Harnessing Horsepower from Horse Manure at the EARTH Centre in South Africa: Biogas Initiative Improve the Facility’s Operational Sustainability

Abstract

1. Introduction

2. Materials and Methods

2.1. Baseline Energy Audit

2.2. Elemental Analysis Methods

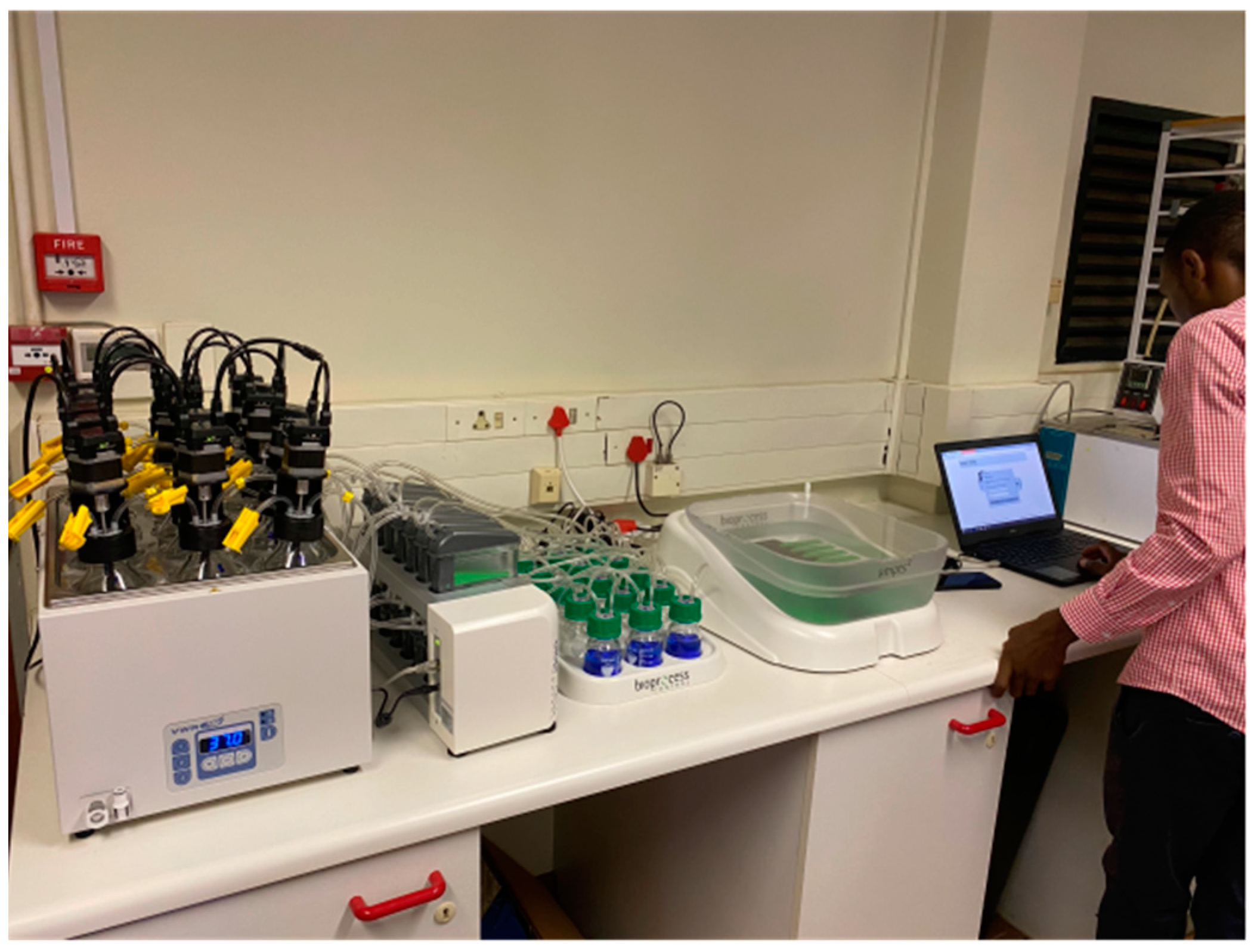

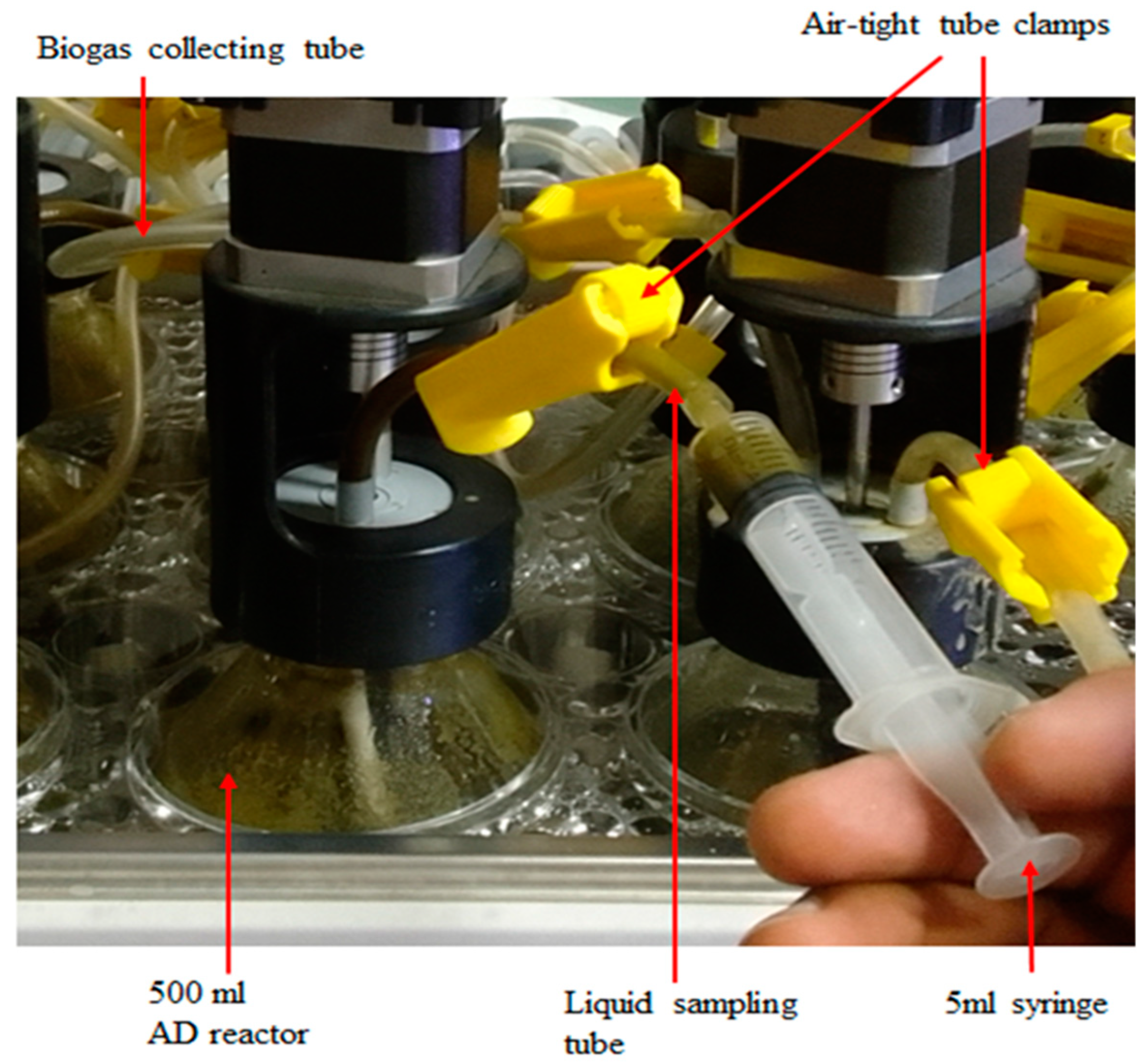

2.3. Biomethane Potential Analysis

2.4. Microbial Analysis

- i.

