An Artificial-Neural-Network-Based Direct Power Control Approach for Doubly Fed Induction Generators in Wind Power Systems

Abstract

1. Introduction

1.1. Overview

1.2. Literature

1.3. Contribution and Organization of This Manuscript

- -

- Development of an innovative artificial-neural-network-based direct power control (DPC-ANN) strategy for DFIGs that overcomes the limitations of conventional control techniques.

- -

- Demonstration of significant performance improvements, including the following:

- Enhanced power control accuracy;

- Improved dynamic response under varying wind conditions;

- Reduced harmonic distortion;

- Maintenance of the near-unity power factor.

- -

- Comprehensive validation through simulation and real-time implementation, providing empirical evidence of the approach’s effectiveness in practical wind energy applications.

2. Wind Power Generation System Modeling

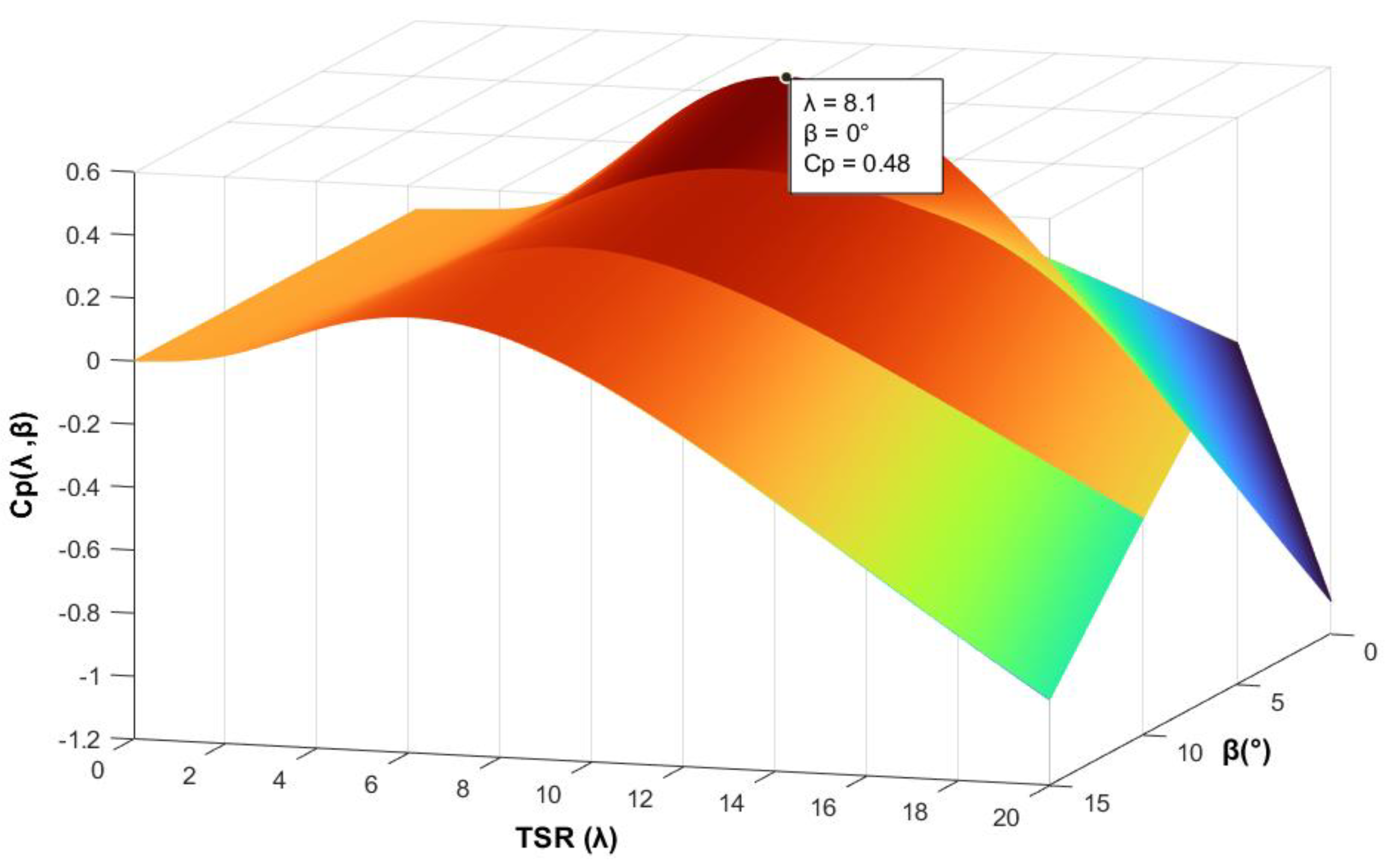

2.1. Turbine Modeling

2.2. DFIG Modeling

- -

- Electrical equation.

- -

- Magnetic equation

- -

- The equations describing the electromagnetic torque, active power, and reactive power generated by the DFIG are as follows [33]:

- -

- Powers estimation.

