Effect of Air Pressure on the Aging and Lifetime of Electrical Insulation in Winding Wires

Abstract

1. Introduction

2. Aging Studies

- Investigation of the time it takes for the insulation system to fail under a constant but increased electric field intensity (compared to the operational field strength).

- Testing the dielectric breakdown voltage of the sample, which fails as a result of exceeding the dielectric strength of the insulation material (determination of the breakdown voltage).

3. Statistical Analysis of the Test Results

4. Research Methodology

5. Results

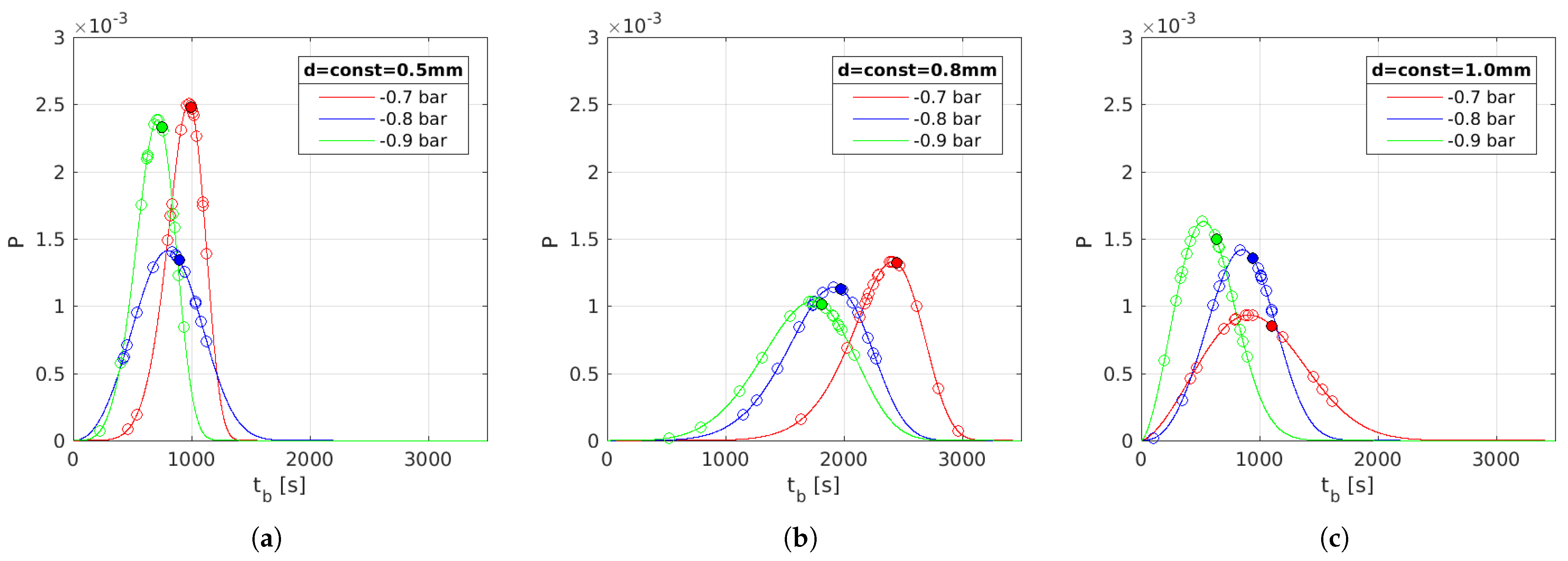

- The conductor thickness affects the dispersion of the results. It is clearly visible that in the case of the thinnest sample (Figure 4a), the experimental result regarding the dispersion is the smallest.

- The influence of air pressure on the sample lifetime is evident. In each case, the sample lifetime decreases as the air pressure in the chamber is reduced.

- The higher the air pressure and the larger the wire diameter, the greater the dispersion of the breakdown time results ( is smaller). At the same time, no clear pattern of lifetime variation was observed.

- It was observed that the insulation thickness of the conductor had a significant impact on the experimental results (Figure 4b). The wire with had the thickest insulation, a measuring 0.0232 mm, which was considerably thicker than in the other samples. This could explain the significantly longer lifetime of these samples compared to the others.

- The simulations were conducted at a voltage corresponding to the aging voltage applied to the samples (peak-to-peak value of 2.8 kV).

- The nominal diameter of the conductor and the insulation enamel a were assumed as specified in Table 1.

- It was assumed that the conductors were in contact with each other, not at a single point, but over an area of contact.

- A single winding wire consists of two materials: a conductor and an insulating material with a relative permittivity of [12].

