A Comprehensive System for Protection of Photovoltaic Installations in Normal and Emergency Conditions

Abstract

1. Introduction

2. Conception of a Safety System for PV Installations

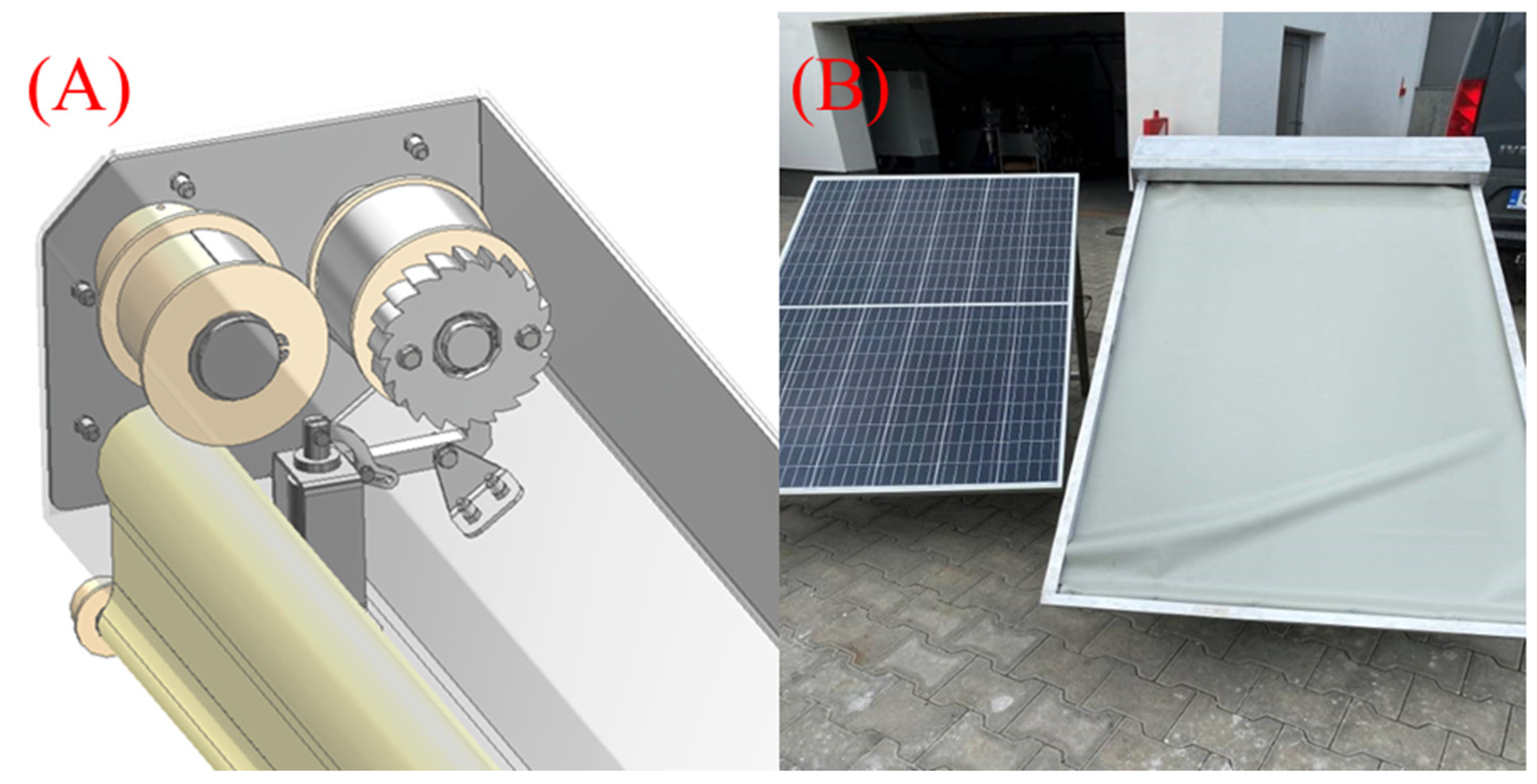

2.1. A Blind Limiting UV Radiation Access to PV Panels

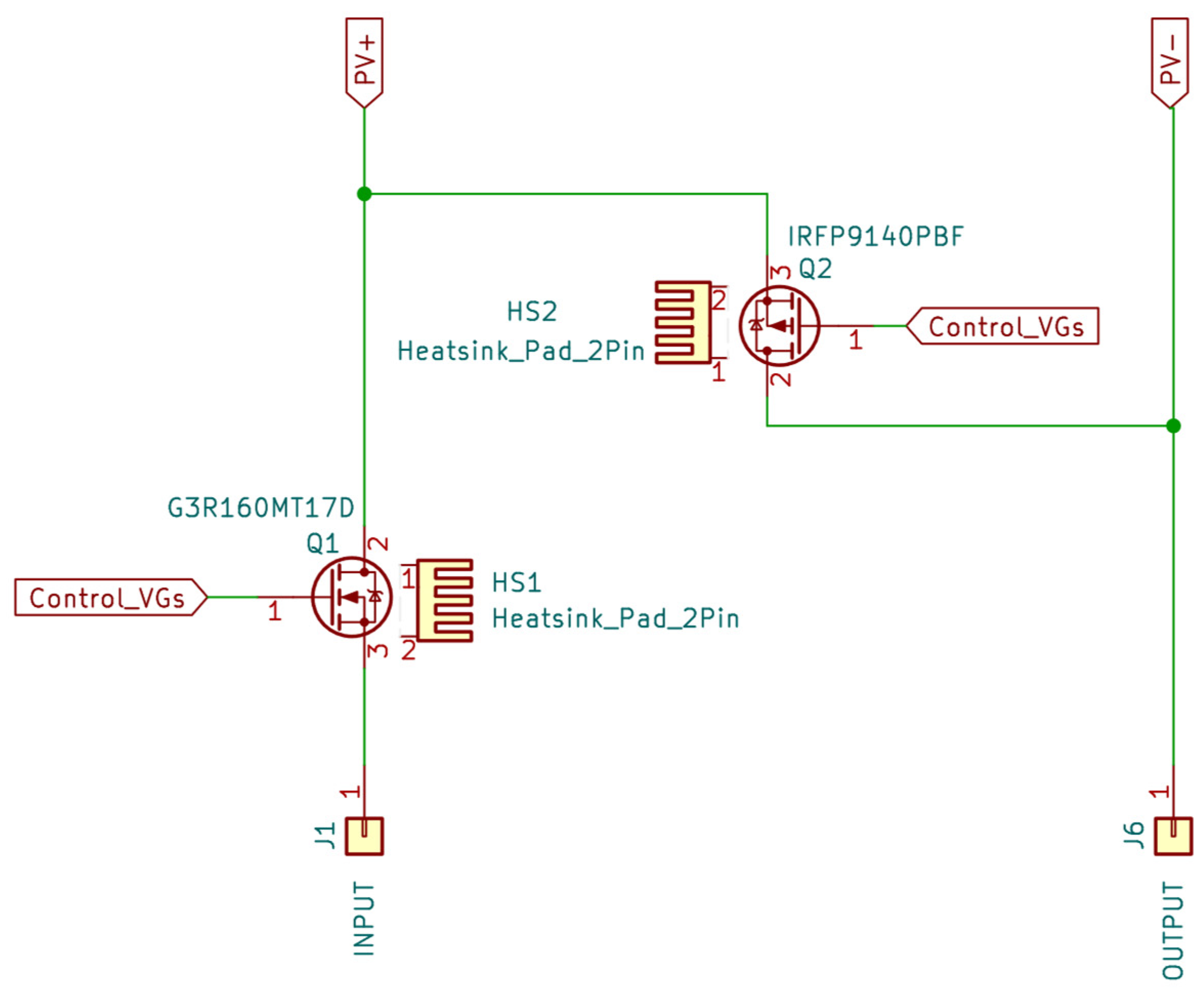

2.2. Limiting the Voltage of PV Panels Using a Safety Switching Device

3. Numerical Simulations of the Proposed System

3.1. Numerical Simulations of the Touch Current

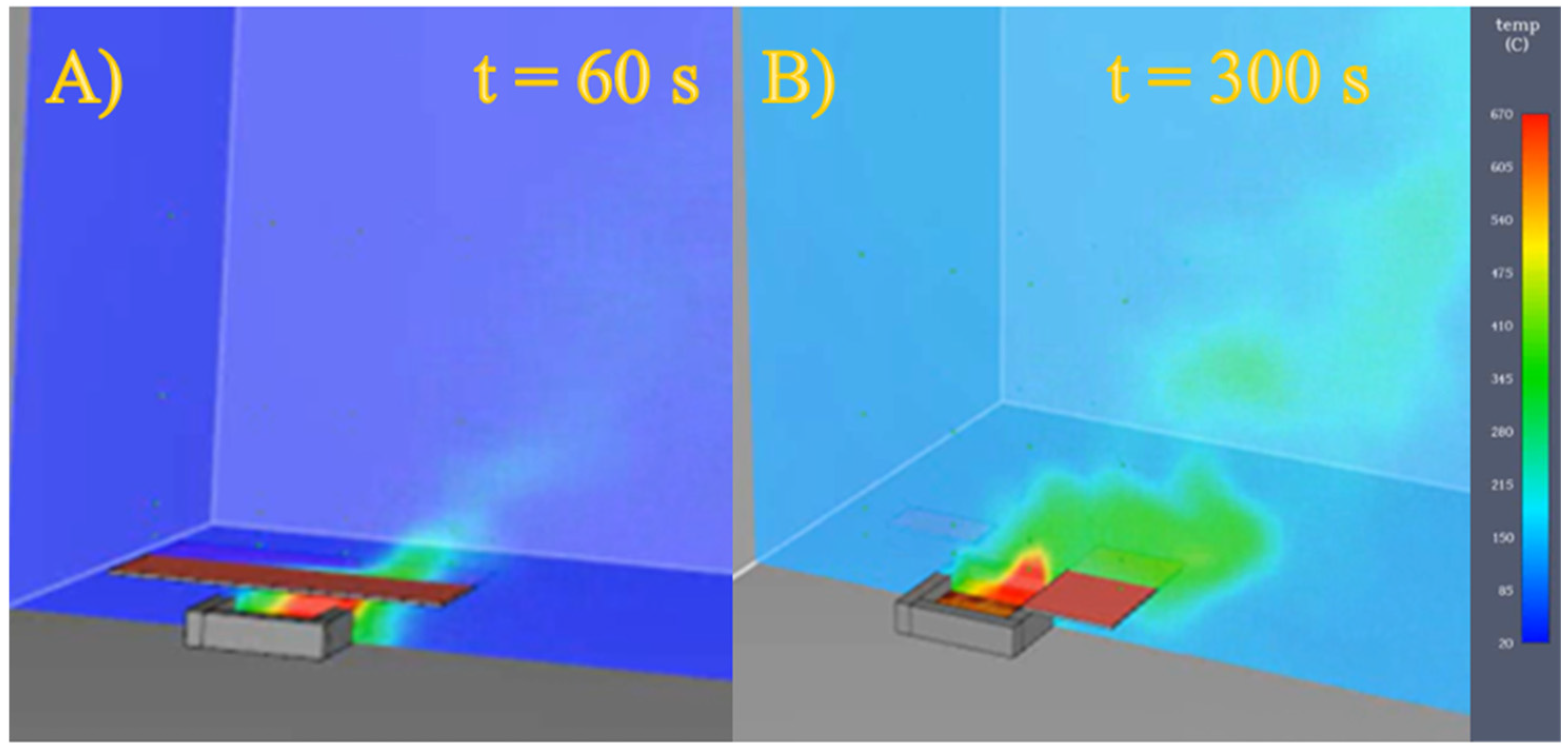

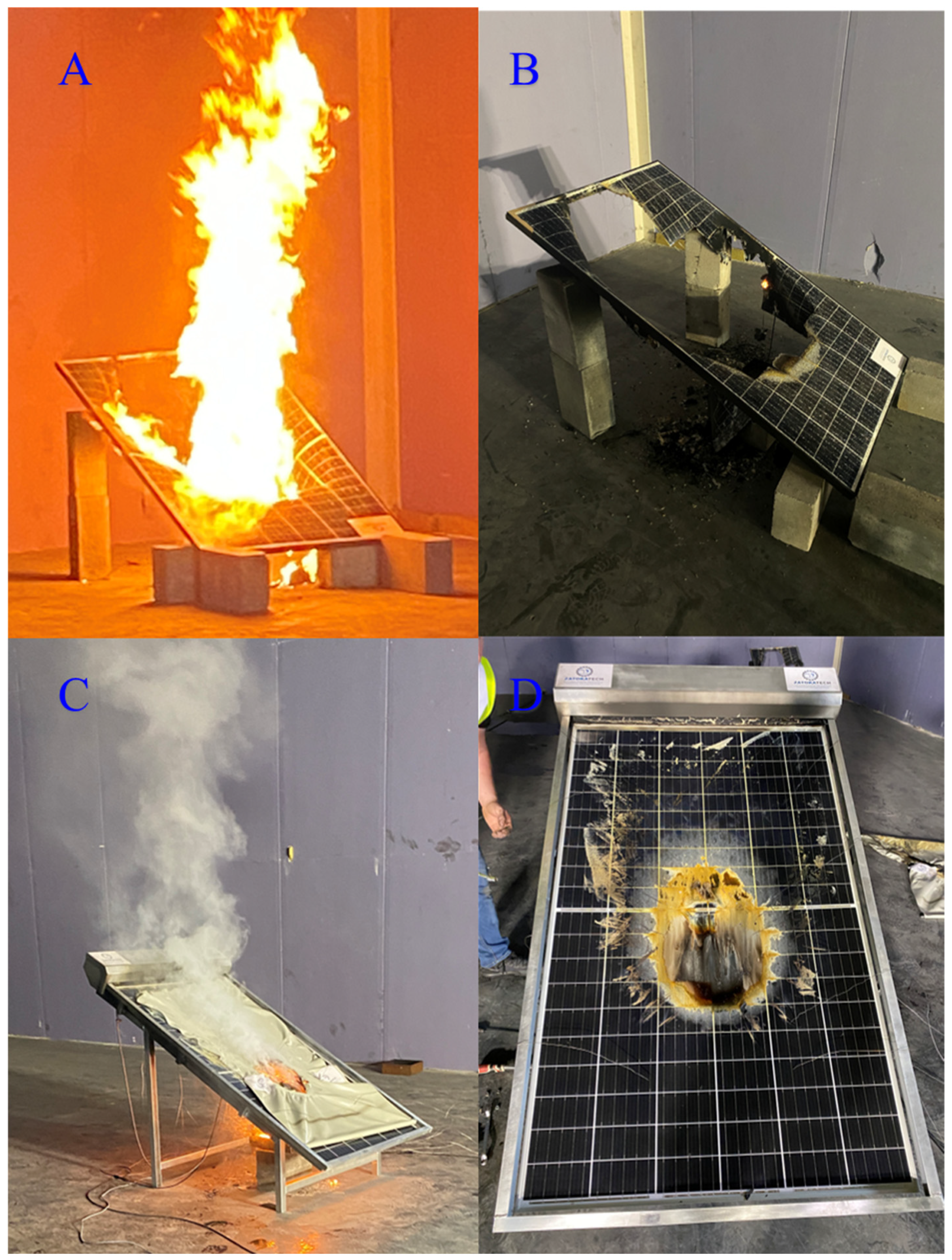

3.2. Numerical Simulations of the Fire Protection

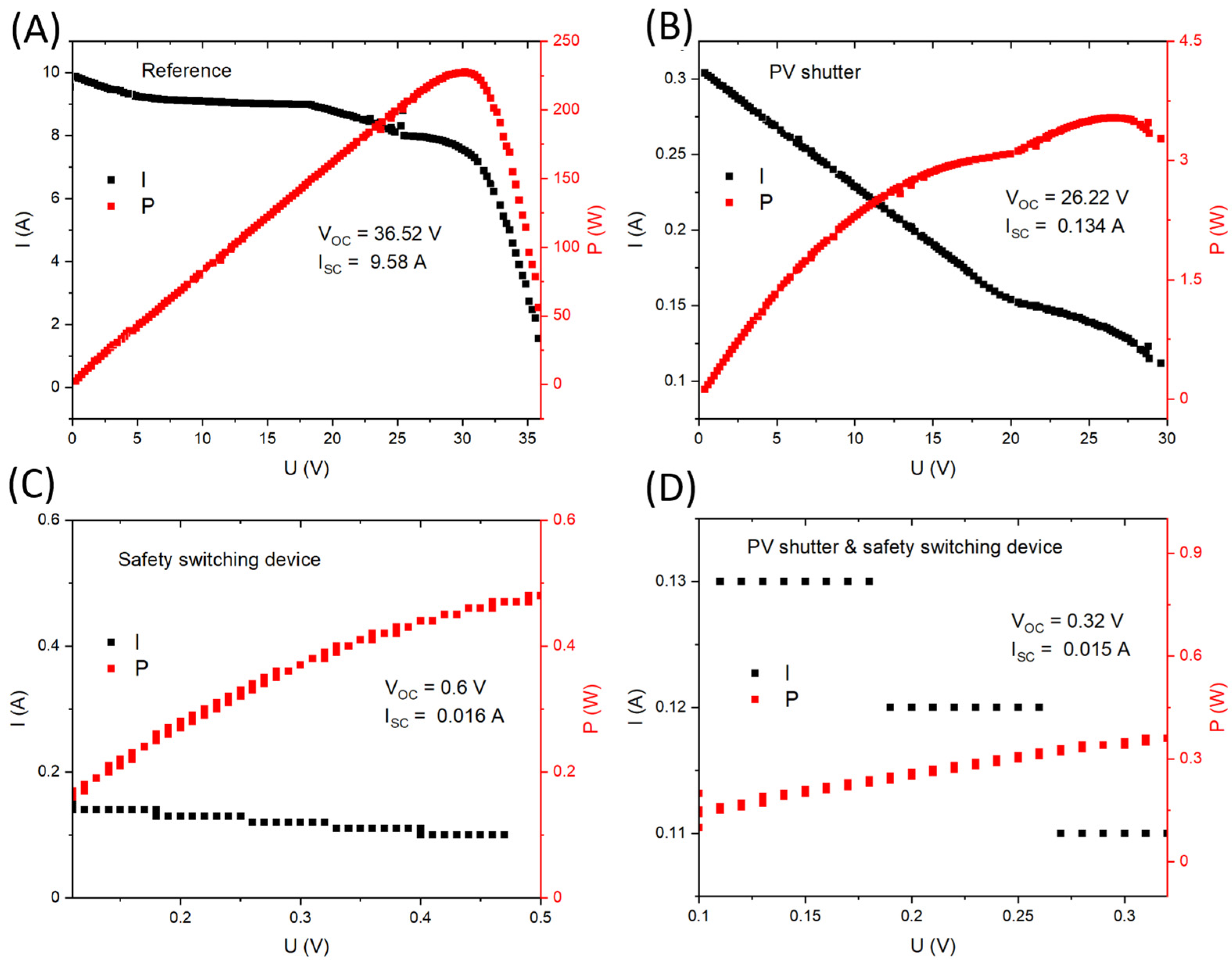