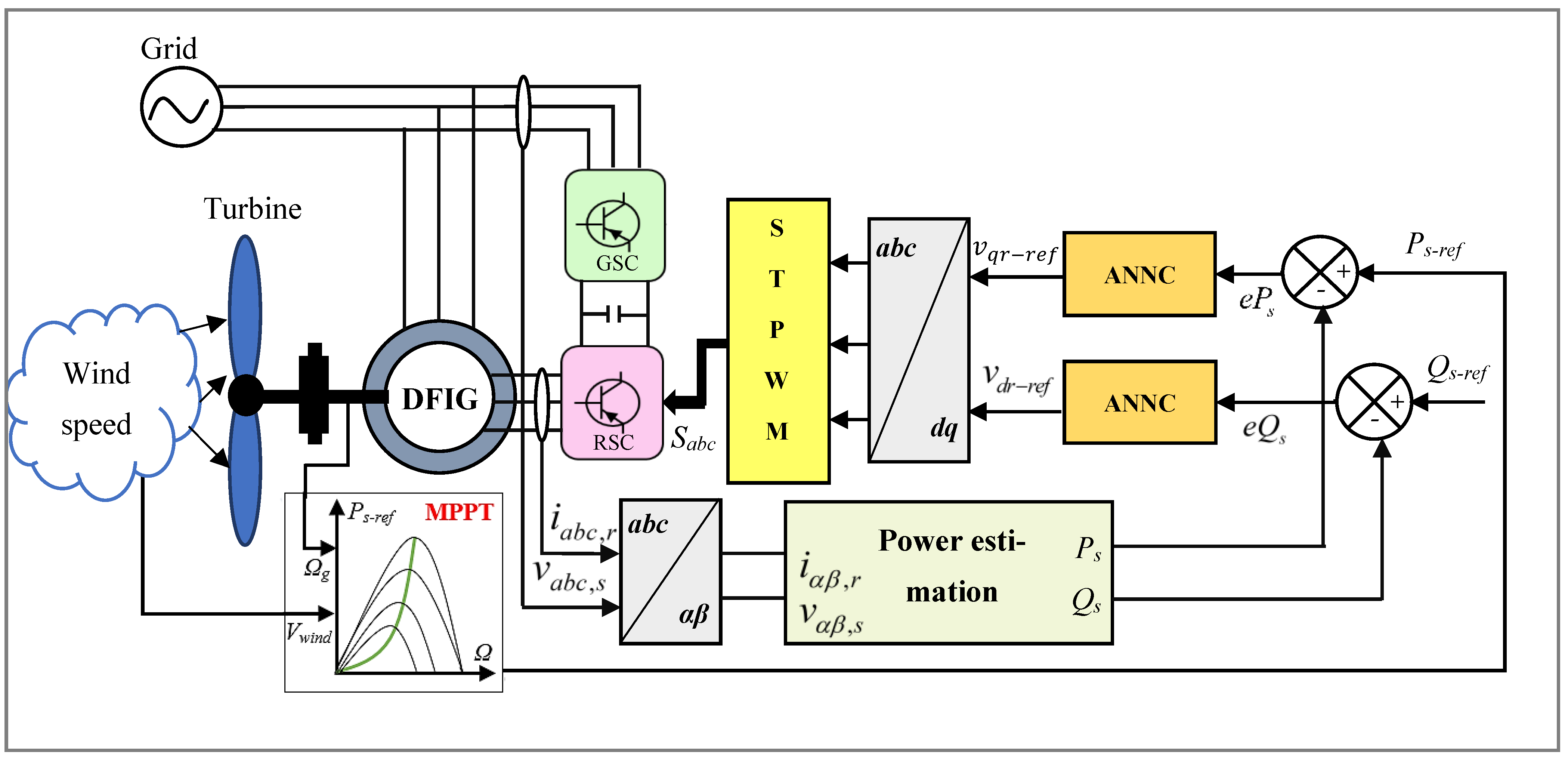

3. The Proposed DPC-ANN Technique

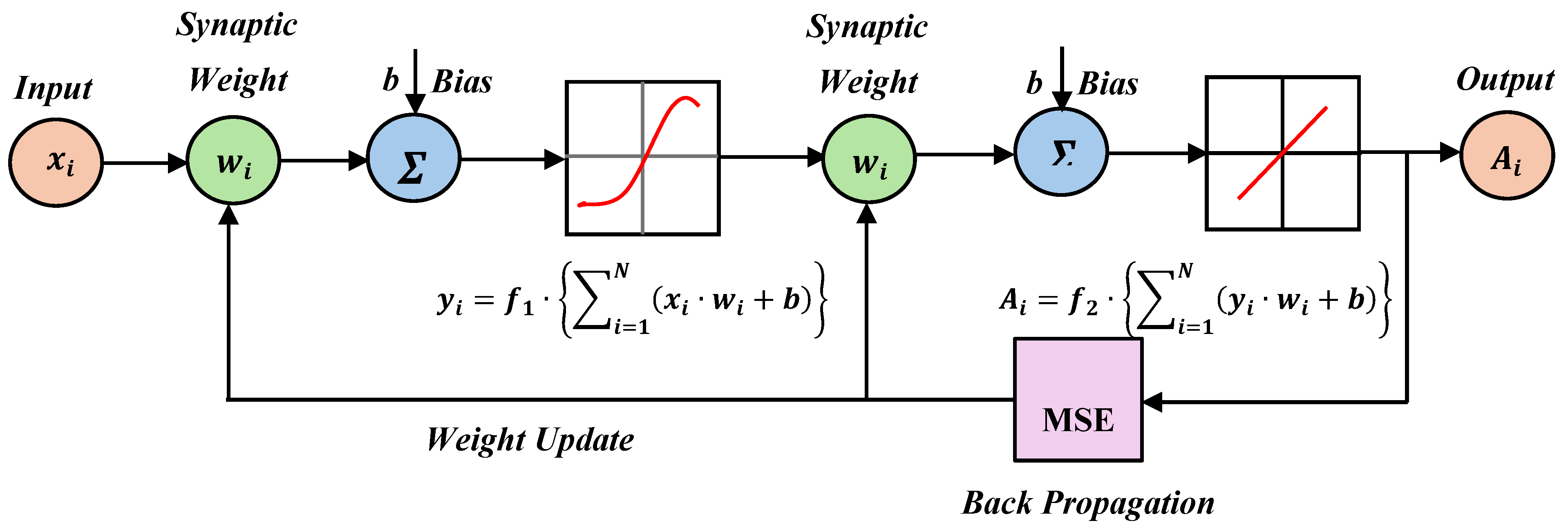

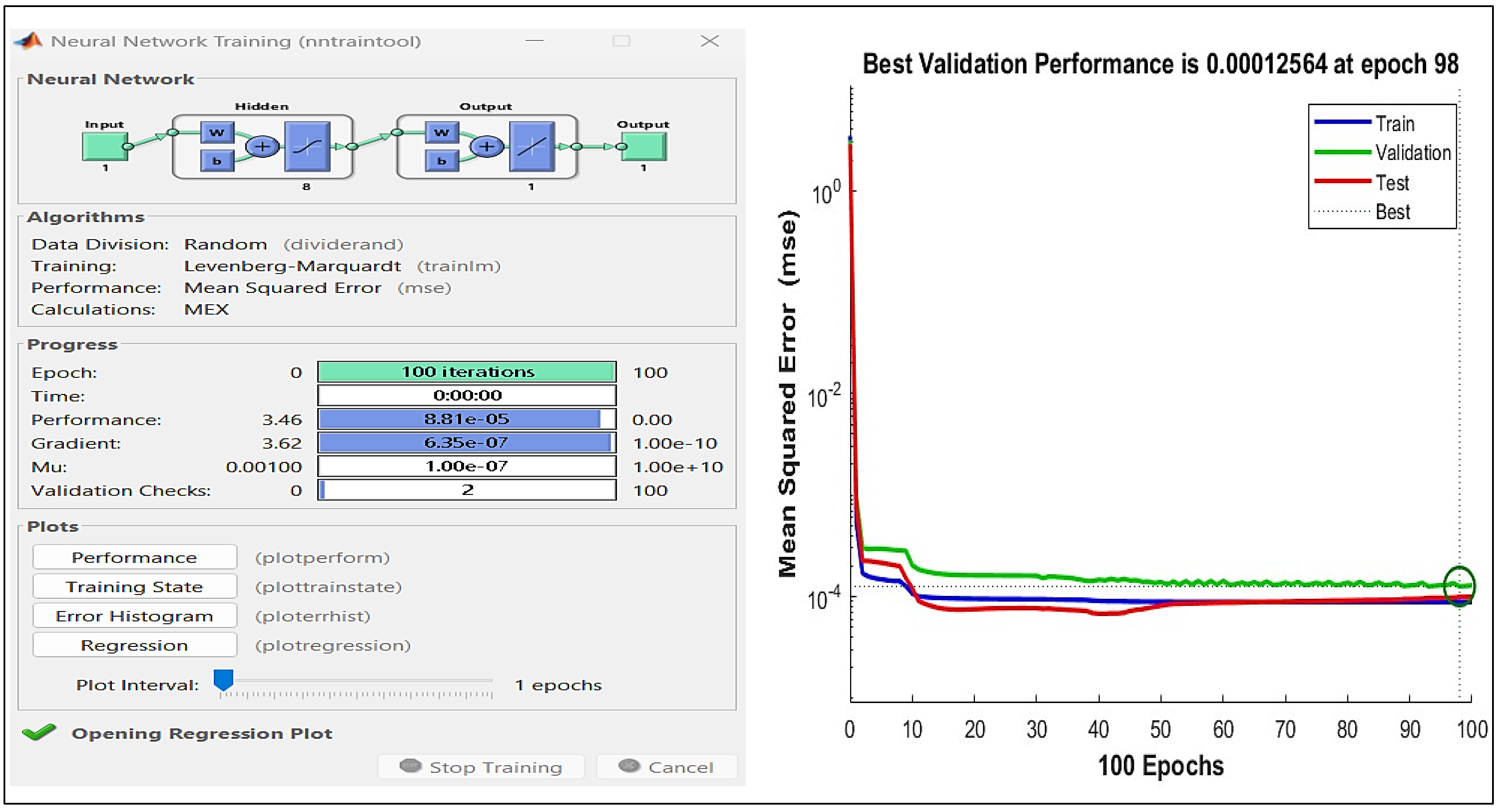

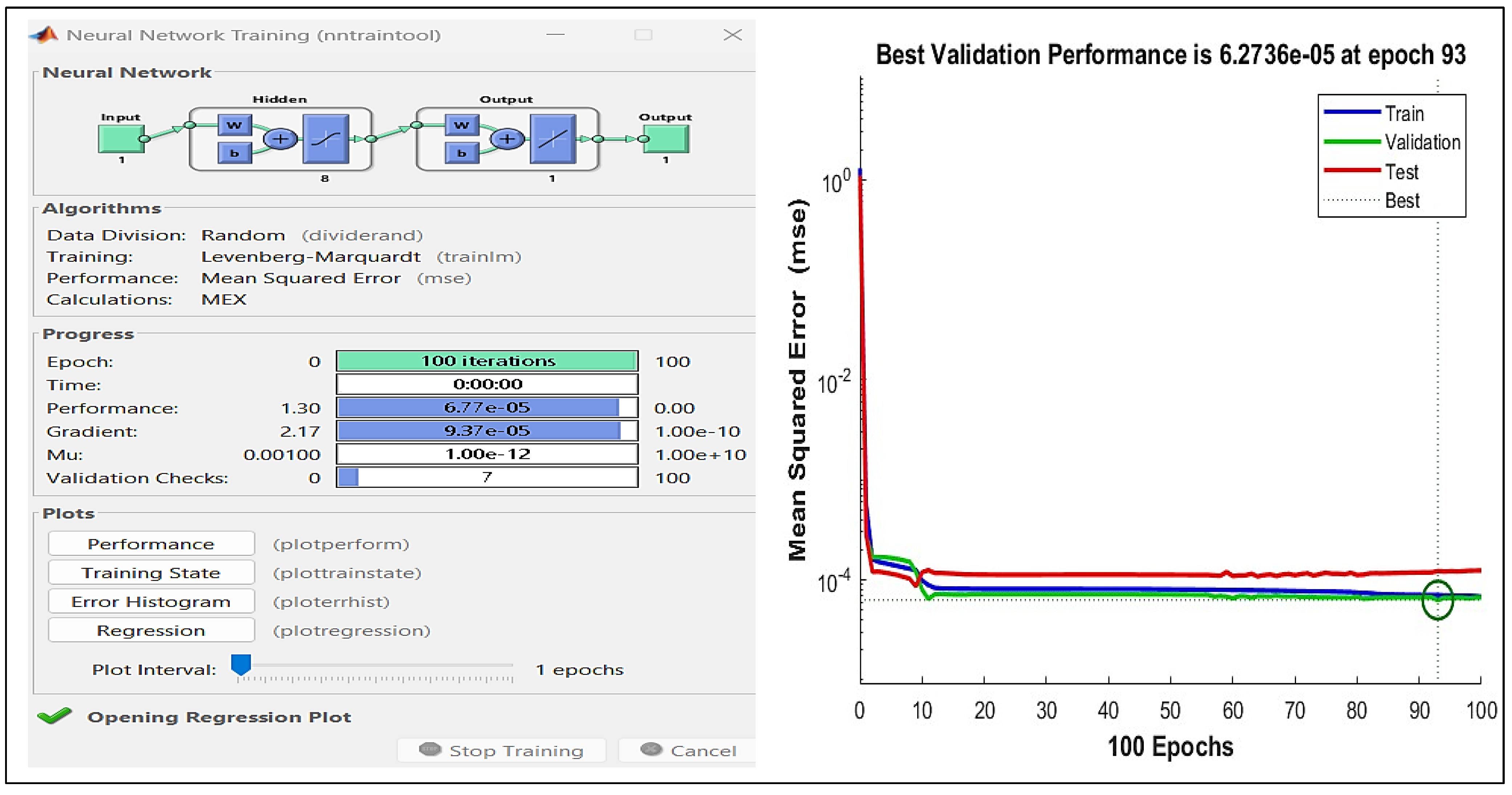

3.1. ANN Structure

3.2. Training Process

