Abstract

With the transformation of the world’s energy structure and the promotion of clean energy, nuclear power has come to the fore as an efficient and environmentally friendly form of energy. As critical components in the operation of nuclear power plants (NPPs), suction and transportation devices for thermal traps—designed to prevent and control floating bodies—are directly linked to the safety of power generation, the stability of operations, and the reliability of the power grid in NPPs. Technical research and advancements in these devices play a crucial role in enhancing their effectiveness. In view of the intrusion and blockage of floating bodies in the sewage network pocket of the water intake with the cold-source system for coastal NPPs, the key technologies to prevent and control floating bodies that may impair cooling resources in NPPs’ thermal traps is discussed. This paper introduces the safety risks and social impacts associated with water intake, highlights the importance of the water-intake system, and discusses the interception and transportation mechanisms in NPPs. The progress of explosive floating bodies’ interception, cleaning, suction, transportation, and intelligent monitoring technology is introduced through the technical progress in the types of floating bodies, as well as cutting, crushing, suction, and transportation devices. The technical progress of efficient treatment is realized, which provides reference for the research and practice of the key technologies for suction and transportation devices to prevent and control floating bodies’ suction and transportation devices in NPPs’ thermal traps.

1. Introduction

In order to support the realization of the major national strategies of carbon peak and carbon neutrality, accelerating the safe and orderly development of nuclear power will become an important part of China’s energy-structure adjustment in the “14th Five-Year Plan” and a long period in the future [1]. As a clean energy [2], nuclear power is of strategic significance in meeting China’s energy needs, optimizing its energy structure, ensuring energy security, and promoting sustainable economic development [3]. However, the construction of coastal NPPs [4,5] also faces many challenges, one of which is the pollution problem of floating bodies at the water intake. In recent years, with the change in marine environment and global warming, the growth rate of marine organisms has become faster, and the ecological imbalance in local sea areas has increased. This has led to the frequent occurrence of the large-scale accumulation of marine organisms or sundries blocking the cold-source water-intake system of coastal NPPs, and the situation regarding the safety of cold source is very serious [1,6,7,8,9,10].

Climate change [11] and human factors [12] are the main factors affecting the safety of the cold-water system in NPPs. With the warming of the climate, a large number of marine organisms such as jellyfish, acaudina molpadioides, and phaeocystis [12,13,14] have grown faster, resulting in blockage of the water intake. For example, Ningde NPP Unit 3 and Ling’ao NPP Unit 2 have caused an emergency shutdown of the reactor due to marine biological invasion [15]. Human activities such as domestic waste, marine oil spill, crop straw, and so on lead to the blockage of water intake, such as the blockage of wheat straw at the water intake of Tianwan NPP [15]. These factors will lead to NPPs’ unit shutdown, power reduction [11,12,16], and other accidents, and even lead to partial loss of cold source [17] and reactor overheating, increasing the risk of nuclear leakage and threatening the safe and stable operation of NPPs. Since 1997, there have been hundreds of blockage events in NPPs around the world [1,12]. Up to 80% of them have caused power reduction and 20% have caused reactor shutdowns and other consequences [18]. Table 1 shows the typical events of domestic NPPs cold-source water-intake operation safety in recent years [2].

Table 1.

Domestic NPPs’ cold-source water-intake operation safety typical events in recent years.

Obviously, the water-intake safety of the cold-source system affects the safety, stability, and economy of NPPs to a certain extent, so it has attracted wide attention from governments, related industries, and related research institutions. A comprehensive and in-depth investigation of the water-intake safety of coastal NPPs has become an important part of ensuring the safe development of nuclear power [12].

The water-intake system of NPPs is a vital part of the operation of NPP. It includes offshore monitoring and an early warning system, an open-channel dredging system, step filtration, an interception device, and a cleaning device.

The offshore monitoring and early warning system are the first line of defense for the water-intake system of NPPs. It ensures water-quality safety and warns of potential risks by monitoring the offshore environment in real time.

The open-channel dredging system introduces external seawater to the NPP to ensure the smooth flow of water. The system is composed of an open channel, a pumping station, a gate, and so on.

In order to ensure that the water quality into the NPP is up to standard, the water-intake system is equipped with a multi-level filtration device [19]. Some fixed filtration equipment such as a trash net, coarse grille, fine grille, and drum filter are used for cascade filtration and in-depth defense [20]; that is, a stepped filtration system.

The interception device of the cold-source water intake is the first safety barrier of the water system of the NPP [21]. The interception device is the key equipment in the water-intake system to prevent large floating objects, aquatic organisms, etc., from entering the water intake. The establishment of a marine biological interception system with an interception network as the main body, including interception network layout, cleaning and maintenance, and condition monitoring, has realized the sea biological interception of water intakes from scratch, from simple to systematic operation [22].

The cleaning device is used to regularly clean the sediments, algae, and attachments in the water-intake system to maintain the smooth and efficient operation of the system. The water intake, open channel, and filtration device can be cleaned regularly by mechanical cleaning, high-pressure water washing, or chemical treatment. At the same time, it is necessary to periodically inspect and repair the water-intake system to ensure the normal operation of the system and prolong the service life.

The NPP water intake system is an integrated system that combines monitoring, dredging, filtering, interception, and cleaning systems. Through the synergy of various links, the safe and efficient water intake of NPPs is ensured, as well as ensuring stable operation. Therefore, the efficient treatment of floating bodies’ cleaning and transportation technology is of great significance for ensuring the safe and stable operation of NPPs. In this paper, the key technical progress and future development trend for suction and transportation deceives to prevent and control floating bodies that may impair cooling in NPP thermal traps are reviewed in detail.

2. Technologies to Prevent and Control Floating Bodies

2.1. Interception Technology

2.1.1. Interception of Trash Net

The interception net at the water intake is the first line of defense for water-intake safety and the basic guarantee for the reliable operation of downstream equipment [23].

- Interception object

According to the marine organisms’ survey data of the water-intake area of coastal power plants in China and the relevant experience feedback of power plants at home and abroad [23,24], the main marine organisms’ classifications affecting the water-intake safety of coastal power plants are shown in Table 2.

Table 2.

Classification of main marine organisms.

- 2.

- Interception technology analysis

To prevent blockage of the blockage of NPPs’ water-intake system leading to reactor shutdown or reduction in power generation, appropriate interception equipment, including trash traps and oil barriers, is installed upstream of the water intake to catch marine organisms or debris that may affect the water intake [16,26,27].

As a flexible and porous structure, the sewage network will undergo large deformations and large displacements under the action of waves and currents. The dynamic characteristics and failure process of the structure are highly nonlinear [28]. The guide net pocket has a gradient closing design, and the water surface can be presented for cleaning and repair work. The collection net bag can be separated from the guide net bag for easy replacement and maintenance [29].

The blockage in the water intake system primarily occurs on the rotating filter screens. Conventional coarse-bar screens are ineffective at intercepting small marine organisms due to their oversized spacing. According to the National Marine Environmental Monitoring Center’s “Marine Organisms Survey Report in the Red River Waters” [22], the size of the main marine organisms is shown in Table 3.

Table 3.

Main marine organisms’ size.

Therefore, it is necessary to set up multiple trash nets along the open channel of the water intake [27,30].

2.1.2. Intercepting Ability of Bubble Curtain

- Interception target

The intercepting ability of the bubble curtain is generally aimed at swimming organisms such as fish and shrimp.

- 2.

- Interception technology analysis

According to domestic and foreign research, bubble-screen interception technology can influence the behavior of marine organisms through their vision, hearing, and touch, and achieve effective interception [31].

At present, many scholars have studied the effect of bubble curtain on the behavior of different fish. Chen Zhao [32] adjusted the hole spacing and aperture of the bubble curtain to investigate the blocking effect of the fixed bubble curtain on Sebastes schlegelii. It was found that the bubble curtain with a hole spacing of 2.0 cm had the highest blocking rate of 95.24%, and the bubble curtain with an aperture of 1.0 mm had the highest blocking rate of 100%. Chen [33] studied the interception effect of eight types of bubble curtains on takifugu rubripes from three aspects: hole spacing, hole diameter, and compressed air pressure, and found that the best interception rate was 71.0%. By studying the blocking effect of a fixed bubble curtain with different hole spacing on black sea bream, Zhao Xiguang [34] found that the bubble volume was moderate and uniform, and the interception rate was 70~80% when the hole spacing was 5.0 cm and the aperture was 0.5 mm. Liu Lidong [35] studied the reaction of five species of freshwater fish to the fixed bubble curtain, and found that the blocking rate was different, which was 53% for tilapia, 44.6% for silver carp, 27.6% for bighead carp, 23.3% for grass carp, and 21.7% for crucian carp. It is proven that the bubble curtain has a blocking effect on these freshwater fish, but the effect is not obvious. Therefore, the bubble curtain has a certain interception effect on different fish, but the interception efficiency is different and some effects are not obvious.