4. Experimental Verification of the Adopted Solutions

5. Economic Analysis of the Proposed System

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Supplementary Data

References

- Rynska, E. Review of PV Solar Energy Development 2011–2021 in Central European Countries. Energies 2022, 15, 8307. [Google Scholar] [CrossRef]

- Cader, J.; Olczak, P.; Koneczna, R. Regional dependencies of interest in the ‘My Electricity’ photovoltaic subsidy program in Poland. Polityka Energetyczna–Energy Policy J. 2021, 24, 97–116. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, J.; Meng, F.; Zoras, S.; McKechnie, J.; Chu, J. Energy assessment and economic sensitivity analysis of a grid-connected photovoltaic system. Renew. Energy 2020, 150, 101–115. [Google Scholar] [CrossRef]

- Sanchez-Sutil, F.; Hernández, J.C.; Tobajas, C. Overview of electrical protection requirements for integration of a smart DC node with bidirectional electric vehicle charging stations into existing AC and DC railway grids. Electr. Power Syst. Res. 2015, 122, 104–118. [Google Scholar] [CrossRef]

- HernÁndez, J.C.; Vidal, P.G. Guidelines for Protection Against Electric Shock in PV Generators. IEEE Trans. Energy Convers. 2009, 24, 274–282. [Google Scholar] [CrossRef]

- Czapp, S.; Swisulski, D. LabVIEW-based intelligent system of protection against electric shock for photovoltaic installations. In Proceedings