Green Synthesis of Core/Shell Phase Change Materials: Applications in Industry and Energy Sectors

Abstract

1. Introduction

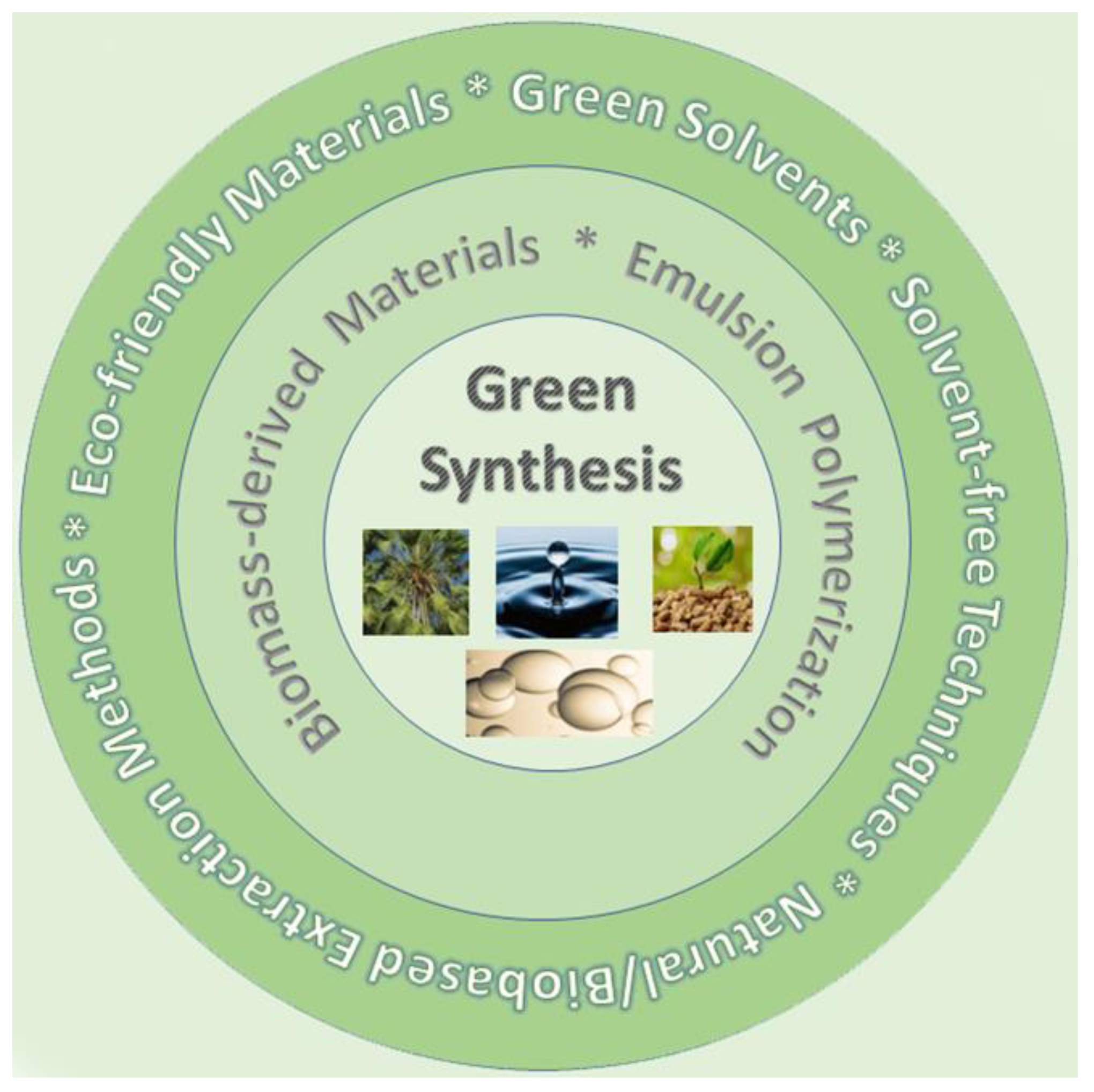

2. Synthesis and Characterization of Core/Shell Composite Phase Change Materials

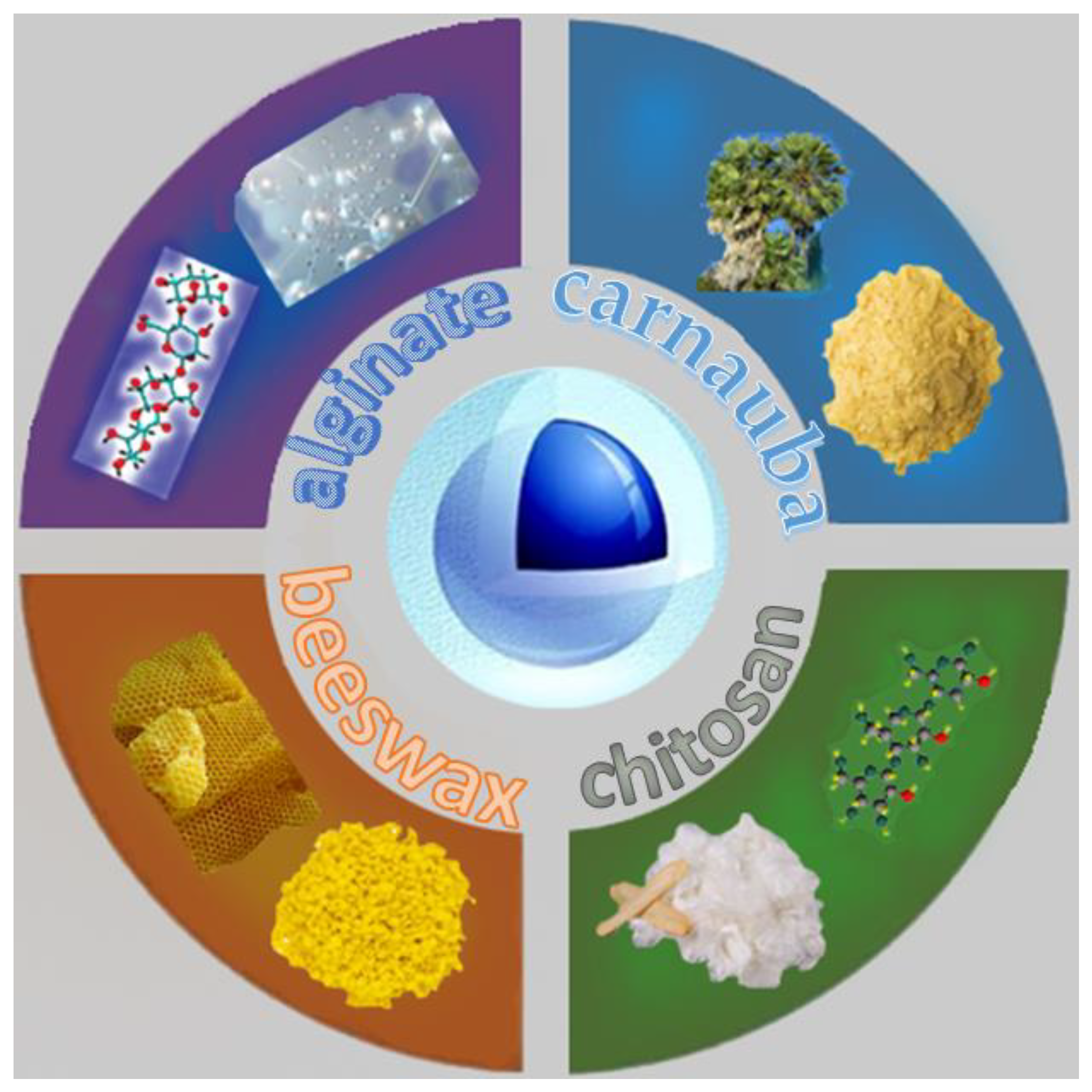

2.1. Eco-Friendly Materials

2.2. Green Solvents

