Development of Efficient Cooling Regimes for the Lining of a Ferroalloy Production Casting Ladle

Abstract

1. Introduction (Problem Statement)

- -

- The thermal stresses arising in the lining due to the presence of temperature differences across its cross-section;

- -

- The influence of demanding operating environments;

- -

- The mechanical impacts of the upper layers of the lining on the lower ones, as well as the mechanical impacts on the lining from the outside;

- -

- The dissolution of the lining in a high-temperature operating environment;

- -

- Other operational factors.

- -

- The difficulty of taking into account the thermophysical and thermomechanical properties of the refractory lining materials, which change during operation;

- -

- The data obtained from physical modeling are not always correct due to the low reliability of the scale factor.

- -

- The use of refractory materials with higher thermal strength characteristics;

- -

- Streamlining the lining design (including changing the thickness of the refractory layer);

- -

- Streamlining the thermal operating conditions for the linings of high-temperature aggregates.

2. Materials and Methods

- -

- The lining is homogeneous and isotropic;

- -

- The temperature field is one-dimensional;

- -

- There are no internal heat sources.

- -

- Firstly, minimizing the thermal stresses that arise in the lining during cooling;

- -

- Secondly, minimizing the cooling time.

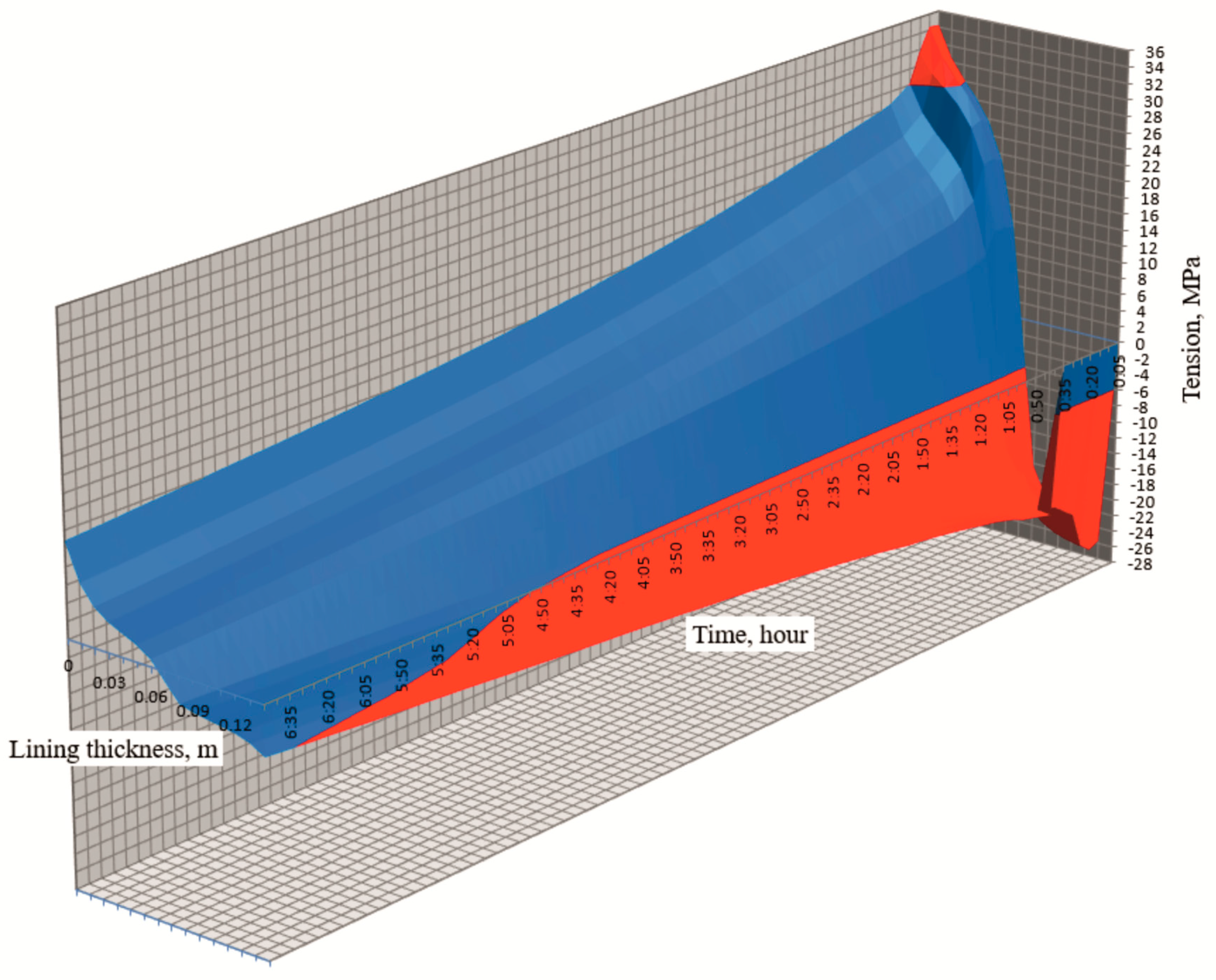

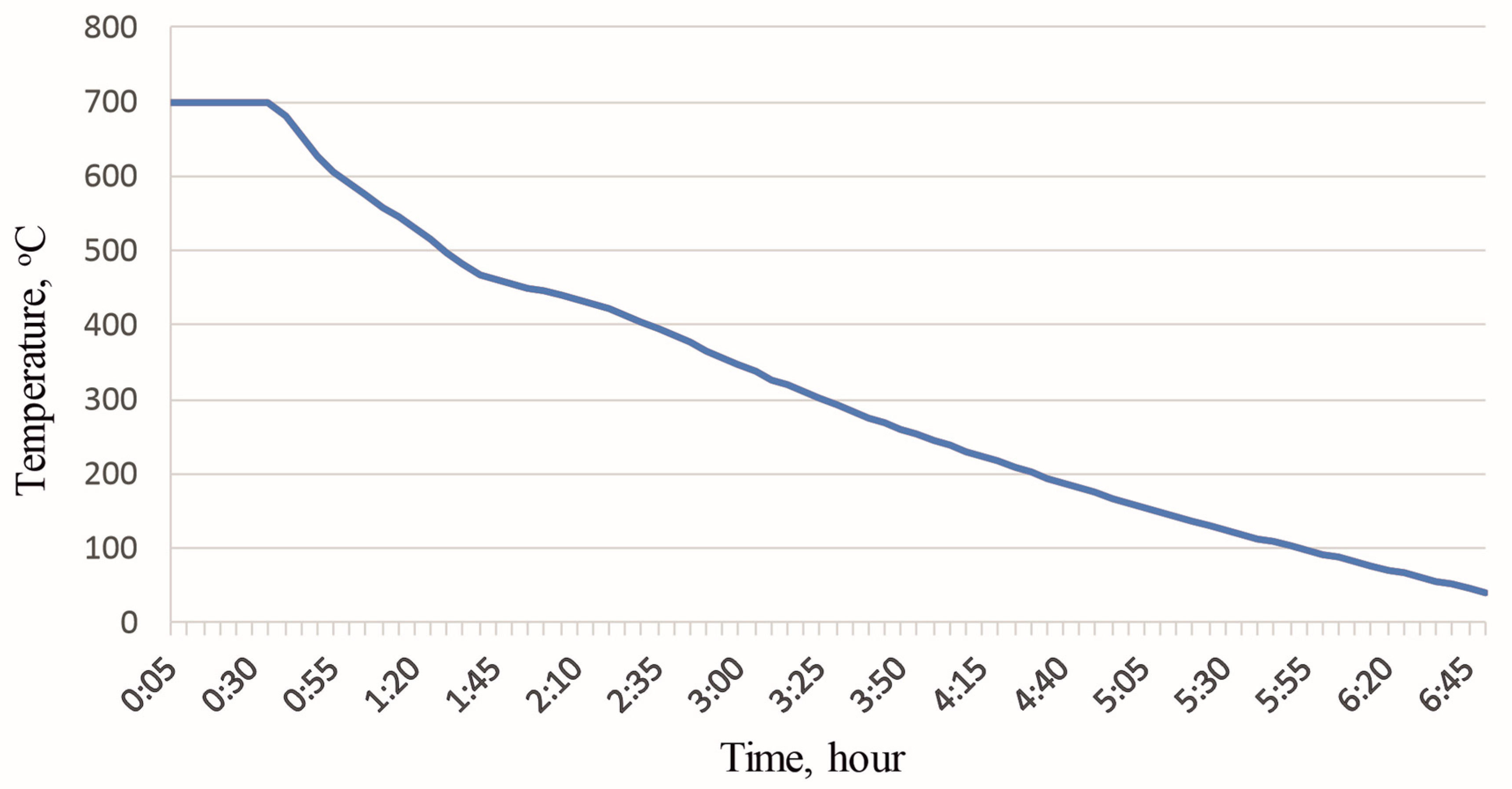

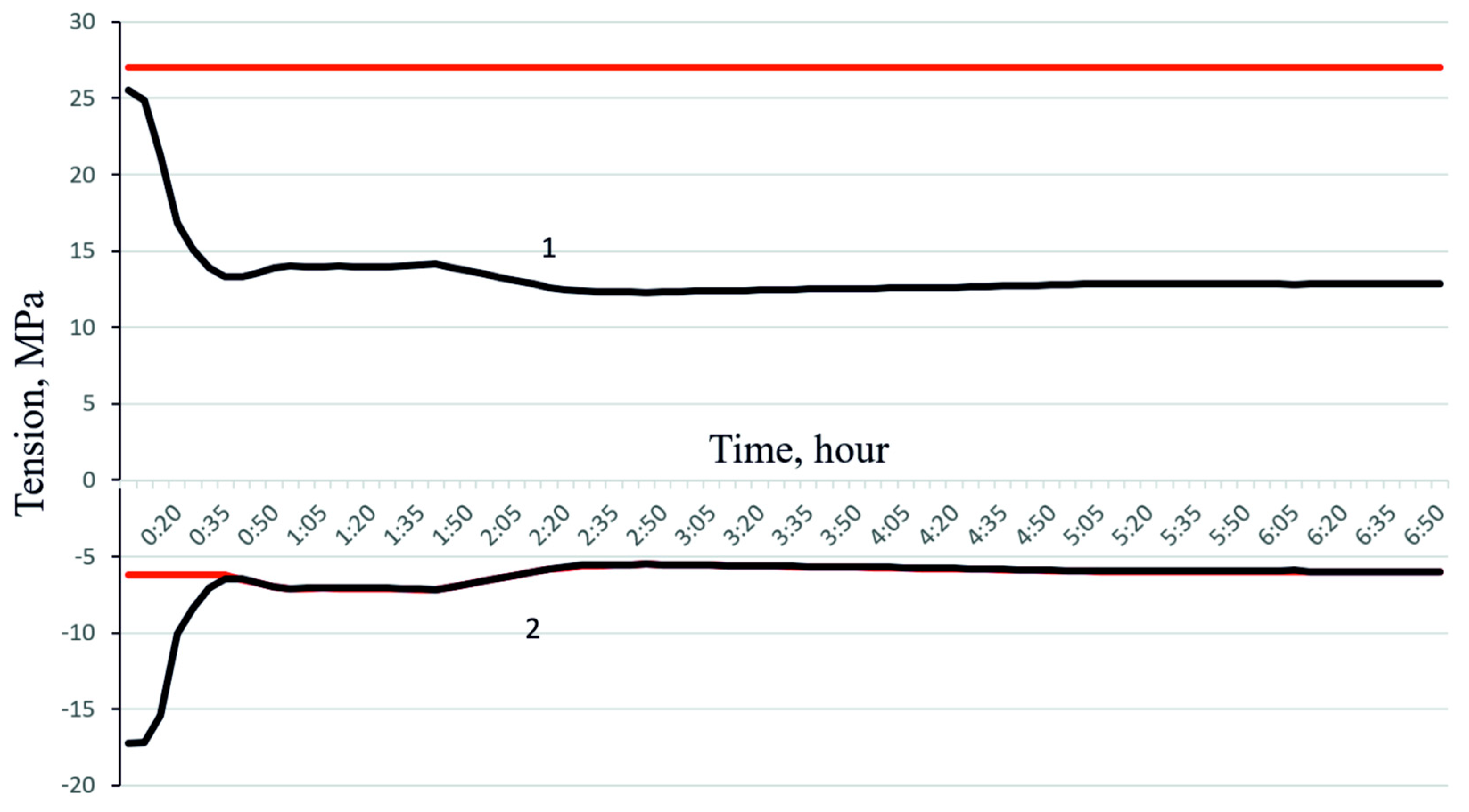

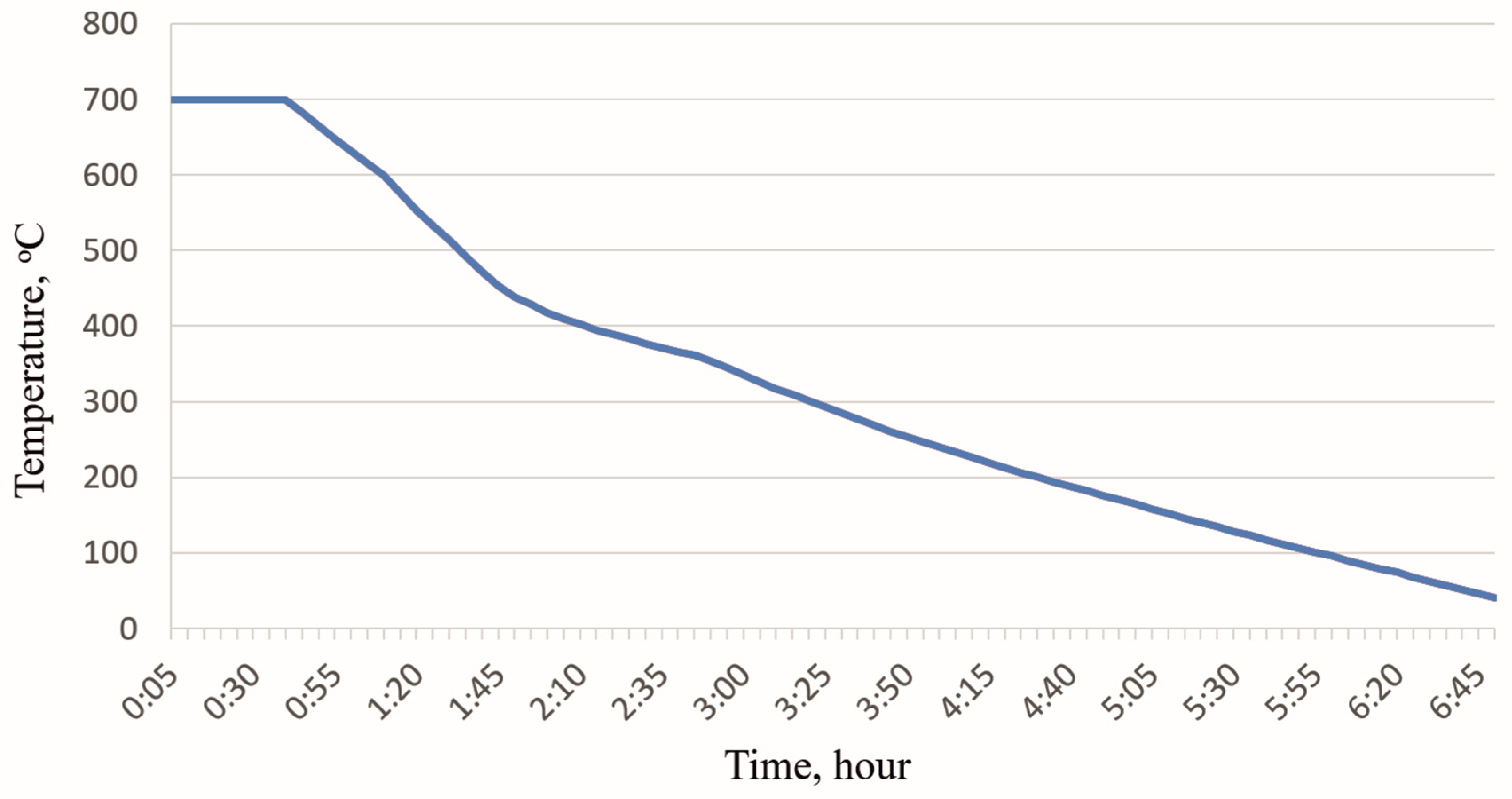

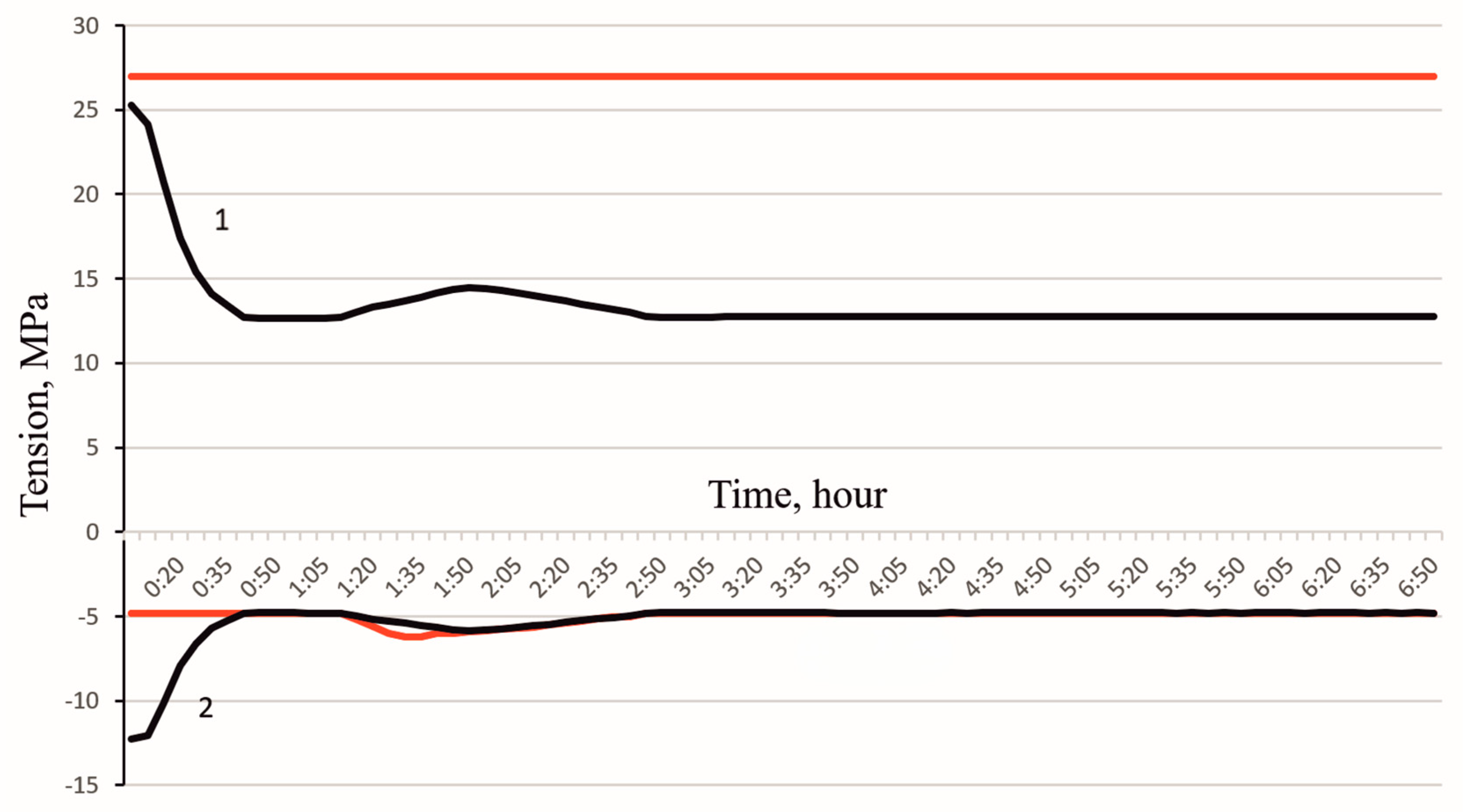

3. Results and Discussion

4. Conclusions and Future Research Direction

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guillin-Estrada, W.D.; Albuja, R.; Davila, I.B.; Rueda, B.S.; Corredor, L.; Gonzalez-Quiroga, A.; Maury, H. Transient operation effects on the thermal and mechanical response of a large-scale rotary kiln. Results Eng. 2022, 14, 100396. [Google Scholar] [CrossRef]

- Pagliosa, C.; Resende, C.; Da Luz, A.; Pandolfelli, V. Designing stronger and tougher MgO-C bricks for basic oxygen furnace (BOF). Refract. World Forum 2017, 9, 89–93. [Google Scholar]