of the 2017 52nd International Universities Power Engineering Conference (UPEC), Heraklion, Greece, 28–31 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Pons, E.; Tommasini, R. Lightning protection of PV systems. In Proceedings of the 2013 4th International Youth Conference on Energy (IYCE), Siófok Hungary, 6–8 June 2013; pp. 1–5. [Google Scholar]

- Christodoulou, C.A.; Ekonomou, L.; Gonos, I.F.; Papanikolaou, N.P. Lightning protection of PV systems. Energy Syst. 2016, 7, 469–482. [Google Scholar]

- Fallah, N.; Gomes, C.; Ab Kadir, M.Z.A.; Nourirad, G.; Baojahmadi, M.; Ahmed, R.J. Lightning protection techniques for roof-top PV systems. In Proceedings of the 2013 IEEE 7th International Power Engineering and Optimization Conference (PEOCO), Langkawi, Malaysia, 3–4 June 2013; pp. 417–421. [Google Scholar]

- Litzbarski, L.; Olesz, M.; Seklecki, K.; Nowak, M. Ryzyko strat odgromowych a systemy fotowoltaiczne. Przeglad Elektrotechniczny 2023, 1, 295–297. [Google Scholar]

- MFalvo, C.; Capparella, S. Safety issues in PV systems: Design choices for a secure fault detection and for preventing fire risk. Case Stud. Fire Saf. 2015, 3, 1–16. [Google Scholar] [CrossRef]

- Mazziotti, L.; Cancelliere, P.; Paduano, G.; Setti, P.; Sassi, S. Fire risk related to the use of PV systems in building facades. MATEC Web Conf. 2016, 46, 5001. [Google Scholar] [CrossRef]