4. Simulation Results and Discussion

4.1. Aerodynamic Performance Analysis

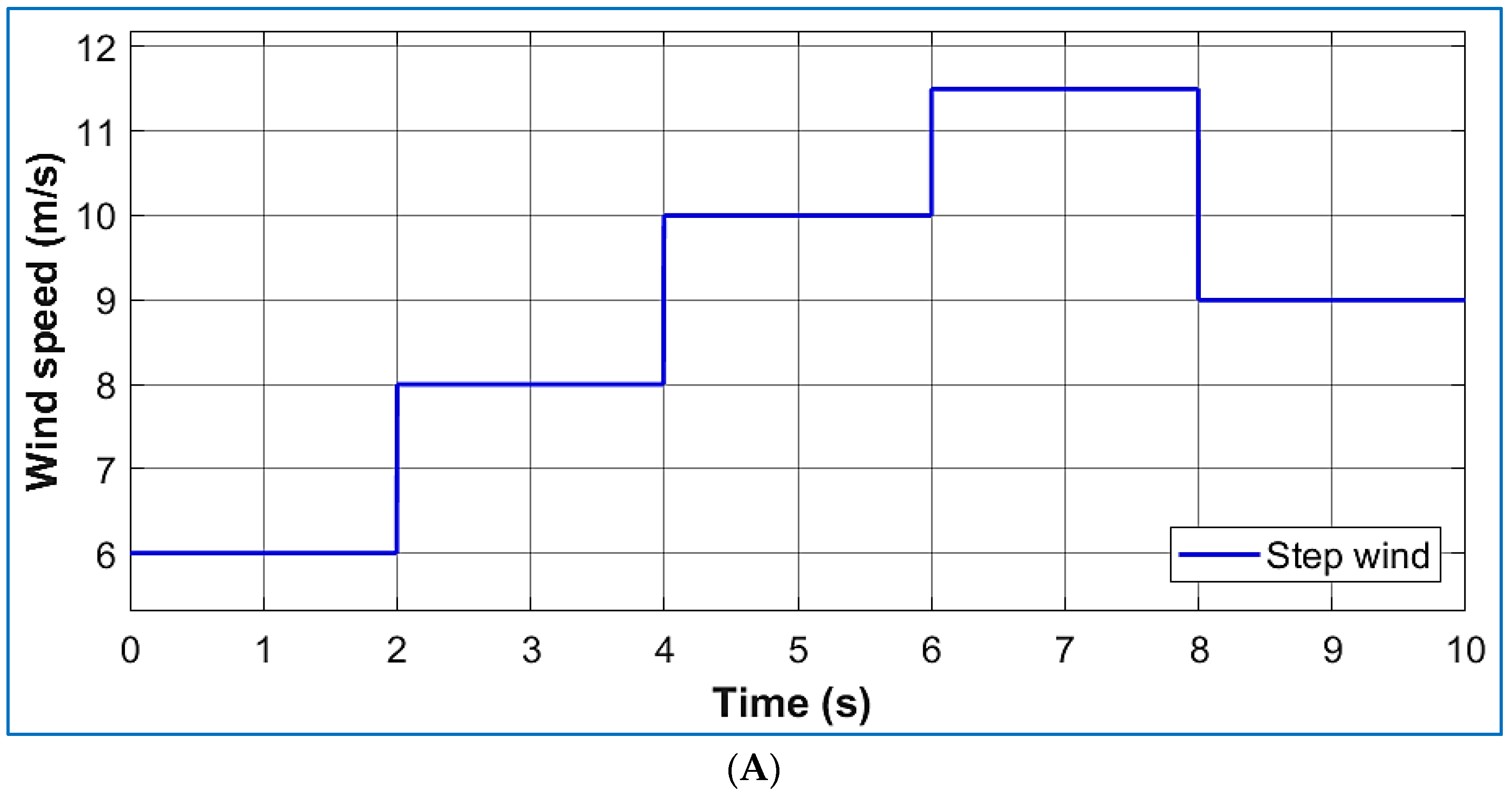

Wind Speed Profile and Dynamic Response

4.2. Real-Time Simulation Performance

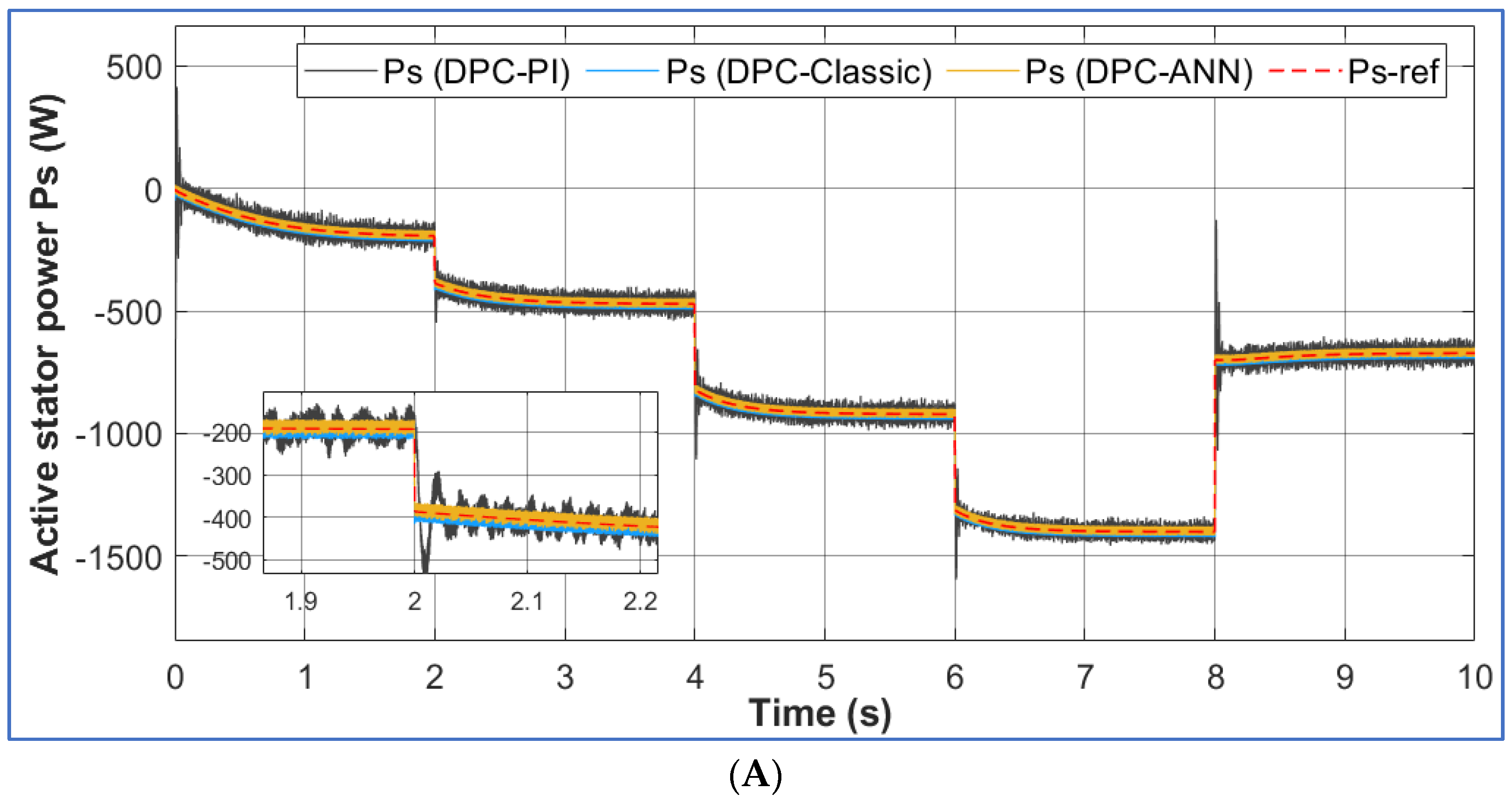