At present, bubble-curtain technology has been widely used in NPPs in China, the United States, Britain, Japan, South Korea and other places [14]. With the application of computer technology, underwater photography technology, and high-performance optical and acoustic equipment, the research methods of bubble curtain will continue to increase [8,12].

2.1.3. Project Cases

At present, NPPs generally use interceptor nets as the first barrier for cold-source safety, and each NPP arranges the interceptor nets according to its own needs.

The intake area of the Lingao NPP is equipped with four interception nets to form an interception system. A row of piles is constructed on the outermost side as the suspension point of the net, the first flat net is set up on the outer side, which is mainly used to catch large floating objects such as marine debris, followed by the second and third bib nets, which are used to catch small organisms such as small shoals of fish and hairy shrimp; finally, the fourth bib net is set up, which is used to seek the emergency response time for the cold source if the first three nets are ineffective.

The Hongyanhe NPP Interceptor System consists of five interceptor nets. The outermost set net 5, a water pontoon-mounted plane interceptor net, is used to intercept most of the large floating objects, followed by net 4, a plane net, and net 3, a net-pocket-type interceptor net, used to intercept a large number of sea moon jellyfish in the period of outbreaks; the use of the tail pocket makes it easy to replace the characteristics of the formation of the rapid disposal mechanism of the Red River NPP in the summer whilst protecting the cold source, and the amount of marine organisms intercepted in general is larger, so the establishment of two pockets of net, that is, net 1 and net 2, further enhance the protection ability.

A total of 11 interceptor nets are installed at the water intake of Phase 1 of the Ningde NPP, all of which use a planar net design. Among them, net No. l is a copper alloy net used to catch a large number of bamboo canes floating in the sea; among the following 10 interceptor nets, except for nets No. 3, 4, and 5, which are specific target organisms, i.e., eel fry interceptor nets, the others are general-purpose interceptor nets.

2.2. Cleaning Technology

2.2.1. Artificial Sea Clean-Up

The cooling of each reactor in the NPP requires a large amount of seawater for cooling and the safety of the cold source is critical to the NPP. At present, the cold-source system is usually protected by the method of ’net snout interception + artificial sea fishing vessel barge cleaning’ [27]. The cleaning work is carried out on the water; the cleaner places the collecting net snout on the tugboat, then opens the rope at the end of the collecting net snout and rakes out the rubbish [29]. However, manual salvage is labor intensive, costly, has a limited salvage capacity, and is vulnerable to bad weather [11]. Overlapping the outbreak period of marine organisms, the manual barge cleaning of fishing vessels cannot be implemented, which directly affects the safe operation of NPPs and the cost of manual offshore fishing vessel barge-cleaning operations is high, which requires a lot of manpower and material resources [20,22,30,36].

2.2.2. Divers into the Water to Clean-Up

Sending divers into the water to clean up is the current conventional cleaning method; underwater operations require a flow rate < 0.5 m/s, a regional wind speed <4, a surge height <0.5 m, and diving operations need to cooperate with each other above water and underwater [29]. However, there are many problems with this approach. For example, diving operations are difficult, long-lasting, costly, and involve safety risks. They are high-risk, government-controlled operations, and there are safety risks of divers drowning and becoming entangled in gas pipelines. The use of diving operations is easily limited by water flow, wind speed, waves, etc. The effects of biological outbreaks in the sea are long-lasting and the cost of diving courses is high [37]. Furthermore, if the damage to the net cannot be partially repaired and the net is replaced as a whole, its marine biological interception function cannot be realized during the replacement period [17].

2.2.3. Project Cases and Conclusion

Currently, when NPPs are faced with the invasion of marine organisms, they generally respond by installing additional fouling nets and adopting manual salvage methods. Manual salvage has a limited capacity and is susceptible to bad weather. Two intake blockage incidents in 2016 and 2017 inhibited the carrying out of manual salvage due to bad weather, and the intake blockage incident at a NPP in the southeast on 7 August 2015 also prevented manual salvage operations at sea due to a typhoon, which put greater pressure on the intake interceptor nets and the CFI system.

Therefore, the development of weather-independent equipment for marine salvage, such as pollution removal robots, instead of manual salvage, can greatly enhance the efficiency of salvage. At the same time, these can still be put into operation in bad weather, which can effectively reduce the risk of NPPs intake blockage in bad weather.

2.3. Suction Technology

The high-speed rotating impeller of the traditional vane pump in operation is likely to cause fish damage or even death [38,39,40,41], which is not conducive to fish welfare and ecosystem stability.

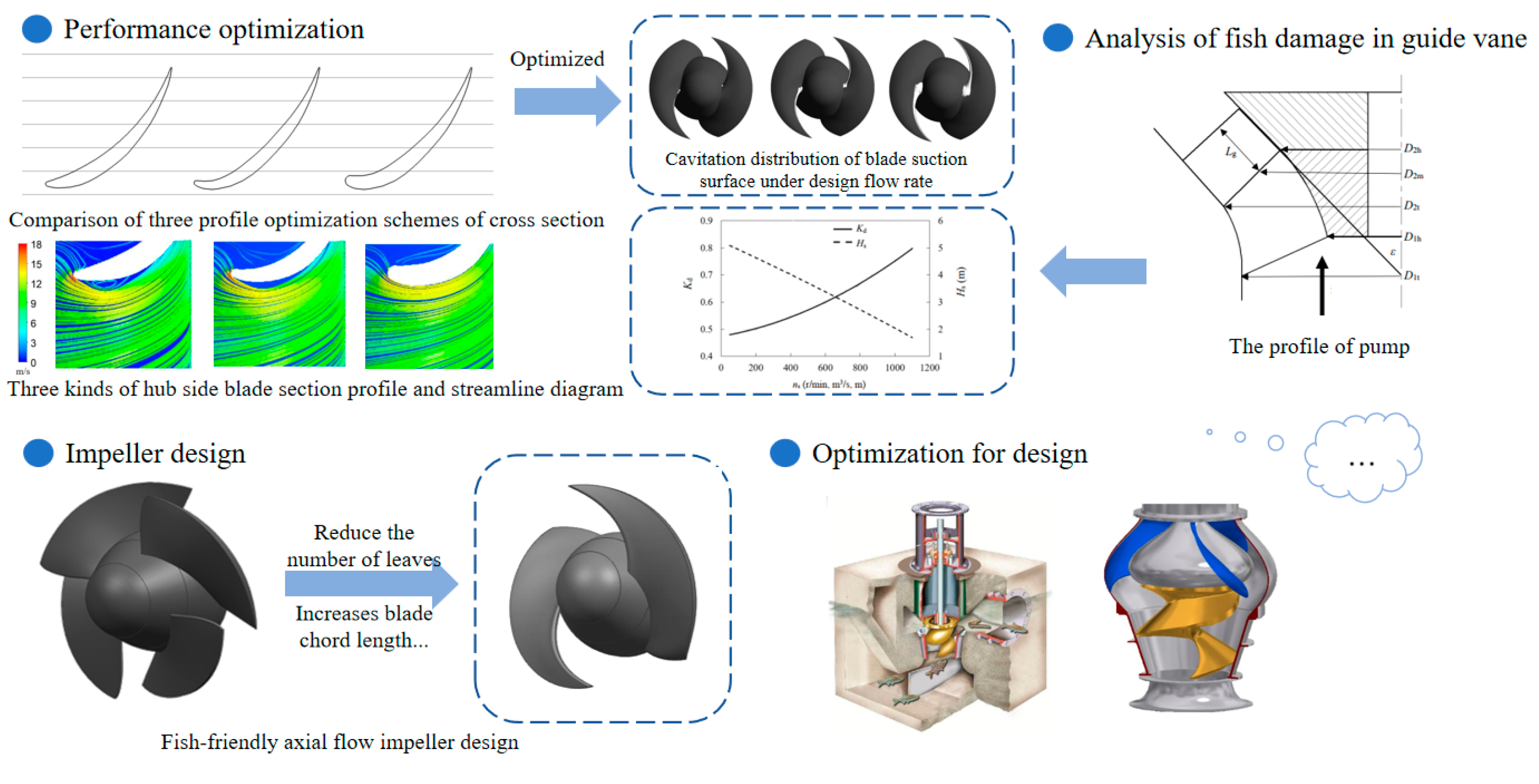

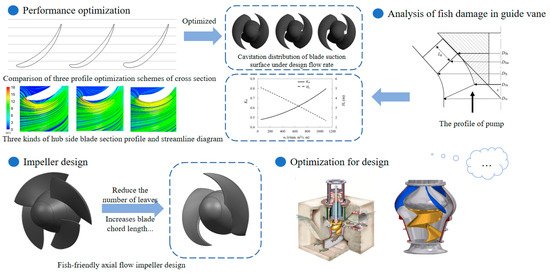

In order to improve the survival rate of fish after flowing through the flow channel of the pumping station and reduce the impact of NPP construction on the marine ecological environment, experts and scholars have improved the survival rate of fish by optimizing design and other measures. Figure 1 shows the main measures to improve the survival rate of fish after flowing through the flow channel of the pumping station.