- Horse manure

2.5. Metabolomic Analysis

2.6. Digester Designs, Installation and Commissioning

2.7. Troubleshooting and Optimization

3. Results

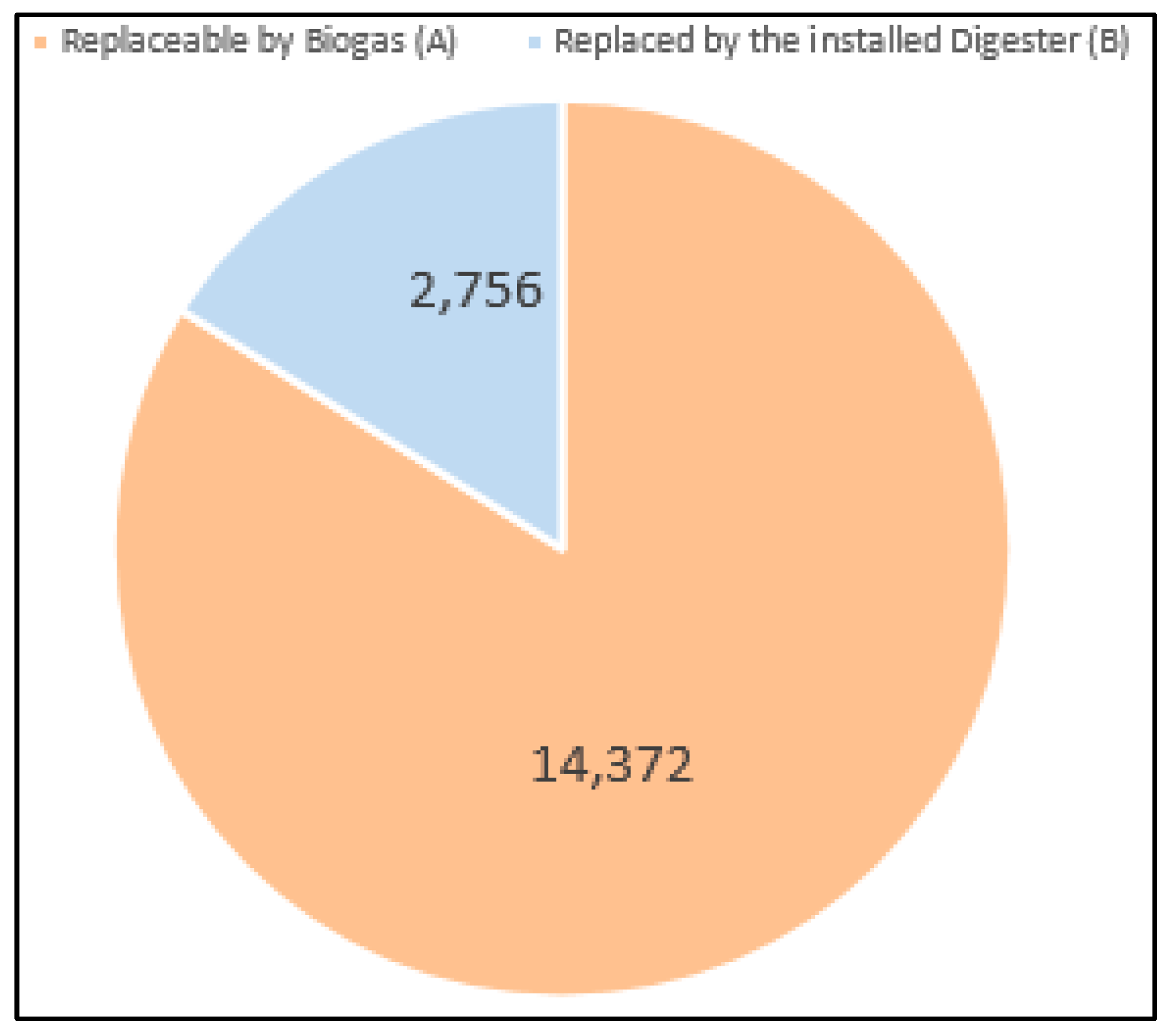

3.1. Energy Audit

3.2. Elemental Analysis Results

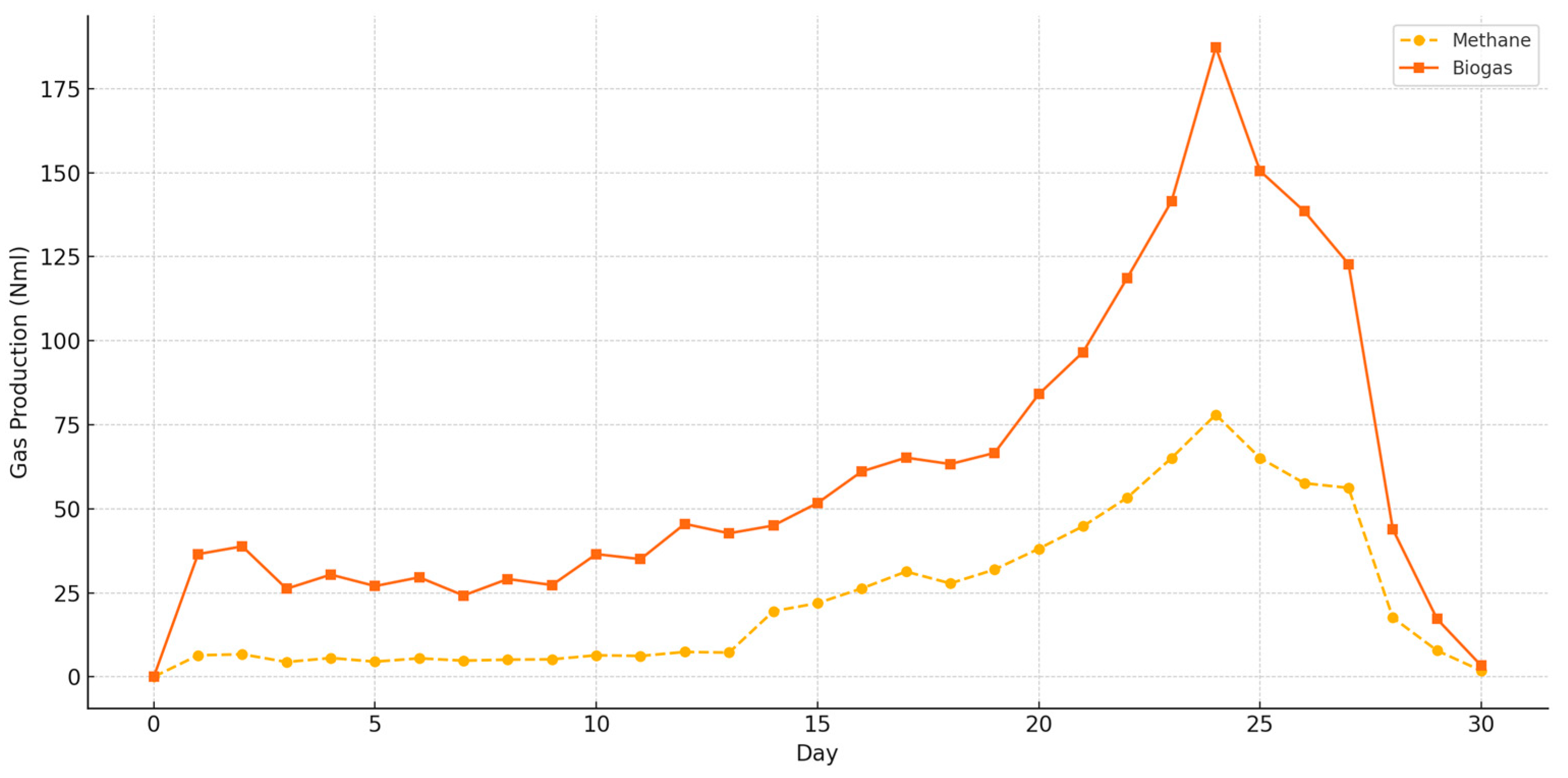

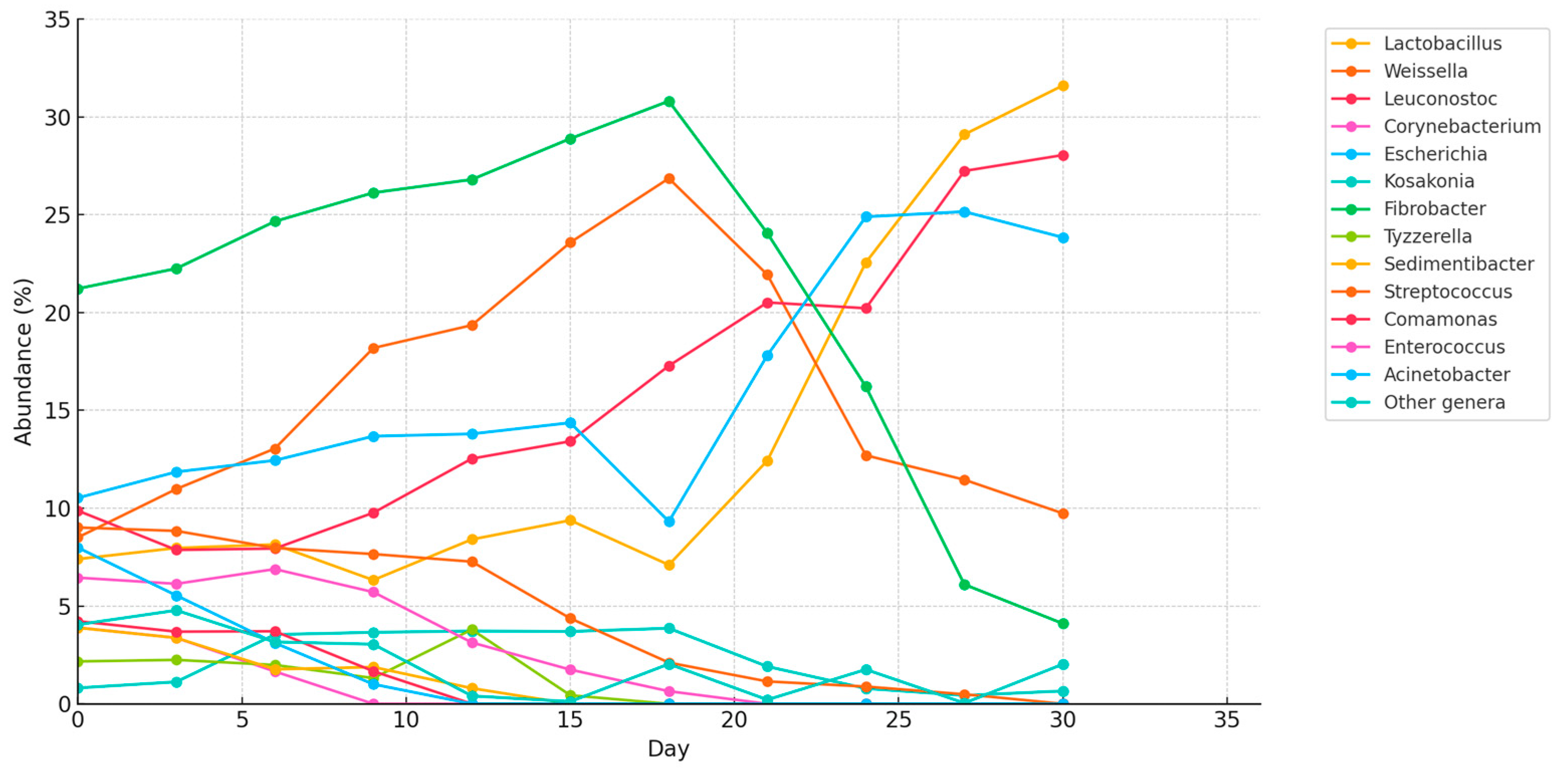

3.3. Gas Production, Microbial and Metabolomic Analysis

- Phase 1—Hydrolysis

- Phase 2—Intermediate phase

- Phase 3—Late phase

- Summary of AD process dynamics observed for horse manure

3.4. Designs

4. Discussion

| SDG Name (Number) 1 | Project Findings | Comparison to Other Research and Significance |

|---|---|---|

| Affordable and clean energy (7) | Biogas use replaced 5512 kWh/year of coal-fired grid electricity. Biogas combustion is cleaner than coal in terms of particulate emissions. | Biogas is obtained at no additional operational cost. Daily maintenance of the digester takes only 20 min from the employee’s daily routines. Burning coal in power plants generates 81 mg/MJ of particulates versus a near-zero emission from biogas combustion [60] |

