Abstract

Future decarbonization targets demand a higher penetration of renewable energy (RE) sources into the system. However, challenges such as an uneven spatial and temporal distribution of various RE sources’ potential for green electricity (GE) generation demand alternative ways to store and later utilize the generated energy. In addition to that, sustainable development goals (SDGs) highlight the need for the responsible use of resources with increased recycling and a reduction in corresponding waste generation while ensuring access to affordable, reliable, sustainable, and modern energy for all. In this paper, an attempt is made to address both the issues of biodegradable waste (BW) processing and sustainable hydrogen (SH) production through it. Thermochemical conversion technology (TCC) and, within that, especially ‘thermocatalytic reforming’ (TCR®) technology have been explored as options to provide viable solutions. An added advantage of decentralized hydrogen production can be envisioned here that can also contribute to regional energy security to some degree. To analyze the concept, the Bavarian region in Germany, along with open-source data for bio-waste from two main sources, namely domestic household and sewage sludge (SS), were considered. Based on that, the corresponding regional hydrogen demand coverage potential was analyzed.

1. Introduction

The prospects put forward in the Paris Agreement to limit global temperature increases well below 2 °C requires a profound endeavor. The European Union (EU) has set itself a goal of reducing greenhouse gas emissions by 80–95% until 2050 compared with 1990 levels [1]. Between 1990 and 2018, the EU’s economy reduced greenhouse gas emissions by 23%, while the economy grew by 61% [2]. However, current sustainable development and decarbonization policies will only reduce greenhouse gas emissions by 60% by 2050; if 2030 climate and energy targets are to be achieved, they will require USD 260 billion of additional annual investment which roughly translates to 1.5% of the 2018 GDP figure of Europe [2]. The transition toward more sustainable energy and de-carbonization involves some local as well as regional challenges. Demographic development, a lack of social acceptance, and renewable resource volatility are some of the associated challenges related to the sustainable energy transition [3]. Hydrogen and more specifically sustainable hydrogen play an important role in the perceived decarbonization targets all around the world. Hydrogen (in gaseous form) has a relatively high energy release potential (somewhere around 142.35 MJ·kg−1) when reacting with oxygen if we compare this value with that of natural gas (with a potential somewhere between 35 and 45 MJ·kg−1) [4,5]. Badea N.I. highlighted the fact that to reach the ambitious green policy requirements put forward in the EU, considerable changes have to be achieved in the overall energy grid [6]. The production and storage of hydrogen provide similar flexibility to energy infrastructure as what the current gas and electricity grid offers [6]. Jaradat et al. mentioned the pivotal role of hydrogen in the advancement toward a sustainable energy landscape; their key argument was that to achieve a carbon-neutral energy system, green hydrogen needs to become the dominant form of energy carrier [7]. Noyan et al. not only mentioned the quintessential role of green hydrogen but also underlined the role of green hydrogen as an energy security option in the wake of uncertainties in energy markets due to ongoing conflicts on the global stage [8]. It has to be considered, however, that most of the SH production scenarios for the future are based on the availability of green electricity and corresponding electrolysis potential. This, in turn, poses three questions for sustainable development scenarios.

- How will the availability and secure GE supply be ensured to generate sustainable fuels (SF) along with the direct primary applications of GE?

- How we will address the water availability for electrolysis applications, considering future possible water scarcity and increased SH demand?

- What is the impact of limited RE potential on SH generation in Bavaria?

However, one of the major future challenges would be the sustainable utilization of resources and waste processing. Germany’s above-average per capita consumption of resources makes it especially important to look for more sustainable options that will address the issue of waste processing and hydrogen production simultaneously [9]. This fact makes it essential to recover the raw materials and energy from waste [9]. The future population growth and rapid urbanization will pose new challenges in waste processing, providing sustainable energy for all.

The objective of this study was to identify the potential for SH production and BW processing simultaneously. In general, BW and the municipal solid waste (MSW) (henceforth termed simply BW) contents are highly abundant with energy contents being comparable to those of coal (on a dry basis) [10]. The conventional approach to getting rid of the BW is either with landfills or incineration; both options are relatively environment polluting compared with TCC technologies [10]. It has been observed that the treatment of the organic fraction of the BW with certain TCC processes produces syngas with relatively higher concentrations of H2 when compared with other methods of treatment such as gasification (36 vol.%) [10]. TCC processes based on the treatment of the organic fraction of BW are economically comparable to traditional incineration as well as the landfill [10].

In this work, an approach is developed to understand the potential of SH production using the TCC technology developed at Fraunhofer UMSICHT to process biodegradable waste. Section 2 provides a literature overview of the sustainable hydrogen production landscape using RE technology options. In Section 2.5, we define the research question at hand. Section 3 overviews the region under consideration. Section 4 outlines the methodology used in this work along with the scenarios considered for the study. The results are highlighted in Section 5. Finally, the outcomes are discussed in Section 6,which is followed by the conclusion in Section 7. Some recommendations and suggestions for possible future work are stated in Section 8.

2. Literature Review

2.1. Sustainable Hydrogen Production and Perceived Use Landscape

The transition from conventional energy sources to sustainable energy sources requires the bridging potential of energy storage options. Bhandari et al. addressed the challenge of the energy transition to sustainable energy sources through energy storage aspects, for which they considered Cologne (Germany) as their area of consideration, and solar photovoltaic (PV) technology coupled with SH-producing electrolyzers as a system—hence, a power-to-gas (PtG) system [11]. During their study, it was identified that grid-connected solar PV systems coupled with alkaline electrolyzers for hydrogen production are proving to be the most cost-efficient option with the levelized cost of hydrogen (LCOH) being 6.23 €·kg−1 of hydrogen produced [11]. Grunow also analyzed the PtG system for small household applications of combined heat and power (CHP) systems, where hydrogen would also act as a heating media helping to lower the electric peak demand for domestic heating [12]. The potential application of ‘plasmalysis’ technology in treating biomass has also been mentioned, which gives a theoretical hydrogen generation capacity of 65 TWh across Germany [12]. However, the use of available biomass coupled with green electricity and corresponding electrolysis has been considered in this case and not the thermal treatment of the BW [12]. Welder et al. also talk about PtG systems as an effective tool to address the problem of spatial mismatch between electricity supply and consumer demand due to the high penetration of RE sources into the system [13]. Onshore wind turbines-based electricity generation and salt caverns for hydrogen storage are considered with this setup; overall, hydrogen prices below the current price of 9.50 €·kg−1 can be obtained [13]. Michalski et al. highlighted the possible critical future role of SH in mobility as well as in industry [14]. However, their approach also includes mainly the analysis of PtG systems coupled with salt caverns-based SH storage. The main application areas were identified as the northern region of Germany and the middle as well as the eastern part of Germany; however, the production of SH via the PtG way and storage in salt caverns is not seen as an economical or feasible way for the southern part of Germany, including Bavaria [14]. Kendziorski et al. highlighted interesting aspects of decentralized energy and hydrogen production and the security of supply through it; however, hydrogen generation is mostly envisioned based on GE availability and electrolyzer availability. The analysis covers the ‘Nomenclature of Territorial Units for Statistics-2’ (NUTS-2) based regions of Germany, but no consideration is given to the BW processing [15]. Kalchschmid et al. also talk about the critical role of decentralized hydrogen production using GE and electrolyzers and usage for the industry as a way to ensure the security of supply [16]. Hydrogen production and use have been considered on multiple levels to cover multiple applications associated with industry processes [16]. Murray et al. also analyzed decentralized systems, with hydrogen as an energy storage option for rural and urban neighborhoods, but in Switzerland [17]. The specific emphasis is given to the PtG systems, and in that, power-to-hydrogen systems [17]. Lahnaoui et al. considered Germany and France as a geographical area to understand the SH generation (mainly using wind energy) and its distribution to the demand sites via road networks [18]. In the long-term scenario until 2050, Germany has to rely on hydrogen inputs if only the wind energy-based SH production is considered within Germany [18]. Franzmann et al. explored the concept of SH production in high solar potential countries such as countries in Africa and Middle Eastern regions; a very important point of sustainable water availability is mentioned in their work, which is critical for SH production without stressing the domestic fresh water supply [19]. A study conducted by bifa Umweltinstitut sheds light on the SH production potential via commercial waste processing in Bavaria; however, the main focus here is on the gasification technique [20].

It is evident that hydrogen will play a crucial role as an energy carrier media in the overall transition toward a sustainable energy future. However, hydrogen faces some challenges as an energy carrier media in the form of storage and delivery system complexity [21]. Various alternative pathways to hydrogen storage and transport are envisioned and discussed. Negro et al. explored the possibility of ammonia as a hydrogen storage and transport media; their analysis highlighted the fact that although ammonia is an attractive alternative for hydrogen transport and storage, some critical issues remain to be addressed [22]. Similar analysis outcomes were shown by Asif et al., according to their study, there are various challenges in production, and especially the transportation and storage of the hydrogen where ammonia can play a crucial role [23]. In cases where ammonia is considered a hydrogen storage and transport media, greater advantages can be achieved if the ammonia is directly used in final applications [22]. Yousefi Rizi and Shin also mentioned the prospects of ammonia as a hydrogen storage and transportation media; however, their suggestion was to opt for the conversion of ammonia back to hydrogen and then use it, as it averts the NOx production [24]. In a general sense, most of the efforts are directed toward the generation of SH using green electricity-based electrolysis. This highlights the fact that a greater availability and scale-up of RE technologies are needed in the future. However, the demand for GE will be higher in the other areas of industry where the direct application and use of GE is perceived. This might push the overall prices of the GE even further to higher ends and may result in an overall increase in SH prices.

2.2. Bio-Waste Processing Landscape

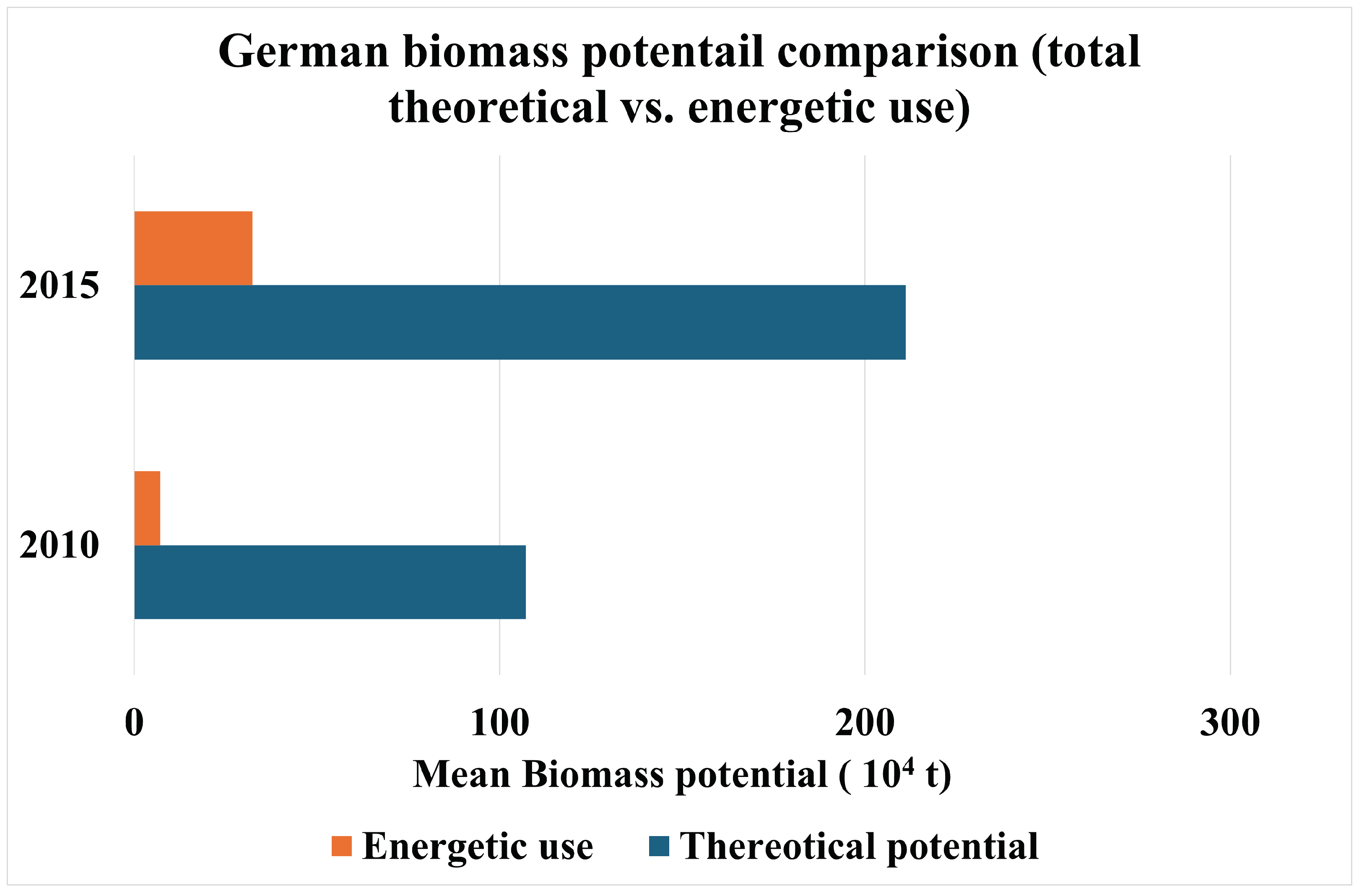

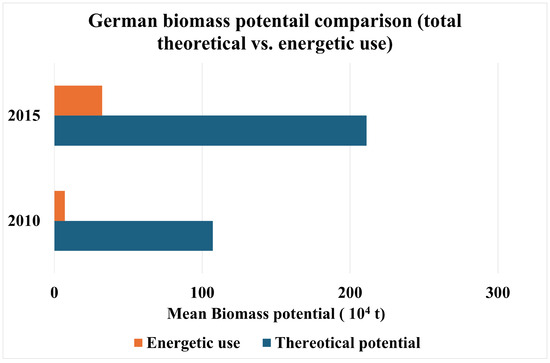

Since 2010, nearly 50% of the total primary energy from renewable sources worldwide has been provided by biomass [25]. Figure 1 shows the comparison between the total mean theoretical biomass potential and corresponding energetic use of available biomass for the years 2010 and 2015 for the Bavarian region of Germany [26]. It can be seen that the share of energetic use of biomass is less compared to the other methods of biomass use and processing.

Figure 1.

Comparison between total mean theoretical potential and actual corresponding energetic use of the biomass across Germany [26].

Forest resources are one of the main sources of the wood biomass supply in Bavaria. Wood has been used for various applications in Bavaria, including power generation and heat production. However, even sustainably grown wood need not be completely climate-neutral. Klein et al. put light on the sustainability of such wood sources, and their analysis shows that there is a broad spectrum of factors affecting the sustainability of the wood, and even such forest-grown wood need not be completely sustainable, rather than having a low environmental impact [27]. The estimated value for CO2 equivalent emissions comes somewhere near 18.95 kg CO2 eq·m−3 for the Bavarian forestry sector [27]. It means that even if such sources are used in the long term for SH production, their overall impact will be higher in proportion to the increasing usage. Over a longer period and in the future, wood biomass-based hydrogen production will not be suitable. Alternative sources of biomass such as bio-waste must be considered. Full et al. have already addressed one of the main questions relevant to this study: ‘What is the feasible bioenergy potential of several biohydrogen production processes from the organic residues and waste materials in Germany?’ [5]. Their research work highlighted the fact that there is no dedicated study that addresses the bioenergy potential for biohydrogen production [5]. In the year 2017, around 8.9 TWh of electricity production and around 123 PJ of total generated heat as well as around 18.4 PJ of biofuels for transportation were supplied by biomass-based inputs for the region of Bavaria [3]. According to Goers et al., it was estimated that up until the year 2022, there was an additional 1 GW of potential for biomass-based sources [3]. Globally, for the past few years, approximately 2 billion tons of municipal solid waste (MSW) has been produced, of which 11% has been recycled, 19% is used for the production of energy, and around 70% ends up in landfill [28]. Within the scope of this paper, domestic, household biodegradable organic waste has been considered. Categories such as MSW, BW, organic waste and biodegradable waste are all analogous in this light and henceforth represent household biodegradable waste labeled as BW. Taking these facts into consideration, it can be said that bio-waste is a possible alternative option for conventional biomass. Such BW can be a simple domestic municipal waste, which contributes significantly to overall GHG emissions. If we just consider food wastage as an example, then according to the study conducted by Auer and Rogers for the year 2022, the food wastage contributed around 4% of the total GHG emissions in Germany [29].