- Wu, Z.; Hu, Y.; Wen, J.X.; Zhou, F.; Ye, X. A Review for Solar Panel Fire Accident Prevention in Large-Scale PV Applications. IEEE Access 2020, 8, 132466–132480. [Google Scholar] [CrossRef]

- Seklecki, K.; Litzbarski, L.; Wójcik, K.; Cieślikowska, Z.; Włas, M.; Grochowski, J. Instalacje fotowoltaiczne w budownictwie wielorodzinnym. Przeglad Elektrotechniczny 2024, 2024, 81–83. [Google Scholar] [CrossRef]

- Litzbarski, L.S.; Seklecki, K.; Adamowicz, M.; Grochowski, J. PV installations and the safety of residential buildings. Inżynieria Bezpieczeństwa Obiektów Antropog. 2023, 4, 1–10. [Google Scholar]

- Ong, N.A.F.M.N.; Tohir, M.Z.M.; Mutlak, M.M.; Sadiq, M.A.; Omar, R.; Said, M.S.M. BowTie analysis of rooftop grid-connected photovoltaic systems. Process. Saf. Prog. 2022, 41, S106–S117. [Google Scholar] [CrossRef]

- Backstrom, R.; Dini, D. Firefighter safety and photovoltaic installations research project. In Proceedings of the Reliability of Photovoltaic Cells, Modules, Components, and Systems V, San Diego, CA, USA, 12–16 August 2012; pp. 78–92. [Google Scholar]

- Ramali, M.R.; Ong, N.A.F.M.N.; Said, M.S.M.; Yusoff, H.M.; Baharudin, M.R.; Tharima, A.F.; Akashah, F.W.; Tohir, M.Z.M. A Review on Safety Practices for Firefighters During Photovoltaic (PV) Fire. Fire Technol. 2023, 59, 247–270. [Google Scholar] [CrossRef] [PubMed]

- Young-chan, O.; Kawshalya, R.; Jin, P.; Lim, H. Study on Fire Breakout Prevention of Solar Power System. Int. J. Energy Environ. Econ. 2020, 26, 31. [Google Scholar]

- Cancelliere, P.; Puccia, V.; Longobardo, G.; Liciotti, C.; Cardinali, M. Behavior of the Electrical Parameters of PV Modules Subject to a Flame Ignition. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Paris, France, 30 September–4 October 2013. [Google Scholar]

- Kiryu, K.; Tanaka, T.; Seki, K.; Satou, K. Verification of arc discharge phenomenon and connection reliability. In Proceedings of the 2019 IEEE Third International Conference on DC Microgrids (ICDCM), Matsue, Japan, 20–23 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Baumgartner, F. 5-Photovoltaic (PV) balance of system components: Basics, performance. In The Performance of Photovoltaic (PV) Systems; Pearsall, N., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 135–181. [Google Scholar] [CrossRef]

- Kobrin, B. Self-Cleaning Technologies for Solar Panels; n-Tech Research Publication: Glen Allen, VA, USA, 2018. [Google Scholar]

- Hossain, M.S.; Pandey, A.K.; Rahim, N.A.; Selvaraj, J.; Tyagi, V.V.; Islam, M.M. Self-cleaning assisted photovoltaic system with thermal energy storage: Design and performance evaluation. Sol. Energy 2020, 206, 487–498. [Google Scholar] [CrossRef]

- Khan, M.U.; Abbas, M.; Khan, M.M.; Kousar, A.; Alam, M.; Massoud, Y.; Jafri, S.H.M. Modeling and design of low-cost automatic self cleaning mechanism for standalone micro PV systems. Sustain. Energy Technol. Assess. 2021, 43, 100922. [Google Scholar] [CrossRef]

- Styszko, K.; Jaszczur, M.; Teneta, J.; Hassan, Q.; Burzyńska, P.; Marcinek, E.; Łopian, N.; Samek, L. An analysis of the dust deposition on solar photovoltaic modules. Environ. Sci. Pollut. Res. 2019, 26, 8393–8401. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Rudnicka, M. The Analysis of Working Parameters Decrease in Photovoltaic Modules as a Result of Dust Deposition. Energies 2020, 13, 4138. [Google Scholar] [CrossRef]

- Litzbarski, L.; Olesz, M.; Seklecki, K. Measurement practice of photovoltaic installations leading to the determination of the actual technical condition; [Praktyka wykonywania pomiarów instalacji fotowoltaicznych prowadząca do określenia rzeczywistego stanu technicznego]. Przeglad Elektrotechniczny 2024, 2024, 84–86. [Google Scholar] [CrossRef]

- Simon, M.; Meyer, E.L. Detection and analysis of hot-spot formation in solar cells. Sol. Energy Mater. Sol. Cells 2010, 94, 106–113. [Google Scholar] [CrossRef]

