Advances in the Research of Superconducting Dynamic Synchronous Condenser Technology

Abstract

1. Introduction

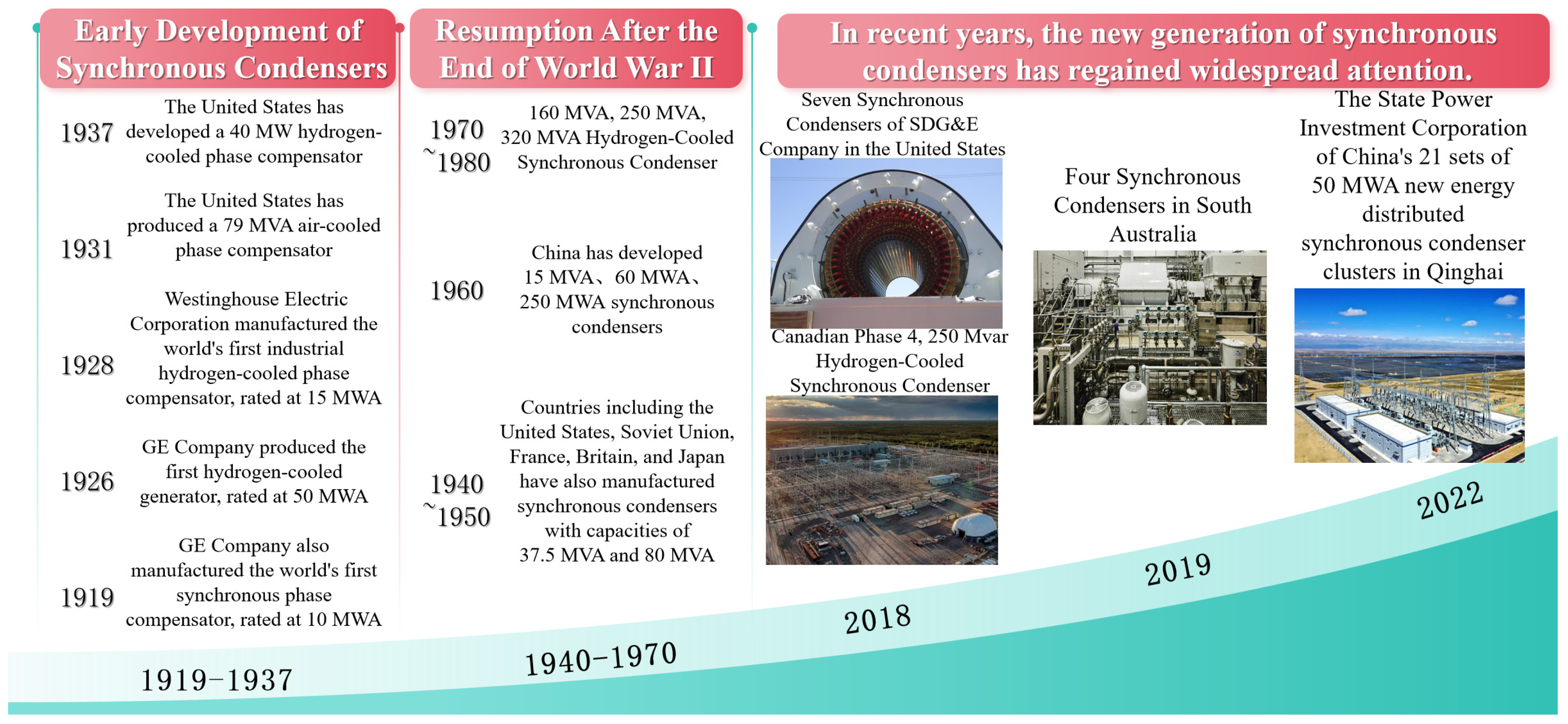

1.1. The Development Process of Traditional DSCs

1.2. Overview of SDSCs

1.3. Comparison Between Conventional and Superconducting Condensers

2. Development Progress of SDSCs

2.1. Research Progress in Europe and America

2.2. Research Progress in China

3. Overall Design and Excitation Winding

3.1. Overall Design

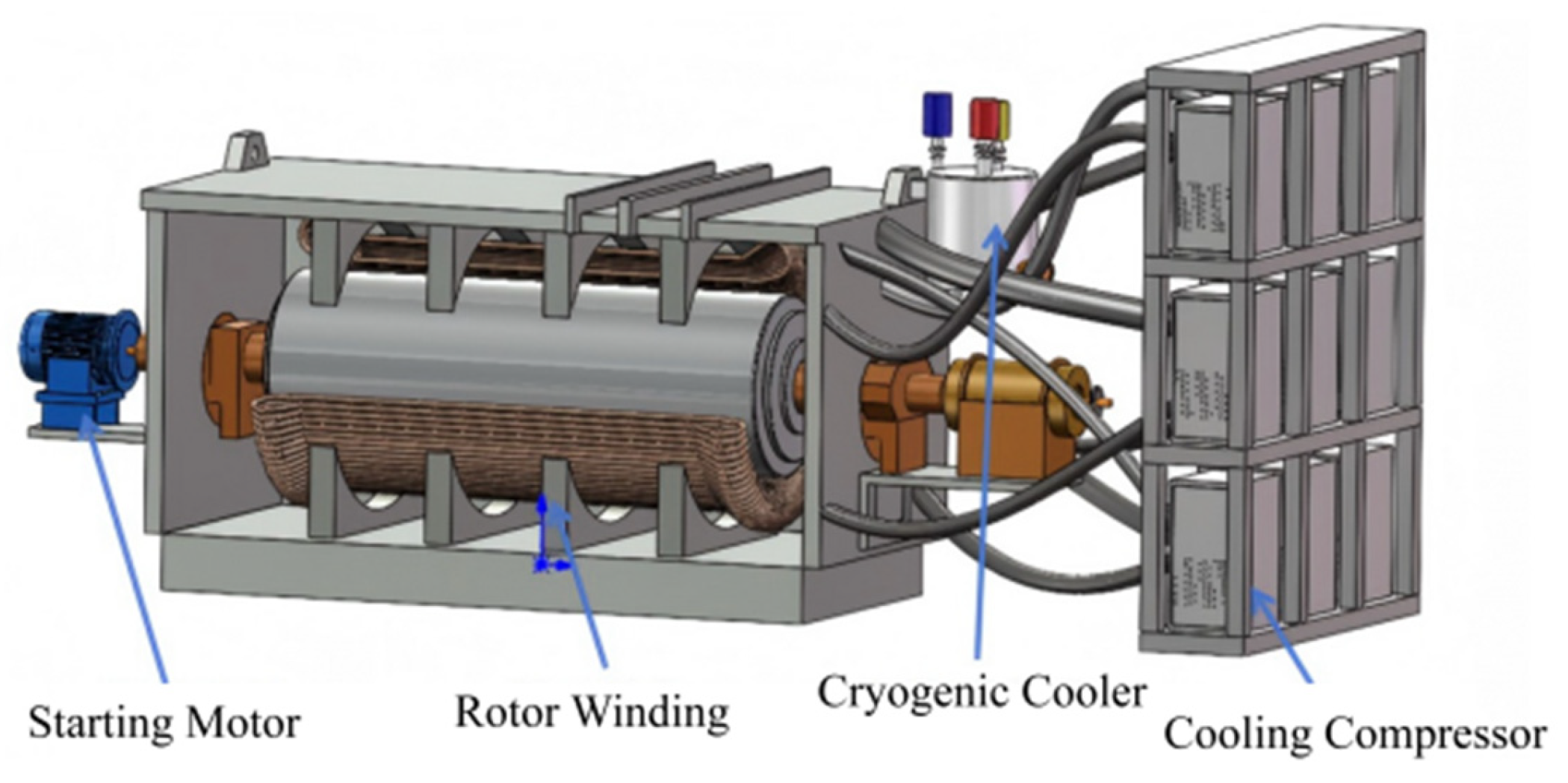

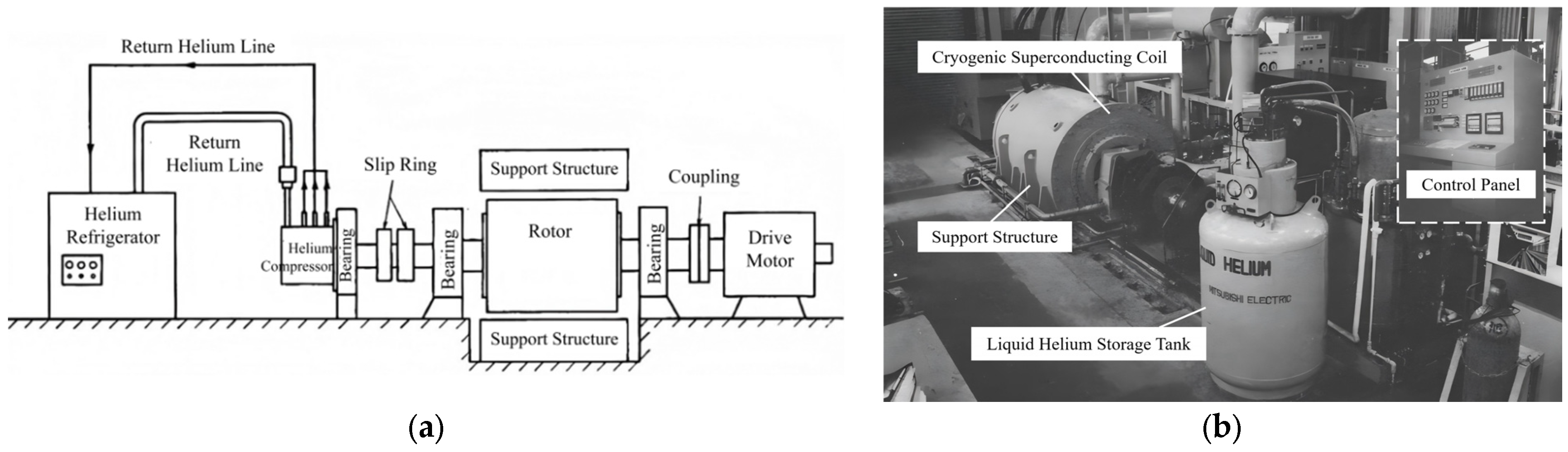

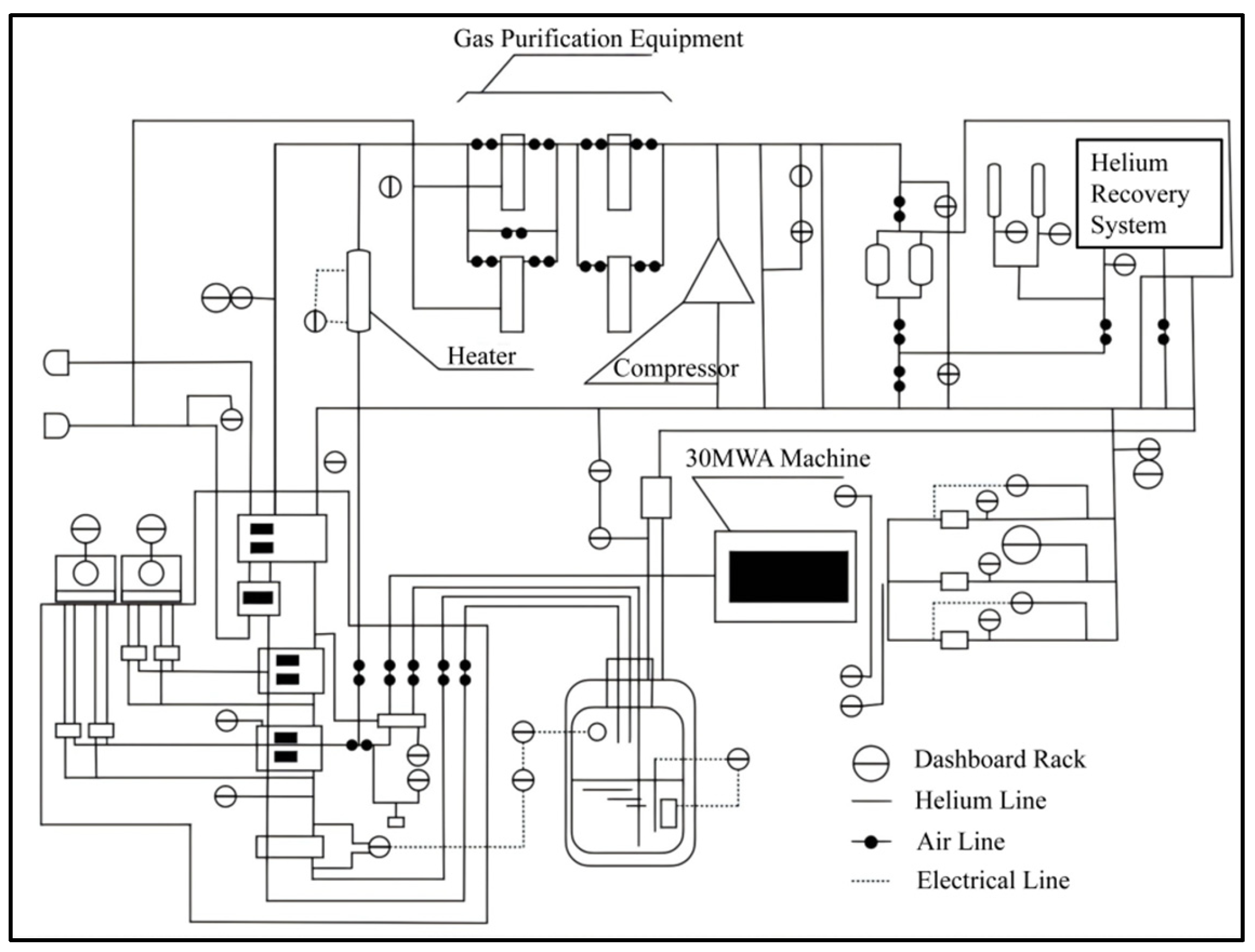

3.1.1. Japan 30 Mvar LTS DSC

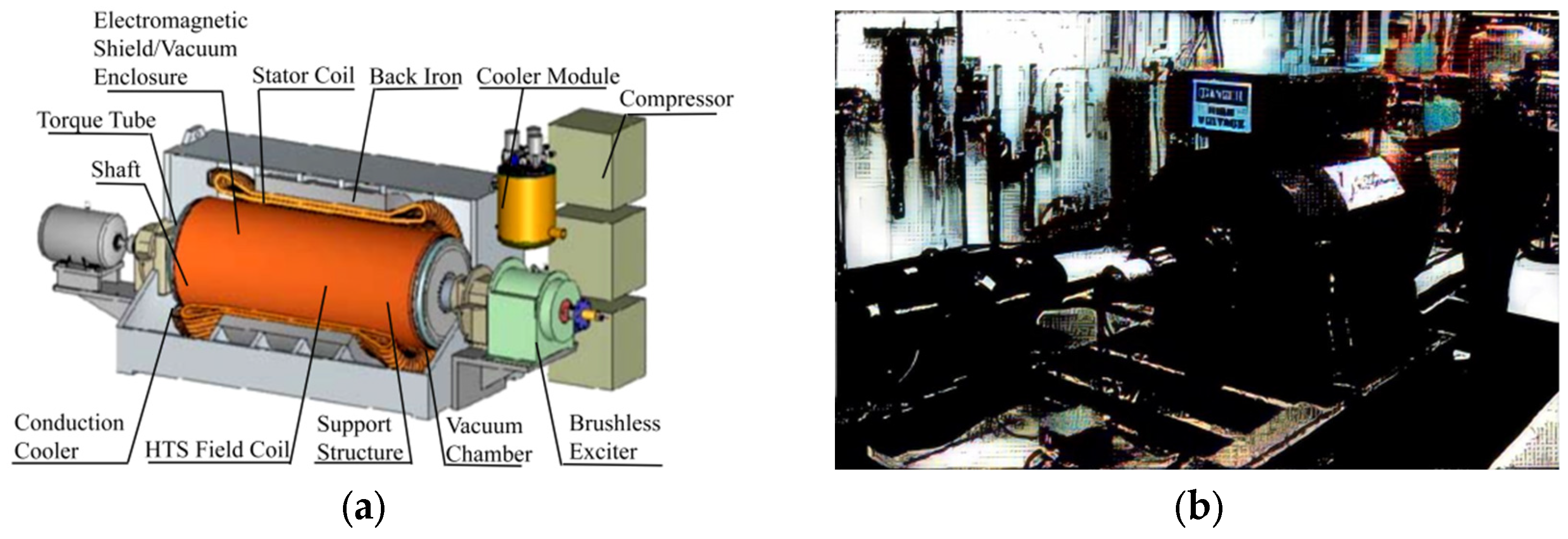

3.1.2. United States AMSC 8 Mvar HTS DSC

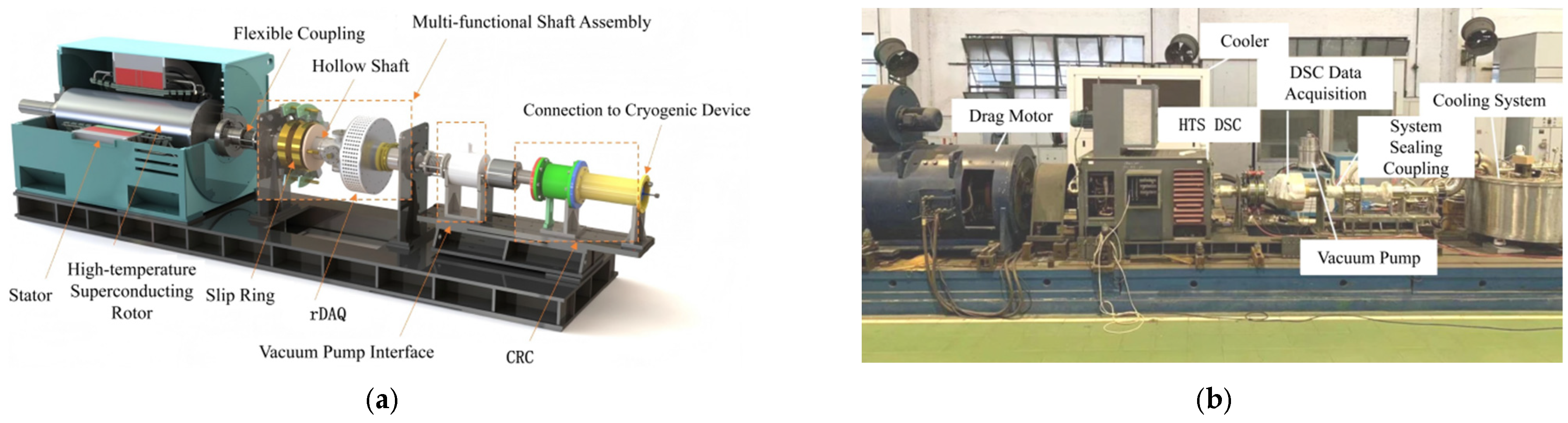

3.1.3. China Southern Power Grid HTS DSC

3.2. Design and Control Strategy of Excitation Power Supply

4. Stator Structure

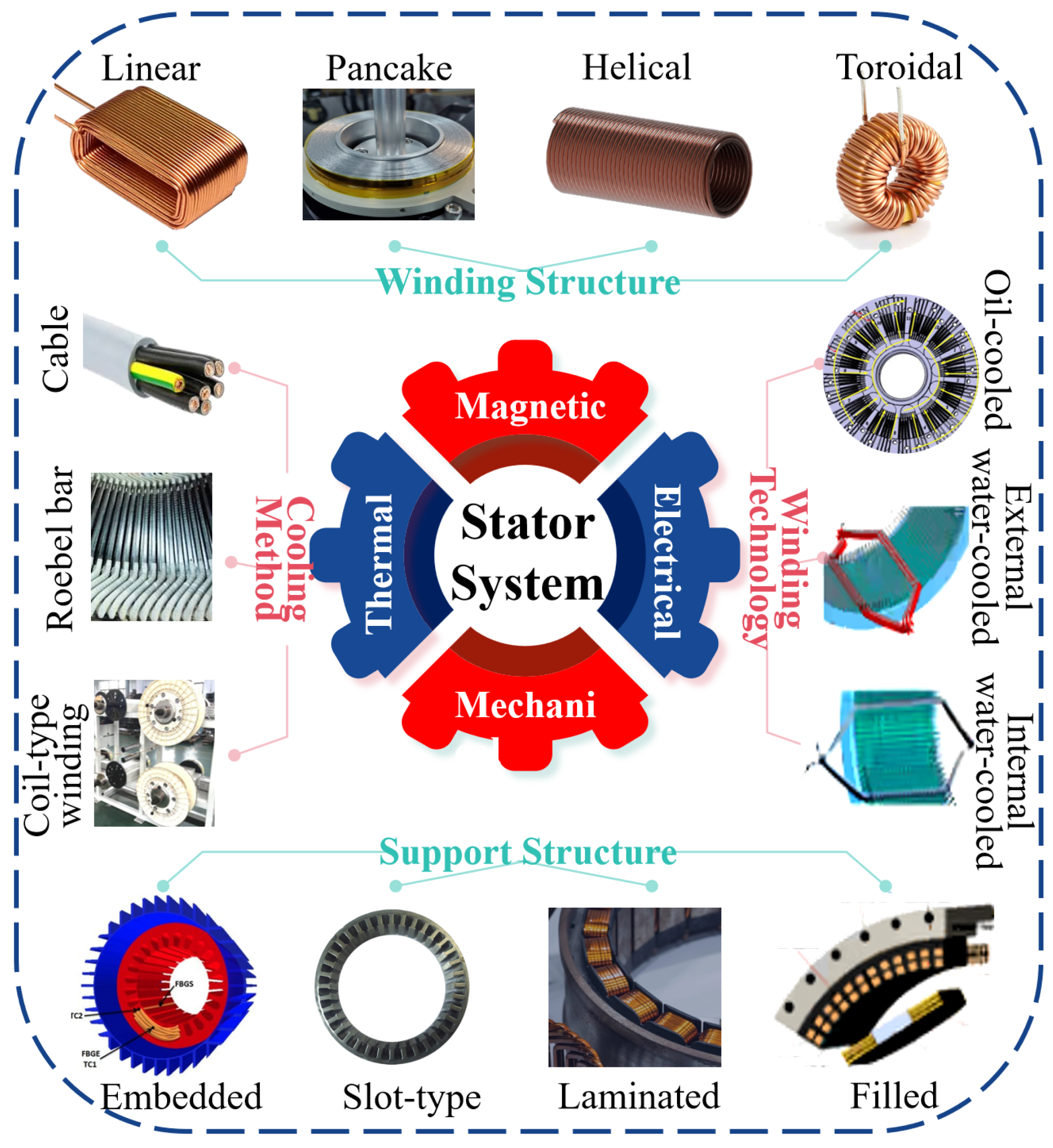

4.1. Overview of the Stator System

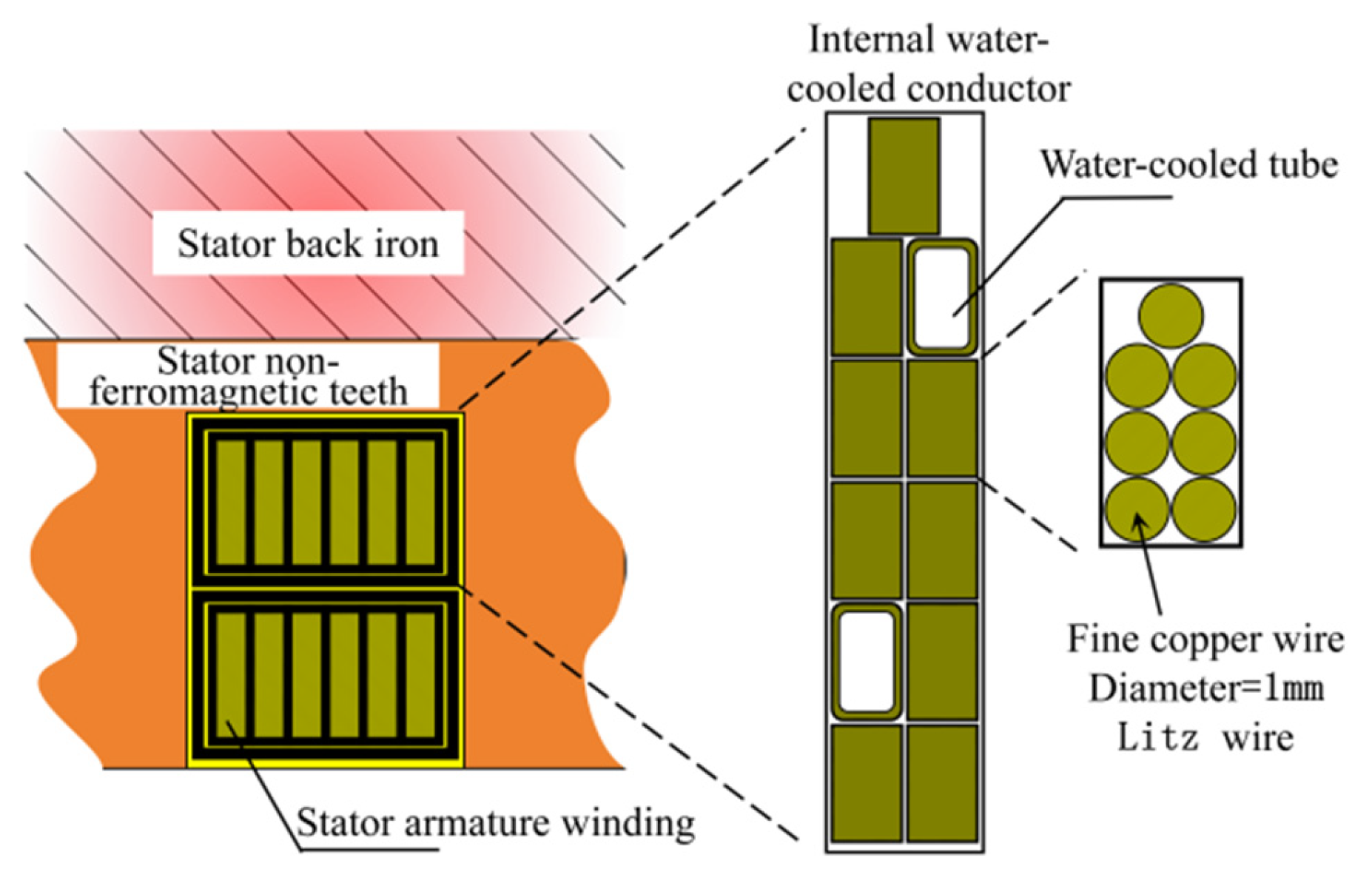

4.2. Structure of the Stator System

4.2.1. Non-Magnetic Tooth Design

4.2.2. Dual-Stator Design

5. Rotor Systems

5.1. Overview of Superconducting Rotors

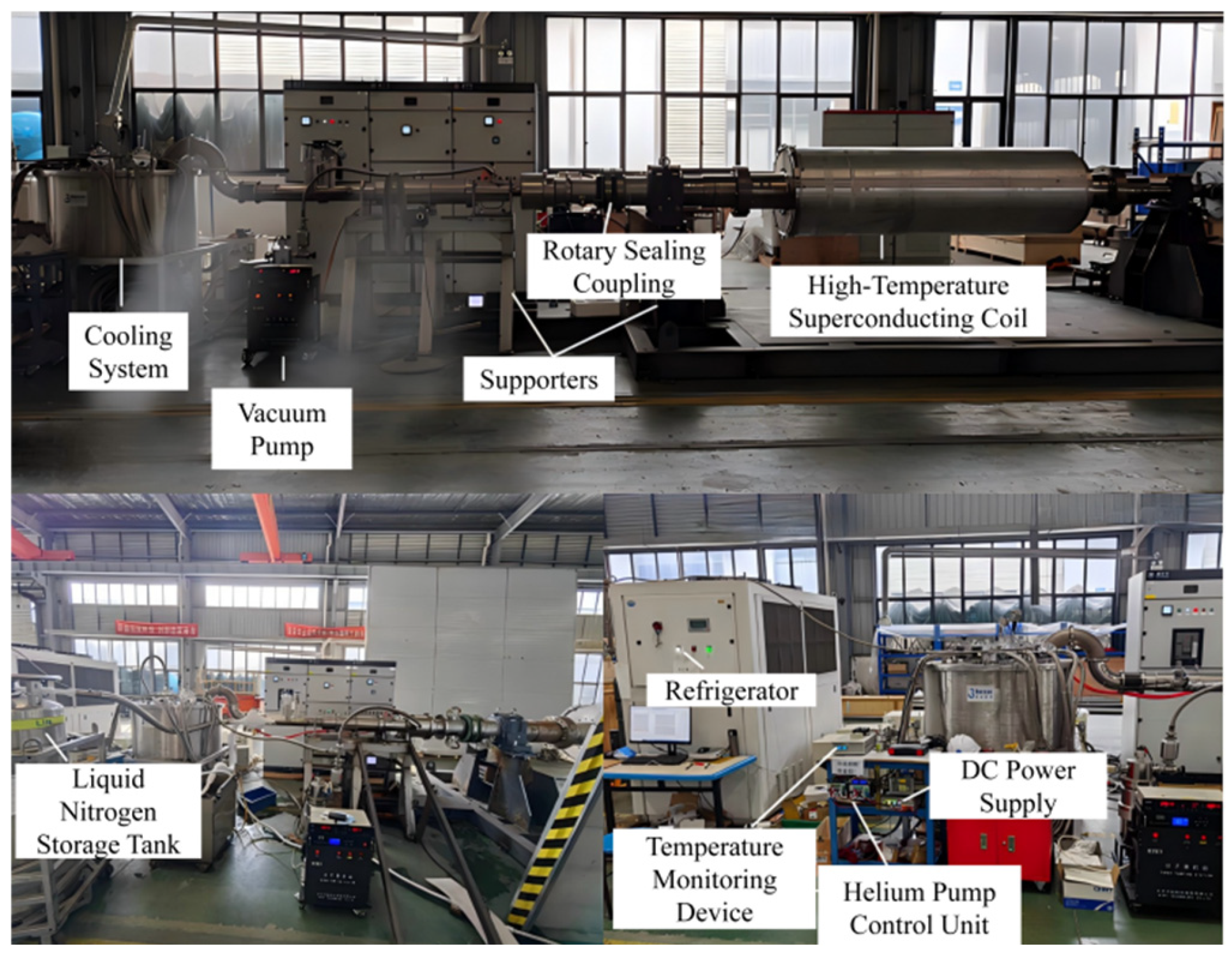

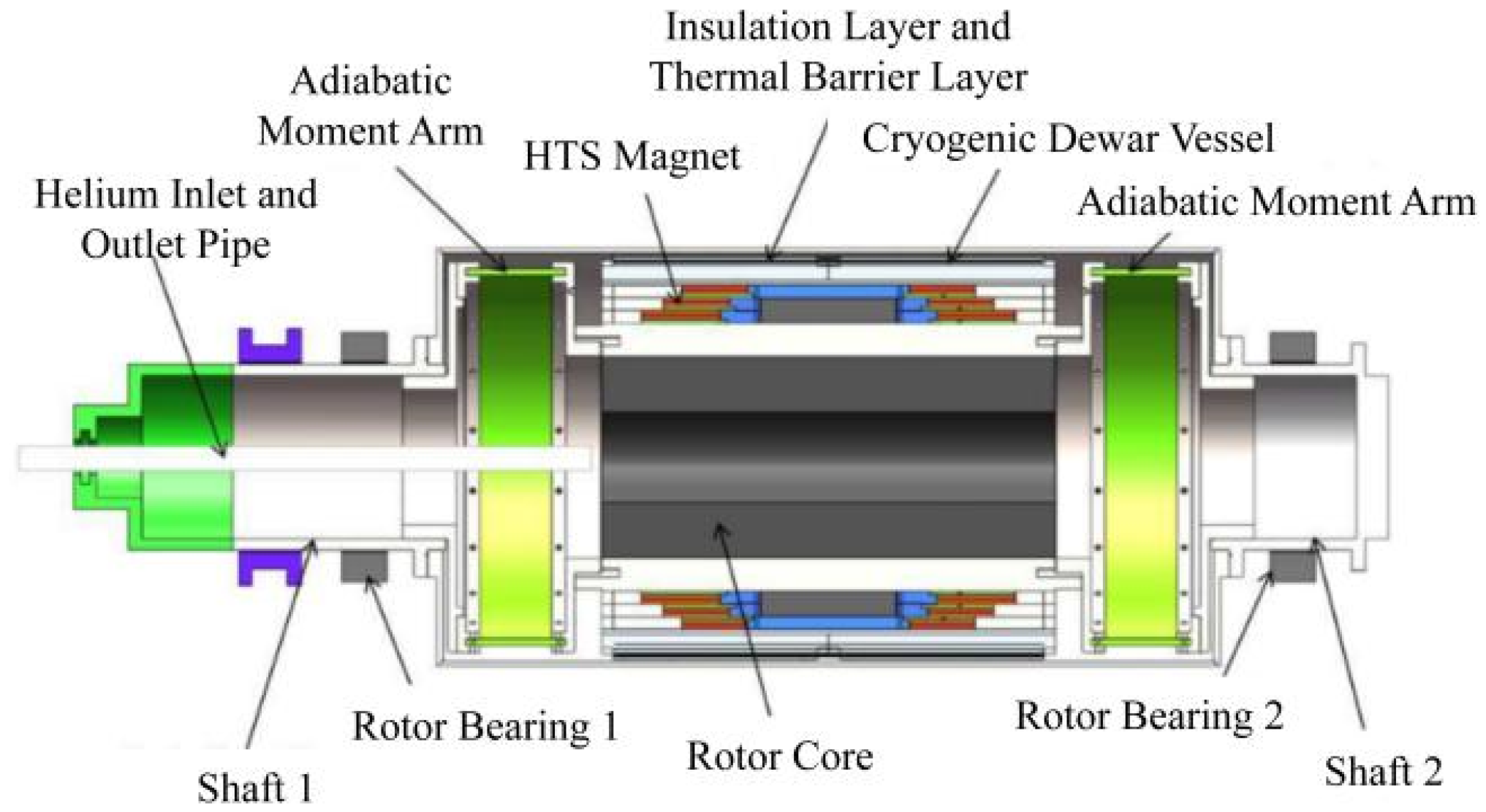

5.2. Typical Superconducting Rotor Structure

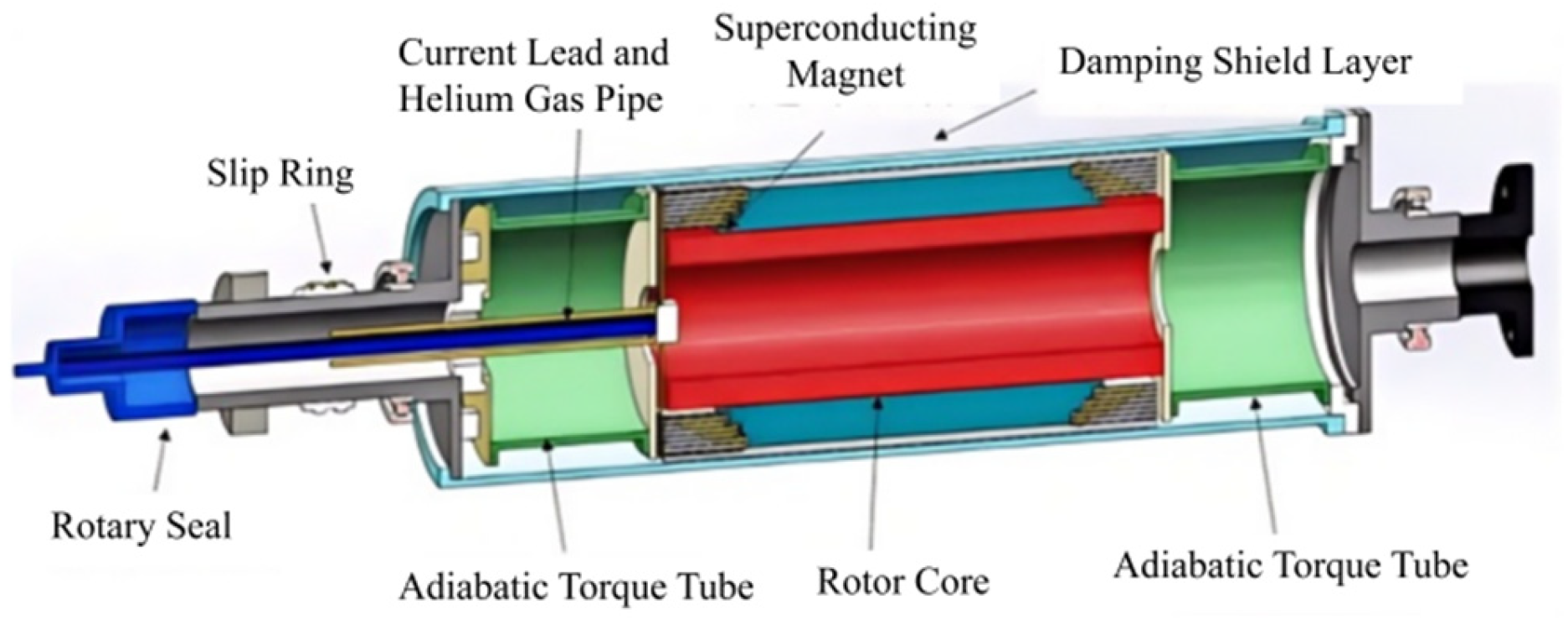

5.2.1. LTS Rotor

5.2.2. REBCO-Based HTS Rotor

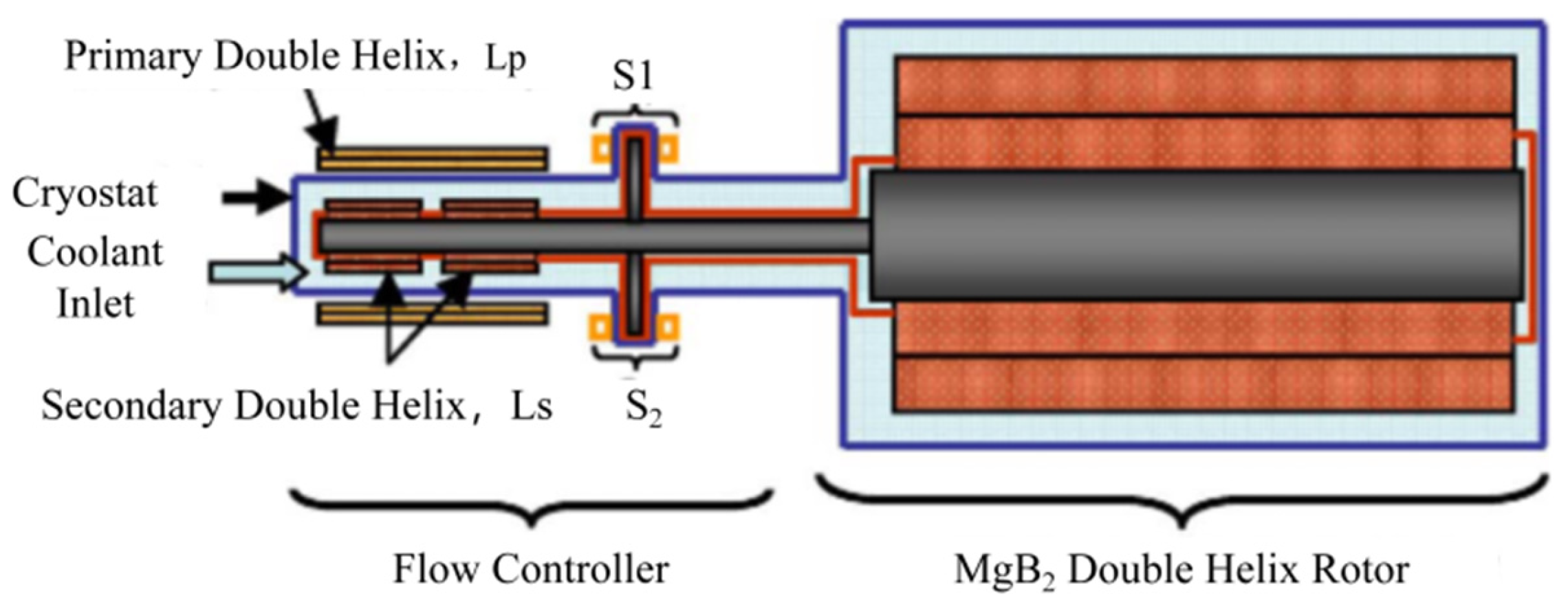

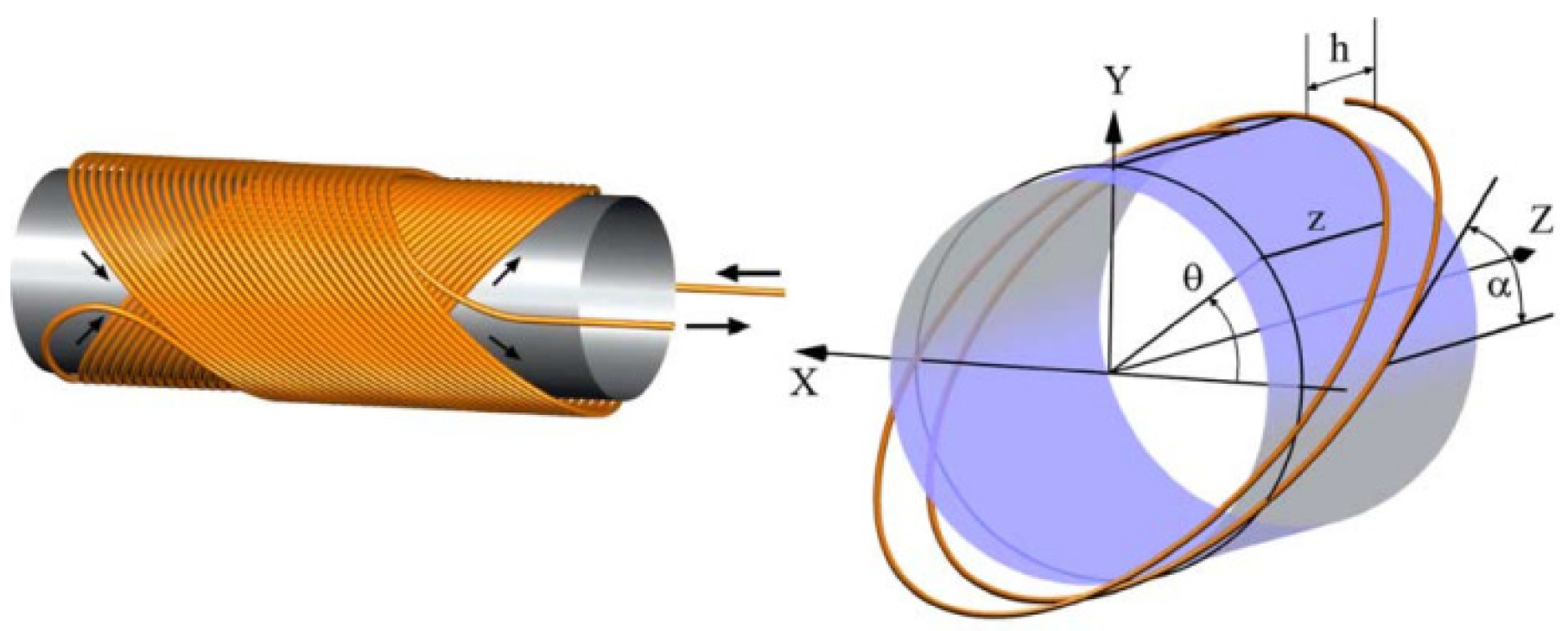

5.2.3. MgB2-Based Double-Helix Rotor

5.3. Typical Superconducting Rotor Magnet

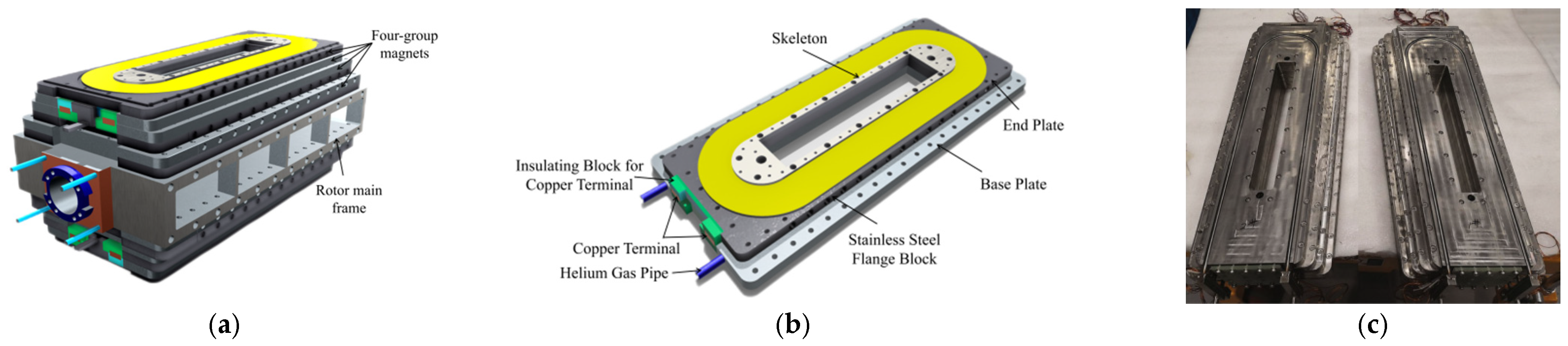

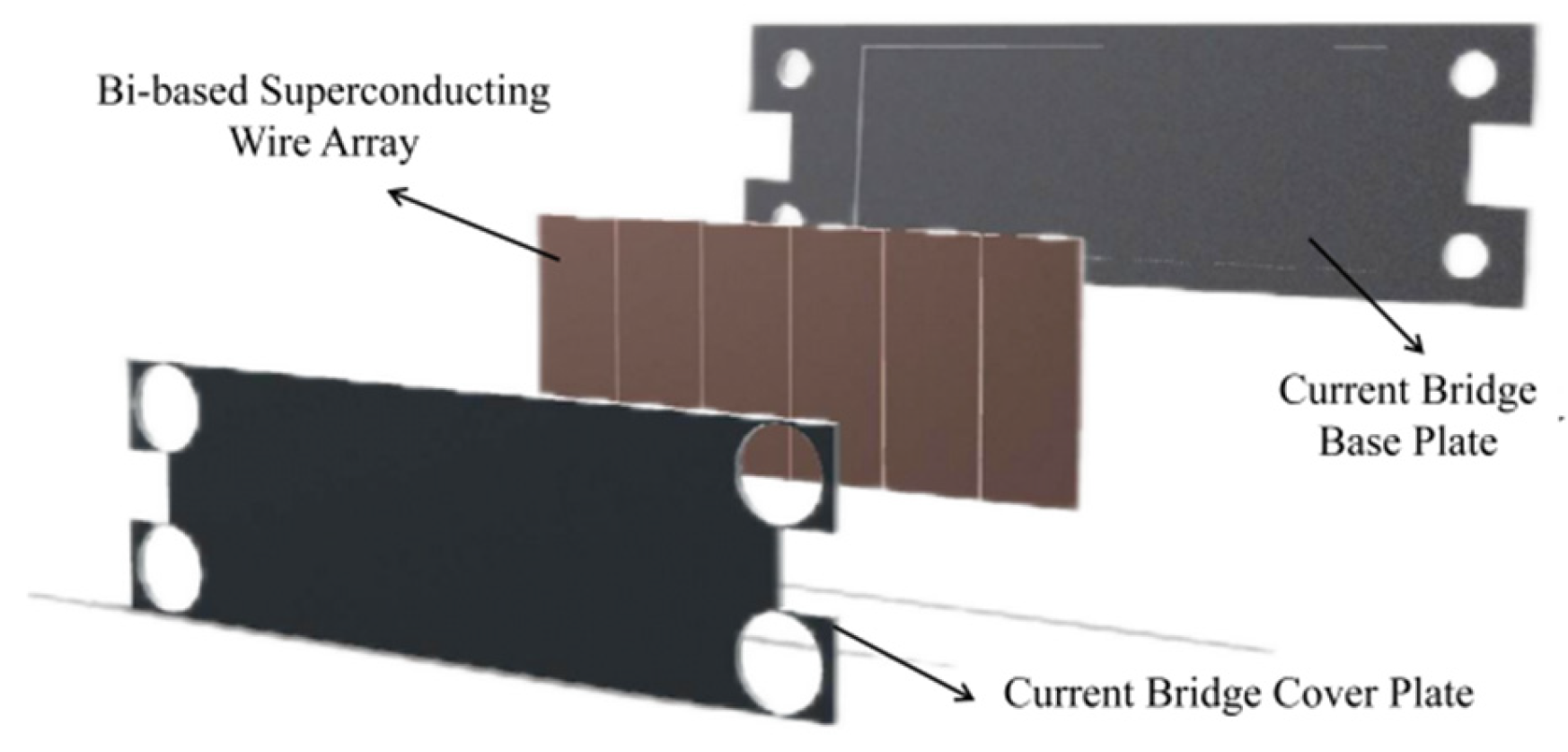

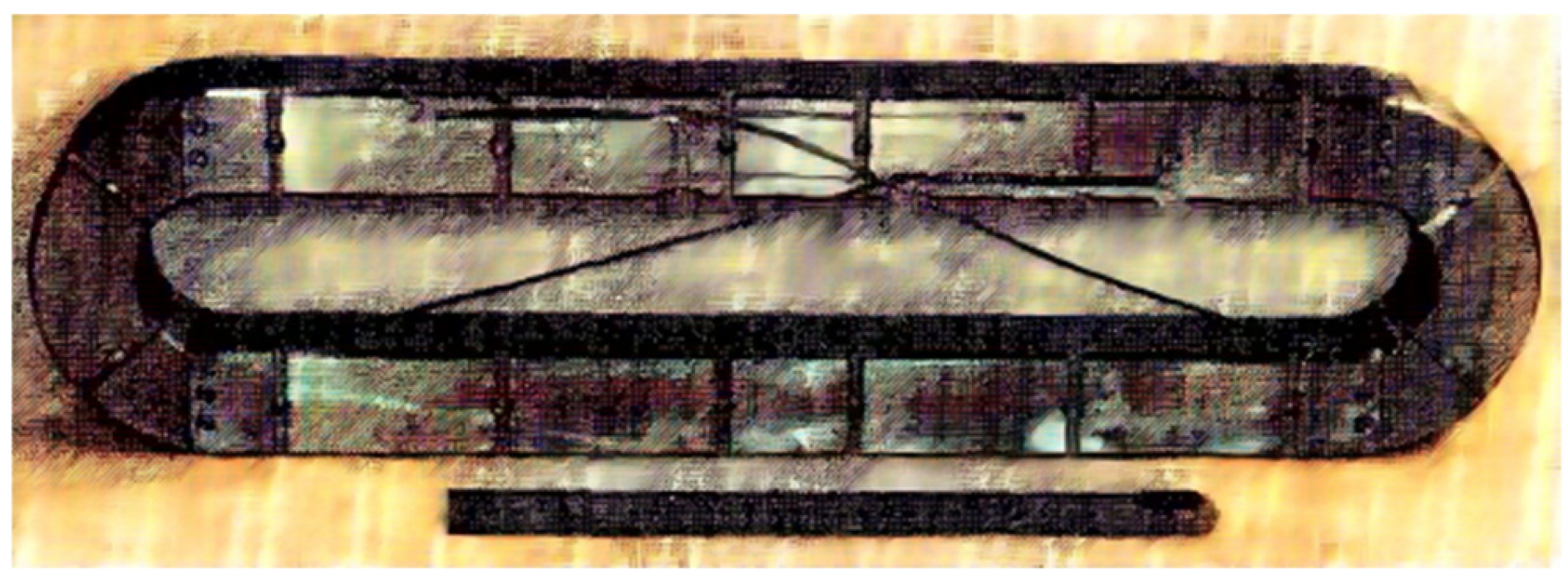

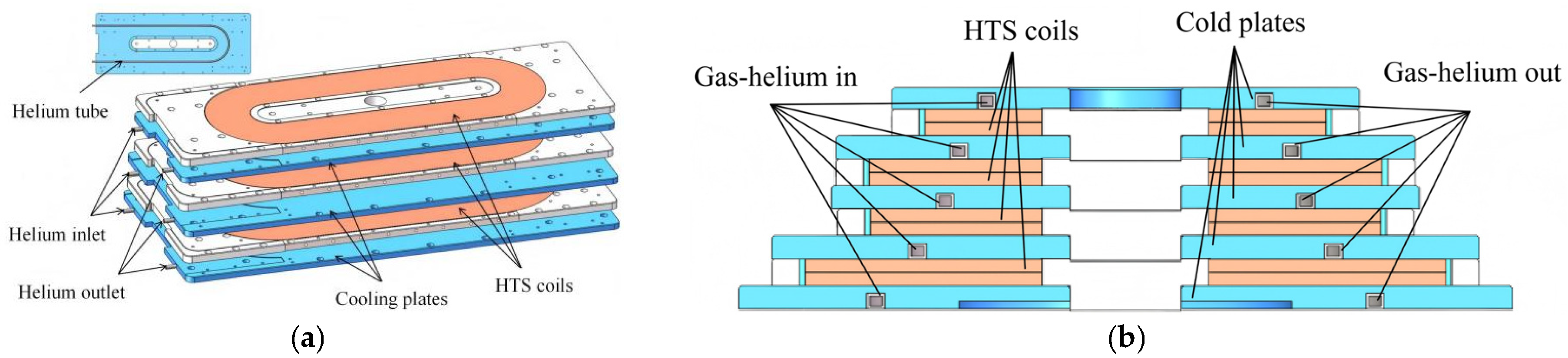

