhouse-like effect of an inner increase of the temperature, as expected. Needless to say, the sun sign (solar irradiance) reaches the maximum at 12 h and remains there for a few hours before gradually dropping in later in the afternoon (beyond 17 h). On the other hand, the implementation of the PCM in the building structures reduced the room temperature peak load by 5 °C for the same time period (between 16 h and 17 h). This lowering in the peak temperature inside the room and the creation of thermal comfort is attributed to the effect of the heat storage capacity of the PCM on the temperature variation. Actually, during the first few hours of the day (up to 12 h), paraffin absorbed the latent heat from the room environment and then underwent phase transformation, thereby reducing the peak temperature. However, with the decrease of the sun sign (beyond 17 h), the latent heat is slowly released into the atmosphere. The temperature fluctuation in this case is much weaker than the one without PCM incorporated in the building. It is evident that the greenhouse effect was much lowered in the presence of PCM. This verifies the environmental friendliness of PCM when used in building management and architecture.

Figure 5.

Temperature variation of the test rooms with and without PCM (REF) at a 1.5 m height in the month of August.

Figure 5.

Temperature variation of the test rooms with and without PCM (REF) at a 1.5 m height in the month of August.

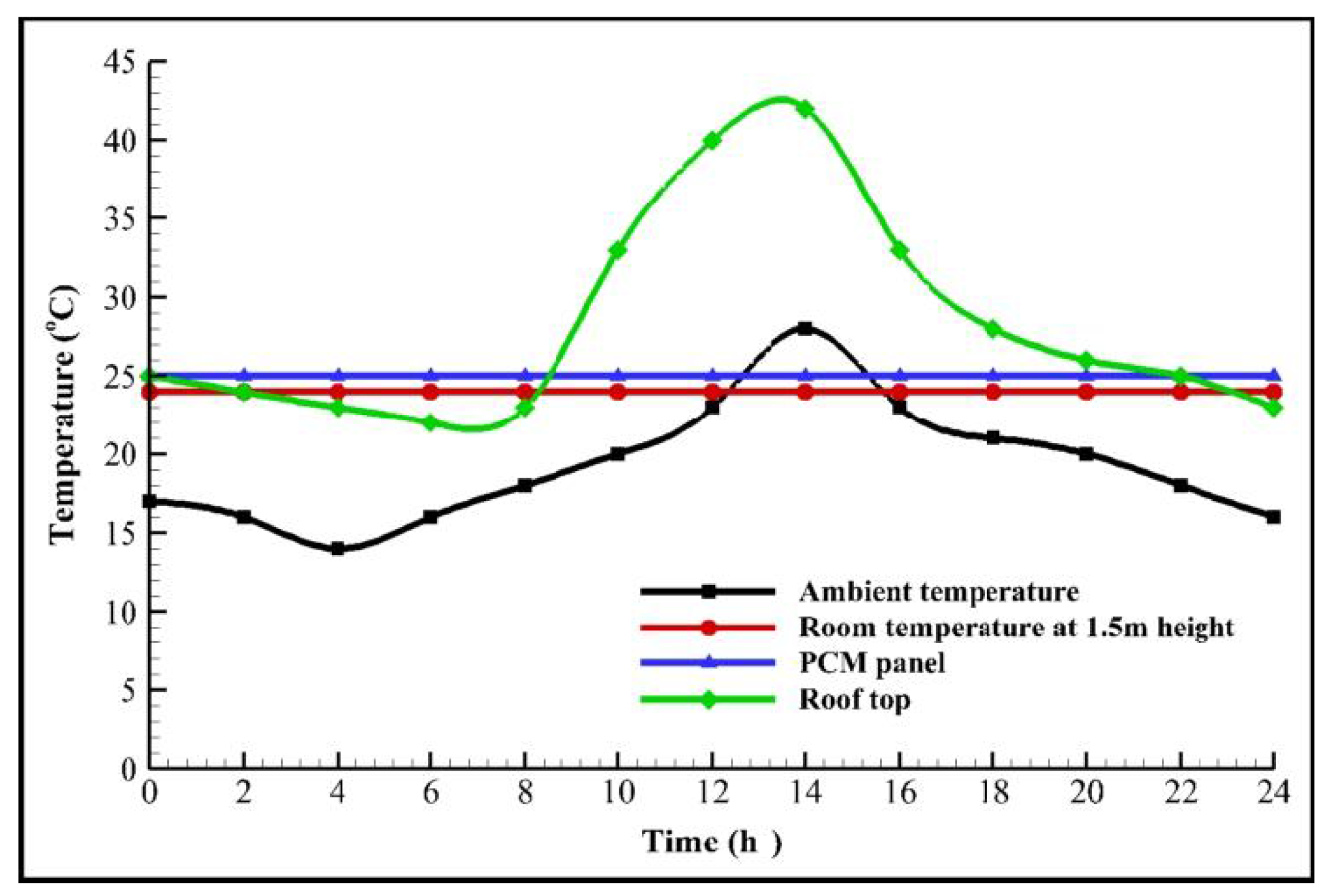

Figure 6 depicts the average variation of ambient temperature and the temperature inside the test rooms with and without PCM at a 1.5 m height in the month of January. The temperature of the room without PCM started to increase at 10 h and reached its peak load at 20 h. The temperature of the roof top reaches the maximum between 12 h and 16 h before dropping. The higher value of the roof top temperature compared to the ambient and inside ones clearly indicates the role of both radiation and convection throughout the day, as long as the sun signs; while the temperature inside the room with PCM in the winter month of January is stable all day under ambient temperature. This stability is due to the effect of using the PCM, which acts as a heat storage capacitor and diminishes the rapid temperature fluctuation via phase transformation. During phase conversion in paraffin, a huge amount of latent heat exchange occurs at a constant temperature. This elevated absorption of heat by the PCM materials is indeed responsible for the reduction of the heat flux inside the room and the maintenance of thermal comfort. Specifically, the use of PCM in the building walls and roof increased their thermal resistance and thereby reduced the overall heat transfer through the walls with much lowered heat load compared to the building without PCM.