- Rijvers, L.; Rindt, C.; de Keizer, C. Numerical Analysis of a Residential Energy System That Integrates Hybrid Solar Modules (PVT) with a Heat Pump. Energies 2022, 15, 96. [Google Scholar] [CrossRef]

- Ju, X.; Xu, C.; Liao, Z.; Du, X.; Wei, G.; Wang, Z.; Yang, Y. A review of concentrated photovoltaic-thermal (CPVT) hybrid solar systems with waste heat recovery (WHR). Sci. Bull. 2017, 62, 1388–1426. [Google Scholar] [CrossRef]

- Vittorini, D.; Castellucci, N.; Cipollone, R. Heat recovery potential and electrical performances in-field investigation on a hybrid PVT module. Appl. Energy 2017, 205, 44–56. [Google Scholar] [CrossRef]

- Dini, D.A.; Brazis, P.W.; Yen, K.-H. Development of Arc-Fault Circuit-Interrupter requirements for Photovoltaic systems. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 1790–1794. [Google Scholar]

- Ramos, F.; Neto, J.; Almeida, F.; Velázquez, S.; Lima, B. Compliance Analysis of Series Arc-fault in AFCI- Equipped Inverters in Accordance with IEC 63027. IEEE Lat. Am. Trans. 2024, 22, 761–770. [Google Scholar] [CrossRef]

- Bower, W.; Wiles, J. Investigation of ground-fault protection devices for photovoltaic power system applications. In Proceedings of the Conference Record of the Twenty-Eighth IEEE Photovoltaic Specialists Conference—2000 (Cat. No.00CH37036), Anchorage, AK, USA, 15–22 September 2000; pp. 1378–1383. [Google Scholar] [CrossRef]

- Zetawi, E.A.; Abdulhadi, E.O.; Shahroury, F.R.; Ahmad, H.H.; Akour, A. Components and Specification of Rapid Shutdown for Roof PV Systems. In Proceedings of the 2021 International Conference on Microelectronics (ICM), New Cairo City, Egypt, 19–22 December 2021; pp. 182–185. [Google Scholar] [CrossRef]

- Cordova, A.; Merz, C.; Bettenwort, G.; Hopf, M.; Knopf, H.; Laschinski, J. Rapid Shutdown with Panel Level Electronics—A suitable safety measure? In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 1965–1967. [Google Scholar] [CrossRef]

- Yalçın, C. Thermal imaging-based fault detection and energy efficiency analysis in a 1.6 MW photovoltaic system in Bağyurdu OIZ, Türkiye. Energy Storage Convers. 2025, 3, 1984. [Google Scholar] [CrossRef]

- Kandeal, A.; Elkadeem, M.; Thakur, A.K.; Abdelaziz, G.B.; Sathyamurthy, R.; Kabeel, A.; Yang, N.; Sharshir, S.W. Infrared thermography-based condition monitoring of solar photovoltaic systems: A mini review of recent advances. Sol. Energy 2021, 223, 33–43. [Google Scholar] [CrossRef]

- Ohuchi, T.; Ishikawa, N.; Kozawa, Y. Improvement of the fire-proofing and fire-resistance properties of PV modules for building’s exterior walls. In Proceedings of the Conference Record of the Twenty-Eighth IEEE Photovoltaic Specialists Conference—2000 (Cat. No.00CH37036), Anchorage, AK, USA, 15–22 September 2000; pp. 1533–1538. [Google Scholar] [CrossRef]

- Brito, M.d.F.; de Lima, L.C.; Batista, N.E. Batista Use of artificial intelligence in fire safety in solar photovoltaic systems. Res. Soc. Dev. 2023, 12, e106121444567. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, P.; Wang, Y.; Li, D.; Liu, B. A DC arc detection method for photovoltaic (PV) systems. Results Eng. 2024, 21, 101807. [Google Scholar] [CrossRef]

- Kitai, A. Principles of Solar Cells, LEDs and Diodes: The Role of the PN Junction; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Abdelhady, S.; Abd-Elhady, M.S.; Fouad, M.M. An Understanding of the Operation of Silicon Photovoltaic Panels. Energy Procedia 2017, 113, 466–475. [Google Scholar] [CrossRef]

- Koźbiał, T. Generatory fotowoltaiczne w kontekście doboru elementów składowych oraz ochrony przeciwpożarowej. Przegląd Elektrotechniczny 2019, 96, 208–212. [Google Scholar] [CrossRef]

- IEC 60990; Methods of Measurement of Touch Current and Protective Conductor Current. British Standard: London, UK, 2016.