Ouadi et al. identified the problem associated with the traditional methods of dealing with BW disposal such as landfills and incineration [10]. Their main focus for study was also on BW as an input material and thermochemical conversion technology and especially the pyrolysis technique as a processing technology to deal with the BW [10]. The important cost implications associated with rising landfill taxes and transport costs are mentioned in their work. Rada et al. also highlighted the fact that incineration has been the state-of-the-art technology for BW treatment for a long time, and in comparison, techniques such as pyrolysis are not so prominently used for BW treatment [30]. The efforts given to understand the applicability of thermochemical conversion techniques such as pyrolysis for BW processing is limited. Zaman and Atiq UZ did, however, compare the life cycle analysis of the fast pyrolysis technique with that of anaerobic digestion, incineration, and landfill techniques for BW processing [31]. Ates et al. investigated the possibility of pyrolysis process application for BW processing using a laboratory-scale model along with the use of various catalysts [32]. Chen et al. even went one step further in understanding the BW application as input material for industrial pyrolysis processes; however, they also suggested the use of downstream processes such as gasification and combustion [33]. Moreno et al. analyzed the use of the pyrolysis technique as a BW processing technology option; however, they consider two variants of agricultural waste [25]. In traditional terms, landfill and incineration are the two options considered for BW processing. The efforts to utilize TCC techniques for BW processing are explored in limited contexts, and on top of that, no specific efforts have been made to understand the potential of simultaneous hydrogen production using TCC techniques.

2.3. Hydrogen Demand Landscape

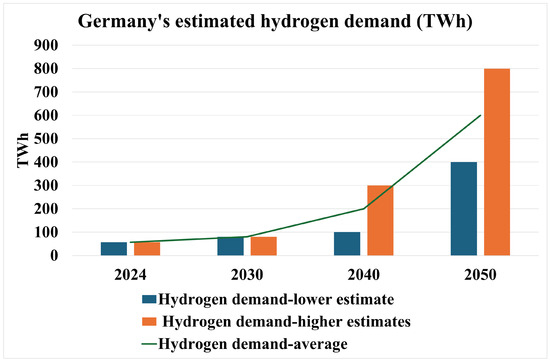

Germany’s current hydrogen production is around 57 TWh·a−1 and is mainly dominated by fossil fuel-based sources [34,35]. From 2030 onwards, the hydrogen demand will be somewhere in the range of 80 TWh·a−1 [34,35]. This is a relatively rapid increase in the overall hydrogen demand. However, beyond the year 2030, the hydrogen demand will skyrocket, going in the range of 100–300 TWh·a−1 by 2040, and even in the range of 400–800 TWh·a−1 by the year 2050 [34,35]. In the near future, heavy industries will represent the highest share of hydrogen consumption with estimates ranging from 157 TWh·a−1 to 435 TWh·a−1 for the year 2045 in Germany alone [36]. But if we consider the general estimated hydrogen demand for the entire EU, then it comes somewhere in the range of 0.3 to 1 PWh·a−1.

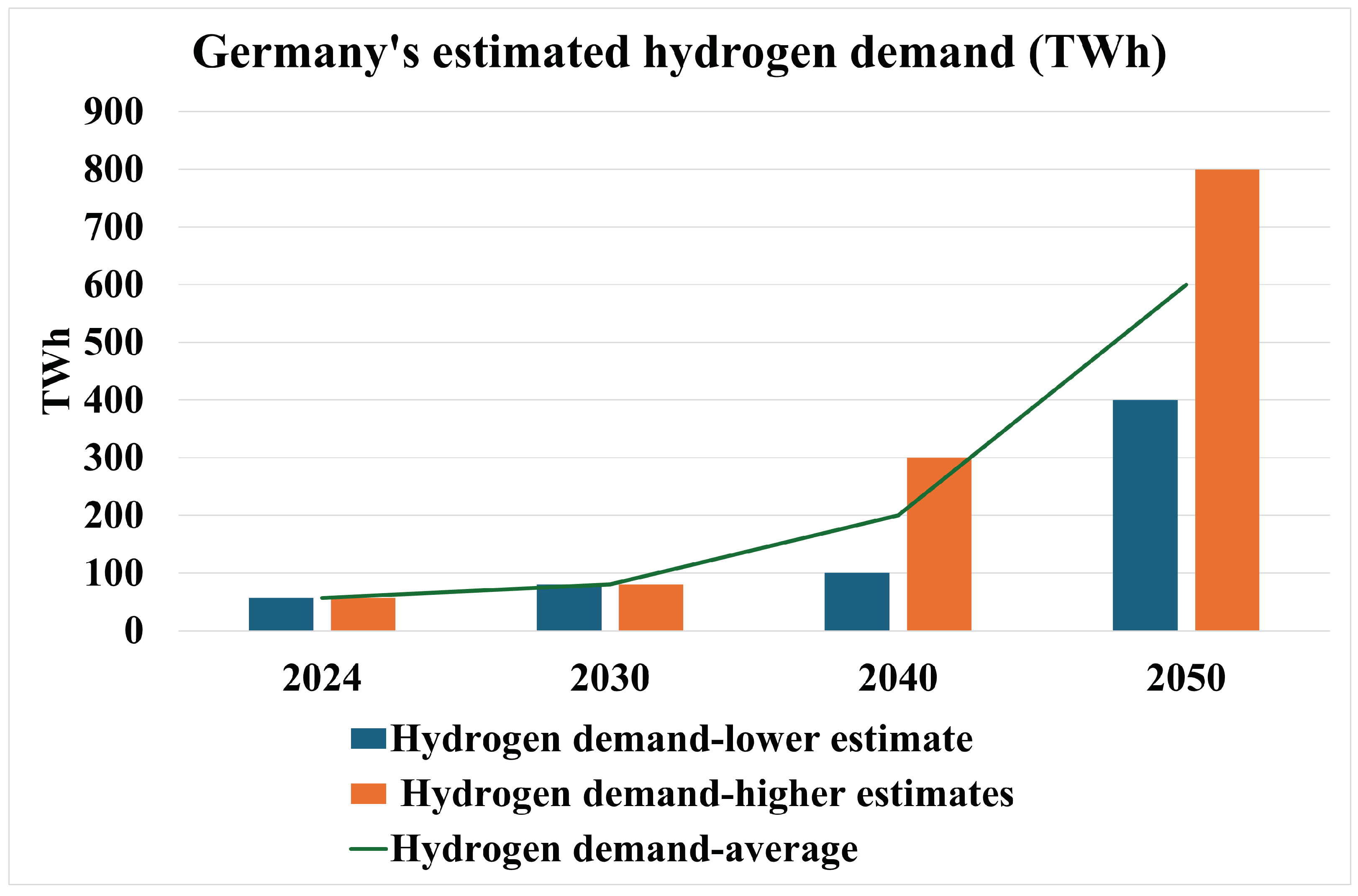

Figure 2 shows the ever-increasing trend of hydrogen demand in Germany. If we keep the aim of reducing GHG emissions by 80% compared to the 1990s levels, the use of hydrogen becomes crucial and undeniable [37]. Globally, it is estimated that hydrogen will be constituting 4–11% of the final energy consumption by the year 2050; in that way, hydrogen will be an important energy carrier but not the dominant one [37]. In the year 2020 itself, global hydrogen production reached somewhere around 50 Mt, and 59% of this hydrogen was produced from natural gas [38]. Refineries were one of the biggest consumers of this produced hydrogen, amounting to 40 Mt of hydrogen consumption globally for the year 2020 [38]. According to some estimates, the transportation sector will have the highest use of hydrogen while the building sector will have the least use cases for hydrogen, especially in the EU region [37]. Future applications of hydrogen vary depending on the area of application; for example, in the case of industry, hydrogen is seen primarily as a feedstock, whereas in the transportation sector, it is primarily considered as a fuel. Scheller et al. also highlighted the fact that the hydrogen carrier demand will be somewhere in the range of 480 TWh·a−1 for the year 2050 [39]. Estimating precise hydrogen demand for a particular year is a challenging task. In particular, this is because the demand landscape changes based on the application scenario, the sector considered, and the level of optimism assumed for the future penetration of hydrogen in the system. Wappler et al. addressed this exact point in their work; they found out that the hydrogen demand varies greatly based on several factors [38]. The average global hydrogen demand for the year 2030 can be somewhere in the range of 110 Mt [38]. However, according to the International Renewable Energy Agency (IRENA) report, the share of SH in it would be somewhere around 15 Mt and 95 Mt for the years 2030 and 2050, respectively [40]. On the other hand, the report presented by Hydrogen Council and McKinsey & company estimates total hydrogen demand around 140 Mt and 660 Mt for the years 2030 and 2050, respectively [41]. However, according to this study, the share of SH would be somewhere around 75 Mt [41].

Figure 2.

Germany’s estimated hydrogen demand landscape (in TWh·a−1) [34,35,36].

Focusing specifically on the Bavarian region of Germany, ‘Hydrogen Roadmap Bavaria’ provides critical insight. The Bavarian region has set an ambitious goal of being climate neutral by the year 2040 [42]. This goal of being climate neutral is independent of the German federal government’s goal of being climate neutral and hence requires urgent course correction [42]. In Bavaria, the hydrogen demand will be dominated by mobility, the petrochemical industry, electricity, and the heat sector [42]. The overall hydrogen demand for Bavaria in terms of equivalent energy demand would be somewhere around 10 TWh for the year 2030 [42]. According to Bique and Zondervan, the Bavarian region might need around 0.17 to 0.5 Mt·a−1 of hydrogen for the years 2030 and 2050, respectively [43]. However, a study conducted by bifa Umweltinstitut estimates that the hydrogen demand in Bavaria will be somewhere in the range of 0.5 Mt·a−1 in the year 2030 itself [20]. It has been identified that there is a limited capacity for producing SH using the electrolysis method due to the low potential for RE in Bavaria [42]. In this light, the use of biomass for hydrogen production is seen as a crucial factor in Bavaria [42]. One of the key points mentioned in the ‘Hydrogen Roadmap Bavaria’ report highlights the fact that electricity generation via RE is not a viable option for large-scale hydrogen production through electrolysis [42]. It has also been categorically mentioned that there is a lack of sufficient infrastructure and production capacity for the large-scale import of hydrogen in the Bavarian region [42]. Hence, it is advisable to go for decentralized hydrogen production, which will reduce the need for hydrogen distribution infrastructure development. The essential role of biomass and organic residue-based input materials for hydrogen production is also put into light, which will be paramount for developing the regional capacity for hydrogen production [42]. To achieve the climate-neutrality goal for Bavaria, there is a need for the local production of hydrogen [42].

Table 1 shows the color-coded classification of the hydrogen production technologies based on the inputs and the adopted methods. Hydrogen production via the TCC-based technique and BW as well as SS as input can be placed under the green hydrogen production category, as the inputs are simply BW or SS, and the process heating as well as electricity required can be provided through RE sources. In this sense, the process is carbon neutral.

Table 1.

Various hydrogen production pathways and color coding are based on the source material and methods used [38].

2.4. Overview of Possible Suitable Thermochemical Conversion Technologies

Thermochemical conversion technology facilitates the decay of organic materials to produce three component byproducts with further energetic uses: namely, bio-oil, gaseous components, and stable fuels (such as char). The general categories for the TCC can be pyrolysis, gasification, torrefaction, and natural combustion.

Natural combustion is probably the most widespread TCC method used for waste treatment. The primary output of such a process can simply be heat. However, with this method, other by-products are rarely produced. On the other hand, another TCC method called pyrolysis, which is a deterioration of the carbonaceous substances via thermal energy in the absence of oxygen, produces three by-products with further energetic values. These products are bio-oil, syngas, and char. In another approach, a different TCC method called gasification converts the input materials to biogas typically consisting of H2, CO, methane, CO2, water vapor, N2, and different contaminants like tar vapor. The further two TCC processes are torrefaction and the hydrothermal processing of organic matter. Torrefaction is the processing of input material under a complete lack of oxygen at around (200–300) °C for 30–60 min. The main by-product of such a method is char fraction. Whereas, hydrothermal processing liquefies the organic matter by cracking down the macromolecules into more subordinate molecular mass into the aqueous phase.