6. Conclusions

- The air pressure in the chamber influences the sample lifetime ; in all cases, the lifetime decreases as the air pressure is reduced. This effect occurs because a decrease in air pressure leads to a lower electrical breakdown strength. In an insulation system with dimensions as small as those in the TP samples, Paschen’s law applies [24]. As the breakdown strength of air decreases, the intensity of partial discharges increases, leading to insulation degradation.

- The insulation thickness of winding wires significantly affects the dispersion of measurement results (in the context of a normal distribution, dispersion is characterized by the standard deviation , while for the Weibull distribution, it is described by the shape parameter , where a higher indicates lower variability in the experimental results). In Table 2, the influence of insulation thickness is noticeable for samples with mm, where the insulation thickness was mm. This parameter still meets the standard requirements [19]; see Table 1.

7. Discussion

- Under certain environmental conditions, accelerated degradation of electrical machine insulation systems may occur. Such conditions are particularly relevant in aviation, where modern aircraft commonly utilize PWM converters that control electric motors driving various mechanisms.

- The insulation thickness of conductors is not constant and depends on various factors, such as the thickness d of the enameled wire and the viscosity of the liquid enamel in which the conductor is immersed, among others. These factors influence not only the final insulation thickness but also its electrical strength and aging resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Driendl, N.; Pauli, F.; Hameyer, K. Modeling of Partial Discharge Processes in Winding Insulation of Low-Voltage Electrical Machines Supplied by High du/dt Inverters. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 7102–7107. [Google Scholar] [CrossRef]

- Hammarström, T.J.; Gubanski, S.M. Square-Shaped Waveform Pulse Control to Minimize PD Exposure Within Motor Insulation. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1850–1857. [Google Scholar] [CrossRef]

- Cavallini, A.; Lusuardi, L.; Meyer, D.R.; Machipeddy, S. Modelling Partial Discharge Inception in Magnet Wires at Different Altitudes. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 449–452. [Google Scholar] [CrossRef]

- ISO 2533:1975; Standard Atmosphere. International Organization for Standardization: Geneva, Switzerland, 1975.

- Abadie, C.; Billard, T.; Lebey, T. Influence of Pressure on Partial Discharge Spectra. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 507–510. [Google Scholar] [CrossRef]

- Rao, S.N.; Elanseralathan, K. Influence of PWM technique on breakdown in twisted pairs. In Proceedings of the 2017 3rd International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Rupnagar, India, 16–18 November 2017; pp. 427–431. [Google Scholar] [CrossRef]

- Madonna, V.; Giangrande, P.; Galea, M. Weibull Distribution and Geometrical Size Factor for Evaluating the Thermal Life of Electrical Machines’ Insulation. In Proceedings of the IECON 2020—The 46th Annual Conference of the IEEE Industrial Electronics Society, Virtual, 18–21 October 2020; pp. 1114–1119. [Google Scholar] [CrossRef]

- Meyer, D.R.; Cavallini, A.; Lusuardi, L.; Barater, D.; Pietrini, G.; Soldati, A. Influence of Impulse Voltage Repetition Frequency on RPDIV in Partial Vacuum. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 873–882. [Google Scholar] [CrossRef]

- Lusuardi, L.; Rumi, A.; Cavallini, A.; Barater, D.; Nuzzo, S. Partial Discharge Phenomena in Electrical Machines for the More Electrical Aircraft. Part II: Impact of Reduced Pressures and Wide Bandgap Devices. IEEE Access 2021, 9, 27485–27495. [Google Scholar] [CrossRef]

- Petri, T.; Keller, M.; Schuller, F.; Parspour, N. Lifetime Analysis of the Insulation System of Traction Machines Based on the Partial Discharge Behavior of Hairpin Wire Pairs and Conventional Twisted Wire Pairs. In Proceedings of the 2023 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 15–19 October 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Kodama, S.; Takahashi, T.; Tanaka, Y.; Mizuno, M.; Kato, H. Life Estimation of Enamel Twisted Pair Suffering Partial Discharge under Repetitive Impulse Voltage. In Proceedings of the 2022 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 19–23 June 2022; pp. 225–228. [Google Scholar] [CrossRef]

- Roehrich, J. Analiza Mechanizmów Procesów Degradacji w Polimerowych ukłAdach Izolacyjnych Wysokich Napięć [Analysis of Mechanisms of Degradation Processes in Polymer High-Voltage Insulation Systems]. Ph.D. Thesis, AGH University of Krakow, Kraków, Poland, 2013. (In Polish). [Google Scholar]