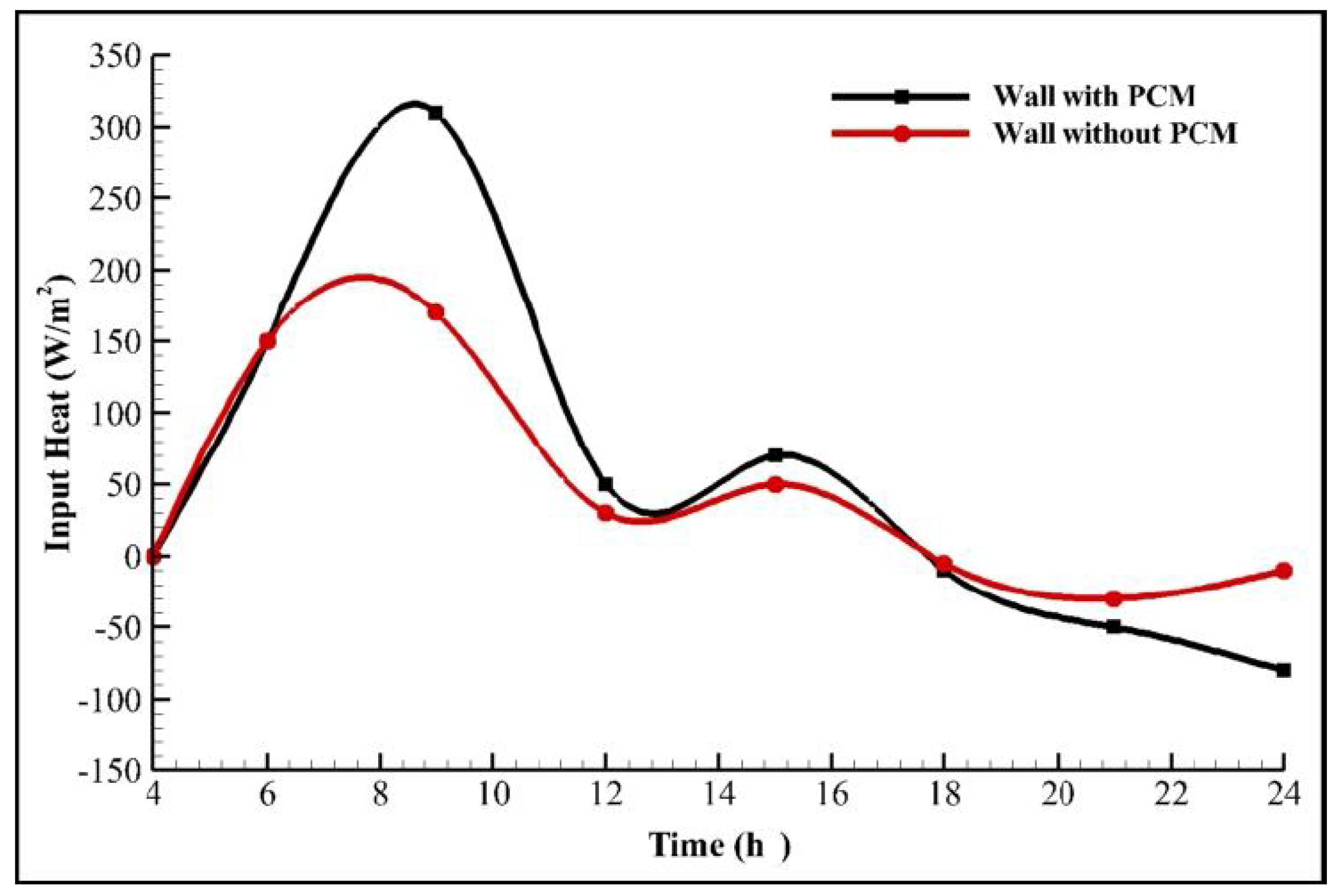

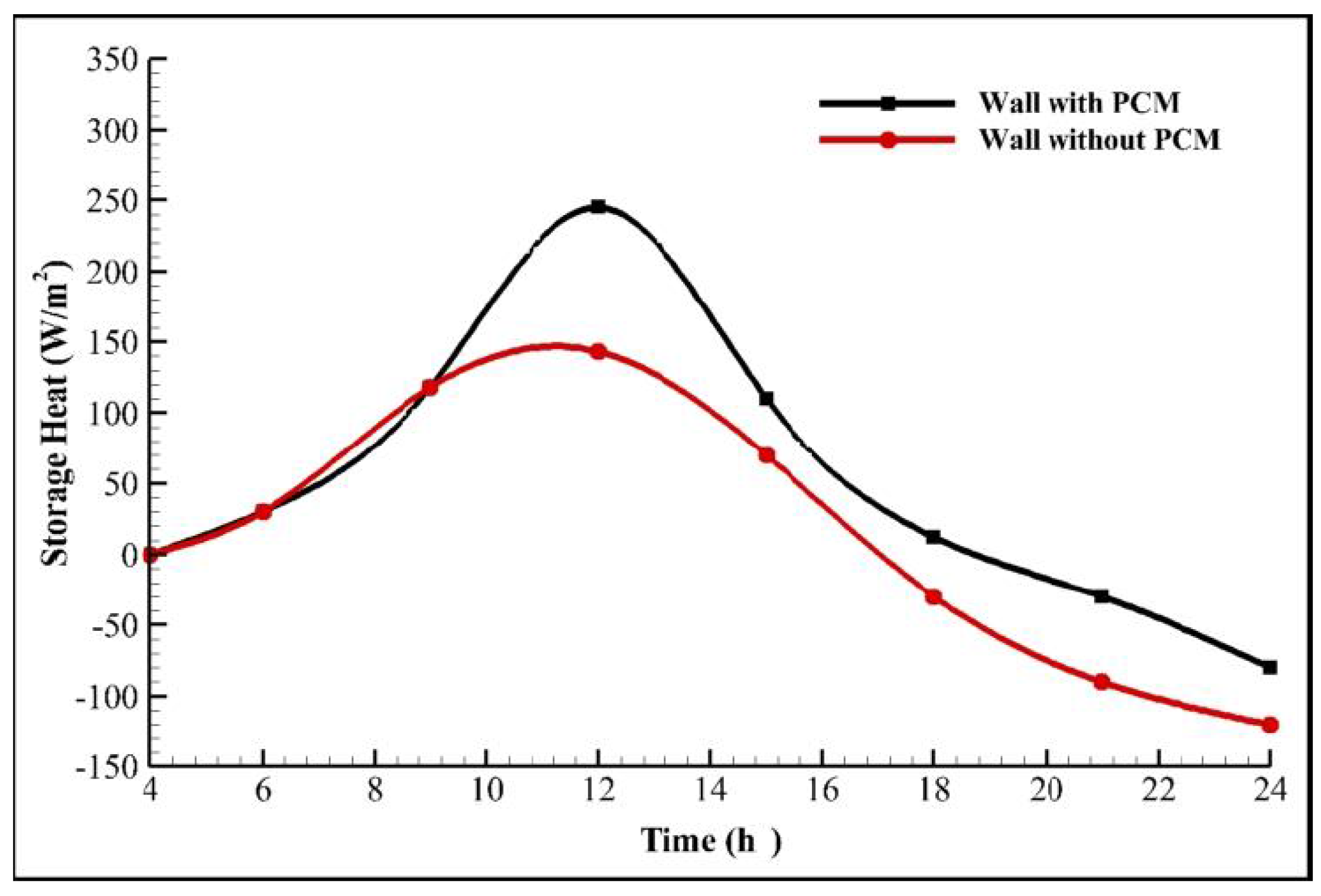

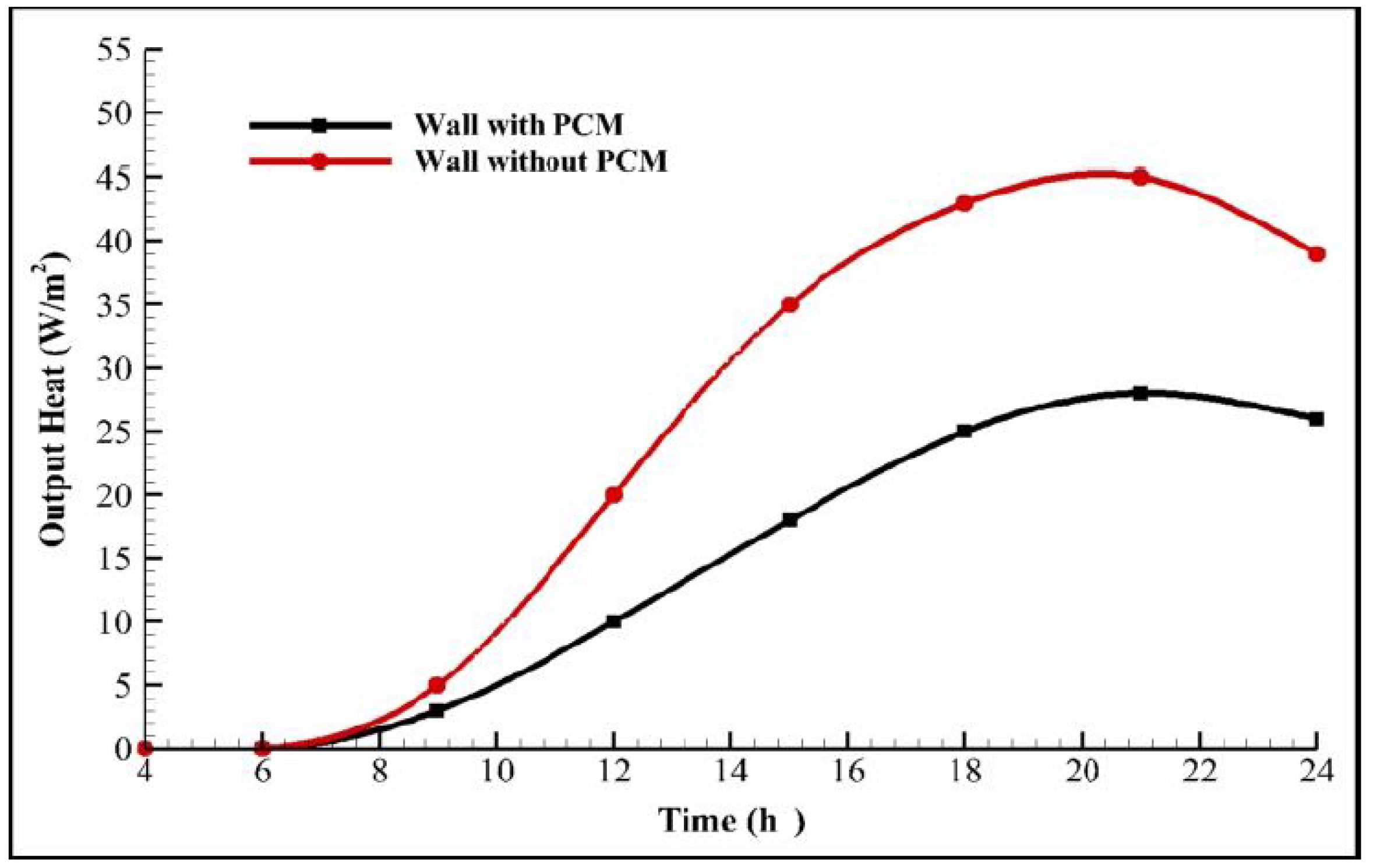

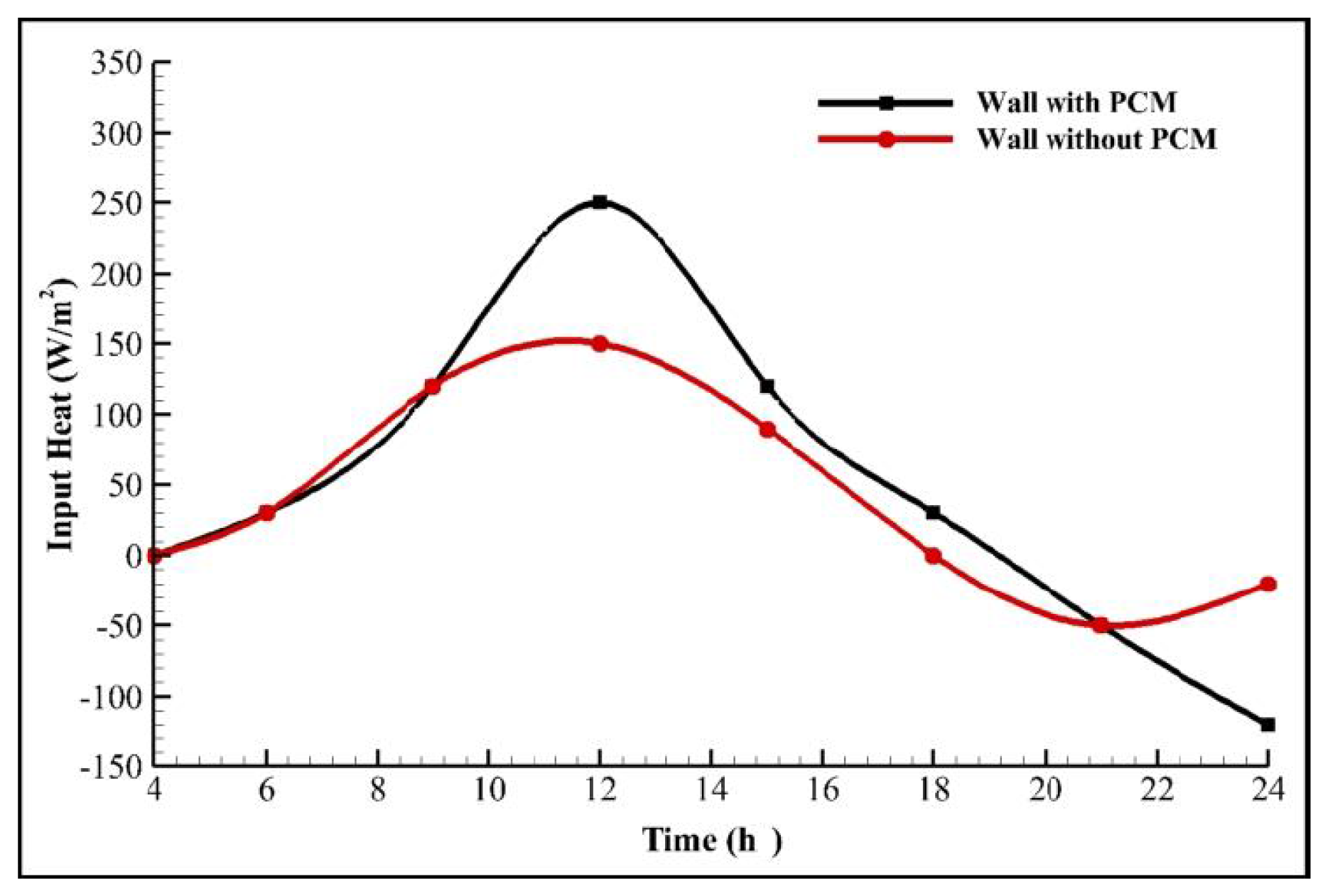

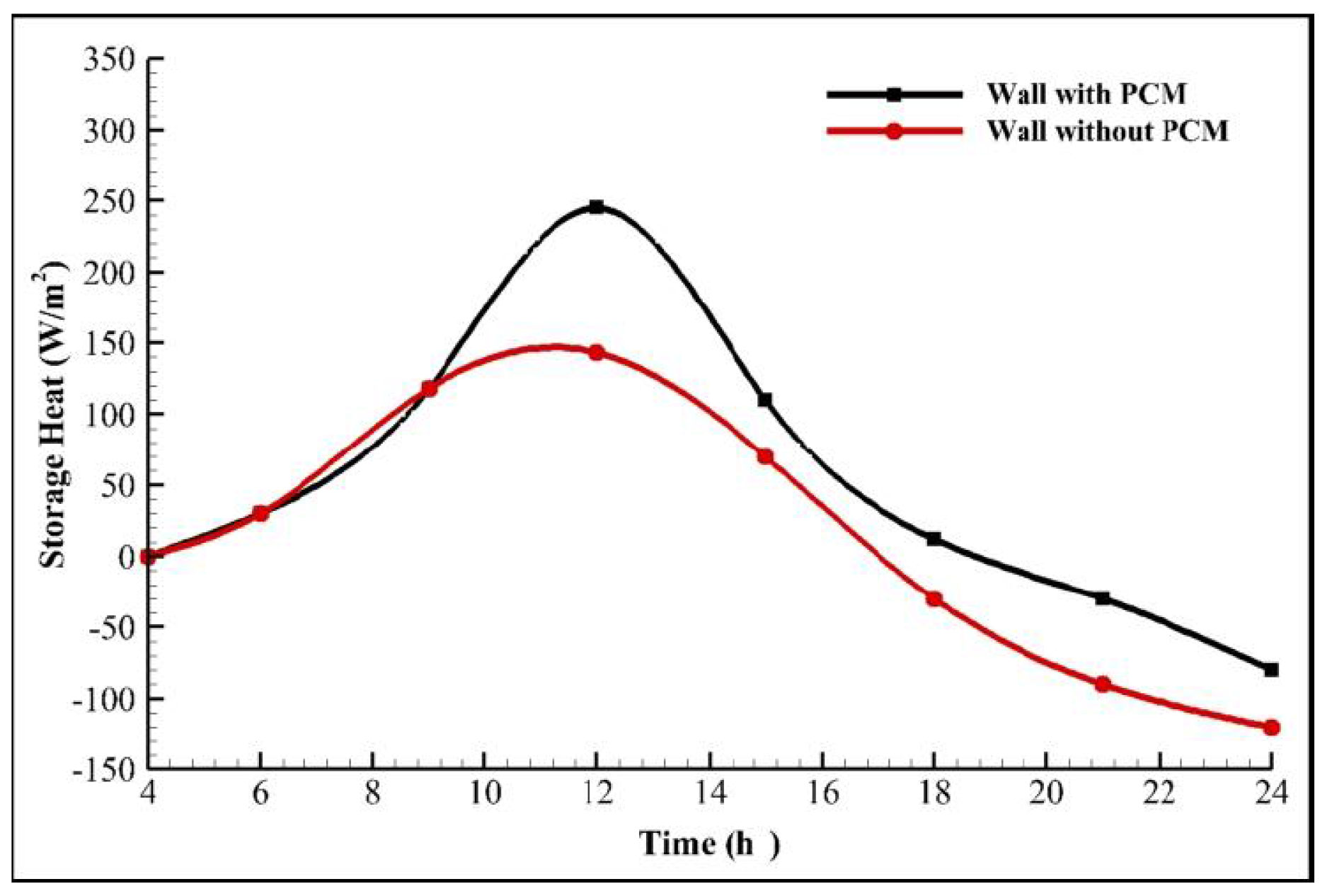

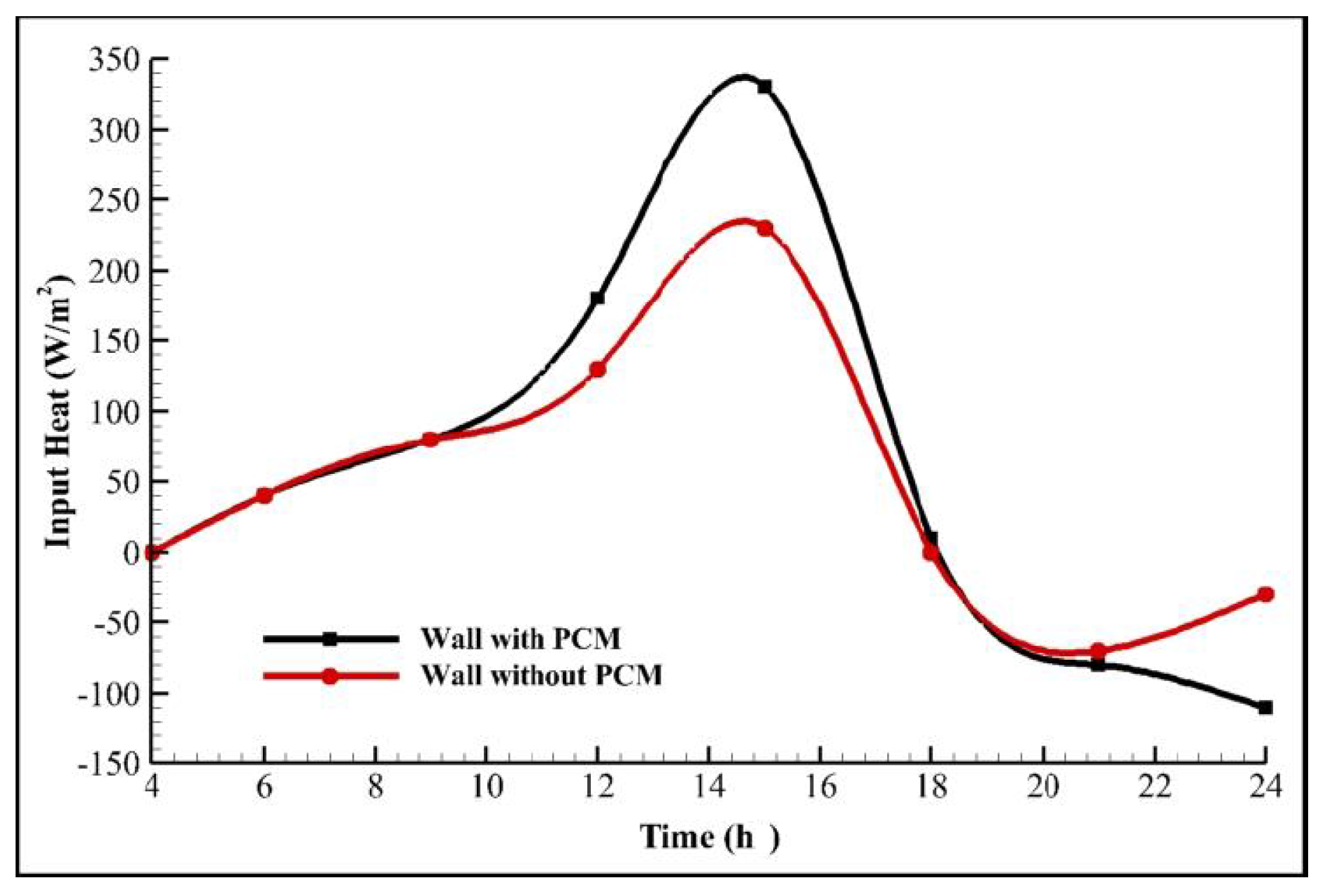

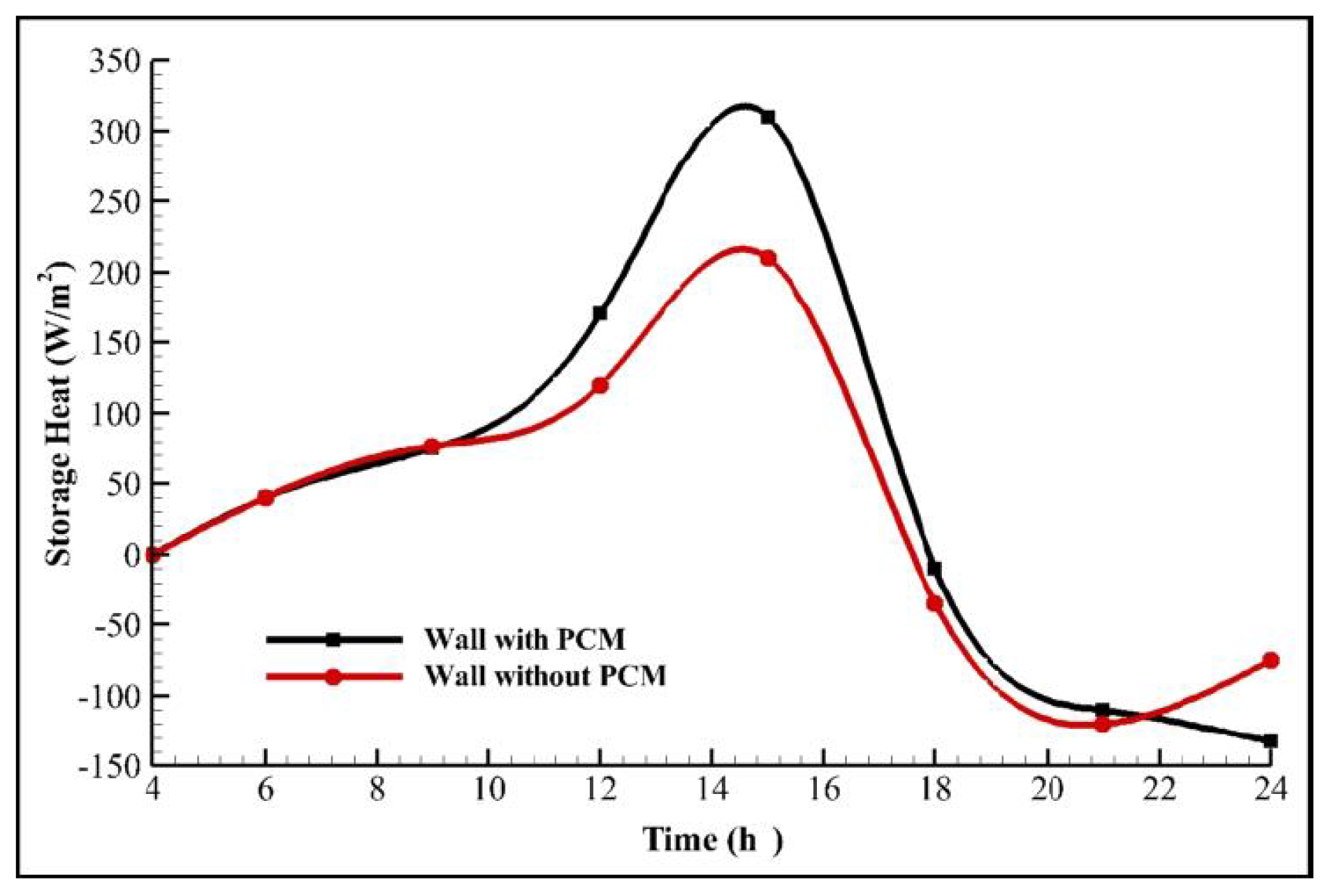

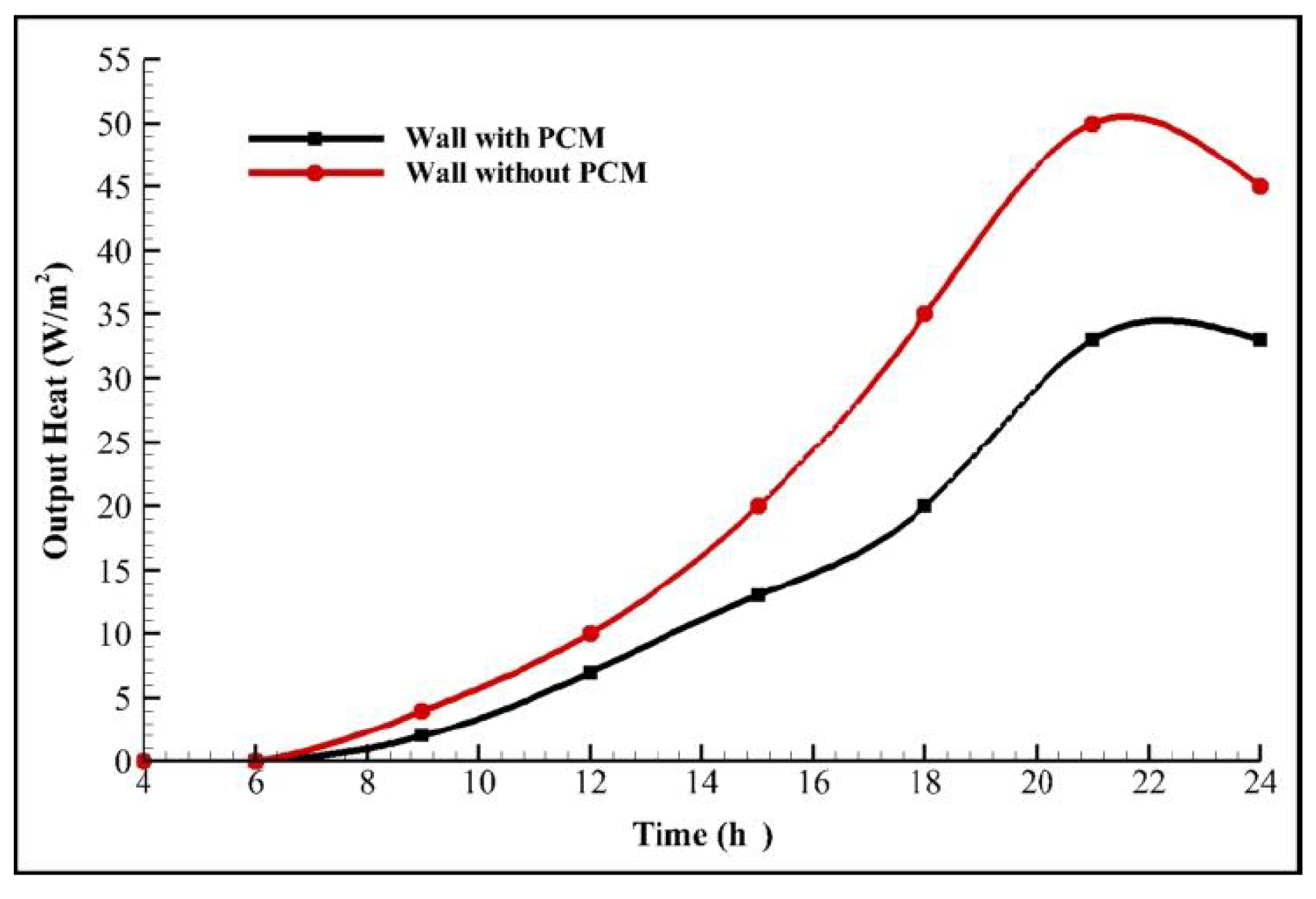

The temperature variation for the PCM and non-PCM walls is theoretically examined. The east, south and west walls are used to calculate the heat flux through the external and internal walls’ surface and the amount of heat storage in the walls. In

Figure 7,

Figure 8 and

Figure 9, the external heat flux, heat storage and internal heat flux on the east wall of both types of rooms have been compared.

Figure 9 (heat flux through the external wall) clearly reveals that the heat flux for the PCM incorporated room is slightly higher than the one without PCM on the walls. This observation is attributed to the low thermal conductivity of the liquid PCM, which reduced the