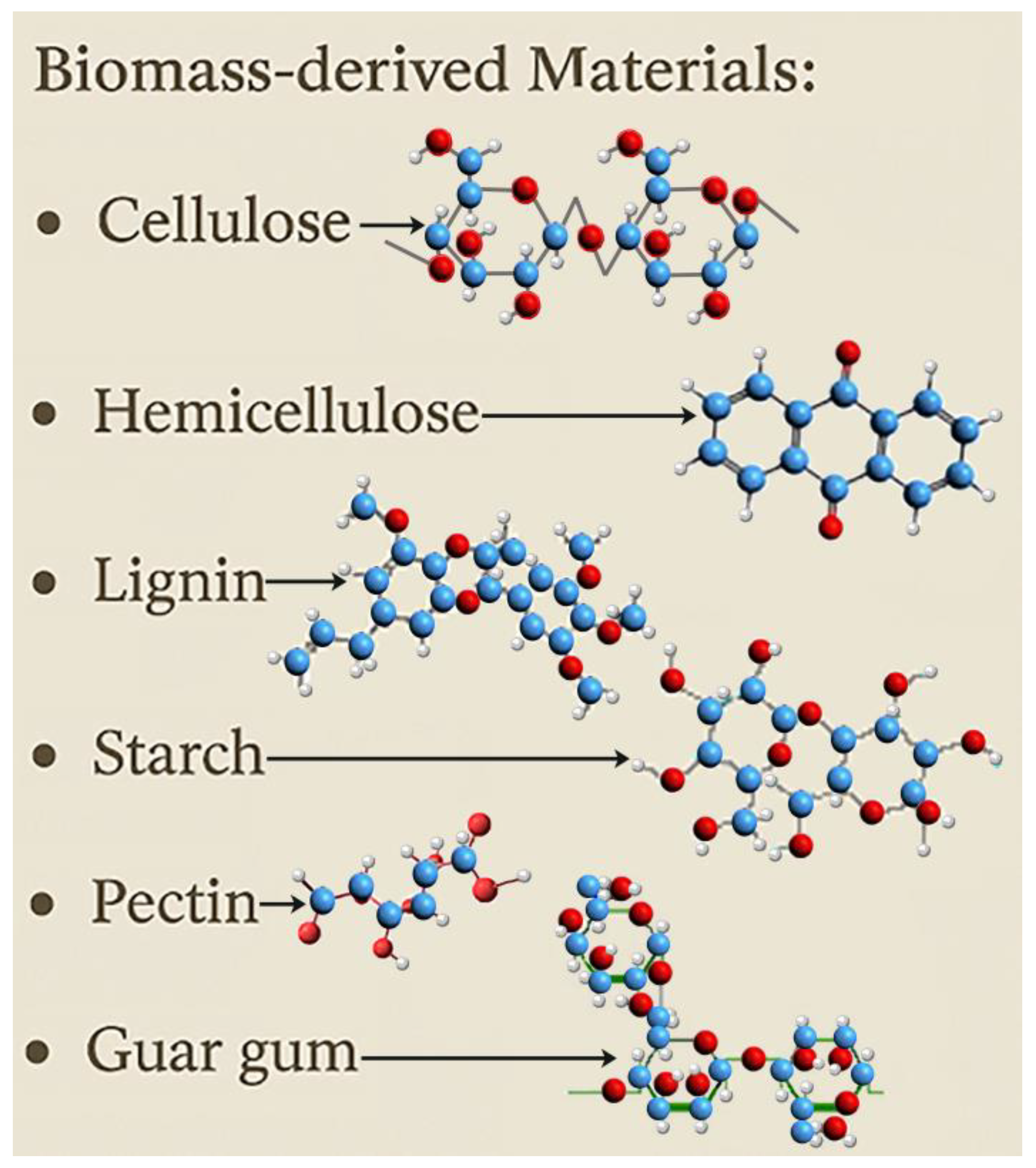

2.3. Biomass-Derived Materials

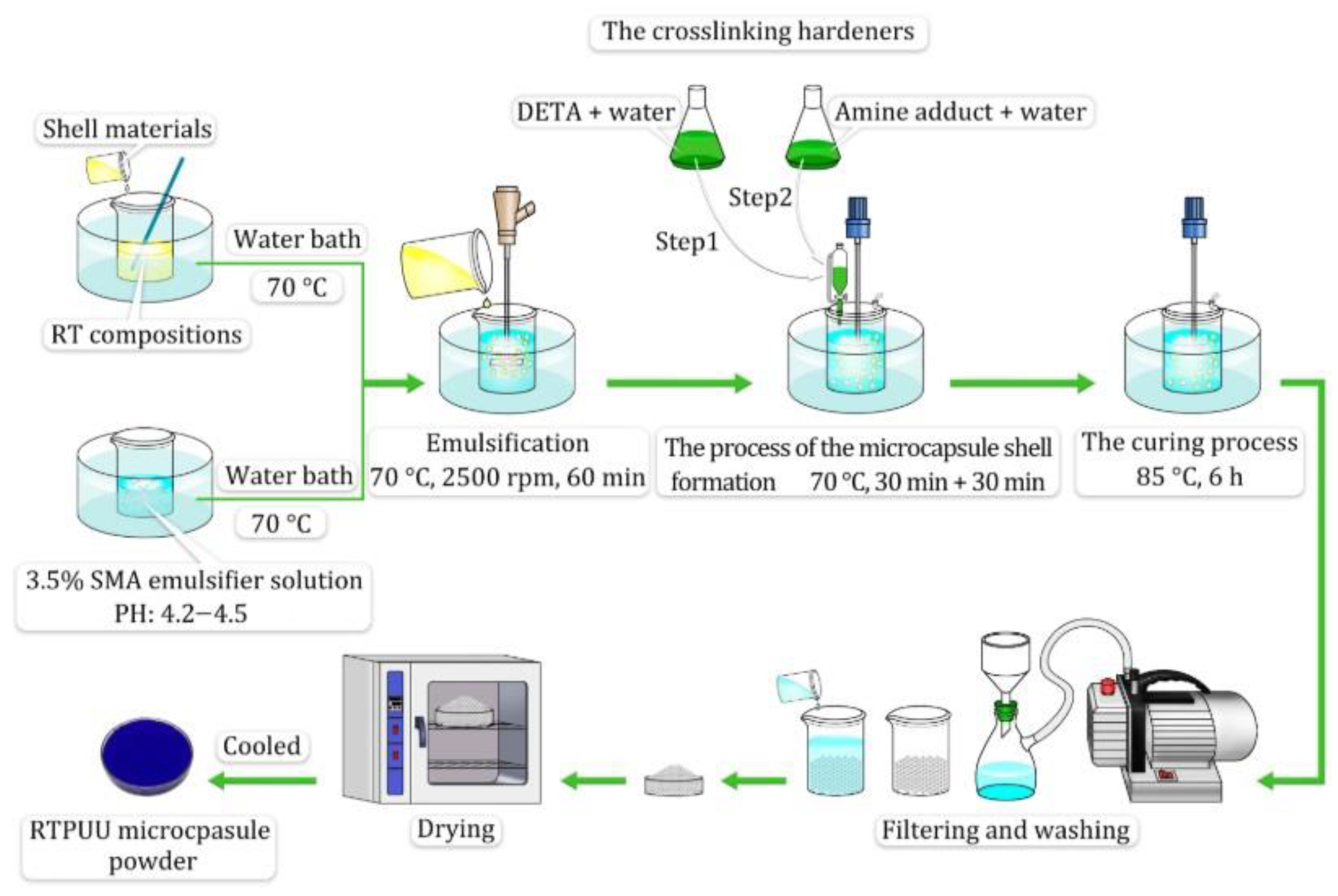

2.4. Emulsion Polymerization

2.5. Solvent-Free Techniques

2.6. Natural/Biobased Extraction Methods

2.7. Comparative Discussion

2.8. Shell Integration

2.9. Shell Composition

2.10. Characterization Techniques

3. Application Fields in Industrial and Energy Sectors