| Climate action (13) | Approximately 1000 m3 of methane gas emissions from open manure heaps were diverted to energy use, thus reducing the global warming potential (GWP) effect of open dumped manures. | Instead of methane going into atmosphere and damaging the ozone, it is captured and then used in a controlled complete combustion technology where the only GHG generated is carbon dioxide. Methane GWP effect is 25 times stronger than that of carbon dioxide [61]. |

| Zero hunger (2) | At least 3 employees have 3 meals per day with vegetables grown onsite using digestate, saving almost US$5 on relish expenses per day. | Liquid digestate was evaluated and it was demonstrated that 58% of the different samples met the minimum N, Zn and Cu requirements for agriculture [62]. |

| Good health (3), Clean water and sanitation (6) | Reducing coal usage in power plants by using biogas reduces the associated pollution from power plants. Flies around the Sables were reduced. Manures are no longer washed away into open environments. | Coal power plants emit 1360 mg/MJ of SOx and 583 mg/MJ of NOx of power produced [60]. These emissions have a negative impact on the health of humankind. |

| Quality education (4) | The EARTH Centre is used for promoting STEM education in the Gauteng province of South Africa. | Students visit the EARTH Centre for science demonstrations and University postgraduates formulate research problems and acquire field data from the installation. |

| Life (14 and 15) | Plant life (lawn and flowers) growth improved at the EARTH Centre after the use of digestate on the lawns. This was witnessed by an increase in frequency of lawn mowing and flower tree pruning from 1 to 2 times per month before and after the digestate use periods. | Jurgutis et al. [63] applied digestate on grass at a rate of 170 kgN/ha and the grass biomass grew 3 times compared to the grass that had no digestate application. |

| Partnerships for the goals (17) | Government, Academia and Not-for-Profit partners were involved | University of South Africa (Academia), South African Energy Institute (Government) then EARTH Centre (Not-for-Profit) |