- Czapp, S.; Seklecki, K.; Litzbarski, L.; Olesz, M. Zagrożenie porażeniem podczas gaszenia pożaru w budynkach z fotowoltaicznymi źródłami energii. Przegląd Elektrotechniczny 2024, 66–72. [Google Scholar] [CrossRef]

- Czapp, S. Residual current devices in installations with PV energy sources. Przegląd Elektrotechniczny 2022, 98, 100–104. [Google Scholar]

- Tsai, H.-L.; Tu, C.-S.; Su, Y.-J. Development of generalized photovoltaic model using MATLAB/SIMULINK. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 22–24 October 2008; pp. 1–6. [Google Scholar]

- Chinen, K.; Kinjo, I.; Zamami, A.; Irei, K.; Nagayama, K. New equivalent-electrical circuit model and a practical measurement method for human body impedance. Bio-Med. Mater. Eng. 2015, 26, S779–S786. [Google Scholar] [CrossRef]

- Solar Swiss. Available online: https://www.swissenergy-solar.ch/product/ibex-120mhc-eiger-450-460-full-black-en/ (accessed on 7 March 2025).

- IEC 61730-2; Photovoltaic (PV) Module Safety Qualification—Part 2: Requirements for Testing. IECEE: Geneva, Switzerland, 2023.

- Abràmoff, M.D.; Magalhães, P.J.; Ram, S.J. Image processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Kut, P.; Nowak, K. Design of Photovoltaic Systems using Computer Software. J. Ecol. Eng. 2019, 20, 72–78. [Google Scholar] [CrossRef]

- Forbes. Available online: https://www.forbes.com/home-improvement/solar/cost-of-solar-panels/ (accessed on 7 March 2025).

| Parameter | Title 2 |

|---|---|

| Model | IBEX 120 |

| MHC_EIGER | |

| Maximum power (Pmax) | 450 W |

| Open circuit voltage (Voc) | 49.03 V |

| Short-circuit current (Isc) | 11.04 A |

| Voltage at Pmax (Vmp) | 41.40 V |

| Current at Pmax (Imp) | 10.87 A |

| Module efficiency | 20.85% |

| Power of PV System (kWp) | Number of PV Panels | Number of Strings | Cost of PV Installation (USD) | Cost of Safety System (USD) | Total Cost (USD) | |

|---|---|---|---|---|---|---|

| Single-family house | 13 | 95 | 2 | 39,000.00 | 9600.00 | 48,600.00 |

| Multi-family residential building | 41 | 299 | 6 | 123,000.00 | 30,200.00 | 153,200.00 |

| School building | 322 | 2369 | 60 | 966,000.00 | 239,900.00 | 1,205,900.00 |

| PV farm | 1128 | 8293 | 120 | 3,384,000.00 | 835,300.00 | 4,219,300.00 |

| BoS Component | Cost [$/Wp] | Ref. |

|---|---|---|

| Robotic cleaning system | 10–12 | [23] |

| Arc fault circuit interrupter | 0.947 | [41] |

| Comprehensive safety system | 0.739 | This article |

| Automatic self-cleaning mechanism (ASCM) | 0.189 | [25] |

| CPVT system with active cooling and a storage tank | 0.067 | [31] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seklecki, K.; Olesz, M.; Adamowicz, M.; Nowak, M.; Litzbarski, L.S.; Balcarek, K.; Grochowski, J. A Comprehensive System for Protection of Photovoltaic Installations in Normal and Emergency Conditions. Energies 2025, 18, 1749. https://doi.org/10.3390/en18071749

Seklecki K, Olesz M, Adamowicz M, Nowak M, Litzbarski LS, Balcarek K, Grochowski J. A Comprehensive System for Protection of Photovoltaic Installations in Normal and Emergency Conditions. Energies. 2025; 18(7):1749. https://doi.org/10.3390/en18071749

Chicago/Turabian StyleSeklecki, Konrad, Marek Olesz, Marek Adamowicz, Mikołaj Nowak, Leszek Sławomir Litzbarski, Kamil Balcarek, and Jacek Grochowski. 2025. "A Comprehensive System for Protection of Photovoltaic Installations in Normal and Emergency Conditions" Energies 18, no. 7: 1749. https://doi.org/10.3390/en18071749

APA StyleSeklecki, K., Olesz, M., Adamowicz, M., Nowak, M., Litzbarski, L. S., Balcarek, K., & Grochowski, J. (2025). A Comprehensive System for Protection of Photovoltaic Installations in Normal and Emergency Conditions. Energies, 18(7), 1749. https://doi.org/10.3390/en18071749