3.1. Building and Construction

3.2. Textiles

3.3. Electronics

3.4. Food Packaging

3.5. Automotive

3.6. Renewable Energy Systems

3.7. Healthcare

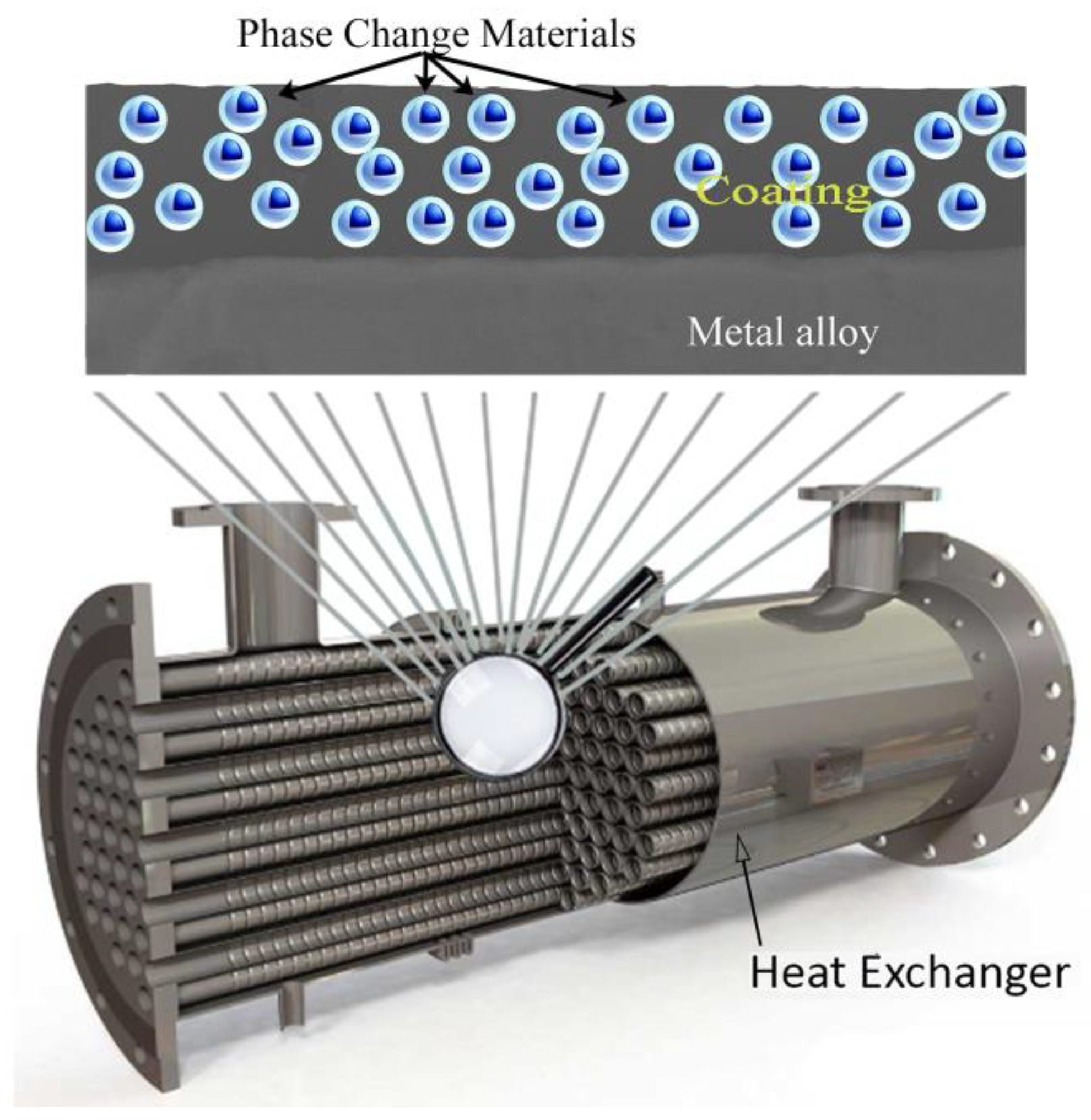

3.8. Industrial Processes

3.9. Smart Materials

4. Challenges

5. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PCMs | Phase change materials |