2.5. Identification of Research Gap

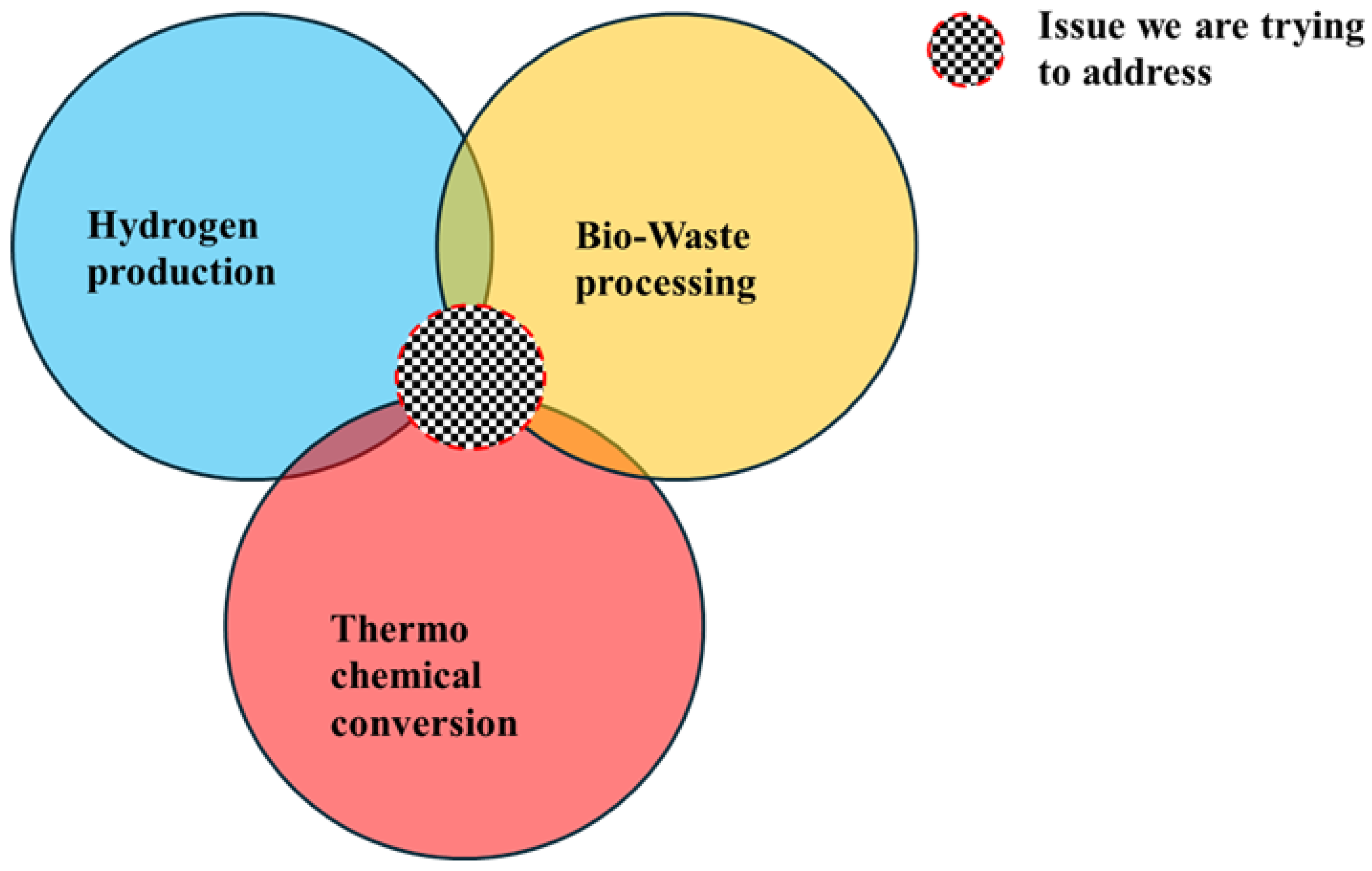

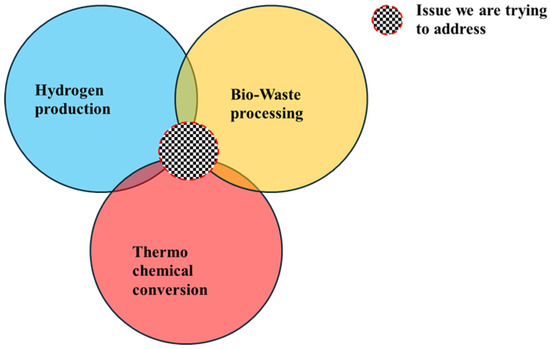

There are various research works addressing different aspects of bio-waste processing, hydrogen production as well as TCC techniques. Also, there are research works which are addressing the cross-sectorial aspects of these three themes, such as hydrogen production using TCC techniques, hydrogen production using bio-waste, and waste processing and disposal using TCC techniques. However, the research approach to address the question of bio-waste processing using a TCC-based process to generate hydrogen for the Bavarian region of Germany is missing.

Figure 3 shows the area we are trying to address through this research work: understanding the potential of hydrogen production with the overlap between the themes of hydrogen production, waste processing, and the TCC technique to process the waste, keeping the Bavaria region of Germany in focus.

Figure 3.

There are multiple research works covering various aspects related to bio-waste processing, hydrogen production and the pyrolysis technique for bio-waste processing. However, no research work encompasses all three areas for the Bavarian region of Germany.

3. Bavaria Region

Bavaria is the largest of all the federal German states in terms of area and the second largest in terms of gross regional product and population [3]. The Bavaria region is especially at an advantage with the availability of cutting-edge knowledge and the potential to fulfill a large amount of energy needs with renewable energy sources. There are already tested and proven concepts where some municipal public utilities (generally called ‘Stadtwerk’) provide 100 % renewable energy to their inhabitants. One example is Stadtwerk Munich, which has the capacity to provide 100% green electricity for its more than 1 million inhabitants and also to its internal public transit systems [3,44]. The energy policy shift can be traced back to the year 2011 when the ‘German energy policy’ was altered to gradually shift the focus from nuclear energy toward more sustainable energy sources [12,45,46]. In the perceived plan for energy security and reliable as well as sustainable energy supply for the region of Bavaria, three key ways are foreseen as options for further steps [46]:

- Spatial expansion of capacity (such as the expansion of the electrical grid);

- Temporal expansion of the capacity (employing energy storage options);

- Improved flexibility (by providing gas as well as hydrogen-based power generation options).

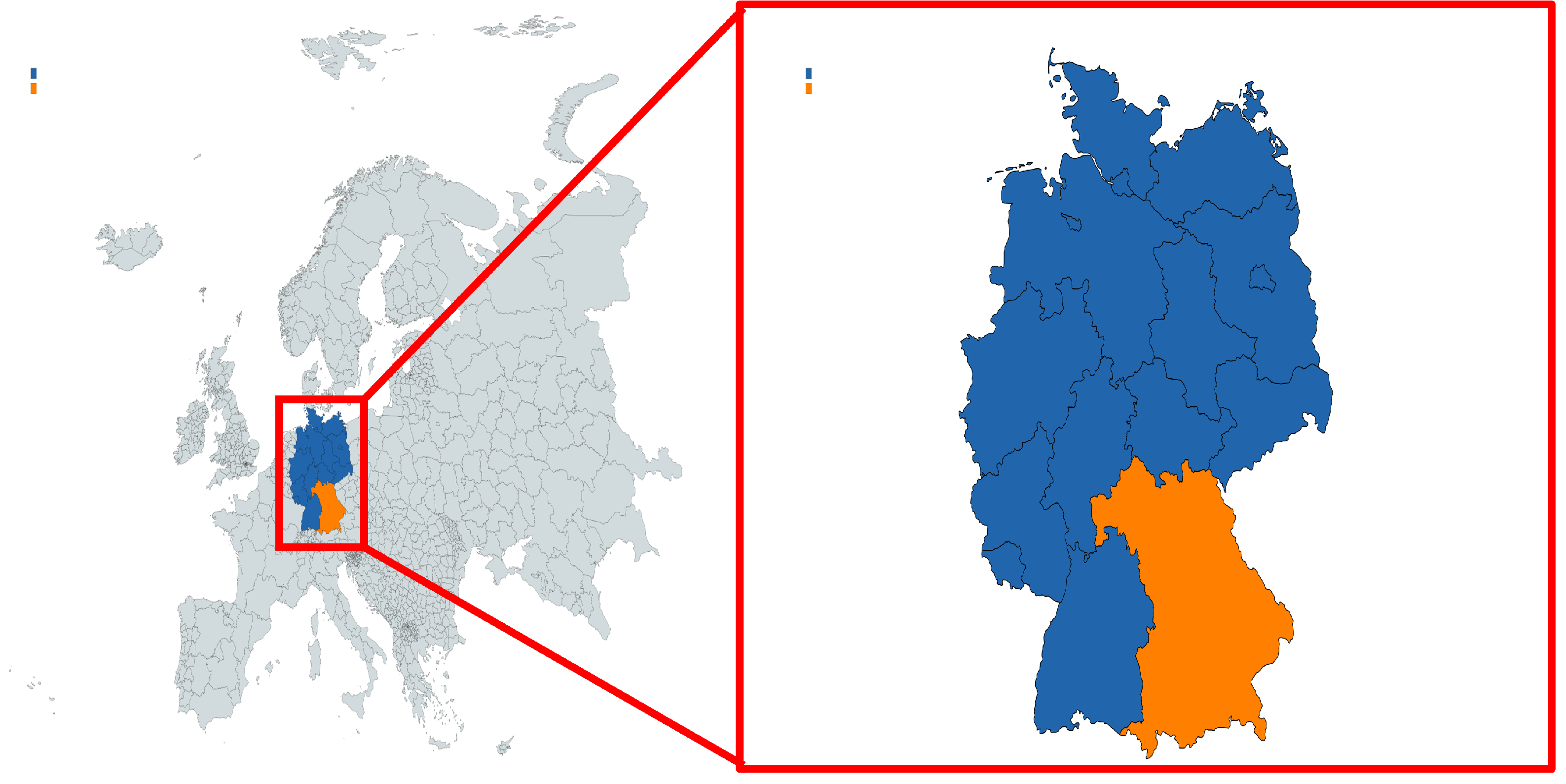

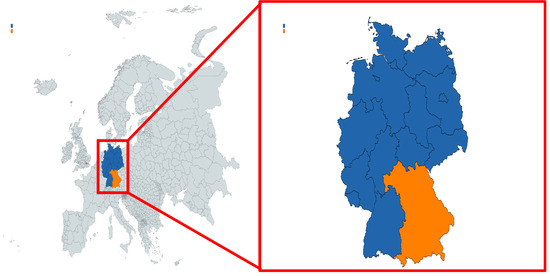

Figure 4 shows the Bavaria region of Germany, which is considered for the study. The adoption of an individual as well as a combination of the above-mentioned options is the key to the provision of a secure and safe supply of energy all the time. However, the provision of flexibility through hydrogen-based power plants provides the added advantage of distributed power generation along with the penetration of hydrogen processing as well as distribution expertise. The role of energy storage technologies will be pivotal in the future energy mix of the Bavarian region [46]. According to Goers et al., regions like Bavaria have the potential to integrate renewables with decentralized energy generation coupled with energy storage [3]. This once again highlights the importance of hydrogen, having a dual role as a fuel and as an energy storage media in case of the greater penetration of renewable energies in the mix.

Figure 4.

Location of the region under consideration: Bavaria, Germany (shown in orange).

4. Materials and Methods

4.1. Input Materials Considered

The BW considered within the scope of this paper is the organic waste from the ‘organic waste bin’ and ‘general biodegradable waste’. Such BW has a usual moisture content in the range of 35% and is the heterogeneous mixture of materials. Apart from that, there is one more category considered within the scope of this paper, and that is domestic sewage sludge (SS) in already dried form. The data are primarily acquired from the open source, public data domains such as ‘Bayerisches Landsamt für Statistik’ [47] and DBFZ databank [26,48,49]. The quantities considered here are the generated and treated fractions of the biodegradable waste by local waste processing plants in Bavaria. The SS fraction can be treated with multiple methods with three main categorizations representing the SS handling:

- Recycling;

- Thermal disposal;

- Other methods of direct disposal.

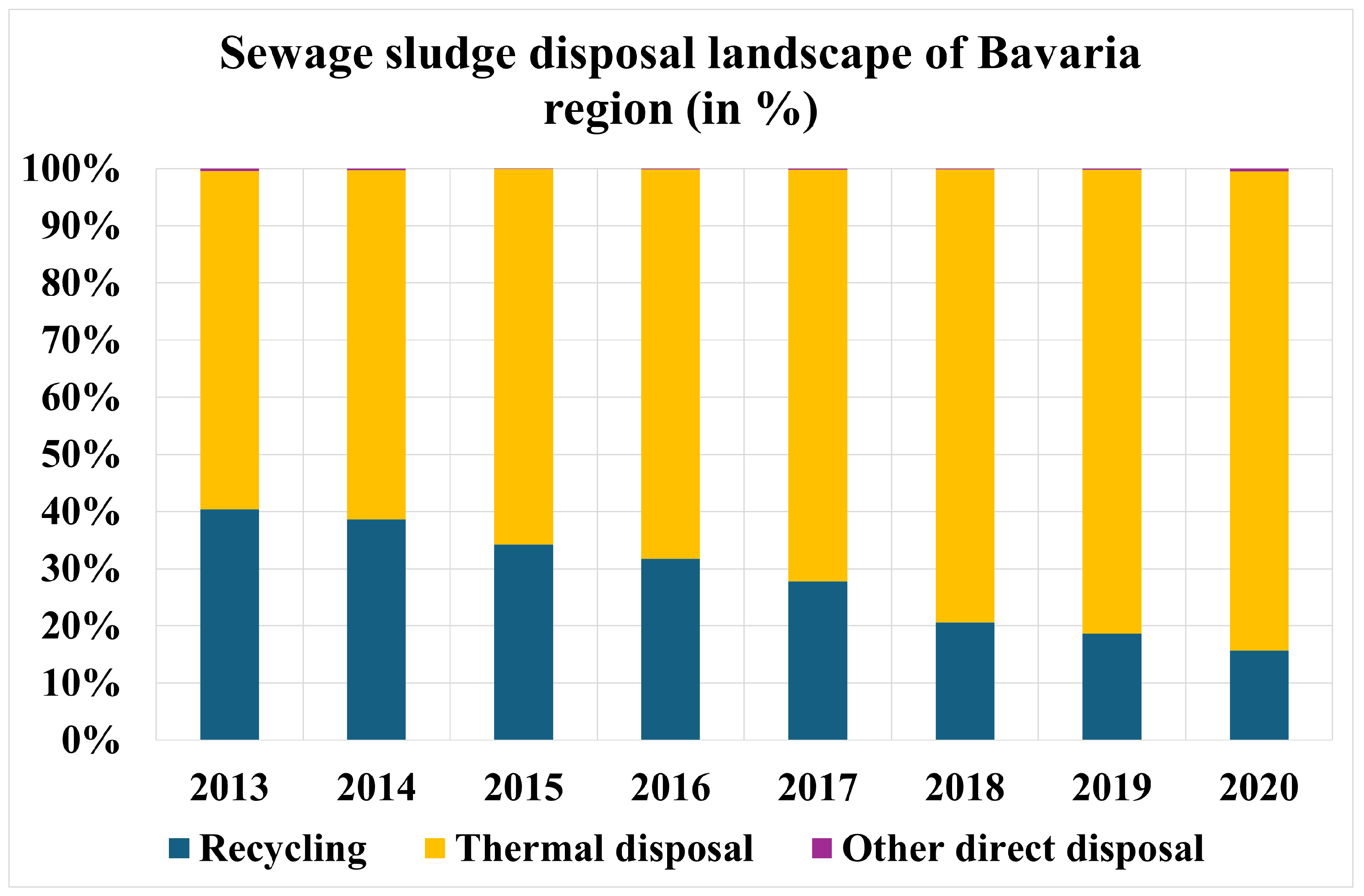

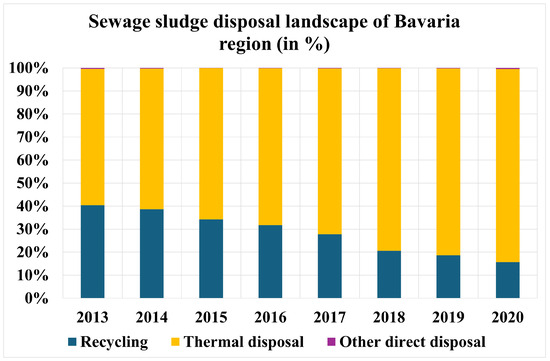

Figure 5 shows the SS treatment landscape in Bavaria over the period. It can be seen that the share of recycling of the SS is reducing over the period, whereas the share of thermal disposal of the SS has increased over the period. It means that over the period, the energy demand has to be increasing to treat the SS thermally.

Figure 5.

Various methods of sewage sludge processing for the region of Bavaria [47].