Figure 1.

The main measures to improve the survival rate of fish after flowing through the flow channel of pumping station [42,43,44,45,46,47].

2.3.1. Impeller Design and Performance Optimization

- (1)

- Reducing the number of leaves: Pan [42,43,46,47] found that when the number of blades was reduced by half, the head was reduced by almost 40%. The head of the pump was reduced by three quarters when the speed was reduced by half. It is found that changing the number of blades has a relatively small effect on the head, which reduces the probability of blade leading-edge impact [48,49,50].

- (2)

- The shape of the leading edge of the blade: Pan Qiang [42,43,46,47] bent the leading edge of the blade to form an impact angle of less than 90°. It was found that the impact velocity at the hub was reduced by about 30% and the impact velocity at the rim was reduced by almost 60%.

- (3)

- Increasing the blade chord length: Pan Qiang [42,43,46,47] gradually increased the ratio of blade chord length from 1.4 at the hub to 1.7 at the rim.

- (4)

- The shape of the leading edge: Pan [42,43,46,47] found that when the leading edge collides with the fish body, the impact velocity of 4.8 m/s can guarantee the 100% survival rate of the fish by using the cross-sectional shape of the leading edge of the semicircular blade with large thickness. Yang [51] invented a fish-friendly axial-flow vane pump, and found that it can greatly reduce the probability of collision and friction between fish and the axial-flow vane pump. It can also improve the hydraulic performance and cavitation performance of the axial-flow pump, as well as improving its manufacturing accuracy and mobility.

- (5)

- Performance optimization: Pan Qiang [42,43,46,47] adopted the iterative process of optimization design, simulation calculation, flow field analysis, and parameter correction to optimize the blade section-profile parameters until the blade inlet profile matched the flow and a reasonable blade inlet angle was obtained. A profile is added to the hub side of the impeller to constrain the shape of the blade head and the optimum scheme eliminates the vortex on the hub-side suction surface. Yang Dandan [51,52] used the combination of immersion boundary, fluid–solid coupling, and large eddy simulation to numerically simulate the flow field in the pump and the movement process of the fish body through the pump channel. It is found that the error between the calculated head coefficient and the experimental value at the same Reynolds number is only 2.7%, which confirms that the IB-FSI-LES method is suitable for simulating the internal flow of the axial-flow pump. Zhang Fan [53] obtained the average pressure difference along the circumferential direction of the impeller based on the CFD numerical simulation results. The influence of the fish body on the blade impact probability formula is modified, which can effectively reduce the prediction error of the blade impact probability. It makes the prediction of blade impact probability and blade impact mortality more accurate.

2.3.2. Damage Analysis and Optimization Design of Fish in Guide Vane

- (1)

- Damage analysis: The most important factor causing damage to fish in turbomachinery is the impact of moving vanes. Pan [42,43,46,47] established the corresponding relationship between the impact velocity of the leading edge of the guide vane and the specific speed and head of the pump by analyzing the influence of the guide vane on the impact damage and death of the fish. It can be seen that the higher the specific speed and head, the higher the impact velocity of the leading edge of the guide vane. The head safety value can be obtained by setting the impact velocity at the threshold value of 4.8 m/s, which causes fish mortality. At this head, the impact will not cause fish mortality. Zhang [44] optimized the drag calculation model by modifying the coupling interface code based on the CFD-DEM coupling method. The results show that the impact force threshold of fish mortality is 2446 N when the ratio of fish body length to blade leading-edge thickness (L/d) is 2 through numerical simulation and experimental fitting.

- (2)

- Optimized design: Pan Qiang [42,43,46,47] designed a pump with an impeller and a guide vane. By reducing the number of guide vane blades, increasing the gap ratio, and bending the leading edge of the guide vane, it was found that the fish mortality rate was reduced from 68% to 13% and the effect was significant. Sun [45] simulated the three-dimensional shape of fish by using spherical particles to knead fish in vitro based on the CFD-DEM coupling model. The movement process of the fish through the axial-flow pump was numerically simulated. By predicting the impact probability, it was found that the impact probability was reduced from 68% of the prototype pump to 34%.

2.4. Transportation Technology

The floating bodies’ transportation technology of NPPs’ water intake involves the design and operation of the NPPs’ cooling water system. It is very important to ensure that the cooling water can enter the NPP smoothly and efficiently.

However, if there are a large number of hazardous floating objects in the water-intake area, such as seaweed, aquatic grass, mussels, shrimps, jellyfish, fish, other marine organisms, silt, debris, sediment, and other debris, as well as plastic or other foreign objects, these can block the water intake and affect the supply of cooling water. In addition, the traditional vane pump is prone to clogging, twisting, and damage when handling complex media. As a result, the transport efficiency is low or even impossible, and emergency clean-up is not possible.

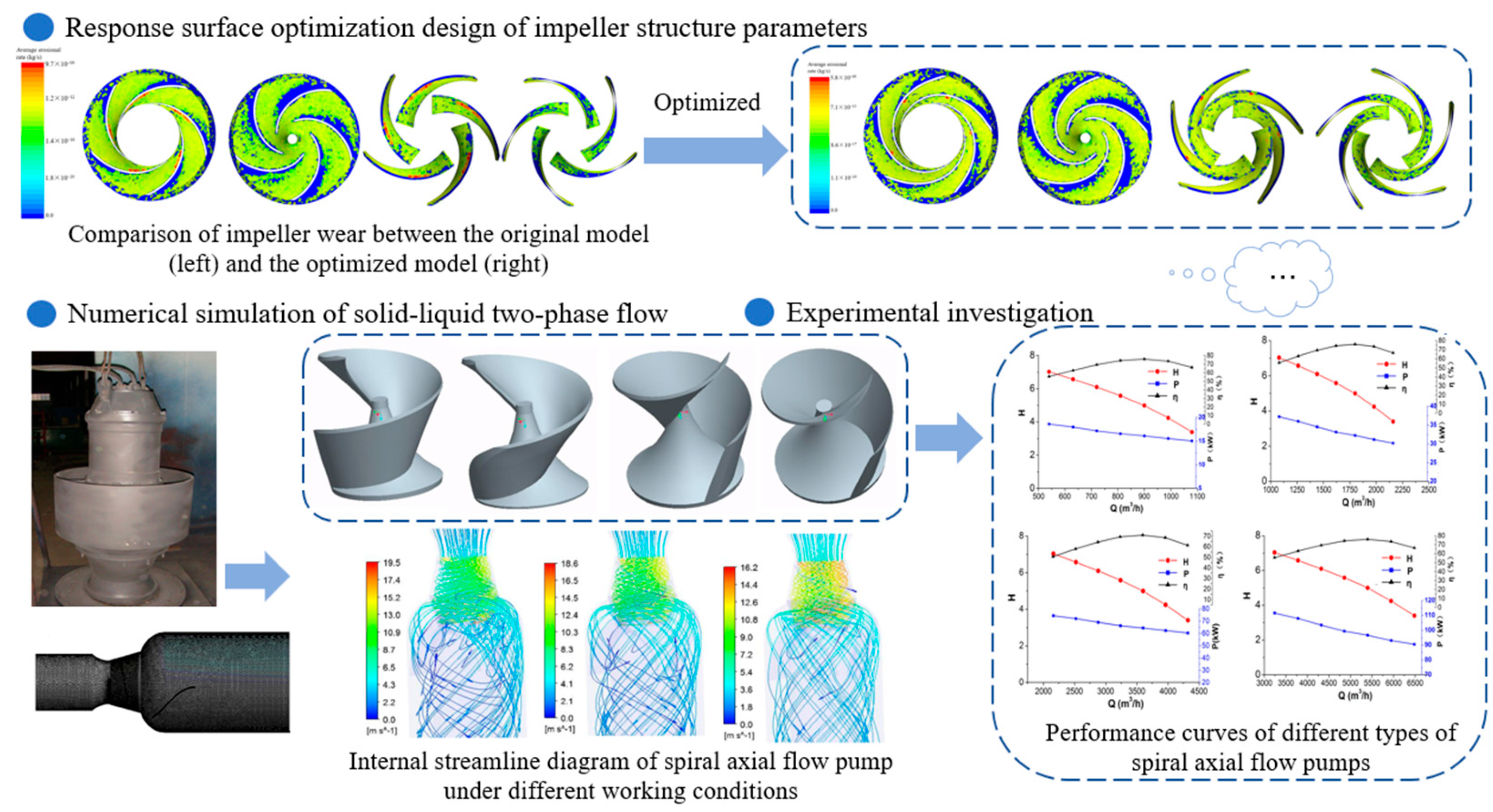

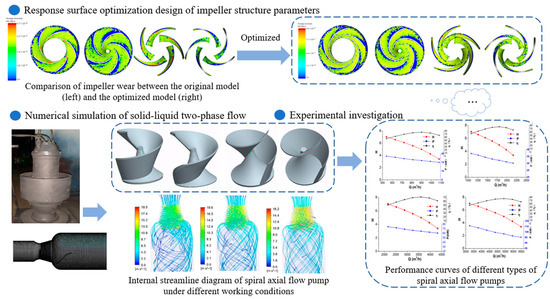

In order to effectively deal with various solid particles and liquid mixtures, and to reduce the impact of NPP construction on the marine ecological environment, experts and scholars have improved the transportation technology by optimizing the design and other measures. These measures include but are not limited to the response surface optimization design of the impeller structure parameters, the numerical simulation of the solid–liquid two-phase flow of the spiral axial-flow pump, and the experimental research. Figure 2 shows the main measures to improve the floating bodies’ transportation technology.