5.3.1. Pole Racetrack-Shaped Double-Pancake HTS Coils

5.3.2. Winding-Reaction Method for LTS Magnet Coils

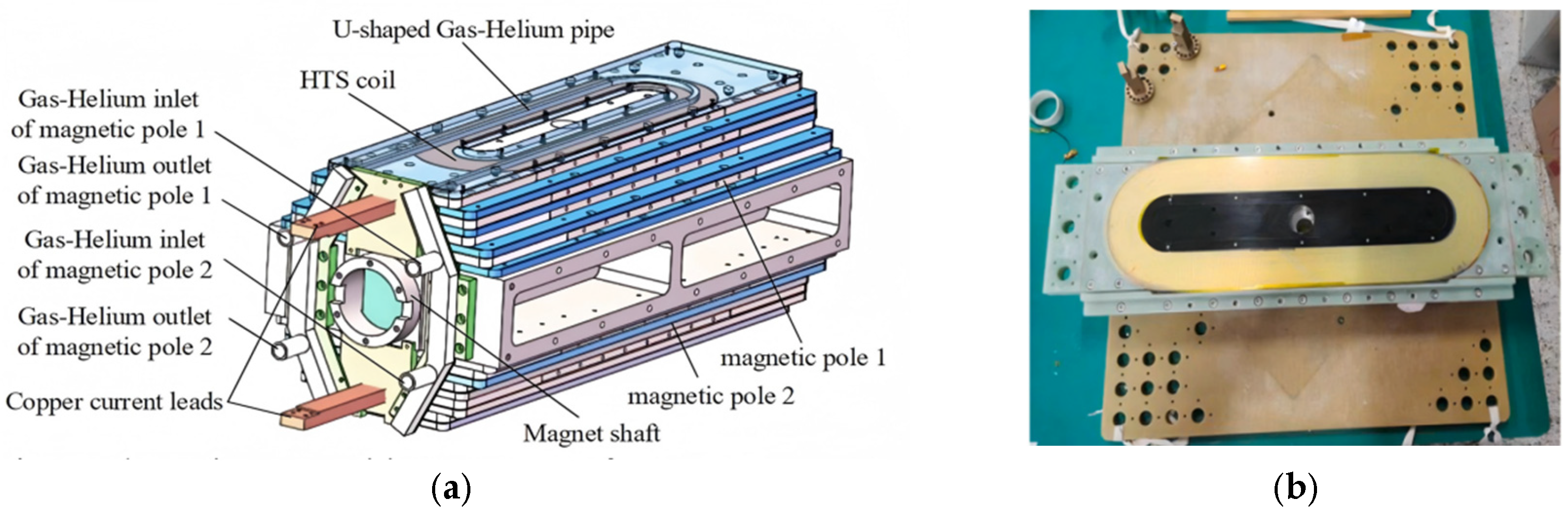

5.3.3. Two Sets of HTS Magnets

5.4. Material Selection

6. Cooling System

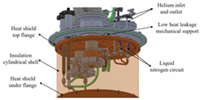

6.1. Overview of the Cooling System and Selection of Technical Solutions

6.2. Innovation and Application of Efficient Cooling Technologies

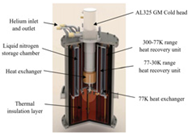

6.2.1. Helium Liquefaction Cooling

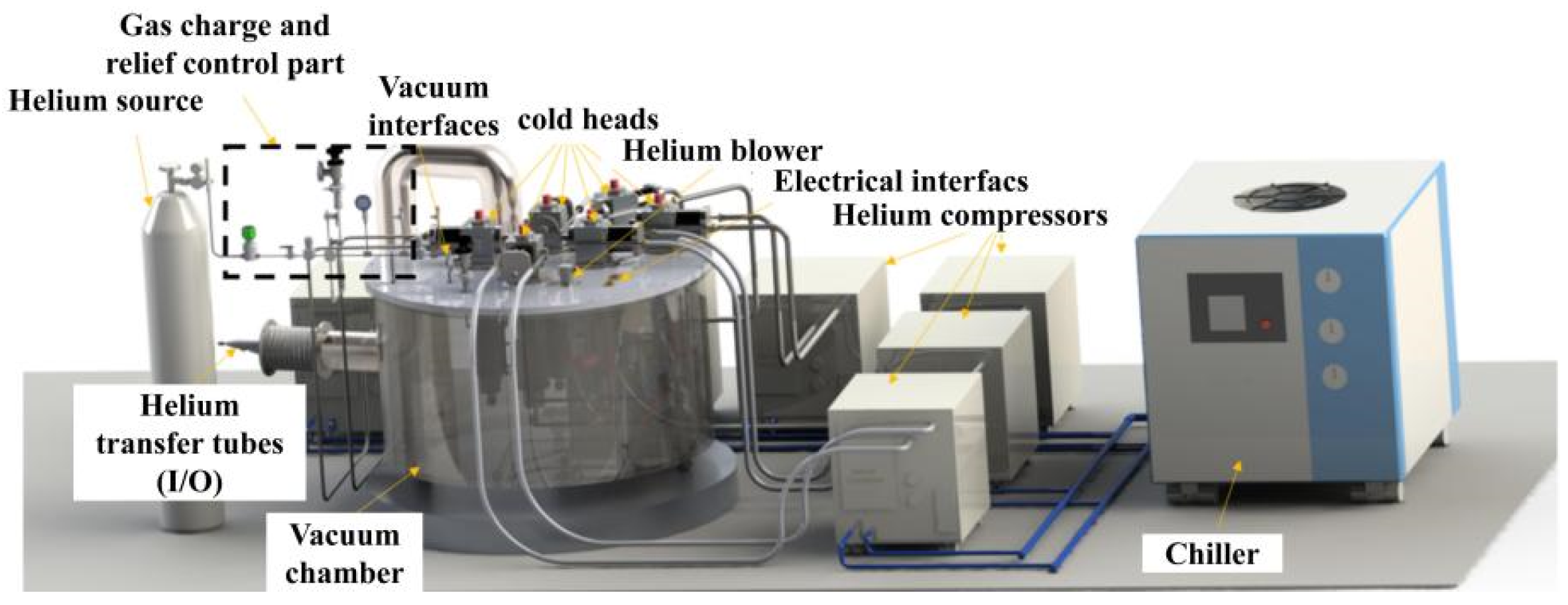

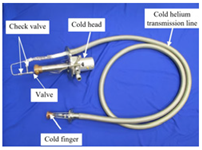

6.2.2. Cryogenic Helium Circulation Cooling System

7. Practical Application Cases

- (1)

- When the motor operates at rated power, its transient dynamic voltage support and stability performance (including leading and lagging VARS) are excellent, making it suitable for various voltage regulation and power quality issues related to reactive compensation;

- (2)

- Compared to traditional DSC, this synchronous condenser significantly reduces operating costs, especially under partial load conditions, where motor losses are minimal. Additionally, the elimination of thermal cycling avoids the costs associated with rotor rewinding;

- (3)

- The harmonic levels generated by the condenser are extremely low, eliminating the need for additional filters;

- (4)

- The installation process is straightforward, as it is a pre-packaged, independent modular unit;

- (5)

- It can operate normally on the low-voltage side of transmission and distribution transformers, with a stator suitable for distribution-level voltages not exceeding 13.8 kV. In most applications, no additional step-up transformers are required.

