1. Introduction

Modular multilevel converters have been widely applied to many HVDC projects worldwide due to their advantages of bidirectional power transmission, commutation failure-less problems, good power quality, and high reliability [

1]. The reliability of HVDC power transmission has become more and more significant, and it is vital for the safety and steady operation of HVDC systems [

2,

3]. Nowadays, most research on MMC-HVDC is focused on topologies, modulation and control strategies, circulating current suppression, and capacitor voltage balance [

4]. However, EMI problems are rarely considered [

5]. Submodules are the core components of MMC-HVDC, and the reliability is important to the safe operation of converter valves. According to the failure statistics of converter valves in typical VSC-HVDC projects in China, the failure rate caused by IGBTs accounts for 2% of all the failure cases. Meanwhile, the failure rate caused by the secondary equipment, like the drive unit, control unit, and communication unit, is over 80% [

2,

4]. With the development of wideband gap devices towards higher power density, the di/dt and dv/dt will be even more harsh, and the influence of EMI on the secondary equipment will be much more severe [

6]. With the utilization of 4.5 kV/5 kA and 6.5kV/3kA IGBTs in the UHVDC projects, the di/dt and dv/dt may be even more harsh.

As it is known, EMI includes three key elements: EMI sources, propagation paths, and sensitive devices. Usually, di/dt and dv/dt of the power electronics switches in the submodule, such as IGBTs, are considered to be the primary sources of EMI. The values of dv/dt and di/dt during the switching period of the IGBT in MMC are much higher, and the maximum dv/dt of the IGBT can be 1.8 kV/μs [

7]. The over-voltage and ringing induced by the di/dt noise could cause high-voltage stress, extra loss, and severe radio frequency emission problems. Spurious gate voltage, crosstalk issues, and high common mode (CM) voltage generated by the high dv/dt noise may lead to the false trigger of gate drive ICs [

7,

8]. Regarding the MMC EMI source suppression techniques, research on modulation strategies is conducted. By optimizing the pulse width modulation (PWM) strategy, low-frequency EMI noise (from 150 kHz to several megahertz) can be reduced without adding any passive equipment. By adjusting the frequency, amplitude, and phase of the carrier, spread-spectrum technology, an emerging method, can be used to optimize the PWM strategy. There are three types of spread-spectrum technology: random PWM, periodic PWM, and programmed PWM [

9]. In [

10], a space spread-spectrum strategy is put forward to relieve EMI harmonic surges by making the carrier frequency of each submodule different while keeping carrier frequencies fixed instead of changing with time. Sun verified that nearest-level modulation performs better than phase-shifting carrier pulse width modulation in EMI suppression [

11]. In the aspect of conducted EMI reduction measures, several modulation-based methods to reduce the common-mode (CM) voltage of the output middle point are proposed in [

4,

5,

10,

12,

13,

14].

According to the propagation paths, EMI could be divided into conducted EMI and radiated EMI. As for the mechanisms of conducted EMI of MMC, research has been undertaken. The common-mode voltage of MMC with the nearest-level modulation scheme is analyzed in [

14]. The scheme proposed can mitigate the common-mode voltage and common-mode current caused by the modulation without causing obvious power-quality degradation and the utilization of the DC bus. In [

15], a piecewise approximation method is adopted to simulate the switching voltage and current of the real device, which can promote the accuracy of high-frequency EMI modeling. In [

16], the GPU’s massive parallelism technique was employed to simulate the conducted EMI characteristics of the MMC-HVDC system. By separating all the two-port networks and MMC SMs, a fine-grained network is obtained. In the aspect of EMI modeling, Chen built a CM EMI model for the submodule auxiliary power supply [

14]. EMI filters, active gate drivers, and snubber circuits are techniques utilized to reduce high-frequency EMI from the source (up to 30 MHz) [

10].

Studies on radiated EMI of MMC-HVDC are also performed. Measurements of the radiated electric field characteristics for a multi-terminal MMC-HVDC converter system are studied in [

17]. The converter valve tower is modeled as a complex antenna structure, and the calculation of near-field radiation intensity for the converter valve tower is performed in commercial software [

18]. In [

19], a novel method, which combines the method of moments with antenna theory to analyze the radiated EM disturbance of the VSC-HVDC converter system, is presented. With the utilization of a large number of IGBTs in MMC, for instance, the maximum number of submodules per arm has exceeded 400 [

5], which brings many potential EMI sources into the power system and forms an extremely complex EM environment [

20]. This complex EMI source may disturb normal operations of components of the secondary system, which are vulnerable to EM disturbance, such as sensors, control units, and driver units [

4,

5]. Research on the radiated EMI of the converter valve only is commonly made. It is intuitively believed and verified that the gate driver PCB is strongly influenced by the dv/dt and di/dt generated by the closest IGBTs, and the magnetic field disturbance contributed by its nearest submodel can be up to about 90% [

21]. Generally, the gate-driver PCB is recognized to experience the most critical EMI environment under the double pulse test (DPT). However, studies on the EMI environment of submodules under DPT have not examined IGBTs up to 4.5 kV/5 kA, which may lead to operation failure during the switching period and deteriorate the safety operation of the MMC-HVDC converter valve.

Apparently, EMI problems have been studied by researchers. However, most of them are not press-pack structures used in MMC-HVDC projects. The maximum rated value of the DC collector current is up to 5 kA, which is the highest in the available commercial IGBT products. For such a new device, its operating condition, such as the current handled, is different compared to other IGBTs. The di/dt and the EMI caused by it for such an IGBT are necessary to be studied since they are quite important and expensive for MMC-HVDC submodules and valve stations. Since the near-field generated by the IGBT is often considered to have a strong influence on the electromagnetic-sensitive component, a near-field simulation model is proposed to accurately calculate the near-field caused by the di/dt during the switching period by combining the dynamic switching behavior of IGBTs with the quasi-static Maxwell model. The organization of this paper is shown as follows. Firstly, the dynamic behavior of 4.5 kV/5 kA IGBTs and freewheeling diodes is introduced during the switching period. Then, this dynamic behavior model is simulated by using commercial software, and it is validated by using DPT. Finally, a near-field model is built by combining the dynamic behavior model and the quasi-static Maxwell equations to approximate the full-wave Maxwell equations, and its effectiveness is verified by measuring the magnetic field strength generated by the DPT.