heat transmission to the room and thereby increased the wall top surface temperature. The maximum value of heat flux through the PCM including and excluding the external wall at 9 h is found to be 312 W/m

2 and 162 W/m

2, respectively. Conversely, the heat flux (at 21.5 h) through the internal east wall of the room with and without PCM is discerned to be 26 W/m

2 and 44 W/m

2, respectively. Furthermore, heat storage is observed to be maximum at 12 h with values of 240 W/m

2 and 135 W/m

2 for the PCM integrated and non-integrated east walls, respectively.

Figure 6.

Temperature variation of the test room with and without PCM (REF) at a height of 1.5 m in the month of January.

Figure 6.

Temperature variation of the test room with and without PCM (REF) at a height of 1.5 m in the month of January.

Figure 7.

Heat flux through the external surface of the non-PCM- and PCM-treated east walls.

Figure 7.

Heat flux through the external surface of the non-PCM- and PCM-treated east walls.

Figure 8.

Amount of heat storage in the non-PCM- and PCM-treated east walls.

Figure 8.

Amount of heat storage in the non-PCM- and PCM-treated east walls.

Figure 9.

Heat flux through the internal surface of the non-PCM- and PCM-treated east walls.

Figure 9.

Heat flux through the internal surface of the non-PCM- and PCM-treated east walls.

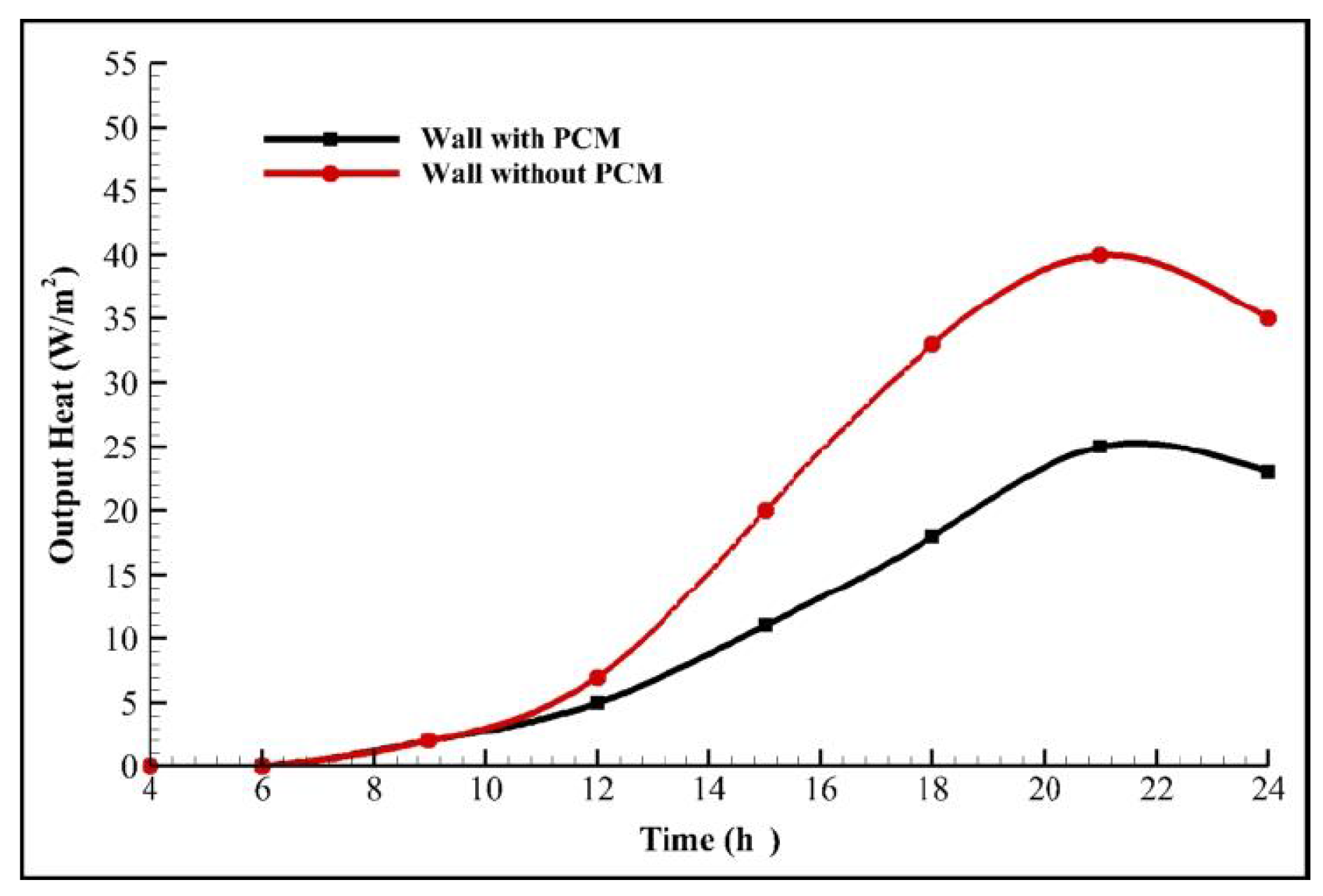

The variation of heat flux and storage for the south and west walls for the rooms with and without the incorporation of PCM is demonstrated in

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14 and

Figure 15. These variations in heat and storage profiles are similar to those of the east wall.

The value of thermal flow and heat storage through a selected wall is computed using finite volume method (FVM), where the thermal flow (through the wall for both the internal and external surface) is calculated. A fixed value of the internal and external heat transfer coefficient is used, which is 7.73 W/m2·°C and 23.3 W/m2·°C for the internal and external wall surface, respectively. The amount of stored heat in the walls containing PCMs is found to be larger than the traditional (REF) walls. This elevated storage in PCM walls is ascribed to the high heat capacity and heat-retaining susceptibility without connecting any storage space to the air conditioner. The observed higher thermal storage for the western walls is related to the longest exposure to the solar radiation.

Figure 10.

Heat flux through the external surface of the non-PCM- and PCM-treated south walls.

Figure 10.

Heat flux through the external surface of the non-PCM- and PCM-treated south walls.

Figure 11.

Amount of heat storage of the non-PCM- and PCM-treated south walls.

Figure 11.

Amount of heat storage of the non-PCM- and PCM-treated south walls.

Figure 12.

Heat flux through the internal surface of the non-PCM- and PCM-treated south walls.

Figure 12.

Heat flux through the internal surface of the non-PCM- and PCM-treated south walls.