Figure 2.

Main measures to improve the floating bodies’ transportation technologies [54,55].

2.4.1. Response Surface Optimization Design of Impeller Structural Parameters

Huang Kai [56] carried out the response surface optimization design of impeller structural parameters and found that the head was almost the same before and after optimization. At the same time, the efficiency was improved after optimization and the peak value of the impeller wear area and average wear rate were reduced. Shi [57] analyzed the motion law and flow-field characteristics of different particles transported by the swirl pump by combining the numerical simulation method and the experimental research method. They verified the reliability of the coupling algorithm and three different transport modes and optimization directions of the particles of the open-design swirl pump were provisionally obtained.

2.4.2. Numerical Simulation of Solid–Liquid Two-Phase Flow in Helical Axial-Flow Pump

Lin [54] studied the internal solid–liquid two-phase flow law by using clear water and solid–liquid two-phase flow sand. It was found that the calculated curves of head and efficiency curves were basically in agreement with the experimental curves. At the same time, the error value of head efficiency was about 3%. Zhu Rongsheng [55] used a solid-particle diameter of 2 mm and an initial volume fraction of liquid oil of 5%, 10%, and 15%, respectively, to numerically calculate the internal variation in the solid–liquid two-phase flow field in the impeller channel of the helical axial-flow pump. The results showed that the distribution of sand and oil was similar.

2.4.3. Experimental Research

Lin Peng [54] used four different types of pumps to carry out pump test research. It was found that the flow head curve drops sharply and the power curve drops smoothly. The whole process is without hump and overload phenomenon. Zhao [58] selected rapeseed particles to numerically simulate and experimentally study the solid–liquid two-phase flow field of the vortex pump under different flow conditions and particle volume fractions based on the CFD-DEM coupling model. It is found that the circulating flow plays a greater role in the transport of entrained particles, which enhances transport performance of the pump.

2.5. Cutting or Grinding Technology

2.5.1. Floating Bodies and Their Classification

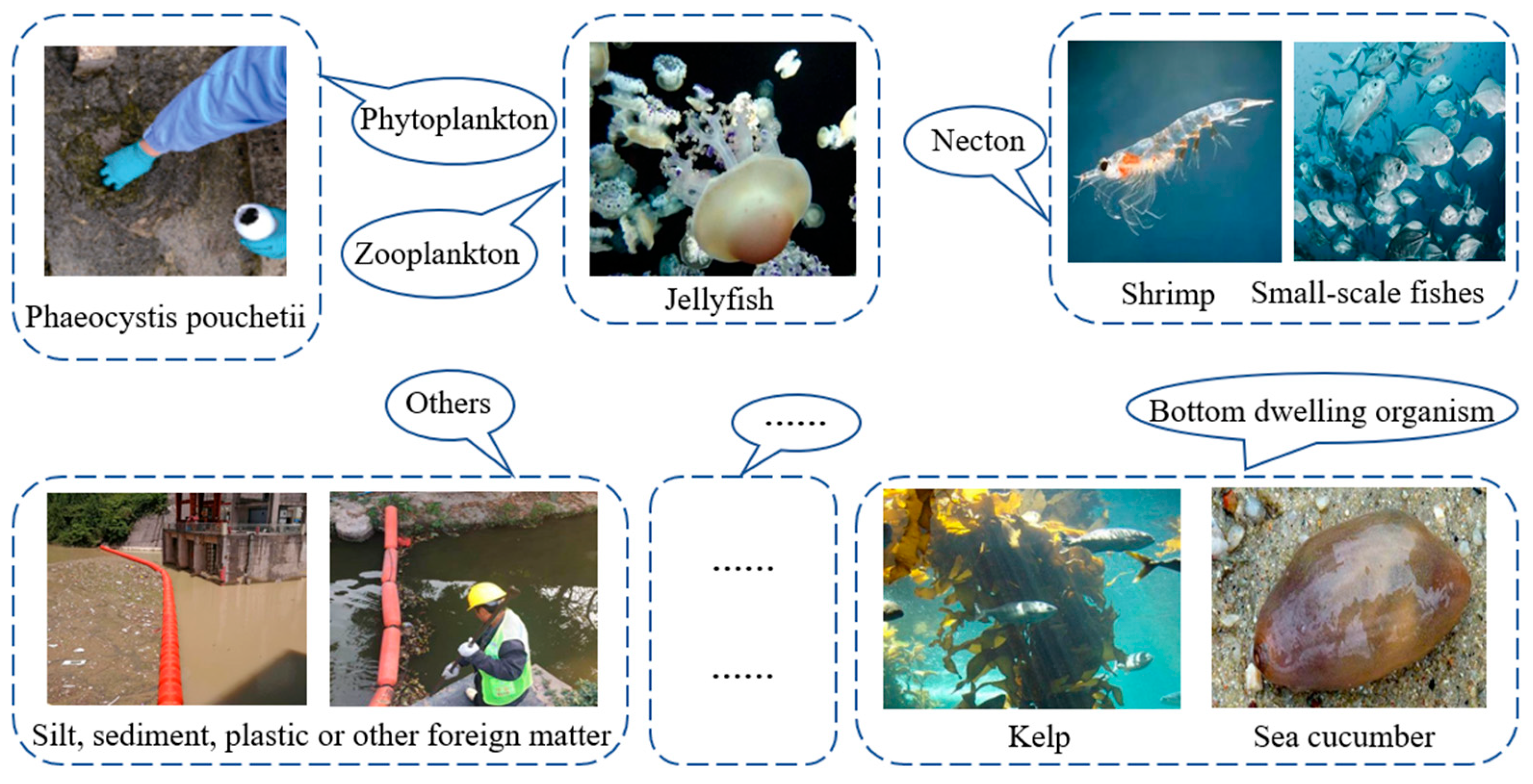

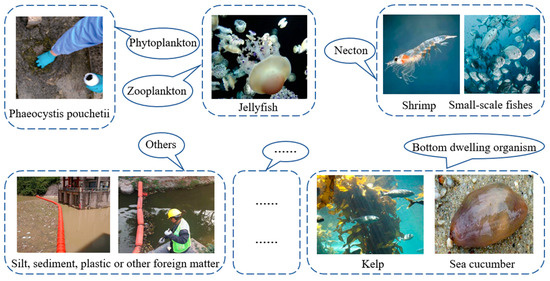

In order to ensure the safety of the water intake, hazardous floating bodies [15,18,39,59,60,61] should be removed in a timely manner. Figure 3 shows the main hazard floating bodies and their classification.

Figure 3.

Main hazard floating bodies and their classifications.