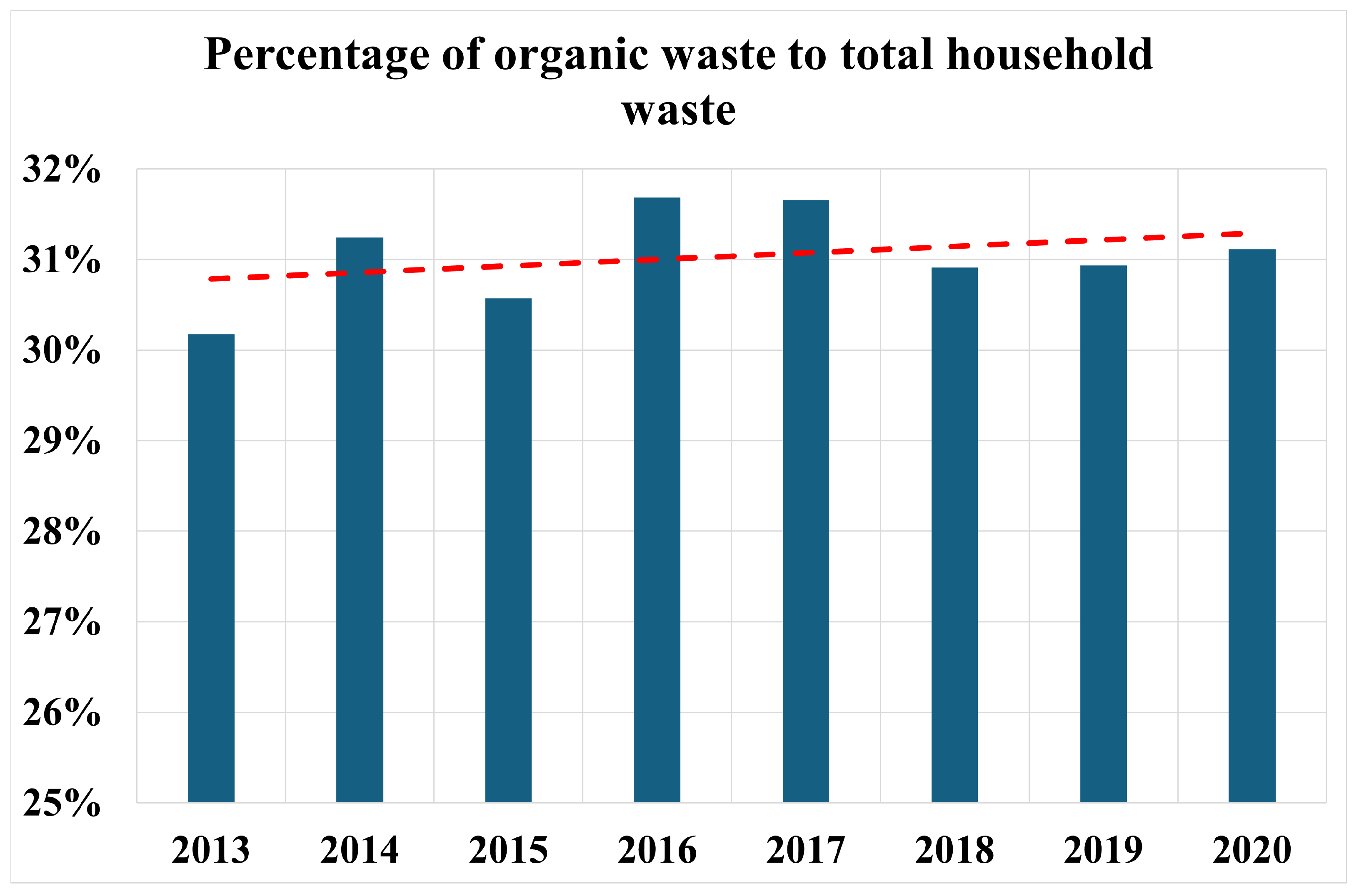

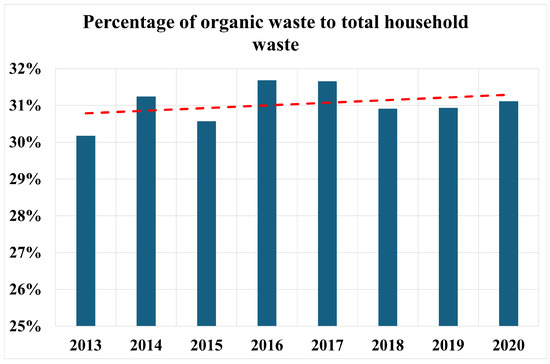

Figure 6 shows the percentage of organic biodegradable waste in the corresponding household waste for the region of Bavaria. The red dotted line shows the trend over the period. Although the trend is not aggressive, it can be safely said that there is an upward trend for organic waste generation in the overall household waste.

Figure 6.

Percentage proportion of organic waste in that of total household waste for the region of Bavaria [47].

Table 2 shows the composition comparison between BW and SS. The differences in the carbon, nitrogen, oxygen, sulfur, and ash contents result in various heating values [10,50,51].

Table 2.

Composition comparison between MSW (BW) and SS [10,50,51].

The input waste material has to be subjected to the pre-treatment stage before it has been subjected to the TCR process. These pre-treatment steps include drying, sorting, shredding, and pelletizing. For the SS fraction, primarily de-watered SS is considered which comprises roughly 50–70% of the organic matter. The primary pre-treatment steps for both types of input materials (BW and SS) included the initial screening into two size fractions: the oversized and smaller. The oversized fraction is further analyzed visually for any unwanted material. In the next step, this oversized fraction is further shredded to mix back with a smaller fraction. This step is followed by the drying step to bring the moisture of the input material up to the desired value, which is usually in the range of 15–30 wt.% The dried material is then pelletized. The size of the pallets obtained is in the range of 8 mm in diameter and around 30–35 mm in length. The final residual moisture could be somewhere in the range of 10 wt.%.

4.2. Assessing Organic Waste (Domestic BW and SS) Generation Landscape for the Bavarian Region

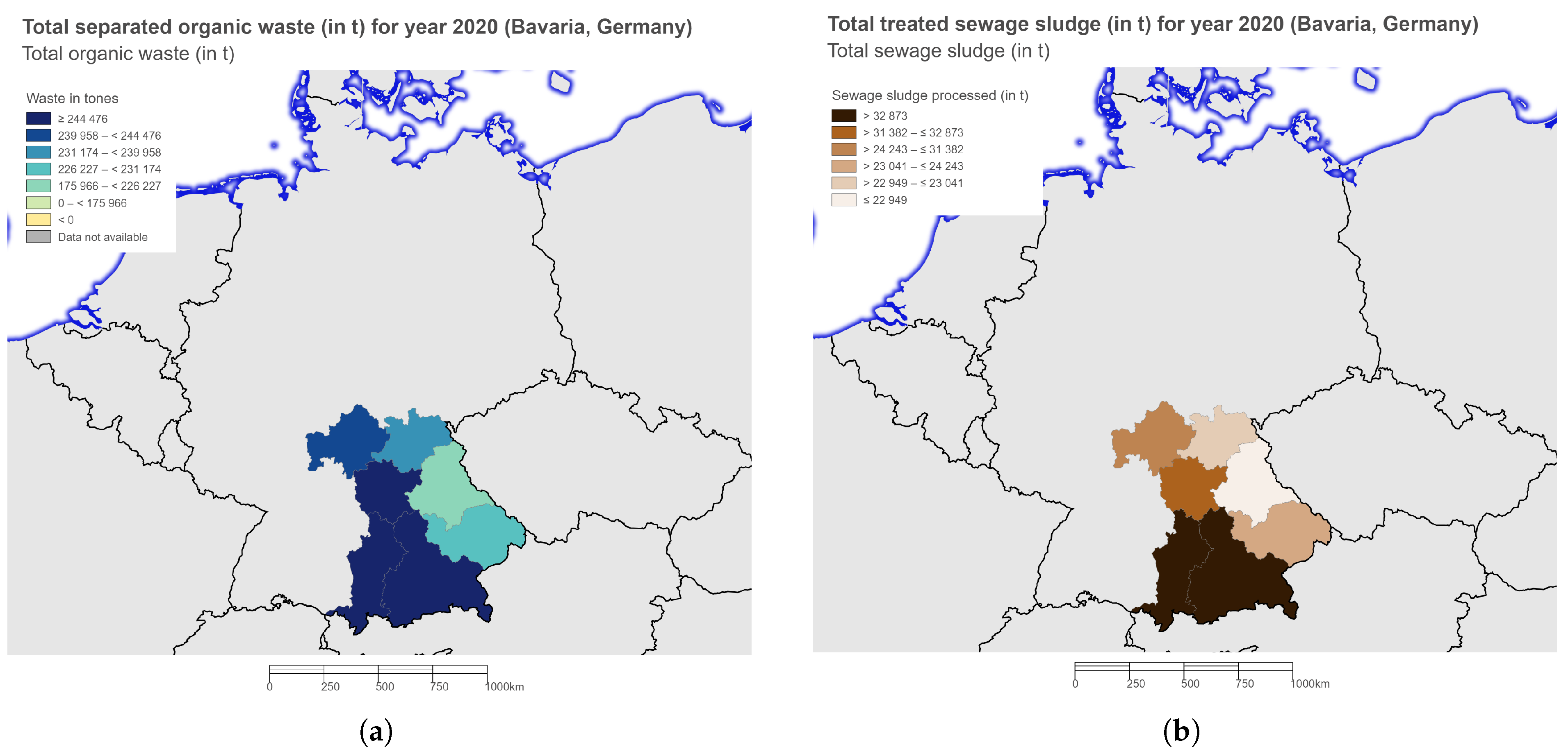

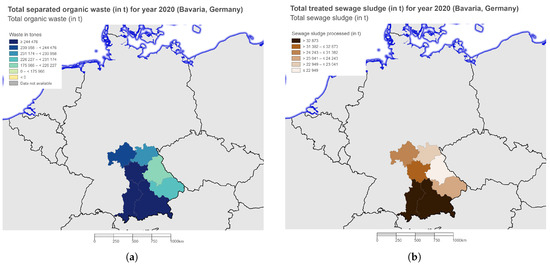

Schmidt and Singh assessed the current state of the recycling centers in Bavaria along with the effect of closing some of these recycling centers from a public access perspective [52]. Currently, there are around 14 municipally owned recycling centers that treat the BW thermally [20]. Figure 7 shows the domestic BW and SS processing potential for the Bavarian region in the year 2020 based on the NUTS-2 classification.

Figure 7.

Quantity of total separated biodegradable waste and treated sewage sludge in Bavaria region for the year 2020 [47]. (a) Total separated organic waste (in t) for the year 2020 (Bavaria, Germany). (b) Total treated sewage sludge for the year 2020 (Bavaria, Germany).

Considering the total combined potential (BW+SS) for the entire Bavarian region for the year 2020, the treatable quantity comes somewhere around 23.13 × 105 t·a−1 or 2.313 Gt·a−1 [47]. Figure 6 shows the increasing trend of BW fraction in overall household waste. The rough simple linear projection can be made on the basis of past available data, which shows an upward trend. The total tracked quantity for such domestic BW in the year 2020 for the region of Bavaria was 20.27 × 105 t·a−1 or 2.027 Gt·a−1 [47].

For TCR process-based calculations, the final average processable quantity has been determined by combining the average quantities of total organic BW fraction from domestic waste and treatable SS, which comes out to be 2.05 × 106 t·a−1 or 2.05 Gt·a−1 [47].

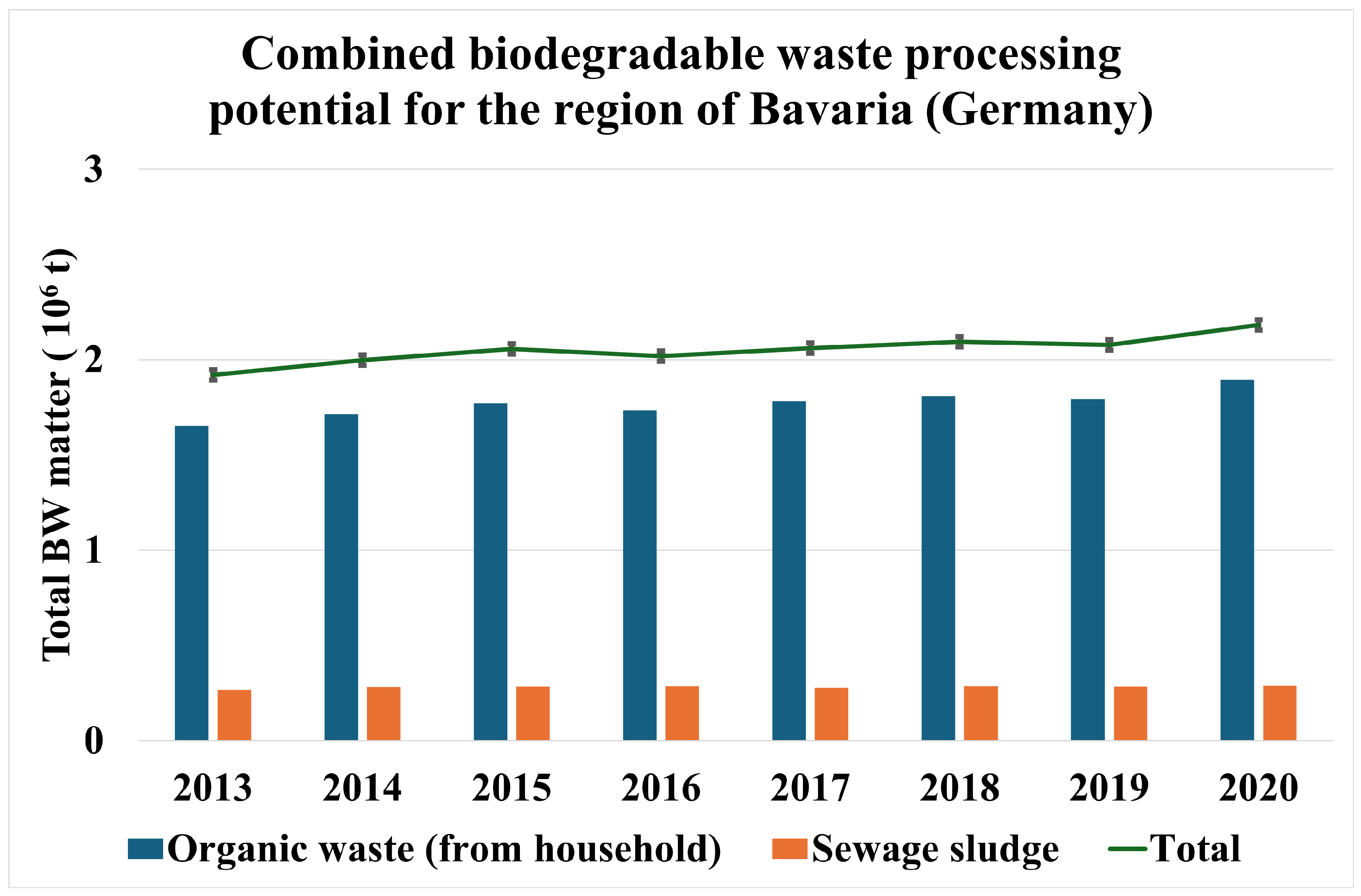

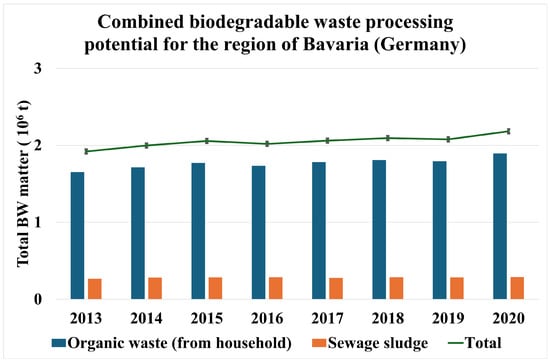

Figure 8 shows the possible combined potential of the BW and SS as an input material for SH production in the Bavaria region. The average quantity of the BW and SS produced over the years 2013 to 2020 is calculated and considered for this study as a quantity of the input material for the TCR process. Table 3 shows the individual average quantity of BW and SS as well as the combined average quantity of both. These figures are taken as a basis for further calculations.

Figure 8.

Waste processing potential for the organic waste and sewage sludge for the region of Bavaria (Germany).

Table 3.

Total average organic household waste (BW) and average sewage sludge (SS) production in the region of Bavaria (Germany) for the period of 2013 to 2020 [47]. Values are in 1000 t.