2. Behavior Model of 4.5 kV/5 kA IGBTs and Freewheeling Diodes

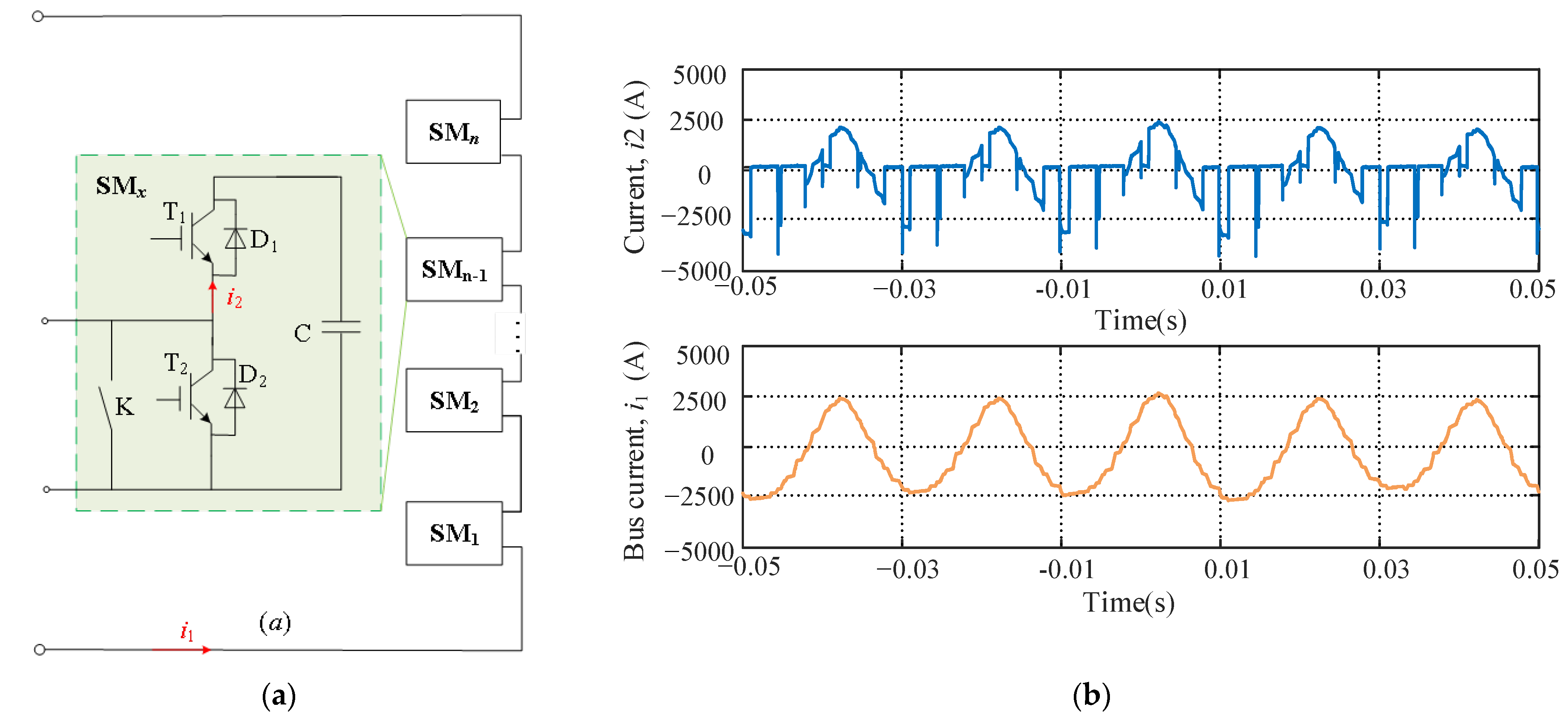

A schematic diagram of the main circuit of a three-phase MMC is shown in

Figure 1a. A typical MMC-HVDC usually consists of three phases, each including a lower and an upper arm. A series of submodules is interconnected to form an MMC-HVDC valve, and a multilevel voltage waveform is generated at its terminals. The submodules can be interconnected according to the application’s requirement, such as the DC to three-phase topology as shown in

Figure 1a, which is widely used in HVDC power transmission. For a real MMC-HVDC project, it may have more than 200 submodules per arm to generate a high-quality sinusoidal voltage waveform by selectively inserting or bypassing SMs via switching actions. The stepped output voltage, formed by aggregating SM capacitor voltages, approximates a sine wave with minimal harmonic distortion. A typical architecture of an MMC valve tower is shown in

Figure 1b.

A typical submodule, illustrated in

Figure 1c, usually consists of the primary part, such as IGBTs, capacitors, and diodes, and the secondary part, such as the drive unit, power supply unit, and control unit. Submodules are the basic and key components of an MMC valve. A variety of topologies of the submodule, such as the half-bridge, full-bridge, cross-connected submodule, and so on, have been proposed and studied. The half-bridge submodule has been widely adopted nowadays for its cost-effective topology. As one of the key components of MMC submodules, IGBTs play an important role in the DC and AC energy conversion. As it is mentioned, the high d

v/d

t and d

i/d

t during the switching period of IGBTs are the main sources of EMI. Therefore, an accurate IGBT and its recovery diode model are essential for the EMI analysis. The internal structure of a 4.5 kV/5 kA press-pack IGBT is shown in

Figure 1d. It is shown that the details of the internal structure of the press-pack IGBT are very complex.

To accurately model the electrical behavior of the IGBT is quite difficult since all the geometry and material parameters are needed and hard to acquire. The model of semiconductor devices, such as IGBT, involves the drift and diffusion of carriers, which is usually formulated by the ambipolar diffusion equation (ADE). It is quite cumbersome to solve this equation, and some of the parameters need to be extracted from the device’s transient waveforms; dedicated characteristic test equipment is also needed. Here, an advanced dynamic IGBT model and a dynamic freewheeling diode behavior model are adopted [

16,

22,

23].