| AlN | Aluminum nitride |

| CMC | Carboxymethyl cellulose |

| DMA | Dynamic mechanical analysis |

| DSC | Differential scanning calorimetry |

| EGA | Expanded glass aggregate |

| EVA | Ethylene-vinyl acetate |

| FTIR | Fourier transform infrared |

| HIB | High-speed impact blending |

| MCTMs | Mixed-colorant thermochromic microcapsules |

| MMA | Methyl methacrylate |

| MPF | Melamine–paraformaldehyde |

| MWCNTs | Multi-walled carbon nanotubes |

| NGH | Natural gas hydrate |

| NMR | Nuclear magnetic resonance |

| PDA | Polydopamine |

| PEG | Polyethylene glycol |

| PMMA | Polymethylmethacrylate |

| PU | Polyurethane |

| PUU | Poly(urethane-urea) |

| PV | Photovoltaic |

| RT-mPCMs | Reversible thermochromic micro-PCMs |

| SA | Stearic acid |

| SAH | Solar air heater |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| TGA | Thermogravimetric analysis |

| UV | Ultra–visible |

| XRD | X-ray diffraction |

References

- Awan, A.; Kocoglu, M.; Subhan, M.; Utepkaliyeva, K.; bte Mohamed Yusoff, N.Y.; Hossain, M.E. Assessing energy efficiency in the built environment: A quantile regression analysis of CO2 emissions from buildings and manufacturing sector. Energy Build. 2025, 338, 115733. [Google Scholar] [CrossRef]

- Teng, J.; Yin, H. Forecasting the carbon footprint of civil buildings under different floor area growth trends and varying energy supply methods. Sci. Rep. 2023, 13, 21978. [Google Scholar] [CrossRef] [PubMed]

- UCL; BPIE; UNEP CCC; IEA. Global Status Report for Buildings and Construction 2024/2025: Not Just Another Brick in the Wall; United Nations Environment Programme, Global Alliance for Buildings and Construction: Paris, France, 2025; ISBN 978-92-807-4215-2. [Google Scholar] [CrossRef]

- Li, C.; Sun, Z.; Wang, Y.; Zhu, J.; Wu, J.; Feng, L.; Wen, X.; Cai, W.; Yu, H.; Wang, M.; et al. A novel biogenic porous core/shell-based shape-stabilized phase change material for building energy saving. J. Energy Storage 2024, 95, 112504. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, S.; Shao, J.; Shi, W.; Guo, L. Preparation of PU/SiO2 composite shell microencapsulated phase change materials with high thermal stability and thermal conductivity. Polymer 2024, 311, 127518. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Wang, J.; Sun, L.; Xie, T.; Yang, K.; Li, Z. Preparation and characterization of high efficiency microencapsulated phase change material based on paraffin wax core and SiO2 shell derived from sodium silicate precursor. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126905. [Google Scholar] [CrossRef]

- Miao, J.; Zhao, Q.; Qian, L.; Fan, K.; Wen, J.; Mo, L.; Qin, Z. Preparation and characterization of functionally antibacterial multi-layer lignin core-shell structure material with adsorption and high efficiency of photocatalysis for Cr(Ⅵ). Ind. Crops Prod. 2024, 222, 119574. [Google Scholar] [CrossRef]

- Irsyad, M.; Amrizal; Harmen; Amrul; Susila Es, M.D.; Diva Putra, A.R. Experimental study of the thermal properties of waste cooking oil applied as thermal energy storage. Results Eng. 2023, 18, 101080. [Google Scholar] [CrossRef]

- Guerron, G.; Nicolalde, J.F.; Martínez-Gómez, J.; Dávila, P.; Velásquez, C. Experimental analysis of a pilot plant in Organic Rankine Cycle configuration with regenerator and thermal energy storage (TES-RORC). Energy 2024, 308, 132964. [Google Scholar] [CrossRef]

- Jin, X.; Haider, M.Z.; Ahn, J.; Fang, G.; Hu, J.W. Development of nanomodified eco-friendly thermal energy storing cementitious composite using PCM microencapsulated in biosourced encapsulation shell. Case Stud. Constr. Mater. 2023, 19, e02447. [Google Scholar] [CrossRef]

- Song, Y.; Qiu, X.; Liu, H.; Han, Y. Microencapsulated phase change materials (MicroPCMs) with TiO2-modified natural polymer shell and macrocapsules containing MicroPCMs for thermal energy storage and UV-shielding. Sol. Energy Mater. Sol. Cells 2024, 271, 112860. [Google Scholar] [CrossRef]

- Xu, X.; Yin, S.; Zhai, X.; Wu, Z.; Wang, J.; Ma, J.; Peng, X.; Peng, H. Chitosan-based bilayer shell phase change nano-capsules with excellent anti-permeability for thermal regulation dressings. J. Energy Storage 2024, 99, 113496. [Google Scholar] [CrossRef]

- El Majd, A.; Sair, S.; Ousaleh, H.A.; Moulakhnif, K.; Younsi, Z.; Belouaggadia, N.; El Bouari, A. Advanced gypsum/PCM composites incorporating biopolymer-encapsulated phase change materials for enhanced thermal management in buildings. Constr. Build. Mater. 2024, 451, 138872. [Google Scholar] [CrossRef]

- Anand, V.; Ksh, V.; Kar, A.; Varghese, E.; Vasudev, S.; Kaur, C. Encapsulation efficiency and fatty acid analysis of chia seed oil microencapsulated by freeze-drying using combinations of wall material. Food Chem. 2024, 430, 136960. [Google Scholar] [CrossRef]