8. Current Technical Challenges and Future Prospects

8.1. Electromagnetic Design and Manufacturing Process

8.2. Cooling and Insulation Technology

8.3. Quench Issues in Superconducting Magnets Under Alternating Current

8.4. Torque Tube Transmission Torque Technology

9. Conclusions

- (1)

- Cooling and insulation technology: developing efficient and low-cost low-temperature cooling solutions remains a critical barrier to widespread adoption.

- (2)

- Quenching and stability issues: understanding and mitigating the alternating current losses and quenching behavior of superconducting magnets under dynamic grid conditions are essential for improving long-term reliability.

- (3)

- Scalability and cost of manufacturing: the high cost of superconducting materials and the complexity of the manufacturing process currently limit large-scale commercialization.

- (4)

- Integration with modern power grids: further research on dynamic response, fault tolerance, and control strategies is needed to ensure seamless integration with high-voltage transmission networks.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SDSC | Superconducting Dynamic Synchronous Condensers |

| DSC | Dynamic Synchronous Condensers |

| AC | Alternating Current |

| SVCs | Static Var Compensators |

| STATCOMs | Static Synchronous Compensators |

| HTS | High-Temperature Superconducting |

| DSC | Dynastic Synchronous Condenser |

| LTS | Low-temperature Superconducting |

| AMSC | American Superconductor Corporation |

| TVA | Tennessee Valley Authority |

| CSIC | China Shipbuilding Industry Corporation |

| CRC | Cryogenic Rotary Coupling |

| rDAQ | Rotating Data Acquisition Device |