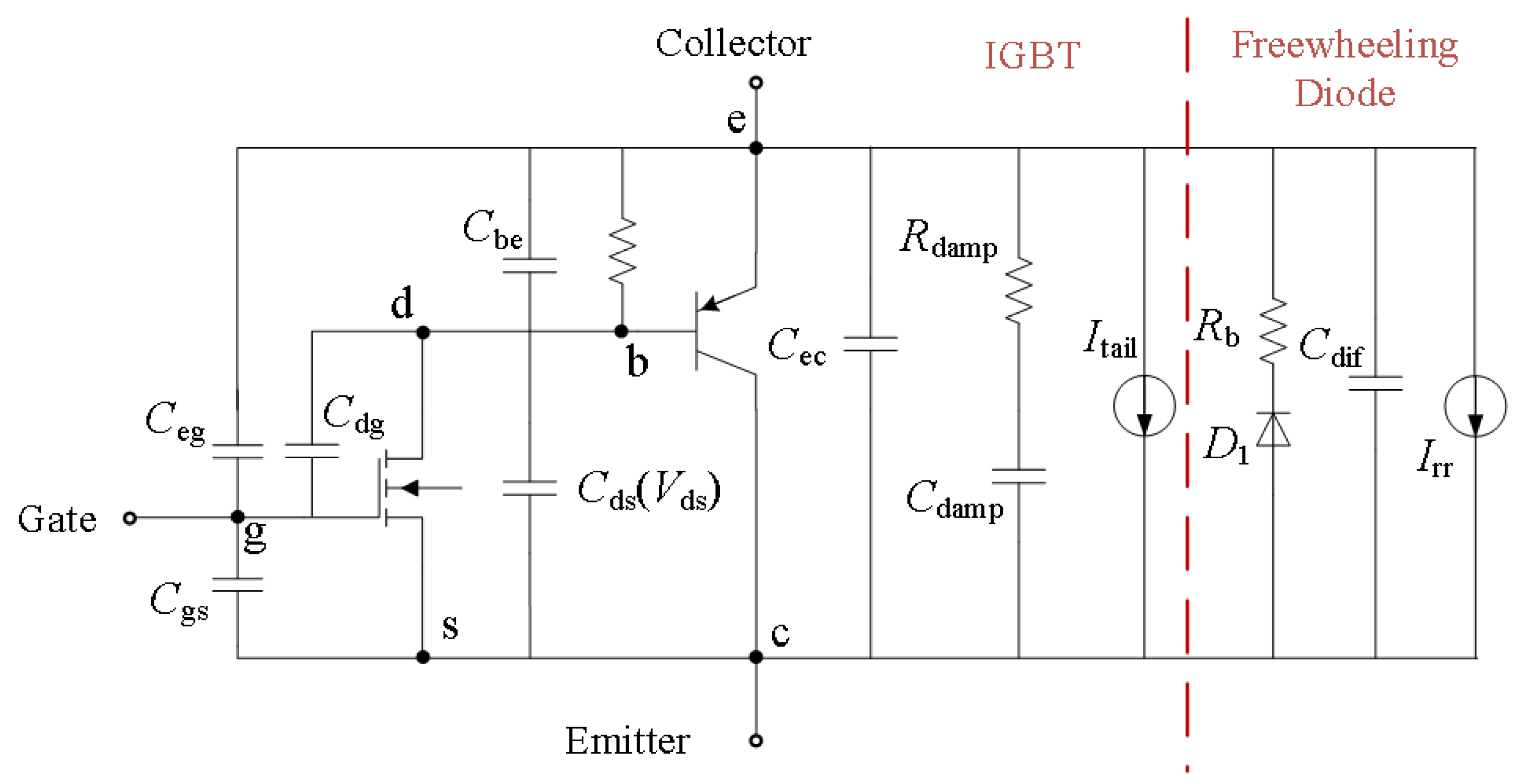

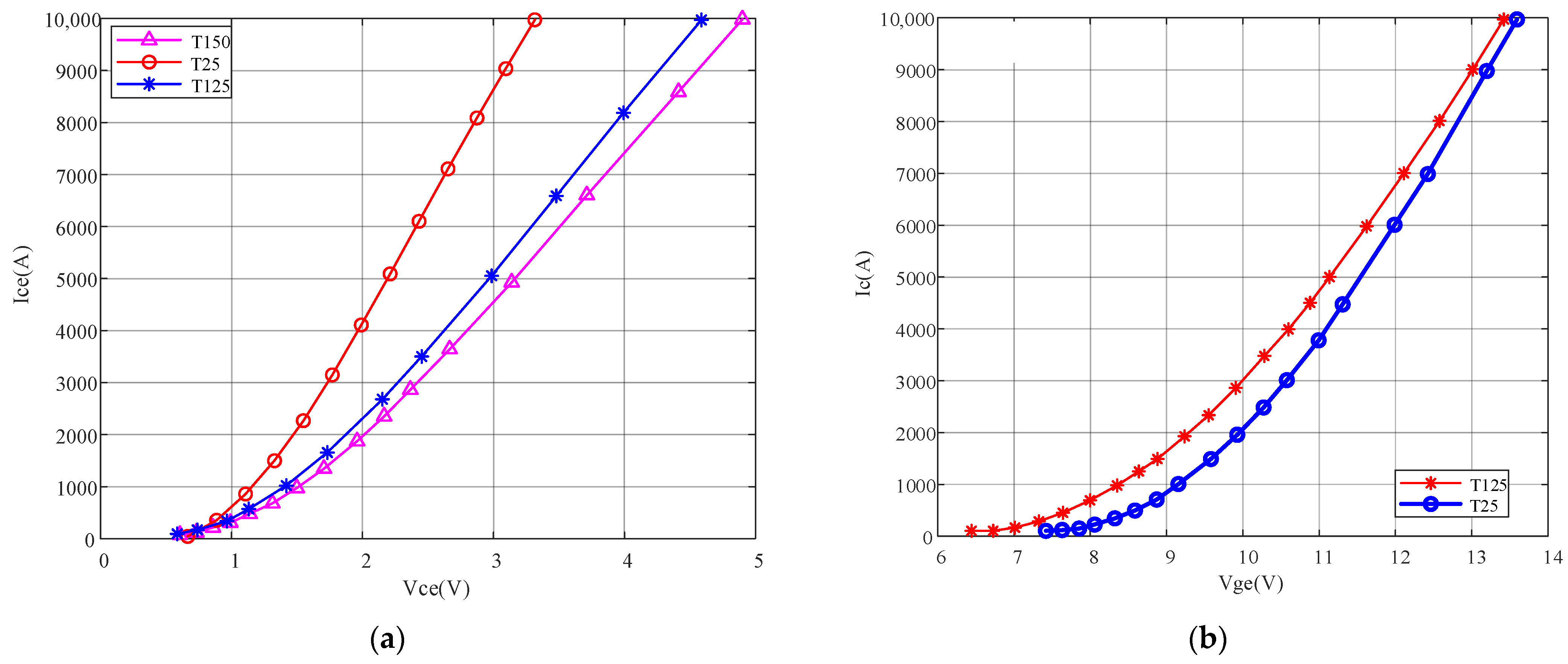

The data needed for building this behavior model of the 4.5 kV/5 kA IGBT and its freewheeling diode during the turn-on/turn-off period can be acquired from the manufacturer’s datasheet, which can be easily obtained. The behavior model utilized here is characterized by the parasitic capacitances and inductances, as shown in

Figure 2. These electrical components of this behavior model can be extracted from information such as the IGBTs’ transfer characteristics and output characteristics [

16,

22,

23].

2.1. IGBT Model

The static characteristics of IGBT can be modeled by using a bipolar junction transistor (BJT) and a metal oxide semiconductor field effect transistor (MOSFET) in a Darlington connection. The dynamic characteristic during the switching process can be represented by the junction capacitance and diffusion capacitance. The output characteristics for the linear and saturation regions of the MOSFET can be modeled by the Shichman–Hodges model, which can be formulated by Equations (1)–(4).

The drain current within the linear region (

VDS <

VGS),

The drain current for the saturation region (

VDS ≥

VGS),

Here, KLM is the model parameter to be identified. Usually, the drain current ID is equal to the source current Is.

The forward conduction characteristics of the BJT considered here can be formulated by,

In general,

Isat_BJT is equal to

ID.

VT is the temperature voltage, which can be solved by

As is known, the transient switching characteristics of IGBTs are primarily influenced by the junction capacitances between terminals. The corresponding capacitance for the p-n junction under the positive-biased enhanced state and negative-biased depleted state is shown as follows.

Enhanced state (

):

depleted state (

):

For Ceg, Cdg, Cec, Cds, Cgs, VJCT is Veg, Vdg, Vec, Vds, and Vgs, respectively.

The diffusion capacitance within the freewheeling diode is modeled using the same approach can be defined as

Here, i(t) is equal to ib and id for Cbe and Cdf, respectively.

The switch-off current edge is affected by parameters

τtail and

δtail because

δtail shapes the falling edge, while

τtail is the duration time. The injected current

Itail, at load current

Iload is expressed as

2.2. Diode Model

The freewheeling diode is modeled as an ideal diode in series with a current-dependent resistor. The static current of the freewheeling diode and resistor can be given by the following equations,