- Ye, C.; Zhang, M.; Yang, S.; Mweemba, S.; Huang, A.; Liu, X.; Zhang, X. Application of copper slags in encapsulating high-temperature phase change thermal storage particles. Sol. Energy Mater. Sol. Cells 2023, 254, 112257. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Kuang, D.; Huan, X.; Zeng, Z.; Qi, C.; Han, S.; Li, G. Unlocking thermal management capacity: Optimized organic-inorganic hybrid shell phase change microcapsules with controllable structure and enhanced conductivity. Compos. Sci. Technol. 2024, 257, 110836. [Google Scholar] [CrossRef]

- Liu, H.; Deng, Y.; Ye, Y.; Liu, X. Reversible Thermochromic Microcapsules and Their Applications in Anticounterfeiting. Materials 2023, 16, 5150. [Google Scholar] [CrossRef]

- Ju, S.; Wang, F.; Zhang, J.; Shi, J.; Jiang, J.; Wang, L.; Liu, Z. A robust, compatible, and effective core-shell structured phase change materials for controlling the temperature rise caused by cement hydration. J. Build. Eng. 2023, 80, 107906. [Google Scholar] [CrossRef]

- Arman, Z.; Bora, P.; Das, D.; Phukan, M.M. Green form-stable biocomposite of biochar from tea industry waste and organic phase change material. J. Energy Storage 2024, 101, 113815. [Google Scholar] [CrossRef]

- Kalidasan, B.; Pandey, A.K.; Saidur, R.; Aljafari, B.; Yadav, A.; Samykano, M. Green synthesized 3D coconut shell biochar/polyethylene glycol composite as thermal energy storage material. Sustain. Energy Technol. Assess. 2023, 60, 103505. [Google Scholar] [CrossRef]

- Zheng, C.W.; Zhang, H.Y.; Xu, L.L.; Xu, F.C. Production of multifunctional bamboo-based phase change encapsulating material by straightforward dry ball milling. J. Energy Storage 2022, 46, 103630. [Google Scholar] [CrossRef]

- Luo, Y.; Gao, R.; Pan, Z.; Xiao, X.; Zhang, F.; He, X. Biomass waste lotus shell-based shape-stabilized phase change composites with improved thermal conductivity for thermal management. Mater. Today Commun. 2024, 39, 108769. [Google Scholar] [CrossRef]

- Du, M.; Zhou, L.; Wang, X.; Zhang, Z.; Chen, H.; Zhu, G.; Zhang, G. Synthesis and encapsulation of 1, 4-butanediol esters as energy storage phase change materials for overheating protection of electronic devices. J. Energy Storage 2022, 53, 105239. [Google Scholar] [CrossRef]

- Singh, J.; Parvate, S.; Vennapusa, J.R.; Maiti, T.K.; Dixit, P.; Chattopadhyay, S. Facile method to prepare 1-dodecanol@poly(melamine-paraformaldehyde) phase change energy storage microcapsules via surfactant-free method. J. Energy Storage 2022, 49, 104089. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Chang, T.; Wang, J.; Wang, X.; Zhou, G. Phase change material microcapsules with melamine resin shell via cellulose nanocrystal stabilized Pickering emulsion in-situ polymerization. Chem. Eng. J. 2022, 428, 131164. [Google Scholar] [CrossRef]

- Aoki, M.; Jeem, M.; Shimizu, Y.; Kawaguchi, T.; Kondo, M.; Nakamura, T.; Fushimi, C.; Nomura, T. High-temperature ternary Cu–Si–Al alloy as a core–shell microencapsulated phase change material: Fabrication via dry synthesis method and its thermal stability mechanism. Mater. Adv. 2024, 5, 675–684. [Google Scholar] [CrossRef]

- Du, J.; Zhang, X.; Zhang, D.; Wu, J.; Du, X. High-temperature solar energy absorption enhancement of mixed-phase core–shell spherical Al-based composite particles. Appl. Therm. Eng. 2025, 259, 124934. [Google Scholar] [CrossRef]

- Reddy, V.J.; Dixit, P.; Singh, J.; Chattopadhyay, S. Understanding the core-shell interactions in macrocapsules of organic phase change materials and polysaccharide shell. Carbohydr. Polym. 2022, 294, 119786. [Google Scholar] [CrossRef]

- Bragaglia, M.; Lamastra, F.R.; Berrocal, J.A.; Paleari, L.; Nanni, F. Sustainable phase change materials (PCMs): Waste fat from cooking pork meat confined in polypropylene fibrous mat from waste surgical mask and porous bio-silica. Mater. Today Sustain. 2023, 23, 100454. [Google Scholar] [CrossRef]

- Nicolalde, J.F.; Martinez-Gómez, J.; Guerrero, V.H.; Chico-Proano, A. Experimental performance of avocado seed oil as a bio-based phase change material for refrigeration applications. Int. J. Refrig. 2024, 168, 632–647. [Google Scholar] [CrossRef]

- Li, Y.; Li, B. Biomass materials self-assembled core-shell CL-20 @Biomass materials-TiO2 energetic composites with reduced impact sensitivity and enhanced thermal stability. Colloids Surf. A Physicochem. Eng. Asp. 2024, 685, 133160. [Google Scholar] [CrossRef]

- Mba, J.C.; Sakai, H.; Dong, K.; Shimizu, Y.; Kondo, M.; Nakamura, T.; Jeem, M.; Nomura, T. Suppression of supercooling and phase change hysteresis of Al-25mass%Si Micro-Encapsulated Phase Change Material (MEPCM) synthesized via novel dry synthesis method. J. Energy Storage 2024, 94, 112066. [Google Scholar] [CrossRef]

- Kawaguchi, T.; Sakai, H.; Ishida, R.; Shimizu, Y.; Kurniawan, A.; Nomura, T. Development of core-shell type microencapsulated phase change material with Zn-30 mass% Al alloy and its shell formation mechanism. J. Energy Storage 2022, 55, 105577. [Google Scholar] [CrossRef]

- Ismail, A.; Bahmani, M.; Wang, X.; Aday, A.; Odukomaiya, A.; Wang, J. Enabling thermal energy storage in structural cementitious composites with a novel phase change material microcapsule featuring an inorganic shell and a bio-inspired silica coating. J. Energy Storage 2024, 83, 110677. [Google Scholar] [CrossRef]

- Hassan, A.; Cotton, J.S. An investigation of the electroconvection flow and solid extraction during melting of phase-change materials. J. Electrost. 2024, 128, 103904. [Google Scholar] [CrossRef]