| DC | Direct Current |

| REBCO | Rare Earth Barium Copper Oxide |

| GFRP | G-10 Glass Fiber Reinforced Epoxy Resin |

| FPT | Flux Pump Transformer |

| MgB2 | Magnesium diboride |

| BSCOO | Bismuth Strontium Calcium Copper Oxygen |

| YBCO | Yttrium Barium Copper Oxide |

| NbTi | Niobium Titanium |

| Nb3Sn | Niobium-Tin |

| LN2 | Liquid Nitrogen |

| GHe | Gaseous Helium |

| GM | Gifford-McMahon |

| UHVDC | Ultra-High Voltage Direct Current |

| CFD | Computational Fluid Dynamics |

| FEA | Finite Element Analysis |

| MIS | Microsphere Insulation System |

| MLI | Multilayer Insulation |

References

- Liu, Z.; Qin, L.; Yang, S.; Zhou, B.; Wang, Q.; Zheng, J.; Liu, K. Review of Virtual Synchronous Control Method of Power Electronic Converter for Novel Power System. Power Syst. Technol. 2023, 47, 1–16. (In Chinese) [Google Scholar] [CrossRef]

- Guo, Q.; Li, Z. A Review of the Development of Synchronous Condenser. Proc. CSEE 2023, 43, 6050–6064. (In Chinese) [Google Scholar] [CrossRef]

- Cheng, M.; Tian, W.; Wang, W.; Wei, C. Key Technologies and Research Progress of New Synchronous Condensers. Electr. Power Eng. Technol. 2020, 39, 2–9. (In Chinese) [Google Scholar]

- Li, Y.; Cheng, H.; Fang, W.; Zhang, Y. Survey on the Application of Reactive Power Compensation Device in Power System. Guangdong Electr. Power 2016, 29, 87–92. (In Chinese) [Google Scholar]

- Dai, Q. Characteristics and Applications of Synchronous Condenser. Dongfang Electr. Rev. 2016, 30, 47–51. (In Chinese) [Google Scholar] [CrossRef]

- Dou, H.; Chen, J.; Zhang, K. Research and Analysis of New Energy in New Power System. J. Appl. Energy Technol. 2022, 4, 36–38. (In Chinese) [Google Scholar]