2.5.2. Cutting or Grinding Technology of Floating Bodies

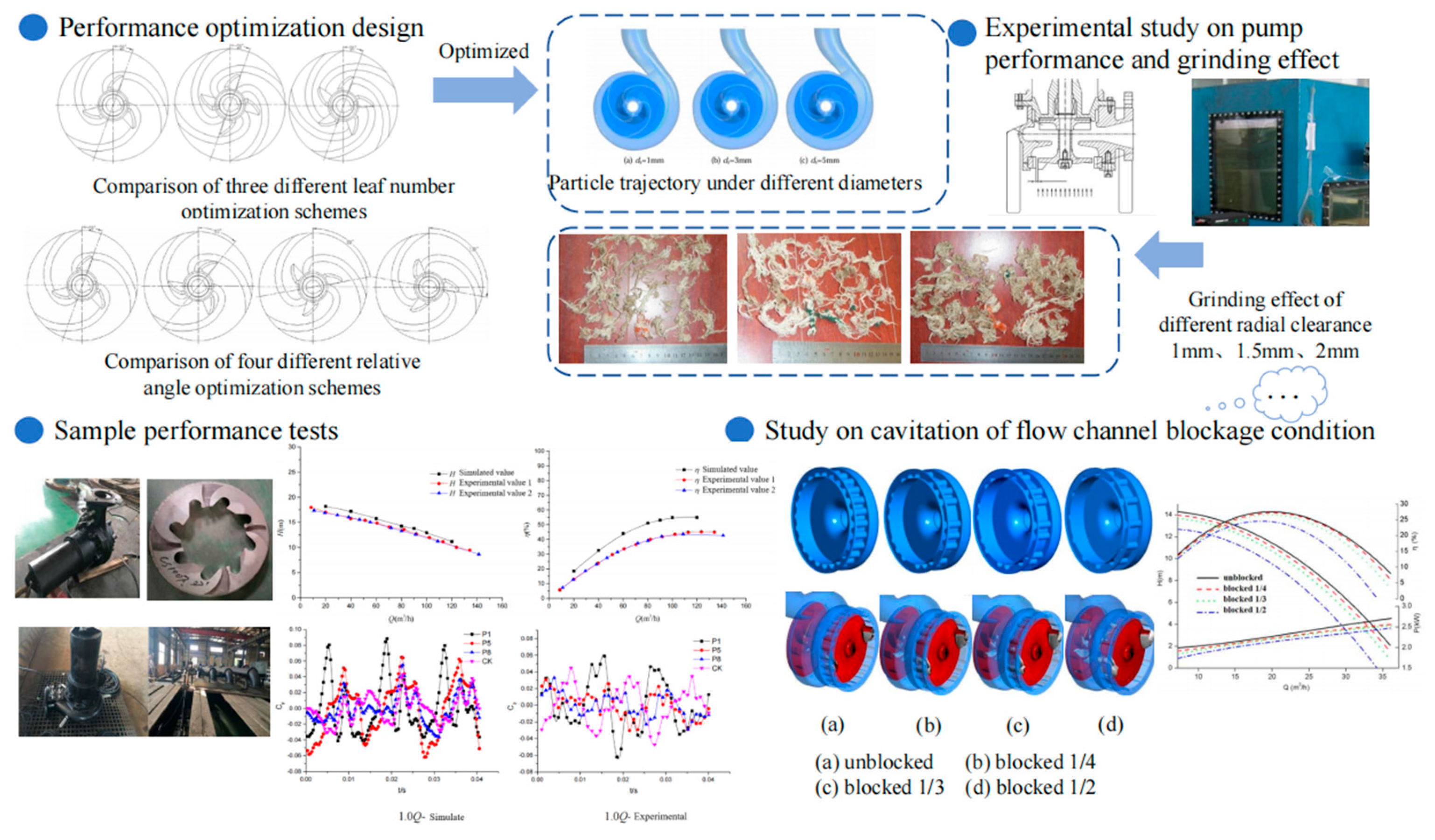

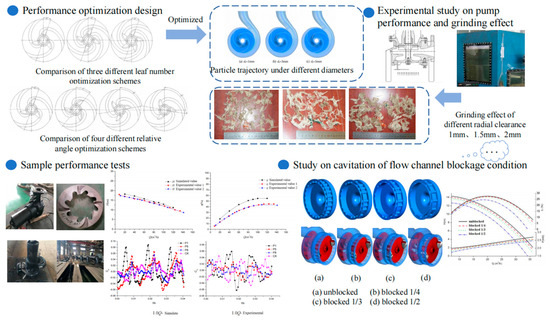

To effectively deal with various marine organisms, such as kelp [39,61], several meters in diameter and several meters in length, and jellyfish [15,59], half a meter in diameter and half a meter in diameter, and so on, a pump product with cutting and grinding functions is being developed to cut or grind kelp, jellyfish, debris, etc., and then transport them. Experts and scholars have improved the cutting and grinding technology through design optimization by optimizing the design and other measures. These measures include but are not limited to performance optimization design, prototype performance testing, experimental research on pump performance and grinding effect, and cavitation research. Figure 4 shows the main measures taken to improve the cutting or grinding technology of floating bodies.

Figure 4.

Main measures to improve the cutting or grinding technologies [62,63,64,65,66,67].

- Performance optimization design:

Jiang [66] completed the optimization design by investigating the influence of several parameters such as several blades, relative angle, and blade thickness on the performance of the cutting pump. The trajectories of solid particles with solid-particle diameters of 1 mm, 3 mm, and 5 mm were compared. The larger the diameter, the greater the inertia of the particles, and the particles move close to the inner wall of the spiral. As the solid-particle diameter increases, the volume distribution decreases. Wang [68] selected the intelligent optimization algorithm by impeller optimization and used the particle-swarm optimization algorithm for automatic optimization design. Without manual intervention, the efficiency reaches the global optimum after 13 iterations over 8 h, which improves the impeller efficiency.

- 2.

- The prototype performance test:

Jiang [66] carried out the performance test of the cutting pump prototype and then found that the external characteristic test results and the simulation results maintained a high consistency in trend. The experimental results and simulation results of pressure pulsation show good periodicity. The number of peaks and valleys in the time-domain diagram is consistent with the simulation results, and the fluctuation trend with the increase in flow rate is also consistent. Cao [67] predicted the wear condition and analyzed the influence of the solid and liquid phases on the internal flow field. It was found that different flow conditions have an obvious influence on pressure distribution, velocity distribution, and solid phase distribution. Zhang Desheng [69] selected two kinds of double-channel pumps with specific speeds of 77 and 122, then cut the impeller five times and carried out an external characteristic test of the pump. It was found that the flow rate, head, shaft power, and efficiency of the double-channel pump decreased as the impeller diameter decreased.

- 3.

- Experimental study on pump performance and grinding effect:

Zhu [62] carried out the performance test of adding abrasive and non-abrasive devices to the non-blocking submersible abrasive pump. It is concluded that the head and flow of the abrasive device decreases, the power increases, and the overall performance of the pump decreases. Wang [65] studied the grinding effect by using different radial clearances of dynamic and static cutters. The results showed that the grinding effect was the best when the clearance was 1 mm. Wang [63,64] simulated and improved the optimization scheme of the non-blocking submersible grinding pump by establishing an optimization scheme. It was found that the number of cutter heads of the grinding pump was two and the gap between the dynamic and static cutter heads was 1.5 mm.

- 4.

- Cavitational study of flow channel blockage:

Wang Zhenwei [65] carried out a numerical simulation of cavitation using three models of flow-channel blockage 1/4, 1/3, and 1/2, which determined the change law of pump performance under different blockage conditions with a static cutter head and obtained the influence law of flow-channel blockage on cutter-head cavitation. Fu Qiang [70] experimentally verified the external characteristics of the non-blocking submersible grinding pump. It was found that as the degree of blockage of the flow channel increases, the degree of cavitation near the cutter head increases. When the blockage ratio reaches a certain level, cavitation also begins to occur at the back of the impeller inlet.

2.6. Intelligent Monitoring and Early Warning Technology

Recent cold-source safety incidents at NPPs have shown that the intervention time available to operators in the main control room is very short. Therefore, the use of various monitoring methods, early warning of emergencies, early preparation, and intervention can effectively reduce the consequences of many marine biological invasions [19]. These approaches foster collaborative observation and technological synergy [71,72].

The monitoring and early warning of floating bodies and the intelligent response and control of filtration systems at all levels is a comprehensive technical system. Advanced technology is used to monitor floating objects that could cause disasters in real time, and early warning is given if anomalies are detected. At the same time, the intelligent response and regulation of filtering systems at all levels reduces the likelihood of a disaster occurring or its impact.

The intelligent monitoring and early warning systems of the pump are an important part of this system. As a key piece of fluid-handling equipment, the operating condition of the pump is directly related to the safety and stability of the entire system. Therefore, the intelligent monitoring and early warning systems of the pump can detect the abnormal condition of the pump in time and prevent system paralysis or accidents caused by the failure of the pump. The intelligent monitoring and early warning systems of the pump mainly include the following aspects:

- (1)

- Data acquisition:

By installing sensors and other equipment, the real-time data of the pump, including flow, pressure, temperature, vibration, and other parameters, can be collected in all weather conditions. These data can reflect the operating conditions and performance of the pump.

- (2)

- Data analysis:

Analyze and process the collected data to extract valuable information. By comparing and analyzing historical data and real-time data, the abnormal condition or trend of the pump can be found, providing early warning and decision support.

- (3)

- Early warning mechanism:

Set the alarm threshold according to the results of the data analysis. If any parameter of the pump exceeds or falls below the warning threshold, the system will automatically trigger the warning mechanism and issue an alarm message. Early warning information can be delivered in a variety of ways, such as mobile-phone text messages, e-mail, APP push, etc., allowing managers to take timely action.

- (4)

- Intelligent control:

In addition to the early warning mechanism, the intelligent monitoring and early warning system of the pump also has intelligent control functions. The remote control system allows managers to remotely start and stop the pump, adjust parameters, and perform other operations. In the event of pump failure or abnormal conditions, the system can also automatically switch to the standby pump or take other emergency measures to ensure normal system operation.