- Chen, Y.; Cui, Z.; Ding, H.; Wan, Y.; Tang, Z.; Gao, J. Cost-Effective Biochar Produced from Agricultural Residues and Its Application for Preparation of High Performance Form-Stable Phase Change Material via Simple Method. Int. J. Mol. Sci. 2018, 19, 3055. [Google Scholar] [CrossRef]

- Serin, H.; Güzel, G.; Kumlu, U.; Akar, M.A. Potential of Using Agricultural Waste Composites as Thermal Insulation Material. Macromol. Symp. 2022, 404, 2100409. [Google Scholar] [CrossRef]

- Lajoie, L.; Fabiano-Tixier, A.S.; Chemat, F. Water as Green Solvent: Methods of Solubilisation and Extraction of Natural Products-Past, Present and Future Solutions. Pharmaceuticals 2022, 15, 1507. [Google Scholar] [CrossRef]

- Dupont, H.; Laurichesse, E.; Heroguez, V.; Schmitt, V. Green Hydrophilic Capsules from Cellulose Nanocrystal-Stabilized Pickering Emulsion Polymerization: Morphology Control and Spongelike Behavior. Biomacromolecules 2021, 22, 3497–3509. [Google Scholar] [CrossRef]

- Fujisawa, S.; Tanaka, R.; Hayashi, Y.; Yabuhara, Y.; Kume, M.; Saito, T. Effect of nanocellulose length on emulsion stabilization and microparticle synthesis. Polym. J. 2023, 55, 223–228. [Google Scholar] [CrossRef]

- Fan, X.; Pu, Z.; Zhu, M.; Jiang, Z.; Xu, J. Solvent-free synthesis of PEG modified polyurethane solid-solid phase change materials with different Mw for thermal energy storage. Colloid Polym. Sci. 2021, 299, 835–843. [Google Scholar] [CrossRef]

- Parsamanesh, M.; Shekarriz, S.; Montazer, M. Enhanced thermal stability of eutectic PCMs via microencapsulation: Inverse emulsion polymerization with silica shells. Therm. Sci. Eng. Prog. 2025, 60, 103420. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Rath, P.; Bhattacharya, A. Core-shell PCM encapsulation model for thermoregulation of asphalt pavements. Therm. Sci. Eng. Prog. 2024, 50, 102488. [Google Scholar] [CrossRef]

- Aiswarya, V.; Das, S. Synthesis and characterization of paraffin microcapsules with magnetized graphene oxide core/shell interface for thermal management applications. Appl. Therm. Eng. 2025, 261, 125173. [Google Scholar] [CrossRef]

- Leroy, M.; Louvet, N.; Metivier, C.; Jannot, Y. Micro-encapsulated phase change material suspensions for heat and mass transfer: A thermo-physical characterization. Thermochim. Acta 2024, 740, 179831. [Google Scholar] [CrossRef]

- Rostamian, F.; Etesami, N.; Mehrali, M. Microencapsulation of eutectic phase change materials for temperature management of the satellite electronic board. Appl. Therm. Eng. 2024, 236, 121592. [Google Scholar] [CrossRef]

- Yang, G.; Lei, G.; Liu, T.; Zheng, S.; Qu, B.; Que, C.; Feng, Y.; Jiang, G. Development and application of low-melting-point microencapsulated phase change materials for enhanced thermal stability in cementing natural gas hydrate layers. Geoenergy Sci. Eng. 2024, 238, 212846. [Google Scholar] [CrossRef]

- Jin, X.; Haider, M.Z.; Hu, J.W. Enhancing thermal energy storage efficiency at low temperatures with innovative macro-encapsulation of nano phase change material in cementitious composites. Constr. Build. Mater. 2024, 449, 138187. [Google Scholar] [CrossRef]

- Wang, X.; Kuang, D.; Chen, H.; Xue, H. Capsulated phase-change materials containing paraffin core/polymethyl methacrylate shell: Thermoregulation modifier for asphalt binder. Constr. Build. Mater. 2023, 369, 130574. [Google Scholar] [CrossRef]

- Azadani, H.N.; Ardekani, A. Effect of applying phase change materials (PCM) in building facades on reducing energy consumption. Next Energy 2025, 6, 100210. [Google Scholar] [CrossRef]

- Gao, Y.; Zheng, Q.; Jonsson, J.C.; Lubner, S.; Curcija, C.; Fernandes, L.; Kaur, S.; Kohler, C. Parametric study of solid-solid translucent phase change materials in building windows. Appl. Energy 2021, 301, 117467. [Google Scholar] [CrossRef]

- Shaik, S.; Vishnu Priya, A.; Maduru, V.R.; Rahaman, A.; Arıcı, M.; Kontoleon, K.J.; Li, D. Glazing systems utilizing phase change materials: Solar-optical characteristics, potential for energy conservation, role in reducing carbon emissions, and impact on natural illumination. Energy Build. 2024, 311, 114151. [Google Scholar] [CrossRef]

- Yousefi, A.; Tang, W.; Khavarian, M.; Fang, C. Development of novel form-stable phase change material (PCM) composite using recycled expanded glass for thermal energy storage in cementitious composite. Renew. Energy 2021, 175, 14–28. [Google Scholar] [CrossRef]

- Aksoy, S.A.; Yılmaz, D.; Maleki, H.; Rahbar, R.S.; Barani, H. Fabrication and characterization of nanoencapsulated PCM-doped cotton/PAN nanofiber based composite yarns for thermoregulation. J. Energy Storage 2024, 101, 113849. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, M.; Shi, W.; Zhao, Z.; Królczyk, G.; Li, Z. Preparation and characterization of low-yellowing cross-linked shell microencapsulated phase change materials for latent thermal energy storage. J. Energy Storage 2022, 52, 104918. [Google Scholar] [CrossRef]

- Dubey, I.; Kadam, V.; Babel, S.; Jose, S.; Kumar, A. 1-Tetradecanol phase change material microcapsules coating on cotton fabric for enhanced thermoregulation. Int. J. Biol. Macromol. 2024, 280, 135926. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hu, J.; Jia, Y.; Dong, L.; Bao, L.; Sui, J.; Liu, P.; Kang, Y.; Wang, J. Nano-structured multicores-sheath thermoregulation textile with room temperature phase change point via coaxial electrospinning. J. Energy Storage 2024, 100, 113639. [Google Scholar] [CrossRef]