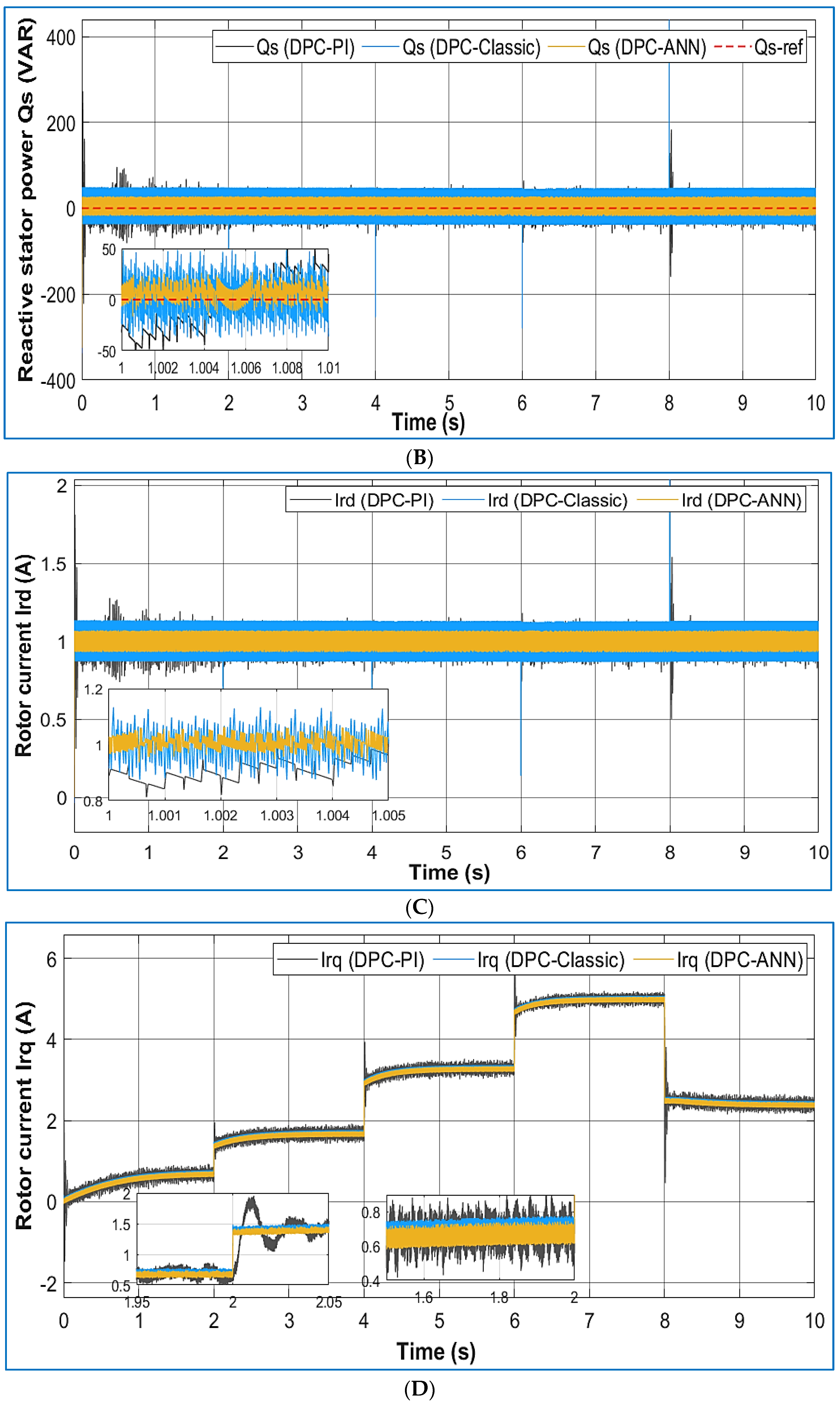

Power Flow and Electrical Parameter Control

4.3. Comparative Control Strategy Analysis

4.4. Implications and Recommendations

5. Conclusions

- -

- The DPC-ANN controller demonstrated superior active and reactive power control, maintaining effective tracking of reference values despite wind speed variations.

- -

- The DPC-ANN strategy proved effective in mitigating current ripples and achieving a near-unity power factor, indicating improved power quality.