- Zhang, D.; Zhang, G.; Xu, L.; Gao, S. Development and Application of Condenser in Power System and Dynamic Characteristics. South. Energy Constr. 2024, 11, 31–41. (In Chinese) [Google Scholar] [CrossRef]

- Qiu, W.; He, J.; Fan, X.; Xu, T.; Yu, Z.; Zhang, J.; He, F.; Lan, H.; Ye, J.; Zhang, Y.; et al. A Review of Stabilization Measures to Deal with Large Disturbances in UHVDC. Power Syst. Technol. 2022, 46, 3049–3067. (In Chinese) [Google Scholar] [CrossRef]

- Wang, B. The World’s Largest New Energy Distributed Condenser Group Was Put into Operation in Qinghai. Energy Res. Inf. Technol. 2022, 38, 62. (In Chinese) [Google Scholar]

- Duan, X.; Shi, Z.; Song, M.; Mei, G.; Song, P. Application Prospects of the Superconducting Dynamic Synchronous Condenser. IEEE Trans. Appl. Supercond. 2022, 32, 5202405. [Google Scholar] [CrossRef]

- Chow, C.C.T.; Ainslie, M.D.; Chau, K.T. High Temperature Superconducting Rotating Electrical Machines: An overview. Energy Rep. 2023, 9, 1124–1156. [Google Scholar] [CrossRef]

- Song, D.; Yan, J.; Yang, W.; Zhang, Y.; Zhang, L.; Wang, X.; Liu, Y.; Li, Z.; Zhang, J.; Wang, Y.; et al. Research and Development of High-Temperature Superconducting Motor Technology for Electric Aviation. J. Aeronaut. Astronaut. 2023, 44, 135–160. (In Chinese) [Google Scholar]

- Kynev, S.; Pilz, G.; Schmitt, H. Comparison of Modern STATCOM and Synchronous Condenser for Power Transmission Systems. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016; IEEE: New York, NY, USA, 2016; pp. 1–6. [Google Scholar]

- Teleke, S.; Abdulahovic, T.; Thiringer, T.; Svensson, J. Dynamic Performance Comparison of Synchronous Condenser and SVC. IEEE Trans. Power Deliv. 2008, 23, 1606–1612. [Google Scholar] [CrossRef]