4.3. Accessing TCR Potential for SH Production

The various thermochemical conversion technologies depicted in Section 2.4 can be taken as a basis for evaluating the SH production potential via waste processing. One such example can be the novel TCR technology developed at Fraunhofer UMSICHT. The TCR reactor combines the intermediate pyrolysis with an additional catalytic reforming of the products of the pyrolysis [50]. It has two stages with the capability to process input materials using the pyrolysis technique while bio-oil, bio-char, and syngas are produced as by-products of the process [53]. The pyrolysis process operating temperature is in the range of 300–800 °C [54,55]. The intermediate pyrolysis step which occurs at around 400–500 °C is the first step followed by the relatively high-temperature post-reforming process happening between 500 and 700 °C [53]. This higher post-reforming temperature forms a higher yield of syngas, which is condensed further to receive around a 27–44 % gas fraction from it [53]. At maximum, 55 vol.% is the hydrogen from this syngas fraction [53].

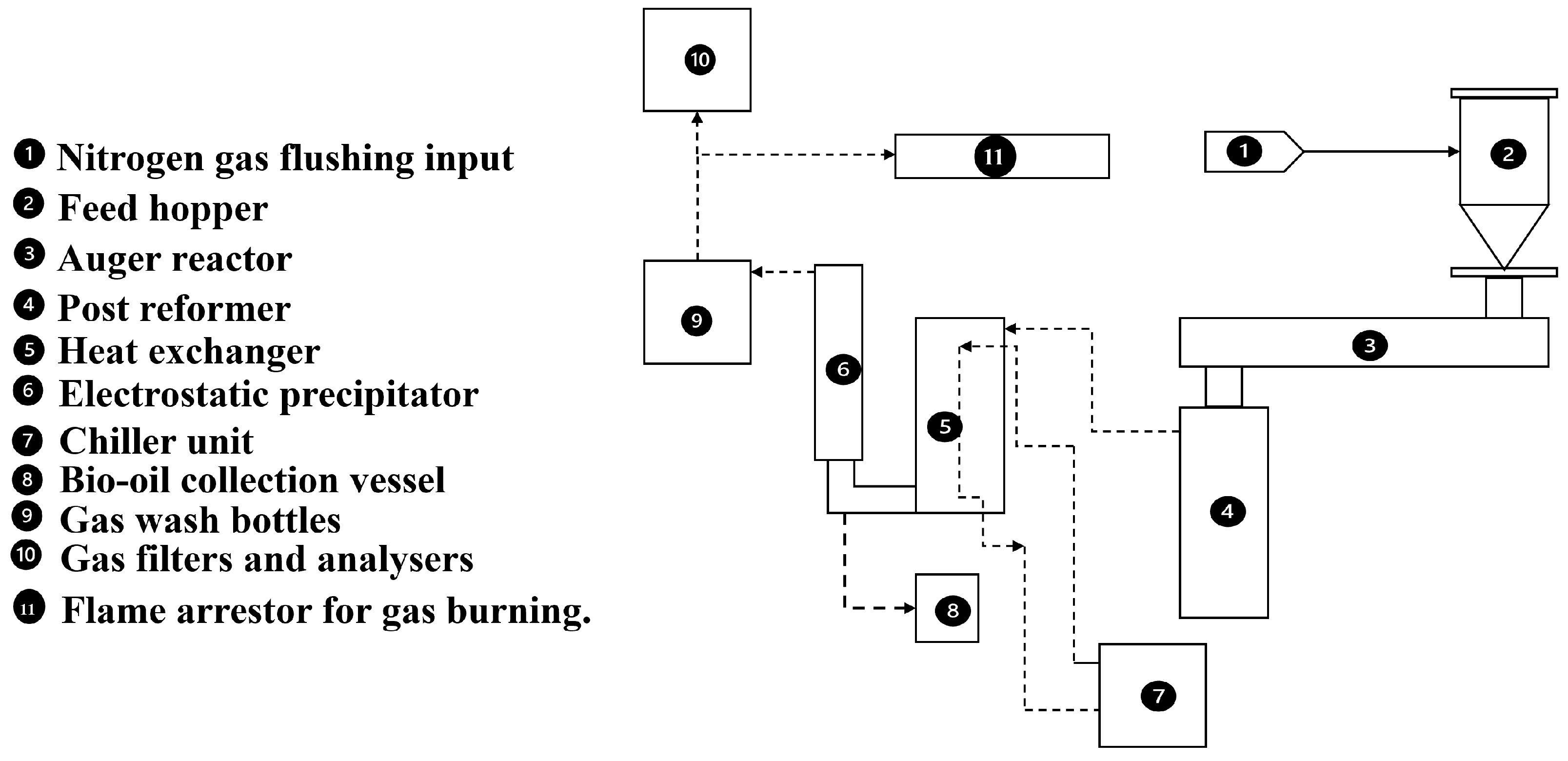

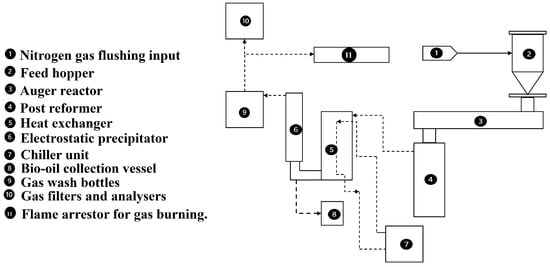

Figure 9 shows the process flow of the syngas and corresponding components of the experimental TCR-2 reactor installed at the Fraunhofer UMSICHT (Sulzbach-Rosenberg, Bavaria, Germany). The experimental TCR-2 reactor is the complete system comprising the sealed hopper, having a holding capacity of 5 kg for input material, followed by the auger reactor having a throughput capacity of 2 kg per hour.

Figure 9.

Process flow for syngas and corresponding components of the experimental TCR-2 reactor installed at Fraunhofer UMSICHT.

The complete system is purged with nitrogen to flush out oxygen from the system. The input material is conveyed through the reactor by means of the auger screw. In the second step, the input material enters the post-reforming stage. In this post-reforming stage, pyrolysis vapors are converted into hydrogen-rich synthesis gas. This produced gas is a mixture of hydrogen-rich components and condensable organic vapor fraction with improved fuel physical and chemical properties. This particular step is achieved by the reforming reactions between the char and condensable organic vapors. In the final stage of the processing of these gases further, the quenching step is followed. This quenched gas is then passed through two gas wash bottles and a filter system to protect the downstream gas analyzer unit. The synthesis gas is then passed through the gas totalizer meter and online gas analyzer unit as well as the calorimeter.

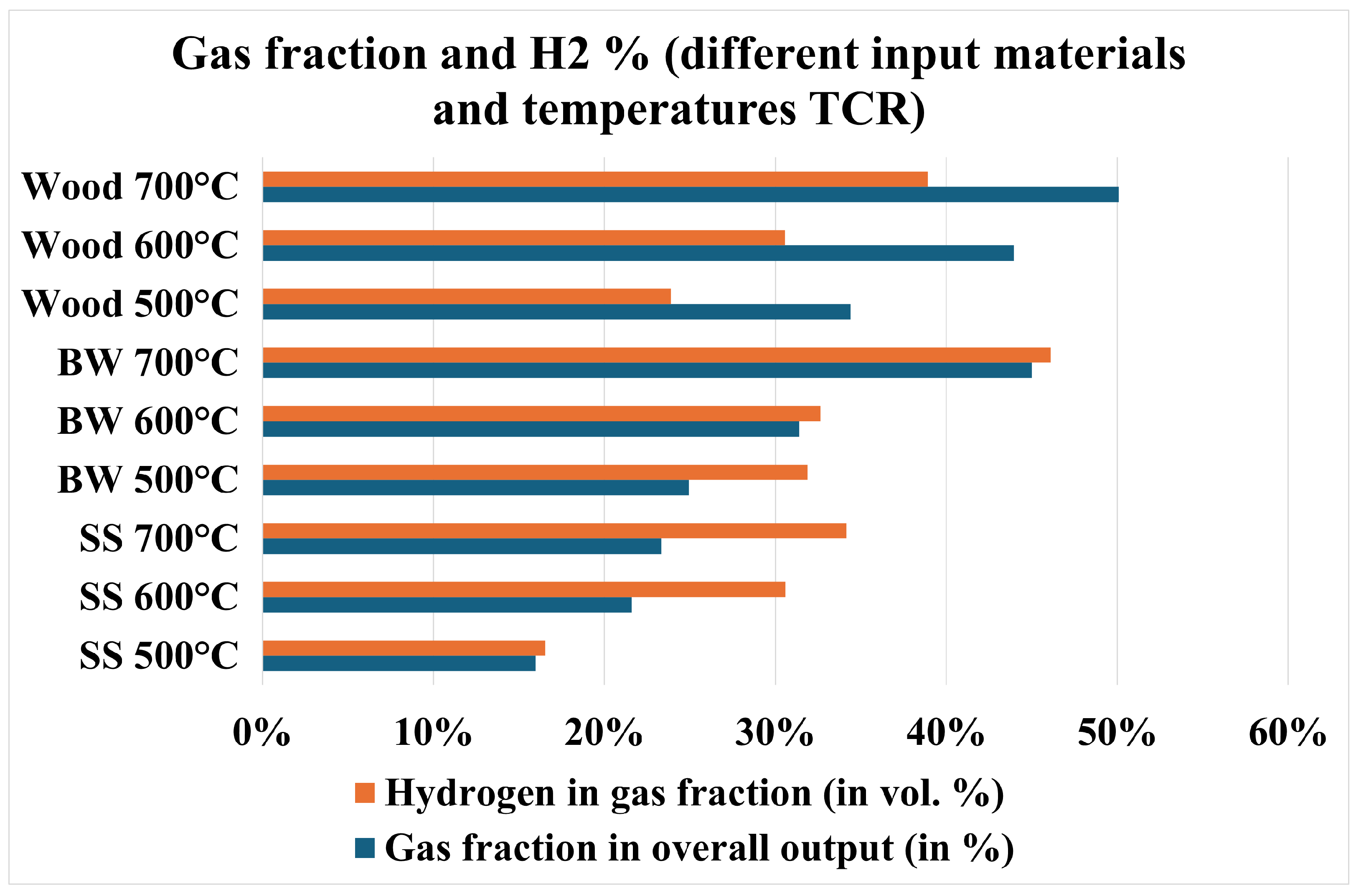

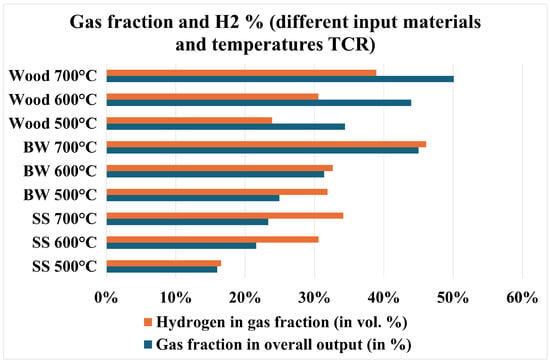

The gas fraction from the TCR process can be used as a fuel for the combined heat and power units (CHPs) [53]. However, the high hydrogen percentages in the syngas mean this hydrogen fraction can be separated and purified further to use for specific applications. Based on the required purity by further applications, the produced syngas can be treated subsequently down the line. Applications requiring minimal purity of hydrogen can utilize the hydrogen fraction of the TCR gas phase with minimum extra processing. In the traditional view, the high amount of SH produced in the TCR process is envisioned to be utilized for the hydrotreatment of the TCR-produced bio-oil or even conventional fossil fuels [53]. It has been identified that the post-reforming stage is essential for improving product quality [50,56]. As the post-reforming temperature increases, the gas yield increases from 27 wt% (at 500 °C) to 44 wt% (at 700 °C) [50]. The separation of gases is achieved using the quenching at around 273 K [50]. Approximately 41.5% of energy in the feedstock is transferred to the syngas generated during the TCR process-based treatment of BW [10]. Figure 10 shows the comparison between gas production potential and the corresponding H2 production potential of SS and BW at different post-reformer temperatures. Traditional wood (biomass) has also been shown just for comparison.

Figure 10.

Comparison between gas fraction in the output of TCR and corresponding H2% in it for different input materials and post-reformer temperatures.

The generated gas fraction during the execution of the process is measured at different locations using the gas flow meters which state the volume of gas produced in m3. During normal operation of the TCR equipment, continuous nitrogen flushing has been performed to achieve an oxygen-deprived atmosphere throughout the test run. The overall H2 gas produced in relation to the amount of input material can be calculated as follows:

where V is the total volume of the products (syngas, oil, and char) and , and represent the individual volume of gas, oil and char, respectively. All the volumes are represented in %. The gas volume can further be divided into two components:

- H2 fraction in volume percentage;

- Other gases in volume percentage.

Equation (2) denotes both fractions, where ‘x1’ is the measured H2 value in percentages and ‘x2’ is the total nitrogen flushed through TCR over the complete cycle measured in liters, whereas ‘x’ is the total gas produced over the complete cycle measured in liters.

4.4. Scenario Creation

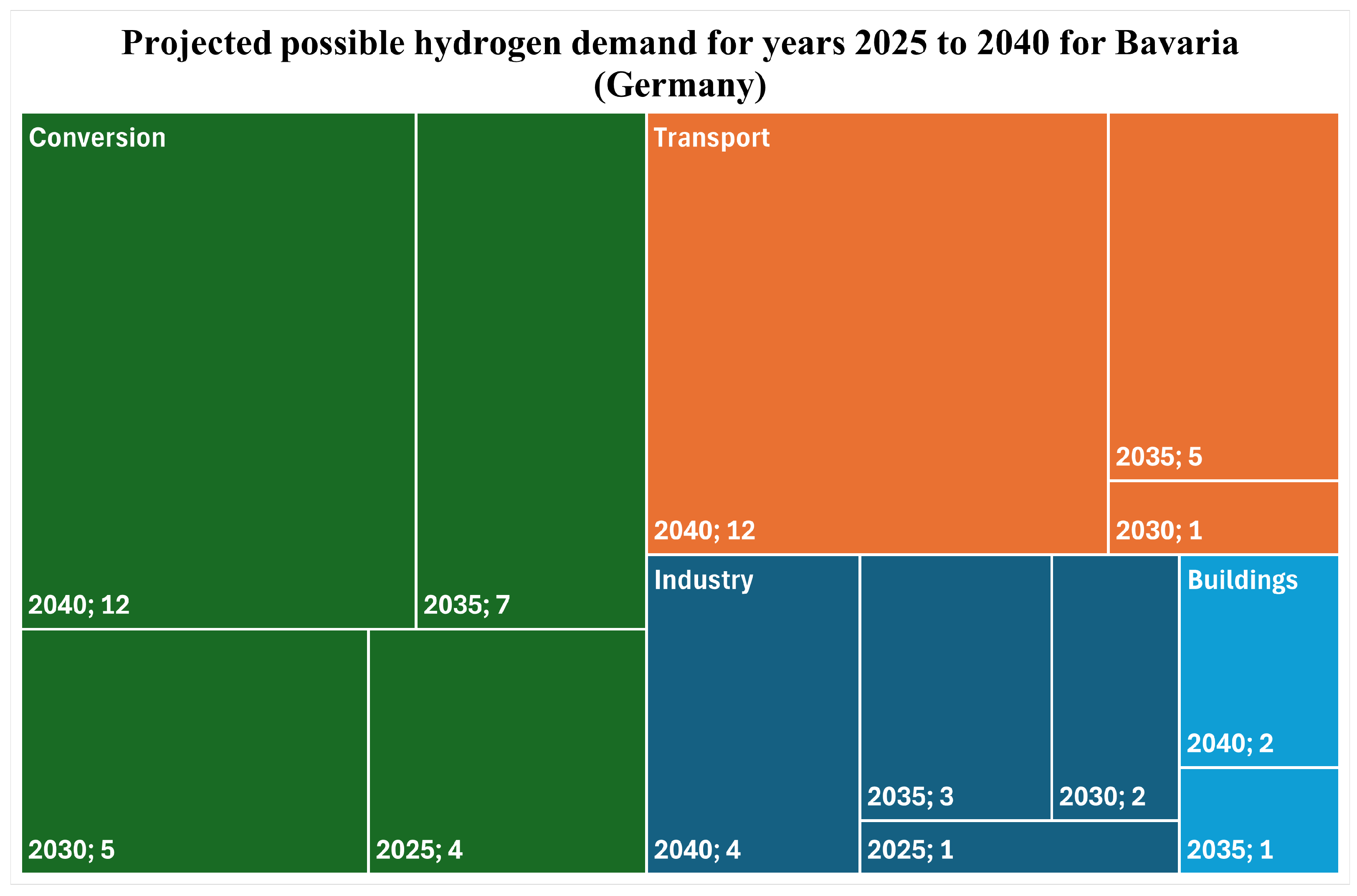

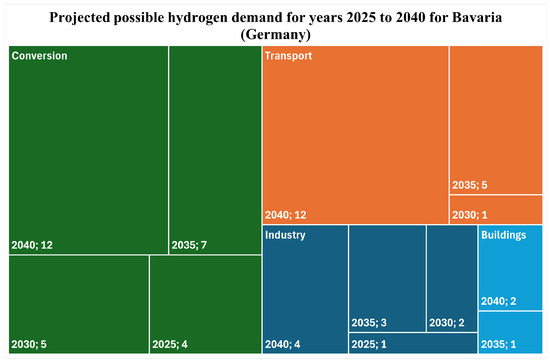

The future demand for hydrogen can roughly be categorized into four different categories based on the area of operations or application as well as use: namely, industry, transportation, conversion, and buildings [42]. The application and use of hydrogen in each of these sectors vary; for example, in the transportation sector, the SH will be primarily used as a fuel, whereas in the industry, it can be used either as a feedstock or as a fuel. Based on these considerations, hydrogen demand projections are taken from the year 2025 to 2040 in five-year successions. Figure 11 shows the projected hydrogen demand and its corresponding share in the overall demand mix. To understand the SH generation potential, the following steps were considered.