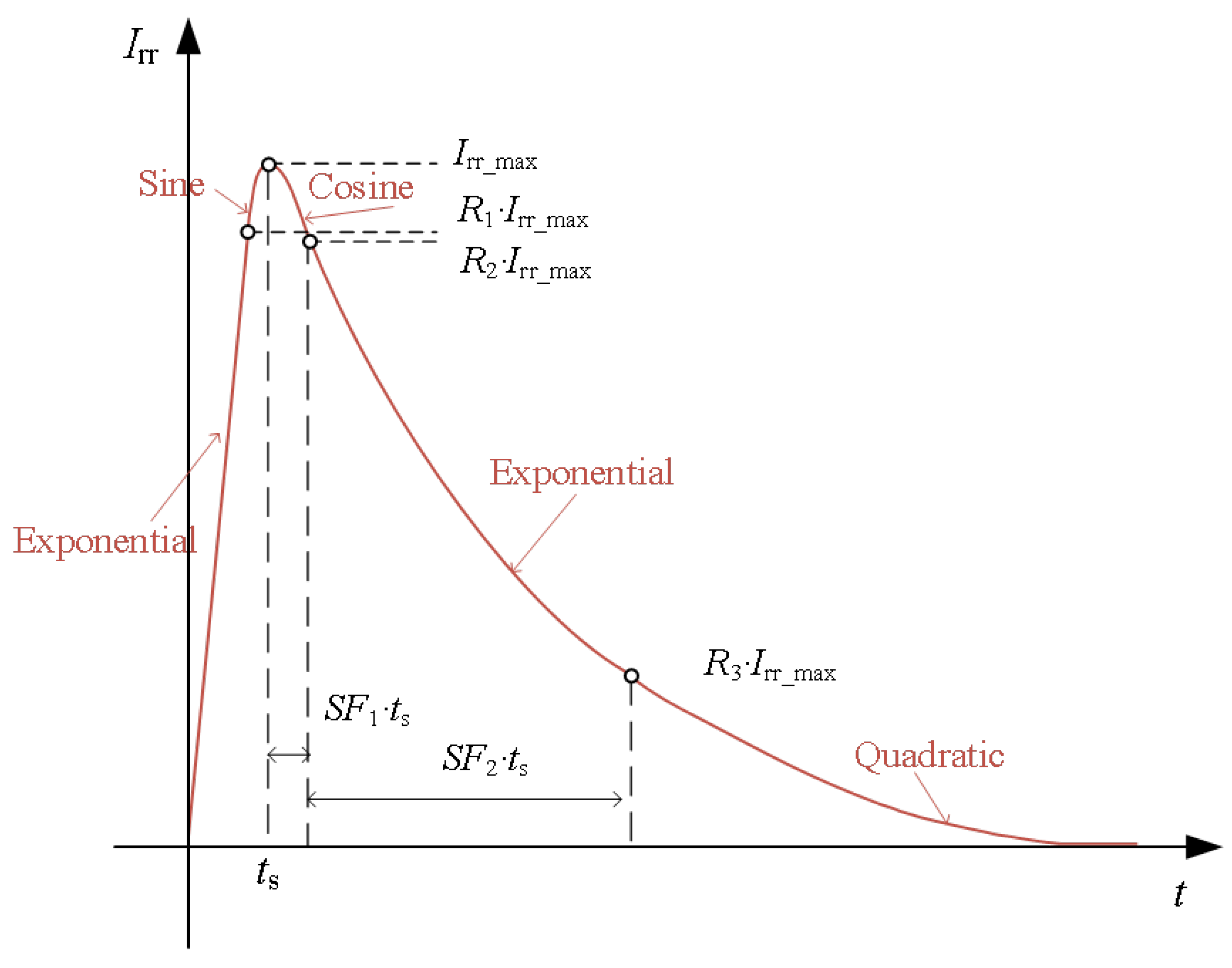

The waveform of the diode reverse recovery current can be defined as a form of piece-wise function with five sections, as depicted in

Figure 3. These sections are connected in a way to maintain differentiability at the boundary from one region to the other. The maximum current

Irr_max, is formulated by

Time ts can be calculated from the reverse recovery charge

Qrr and the form factors when

Irr max is reached. The IGBTs’ transfer characteristics and output characteristics used for this behavior model determination are given in

Figure 4a and

Figure 4b, respectively.

As for the dynamic properties of the IGBT, they can be determined by the turn-on/turn-off energy and turn-on/turn-off time. These values are set to be the reference values for optimization during the electrical components’ extraction process of this behavior model. The optimal results are listed in

Table 1, and the overall error is less than 10%.

3. Double Pulse Test Simulation and Validation

As mentioned above, it consists of several hundred submodules for a real MMC valve tower. An approximated sine wave can be obtained. By measuring the current at different positions of an MMC assembly shown in

Figure 5a, we can observe its characteristics. From

Figure 5b, it can be observed that current

i1 through the phase leg is close to a sine wave. However, the waveform of the current through the IGBT is quite different from

i1. It has many square-like waves. Apparently, the di/dt of these waves is much larger than that of a sin wave. Hence, a DPT is adopted here to model these square-like waves.

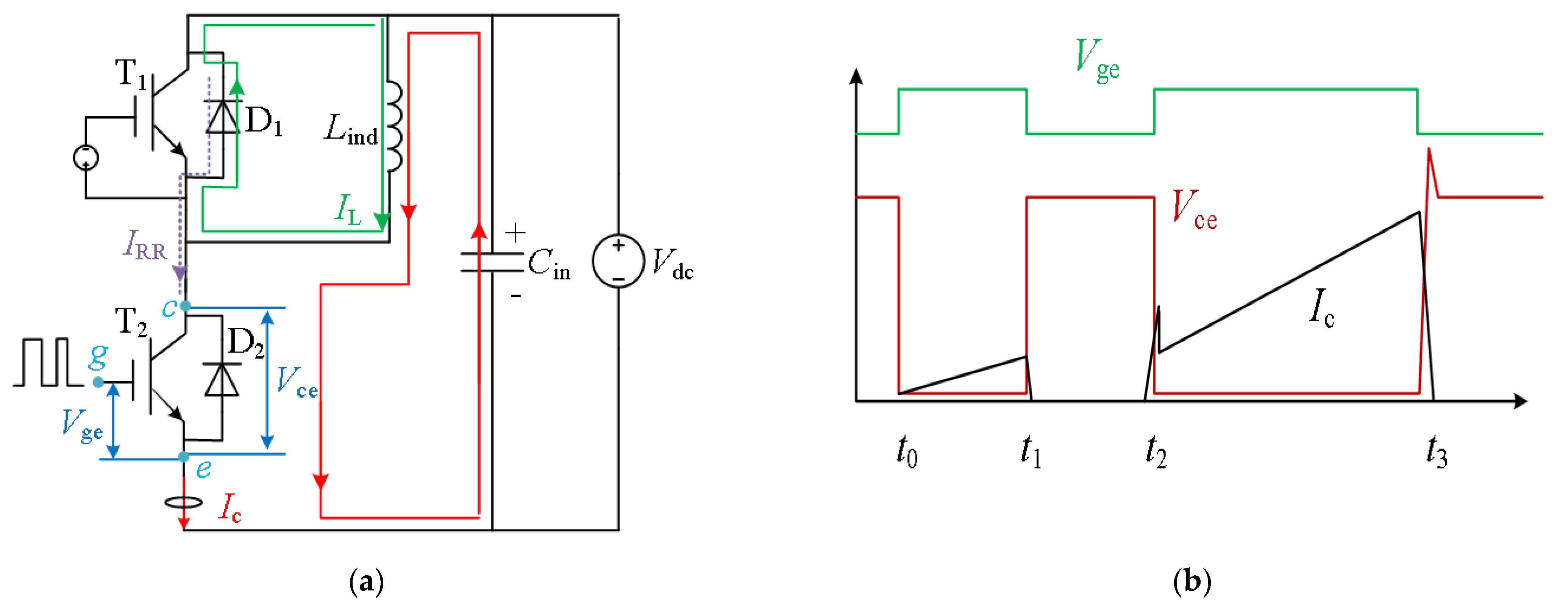

Firstly, to validate the adopted behavior model of the IGBT, a DPT is conducted. The schematic diagram of a DPT for half-bridge topology is shown in

Figure 6a. A DPT enables IGBTs to be switched on and off at different current levels. By adjusting the switching times (

t0~

t1,

t1~

t2,

t2~

t3) in

Figure 6b, the turn-on and turn-off waveforms, such as

Vge,

Vce, and

Ic, of the IGBTs can be controlled and measured over the full range of operating conditions. It is a standard method for measuring switching parameters, such as turn-on energy, turn-off energy, turn-on time, turn-off time, leakage inductance, reverse recovery current, and so on. To be noticed, IGBT T

1 is always set to be in the OFF state during the whole process for the half-bridge submodule. Before

t0, the capacitor

Cin is charged. At

t0, a positive value of

Vge (+15 V) is applied, and current

Ic goes through

Cin-

Lind-

T2-C

in, which is shown in

Figure 6a with a red solid line. During

t0~

t1, current

Ic increases with time, and

Ic =

IL,

IRR = 0, and

Vce = 0. At

t1, a negative value of

Vge (−15 V) is applied. Then, during

t1~t

2, current

IL goes through

Lind-

D1-

Lind, which is illustrated as the green line in

Figure 6a, and

Ic = 0.

The turn-off current is about 10 kA at t3 for the DPT. The pre-charged voltage for the capacitor,

Cin, is about 3200 V at t0. The inductance,

Lind, is 56 μH, and the capacitance, C

in, is 27 mF. The resistance for the driver during the turn-on state is 1.3Ω, while the resistance for the turn-off is 7.8Ω. The stray inductance,

Lloop, for the current loop is about 185 nH.

T1 and

T2 are 4.5 kV/5 kA IGBTs with the built-in behavior model. A zero voltage is applied to the gate driver for

T1 to ensure that the IGBT

T1 is turned off. A double pulse signal is applied to the gate driver of

T2. The turn-on voltage is 15 V, and the turn-off voltage is −10 V. Current

Ic is measured by using a Rogowski coil, and voltages

Vce and

Vge are also measured. By using the behavior model acquired for the 4.5 kV/5 kA IGBT, a DPT simulation model is built by using ANSYS Electronic Desktop 2023R2 Simplorer, as shown in

Figure 7. A basic block diagram of the IGBT used for the DPT experimental setup is shown in

Figure 8.