5. Future Actions for a Sustainable EARTH Centre

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AMPTS | Automatic Methane Potential Testing System |

| SDG | Sustainable Development Goals |

| AD | Anaerobic Digestion |

| SANEDI | South African National Energy Development Institute |

| UNISA | University of South Africa |

| IDEAS | UNISA’s Institute for the Development of Energy for African Sustainability |

| CAES | UNISA’s College of Agriculture and Environmental Sciences |

| GHG | Greenhouse Gas |

References

- Mastrangelo, M.E.; Perez-Harguindeguy, N.; Enrico, L.; Bennett, E.; Lavorel, S.; Cumming, G.S.; Abeygunawardane, D.; Amarilla, L.D.; Burkhard, B.; Egoh, B.N.; et al. Key knowledge gaps to achieve global sustainability goals. Nat. Sustain. 2019, 2, 1115–1121. [Google Scholar]

- Filho, W.L.; Tripathi, S.K.; Guerra, A.J.; Gine-Garriga, R.; Lovren Orlovic, V.; Willats, J. Using the sustainable development goals towards a better understanding of sustainability challenges. Int. J. Sustain. Dev. World Ecol. 2019, 26, 179–190. [Google Scholar] [CrossRef]

- Gbejewoh, O.; Keesstra, S.; Blancquaert, E. The 3Ps (Profit, Planet, and People) of Sustainability amidst Climate change: A South African Grape and Wine Perspective. Sustainability 2021, 13, 2910. [Google Scholar] [CrossRef]

- Matambo, T.S.; Rashama, C. The fulfilment of sustainable development goals through a greener biogas industry. In Innovations in the Global Biogas Industry; Woodhead Publishing: Cambridge, UK, 2025; pp. 343–359. [Google Scholar]

- Meeks, R.; Sims, K.R.E.; Thompson, H. Waste not: Can household biogas deliver sustainable development? Environ. Resour. Econ. 2019, 72, 763–794. [Google Scholar] [CrossRef]

- Lohani, S.P.; Dhungana, B.; Horn, H.; Khatiwada, D. Small-scale biogas technology and clean cooking fuel: Assessing the potential and links with SDGs in low-income countries—A case study of Nepal. Sustain. Energy Technol. Assess. 2021, 46, 101301. [Google Scholar] [CrossRef]

- Votteler, G.R.; Brent, A.C. A literature review on the potential of renewable electricity sources for mining operations in South Africa. J. Energy S. Afr. 2016, 27, 1–21. [Google Scholar]

- Dell’Orto, A.; Trois, C. Double-Stage Anaerobic Digestion for Biohydrogen Production: A Strategy for Organic Waste Diversion and Emission Reduction in a South African Municipality. Sustainability 2024, 16, 7200. [Google Scholar] [CrossRef]

- Mitchell, P. The Horse in Southern Africa. In Oxford Research Encyclopedia of African History; Oxford University Press: Oxford, UK, 2022. [Google Scholar] [CrossRef]

- van der Kolk, J.H.; Veldhuis Kroeze, E.J.B. Infectious Diseases of the Horse: Diagnosis, Pathology, Management, and Public Health, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, W.; Huang, W. Antibiotic Inhibition on Anaerobic Digestion of Animal Manure and Controlling Strategies: A Short Review. Clean–Soil Air Water 2019, 47, 1700653. [Google Scholar] [CrossRef]

- Hadin, A.; Eriksson, O. Horse manure as feedstock for anaerobic digestion. Waste Manag. 2016, 56, 506. [Google Scholar] [CrossRef]

- Lopes, M.; Baptista, P.; Duarte, E.; Moreira, A.L.N. Enhanced biogas production from anaerobic co-digestion of pig slurry and horse manure with mechanical pre-treatment. Env. Tech. 2019, 40, 1289–1297. [Google Scholar] [CrossRef]

- Krotz, L.; Giazzi, G. Nitrogen, Carbon and Sulfur Determination in Paper by Flash Combustion; Thermo Fisher Scientific: Parma, Italy, 2014; pp. 1–7. [Google Scholar]

- Bioprocesscontrol. AMPTS II & AMPTS II Light Automatic Methane Potential Test System—Operation and Maintenance Manual; Bioprocess Control Sweden AB: Lund, Sweden, 2016; pp. 1–95. [Google Scholar]

- Selvarajan, R.; Sibanda, T.; Venkatachalam, S.; Ogola, H.J.O.; Christopher Obieze, C.; Msagati, T.A. Distribution, Interaction and Functional Profiles of Epiphytic Bacterial Communities from the Rocky Intertidal Seaweeds, South Africa. Sci. Rep. 2019, 9, 1–13. [Google Scholar] [CrossRef]

- Nkuna, R.; Roopnarain, A.; Adeleke, R. Effects of organic loading rates on microbial communities and biogas production from water hyacinth: A case of mono- and co-digestion. J. Chem. Technol. Biotechnol. 2019, 94, 1294–1304. [Google Scholar] [CrossRef]

- Mysara, M.; Vandamme, P.; Props, R.; Kerckhof, F.; Leys, N.; Boon, N.; Monsieurs, P. Reconciliation between operational taxonomic units and species boundaries. FEMS Microbiol. Ecol. 2017, 93, fix029. [Google Scholar] [CrossRef]

- Mutungwazi, A.; Awosusi, A.; Matambo, T.S. Comparative functional microbiome profiling of various animal manures during their anaerobic digestion in biogas production processes. Biomass Bioenergy 2023, 170, 106728. [Google Scholar] [CrossRef]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilisation: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- Tsai, W.; Liu, S. Thermochemical characterization of cattle manure relevant to its energy conversion and environmental implications. Biomass Convers. Biorefinery 2016, 6, 71–77. [Google Scholar] [CrossRef]