Figure 11.

Treemap showing future hydrogen demand for the Bavarian region of Germany with years followed by the corresponding hydrogen demand in TWh (values rounded off) [42].

In the first step, the SH generation capacity via TCR is calculated. To obtain an idea about pessimistic (or baseline) and optimistic gas generation potential via the TCR process, two post-reforming temperatures were considered. The lower temperature post-reforming process (at 500 °C) produces only 27 wt.% syngas fraction. This scenario is considered a baseline scenario, whereas the relatively higher post-reforming temperature process (at 700 °C) produces around 44 wt.% syngas fraction. This scenario is considered an optimistic scenario. In both cases, a maximum hydrogen fraction of 55 wt.% has been considered:

- Baseline (27% gas output from TCR process with 55% H2 fraction in it);

- Optimistic (44% gas output from TCR process with 55% H2 fraction in it).

In the next step, based on these two assumptions, the hydrogen generation potential was estimated. For this, three different combinations of input materials were considered per scenario, which gave rise to the following six possibilities:

- BW only (Baseline);

- SS only (Baseline);

- BW+SS (Baseline);

- BW only (Optimistic);

- SS only (Optimistic);

- BW+SS (Optimistic).

In the third step, open source publicly available data have been used for hydrogen demand projection. These figures gave projections for hydrogen demand across Germany for various time stamps. Different sectors were considered with their corresponding hydrogen demand. The required amount of SH has been calculated in terms of Mt·H2 based on the following two conversion assumptions [57]:

- 1 kg of H2 = 33.3 kWh equivalent of H2;

- 1 TWh equivalent H2 = 30.030 × 103 Mt of H2.

In the final step, the percentage coverage of the regional hydrogen demand with corresponding SH production via TCR technology was estimated for each sector and for a particular year. This gave us a foundation for the comparison and analysis of the suitable sectors and corresponding years of application.

5. Results

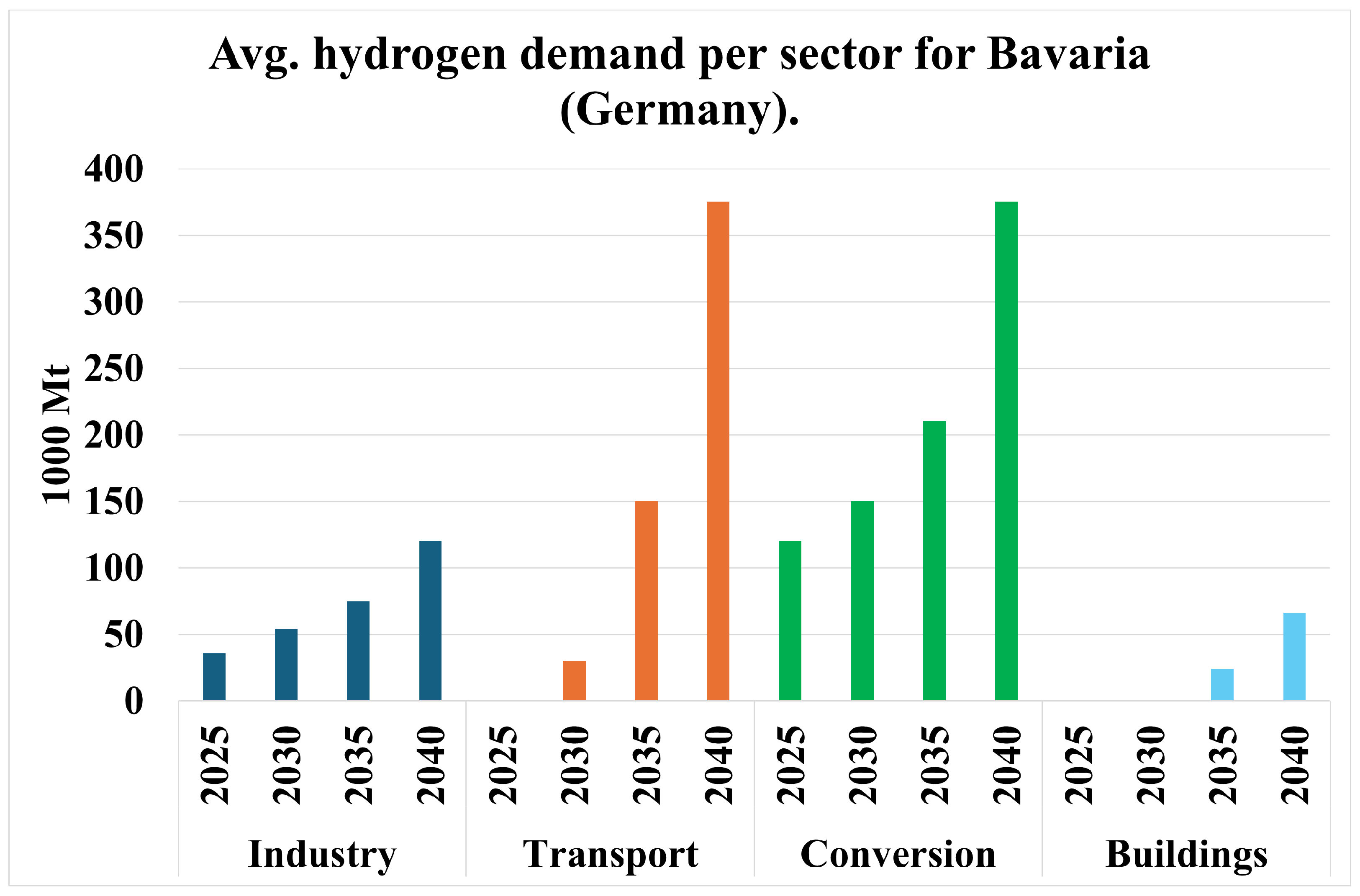

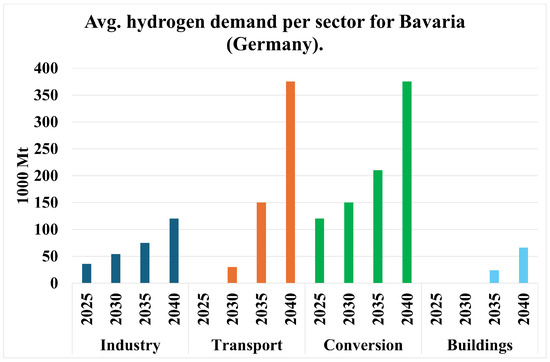

Figure 12 shows the projected hydrogen demand for Bavaria region in Mt. In particular, the transport and conversion sectors will have an increasing demand for hydrogen in the near as well as distant future. The transportation sector will have a hydrogen demand mainly in the form of primary fuel option [42].

Figure 12.

Projected hydrogen demand for the region of Bavaria (Mt) [42].

Whereas in the case of the conversion sector, the hydrogen will most probably be used as a feedstock for secondary processes [34,37,42]. A similar application can be envisioned for the industry sector, but buildings or more specifically residential as well as commercial buildings will use hydrogen as a space heating media [42]. However, the application of hydrogen as a direct heating media will not be as widespread as other available space heating options [34,37,58].

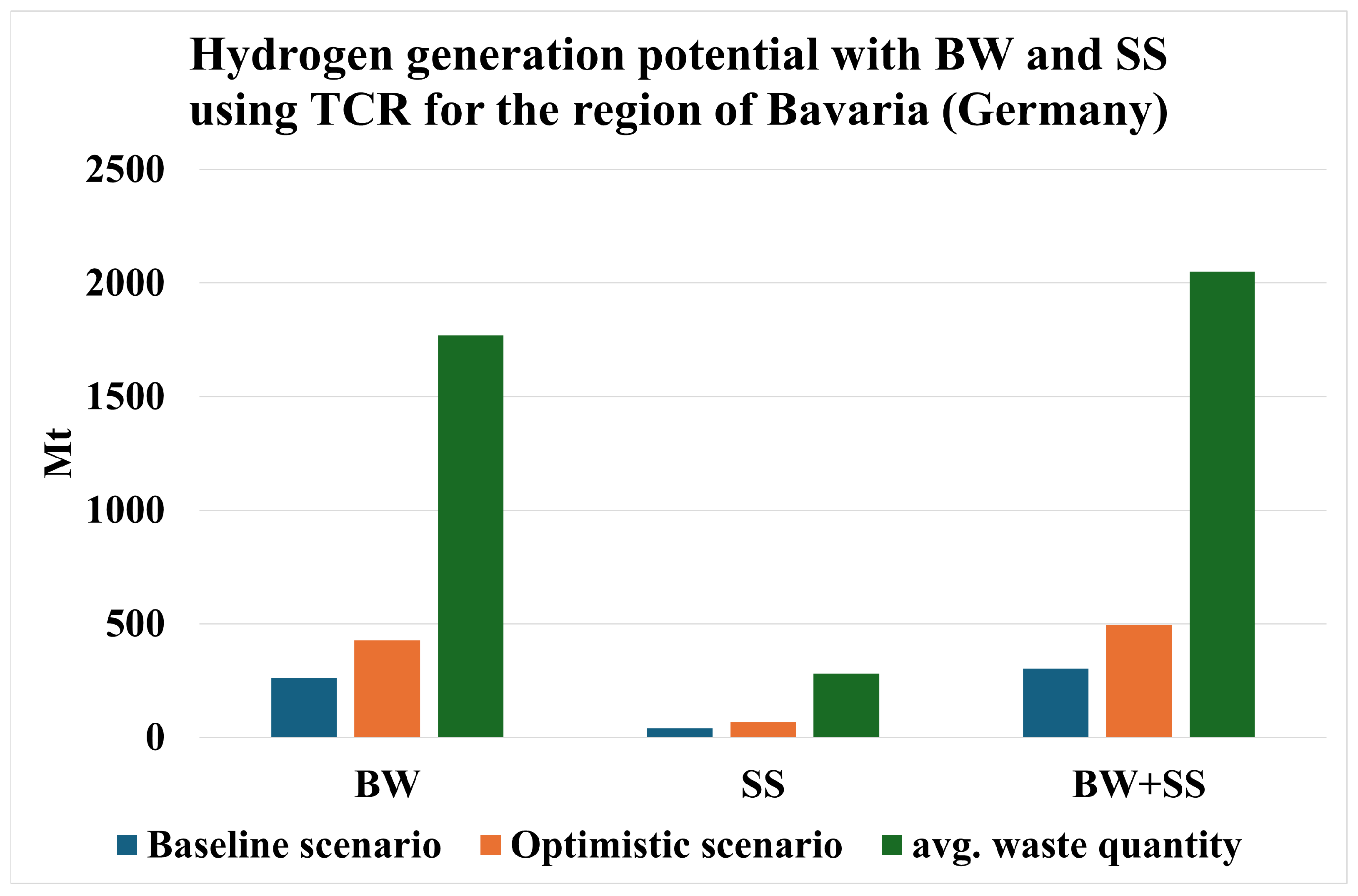

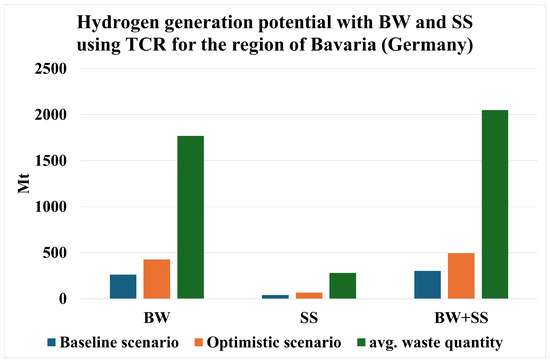

Figure 13 shows the average waste quantity as well as the possible SH generation potential based on baseline and optimistic scenarios explained in Section 4.4. The domestic SH production capacity purely based on BW and SS processing coupled with TCC technologies such as TCR is limited compared to projected demand.

Figure 13.

SH generation potential based on the available waste quantity and the TCR technology for the region of Bavaria (Germany).