- Geng, X.; Gao, Y.; Wang, N.; Han, N.; Zhang, X.; Li, W. Intelligent adjustment of light-to-thermal energy conversion efficiency of thermo-regulated fabric containing reversible thermochromic MicroPCMs. Chem. Eng. J. 2021, 408, 127276. [Google Scholar] [CrossRef]

- Zhou, L.; Ye, J.; Cai, Q.; Liu, G.; Dadgar, M.; Zhu, G.; Zhang, G. Study on preparation, characterization and application of mixed-colorants thermochromic microcapsules. Particuology 2024, 88, 89–97. [Google Scholar] [CrossRef]

- Liang, Y.; Yang, H.; Tang, H.; Chen, J.; Wang, Y.; Cui, H. Influence of metal encapsulation on thermophysical properties and heat transfer in salt hydrate phase change material for air conditioning system. Sustain. Energy Technol. Assess. 2024, 62, 103618. [Google Scholar] [CrossRef]

- Su, Y.; Shen, J.; Chen, X.; Xu, X.; Shi, S.; Wang, X.; Zhou, F.; Huang, X. Bio-based eutectic composite phase change materials with enhanced thermal conductivity and excellent shape stabilization for battery thermal management. J. Energy Storage 2024, 100, 113712. [Google Scholar] [CrossRef]

- Chen, R.; Ge, X.; Li, X.; Zhang, G.; Zhang, J.; Ke, X. Facile preparation method of phase change microcapsule with organic-inorganic silicone shell for battery thermal management. Compos. Sci. Technol. 2022, 228, 109662. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Li, Y.; He, F.; Chen, Z.; Li, X.; Wang, P.; He, G.; Yang, W. Flexible phase change composites with multiple colors and reversible thermochromic for temperature indication and battery thermal management. Compos. Sci. Technol. 2024, 249, 110481. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Lu, R.; Zhang, S.; Hai, A.M.; Tang, B. Form-stable cold storage phase change materials with durable cold insulation for cold chain logistics of food. Postharvest Biol. Technol. 2023, 203, 112409. [Google Scholar] [CrossRef]

- Jafarpour, M.; Fathi, M.; Soltanizadeh, N. Encapsulation of polyethylene glycol as a phase change material using alginate microbeads to prevent temperature fluctuation- Case study: Fish packaging. Food Hydrocoll. 2023, 134, 108029. [Google Scholar] [CrossRef]

- Singh, J.; Vennapusa, J.R.; Dixit, P.; Maiti, T.K.; Chattopadhyay, S. A novel strategy for temperature controlling of chocolates through 1-dodecanol embedded polyurea coated barium alginate beads. J. Taiwan Inst. Chem. Eng. 2022, 138, 104497. [Google Scholar] [CrossRef]

- Mwenya, J.; Saengrayap, R.; Arwatchananukul, S.; Aunsri, N.; Kamyod, C.; Jakkaew, P.; Kitazawa, H.; Mahajan, P.; Padee, S.; Prahsarn, C.; et al. Efficient temperature control in okra transportation using phase change materials inside packaging box. Food Packag. Shelf Life 2024, 46, 101383. [Google Scholar] [CrossRef]

- Saghafian-Aski, A.; Jafari, S.-M.; Ziaiifar, A.-M.; Alehosseini, E. Thermo-resistant films based on core-shell nanofibers loaded with phase change materials for butter packaging; fabrication, characterization, application. Future Foods 2025, 11, 100598. [Google Scholar] [CrossRef]

- Srusti, B.; Shyam Kumar, M.B. A novel method to investigate the influence of phase change material orientation in reduction of car cabin temperature. J. Energy Storage 2022, 47, 103650. [Google Scholar] [CrossRef]

- Riad, A.; Ben Zohra, M.; Alhamany, A. Enhancing electric car lithium-ion batteries by using adaptive materials to improve heat transfer and reduce fatigue. Prog. Eng. Sci. 2024, 1, 100025. [Google Scholar] [CrossRef]

- Pan, J.; Chen, S.; Fu, J.; Zhu, H.; Cheng, M. Encapsulation effectiveness and thermal energy storage performance of aluminum-graphite composite phase change materials subjected to oxide coating. J. Energy Storage 2024, 89, 111722. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, S.; Hao, S.; Zhang, Z.; An, H.; Tian, W.; Chan, M.; Bai, H. Fabrication and properties of nanoencapsulated stearic acid phase change materials with Ag shell for solar energy storage. Sol. Energy Mater. Sol. Cells 2022, 239, 111653. [Google Scholar] [CrossRef]

- Farzan, H.; Mahmoudi, M.; Moradnejad, O.; Rezvani, F.R. Study on energy and exergy performance of a new hybrid perforated photovoltaic/solar air heater integrated with encapsulated phase change materials: An experimental study. Sol. Energy 2024, 284, 113062. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Wang, Y.; Wang, B.; Feng, X.; Mao, Z.; Sui, X. Flexible and resilient photothermal polyurethane film from polydopamine-coated phase change microcapsules. Sol. Energy Mater. Sol. Cells 2021, 227, 111111. [Google Scholar] [CrossRef]

- Karami, B.; Azimi, N.; Ahmadi, S. Increasing the electrical efficiency and thermal management of a photovoltaic module using expanded graphite (EG)/paraffin-beef tallow-coconut oil composite as phase change material. Renew. Energy 2021, 178, 25–49. [Google Scholar] [CrossRef]

- Al Hajaj, Z.; Ziad Saghir, M. Numerical study on the influence of embedded PCM tubes on the energy storage properties of the geothermal energy pile. Int. J. Thermofluids 2023, 20, 100416. [Google Scholar] [CrossRef]

- Roshani, M.; Hosseini, M.J.; Ranjbar, A.A.; Torbatinejad, A. Enhancing geothermal heat pump efficiency with fin creation and microencapsulated PCM: A numerical study. J. Energy Storage 2024, 95, 112664. [Google Scholar] [CrossRef]

- Mohammadi, B.; Shekaari, H.; Zafarani-Moattar, M.T. Study of the nano-encapsulated vitamin D3 in the bio-based phase change material: Synthesis and characteristics. J. Mol. Liq. 2022, 350, 118484. [Google Scholar] [CrossRef]

- Wildy, M.; Wei, W.; Xu, K.; Schossig, J.; Hu, X.; la Cruz, D.S.; Hyun, D.C.; Lu, P. Exploring temperature-responsive drug delivery with biocompatible fatty acids as phase change materials in ethyl cellulose nanofibers. Int. J. Biol. Macromol. 2024, 266, 131187. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.; Tu, H.; Zheng, H.; Xiang, Y.; Zhang, T.; Huang, X.; Lu, F.; Yu, K.; Hu, E.; et al. Photothermal-manipulatable shape memory polyacrylamide/gelatin Janus hydrogel with drug carrier array for invasive wound closure and responsive drug release. Int. J. Biol. Macromol. 2025, 293, 139255. [Google Scholar] [CrossRef]