- Ji, Y.; Zhang, P.; Giangrande, P.; Zhao, W.; Buticchi, G.; Galea, M. Effect of Test Voltage Waveforms on Partial Discharge Inception Voltage Considering Different Environmental Conditions. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Xi’an, China, 10–13 October 2024; pp. 33–38. [Google Scholar] [CrossRef]

- Montanari, G.C.; Mazzanti, G.; Cacciari, M.; Fothergill, J.C. Optimum estimators for the Weibull distribution of censored data. Singly-censored tests [electrical breakdown test data]. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 157–164. [Google Scholar] [CrossRef]

- Montanari, G.C.; Mazzanti, G.; Cacciari, M.; Fothergill, J.C. Optimum estimators for the Weibull distribution from censored test data. Progressively-censored tests [breakdown statistics]. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 462–469. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- IEC 62539:2007; IEC/IEEE Guide for the Statistical Analysis of Electrical Insulation Breakdown Data (Adoption of IEEE Std 930-2004). International Electrotechnical Commission: Geneva, Switzerland, 2007. [CrossRef]

- White, J.S. The moments of log-Weibull order statistics. Technometrics 1969, 11, 373–386. [Google Scholar] [CrossRef]

- IEC 60317-13:2010; Specifications for Particular Types of Winding Wires—Part 13: Polyester or Polyesterimide Overcoated with Polyamide-Imide Enamelled Round Copper Wire, Class 200. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- IEC 60034-18-41:2014; Rotating Electrical Machines—Part 18-41: Partial Discharge Free Electrical Insulation Systems (Type I) Used in Rotating Electrical Machines Fed from Voltage Converters—Qualification and Quality Control Tests. International Electrotechnical Commission: Geneva, Switzerland, 2014.

- IEC 60851-5:2008; Winding Wires—Test methods—Part 5: Electrical Properties. International Electrotechnical Commission: Geneva, Switzerland, 2008.

- Ji, Y.; Giangrande, P.; Zhao, W.; Madonna, V.; Zhang, H.; Galea, M. Lifetime Estimation of Corona-Resistance Wire for Electrical Machines Operating Under the Partial Discharge Regime. In Proceedings of the 2023 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Newcastle upon Tyne, UK, 13–14 April 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Liu, X. Low Pressure Partial Discharge Investigation with FEM Modeling for a Twisted Pair of Insulated Conductors. In Proceedings of the 2006 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MO, USA, 15–18 October 2006; pp. 611–614. [Google Scholar] [CrossRef]

- Kuffel, E.; Zaengl, W.S.; Kuffel, J. High Voltage Engineering: Fundamentals, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2000; ISBN 978-0-7506-3634-6. [Google Scholar]

- Florkowska, B.; Florkowski, M.; Furgal, J.; Roehrich, J.; Zydron, P. Impact of Fast Transient Phenomena on Electrical Insulation Systems; Wydawnictwa AGH: Kraków, Poland, 2012; ISBN 978-83-7464-480-8. [Google Scholar]

| [mm] | [mm] | [mm] | a [mm] |

|---|---|---|---|

| 0.5 | 0.024 | 0.544 | 0.0200 |

| 0.8 | 0.030 | 0.855 | 0.0232 |

| 1.0 | 0.034 | 1.062 | 0.0178 |

| Air Pressure | d = 0.5 mm | d = 0.8 mm | d = 1.0 mm |

|---|---|---|---|

| −0.7 bar | = 1001 | = 2447 | = 1104 |

| = 6.73 | = 8.79 | = 2.56 | |

| −0.8 bar | = 898 | = 1977 | = 944 |

| = 3.27 | = 6.04 | = 3.48 | |

| −0.9 bar | = 750 | = 1814 | = 636 |

| = 4.76 | = 4.98 | = 2.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pająk, P.; Roehrich, J.; Benesz, M. Effect of Air Pressure on the Aging and Lifetime of Electrical Insulation in Winding Wires. Energies 2025, 18, 1595. https://doi.org/10.3390/en18071595

Pająk P, Roehrich J, Benesz M. Effect of Air Pressure on the Aging and Lifetime of Electrical Insulation in Winding Wires. Energies. 2025; 18(7):1595. https://doi.org/10.3390/en18071595

Chicago/Turabian StylePająk, Piotr, Józef Roehrich, and Mariusz Benesz. 2025. "Effect of Air Pressure on the Aging and Lifetime of Electrical Insulation in Winding Wires" Energies 18, no. 7: 1595. https://doi.org/10.3390/en18071595

APA StylePająk, P., Roehrich, J., & Benesz, M. (2025). Effect of Air Pressure on the Aging and Lifetime of Electrical Insulation in Winding Wires. Energies, 18(7), 1595. https://doi.org/10.3390/en18071595