- Simbayi, T.M.; Rashama, C.; Awosusi, A.A.; Nkuna, R.; Christian, R.; Matambo, T.S. Investigating the Anaerobic Digestion of Water Hyacinth (Eichhornia crassipes) Sourced from Hartbeespoort Dam in South Africa. Fermentation 2023, 9, 685. [Google Scholar] [CrossRef]

- Mutungwazi, A.; Ijoma, G.N.; Ogola, H.J.O.; Matambo, T.S. Physico-Chemical and Metagenomic Profile Analyses of Animal Manures Routinely Used as Inocula in Anaerobic Digestion for Biogas Production. Microorganisms 2022, 10, 671. [Google Scholar] [CrossRef]

- Castillo-González, A.R.; Burrola-Barraza, M.E.; Domínguez-Viveros, J.; Chávez-Martínez, A. Rumen microorganisms and fermentation. Arch. Med. Vet. 2014, 46, 349–361. [Google Scholar] [CrossRef]

- Henderson, G.; Cox, F.; Ganesh, S.; Jonker, A.; Young, W.; Janssen, P.H.; Abecia, L.; Angarita, E.; Aravena, P.; Arenas, G.N.; et al. Rumen microbial community composition varies with diet and host, but a core microbiome is found across a wide geographical range. Sci. Rep. 2015, 5, 14567. [Google Scholar] [CrossRef]

- Orlando, M.Q.; Borja, V.M. Pretreatment of animal manure biomass to improve biogas production: A review. Energies 2020, 13, 3573. [Google Scholar] [CrossRef]

- Vyas, P.; Kumar, A.; Singh, S. Biomass breakdown: A review on pretreatment, instrumentations and methods. Front. Biosci.—Elite 2018, 10, 155–174. [Google Scholar] [CrossRef]

- Heller, R.; Roth, P.; Hülsemann, B.; Böttinger, S.; Lemmer, A.; Oechsner, H. Effects of Pretreatment with a Ball Mill on Methane Yield of Horse Manure. Waste Biomass Valorization 2023, 14, 3723–3737. [Google Scholar] [CrossRef]

- De Fombelle, A.; Varloud, M.; Goachet, A.G.; Jacotot, E.; Philippeau, C.; Drogoul, C.; Julliand, V. Characterization of the microbial and biochemical profile of the different segments of the digestive tract in horses given two distinct diets. Anim. Sci. 2003, 77, 293–304. [Google Scholar] [CrossRef]

- Fusco, V.; Quero, G.M.; Cho, G.S.; Kabisch, J.; Meske, D.; Neve, H.; Bockelmann, W.; Franz, C.M.A.P. The genus Weissella: Taxonomy, ecology and biotechnological potential. Front. Microbiol. 2015, 6, 1–22. [Google Scholar] [CrossRef]

- Jensen, M.B.; de Jonge, N.; Dolriis, M.D.; Kragelund, C.; Fischer, C.H.; Eskesen, M.R.; Noer, K.; Møller, H.B.; Ottosen, L.D.M.; Nielsen, J.L.; et al. Cellulolytic and Xylanolytic Microbial Communities Associated with Lignocellulose-Rich Wheat Straw Degradation in Anaerobic Digestion. Front. Microbiol. 2021, 12, 1–13. [Google Scholar] [CrossRef]

- Moestedt, J.; Müller, B.; Nagavara Nagaraj, Y.; Schnürer, A. Acetate and Lactate Production During Two-Stage Anaerobic Digestion of Food Waste Driven by Lactobacillus and Aeriscardovia. Front. Energy Res. 2020, 8, 1–15. [Google Scholar] [CrossRef]

- Wirth, R.; Kovács, E.; Maráti, G.; Bagi, Z.; Rákhely, G.; Kovács, K.L. Characterization of a biogas-producing microbial community by short-read next generation DNA sequencing. Biotechnol. Biofuels 2012, 5, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Mutungwazi, A.; Ijoma, G.N.; Matambo, T.S. The significance of microbial community functions and symbiosis in enhancing methane production during anaerobic digestion: A review. Symbiosis 2020, 1, 1–24. [Google Scholar] [CrossRef]

- Menzel, T.; Neubauer, P.; Junne, S. Role of microbial hydrolysis in anaerobic digestion. Energies 2020, 13, 5555. [Google Scholar] [CrossRef]

- Wang, H.T.; Hsu, J.T. Optimal protease production condition for Prevotella ruminicola 23 and characterization of its extracellular crude protease. Anaerobe 2005, 11, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Guo, X.; Wang, Y.; He, M.; Ma, K.; Wang, H.; Chen, X.; Kong, D.; Yang, Z.; Ruan, Z. Terrisporobacter petrolearius sp. Nov., isolated from an oilfield petroleum reservoir. Int. J. Syst. Evol. Microbiol. 2015, 65, 3522–3526. [Google Scholar] [CrossRef]

- Gerritsen, J.; Fuentes, S.; Grievink, W.; van Niftrik, L.; Tindall, B.J.; Timmerman, H.M.; Rijkers, G.T.; Smidt, H. Characterization of Romboutsia ilealis gen. nov., sp. nov., isolated from the gastro-intestinal tract of a rat, and proposal for the reclassification of five closely related members of the genus Clostridium into the genera Romboutsia gen. nov., Intestinib. Int. J. Syst. Evol. Microbiol. 2014, 64, 1600–1616. [Google Scholar] [CrossRef] [PubMed]

- Saini, J.; Deere, T.M.; Chanderban, M.; McIntosh, G.J.; Lessner, D.J. Methanosarcina acetivorans. Trends Microbiol. 2022, 47, 971–978. [Google Scholar] [CrossRef]

- Oleskowicz-Popiel, P.; Jankowska, E.; Chwiałkowska, J.; Stodolny, M. Effect of pH and retention time on volatile fatty acids production during mixed culture fermentation. Bioresour. Technol. 2015, 190, 274–280. [Google Scholar]