- Kukartsev, V.A.; Kukartsev, V.V.; Tynchenko, V.S.; Kurashkin, S.O.; Sergienko, R.B.; Tynchenko, S.V.; Panfilov, I.A.; Eremeeva, S.V.; Panfilova, T.A. Study of the Influence of the Thermal Capacity of the Lining of Acid Melting Furnaces on Their Efficiency. Metals 2023, 13, 337. [Google Scholar] [CrossRef]

- Demeter, J.; Buľko, B.; Demeter, P.; Hrubovčáková, M. Evaluation of Factors Affecting the MgO–C Refractory Lining Degradation in a Basic Oxygen Furnace. Appl. Sci. 2023, 13, 12473. [Google Scholar] [CrossRef]

- Aripova, N.M.; Nikiforov, A.S.; Paramonov, A.M.; Prikhod’ko, E.V.; Kinzhibekova, A.K.; Karmanov, A.E. Assessment of Reliability and Technical Risks in the Operation of Heat Engineering Units. Refract. Ind. Ceram. 2023, 64, 206–213. [Google Scholar] [CrossRef]

- Santos, D.P.; Pelissari, P.I.G.; de Oliveira, B.S.; Leiva, D.R.; de Mello, R.F.; Pandolfelli, V.C. Materials selection of furnace linings with multi-component refractory ceramics based on an evolutionary screening procedure. Ceram. Int. 2020, 46, 4113–4125. [Google Scholar] [CrossRef]

- Fang, L.; Su, F.; Kang, Z.; Zhu, H. Finite element (FE) analysis of thermal stress in production process of multi-layer lining ladle. Case Stud. Therm. Eng. 2024, 57, 104307. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Yuan, F.; Zhao, L.; Li, Y.; Ma, J. Thermal Stress Analysis of Blast Furnace Hearth with Typical Erosion Based on Thermal Fluid-Solid Coupling. Processes 2023, 11, 531. [Google Scholar] [CrossRef]

- Prikhodko, E.; Nikiforov, A.; Kinzhibekova, A.; Aripova, N.; Karmanov, A.; Ryndin, V. Analysis of the Cooling Modes of the Lining of a Ferroalloy-Casting Ladle. Energies 2024, 17, 1229. [Google Scholar] [CrossRef]

- Akishev, A.K.; Fomenko, S.M.; Tolendiuly, S. Effect of Refractory Thermal Stresses and Parameters on Development of the Internal Temperature Field. Refract. Ind. Ceram. 2020, 60, 561–565. [Google Scholar] [CrossRef]

- Smirnov, A.N.; Smirnov, A.N.; Nemsadze, G.G.; Sharandin, K.N. Rotary Furnace for Comparative Evaluation of Heating Unit Refractory Object Erosion Resistance. Refract. Ind. Ceram. 2018, 59, 227–230. [Google Scholar] [CrossRef]

- Molchanov, L.; Golub, T.; Synehin, Y.; Semykin, S. Physical Model of Influence of CaO–FeO–SiO2 Powder Fraction on the Heat Transfer from Torch. Sci. Innov. 2022, 18, 64–71. [Google Scholar] [CrossRef]

- Istadi, I.; Bindar, Y. Improved cooler design of electric arc furnace refractory in mining industry using thermal analysis modeling and simulation. App. Therm. Eng. 2014, 73, 1129–1140. [Google Scholar] [CrossRef]

- Samadi, S.; Jin, S.; Gruber, D.; Harmuth, H. Thermomechanical finite element modeling of steel ladle containing alumina spinel refractory lining. Finite Elem. Anal. Des. 2022, 206, 103762. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, W.; Li, Q.; Wei, Z.; Lei, W.; Zhang, L. An analytical method to estimate temperature distribution of typical radiant floor cooling systems with internal heat radiation. Energy Explor. Exploit. 2021, 39, 1283–1305. [Google Scholar] [CrossRef]

- Zhang, S.; Yue, Z.; Sun, T.; Zhang, J.; Huang, B. Analytical determination of the soil temperature distribution and freezing front position for linear arrangement of freezing pipes using the undetermined coefficient method. Cold Reg. Sci. Technol. 2021, 185, 103253. [Google Scholar] [CrossRef]