- Kalsi, S.; Madura, D.; Howard, R.; Snitchler, G.; MacDonald, T.; Bradshaw, D.; Grant, I.; Ingram, M. Superconducting Dynamic Synchronous Condenser for Improved Grid Voltage Support. In Proceedings of the 2003 IEEE PES Transmission and Distribution Conference & Exposition, Dallas, TX, USA, 7–12 September 2003; IEEE: New York, NY, USA, 2003; pp. 742–747. [Google Scholar]

- Tian, Y. Analysis on the Research Status of Reactive Power Compensation Technology in Power Grid. J. Commun. Power Supply Technol. 2019, 36, 39–43. (In Chinese) [Google Scholar] [CrossRef]

- Nakamura, S.; Yamada, T.; Nomura, T.; Iwamoto, M.; Shindo, Y.; Nose, S.; Ishihara, A.; Fujino, H. 30 MVA Superconducting Synchronous Condenser: Design and Its Performance Test Results. IEEE Trans. Magn. 1985, 21, 783–790. [Google Scholar] [CrossRef]

- Kalsi, S.S.; Madura, D.; Snitchler, G.; Ross, M.; Voccio, J.; Ingram, M. Discussion of Test Results of a Superconductor Synchronous Condenser on a Utility Grid. IEEE Trans. Appl. Supercond. 2007, 17, 2026–2029. [Google Scholar] [CrossRef]

- Imai, Y.; Hasegawa, K.; Kanamori, Y.; Kusafuka, H.; Shibuya, M.; Nagamura, H.; Miyaike, K.; Hasegawa, H.; Nishijima, K. Field Test of a 70-MW-Class Superconducting Generator in the Mode of a Synchronous Condenser. Electr. Eng. Jpn. 2002, 141, 17–24. [Google Scholar] [CrossRef]

- Kalsi, S.S.; Madura, D.; MacDonald, T.; Ingram, M.; Grant, I. Operating Experience of a Superconductor Dynamic Synchronous Condenser. In Proceedings of the 2005/2006 IEEE PES Transmission and Distribution Conference and Exhibition, Dallas, TX, USA, 21–24 May 2006; IEEE: New York, NY, USA, 2006; pp. 899–902. [Google Scholar]