Figure 13.

Heat flux through the external surface of the non-PCM- and PCM-treated west walls.

Figure 13.

Heat flux through the external surface of the non-PCM- and PCM-treated west walls.

Figure 14.

Amount of heat storage in the non-PCM- and PCM-treated west walls.

Figure 14.

Amount of heat storage in the non-PCM- and PCM-treated west walls.

Figure 15.

Heat flux through the internal surface of the non-PCM- and PCM-treated west walls.

Figure 15.

Heat flux through the internal surface of the non-PCM- and PCM-treated west walls.

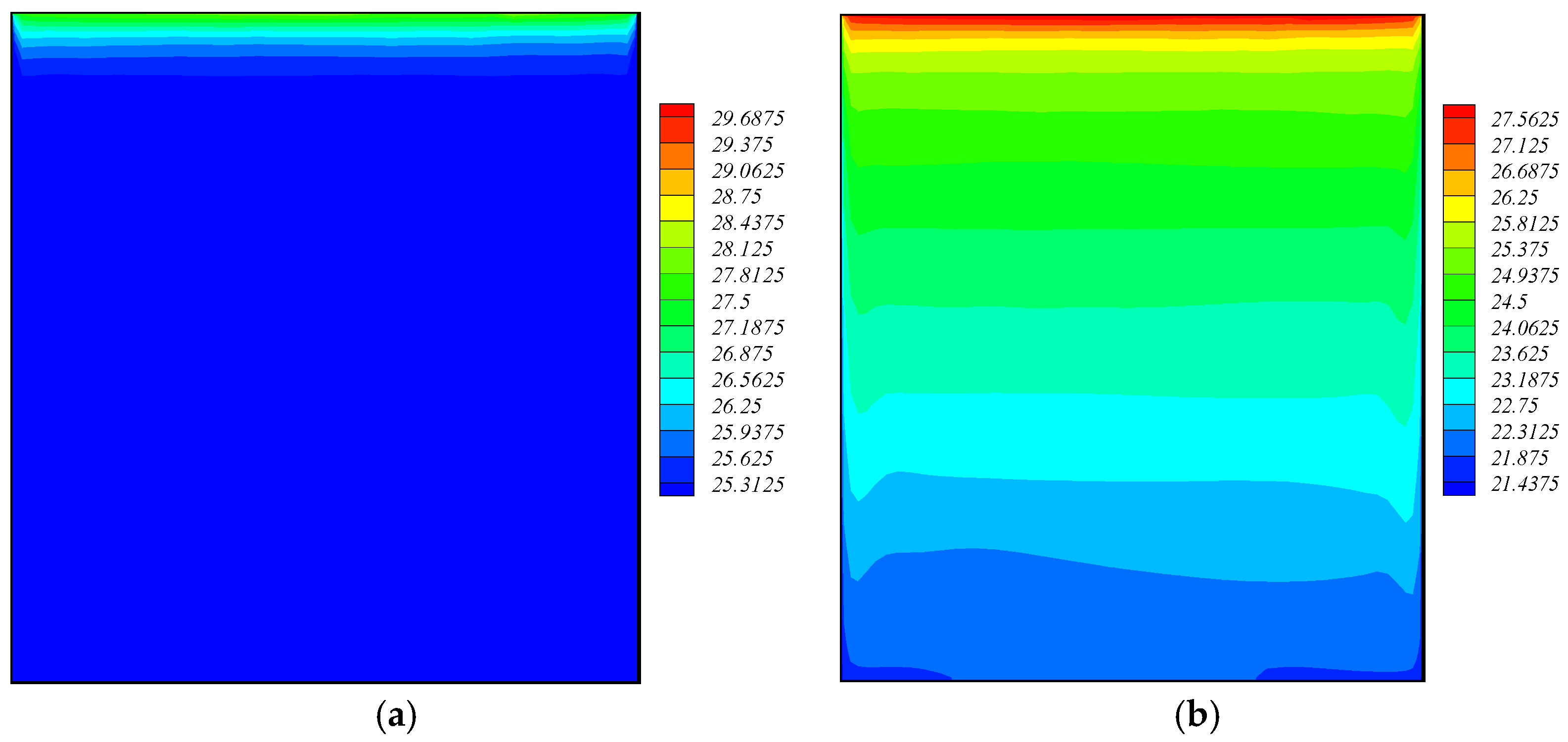

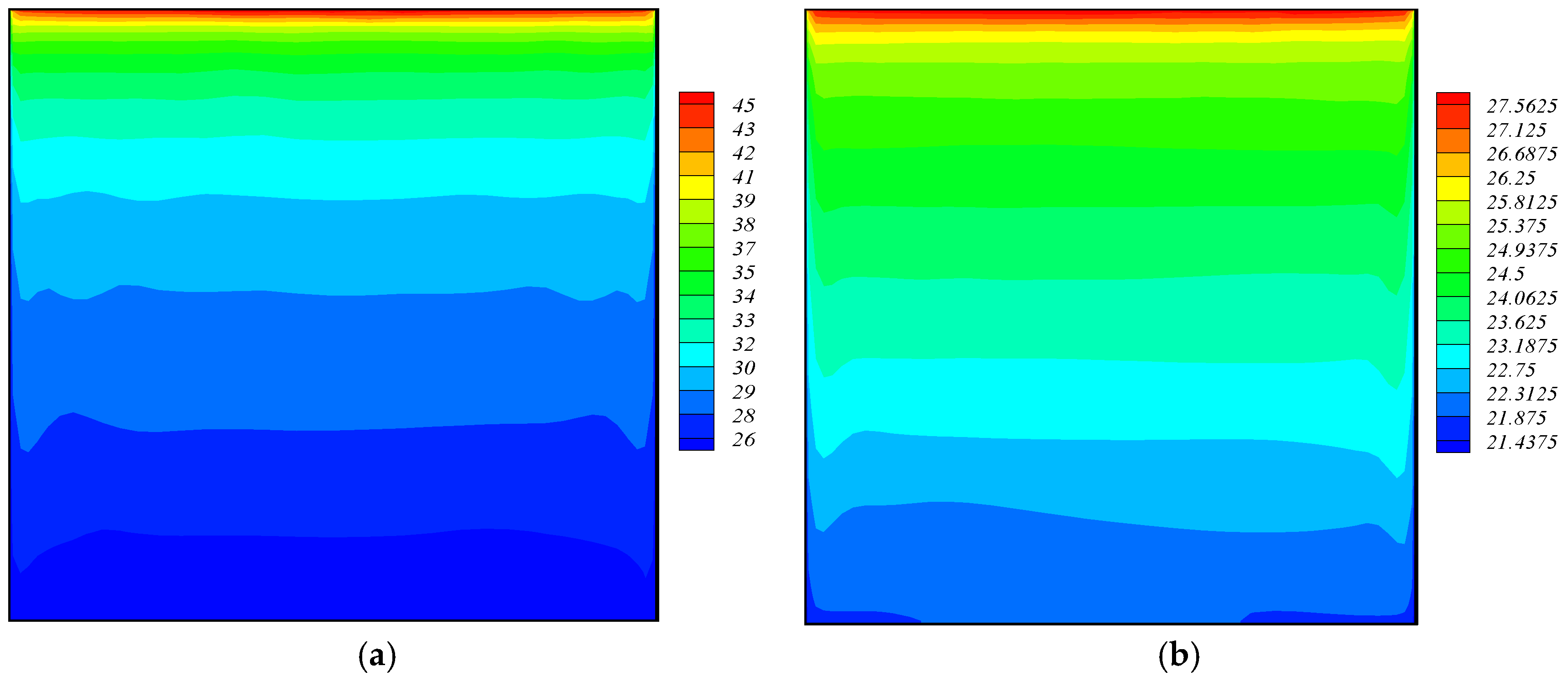

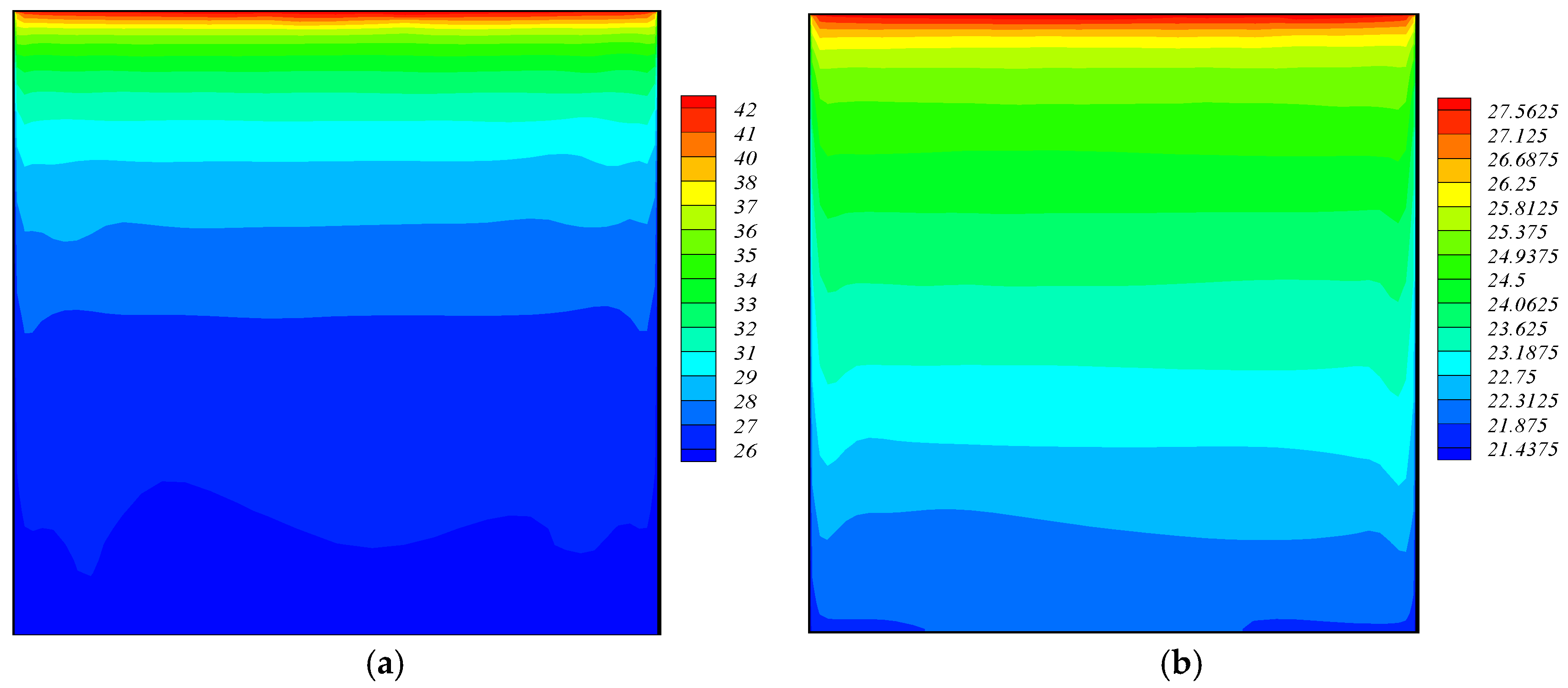

The simulated temperature contours for REF and PCM2 at different times over the day are illustrated in

Figure 16,

Figure 17,

Figure 18 and

Figure 19. It is evident that the room with PCM integration in the roof achieves a superior temperature distribution throughout the day than the one without PCM. However, with the increase of sun sign, the temperature fluctuation became more prominent (at 12 h) for the REF room, as shown in

Figure 20a. The temperature fluctuation kept on increasing at 16 h and 18 h, as depicted in

Figure 21a and

Figure 22a.

Figure 16.

Temperature counters of the roof at 8 h for the room: (a) without and (b) with PCM.

Figure 16.

Temperature counters of the roof at 8 h for the room: (a) without and (b) with PCM.

Figure 17.

Temperature counters of the roof at 12 h for the room: (a) without and (b) with PCM.

Figure 17.

Temperature counters of the roof at 12 h for the room: (a) without and (b) with PCM.

Figure 18.

Temperature counters of the roof at 16 h for the room: (a) without and (b) with PCM.

Figure 18.

Temperature counters of the roof at 16 h for the room: (a) without and (b) with PCM.

Figure 19.

Temperature counters of the roof at 18 h for the room (a) without and (b) with PCM.

Figure 19.

Temperature counters of the roof at 18 h for the room (a) without and (b) with PCM.