3. Summary

3.1. The Necessity and Importance of Technological Upgrading and Improvement

This study found that there are still problems with the safety of water intake in NPPs, such as the inadequate basis for the design of water-intake nullahs and the interception of sewage nets, weaknesses in early warning and monitoring equipment, the arrangement of marine organisms, the mismatch between fishing capacity and the risk of a large-scale invasion of marine organisms, an inappropriate assessment of the emergency response to eliminate risks to the safety of water intake, weaknesses in the operation and maintenance management of marine-organism interception equipment, weaknesses in the safety culture leading to the implementation of feedback mechanisms, weaknesses in the operation and maintenance management of marine-organism interception equipment, weaknesses in the safety culture that leads to the implementation of feedback of experience, and so on. Therefore, the upgrading and improvement of related technologies is of great importance [73].

Therefore, the upgrading and improvement of related technologies is necessary and important. Through continuous technological innovation and optimization, the performance and reliability of the intake system can be further improved, providing strong support for the long-term development of NPPs.

3.2. Research and Development of New Efficient Interception and Cleaning Technology

3.2.1. Green New Bubble Curtain Technology

Based on the investigation, some experts proposed a green new type of pollution control system that combines “bubble curtain interception and expulsion” and “diversion measures dredging”, and aims to use new green technology to deal with different types of blockage risks. However, to take full advantage of the terrain and hydrodynamic characteristics of the sea area where the NPP is located, the scheme has high individual requirements and must to be adapted to local conditions [74]. Therefore, it is necessary to further conduct physical model tests to verify the effect of preventing and controlling disasters and to explore the applicability of the system to specific projects in future engineering practice.

3.2.2. Automatic Cleaning Equipment

In the face of marine biological invasion, NPPs generally adopt the methods of deploying rubbish nets and manual recovery. Artificial fishing capacity is limited and vulnerable to bad weather. To increase the capacity of non-manual fishing, automatic, weather-independent cleaning equipment is being developed for sea fishing, such as cleaning robots instead of manual salvage, which can greatly increase the efficiency of salvage. At the same time, it can be operated in bad weather, which can effectively reduce the risk of water-intake blockage in NPPs during bad weather [11].

3.2.3. Development of ROV for Underwater Detection

The safety of cold-water sources is an important guarantee of nuclear safety. In the past, NPPs could only be inspected underwater by divers. Not only is the safety risk extremely high, but there is no visual indication of the condition of the underwater target, which is not conducive to subsequent cleaning and repair work [37]. The development of an underwater detection ROV capable of stable and reliable long-term operation in complex aquatic environments is essential. The Remotely Operated Vehicle (ROV) is an important equipment for unmanned diving. Due to its outstanding characteristics of safety, economy, high efficiency, and deep operation, use of the ROV is becoming more and more widespread. It can replace divers for underwater operations, reducing the impact of meteorological and hydrological conditions on underwater inspection work. At the same time, it can reduce manual diving operations and avoid major health and safety risks. It provides a solution to the technical problems of underwater detection of cold-source protection in NPPs [37].

In the current engineering case, for example, two shrimp invasions of water intakes occurred at the Yangjiang NPP on 26 November 2015 and 9 January 2016. The shrimp situation was monitored using a real-time video from the ROV or by intercepting the recorded video. The environmental monitor informed the main control room and the cold-source team about the shrimp situation in the front pool of the intake. The main control room activated the manual switching of the CFI drum net to medium-speed operation and kept the double backwash pumps flushing, trying to ensure that the hairy shrimp did not attach to the top of the drum net, so that the differential pressure of the drum net was maintained at a reasonable level. At the same time, the cold-source group of emergency personnel arranged for an increase in the number of fishing boats and increased manual recovery efforts to reduce the number of shrimps at the mouth of the water intake to ensure the safe operation of the unit.

3.3. Economic Benefits and Ecological Protection

According to research carried out over many years by the World Association of NPP Operators, the risk of water-intake blockage in coastal NPPs cannot be completely ruled out. This is therefore an issue that requires long-term and sustained attention [11,75]. The following measures can be taken to improve the safety of the cold-water-intake system:

- (1)

- Strengthen the monitoring and early warning mechanism of the safety of the water intake of the cold-source system, and strengthen the maintenance and overhaul of the water-intake facilities to ensure their normal operation and safety.

- (2)

- Strengthen collaboration with relevant scientific research institutions and universities to jointly research new technologies and new methods for water-intake safety.

- (3)

- To improve the efficiency and stability of fish-friendly pumps, cutting pumps, grinding pumps, self-priming pumps, and other special pumps, and strengthen intelligent management and control.

At the same time, ecosystem considerations must ensure that economic benefits are achieved without damaging the environment. This can be achieved through the following measures:

- (1)

- Ecological balance and biodiversity conservation should be fully considered when developing new floating-body cleaning and transportation technology. Harm to sensitive and endangered species should be avoided during the cleanup process.

- (2)

- Promoting the resource recycling of clean-up and transportation technology is the key to achieving a win–win situation of economic benefits and ecological environmental protection. Actively explore ways to use the cleaned floating body for resource utilization, such as converting it into energy or making it into other useful materials, reducing waste generation and reducing environmental pollution.

- (3)

- Conduct environmental impact assessment and monitoring, and analyze the potential impact of cleaning and transportation technology on the surrounding ecological environment. Establish a long-term environmental monitoring system to ensure the ecological safety of technology applications.

- (4)

- The combination of technological innovation and green concept. By introducing new technologies, new materials and new processes, the energy consumption and emissions of the technology itself are reduced, and the environmental performance is improved.

In summary, NPPs still need continuous improvement at the technical and management levels to cope with complex and changing conditions [11]. Regarding the ecosystem, the research progress on the technology of cleaning and transporting explosive floating bodies at the water intake of NPPs should be directed towards realizing the harmonious coexistence of economic benefits and ecological environmental protection. To realize the safe and environmentally friendly operation of NPPs, it is believed that with the development of society and the progress of science and technology, there will be more abundant and effective preventive measures and means to ensure the reliability and safety of water intake [12,75].

Author Contributions

Data curation, J.X., Y.L. and R.Z.; writing—original draft preparation, Y.Z.; writing—review and editing, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Science Foundation of China (Grant No. 51906085, Grant U20A20292), the China Postdoctoral Science Foundation Funded Project (2023M733355, Grant No. 2019M651734), Jiangsu University Youth Talent Development Program (2020), the Chunhui Program Cooperative Scientific Research Project of the Ministry of Education, Research Project of State Key Laboratory of Mechanical System and Vibration (MSV202203).

Data Availability Statement

Data will be made available upon request.

Conflicts of Interest

Authors Ji Xing, Rongyong Zhang and Yun Long were employed by the company China Nuclear Power Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| NPP | Nuclear Power Plant |

| ROV | Remotely Operated Vehicle |

References

- He, X.; Han, R.; Lu, X.; Liang, H.; Zhao, Y.; Wu, Q.; Ji, P. Analysis on water entrainment effects of traditional costal nuclear power plants in China. Water Wastewater Eng. 2021, 47, 261–266. (In Chinese) [Google Scholar]

- Krek, A.V.; Ulyanova, M.O.; Krek, E.V.; Bubnova, E.S.; Danchenkov, A.R.; Semenova, A.S.; Dmitrieva, O.A.; Gusev, A.A. Changes in coastal ecosystems affected by overburden dumping from amber open-cut mining on the Sambia Peninsula (Baltic Sea). Mar. Pollut. Bull. 2024, 201, 116180. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.; Yuan, S.; Song, L.; Zhang, Y.; Xu, N.; Liu, X.; Ma, Y. Preliminary study on numerical simulation early warning design for sea ice blocking risk of cold source water intake in Hongyanhe nuclear power plant. Mar. Sci. Bull. 2020, 39, 439–446. (In Chinese) [Google Scholar]

- Nian, V. Progress in Nuclear Power Technology, Encyclopedia of Sustainable Technologies, 2nd ed.; Springer: New York, NY, USA, 2024; Volume 3, pp. 133–157. [Google Scholar]

- Chen, Y.; Lin, H. Overview of the development of offshore wind power generation in China. Sustain. Energy Technol. Assess. 2022, 53, 102766. [Google Scholar] [CrossRef]

- Olenin, S.; Elliott, M.; Minchin, D.; Katsanevakis, S. Marine ecosystem health and biological pollution: Reconsidering the paradigm. Mar. Pollut. Bull. 2024, 200, 116054. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, S.; Cao, R.; Yu, S.; Bai, W.; Zhang, R.; Yang, J.; Dai, L.; Chen, J.; Zhang, Y.; et al. A review on the risk, prevention and control of cooling water intake blockage in coastal nuclear power plants. Nucl. Eng. Technol. 2024, 56, 389–401. [Google Scholar] [CrossRef]