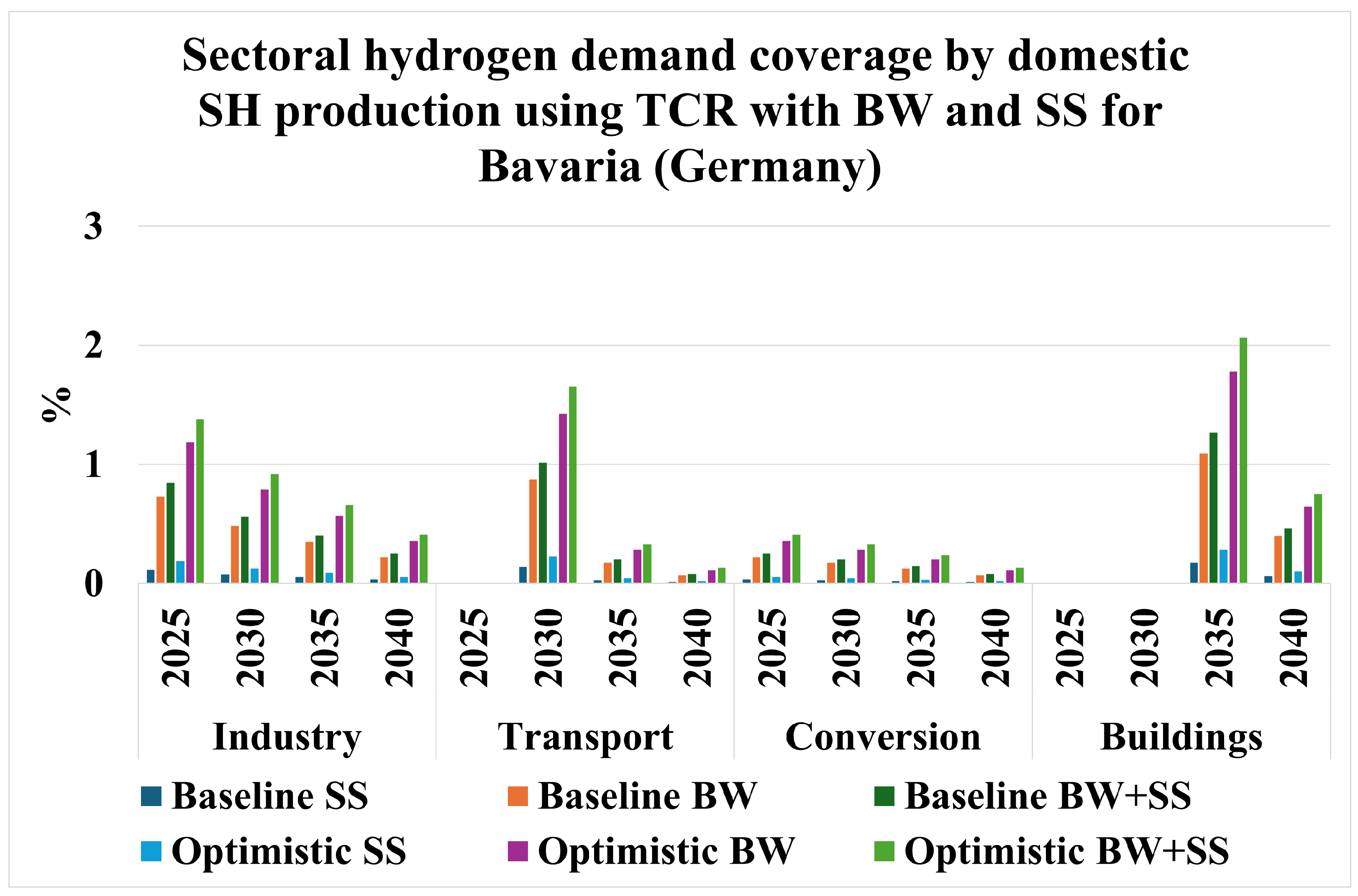

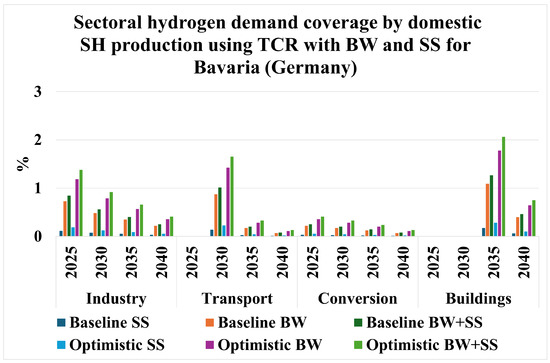

Figure 14 shows in % values roughly how much total projected hydrogen demand can be covered with domestic SH production using BW and SS processing with TCR technology. The possible coverage is relatively limited compared to other hydrogen generation options such as conventional production methods.

Figure 14.

The domestic SH production for the region of Bavaria (Germany) in relation to demand coverage based only on BW and SS processing with thermochemical conversion technologies such as TCR.

However, it is worth noting that for particular sectors and in particular time frames, the SH generation potential covers a significant portion of the demand. If the application of such produced SH is considered exclusively for each sector, a general overall idea can be formed regarding the best possible application of SH production through BW and SS processing and TCC technologies. The following sections consider complete SH generation potential under each scenario for each sector separately and without any inter-dependency with another sector.

5.1. Industry

The combined BW and SS as input materials for the process provide a good considerable option for demand coverage throughout the time period with 0.85% (baseline) and 1.38% (optimistic) in the year 2025 to 0.25% (baseline) and 0.41% (optimistic) in the year 2040. The coverage potential reduces gradually over the period. In the case of the industry sector, SH production provides a consistent demand coverage option. Only BW as an input material is the second-best option in case of demand coverage.

5.2. Transportation

If the BW and SS combined potentials are considered, then both baseline, as well as optimistic scenarios, prove favorable in the short time span (i.e., until the year 2030) in contributing to the SH demand for the transportation sector. It provides somewhere around 1.01% (baseline) and 1.65% (optimistic) of the demand coverage for the year 2030. If the conventional internal combustion (IC) engines upgraded for accommodating lower purity hydrogen fuels are considered, then such a scenario provides a potential option for the fast transition toward more sustainable mobility options. However, after the year 2030, the capacity to contribute significantly to fulfilling hydrogen demand for the transportation sector will reduce due to near-exponential growth in the demand landscape. Considering only BW as an input material is the second-best option for covering demand in this regard with values of 0.87% (baseline) and 1.43% (optimistic) scenario. However, only SS as an input material provides a very low demand coverage capacity.

5.3. Conversion

The production of SH via BW and SS processing through TCR technology is not a significant option, as in the case of the conversion sector, the demand coverage is extremely limited. It might prove beneficial to look for other options for SH productions which might provide greater flexibility for the industries looking for the conversion applications of the SH. In this way, the greater penetration of the GE can be ensured.

5.4. Buildings

Space heating applications are the area where SH production using TCC technologies proves to be of significant benefit in all of the sectors considered here. Here as well, both baseline and optimistic scenarios with BW and SS together as input materials are the best options for the demand coverage especially for the year 2035 with contribution going into the range of 2%. This again can prove as a bridging strategy for a fast transition to sustainable space heating. The decentralized SH production nature proves to be another advantage here, as small community-scale SH production units can be installed to cater to the domestic demands in the community pockets.

6. Discussion

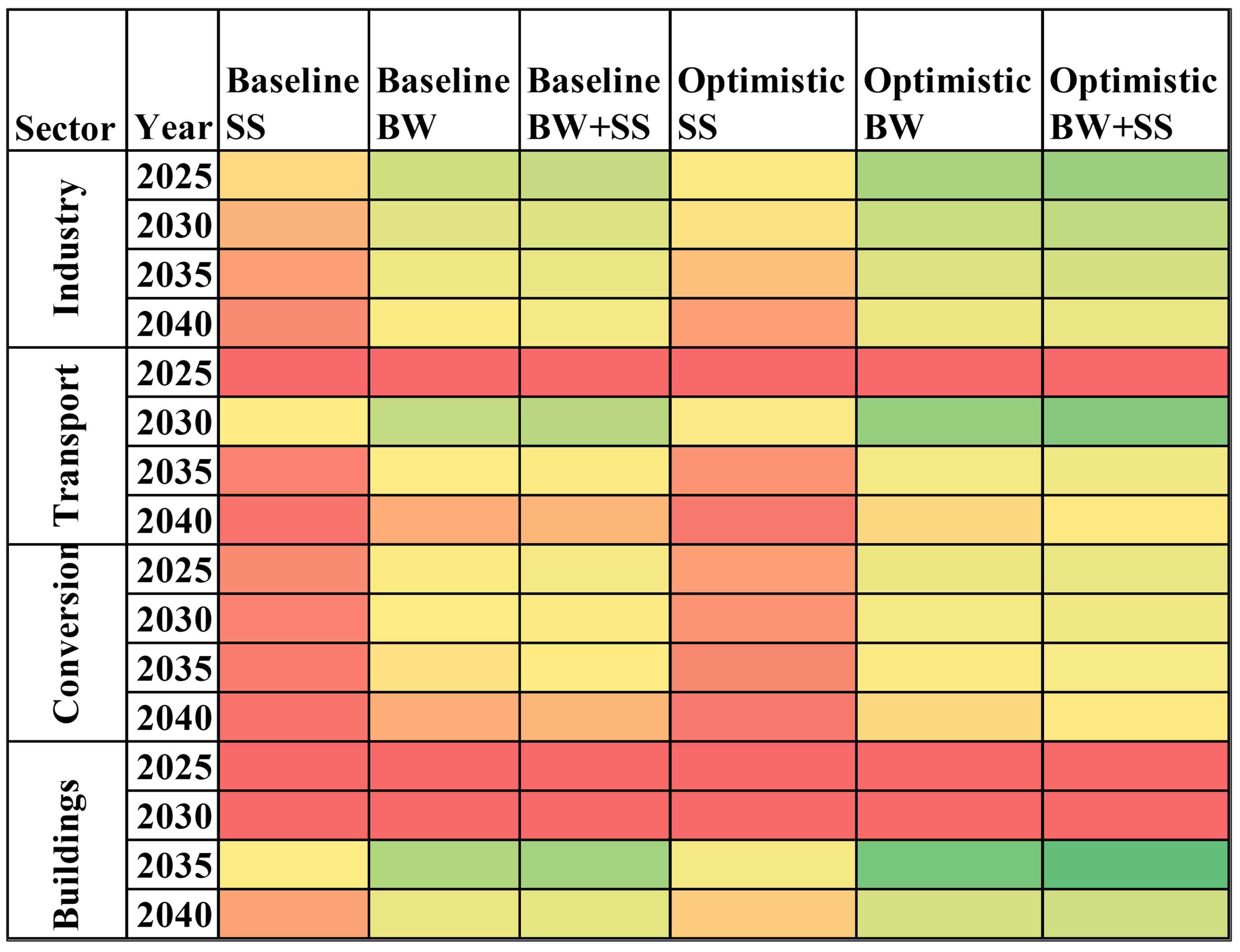

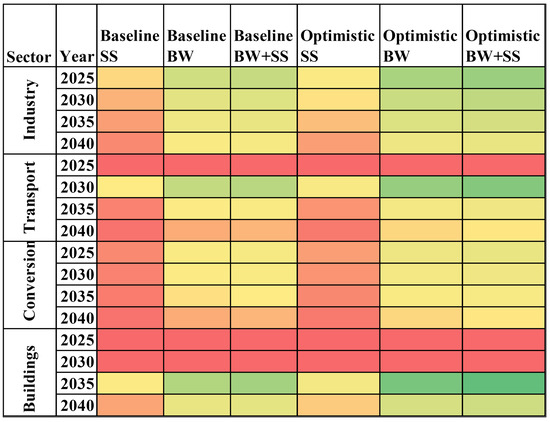

Figure 15 shows the application compatibility heatmap representation. As explained in Section 4.4, three main cases have been considered with BW, SS, and BW+SS as input materials. Further considerations have been given to the gas production scenarios based on the percentage of gas fraction as a by-product of the process.

Figure 15.

A general heatmap representation showing the most suitable application of SH production with that of the corresponding sector based on the assumptions in this study (the color green being the most favorable and red being less suitable).

For calculation of the compatibility heatmap matrix, first, the average quantity of BW and SS has been considered over the period (from 2013 to 2020). In the next step, based on the baseline and optimistic scenario, the gas fraction component has been calculated. This is followed by the actual calculation of hydrogen fraction in the gas component, which gives us the possible hydrogen generation potential in Mt. This hydrogen generation potential is then compared with the demand landscape. The percent of the total demand per sector (exclusively and independent of other sector consideration) for a particular year has been calculated, and the corresponding sectors have been color-coded based on the obtained values. The values below the 50th percentile have been represented in warm colors, and values above 50th percentile have been represented in cool colors. The warmer the shade, the lower the compatibility of such SH production for that particular sector and for a particular year. On the other hand, better compatibility is shown by the cooler shades.

In general, the matrix can be discussed based on two interdependent approaches:

- Based on input materials and scenarios;

- Based on sectors and years under consideration.

While looking at the input materials and scenarios, in particular, baseline as well as optimistic scenarios with only SS as an input material are the least promising options for the production of SH. The BW and BW+SS as input materials for both baseline and optimistic scenarios are the most compatible options.

If we look across the sectors, then in the short term (for years 2025 and 2030), the use of TCC-based SH production for space-heating applications in buildings is the least favorable application area. However, in the mid-term time span, it is most favorable. This might be due to the improvement in efficiencies and corresponding changes in the demand for hydrogen for buildings. It shows an opportunity window where a greater penetration of such methods for SH production is envisioned. The transportation sector shows a similar pattern here; somewhere around the year 2030, the use case becomes favorable. However, on the other hand, industries prove to be favorable for nearly the entire temporal scale assumed under this study.

In the future, such systems can be installed at multiple sites where the waste processing and landfill activities are traditionally taking place. Such systems provide added advantages of waste processing and sustainable hydrogen production. There can be added benefits of site-specific waste processing as well. Such units can be used at multiple locations in different time scales to avoid the use of landfills at overcapacity and in turn address other problems down the line such as leakages and methane emissions from the landfills.

Cost Landscape

The costs for the installation, operation, and maintenance of such plants depend on various factors. The installation location, quantity of input materials, and plant operation capacity are some of the factors influencing the costs associated with plant installation and operation. These costs influence the corresponding hydrogen production costs further down the line. Estimating precise costs for sustainable hydrogen generation with bio-waste in Bavaria requires further analysis and a separate study. However, considerations can be made on the basis of comparable input material and processing with the TCR process. If a TCR processing plant with around 500 kg/h of throughput is considered, such a plant has a CAPEX of somewhere in the range of EUR 4.7 million, and other operating costs are in the range of EUR 363,000 per year. If such a plant configuration is operated with comparable input material (for example Bagasse), then under the best operating conditions and most optimistic scenario, the sustainable hydrogen generation costs should fall in the range of 6–7 EUR/kg of H2 generated. However, it should be noted that even higher operating capacity plants can also be constructed. With such higher processing capacity plants, there is an opportunity to further reduce the costs of sustainable hydrogen production.

7. Conclusions

It is clearly evident that in the near future, hydrogen will play a pivotal role in the sustainable transition of nearly all the sectors. In the coming future, it is necessary to identify the complementary mechanism for electrification which will act in accordance and will also provide the flexibility the current gas grid provides. Hydrogen will play a dual role of energy carrier and energy reserve. The current geopolitical and energy market situations underline the need to address future energy security while keeping the sustainable transition goal relevant. Thermochemical conversion technology, especially thermocatalytic reforming technology, has long been used for bio-oil production from various feedstocks, including waste materials. Under this work, an approach was given to understand its potential as a decentralized hydrogen production unit for the region of Bavaria while addressing the biodegradable waste processing issue through the TCR process. Around 41.5% of energy from the input material is transferred to the syngas produced during the TCR process-based treatment of BW. At maximum, 55% of this syngas is hydrogen. Various sectors at different timestamps were analyzed for the compatibility of the SH produced in this way.

It has been identified that processing only SS as an input material for SH production through the TCR process is not a viable option. In this case, the identification of other ways to process the SS will be advisable. The SS fraction under consideration has a limited to less significant impact on SH production. TCR processes can possibly be seen as a more sustainable way to process SS in this regard; however, it is not a suitable method for SH production. Such a method of SH production can be beneficial for the transportation sector in a mid-term time frame (somewhere around the year 2030), where it can be used as an opportunity for the transportation sector to transition toward more sustainable fuel options. If the conventional IC engines are retrofitted to accommodate the lower purity hydrogen as a fuel, then relatively fast deployment and transition are possible. In all the sectors considered in this study, industries benefit consistently over the period. The main use case for SH here is envisioned as a catalyst or as an additive. Two sectors, transportation and buildings in particular, are at benefit in the short to intermediate time frame with around 1.5% and 1.9% of the corresponding sector demand coverage. On the other hand, the conversion sector is the least favorable application area, whereas buildings (in the mid-term, somewhere around the year 2035) are the most favorable.