- -

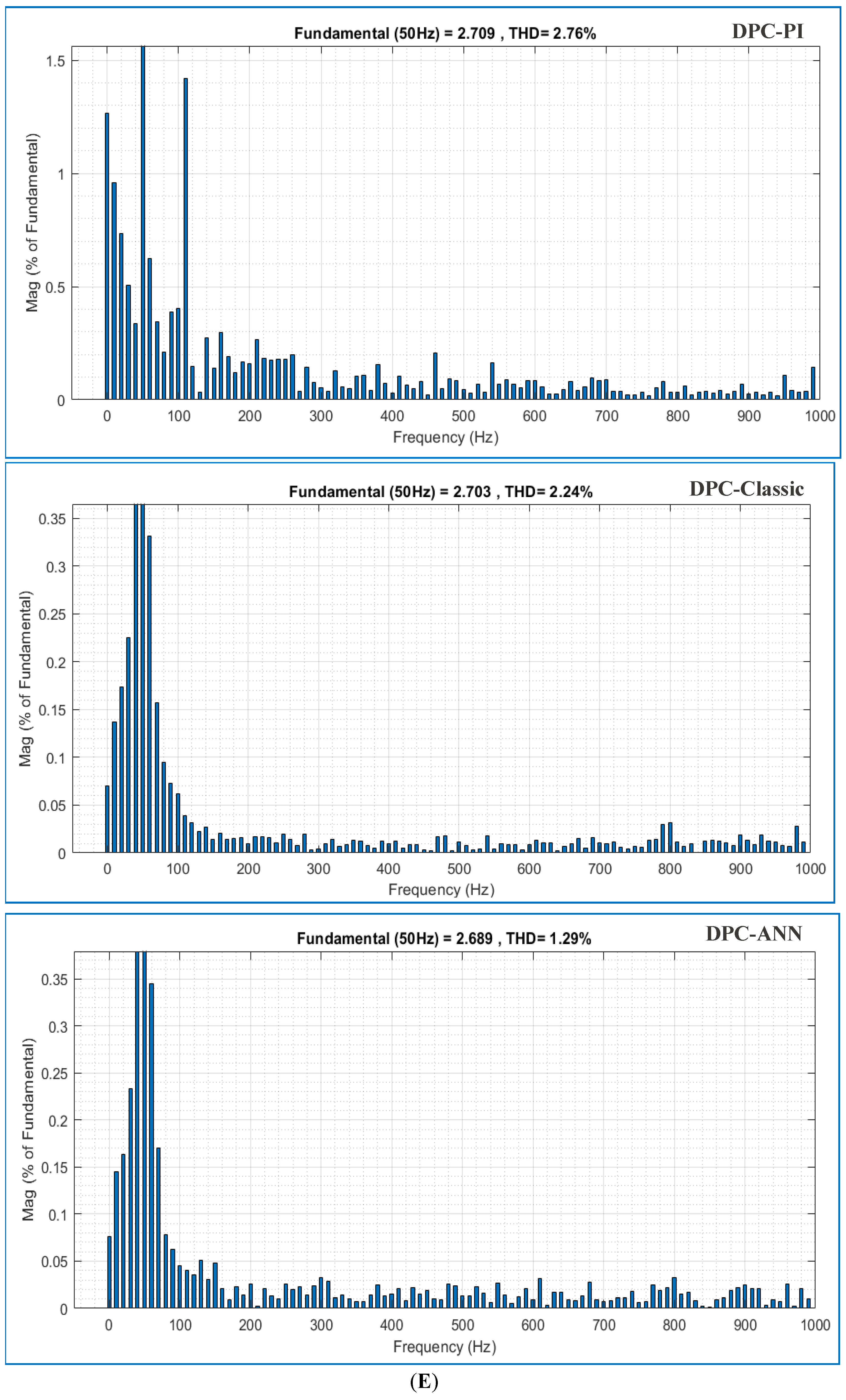

- Spectrum harmonic analysis showed the DPC-ANN controller yielded the lowest stator current THD of 1.29%, outperforming DPC-PI (2.76% THD) and DPC-Classic (2.24% THD).

- -

- The performance evaluation was conducted through both MATLAB/Simulink offline simulations and OPAL-RT real-time implementation, validating robust behavior under realistic operating conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | artificial neural network |

| ANNC | artificial neural network controller |

| DFIG | doubly fed induction generator |

| DPC | direct power control |

| MPPT | Maximum Power Point Tracking |

| MLP | multilayer perceptron |

| MSE | Mean Square Error |

| PI | Proportional–Integral |

| PWM | Pulse Width Modulation |

| RSC | rotor-side converter |

| GSC | grid-side converter |

| WTS | wind turbine system |

| WECS | wind energy conversion system |

| Nomenclature | |

| β (Degree °) | blade pitch angle |

| λ | tip speed ratio |

| Cp (λ, β) | power coefficient |

| ρ (Kg/m3) | air density |

| Vwind (m/s) | wind speed |

| R (m) | blade radius |

| Ωg (rad/s) | mechanical speed on the generator side |

| Ωt (rad/s) | wind turbine speed |

| Paero (W) | aerodynamic power |

| Taero | aerodynamic torque |

| Tem | electromagnetic torque |

| Vdc | DC-link voltage |

| Ps (W), Qs (Var) | stator active and reactive powers |

| , (Wb) | stator and rotor fluxes |

| , (V) | stator and rotor voltages |

| , (A) | stator and rotor currents |

| , (rad/s) | stator and rotor pulsations |

Appendix A

| Rated power | Pn = 1.5 KW |

| Stator rated voltage | vs = 220/380 V |

| Stator current | isn = 5.2 A |

| Rotor current | irn = 8.5 A |

| Number of pair of poles | p = 2 |

| Stator rated frequency | fs = 50 Hz |

| Stator resistance | Rs = 1.18 Ω |

| Rotor resistance | Rr = 1.66 Ω |

| Stator inductance | Lss = 0.20 H |

| Rotor inductance | Lrr = 0.18 H |

| Mutual inductance | Lm = 0.17 H |

| Rotor radius | R = 1 m |

| Number of blades | 3 |

| Gearbox gain | G = 2 |

| Friction coefficient | f = 0.0027 N.m.s/rad |

| Moment of inertia | J = 0.04 kg.m2 |

| ANN Parameters | Value/Methods | |

| ANNC-Ps | ANNC-Qs | |

| Neural network | Multilayer perceptron network (MLP network) | |

| MLP training process | Levenberg–Marquardt algorithm | |

| Proposed structure | 1-8-1 | 1-8-1 |

| Number of repetitions | 100 | 100 |

| Input layer | ePs | eQs |

| Output layer | vqr-ref | vdr-ref |

| Activation functions | Tansig | Tansig |

| Adaption learning function | Trainlm | Trainlm |

References

- International Energy Agency (IEA). Wind Energy—Analysis. 2024. Available online: https://www.iea.org/energy-system/renewables/wind (accessed on 1 April 2025).

- Global Wind Energy Council (GWEC). Global Wind Report 2024. 2024. Available online: https://www.gwec.net/reports/globalofffshorewindreport (accessed on 1 April 2025).