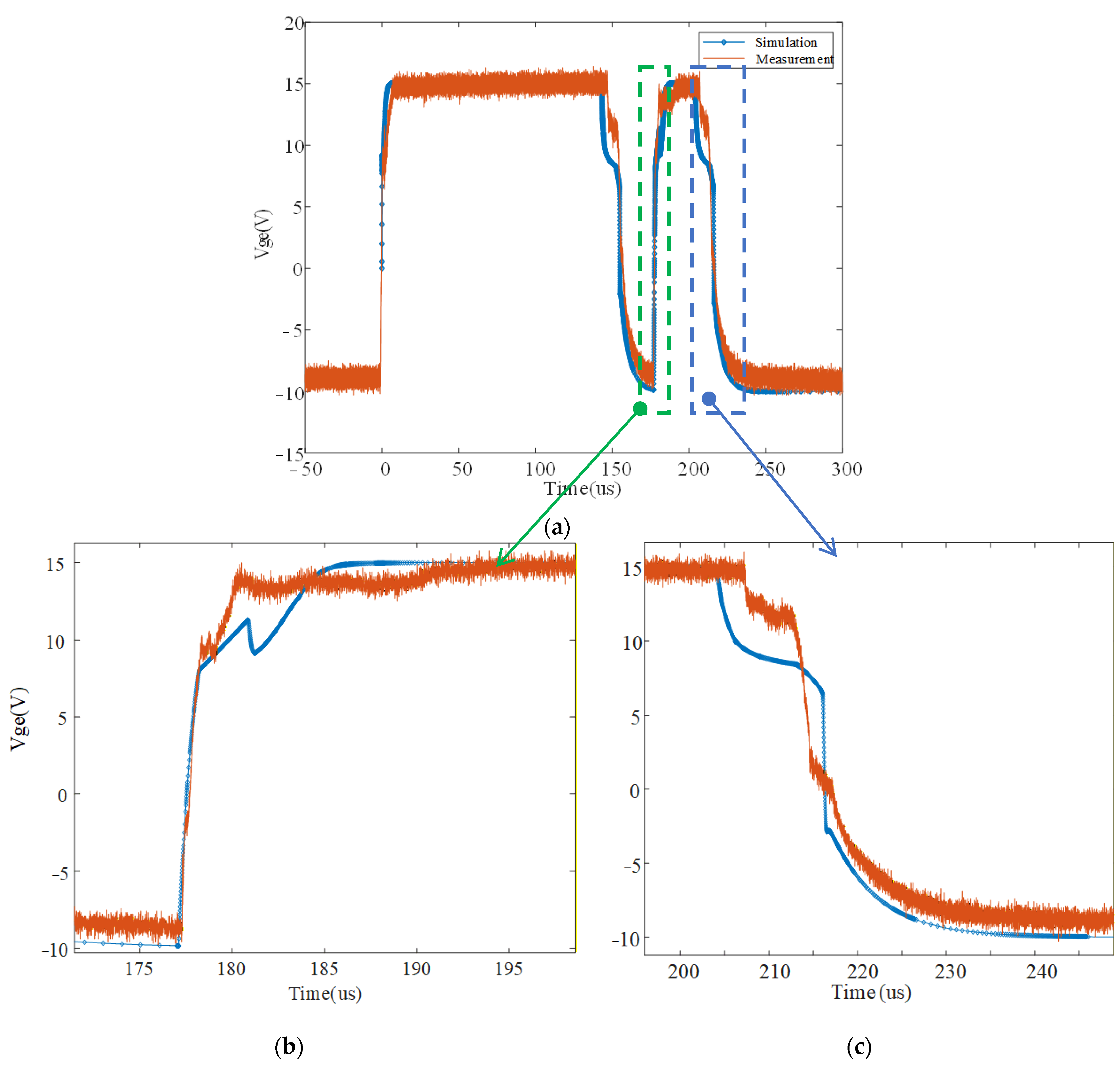

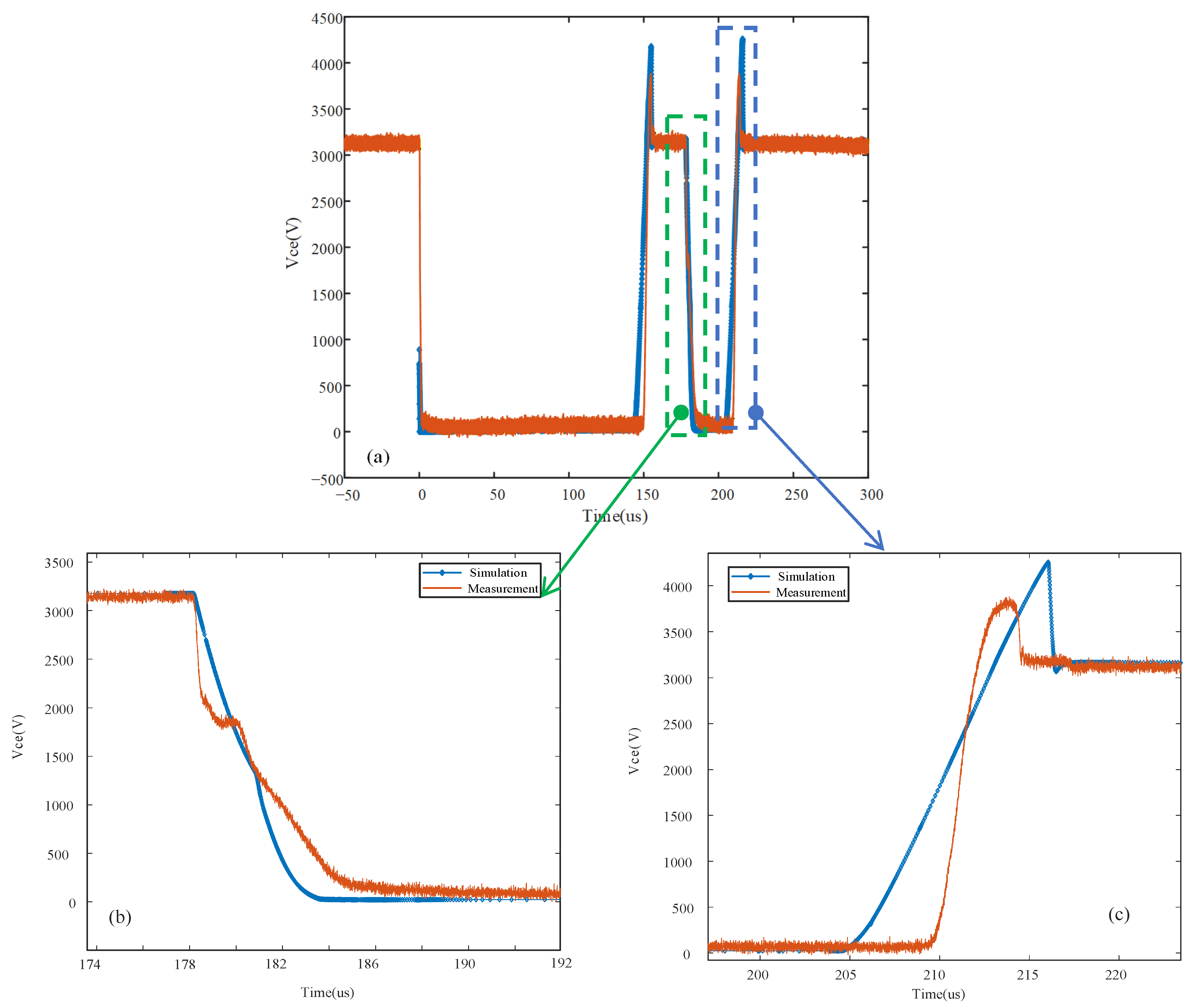

As shown in

Figure 9a,

Figure 10a, and

Figure 11a, simulation results are quite close to the measured data overall. The sensors used for measurement are briefly introduced. A Rogowski coil is used for current measurement, and the bandwidth is up to 13 MHz. The range is up to 30 kA. The bandwidth for the oscilloscope used is from 200 MHz to 1 GHz. The bandwidth of the differential voltage probe used is 200 MHz, and the range is up to 30 kV. By zooming in on results during the turn-on and turn-off period of