- Li, D.; Sun, L.; Shi, L.; Zhang, Y.; Liu, J.; Qiu, M.; Ma, Y.; Kou, N.; Song, W.; Zhuo, L.; et al. Fabrication of natural microcapsule with intrinsic core–shell structure as building blocks for achieving source control of obesity. Chem. Eng. J. 2024, 493, 152585. [Google Scholar] [CrossRef]

- Emara, K.; Abd-Elgawad, A.M.M.M.; Emara, A. Effect of nanofluids-PCM heat exchanging on engine downsizing and heat transfer enhancement via the heat engine’s cooling system: A novel saving tactic. J. Energy Storage 2025, 117, 115815. [Google Scholar] [CrossRef]

- Xie, C.; Yang, X. Heat transfer enhancement of microchannel using nano-encapsulated phase change material for fuel cell thermal management systems. J. Energy Storage 2024, 103, 114370. [Google Scholar] [CrossRef]

- Song, L.; Guo, W.; He, Z.; Zhang, P. Thermal, economic and food preservation performances of a refrigerated warehouse equipped with on-shelf phase change material. Int. J. Refrig. 2024, 165, 16–30. [Google Scholar] [CrossRef]

- Fenton, E.; Bozorgi, M.; Tasnim, S.; Mahmud, S. Solar-powered thermoelectric refrigeration with integrated phase change material: An experimental approach to food storage. J. Energy Storage 2024, 79, 110247. [Google Scholar] [CrossRef]

- Zhu, W.; Tian, L.; Yin, Z.; Feng, Y.; Xia, W.; Wang, H.; Sun, Q.; Li, Y. Wood-based phase change energy storage composite material with reversible thermochromic properties. Ind. Crops Prod. 2024, 222, 120042. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Wu, S.; Xu, H.; Wan, P.; Zhang, J. Preparation and characterization of phase change capsules containing waste cooking oil for asphalt binder thermoregulation. Constr. Build. Mater. 2023, 395, 132311. [Google Scholar] [CrossRef]

- Yunlong, Z.; Meizhu, C.; Yuechao, Z.; Shaopeng, W.; Dongyu, C.; Zhengxu, G.; Yansong, F. Microencapsulated waste cooking oil derivatives for building thermoregulation. Constr. Build. Mater. 2023, 400, 132644. [Google Scholar] [CrossRef]

- Cesari, S.; Baccega, E.; Emmi, G.; Bottarelli, M. Enhancement of a radiant floor with a checkerboard pattern of two PCMs for heating and cooling: Results of a real-scale monitoring campaign. Appl. Therm. Eng. 2024, 246, 122887. [Google Scholar] [CrossRef]

- Wang, K.W.; Yan, T.; Pan, W.G. Optimization strategies of microencapsulated phase change materials for thermal energy storage. J. Energy Storage 2023, 68, 107844. [Google Scholar] [CrossRef]

| Core | Shell | Principle of Green Synthesis | Reference |

|---|---|---|---|

| Paraffin | TiO2-chitosan | Eco-friendly materials | [11] |

| Lauric and stearic acid | PMMA | Eco-friendly materials | [12] |

| 1-dodecanol | Alginate, carboxymethyl cellulose, and chitosan, Al2O3 | Eco-friendly materials | [13] |

| Chia seed oil (fatty acids) | Whey protein, modified tapioca starch | Eco-friendly materials | [14] |

| Aluminum | Copper slag, bauxite | Eco-friendly materials | [15] |

| Paraffin | SiO2-PMMA | Green solvents | [16] |

| Crystal violet lactone, methyl stearate, bisphenol AF | Poly(urethane-urea) | Green solvents | [17] |

| n-octadecane | SiO2 | Green solvents | [18] |

| Paraffin-Cocos nucifera oil | Industry-generated tea waste | Biomass-derived materials | [19] |

| n-octadecane | Rice husk silica, rice husk carbon | Biomass-derived materials | [4] |

| Polyethylene glycol | Carbon-based coconut shell | Biomass-derived materials | [20] |

| Polyethylene glycol | Baboo flour | Biomass-derived materials | [21] |

| N-docosane | Biomass waste lotus shells | Biomass-derived materials | [22] |

| 1, 4-butanediol esters | Silica | Emulsion polymerization | [23] |

| 1-dodecanol | Melamine–paraformaldehyde | Emulsion polymerization | [24] |

| Paraffin wax and n-octadecane | Melamine–formaldehyde | Emulsion polymerization | [25] |

| Cu–Si–Al | α-Al2O3 and AlOOH | Solvent-free techniques | [26] |

| Aluminum | Cu(Mn2O4)/Cu(CrO2), FeMn(SiO4)/Fe2(SiO4), and Cr0.75Fe1.25O3 | Solvent-free techniques | [27] |

| Butyl stearate, hexadecane, caprylic acid | Pectin–barium chloride | Natural/biobased extraction methods | [28] |

| Waste cooking fats | Biosilica, polypropylene | Natural/biobased extraction methods | [29] |

| Avocado seed oil extraction | Biobased matrix | Natural/biobased extraction methods | [30] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feizatidou, A.; Binas, V.; Kartsonakis, I.A. Green Synthesis of Core/Shell Phase Change Materials: Applications in Industry and Energy Sectors. Energies 2025, 18, 2127. https://doi.org/10.3390/en18082127

Feizatidou A, Binas V, Kartsonakis IA. Green Synthesis of Core/Shell Phase Change Materials: Applications in Industry and Energy Sectors. Energies. 2025; 18(8):2127. https://doi.org/10.3390/en18082127

Chicago/Turabian StyleFeizatidou, Aikaterini, Vassilios Binas, and Ioannis A. Kartsonakis. 2025. "Green Synthesis of Core/Shell Phase Change Materials: Applications in Industry and Energy Sectors" Energies 18, no. 8: 2127. https://doi.org/10.3390/en18082127

APA StyleFeizatidou, A., Binas, V., & Kartsonakis, I. A. (2025). Green Synthesis of Core/Shell Phase Change Materials: Applications in Industry and Energy Sectors. Energies, 18(8), 2127. https://doi.org/10.3390/en18082127