- Mohapatra, S.P.; Dash, P.K. A novel control strategy of a variable-speed doubly-fed-induction-generator-based wind energy conversion system. Clean Energy 2024, 8, 153–170. [Google Scholar] [CrossRef]

- Li, C.; Cao, Y.; Li, B.; Wang, S.; Chen, P. A novel power control scheme for distributed DFIG based on cooperation of hybrid energy storage system and grid-side converter. Int. J. Electr. Power Energy Syst. 2024, 157, 109801. [Google Scholar] [CrossRef]

- Chojaa, H.; Derouich, A.; Bourkhime, Y.; Chetouani, E.; Meghni, B.; Chehaidia, S.E.; Yessef, M. Comparative Study of MPPT Controllers for a Wind Energy Conversion System. Lect. Notes Data Eng. Commun. Technol. 2022, 110, 300–310. [Google Scholar] [CrossRef]

- Sguarezi, A. Model Predictive Control for Doubly-Fed Induction Generators and Three-Phase Power Converters; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Dardabi, C.; Akdi, M.; Djebli, A. Comparative Study of Three Types of Controllers for Variable Speed Wind Turbine; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 605, pp. 783–793. [Google Scholar] [CrossRef]

- Duggirala, V.A.; Gundavarapu, V.N.K. Gundavarapu, Improved LVRT for grid connected DFIG using enhanced field-oriented control technique with super capacitor as external energy storage system. Eng. Sci. Technol. Int. J. 2016, 19, 1742–1752. [Google Scholar] [CrossRef]

- Wang, X.; Sun, D.; Zhu, Z.Q. Resonant-Based Backstepping Direct Power Control Strategy for DFIG under Both Balanced and Unbalanced Grid Conditions. IEEE Trans. Ind. Appl. 2017, 53, 4821–4830. [Google Scholar] [CrossRef]

- Sahri, Y.; Tamalouzt, S.; Hamoudi, F.; Belaid, S.L.; Bajaj, M.; Alharthi, M.M.; Alzaidi, M.S.; Ghoneim, S.S. New intelligent direct power control of DFIG-based wind conversion system by using machine learning under variations of all operating and compensation modes. Energy Rep. 2021, 7, 6394–6412. [Google Scholar] [CrossRef]

- Benbouhenni, H.; Boudjema, Z.; Bizon, N.; Thounthong, P.; Takorabet, N. Direct Power Control Based on Modified Sliding Mode Controller for a Variable-Speed Multi-Rotor Wind Turbine System Using PWM Strategy. Energies 2022, 15, 3689. [Google Scholar] [CrossRef]

- Cherifi, D.; Miloud, Y.; Mostefai, M. Performance of Neutral Point Clamped Five Level Inverter Using Space Vector Modulation Control Fed by DPC-VF-SVM Rectifier. WSEAS Trans. Power Syst. 2021, 16, 275–287. [Google Scholar] [CrossRef]

- Hadoune, A.; Mouradi, A.; Mimet, A.; Chojaa, H.; Dardabi, C.; Gulzar, M.M.; Alqahtani, M.; Khalid, M. Optimizing direct power control of DFIG-based WECS using super-twisting algorithm under real wind profile. Front. Energy Res. 2023, 11, 1261902. [Google Scholar] [CrossRef]

- Benbouhenni, H.; Bizon, N.; Mosaad, M.I.; Colak, I.; Djilali, A.B.; Gasmi, H. Enhancement of the power quality of DFIG-based dual-rotor wind turbine systems using fractional order fuzzy controller. Expert Syst. Appl. 2023, 238, 121695. [Google Scholar] [CrossRef]

- Yessef, M.; Bossoufi, B.; Taoussi, M.; Lagrioui, A.; Chojaa, H. Overview of control strategies for wind turbines: ANNC, FLC, SMC, BSC, and PI controllers. Wind. Eng. 2022, 46, 1820–1837. [Google Scholar] [CrossRef]

- Chetouani, E.; Errami, Y.; Obbadi, A.; Sahnoun, S. Self-adapting PI controller for grid-connected DFIG wind turbines based on recurrent neural network optimization control under unbalanced grid faults. Electr. Power Syst. Res. 2023, 214, 108829. [Google Scholar] [CrossRef]

- Babayomi, O.; Li, Y.; Zhang, Z.; Park, K.B. Advanced Control of Grid-Connected Microgrids: Challenges, Advances and Trends. IEEE Trans. Power Electron. 2025, 40, 7681–7708. [Google Scholar] [CrossRef]

- Benjamim, W.; Jlassi, I.; Cardoso, A.J.M. A computationally efficient model predictive current control of synchronous reluctance motors based on hysteresis comparators. Electronics 2022, 11, 379. [Google Scholar] [CrossRef]

- Yay, S.; Soth, P.; Tang, H.; Cheng, H.; Ang, S.; Choeung, C. Power regulation of a three-phase L-filtered grid-connected inverter considering uncertain grid impedance using robust control. Int. J. Robot. Control Syst. 2024, 4, 779–794. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Liu, Z. μ-Synthesis-Based Robust Power Control for Single-Phase Cascaded H-bridge Rectifier in Power Electronic Traction Transformer. IEEE Trans. Transp. Electrif. 2024, 11, 5578–5591. [Google Scholar] [CrossRef]

- Benbouhenni, H.; Mosaad, M.I.; Colak, I.; Bizon, N.; Gasmi, H.; Aljohani, M.; Abdelkarim, E. Fractional-order synergetic control of the asynchronous generator-based variable-speed multi-rotor wind power systems. IEEE Access 2023, 11, 133490–133508. [Google Scholar] [CrossRef]

- Eslahi, M.S.; Vaez-Zadeh, S.; Rodriguez, J. Resiliency enhancement and power quality optimization of converter-based renewable energy microgrids. IEEE Trans. Power Electron. 2023, 38, 7785–7795. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Dao, Q.T.; Bui, N.T. Optimized fuzzy logic and sliding mode control for stability and disturbance rejection in rotary inverted pendulum. Sci. Rep. 2024, 14, 31116. [Google Scholar] [CrossRef]

- Navarrete, E.C.; Trejo Perea, M.; Jáuregui Correa, J.C.; Carrillo Serrano, R.V.; Moreno, G.J.R. Expert Control Systems Implemented in a Pitch Control of Wind Turbine: A Review. IEEE Access 2019, 7, 13241–13259. [Google Scholar] [CrossRef]

- Guediri, A.; Hettiri, M.; Guediri, A. Modeling of a wind power system using the genetic algorithm based on a doubly fed induction generator for the supply of power to the electrical grid. Processes 2023, 11, 952. [Google Scholar] [CrossRef]

- Dardabi, C.; Djebli, A.; Chojaa, H.; Aziz, H.; Mouradi, A.; Mossa, M.A.; Abdelaziz, A.Y.; Alghamdi, T.A.H. Enhancing the control of doubly fed induction generators using artificial neural networks in the presence of real wind profiles. PLoS ONE 2024, 19, e0300527. [Google Scholar] [CrossRef]

- Chojaa, H.; Derouich, A.; Taoussi, M.; Zamzoum, O.; Yessef, M. Optimization of DFIG wind turbine power quality through adaptive fuzzy control. In Digital Technologies and Applications; ICDTA 2021, Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2021; Volume 211. [Google Scholar] [CrossRef]