The decentralized, modular, and scalable nature of the TCR technology provides means of bio-waste processing. Through that, the production of sustainable hydrogen along with two more commercially valuable products—namely, oil and char—is indeed possible, bridging technology that can provide the needed flexibility in current as well as in future scenarios toward sustainable transition.

8. Future Work

The approach can be taken one step further by continuing the work on multiple levels. In the future, it is possible to try different waste materials as input to test the waste processing potential and corresponding SH production potential. In a parallel approach, the hydrogen yields can be improved with additional reactions such as water-gas-shift reactions. A case study with a small community-based application of a pilot plant can also be tested as a proof of concept to understand the actual implementation challenges and market acceptability of the concept. In addition, downstream treatment of process water can also be envisioned, which will assist the process for even greater SH production. A detailed life cycle analysis will shed more light on the overall impact of this process on the environment as well as on possible cost implications.

Funding

This research received no external funding.

Data Availability Statement

Open source data have been used for this study. The data have been taken from public data sets such as ‘Bayerisches Landsamt für Statistik’, DBFZ databank.

Acknowledgments

The author would like to express gratitude to the Fraunhofer Institute for Environmental, Safety, and Energy Technology for their support during this work.

Conflicts of Interest

The author declares that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- IEA. World Energy Outlook; IEA: Paris, France, 2021. [Google Scholar]

- Commission of the European Communities. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Goers, S.; Rumohr, F.; Fendt, S.; Gosselin, L.; Jannuzzi, G.M.; Gomes, R.D.; Sousa, S.M.; Wolvers, R. The role of renewable energy in regional energy transitions: An aggregate qualitative analysis for the partner regions Bavaria, Georgia, Québec, São Paulo, Shandong, Upper Austria, and Western Cape. Sustainability 2020, 13, 76. [Google Scholar] [CrossRef]

- Juhrich, K. CO2 Emission Factors for Fossil Fuels; German Environment Agency: Copenhagen, Denmark, 2016. [Google Scholar]

- Full, J.; Trauner, M.; Miehe, R.; Sauer, A. Carbon-negative hydrogen production (HyBECCS) from organic waste materials in Germany: How to estimate bioenergy and greenhouse gas mitigation potential. Energies 2021, 14, 7741. [Google Scholar] [CrossRef]

- Badea, N.I. Hydrogen as energy sources—Basic concepts. Energies 2021, 14, 5783. [Google Scholar] [CrossRef]

- Jaradat, M.; Almashaileh, S.; Bendea, C.; Juaidi, A.; Bendea, G.; Bungau, T. Green hydrogen in focus: A review of production technologies, policy impact, and market developments. Energies 2024, 17, 3992. [Google Scholar] [CrossRef]

- Noyan, O.F.; Hasan, M.M.; Pala, N. A global review of the hydrogen energy eco-system. Energies 2023, 16, 1484. [Google Scholar] [CrossRef]

- BMUV. Waste Management in Germany 2023; Technical Report; Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV): Berlin, Germany, 2023. [Google Scholar]

- Ouadi, M.; Jaeger, N.; Greenhalf, C.; Santos, J.; Conti, R.; Hornung, A. Thermo-Catalytic Reforming of municipal solid waste. Waste Manag. 2017, 68, 198–206. [Google Scholar] [CrossRef]

- Bhandari, R.; Shah, R.R. Hydrogen as energy carrier: Techno-economic assessment of decentralized hydrogen production in Germany. Renew. Energy 2021, 177, 915–931. [Google Scholar] [CrossRef]

- Grunow, P. Decentral Hydrogen. Energies 2022, 15, 2820. [Google Scholar] [CrossRef]

- Welder, L.; Ryberg, D.S.; Kotzur, L.; Grube, T.; Robinius, M.; Stolten, D. Spatio-temporal optimization of a future energy system for power-to-hydrogen applications in Germany. Energy 2018, 158, 1130–1149. [Google Scholar] [CrossRef]

- Michalski, J.; Bünger, U.; Crotogino, F.; Donadei, S.; Schneider, G.S.; Pregger, T.; Cao, K.K.; Heide, D. Hydrogen generation by electrolysis and storage in salt caverns: Potentials, economics and systems aspects with regard to the German energy transition. Int. J. Hydrog. Energy 2017, 42, 13427–13443. [Google Scholar] [CrossRef]

- Kendziorski, M.; Göke, L.; von Hirschhausen, C.; Kemfert, C.; Zozmann, E. Centralized and decentral approaches to succeed the 100% energiewende in Germany in the European context—A model-based analysis of generation, network, and storage investments. Energy Policy 2022, 167, 113039. [Google Scholar] [CrossRef]

- Kalchschmid, V.; Erhart, V.; Angerer, K.; Roth, S.; Hohmann, A. Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies? Sustainability 2023, 15, 2994. [Google Scholar] [CrossRef]

- Murray, P.; Orehounig, K.; Grosspietsch, D.; Carmeliet, J. A comparison of storage systems in neighbourhood decentralized energy system applications from 2015 to 2050. Appl. Energy 2018, 231, 1285–1306. [Google Scholar] [CrossRef]

- Lahnaoui, A.; Wulf, C.; Dalmazzone, D. Optimization of hydrogen cost and transport technology in France and Germany for various production and demand scenarios. Energies 2021, 14, 744. [Google Scholar] [CrossRef]

- Franzmann, D.; Heinrichs, H.; Lippkau, F.; Addanki, T.; Winkler, C.; Buchenberg, P.; Hamacher, T.; Blesl, M.; Linßen, J.; Stolten, D. Green hydrogen cost-potentials for global trade. Int. J. Hydrogen Energy 2023, 48, 33062–33076. [Google Scholar] [CrossRef]

- Dietz, W.; Reinelt, B.; Thiel, N.; Schönemann, M.; Seitz, M.; Rommel, W. Potenziale einer Wasserstoffgewinnung durch Vergasung von Gewerbeabfall; Technical Report; bifa Umweltinstitut: Augsburg, Germany, 2022. [Google Scholar]

- Hasan, M.H.; Mahlia, T.M.I.; Mofijur, M.; Rizwanul Fattah, I.; Handayani, F.; Ong, H.C.; Silitonga, A. A Comprehensive Review on the Recent Development of Ammonia as a Renewable Energy Carrier. Energies 2021, 14, 3732. [Google Scholar] [CrossRef]

- Negro, V.; Noussan, M.; Chiaramonti, D. The potential role of ammonia for hydrogen storage and transport: A critical review of challenges and opportunities. Energies 2023, 16, 6192. [Google Scholar] [CrossRef]

- Asif, M.; Bibi, S.S.; Ahmed, S.; Irshad, M.; Hussain, M.S.; Zeb, H.; Khan, M.K.; Kim, J. Recent advances in green hydrogen production, storage and commercial-scale use via catalytic ammonia cracking. Chem. Eng. J. 2023, 473, 145381. [Google Scholar] [CrossRef]

- Yousefi Rizi, H.A.; Shin, D. Green hydrogen production technologies from ammonia cracking. Energies 2022, 15, 8246. [Google Scholar] [CrossRef]

- Moreno, V.C.; Iervolino, G.; Tugnoli, A.; Cozzani, V. Techno-economic and environmental sustainability of biomass waste conversion based on thermocatalytic reforming. Waste Manag. 2020, 101, 106–115. [Google Scholar] [CrossRef]

- Naegeli de Torres, F.; Brödner, R.; Cyffka, K.-F.; Fais, A.; Kalcher, J.; Kazmin, S.; Meyer, R.; Radke, K.-S.; Richter, F.; Selig, M.; et al. DBFZ Resource Database: DE-Biomass Monitor. Biomass Potentials and Utilization of Biogenic Wastes and Residues in Germany 2010–2020. Zenodo 2023. [Google Scholar] [CrossRef]

- Klein, D.; Wolf, C.; Schulz, C.; Weber-Blaschke, G. Environmental impacts of various biomass supply chains for the provision of raw wood in Bavaria, Germany, with focus on climate change. Sci. Total. Environ. 2016, 539, 45–60. [Google Scholar] [CrossRef] [PubMed]

- Siwal, S.S.; Sheoran, K.; Saini, A.K.; Vo, D.V.N.; Wang, Q.; Thakur, V.K. Advanced thermochemical conversion technologies used for energy generation: Advancement and prospects. Fuel 2022, 321, 124107. [Google Scholar] [CrossRef]

- Auer, K.; Rogers, H. A research agenda for circular food waste management in Bavaria. Transp. Res. Procedia 2022, 67, 131–136. [Google Scholar] [CrossRef]

- Rada, E.C.; Istrate, I.A.; Ragazzi, M. Trends in the management of residual municipal solid waste. Environ. Technol. 2009, 30, 651–661. [Google Scholar] [CrossRef]

- Zaman, A.U. Life cycle environmental assessment of municipal solid waste to energy technologies. Glob. J. Environ. Res. 2009, 3, 155–163. [Google Scholar]

- Ateş, F.; Miskolczi, N.; Borsodi, N. Comparision of real waste (MSW and MPW) pyrolysis in batch reactor over different catalysts. Part I: Product yields, gas and pyrolysis oil properties. Bioresour. Technol. 2013, 133, 443–454. [Google Scholar] [CrossRef]

- Chen, D.; Yin, L.; Wang, H.; He, P. Pyrolysis technologies for municipal solid waste: A review. Waste Manag. 2014, 34, 2466–2486. [Google Scholar] [CrossRef]

- Wietschel, M.; Zheng, L.; Arens, M.; Hebling, C.; Ranzmeyer, O.; Schaadt, A.; Hank, C.; Sternberg, A.; Herkel, S.; Kost, C.; et al. Metastudie Wasserstoff-Auswertung von Energiesystemstudien; Anschrift und Besucheradresse: Freiburg, Germany, 2021. [Google Scholar]

- Wettengel, J. Germany’s Future Hydrogen Needs Significantly Higher than Expected; Technical Report; Clean Energy Wire: Berlin, Germany, 2021. [Google Scholar]

- Scharf, H.; Sauerbrey, O.; Möst, D. What will be the hydrogen and power demands of the process industry in a climate-neutral Germany? J. Clean. Prod. 2024, 466, 142354. [Google Scholar] [CrossRef]

- Riemer, M.; Zheng, L.; Eckstein, J.; Wietschel, M.; Pieton, N.; Kunze, R. Future Hydrogen Demand: A Cross-Sectoral, Global Meta-Analysis; Fraunhofer ISI Karlsruhe: Munich, Germany, 2022. [Google Scholar]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market–Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Scheller, F.; Wald, S.; Kondziella, H.; Gunkel, P.A.; Bruckner, T.; Keles, D. Future role and economic benefits of hydrogen and synthetic energy carriers in Germany: A review of long-term energy scenarios. Sustain. Energy Technol. Assess. 2023, 56, 103037. [Google Scholar] [CrossRef]

- IRENA. Global Energy Transformation: A Roadmap to 2050; Technical Report; IRENA; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Council, H.; Company, M. Hydrogen for Net-Zero A Critical Cost-Competitive Energy Vector; Technical Report; Hydrogen Council, McKinsey & Company: Brussels, Belgium, 2021. [Google Scholar]

- Philipp Runge, S.D. Hydrogen Roadmap Bavaria Perspectives and Recommendations Towards the Ramp-Up of the Bavarian Hydrogen Economy; Technical Report; Hydrogen Center Bavaria: Nuremberg, Germany, 2022. [Google Scholar]

- Bique, A.O.; Zondervan, E. An outlook towards hydrogen supply chain networks in 2050—Design of novel fuel infrastructures in Germany. Chem. Eng. Res. Des. 2018, 134, 90–103. [Google Scholar] [CrossRef]

- München, S. Stadtwerke München; Verlag Nicht Ermittelbar: Freiburg im Breisgau, Germany, 1997. [Google Scholar]

- Lee, J.; Hong, S.; Cho, H.; Lyu, B.; Kim, M.; Kim, J.; Moon, I. Machine learning-based energy optimization for on-site SMR hydrogen production. Energy Convers. Manag. 2021, 244, 114438. [Google Scholar] [CrossRef]

- Kargbo, H.O.; Zhang, J.; Phan, A.N. Optimisation of two-stage biomass gasification for hydrogen production via artificial neural network. Appl. Energy 2021, 302, 117567. [Google Scholar] [CrossRef]

- Bayerisches Landesamt für Statistik 2024. Available online: https://www.statistik.bayern.de/ (accessed on 12 December 2024).

- National Bioeconomy Strategy, German Federal Ministry of Food and Agriculture. July 2020. Available online: https://www.bmel.de/EN/Home/home_node.html (accessed on 12 December 2024).

- Günther, S.; Karras, T.; Naegeli de Torres, F.; Semella, S.; Thrän, D. Temporal and spatial mapping of theoretical biomass potential across the European Union. Earth Syst. Sci. Data 2023, 16, 59–74. [Google Scholar] [CrossRef]

- Schmitt, N.; Apfelbacher, A.; Jäger, N.; Daschner, R.; Stenzel, F.; Hornung, A. Thermo-chemical conversion of biomass and upgrading to biofuel: The Thermo-Catalytic Reforming process—A review. Biofuels Bioprod. Biorefining 2019, 13, 822–837. [Google Scholar] [CrossRef]

- Conti, R.; Jäger, N.; Neumann, J.; Apfelbacher, A.; Daschner, R.; Hornung, A. Thermocatalytic reforming of biomass waste streams. Energy Technol. 2017, 5, 104–110. [Google Scholar] [CrossRef]

- Schmidt, M.; Singh, B. Selectively closing recycling centers in Bavaria: Reforming waste-management policy to reduce disparity. Networks 2024, 84, 148–160. [Google Scholar] [CrossRef]

- Hornung, A.; Jahangiri, H.; Ouadi, M.; Kick, C.; Deinert, L.; Meyer, B.; Grunwald, J.; Daschner, R.; Apfelbacher, A.; Meiller, M.; et al. Thermo-Catalytic Reforming (TCR)—An important link between waste management and renewable fuels as part of the energy transition. Appl. Energy Combust. Sci. 2022, 12, 100088. [Google Scholar] [CrossRef]

- Mahmood, A.S.; Brammer, J.G.; Hornung, A.; Steele, A.; Poulston, S. The intermediate pyrolysis and catalytic steam reforming of Brewers spent grain. J. Anal. Appl. Pyrolysis 2013, 103, 328–342. [Google Scholar] [CrossRef]

- Klaas, M.; Greenhalf, C.; Ouadi, M.; Jahangiri, H.; Hornung, A.; Briens, C.; Berruti, F. The effect of torrefaction pre-treatment on the pyrolysis of corn cobs. Results Eng. 2020, 7, 100165. [Google Scholar] [CrossRef]

- Neumann, J.; Meyer, J.; Ouadi, M.; Apfelbacher, A.; Binder, S.; Hornung, A. The conversion of anaerobic digestion waste into biofuels via a novel Thermo-Catalytic Reforming process. Waste Manag. 2016, 47, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Whalen, C. Some Rules of Thumb of the Hydrogen Economy. Online Blog Post. June 2021. Available online: https://www.carboncommentary.com/blog/2021/6/11/some-rules-of-thumb-of-the-hydrogen-economy (accessed on 12 December 2024).

- Jensterle, M.; Narita, J.; Piria, R.; Samadi, S.; Prantner, M.; Crone, K.; Siegemund, S.; Kan, S.; Matsumoto, T.; Shibata, Y.; et al. The Role of Clean Hydrogen in the Future Energy Systems of Japan and Germany: An Analysis of Existing Mid-Century Scenarios and an Investigation of Hydrogen Supply Chains; Technical Report; Wuppertal Institut: Wuppertal, Germany, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).