- Mukhuba, M.; Roopnarain, A.; Moeletsi, E.; Adeleke, R. Metagenomic insights into the microbial community and biogas production pattern during anaerobic digestion of cow dung and mixed food waste. J. Chem. Technol. Biotechnol. 2020, 95, 151–162. [Google Scholar] [CrossRef]

- Dalpaz, R.; Konrad, O.; da Silva Cyrne, C.C.; Barzotto, H.P.; Hasan, C.; Filho, M.G. Using biogas for energy cogeneration: An analysis of electric and thermal generation from agro-industrial waste. Sustain. Energy Technol. Assess. 2020, 40, 100774. [Google Scholar] [CrossRef]

- Wang, S.; Ma, F.; Ma, W.; Wang, P.; Zhao, G.; Lu, X. Influence of temperature on biogas production efficiency and microbial community in a two-phase anaerobic digestion system. Water 2019, 11, 133. [Google Scholar] [CrossRef]

- Taleghani, G.; Kia, A.S. Technical-economic analysis of the Saveh biogas power plant. Renew. Energy 2005, 30, 441–446. [Google Scholar] [CrossRef]

- Kafle, G.K.; Chen, L. Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef]

- Kheybari, S.; Rezaie, F.M. Selection of biogas, solar and wind power plants’ locations: An MCDA approach. J. Supply Chain Manag. Sci. 2020, 1, 45–71. [Google Scholar] [CrossRef]

- Tumwesige, V.; Fulford, D.; Davidson, G.C. Biogas appliances in Sub-Sahara Africa. Biomass Bioenergy 2014, 70, 40–50. [Google Scholar] [CrossRef]

- Alfa, M.I.; Owamah, H.I.; Onokwai, A.O.; Gopikumar, S.; Oyebisi, S.O.; Kumar, S.S.; Bajar, S.; Samuel, O.D.; Ilabor, S.C. Evaluation of biogas yield and kinetics from the anaerobic codigestion of cow dung and horse dung: A strategy for sustainable management of livestock manure. Energy Ecol. Environ. 2021, 6, 425–434. [Google Scholar] [CrossRef]

- Turker, G.; Aydin, S.; Akyol, C.; Yenigun, O.; Ince, O.; Ince, B. Changes in microbial community structures due to varying operational conditions in the anaerobic digestion of oxytetracycline-medicated cow manure. Environ. Biotechnol. 2016, 100, 6469–6479. [Google Scholar] [CrossRef]

- Orrico Junior, M.A.P.; Orrico, A.C.A. Quantification, characterization and anaerobic digestion of sheep manure: The influence of diet and addition of criude glycerin. Environ. Prog. Sustain. Energy 2015, 34, 1038–1043. [Google Scholar] [CrossRef]

- Alessandro, C.; da Borso, F.; Guercini, S.; Pezzuolo, A.; Zanotto, M.; Sgorlon, S.; Delle Vedove, G.; Miceli, F.; Stefanon, B. The impact of the dairy cow diet on anaerobic digestion of manure. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019; American Society of Agricultural and Biological Engineers: St Joseph, MI, USA, 2019; p. 1. [Google Scholar]

- Sutaryo, S.; Ward, A.J.; Moller, H.B. The effect of mixed-enzyme addition in anaerobic digestion on methane yield of dairy cattle manure. Environ. Technol. 2014, 35, 2476–2482. [Google Scholar] [CrossRef]

- Weide, T.; Baquero, C.D.; Schomaker, M.; Brugging, E.; Wetter, C. Effects of enzyme addition on biogas and methane yields in the batch anaerobic digestion of agricultural waste (silage, straw, and animal manure). Biomass Bioenergy 2020, 132, 105442. [Google Scholar] [CrossRef]

- Triolo, J.M.; Sommer, S.G.; Møller, H.B.; Weisbjerg, M.R.; Jiang, X.Y. A new algorithm to characterize biodegradability of biomass during anaerobic digestion: Influence of lignin concentration on methane production potential. Bioresour. Technol. 2011, 102, 9395–9402. [Google Scholar] [CrossRef]

- Edwiges, T.; Frare, L.; Mayer, B.; Lins, L.; Mi Triolo, J.; Flotats, X.; de Mendonça Costa, M.S.S. Influence of chemical composition on biochemical methane potential of fruit and vegetable waste. Waste Manag. 2018, 71, 618–625. [Google Scholar] [CrossRef]

- Garcia, N.H.; Mattioli, A.; Gil, A.; Frison, N.; Battista, F.; Bolzonella, D. Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas. Renew. Sustain. Energy Rev. 2019, 112, 1–10. [Google Scholar] [CrossRef]

- Mohamed, A.; Abdallah, S.; Mohamad, A.; Chaouki, G.; Suhair, S. Biogas production from different types of cow manure. In Proceedings of the Advances in Science and Engineering Technology International Conferences (ASET), Sharjah, Abhu Dhabi, 6 February–5 April 2018. [Google Scholar]

- Kumar, A.; Mandal, B.; Sharma, A. Advancement in Biogas Digester. In Energy Sustainability through Green Energy and Technology; Sharma, A., Kar, S., Eds.; Springer: New Delhi, India, 2015; pp. 351–382. [Google Scholar]

- Mutungwazi, A.; Mukumba, P.; Makaka, G. Biogas digester types installed in South Africa: A review. Renew. Sustain. Energy Rev. 2018, 81, 172–180. [Google Scholar] [CrossRef]

- Albina, D.O.; Themelis, N.J. Emissions from waste-to-energy: A comparison with coal-fired power plants. In Proceedings of the ASME International Mechanical Engineering Congress, Washington, DC, USA, 16–21 November 2003; IMECE2003-55295. pp. 1–16. [Google Scholar]