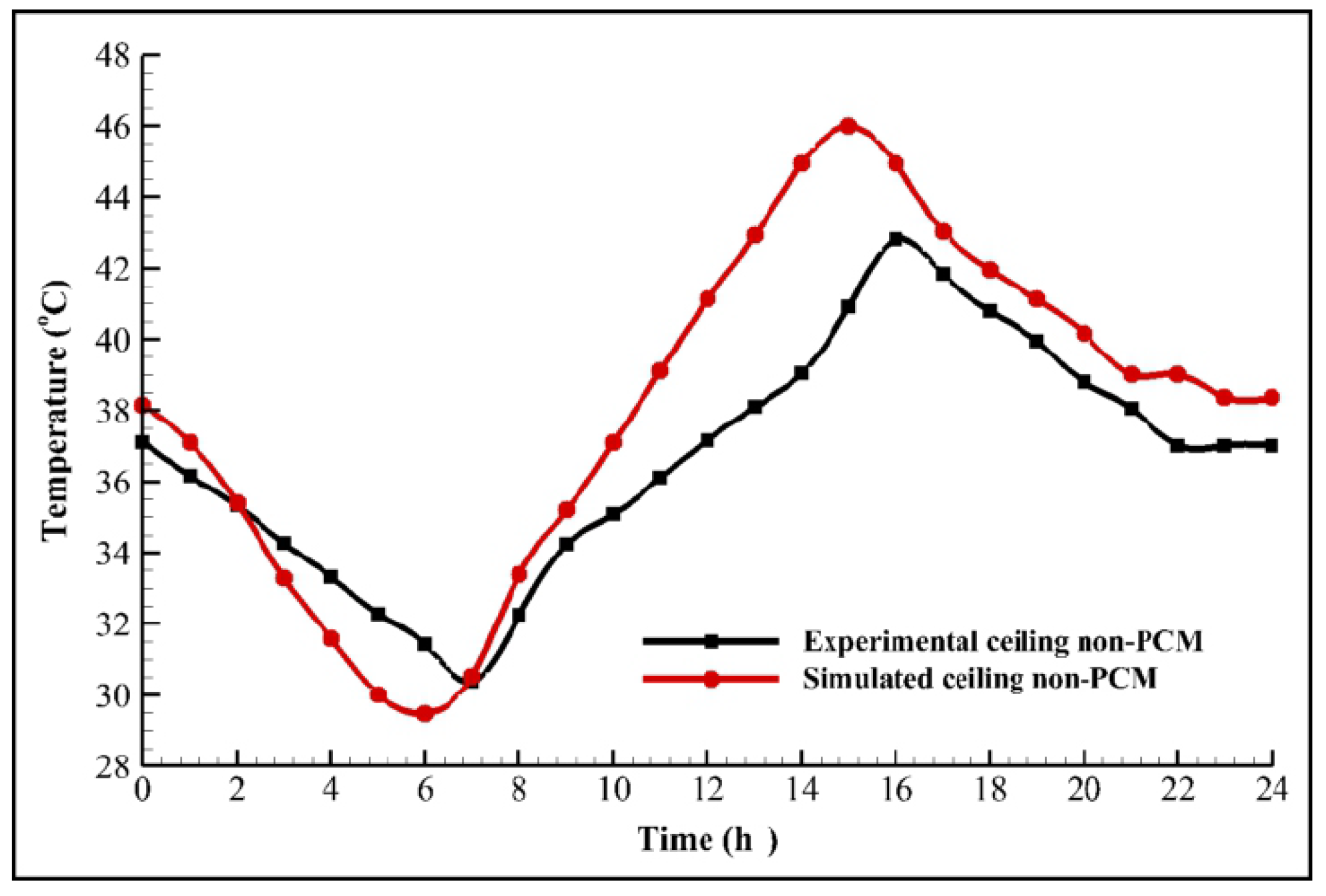

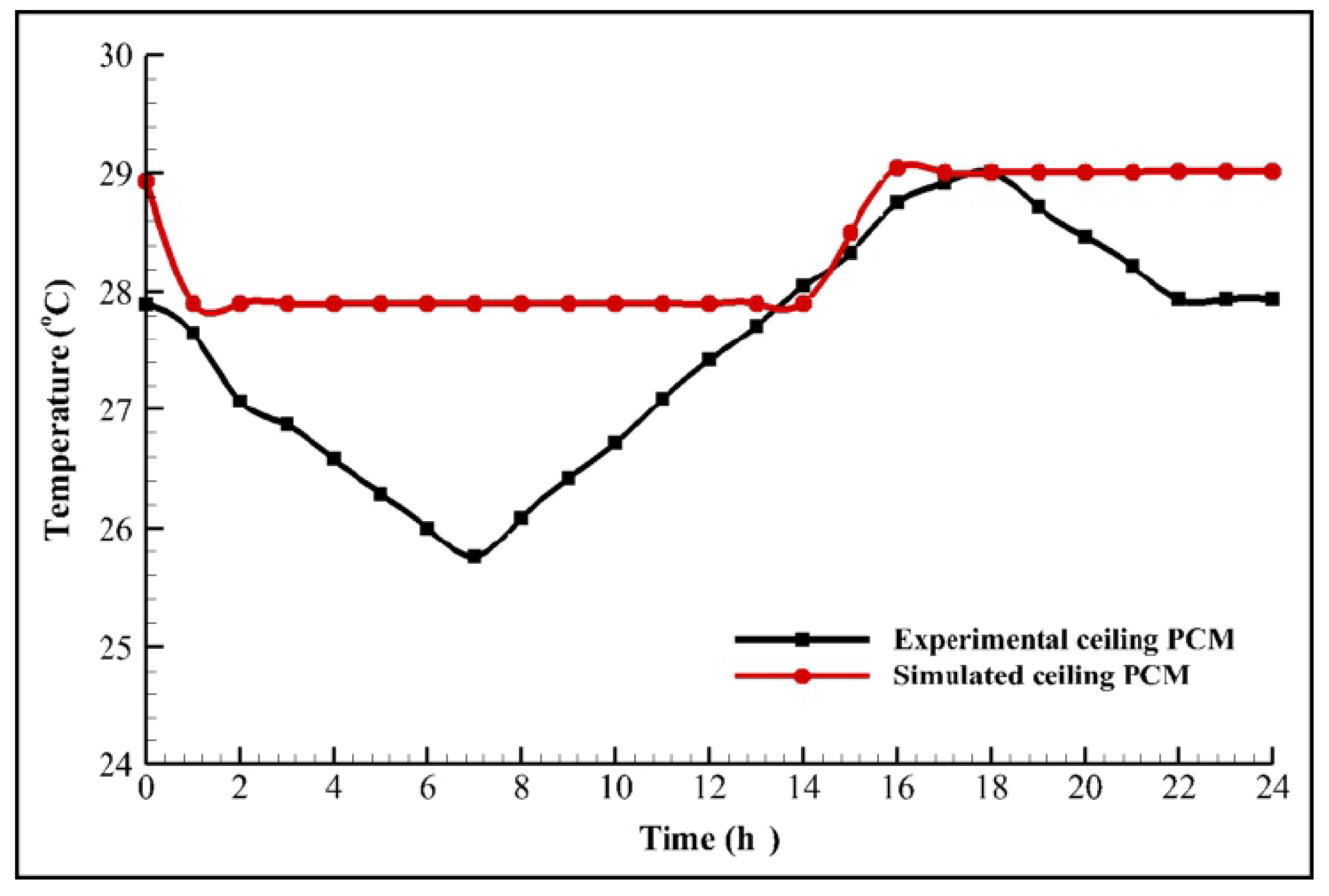

Figure 20 and

Figure 21 compare the simulation and experimental results of the roof temperature for the rooms with and without PCM, respectively.

Figure 20.

Experimental and simulated temperature of the PCM integrated roof.

Figure 20.

Experimental and simulated temperature of the PCM integrated roof.

Figure 21.

Experimental and simulated temperature of the REF roof.

Figure 21.

Experimental and simulated temperature of the REF roof.

It is evident that the ceiling (concrete) temperature of the room containing PCM maintained the temperature constant (27 °C) throughout the day as compared to that of the conventional room. This demonstrates that the environment insignificantly affects the inner surface of the ceiling, because all of the heat energy is absorbed by the PCM installed in the roof. Conversely, a considerable temperature fluctuation is observed in the ceiling of the REF (without PCM), because the outside environment immediately influenced its ceiling. Furthermore, the experimental results for PCM2 revealed a small reduction in ceiling temperature during the day time and slight augmentation during the night time. This diminished temperature fluctuation of PCM2 arose from the large heat storage capacity of the PCM. The occurrence of the observed temperature differences between the simulation and experimental results is ascribed to the following reasons:

- (1)

The room ceiling is influenced by interior condition, where an actual temperature variation occurred.

- (2)

The effective thermal conductivity of the PCM in the experiment is higher due to the presence of uniformly-distributed high conductivity heat exchanger material in the PCM panel.

- (3)

The actual phase change may not occur during the phase change temperature as prescribed in the theory.

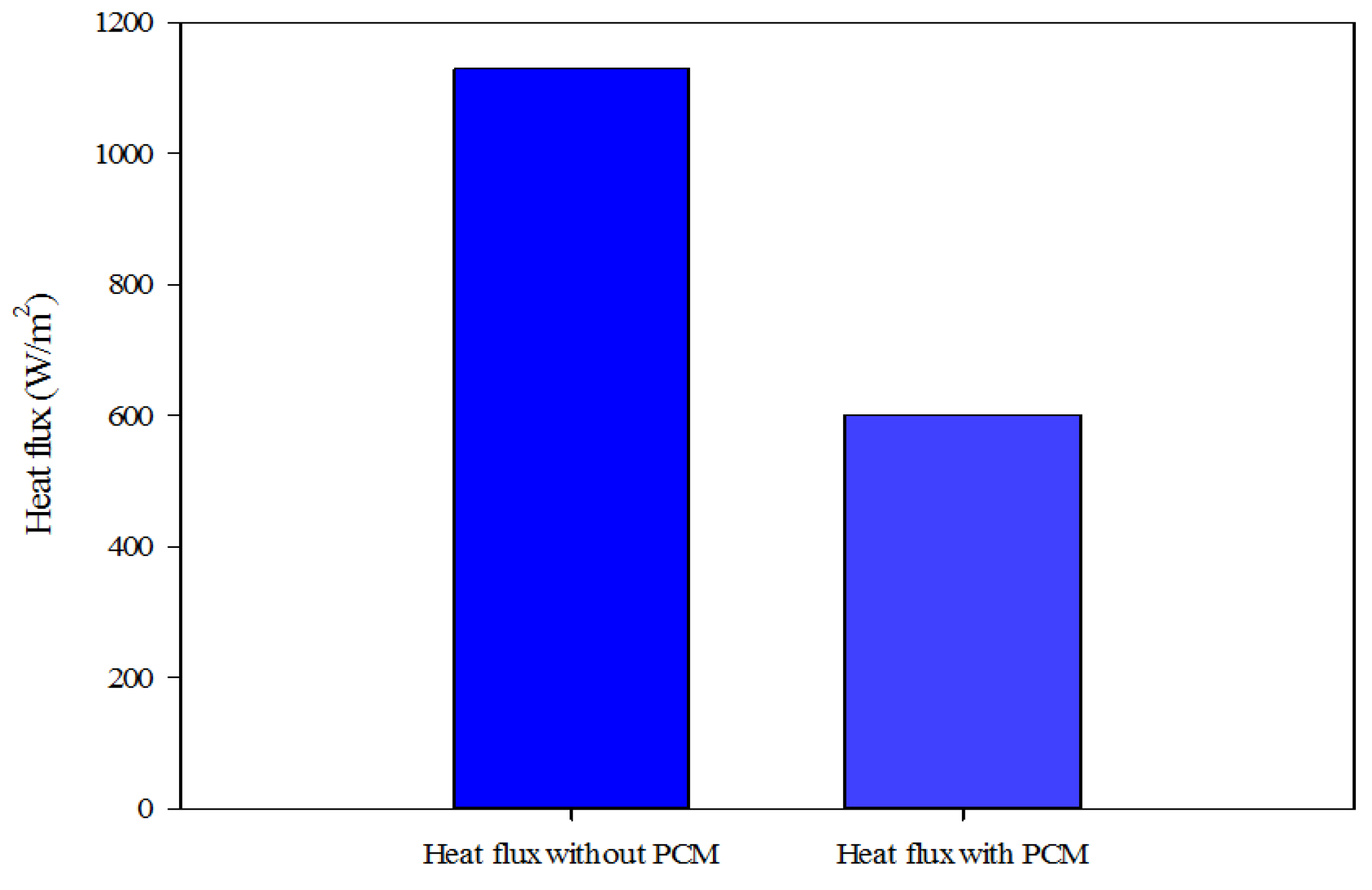

Figure 22 shows the simulated heat flux entering the room. It is clear that the PCM incorporated roof is better than the one without PCM. The implementation of PCM in the building structure remarkably reduced (more than two-thirds) the heat entry compared to the room without PCM integration. Moreover, the presence of PCM reduced the heat transfer by 46.71% which is directly proportional to reduction in the electricity consumption to maintain the room at 25 °C. Hence, the incorporation of PCM in the building architecture of Iraq is recommended because of thermal comfort, cost-effectiveness and environmental friendliness.

Figure 22.

The simulated heat flux entering the room.

Figure 22.

The simulated heat flux entering the room.