- Cembrowska-Lech, D.; Krzemińska, A.; Miller, T.; Nowakowska, A.; Adamski, C.; Radaczyńska, M.; Mikiciuk, G.; Mikiciuk, M. An Integrated Multi-Omics and Artificial Intelligence Framework for Advance Plant Phenotyping in Horticulture. Biology 2023, 12, 1298. [Google Scholar] [CrossRef] [PubMed]

- Sami, I.; Ullah, S.; Amin, S.U.; Al-Durra, A.; Ullah, N.; Ro, J.-S. Convergence Enhancement of Super-Twisting Sliding Mode Control Using Artificial Neural Network for DFIG-Based Wind Energy Conversion. Systems IEEE Access 2022, 10, 97625–97641. [Google Scholar] [CrossRef]

- Behara, R.K.; Saha, A.K. artificial intelligence control system applied in smart grid integrated doubly fed induction generator-based wind turbine: A review. Energies 2022, 15, 6488. [Google Scholar] [CrossRef]

- Ateş, K.T. Estimation of short-term power of wind turbines using artificial neural network (ANN) and swarm intelligence. Sustainability 2023, 15, 13572. [Google Scholar] [CrossRef]

- Kumar, K.; Pande, S.V.; Kumar, T.C.A.; Saini, P.; Chaturvedi, A.; Reddy, P.C.S.; Shah, K.B. Intelligent controller design and fault prediction using machine learning model. Int. Trans. Electr. Energy Syst. 2023, 1, 1056387. [Google Scholar] [CrossRef]

- Boubzizi, S.; Abid, H.; El Hajjaji, A.; Chaabane, M. Comparative study of three types of controllers for DFIG in wind energy conversion system. Prot. Control Mod. Power Syst. 2018, 3, 21. [Google Scholar] [CrossRef]

- Farrar, N.O.; Ali, M.H.; Dasgupta, D. Artificial intelligence and machine learning in grid connected wind turbine control systems: A comprehensive review. Energies 2023, 16, 1530. [Google Scholar] [CrossRef]

- Shao, F.; Shen, Z. How can artificial neural networks approximate the brain? Front. Psychol. 2023, 13, 970214. [Google Scholar] [CrossRef]

- Amir, M. ANN based approach for the estimation and enhancement of power transfer capability. In Proceedings of the 2019 International Conference on Power Electronics, Control and Automation (ICPECA), New Delhi, India, 16–17 November 2019. [Google Scholar]

- Said, M.; Derouich, A.A.; EL Ouanjli, N.; EL Mahfoud, M. Enhancement of the direct torque control by using artificial neuron network for a doubly fed induction motor. Intell. Syst. Appl. 2022, 13, 200060. [Google Scholar] [CrossRef]

- Chicco, D.; Warrens, M.J.; Jurman, G. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. Peerj Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef]

- Benbouhenni, H.; Boudjema, Z.; Belaidi, A. Power control of DFIG in WECS using DPC and NDPC-NPWM methods. Math. Model. Eng. Probl. 2020, 7, 223–236. [Google Scholar] [CrossRef]

- Alhato, M.M.; Bouallègue, S. Direct Power Control Optimization for Doubly Fed Induction Generator Based Wind Turbine Systems. Math. Comput. Appl. 2019, 24, 77. [Google Scholar] [CrossRef]

- Amrane, F.; Chaiba, A.; Babas, B.E.; Mekhilef, S. Design and implementation of high performance field oriented control for grid-connected doubly fed induction generator via hysteresis rotor current controller. Rev. Roum. Sci. Techn. Electrotechn. Energ. 2016, 61, 319–324. [Google Scholar]

- Boudjema, Z.; Meroufel, A.; Djerriri, Y.; Bounadja, E. Fuzzy sliding mode control of a doubly fed induction generator for wind energy conversion. Carpathian J. Electron. Comput. Eng. 2013, 6, 7. [Google Scholar]

- Ayrir, W.; Ourahou, M.; El Hassouni, B.; Haddi, A. Direct torque control improvement of a variable speed DFIG based on a fuzzy inference system. Math. Comput. Simul. 2020, 167, 308–324. [Google Scholar] [CrossRef]

| Performance | DPC-PI | DPC-Classic | DPC-ANN | Improvement | ||

|---|---|---|---|---|---|---|

| vs. DPC-PI | vs. DPC-Classic | |||||

| THD (%) of the current isa | 2.76% | 2.24% | 1.29% | 53.26% | 42.41% | |

| Standard deviation (σ) | σPs | 35.97 | 11.64 | 7.66 | 78.70% | 34.19% |

| σQs | 18.07 | 19.66 | 9.29 | 48.61% | 52.75% | |

| Set-point tracking | Good | Very good | Very good | ----- | ||

| Precision | Medium | High | Very high | ----- | ||

| Oscillation current | High | Medium | Low | ----- | ||

| References | Strategies | THD (%) |

|---|---|---|

| [39] | DPC | 2.62% |

| Backstepping control | 2.45% | |

| DPC with neural algorithm | 2.22% | |

| [40] | DPC with an L-filter | 10.79% |

| DPC with an LCL filter | 4.05% | |

| [37] | DTC | 7.83% |

| DTC with neural algorithm | 3.26% | |

| [41] | FOC | 3.7% |

| [42] | SMC | 3.05% |

| FSMC | 2.85% | |

| [43] | Classic-DTC | 6.7% |

| Fuzzy-DTC | 2.04% | |

| Proposed strategy | DPC-ANN | 1.29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dardabi, C.; Álvarez, S.C.; Djebli, A. An Artificial-Neural-Network-Based Direct Power Control Approach for Doubly Fed Induction Generators in Wind Power Systems. Energies 2025, 18, 1989. https://doi.org/10.3390/en18081989

Dardabi C, Álvarez SC, Djebli A. An Artificial-Neural-Network-Based Direct Power Control Approach for Doubly Fed Induction Generators in Wind Power Systems. Energies. 2025; 18(8):1989. https://doi.org/10.3390/en18081989

Chicago/Turabian StyleDardabi, Chaimae, Santiago Cóbreces Álvarez, and Abdelouahed Djebli. 2025. "An Artificial-Neural-Network-Based Direct Power Control Approach for Doubly Fed Induction Generators in Wind Power Systems" Energies 18, no. 8: 1989. https://doi.org/10.3390/en18081989

APA StyleDardabi, C., Álvarez, S. C., & Djebli, A. (2025). An Artificial-Neural-Network-Based Direct Power Control Approach for Doubly Fed Induction Generators in Wind Power Systems. Energies, 18(8), 1989. https://doi.org/10.3390/en18081989