- Song, X.; Mijatovic, N.; Kellers, J.; Buhrer, C.; Rebsdorf, A.V.; Hansen, J.; Christensen, M.; Krause, J.; Wiezoreck, J.; Putz, H.; et al. A Full-Size High-Temperature Superconducting Coil Employed in a Wind Turbine Generator Setup. IEEE Trans. Appl. Supercond. 2017, 27, 5201105. [Google Scholar] [CrossRef]

- Sun, J.; Neumann, H.; Sanz, S.; Sarmiento, G.; Tropeano, M.; Marino, I.; Pujana, A.; Merino, J.M. Design and Construction of the Cryogenic Cooling System for the Rotating Magnetic Validator of the 10 MW SUPRAPOWER Offshore Superconducting Wind Turbine. IEEE Trans. Appl. Supercond. 2018, 28, 5201105. [Google Scholar] [CrossRef]

- Zheng, J. Analysis on the Research Status and Application Prospect of High-Temperature Superconducting Motor Technology. Adv. Mater. Ind. 2017, 8, 60–65. (In Chinese) [Google Scholar]

- Wu, Q.; Song, P.; Yan, Y.; Shi, Z.; Song, M.; Qu, T. Design and Testing of a Gas-Helium Conduction Cooled REBCO Magnet for a 300 kvar HTS Synchronous Condenser Prototype. IEEE Trans. Appl. Supercond. 2020, 30, 4900805. [Google Scholar] [CrossRef]

- Wu, Q.; Song, P.; Shi, Z.; Zhang, L.; Yan, Y.; Yang, Z.; Shao, L.; Qu, T. Development and Testing of a 300-kvar HTS Synchronous Condenser Prototype. IEEE Trans. Appl. Supercond. 2021, 31, 5201805. [Google Scholar] [CrossRef]

- Li, P.; Wang, C.; Ma, Z.; Wang, L. Calculation of AC Loss Using 2D Homogenization Method for HTS Synchronous Condenser Rotor and Validation. Phys. C Supercond. Its Appl. 2024, 625, 1354578. [Google Scholar] [CrossRef]

- Wu, H.; Wang, L.; Qu, H.; Wang, C.; Wang, L.; Wang, Q. Design and Analysis of Cryogenic System for the Rotor of a 15 Mvar HTS Synchronous Condenser. In Proceedings of the 2023 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Tianjin, China, 27–29 October 2023; IEEE: New York, NY, USA, 2023; pp. 1–2. [Google Scholar]

- Shou, J.; Zhang, J.; Ma, J.; Fang, Y. Performance Analysis and Comparison of Different Damping Shielding Structures Based on 3D Superconducting Condenser Models. Micro Spec. Mot. 2023, 51, 7–14. (In Chinese) [Google Scholar] [CrossRef]

- Wang, L.; Li, G. Finite Element Analysis of Stator Coil Support Structure of Superconducting Condenser Based on ANSYS. Shanghai Large Medium-Sized Electr. Mach. 2021, 3, 9–11. (In Chinese) [Google Scholar] [CrossRef]

- Chubraeva, L.; Timofeev, S. Modern Reactive Power Generators. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Yekaterinburg, Russia, 13–16 November 2017; IOP Publishing: Bristol, UK, 2018; Volume 313, p. 012006. [Google Scholar]

- Song, P.; Shi, Z.; Wu, Q.; Yang, Y.; Zhang, L.; Wu, B.; Song, M.; Qu, T. General Design of a 300-kvar HTS Synchronous Condenser Prototype. IEEE Trans. Appl. Supercond. 2020, 30, 5206905. [Google Scholar] [CrossRef]

- Shi, Z.; Song, P.; Song, M.; Mei, G.; Li, L.; Qu, T. Overall Electromagnetic Design of 10 MVAR Superconducting Synchronous Condenser. China South. Power Grid Technol. 2021, 15, 76–81. (In Chinese) [Google Scholar] [CrossRef]

- Wang, X.; Deng, S.; Niu, X. Research on Method for Improving the Magnetic Density of Air Gap of High-Temperature Superconducting Motor. Mar. Electr. Technol. 2009, 29, 33–37. (In Chinese) [Google Scholar]

- He, J. Design of Excitation Winding for High-Temperature Superconducting Offshore Wind Turbine. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2015. (In Chinese). [Google Scholar]

- Su, X. Finite Element Study on Excitation Magnetic Field of Superconducting Generator. Master’s Thesis, North China Electric Power University, Beijing, China, 2013; pp. 33–37. (In Chinese). [Google Scholar]

- Shi, Z.; Mei, G.; Duan, X.; Meng, S. A Superconducting Synchronous Condenser Excitation Power Supply Device. Chinese Patent CN114597919A, 7 June 2022. (In Chinese). [Google Scholar]

- Xue, M. Research on Excitation Power System of Superconducting Condenser. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. (In Chinese). [Google Scholar] [CrossRef]

- Zhong, H.; Xian, Z.; Shi, J.; Zhang, J. Calculation Method of Stator Winding Strong Excitation Capacity of Superconducting Condenser. Chinese Patent CN115238468A, 25 October 2022. (In Chinese). [Google Scholar]

- Liu, Z. Structural Optimization and Performance Analysis of Superconducting Excitation Synchronous Motor. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2022. (In Chinese). [Google Scholar] [CrossRef]

- Ishmael, S.; Goodzeit, C.; Masson, P.; Meinke, R.; Sullivan, R. Flux Pump Excited Double-Helix Rotor for Use in Synchronous Machines. IEEE Trans Appl. Supercond. 2008, 18, 693–696. [Google Scholar] [CrossRef]

- Shi, Z.; Wu, Q.; Song, P.; Mei, G.; Song, M.; Qu, T. Design and Testing of Rotor Magnet for 300 kvar Superconducting Synchronous Condenser Prototype. Low Temp. Supercond. 2020, 48, 29–33. (In Chinese) [Google Scholar]

- Kalsi, S.S. Applications of High-Temperature Superconductors to Electric Power Equipment; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Park, S.; Kim, J.; Le, T.; Kim, H. Comparison of Superconducting Generator with 2G HTS and MgB2 Wires. Prog. Supercond. Cryogenics 2013, 15, 48–52. [Google Scholar] [CrossRef]

- Patel, A.; Baskys, A.; Mitchell-Williams, T.; McCaul, A.; Coniglio, W.; Hänisch, J.; Lao, M.; Glowacki, B.A. A Trapped Field of 17.7 T in a Stack of High-Temperature Superconducting Tape. Supercond. Sci. Technol. 2018, 31, 09LT01. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, J.-M.; Jiang, G.-Y.; Chen, C.-S.; Wu, W.; Zhang, Z.-W.; Chen, S.K.; Hong, Y.M.; Hong, Z.-Y.; Jin, Z.-J.; et al. Progress in Fabrication of Second-Generation High-Temperature Superconducting Tape at Shanghai Superconductor Technology. Supercond. Sci. Technol. 2019, 32, 044004. [Google Scholar] [CrossRef]

- Yamada, T.; Iwamoto, M.; Nakamura, S.; Oishi, N.; Hashimoto, Y.; Okamoto, K. Nb₃Sn/NbTi Superconducting Windings for 30 MVA Synchronous Rotary Condenser. IEEE Trans. Magn. 1981, 17, 2194–2197. [Google Scholar] [CrossRef]

- Iwamoto, M.; Yoshimura, H.; Yamada, T.; Kodera, H.; Nakamura, S.; Fujino, H.; Ishihara, A.; Ueda, K.; Shindo, Y. Initial Cooling and Heat of Ingress of the Rotor of a 30 MVA Superconducting Synchronous Phase Regulator. Trans. Inst. Electr. Eng. Jpn. 1987, 107, 525–532. (In Japanese) [Google Scholar]

- Zhu, Z.; Qu, R.; Wang, J. Conceptual Design of the Cryostat for a Direct-Drive Superconducting Wind Generator. IEEE Trans. Appl. Supercond. 2013, 24, 5201304. [Google Scholar] [CrossRef]

- Trollier, T.; Tanchon, J.; Icart, Y.; Ravex, A.; Chassaing, C.; Butterworth, J.; Daniel, C.; Briet, R. 150K Pulse Tube Cooler for Micro-Satellites. Cryocoolers 2012, 17, 53–60. [Google Scholar]

- Michael, P.C.; Golfinopoulos, T.; Ihloff, E.; Zhukovsky, A.; Schweiger, S.; Fry, V.; O’Shea, C.; Watterson, A.; Nash, D.; Vieira, R.F.; et al. A 20-K, 600-W, Cryocooler-Based, Supercritical Helium Circulation System for the SPARC Toroidal Field Model Coil Program. IEEE Trans. Appl. Supercond. 2023, 34, 0600113. [Google Scholar] [CrossRef]

- Trollier, T.; Tanchon, J.; Icart, Y.; Ravex, A. High Capacity 30 K Remote Helium Cooling Loop. AIP Conf. Proc. 2014, 1573, 1461–1466. [Google Scholar]

- Wang, C.; Brown, E. A GM Cryocooler with Cold Helium Circulation for Remote Cooling. AIP Conf. Proc. 2014, 1573, 1149–1156. [Google Scholar]

- Ding, H.; Ding, X.; Jiang, C.; Teng, J.; Shi, J.; Chen, D.; Li, W.; Zhang, X.; Yan, S. 160W@20K Helium Circulation Cryogenic System. In Proceedings of the 8th National Conference on Cryogenic Engineering and the 2007 Annual Academic Exchange Meeting of the China Aerospace Cryogenic Information Network, Beijing, China, 2007. (In Chinese). [Google Scholar]

- Chen, B.; Gu, G. Research on Rotor Cooling Technology of High-Temperature Superconducting Motor. Trans. China Electrotech. Soc. 2011, 26, 143–151. (In Chinese) [Google Scholar] [CrossRef]

- Dai, Y.; Dong, Q.; Chen, W.; Zheng, J. Cooling Analysis of Rotor of High-Temperature Superconducting Motor Cooled by Cold Helium Closed Circulation. Low Temp. Supercond. 2019, 47, 12–16. (In Chinese) [Google Scholar] [CrossRef]

- Chen, B.; Gu, G.; Zhang, G. Review of Cooling Technology for High-Temperature Superconducting Motors. Cryogen. Eng. 2007, 5, 15–19+27. (In Chinese) [Google Scholar]

- Shi, Z.; Song, M.; Tan, J.; Song, P.; Xia, Y. Design and Experimental Study of Cryogenic System of Superconducting Synchronous Condenser. Chin. J. Low Temp. Phys. 2021, 43, 319–326. (In Chinese) [Google Scholar] [CrossRef]

- Li, P.; Wang, C.; Wu, H.; Wang, L.; Zhang, J. A Kind of Low-Temperature Test Tooling for High-Temperature Superconducting Condenser. Chinese Patent CN117491772A, 2 February 2024. (In Chinese). [Google Scholar]

- Yoshimura, H.; Kodera, I.; Ogino, O.; Nakamura, S. Cooldown of a 30 MVA Superconducting Synchronous Conductor. In Advances in Cryogenic Engineering: Volume 29; Springer: Boston, MA, USA, 1984; pp. 369–376. [Google Scholar]

- Trollier, T.; Tanchon, J.; Icart, Y.; Ravex, A. Remote Helium Cooling Loops for Laboratory Applications. Cryocoolers 2012, 17, 503–510. [Google Scholar]

- Trollier, T.; Ravex, A.; Tanchon, J.; Lacapere, J. 20 K Cryogenic Helium Forced Flow Circulation Loop. Cryocoolers 2016, 19, 547–556. [Google Scholar]