- Gao, S.; Tang, C.; Luo, W.; Han, J.; Teng, B. A New Analytical Model for Calculating Transient Temperature Response of Vertical Ground Heat Exchangers with a Single U-Shaped Tube. Energies 2020, 13, 2120. [Google Scholar] [CrossRef]

- Damhof, F.; Brekelmans, W.A.M.; Geers, M.G.D. Predictive FEM simulation of thermal shock damage in the refractory lining of steelmaking installations. J. Mater. Process. Technol. 2011, 211, 2091–2105. [Google Scholar] [CrossRef]

- Ali, M.; Sayet, T.; Gasser, A.; Blond, E. Transient Thermo-Mechanical Analysis of Steel Ladle Refractory Linings Using Mechanical Homogenization Approach. Ceramics 2020, 3, 171–189. [Google Scholar] [CrossRef]

- Peng, W.; Chen, Z.; Yan, W.; Schafföner, S.; Li, G.; Li, Y.; Jia, C. Advanced lightweight periclase-magnesium aluminate spinel refractories with high mechanical properties and high corrosion resistance. Constr. Build. Mater. 2021, 291, 123388. [Google Scholar] [CrossRef]

- Wu, G.; Yan, W.; Schafföner, S.; Dai, Y.; Han, B.; Li, T.; Ma, S.; Li, N.; Li, G. A comparative study on the microstructures and mechanical properties of a dense and a lightweight magnesia refractory. J. Alloys Compd. 2019, 796, 131–137. [Google Scholar] [CrossRef]

- Pereira, C.I.; Santos, M.F.; Angélico, R.A.; Moreira, M.H.; Braulio, M.; Iwanaga, T.; Pandolfelli, V.C. Insights into thermomechanical behavior and design parameters of alumina calciner refractory lining. Ceram. Int. 2024, 50, 44008–44016. [Google Scholar] [CrossRef]

- Slovikovskii, V.V.; Gulyaeva, A.V. Corrosion-Erosion-Resistant Carbon-Containing Refractories for Nonferrous Metallurgy Units. Refract. Ind. Ceram. 2016, 56, 490–493. [Google Scholar] [CrossRef]

- Ceylantekin, R.; Aksel, C. Improvements on corrosion behaviours of MgO–spinel composite refractories by addition of ZrSiO4. J. Eur. Ceram. Soc. 2012, 32, 727–736. [Google Scholar] [CrossRef]

- Chen, D.; Huang, A.; Gu, H.; Zhang, M.; Shao, Z. Corrosion of Al2O3–Cr2O3 refractory lining for high-temperature solid waste incinerator. Ceram. Int. 2015, 41, 14748–14753. [Google Scholar] [CrossRef]

- Aksel’rod, L.M.; Rodgol’ts, Y.S.; Paivin, A.A.; Kazakov, V.V.; Toporkova, T.I.; Rossikhina, G.S. Improving the Steel Ladle Lining at the Volzhskii Tube-Making Plant Joint-Stock Co. Refract. Ind. Ceram. 2004, 45, 150–153. [Google Scholar] [CrossRef]

- Hou, A.; Jin, S.; Harmuth, H.; Gruber, D. A Method for Steel Ladle Lining Optimization Applying Thermomechanical Modeling and Taguchi Approaches. JOM. 2018, 70, 2449–2456. [Google Scholar] [CrossRef]

- Kononov, V.A.; Kononov, N.V.; Skrobov, S.N.; Salomakhin, O.A. Improvement in the steel-pouring ladle lining life in open-hearth production of ZAO metallurgical plant Petrostal. Refract. Ind. Ceram. 2009, 50, 89–93. [Google Scholar] [CrossRef]

- Slovikovskii, V.V.; Gulyaeva, A.V. Effect of Heating Unit Lining Warm-Up Regimes and Refractory Storage Duration on Refractory Lining Life. Refract. Ind. Ceram. 2015, 56, 225–229. [Google Scholar] [CrossRef]

- Dai, Y.; Zhu, H.; Zhu, Q.; Wang, F.; Liao, N.; Li, Y.; Konietzky, H.; Aneziris, C.G. Impact of fast heating and cooling on the mechanical behaviour of alumina-magnesia refractory castables. Ceram. Int. 2023, 49, 36507–36515. [Google Scholar] [CrossRef]