- Sha, C.; Yang, J.; Zhang, W.; Zhang, R.; Bai, W. Investigation and analysis for marine biological monitoring technologies of nuclear power plants’ water intake. Water Wastewater Eng. 2020, 56, 13–16. (In Chinese) [Google Scholar]

- Zhang, W.; Yang, J.; Zhang, R. Discussion on technical measures for preventing problems in nuclear power plant cooling water systems during outbursts of blockages. Water Wastewater Eng. 2020, 56, 9–12. (In Chinese) [Google Scholar]

- Xiu, B.; Han, R.; Men, C. Current situation and policy suggestions of cooling water safety about costal nuclear power plants in China. Water Wastewater Eng. 2020, 56 (Suppl. S1), 39–42, 47. (In Chinese) [Google Scholar]

- Zhang, G.; Song, H.; Mu, Y. Reason Analysis and Improvement Measures Evaluation for Water Intake Blockage at Northern Nuclear Power Plants. Nucl. Power Eng. 2019, 40, 111–117. (In Chinese) [Google Scholar]

- Purcell, J.E.; Uye, S.-i.; Lo, W.-T. Anthropogenic causes of jellyfish blooms and their direct consequences for humans: A review. Mar. Ecol. Prog. Ser. 2007, 350, 153–174. [Google Scholar] [CrossRef]

- Daguer, H.; Hoff, R.B.; Molognoni, L.; Kleemann, C.R.; Felizardo, L.V. Outbreaks, toxicology, and analytical methods of marine toxins in seafood. Curr. Opin. Food Sci. 2018, 24, 43–55. [Google Scholar]

- Zubair, M.; Akram, Y. Utilizing MATLAB machine learning models to categorize transient events in a nuclear power plant using generic pressurized water reactor simulator. Nucl. Eng. Des. 2023, 415, 112698. [Google Scholar]

- Xu, C.; Hu, Z. Construction and Research of Cooling-water Interception System for Coastal Nuclear Power Plants. Electr. Saf. Technol. 2019, 21, 45–48. (In Chinese) [Google Scholar]

- Wu, Y.; Wang, Y.; Hou, Q.; Jiao, F.; Sun, G. Experience feedbacks on events of nuclear power plants cold source systems blocked by oceanic foreign matter. Nucl. Saf. 2017, 16, 26–32. (In Chinese) [Google Scholar]

- Basu, P.C. Site evaluation for nuclear power plants-The practices. Nucl. Eng. Des. 2019, 352, 110140. [Google Scholar] [CrossRef]

- Ruan, G. Reason analysis and corresponding strategy for cooling water intake blockage at nuclear power plants. Nucl. Power Eng. 2015, 36 (Suppl. S1), 151–154. (In Chinese) [Google Scholar]

- Chen, G.; Xu, C. The Systematic Guarantee Scheme for Cold Source Safety in Nuclear Power Plant. Electr. Saf. Technol. 2020, 22, 63–67. (In Chinese) [Google Scholar]

- He, X.; Luo, L. Feasibility study of mobile integrated water biological automatic cleaning and treatment device based on nuclear power plant water intake project. Water Wastewater Eng. 2018, 54 (Suppl. S1), 58–62. (In Chinese) [Google Scholar]

- Basso, L.; Rizzo, L.; Marzano, M.; Intranuovo, M.; Fosso, B.; Pesole, G.; Piraino, S.; Stabili, L. Jellyfish summer outbreaks as bacterial vectors and potential hazards for marine animals and humans’ health? The case of Rhizostoma pulmo (Scyphozoa, Cnidaria). Sci. Total Environ. 2019, 692, 305–318. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, Q.; He, G.; Kang, J.; Che, S. Exploration and practice of marine organisms’ interception system in nuclear power plant. Value Eng. 2020, 39, 212–217. (In Chinese) [Google Scholar]

- Chen, K.; Wang, Q.; Liu, Z.; Wu, Q.; Xu, B. Design research on auto clean trash net in cooling water intake of coastal nuclear power plant. Water Wastewater Eng. 2018, 54, 95–98. (In Chinese) [Google Scholar]

- Waqas, M.; Wong, M.S.; Stocchino, A.; Abbas, S.; Hafeez, S.; Zhu, R. Marine plastic pollution detection and identification by using remote sensing-meta-analysis. Mar. Pollut. Bull. 2023, 197, 115746. [Google Scholar]

- Chen, L.; Yang, F.; Zhong, X.; Song, D.; Li, G.; Kang, Z.; Xiong, Y. Review of the life history of Acetes chinensis. J. Shanghai Ocean. Univ. 2022, 31, 1032–1040. (In Chinese) [Google Scholar]

- Xing, X.; Zhang, Z.; Tang, J.; Guo, T.; Wang, S.; Tao, Z. Study on the issue about water intake blockage by marine organism in nuclear power plant. Nucl. Saf. 2021, 20, 103–109. (In Chinese) [Google Scholar]

- Kang, J.; Fan, D. Monitoring and analysis of tension force on main rope of trash interception net in nuclear power plant. Low Temp. Archit. Technol. 2017, 39, 57–59+71. (In Chinese) [Google Scholar]

- Che, S.; Wang, H.; Chen, S.; Xu, T. Numerical simulation of the hydrodynamic response of trash blocking net for nuclear power plant. J. Ocean. Technol. 2022, 41, 96–105. (In Chinese) [Google Scholar]

- Smithers, J. Review of sugarcane trash recovery systems for energy cogeneration in South Africa. Renew. Sustain. Energy Rev. 2014, 32, 915–925. [Google Scholar]

- Alves, C.M.; Gomes, M.A.; Neto, R.; Troncoso, J.S.; Gomes, P.T. Patterns of diversity in subtidal marine macrofaunal communities: Insights from a semi-enclosed bay system in the Northeast Atlantic. Reg. Stud. Mar. Sci. 2024, 72, 103441. [Google Scholar]

- Zhang, G.; Yu, F.; Zhang, Q.; Ou, Y.; Du, H. Research on marine organism expulsion and elimination nearby water intakes of nuclear power plants. Mar. Electr. Electron. Eng. 2019, 39, 22–27. (In Chinese) [Google Scholar]

- Chen, Z.; Huang, L.; Huang, H.; Tang, Y.; Sun, F.; Hao, L.; Dang, R.; Gong, J.; Zhu, Q. Studies on obstructing effects of air-bubble curtain on Sebastes schlegelii. Period. Ocean. Univ. China 2017, 47, 51–57. (In Chinese) [Google Scholar]

- Chen, Y.; Zhang, P.; Zhang, S. The intercepting effects of bubble curtains with different density on Fugu rubiripes. J. Dalian Fish. Univ. 2002, 3, 234–239. (In Chinese) [Google Scholar]

- Zhao, X.; Liu, L.; He, D. A study on the intercepting mechanism of an air-bubble curtain on black porgy. Oceanol. Limnol. Sin. 1998, 1, 35–40. (In Chinese) [Google Scholar]

- Liu, L.; He, D. The reaction of five fresh-water fishes to immovable bubble curtain. J. Xiamen Univ. 1988, 2, 214–219. (In Chinese) [Google Scholar]

- Zhang, J.; Wang, Y.; Ottmann, D.; Cao, P.; Yang, J.; Yu, J.; Lv, Z. Seasonal variability of phytoplankton community response to thermal discharge from nuclear power plant in temperate coastal area. Environ. Pollut. 2023, 318, 120898. [Google Scholar]

- Viel, C. Self-management of the umbilical of a ROV for underwater exploration. Ocean. Eng. 2022, 248, 110695. [Google Scholar]

- Spear, M.J.; Harris, B.S.; Bookout, T.A.; Ickes, B.S.; Jankowski, K.J.; Solomon, L.E.; Maxson, K.A.; Whitten, A.L.; Mathis, A.T.; Schaick, S.J.; et al. Reduction of large vessel traffic improves water quality and alters fish habitat-use throughout a large river. Sci. Total Environ. 2024, 946, 172705. [Google Scholar]

- Crist, D.T. Census of Marine Life, Encyclopedia of Biodiversity, 3rd ed.; Academic Press: Cambridge, MA, USA, 2024; pp. 699–726. [Google Scholar]

- Yang, C.; Li, Q.; Xu, D.; Wu, J.; Zheng, Y.; Zhang, Y.; Yu, A. Fish damage due to tubular turbine: Experiments and CFD simulations. Ocean. Eng. 2023, 272, 113881. [Google Scholar]

- Weirup, L.; Schulz, C.; Seibel, H. Fish welfare evaluation index (fWEI) based on external morphological damage for rainbow trout (Oncorhynchus mykiss) in flow through systems. Aquaculture 2022, 556, 738270. [Google Scholar]

- Pan, Q. Fish Friendly Axial Flow Pump Design and Application Based on Blade Strike Model. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2019. (In Chinese). [Google Scholar]