- Tan, J.; Xue, R.; Tan, H.; Zhang, T.; Zhao, Y.; Zhao, B.; Wu, S.; Zhai, Y.; Dang, H. Design and Experimental Investigations on the Helium Circulating Cooling System Operating at around 20 K for a 300-kvar Class HTS Dynamic Synchronous Condenser. IEEE Trans. Appl. Supercond. 2022, 32, 5400405. [Google Scholar] [CrossRef]

- Frank, M.; Frauenhofer, J.; Gromoll, B.; van Haßelt, P.; Nick, W.; Nerowski, G.; Neumüller, H.; Häfner, H.; Thummes, G. Thermosyphon Cooling System for the Siemens 400 kW HTS Synchronous Machine. AIP Conf. Proc. 2004, 710, 859–866. [Google Scholar]

- Chen, B.; Gu, G.-B.; Zhang, G.-Q.; Song, F.-C.; Zhao, C.-H. Analysis and Design of Cooling System in High-Temperature Superconducting Synchronous Machines. IEEE Trans. Appl. Supercond. 2007, 17, 1557–1560. [Google Scholar] [CrossRef]

- Sato, R.; Felder, B.; Miki, M.; Tsuzuki, K.; Hayakawa, H.; Izumi, M. Helium-Neon Gas Mixture Thermosyphon Cooling and Stability for Large Scale HTS Synchronous Motors. IEEE Trans. Appl. Supercond. 2013, 23, 5200704. [Google Scholar] [CrossRef]

- Felder, B.; Miki, M.; Tsuzuki, K.; Shinohara, N.; Hayakawa, H.; Izumi, M. A 100-W Grade Closed-Cycle Thermosyphon Cooling System Used in HTS Rotating Machines. AIP Conf. Proc. 2012, 1434, 417–424. [Google Scholar]

- Urbahn, J.A.; Ackermann, R.A.; Huang, X.; Laskaris, E.T.; Sivasubramaniam, K.; Steinbach, A. The Thermal Performance of a 1.5 MVA HTS Generator. AIP Conf. Proc. 2004, 710, 849–858. [Google Scholar]

- Kosuge, E.; Gocho, Y.; Okumura, K.; Yamaguchi, M.; Umemoto, K.; Aizawa, K.; Yokoyama, M.; Takao, S. Development of Helium Transfer Coupling of 1 MW-Class HTS Motor for Podded Ship Propulsion System. Proc. J. Phys. Conf. Ser. IOP Publ. 2010, 234, 032032. [Google Scholar] [CrossRef]

- Al-Mosawi, M.; Beduz, C.; Goddard, K.; Sykulski, J.; Yang, Y.; Xu, B.; Ship, K.; Stoll, R.; Stephen, N. Design of a 100 kVA High-Temperature Superconducting Demonstration Synchronous Generator. Phys. C Supercond. 2002, 372, 1539–1542. [Google Scholar] [CrossRef]

- Kalsi, S.; Madura, D.; Ross, M. Performance of Superconductor Dynamic Synchronous Condenser on an Electric Grid. In Proceedings of the 2005 IEEE PES Transmission & Distribution Conference & Exposition: Asia and Pacific, Dalian, China, 18 August 2005; IEEE: New York, NY, USA, 2005; pp. 1–5. [Google Scholar]

- Song, X.; Buhrer, C.; Brutsaert, P.; Ammar, A.; Krause, J.; Bergen, A.; Winkler, T.; Dhalle, M.; Hansen, J.; Rebsdorf, A.V.; et al. Ground Testing of the World’s First MW-Class Direct-Drive Superconducting Wind Turbine Generator. IEEE Trans. Energy Convers. 2019, 35, 757–764. [Google Scholar] [CrossRef]

- Tao, J.; Gu, G.; Lian, G.; Cheng, Y.; Wang, S. Applied to Superconducting Motor Rotor Microvolt DC Voltage Detection Technology Research. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; IEEE: New York, NY, USA, 2015; pp. 1108–1110. [Google Scholar]

- Zhang, Z.; Cheng, J. Heat Leakage Analysis of Adiabatic Moment Tube. South China Agric. Mach. 2021, 52, 43–44. (In Chinese) [Google Scholar]

| Category | Type | Damage Rate | Response Time | Cooling System Requirements | Volume/ Footprint | Technical Maturity and Maintenance Requirements | Features and Advantages | Application Scenarios |

|---|---|---|---|---|---|---|---|---|

| Conventional DSC | 300MVA Class | 1.40% | 3–6 s | Standard air/water cooling | Large | Mature technology, low maintenance | Mature technology, low cost | Substations, traditional power grid scenarios |

| 50MVA Class | 1.40% | 3–6 s | Standard air/water cooling | Large | Mature technology, low maintenance | Mature technology, low cost | Substations, new energy stations | |

| Co-axial Generator | High | >10 s | Additional cooling requirements | Large | Medium technology, moderate maintenance | High inertia, suitable for high inertia demands | High-ratio renewable energy regions | |

| Medium-Frequency Generator + Co-axial Generator | Low | >10 s | Additional cooling requirements | Large | Medium technology, moderate maintenance | High investment, high losses | High-load fluctuation scenarios | |

| Dual-Frequency Condenser + Co-axial Generator | >4% | 5–10 s | Additional cooling requirements | Large | Moderate technology, moderate maintenance | High fault tolerance, stable performance | Multi-level systems, grid restoration | |

| Double-Shaft Excitation DSC | 1.50% | 3–6 s | Air/water cooling, low-temp cooling systems | Medium | Complex technology, moderate maintenance | Dynamic response, suitable for adjustable scenarios | High-ratio renewable energy regions, special power grid structures | |

| SDSC | 1.20% | 1–2 s | Low-temp cooling systems | Small | New technology, high maintenance | Small footprint, low losses, rapid electromagnetic response | Renewable energy integration and grid connection | |

| Unit/Item/Parameter | China Southern Power Grid Company Limited | US AMSC | Japan Mitsubishi and Fuji Electric | |

|---|---|---|---|---|

| Rated Power Pn | 300 kVar HTS DSC | 10 MVA HTS DSC | 8 MVA HTS DSC | 10 MVA LTS DSC |

| Rated Voltage Un/kV | 197.3 | 11 | 13.8 | 30 Mvar |

| Rated Current Ia, n/AI | 5252 | 525 | - | 11 kV |

| Rated Speed n0/(r∙min−1) | 3000 | 1500 | - | 1575 A |

| Rated Frequency f/Hz | 50 | 50 | - | 3600 RPM |

| No-Load Excitation Current If, 0/A | 240 | 375 | - | - |

| Full-Load Excitation Current If, n/A | 277 | 428 | - | 437 A |

| Air Gap Magnetic Flux Density B0/T | 0.7 | 1.4 | - | 742 A |

| Unit/Item/Parameter | China Southern Power Grid Company Limited | |

|---|---|---|

| 300 kVar HTS DSC | 10 MVA HTS DSC | |

| Rotor Poles/Slots | 2/18 | 4/36 |

| Rotor Core Outer Diameter rrbo/mm | - | 225 |

| Damper Screen Inner Diameter rdi/mm | 175 | 370 |

| Damper Screen Thickness hd/mm | 10 | 20 |

| Stator Inner Diameter rs/mm | 20 | 400 |

| Stator Back Iron Outer Diameter rsbo/mm | 380 | 700 |

| Stator Back Iron Length Ieff/mm | 300 | 800 |

| Superconducting Material | Nb3Sn | NbTi |

|---|---|---|

| Manufacturing Process | 1.6 × 3.2 mm | - |

| Cross-Section | 2.7 μm | 1.6 × 3.2 mm |

| Filament Diameter | 29,850 | 40 μm |

| Number of Filaments | 60 mm | 792 |

| Torque | 79% | 25 mm |

| Copper Purity | Nb | 80% |

| Barrier | >1000 A, 5T | - |

| Critical Current | 1.6 × 3.2 mm | >1400 A, 5T |

| Insulation | Sealed with S-glass tape | PVF and semi-cured epoxy-impregnated Nomex tape |

| System Name/Usage | Cooling Temperature | Cooling Capacity (Cooling Distance/Pipeline Length) | Cooling Medium | Cooling Power | Cooling Medium Flow Rate | Circulating Cooling Design/Features | Typical Case | Reference |

|---|---|---|---|---|---|---|---|---|

| Micro-Satellite Platform 150 K Pulse Tube Cryocooler | 150–180 K | 2.5 W | Helium | 11.3 W @ 150 K, 8.9 W @ 80 K | - | Coaxial cooling design, supports regenerative coolers and pulse tubes |  | [49] |

| SPARC Tokamak SuperConducting Magnet Cryogenic System | 20 K | 600 W | Superfluid Helium (SHe) | - | 70 g/s | Forced flow type, designed for 20 bar low hydraulic resistance |  | [50] |

| Large-Capacity 30 K Helium Long-Distance Circulating Cooling System | 20–30 K | 30 W @ 20 K or 80 W @ 30 K | Helium | - | - | Gifford-McMahon compressor, uses two copper heat exchangers and liquid helium cooling |  | [51] |

| GM Cryocooler Long-Distance Cooling System | 80 K | 50 W @ 4.1 kW or 70.5 W @ 6 kW | Helium | 4.1 kW or 6 kW | - | Cryomech AL125 head, alternating vibration-to-direct flow circulation, 5 m vacuum thermal flexible line |  | [52] |

| 160 W @ 20 K Helium Circulation Low-Temperature System | 20 K | 160 W @ 20 K | Helium | - | - | 8 GM cryocoolers, two helium pumps provide loop drive, fully insulated flexible connections | - | [53] |

| 20 K Superconducting Magnet Circulation System | 20 K | 70–100 W | Helium | - | 10 g/s | Cryomech AL325 head, low-loss loop forced flow, 20 bar superfluid helium |  | [54] |

| Helium Gas Intercooler Circulation Loop Cooling System | 27 K | 100 W @ 27 K | Helium | - | 3 m3/h (helium pump flow) | 2 AL GM cryocoolers, helium pump operating speed 1800 rpm, pipeline length 78 m |  | [55] |

| Item | Parameter | Item | Parameter |

|---|---|---|---|

| Rated Power Pn/Mvar | 8 | Field Short Circuit Time Constant /s | 0.05 |

| Voltage Un/kV | 13.8 (Three-phase) | D-Axis Transient Open Circuit Time Constant /s | 860 |

| Ambient Temperature T/°C | −30~+40 | D-Axis Subtransient Open Circuit Time Constant /s | 0.02 |

| Synchronous Reactance Xd/pu | 0.37 | Q-Axis Subtransient Open Circuit Time Constant /s | 0.04 |

| Transient Reactance Xd′/pu | 0.21 | Field Resistance ra/pu | 0.007 |

| Subtransient Reactance Xd″/pu | 0.13 | Inertia Constant/s | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, L.; Liu, S.; Wang, C.; Liu, J.; Wang, Q. Advances in the Research of Superconducting Dynamic Synchronous Condenser Technology. Energies 2025, 18, 1480. https://doi.org/10.3390/en18061480

Chen X, Wang L, Liu S, Wang C, Liu J, Wang Q. Advances in the Research of Superconducting Dynamic Synchronous Condenser Technology. Energies. 2025; 18(6):1480. https://doi.org/10.3390/en18061480

Chicago/Turabian StyleChen, Xin, Lei Wang, Shixian Liu, Cong Wang, Jianhua Liu, and Qiuliang Wang. 2025. "Advances in the Research of Superconducting Dynamic Synchronous Condenser Technology" Energies 18, no. 6: 1480. https://doi.org/10.3390/en18061480

APA StyleChen, X., Wang, L., Liu, S., Wang, C., Liu, J., & Wang, Q. (2025). Advances in the Research of Superconducting Dynamic Synchronous Condenser Technology. Energies, 18(6), 1480. https://doi.org/10.3390/en18061480