- Brander, M.; Davis, G. Greenhouse Gases, CO2, CO2e, and Carbon: What Do All These Terms Mean? Econom. White Pap. 2012, 2–3. [Google Scholar]

- Reuland, G.; Sigurnjak, I.; Dekker, H.; Michels, E.; Meers, E. The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria. Agronomy 2021, 11, 1374. [Google Scholar] [CrossRef]

- Jurgutis, L.; Šlepetienė, A.; Amalevičiūtė-Volungė, K.; Volungevičius, J.; Šlepetys, J. The effect of digestate fertilisation on grass biogas yield and soil properties in field-biomass-biogas-field renewable energy production approach in Lithuania. Biomass Bioenergy 2021, 153, 106211. [Google Scholar] [CrossRef]

- Bansal, V.; Tumwesige, V.; Smith, J.U. Water for small-scale biogas digesters in sub-Saharan Africa. GCB Bioenergy 2017, 9, 339–357. [Google Scholar] [CrossRef]

- Kanter, D.R. Nitrogen pollution: A key building block for addressing climate change. Clim. Change 2018, 147, 11–21. [Google Scholar] [CrossRef]

- Su, X.; Shao, X.; Geng, Y.; Tian, S.; Yixiang, H. Optimization of feedstock and insulating strategies to enhance biogas production of solar-assisted biodigester system. Renew. Energy 2022, 197, 59–68. [Google Scholar] [CrossRef]

| % C | % H | % N | % S | % O | C/N |

|---|---|---|---|---|---|

| 48.0 | 5.6 | 1.9 | 0.3 | 55.8 | 25.26 |

| AD Stage. (Batch Experiments) | Dominant Microorganisms (Abundance) | Remarks | |

|---|---|---|---|

| Cow Manure [41] | Horse Manure [This Study] | ||

| Early stage (first 1.5 weeks) | Ruminiclostridium 1 (39%) Butyrivibrio 2 (20%) Acinetobacter (16%) Aquabacterium (8%) Macellibacteroides (5%) Lactobacillus (3%) Ruminococcaceae UCG-009 (2%) | Fibrobacter (21–27%) Weissella (9–19%) Escherichia (11–14%) Leuconostoc (10–13%) Lactobacillus (7–8%) Streptococcus (9–7%) Enterococcus (6–3%) Acinetobacter (8%). | There is a completely different set of microorganisms in the two digester manure slurries, except for the Acinetobacter and Lactobacillus which are found in both. The Acinetobacter is much more densely populated in the cow manure than it is in the horse manure where it was observed to be decreasing as the reaction progressed to the end. The Lactobacillus abundance is low in both manures. The difference in microbial species and abundance between these two explains the faster hydrolysis in cow manure digesters than in horse manure ones. |

| Mid-stage (2–3 weeks) | Acinetobacter (27%) Ruminiclostridium 1 (16%) Ruminococcaceae UCG-002 (7%) Ruminococcaceae UCG-009 (4%) Saccharofermentans (4%) Desulfovibrio (4%) Macellibacteroides (2%) | Fibrobacter (27–31%) Weissella (19–27%) Escherichia (14–18%) Leuconostoc (13–21%) Lactobacillus (8–12%) | Again, the speciation of microorganisms in the two manures is very different. However, there is more diversity and evolvement of the microbial dynamics in the cow manure than the horse manure. The horse manure microbial population profiles did not change much and this was also reflected in the biogas production rate which was almost stagnant during this period and was only accompanied by a few increases in metabolites. |

| Late stage (4–5 weeks) | Ruminiclostridium 5 (24%) Acinetobacter (14%) Lactobacillus (9%) Bifidobacterium (6%) Haliangium (5%) Lachnospiraceae UCG-004 (4%) Butyrivibrio 2 (4%) Aquabacterium (4%) | Lactobacillus (33%) Leuconostoc (27%) Escherichia (24%) Weissella (10%) Fibrobacter (4%) | In both manures, there were visible microbial shifts with Lactobacillus featuring in both manures. Acinetobacter which was consistently high in the cow manure slurries from the beginning continued to exist in high proportions although this was not the case in horse manure where the Acinetobacter population quickly decreased from the onset of the digester to around day 13 when these genera was never found in horse manure again. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashama, C.; Matambo, T.; Mutungwazi, A.; Riann, C.; Nhamo, G. Harnessing Horsepower from Horse Manure at the EARTH Centre in South Africa: Biogas Initiative Improve the Facility’s Operational Sustainability. Energies 2025, 18, 1808. https://doi.org/10.3390/en18071808

Rashama C, Matambo T, Mutungwazi A, Riann C, Nhamo G. Harnessing Horsepower from Horse Manure at the EARTH Centre in South Africa: Biogas Initiative Improve the Facility’s Operational Sustainability. Energies. 2025; 18(7):1808. https://doi.org/10.3390/en18071808

Chicago/Turabian StyleRashama, Charles, Tonderayi Matambo, Asheal Mutungwazi, Christian Riann, and Godwell Nhamo. 2025. "Harnessing Horsepower from Horse Manure at the EARTH Centre in South Africa: Biogas Initiative Improve the Facility’s Operational Sustainability" Energies 18, no. 7: 1808. https://doi.org/10.3390/en18071808

APA StyleRashama, C., Matambo, T., Mutungwazi, A., Riann, C., & Nhamo, G. (2025). Harnessing Horsepower from Horse Manure at the EARTH Centre in South Africa: Biogas Initiative Improve the Facility’s Operational Sustainability. Energies, 18(7), 1808. https://doi.org/10.3390/en18071808