Vge, waveforms of the simulation and measured data, as shown in

Figure 9b,c, are quite close but with minor differences. The simulated

Vge starts falling about 2 μs earlier than the measured data. For the current Ic shown in

Figure 10c, the simulated

Ic starts falling about 2 μs earlier than the measured data during the turn-off period. The overshoot current of the simulated

Ic is about 2000 A, larger than the measured data during the turn-on period shown in

Figure 10b. For the current Ic, its rising time (from 10% to 90%

Ic) is about 1.08 μs, and the d

i/d

t is about 5.88 kA/μs (from 40% to 60%

Ic). As depicted in

Figure 11c, the simulated

Vce during the turn-off period is about 1000 V larger than the measured data. This is caused by the clamped overshoot voltage

Vce while no voltage clamping measures are taken for the simulation. For voltage,

Vce, shown in

Figure 11b, the two curves agree well overall, and the falling time of the simulated

Vce is faster. For

Vce illustrated in

Figure 11c, the rising speed of the measured data is faster, and the time of the simulated

Vce starting to rise is about 5 μs later than the measured data. The rising speed of

Vce in

Figure 11c is faster than its falling speed in

Figure 11b, and the d

v/d

t is 1.83 kV/μs (from 40~60%

Vce).

There are several reasons causing these mismatches between the simulation results and the measurement data. The first reason is that the behavior model is constructed based on the data obtained from the datasheet. These data cannot fully reflect the dynamic characteristics of the IGBT and diode devices. Especially, the accumulated charge in the base region of the diode cannot be modeled. This may cause the inaccuracy for the current overshoot as shown in

Figure 10b. As for the current ring, it is caused by the parasitic parameters introduced by the IGBT packages, the main circuit, and the gate driver circuit, as well as cables used in the experiment. For

Vce at

Figure 11c, the rising speed of the measurement curve is faster than the simulated data. It is because the equivalent inductance in the test circuit is larger than that of the simulated circuit. Other factors, such as the carrier dynamics and electrothermal coupling effects of IGBTs and diodes, the temperature effect on this behavior model, as well as manufacturing dispersion, may also have an impact on the measurement.

Figure 9.

Comparison of simulation results and the measured data of current Vge during the turn-on period (b), the turn-off period (c), and the whole double pulse period (a).

Figure 9.

Comparison of simulation results and the measured data of current Vge during the turn-on period (b), the turn-off period (c), and the whole double pulse period (a).

Figure 10.

Comparison of simulation results and the measured data of current Ic during the turn-on period (b), the turn-off period (c), and the whole double pulse period (a).

Figure 10.

Comparison of simulation results and the measured data of current Ic during the turn-on period (b), the turn-off period (c), and the whole double pulse period (a).

Figure 11.

Comparison of simulation results and the measured data of current Vce during the turn-on period (b), the turn-off period (c), and the whole double pulse period (a).

Figure 11.

Comparison of simulation results and the measured data of current Vce during the turn-on period (b), the turn-off period (c), and the whole double pulse period (a).

4. Near-Field Simulation and Validation

From the DPT measured data, values of di/dt and dv/dt are quite large. By the IGBT behavior model, its dynamic characteristics are simulated and verified. The secondary equipment is vulnerable and might be affected by the radiated EM field generated by the di/dt and dv/dt. For the radiated EM field, the near-field is generally considered to have a strong influence on the secondary devices. In this section, the near-field around the IGBT’s gate driver PCB is simulated and validated.

Traditionally, square waveforms or trapezoidal waveforms can be used to approximate the current waveforms of

Ic. However, some significant information is lost, and the inaccuracy of the high-frequency characteristics may be caused by this. Therefore, an S-shape waveform model is adopted to approximate current

Ic, and it is also used to estimate the spectral envelope. A typical periodic S-shape waveform, which contains more information than the typical square waveforms and trapezoidal waveforms, is shown in

Figure 12, and the Fourier coefficients of this waveform can be computed based on the periodic impulse train and differentiation properties of the Fourier series. The 1st, 2nd, and 3rd derivative waveforms of a periodic S-shape waveform are illustrated in

Figure 12. The Fourier coefficients of this periodic S-shape waveform are calculated and expressed by (15) and (16) [

26].

Assuming that

A1 =

A2,

τr =

τf,

τr1=

τf1 =

τr2 =

τf2, then the Fourier coefficients of periodic S-shape waveforms can be expressed as,

Then, the three break points,

fc1,

fc2, and

fc3, in the spectral envelope of a symmetrical periodic S-shape waveform shown in

Figure 13 can be solved by,

Therefore, the breakpoints in the spectral envelope, fc1 = 10.6 kHz, fc2 = 159 kH, and fc3 = 1.27 MHz, are from the current waveform of Ic. When the distance to the EMI source is within λ/2π, it is usually considered to be a near field. Here, λ is the wavelength of the EM field. The wavelength of the 1.27 MHz EM field is about 236 m, and λ/2π is equal to 37.58 m. The distance between the gate driver PCB and the IGBTs is about 0.5 m, which is far smaller than λ/2π. Hence, the displacement current can be neglected in the region where the gate driver PCB and the IGBTs are located. In general, the near field can be approximated by an induction EM field when the distance to the EMI source is less than λ/20 = 1.88 m. Moreover, the magnetic field dominates within the near-field region since the EMI source has a larger current (10 kA) and a smaller voltage (3200 V).

The current generated by the double pulse test is similar to an S-shaped waveform. Hence, a transient magnetic field is induced. The rising and falling time is much smaller compared to the pulse width, which implies that the eddy current field would occur. Therefore, a 3D eddy current field is adopted to approximate this near-field. The governing equations for solving the magnetic field are given below.

Figure 13.

The spectral envelope of a symmetric periodic S-shape waveform.

Figure 13.

The spectral envelope of a symmetric periodic S-shape waveform.