- Prikhod’ko, E.V. Analysis of Methods for Heating the Lining of High-Temperature Units. Refract. Ind. Ceram. 2021, 62, 463–466. [Google Scholar] [CrossRef]

- Ramanenka, D.; Gustafsson, G.; Jonsén, P. Influence of heating and cooling rate on the stress state of the brick lining in a rotary kiln using finite element simulations. Eng. Fail. Anal. 2019, 105, 98–109. [Google Scholar] [CrossRef]

- Krasnyansky, M.V.; Katz, Y.L.; Bershitsky, I.M. Efficiency of electrically heating the lining of steel-pouring ladles. Metallurgist 2012, 56, 357–365. [Google Scholar] [CrossRef]

- Schmitt, N.; Berthaud, Y.; Hernandez, J.F.; Meunier, P.; Poirier, J. Damage of monolithic refractory linings in steel ladles during drying. Br. Ceram. Trans. 2004, 103, 121–133. [Google Scholar] [CrossRef]

- Oliveira, R.G.; Rodrigues, J.P.C.; Pereira, J.M. Numerical simulations on refractory linings for steel casting vessels. Fire Saf. J. 2023, 138, 103794. [Google Scholar] [CrossRef]

- Luz, A.P.; Souza, T.M.; Pagliosa, C.; Brito, M.A.M.; Pandolfelli, V.C. In situ hot elastic modulus evolution of MgO–C refractories containing Al, Si or Al–Mg antioxidants. Ceram. Int. 2016, 42, 9836–9843. [Google Scholar] [CrossRef]

- Nikiforov, A.S.; Prikhod’ko, E.V.; Kinzhibekova, A.K.; Karmanov, A.E. Investigation of the Dependence of Refractory Thermal Conductivity on Impregnation with a Corrosive Medium. Refract. Ind. Ceram. 2020, 60, 463–467. [Google Scholar] [CrossRef]

- Luo, B.; Li, G.; Kong, J.; Jiang, G.; Sun, Y.; Liu, Z.; Chang, W.; Liu, H. Simulation Analysis of Temperature Field and Its Influence Factors of the New Structure Ladle. Appl. Math. Inform. Sci. 2017, 11, 589–599. [Google Scholar] [CrossRef]

- Aripova, N.M. Increasing the Energy Efficiency of the Filling Buckets by Rationalizing the Cooling Modes of the Lining. Ph.D. Thesis, Toraighyrov University, Pavlodar, Kazakhstan, 19 June 2024. [Google Scholar]

- Prikhodko, E.; Nikiforov, A.; Kinzhibekova, A.; Paramonov, A.; Aripova, N.; Karmanov, A. Analysis of the Effect of Temperature on the Ultimate Strength of Refractory Materials. Energies 2023, 16, 6732. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aripova, N.; Prikhodko, E.; Nikiforov, A.; Kinzhibekova, A.; Karmanov, A.; Paramonov, A.; Ryndin, V. Development of Efficient Cooling Regimes for the Lining of a Ferroalloy Production Casting Ladle. Energies 2025, 18, 1472. https://doi.org/10.3390/en18061472

Aripova N, Prikhodko E, Nikiforov A, Kinzhibekova A, Karmanov A, Paramonov A, Ryndin V. Development of Efficient Cooling Regimes for the Lining of a Ferroalloy Production Casting Ladle. Energies. 2025; 18(6):1472. https://doi.org/10.3390/en18061472

Chicago/Turabian StyleAripova, Nazgul, Evgeniy Prikhodko, Alexandr Nikiforov, Akmaral Kinzhibekova, Amangeldy Karmanov, Alexandr Paramonov, and Vladimir Ryndin. 2025. "Development of Efficient Cooling Regimes for the Lining of a Ferroalloy Production Casting Ladle" Energies 18, no. 6: 1472. https://doi.org/10.3390/en18061472

APA StyleAripova, N., Prikhodko, E., Nikiforov, A., Kinzhibekova, A., Karmanov, A., Paramonov, A., & Ryndin, V. (2025). Development of Efficient Cooling Regimes for the Lining of a Ferroalloy Production Casting Ladle. Energies, 18(6), 1472. https://doi.org/10.3390/en18061472