- Pan, Q.; Shi, W.; Zhang, D.; Zhao, R. Design and fish survival rate prediction of fish-friendly axial-flow pump for pumping stations. J. Drain. Irrig. Mach. Eng. 2017, 35, 42–49. (In Chinese) [Google Scholar]

- Zhang, D.; Shi, K.; Pan, Q.; Shi, W. Fish strike damage in tubular pump based on fish-shaped particle tracking method. Trans. Chin. Soc. Agric. Mach. 2023, 54, 152–160. (In Chinese) [Google Scholar]

- Sun, Z. Research on Fish Damage Mechanism of Axial Flow Pump Based on CFD-DEM Coupling Method. Master’s Theses, Jiangsu University, Zhenjiang, China, 2020. (In Chinese). [Google Scholar]

- Pan, Q.; Zhang, D.; Shi, W. Optimization design of fish-friendly axial-flow pump based on blade strike model. Trans. Chin. Soc. Agric. Mach. 2015, 12, 102–108. (In Chinese) [Google Scholar]

- Pan, Q.; Zhang, D.; Shi, W.; van Esch, B.P.M. Fish damage assessment during the passage through traditional and fish-friendly axial-flow pumps with Lagrangian tracking approach. Ocean. Eng. 2022, 253, 111188. [Google Scholar]

- Wei, X.; Zhang, K.; Xiong, X.; Wang, Y.; Fang, Y.; Yang, D.; Shang, Z. Effects of cooling water intake structure and its operation on aquatic organisms and mitigation measures at power plants using once-through cooling system. J. Hydroecology 2017, 38, 1–10. (In Chinese) [Google Scholar]

- Tang, S.; Shang, Z.; Huang, H.; Zhang, Y. Ecological impacts of coastal power plants associated with once-through cooling in China and mitigation: A preliminary evaluation. J. Appl. Oceanogr. 2020, 39, 590–599. (In Chinese) [Google Scholar]

- Lawrence, W. Barnthouse. Impacts of entrainment and impingement on fish populations: A review of the scientific evidence. Environ. Sci. Policy 2013, 31, 149–156. [Google Scholar]

- Yang, D.; Zhao, M.; Ye, W.; Shen, L.; Luo, X. Numerical simulations of fish movement in axial pump using immersed boundary method. Shuili Fadian Xuebao/J. Hydroelectr. Eng. 2021, 40, 95–104. [Google Scholar]

- Yang, D.; Zhao, M.; Shen, L.; Luo, X. Analysis of fish movement and strike injury in the axial pump. Hydropower Pumped Storage 2021, 7, 26–31. (In Chinese) [Google Scholar]

- Zhang, F.; Zhu, L.; Shi, X.; Chen, K.; Appiah, D.; Yuan, S.; Zhang, J. Influence of pump noise on the health of fish in a large pumping station. J. Hydrodyn. 2022, 34, 522–531. [Google Scholar]

- Lin, P. Numerical Simulation and Experimental Research of Solid-Liquid Two-Phase in a Screw Axial Flow Pump; Jiangsu University: Zhenjiang, China, 2013. (In Chinese) [Google Scholar]

- Zhu, R.; Lin, P.; Long, Y.; Wang, Z.; Xi, Y. Numerical simulation of solid-liquid two-phase flow in screw axial-flow pump. J. Drain. Irrig. Mach. Eng. 2014, 1, 6–11. (In Chinese) [Google Scholar]

- Huang, K. Performance Research and Optimal Design of Centrifugal Pump Based on CFD-DEM Coupling Calculation. Master’s Theses, Jiangsu University, Zhenjiang, China, 2021. (In Chinese). [Google Scholar]

- Shi, Y. Imulation and Experimental Study of Solid-Liquid Two-Phase Flow in Vortex Pump; Jiangsu University: Zhenjiang, China, 2020. (In Chinese) [Google Scholar]

- Zhao, T.; Gao, X.; Ye, X.; Zhang, D.; Shi, W.; Duan, J.; Wang, J.; Shi, Y. CFD-DEM simulation and experimental study of two-phase flow in vortex pump. J. Irrig. Drain. 2022, 41, 50–58. (In Chinese) [Google Scholar]

- Wang, J.; Li, S. Marine lives harmin sea coastal power plants and countermeasures. Guangdong Electr. Power 2015, 28, 33–36+84. (In Chinese) [Google Scholar]

- He, L.; Song, X.; Yu, F. Potential risk and prevention of phytoplankton outbreak to water-cooling system in nuclear power plant in fangchenggang, guangxi. Oceanol. Limnol. Sin. 2019, 50, 700–706. (In Chinese) [Google Scholar]

- Pechsiri, J.S.; Thomas, J.-B.E.; Risén, E.; Ribeiro, M.S.; Malmström, M.E.; Nylund, G.M.; Jansson, A.; Welander, U.; Pavia, H.; Gröndahl, F. Energy performance and greenhouse gas emissions of kelp cultivation for biogas and fertilizer recovery in Sweden. Sci. Total Environ. 2016, 573, 347–355. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, Z.; Lin, P.; Wang, X. Experimental Study on the Performance and Pulverizing Effect of Non-jamed Submerged Grinder Pump. J. Agric. Mech. Res. 2013, 5, 179–182. (In Chinese) [Google Scholar]

- Wang, X.; Lu, Y.; Zhu, R.; Wang, Z.; Chen, Z.; Zhang, L. Optimal design and experiment of submerged grinder pump grinding device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 77–82, (In Chinese with English Abstract). [Google Scholar]

- Wang, X.; Zhu, R.; Wang, Z. Hydraulic design and test of non-clogging submersible grinding pump. Pump Technol. 2013, 4, 13–15,6. (In Chinese) [Google Scholar]

- Wang, Z. Research on Optimal Design and Characteristics of Cavitation Flow of Non-Jamed Submerged Grinder Pump; Jiangsu University: Zhenjiang, China, 2013. (In Chinese) [Google Scholar]

- Jiang, X. Numerical Simulation and Experimental Study on Internal Flow of Semi-Open Submersible Cutting Pump. Master’s Theses, Jiangsu University, Zhenjiang, China, 2019. (In Chinese). [Google Scholar]

- Cao, W.; Jiang, X.; Zhang, Q.; Xu, Y. Characteristics analysis of solid-liquid two-phase flow in semi open cutting pump. J. Jiangsu Univ. 2019, 40, 531–537. (In Chinese) [Google Scholar]

- Wang, W.; Deng, Q.; Pei, J.; Yuan, S.; Han, Z.; Gan, X.; Zhao, J. Design and development of pump performance optimization platform. J. Drain. Irrig. Mach. Eng. 2023, 41, 454–460. (In Chinese) [Google Scholar]

- Zhang, D.; Wang, C.; Shi, W.; Pan, D.; Zhang, G. Establishment and test of impeller cutting law equation of double channel pump. Trans. Chin. Soc. Agric. Mach. 2014, 1, 73–78. (In Chinese) [Google Scholar]

- Fu, Q.; Lu, Y.; Zhu, R.; Wang, X.; Wang, X. Cavitation and pressure pulsation characteristics of a non-jamed submerged grinder pump. J. Vib. Shock 2016, 35, 95–101, 112. (In Chinese) [Google Scholar]

- Song, Y.; Xing, X.; Lin, C.; Xiong, M.; Zhang, X.; Zhang, Z.; Wu, S.; Zhang, S.; Shi, Y.; Wu, Z.; et al. Advances in the investigation and risk assessment of cold source blockages in nuclear power plants in China. Nucl. Eng. Des. 2024, 420, 112998. [Google Scholar]

- Abbasi, A.; Mirekhtiary, F.; Issa, S.A.M.; Algethami, M.; Zakaly, H.M.H. Nuclear power plant biological complications on marine biota from a probabilistic accident—A case study. Mar. Pollut. Bull. 2024, 205, 116611. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhang, R.; Long, Y.; Jiang, X.; Zhu, R.; Xing, J. Review on development status of comprehensive prevention and control technology for disaster-causing floating bodies at water intake of nuclear power plants. Ann. Nucl. Energy 2025, 212, 111087. [Google Scholar]

- Hilo, A.K.; Hong, J.-W.; Kim, K.-S.; Ahn, B.-K.; Lee, J.-H.; Shin, S.; Moon, I.-S. Study of an air bubble curtain along a wall in water and radiated noise mitigation. Phys. Fluids 2022, 34, 1–13. [Google Scholar] [CrossRef]

- Wang, J.; Meng, Y.; Han, B.; Liu, Z.; Zhang, L.; Yao, H.; Wu, Z.; Chu, J.; Yang, L.; Zhao, J.; et al. Hydrate blockage in subsea oil/gas flowlines: Prediction, prevention, and remediation. Chem. Eng. J. 2023, 461, 142020. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).