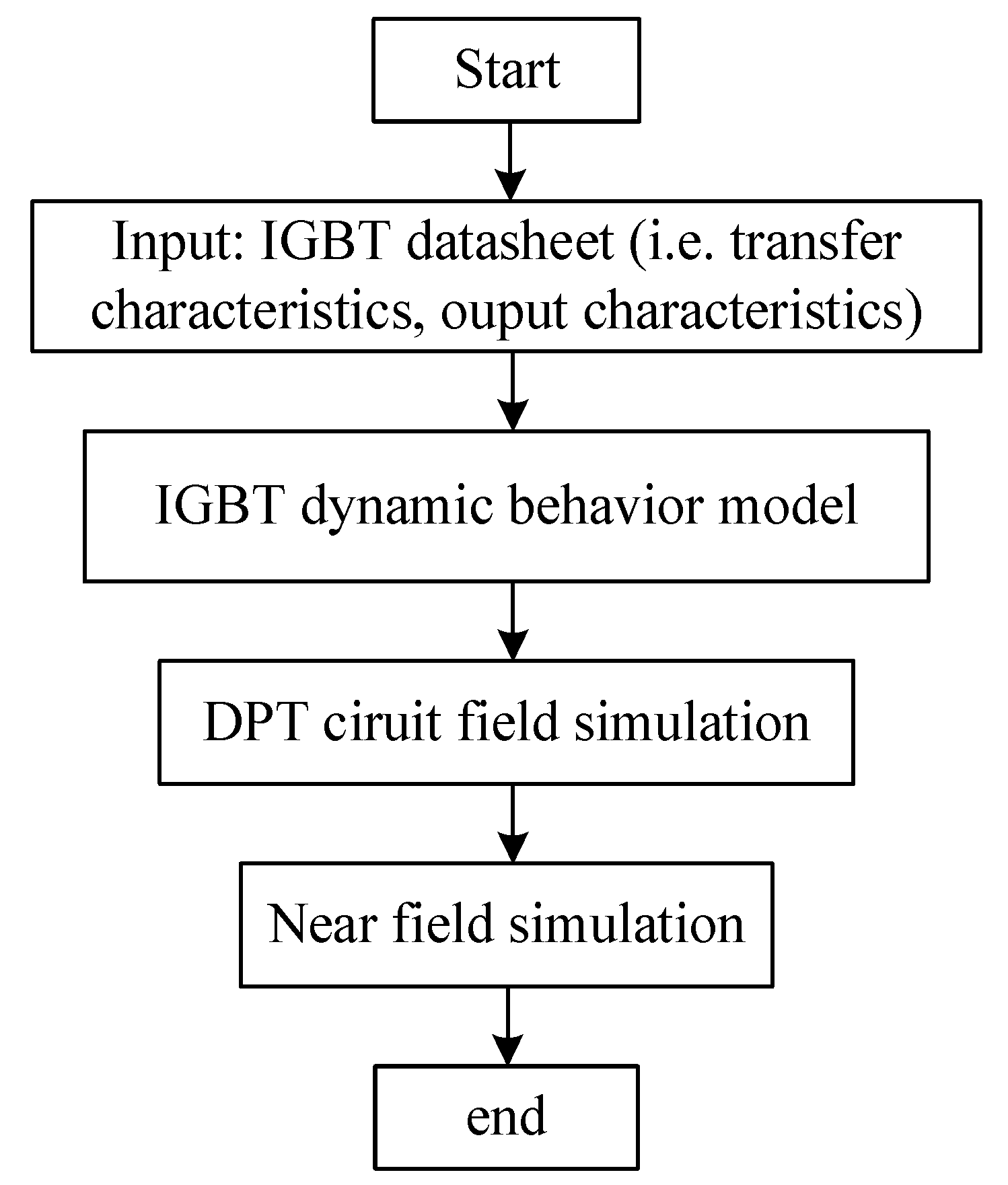

A backward Euler solver is used to solve this time-dependent problem. A variable time-step is adopted; the minimum time-step is 0.4 us, while the maximum time-step is 50 us. An adaptive mesh method is adopted. The domain size surrounded for simulation is about 5 times larger than the MMC submodule. By using this method, the mesh can be automatically refined according to the error obtained during iteration for the simulation. The stop criterion is that the nonlinear residual is 0.005. The mesh and boundary condition parameters are listed in

Table 2. The materials used are given in

Table 3. The brief flowchart diagram is given in

Figure 14. Firstly, we obtain the data, such as the transfer characteristics, from the datasheet of the IGBTs. A dynamic behavior model of the IGBT is built with the help of these data. Based on this dynamic model, a DPT circuit is constructed to obtain the current Ic, which is used as the excitation for near-field simulation. Lastly, the near field is calculated based on the quasi-static Maxwell equations.

By the field-circuit coupling method, the current density,

Js, can be obtained by the following formula listed below.

where

I is the current through the conductor, and Δ is the area of the conductor cross-section.

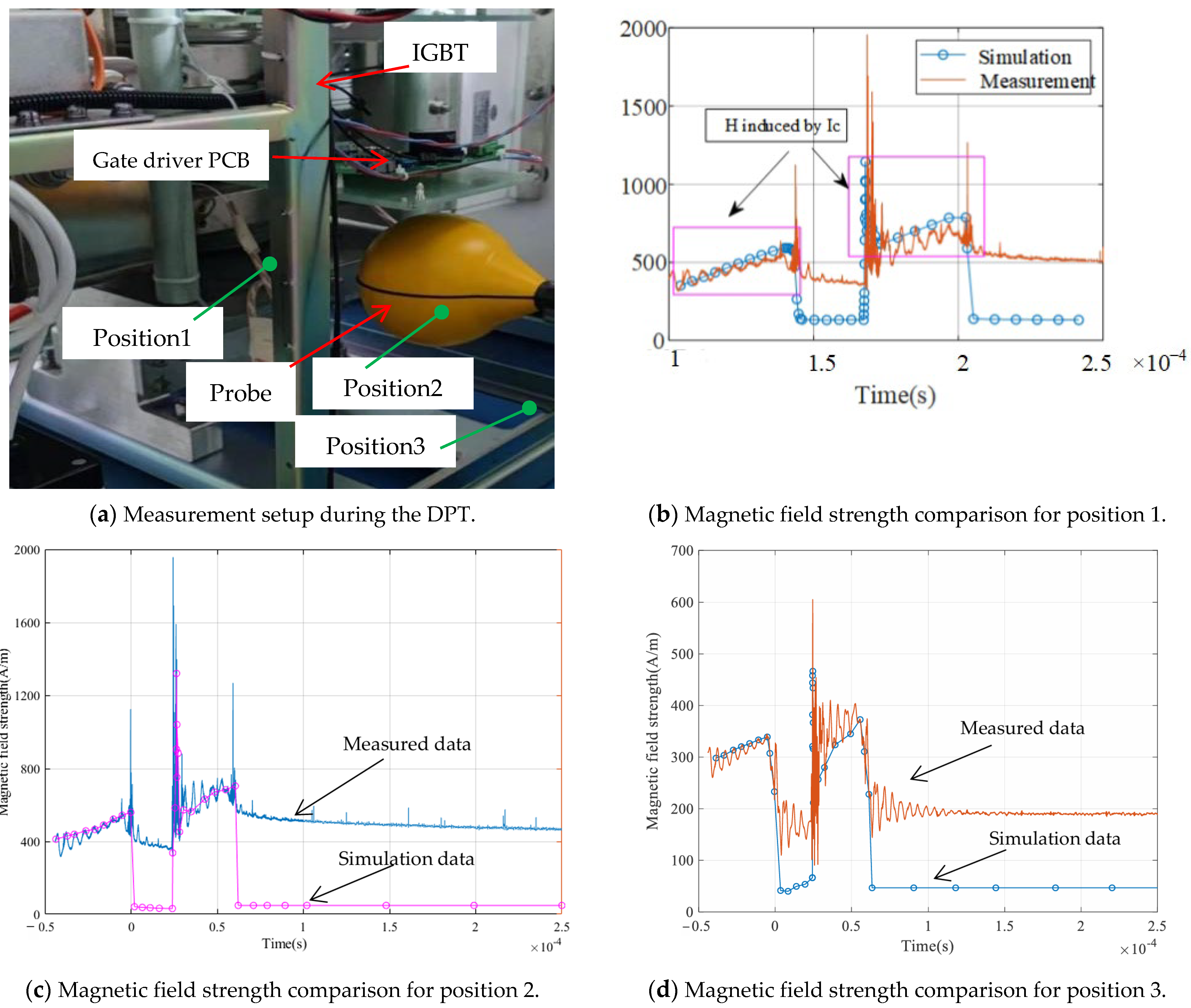

After the determination of

Js, the magnetic field can be simulated. The 3D geometry model of an MMC submodule is given in

Figure 15a, and the schematic diagram of the magnetic field strength measurement setup is given in

Figure 15b. Because of the complexity of the 3D geometry, only the relevant current path conductors are given in

Figure 15a to depict how the current Ic flows in and out. As depicted in

Figure 15a, the current path of

Ic is Cin_p → HT1 → inductor → busbar → HT2 → T2 → HT3 → Cin_n. Here, Cin_p and Cin_n are the positive and negative of capacitors. HT1~HT3 are the heat sinks. IGBT T1 is shorted by an inductor. The inductor is not modeled in this 3D geometry model.

The magnetic field simulated near the PCB of the gate driver is illustrated in

Figure 16. The dominant component of the magnetic field strength for the upper gate driver PCB is parallel with its horizontal direction, while the lower PCB is parallel with its vertical direction, as shown in

Figure 16a. The magnetic field strength of the surface for the magnetic exposure level tester during the measurement process is also shown in

Figure 16b. To validate the effectiveness of the proposed method, a broadband EM field measurement device, namely the magnetic exposure level tester, is utilized to measure the magnetic field of the testing spot near the PCB shown in

Figure 17a. The measured data is transferred to the oscillator by a BNC cable. A comparison between the simulation result and the measured data is illustrated in

Figure 17b. The simulated result agrees with the measurement data roughly during the period when the current

Ic is under excitation, as marked in

Figure 17b–d. A typical waveform of

Ic is illustrated in

Figure 6b. The magnetic field strength,

H, induced by

Ic, which is marked by a rectangular box in

Figure 17b. The magnetic field strength for these two parts agrees with the measured data roughly. There are some discrepancies between them. The reason for this discrepancy is that data noise is brought in during the measurement process, caused by the BNC cable. Though data noise appeared, the simulated data matched the measured data in tendency. As for the result, apart from these rectangular boxes shown in

Figure 17b, the simulated data do not match the measured data. It is because the measured magnetic field strength is generated by the current I

L, which is not considered since we cannot accurately build its current loop. The simulated magnetic field is generated by current

Ic. It is the reason why these parts do not agree with each other during this period. In order to verify the proposed model, the magnetic field at another 2 positions is measured. The simulation result and the measured data are compared as shown in

Figure 17c,d. Similarly to the result given in

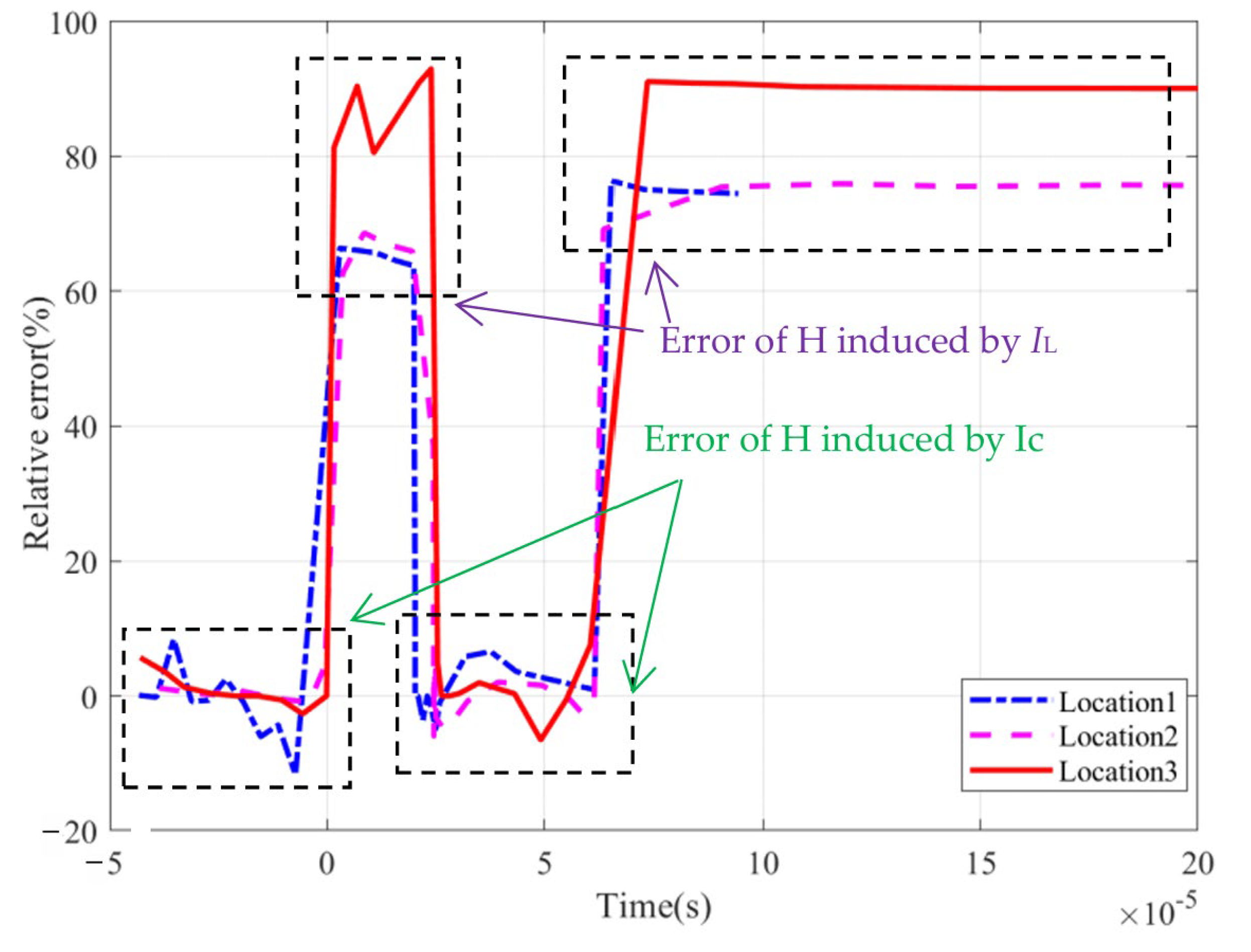

Figure 17b, the magnetic field strength at these 2 positions agrees with the measured data roughly. The reason for the discrepancy is explained above. The relative error is given in

Figure 18. The maximum relative error of the magnetic field induced by the current

Ic, which is the current source for the model simulated, is about 11%. The result with a large discrepancy is caused by the current

IL, which is not modeled in this simulation. The numerical metrics about this simulation in the time window of

Ic workers are also summarized in

Table 4. The mean absolute error is 1.65, while the root mean square error is 16.90. The time shift between measured and simulated signals is about 50 us. It is clear that our model is validated when

Ic dominates.

5. Conclusions

The near field of a 4.5 kV/5 kA IGBT-based press-pack MMC-HVDC submodule with the maximum rated value of the DC collector current up to 5 kA is studied. For such a new device, its operating condition, such as the current handled, is different compared to other types of IGBTs. The di/dt and the EMI caused by it for such an IGBT need to be studied since it is quite important and expensive for MMC-HVDC submodules and valve stations. The gate driver suffering from the IGBT turn-on/off period is susceptible to the EMI since the distance between them is quite close. It is urgent to solve the near-field of gate drivers suffering from the IGBTs near them, and it is practical for the design of the MMC submodule in the case of the arrangement of IGBT gate driver PCBs.

Since the computation cost of the near field solved by the full-wave Maxwell equations is high for a complex 3D geometry model, a simulation method is proposed for the near-field calculation of 4.5 kV/5 kA IGBT-based MMC submodules under dual pulse test. This method integrates the IGBT dynamic switching behavior and the quasi-static Maxwell equations for near-field simulation since the distance between the EMI source and susceptible subject is much smaller than the electromagnetic wavelength. By using this method, we can solve the near-field more cost-effectively with desirable accuracy.

In a word, the novelty and contribution of this paper can be attributed to (1) the near field of a 4.5 kV/5 kA IGBT-based press-pack MMC submodule with the turning-off current up to 10 kA is conducted, which is rarely studied, and (2) an integration method that combines a dynamic behavior model and a quasi-static Maxwell model helps to fasten the calculation speed of the near field with desirable accuracy.

This proposed model can predict the near field caused by the current Ic during the DPT in distances smaller than λ/2π. This means that the transient period cannot be too fast. Because of cables connecting with the inductance, the magnetic field strength will be affected by its current when the IGBT is in the turn-off state. This is the biggest error source between the simulation result and the measured data during these periods. This error source can be fixed by a more comprehensive model, which includes cables connecting the inductance. The proposed model provides a tool to understand the EMI mechanism and its effect on the secondary devices with a desirable accuracy as well as an acceptable cost, and it is helpful for the arrangement of IGBT gate driver PCBs in the design stage.

The next step is to study a more comprehensive model, including the IL loop to eliminate this error, how the secondary devices, such as the driver PCBs, suffer from the magnetic field generated by the IGBT during the turn-on/off period, and methods to suppress the EMI.