Gas−Hydro Coordinated Peaking Considering Source-Load Uncertainty and Deep Peaking

Abstract

1. Introduction

- This paper analyzes the joint operation mode of a gas–hydro coordinated model based on the regulating characteristics of gas power and hydropower;

- In this paper, we propose a method to quantify the risk of system operation caused by source-load uncertainty based on CVaR theory;

- This paper considers the model of deep peak regulation to manage source-load uncertainty and reduce abandoned water;

- Based on 1 and 2, a gas–hydro coordinated peaking model is proposed, aiming at maximizing the net profit of peak shaving with the CVaR theory and the cost of deep peak shaving, and this paper use linearization methods to manage the mixed-integer nonlinear programming model.

2. Gas–Hydro Coordinated Operation Model

3. System Operation Risk Analysis

3.1. System Uncertainty Analysis

3.1.1. Load Uncertainty

3.1.2. Wind–Photovoltaic Joint Uncertainty

3.1.3. Net Load Uncertainty

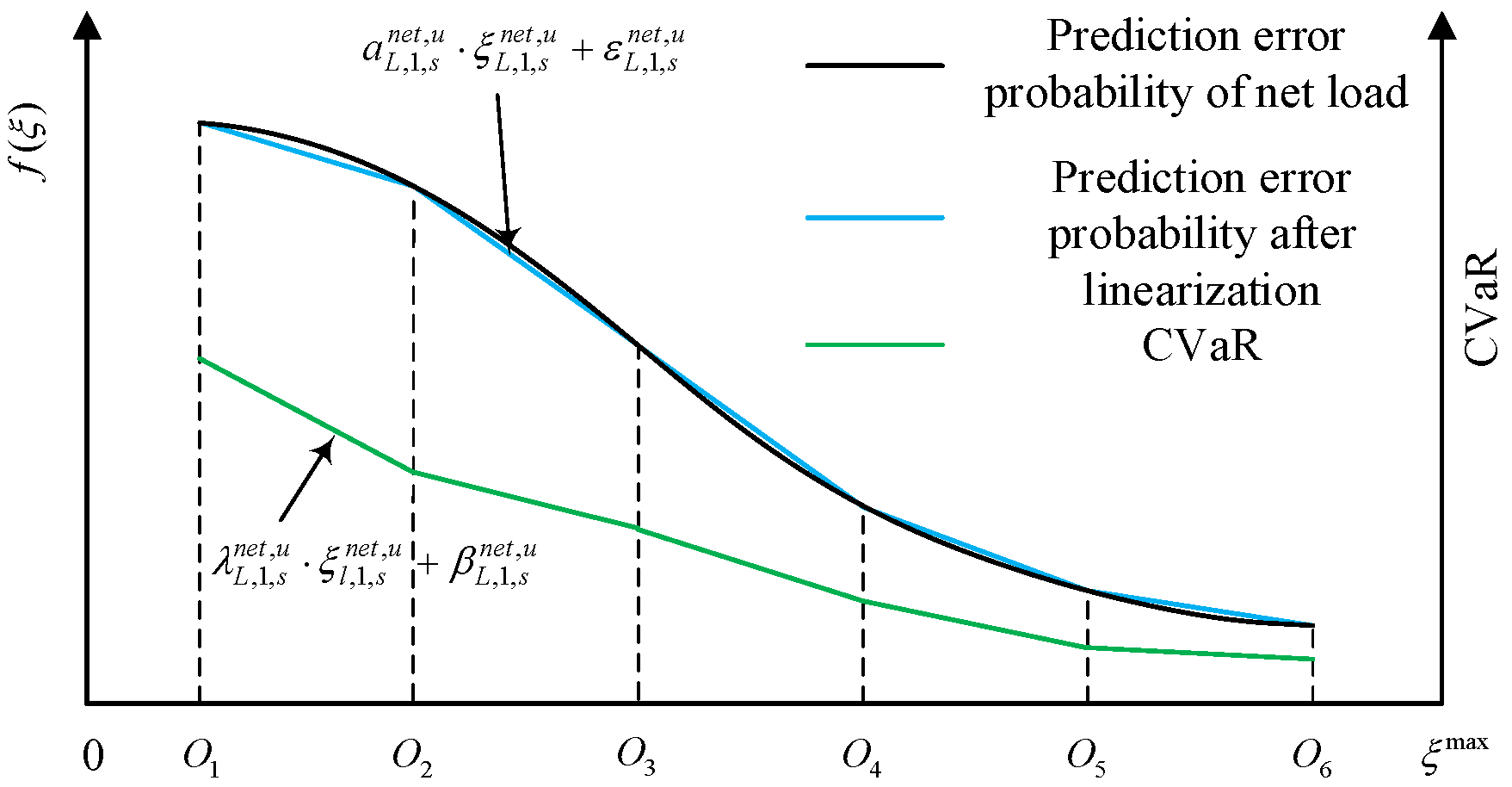

3.2. CVaR-Based Quantification of System Operational Risk

4. Analysis of Deep Peaking of Gas Turbines

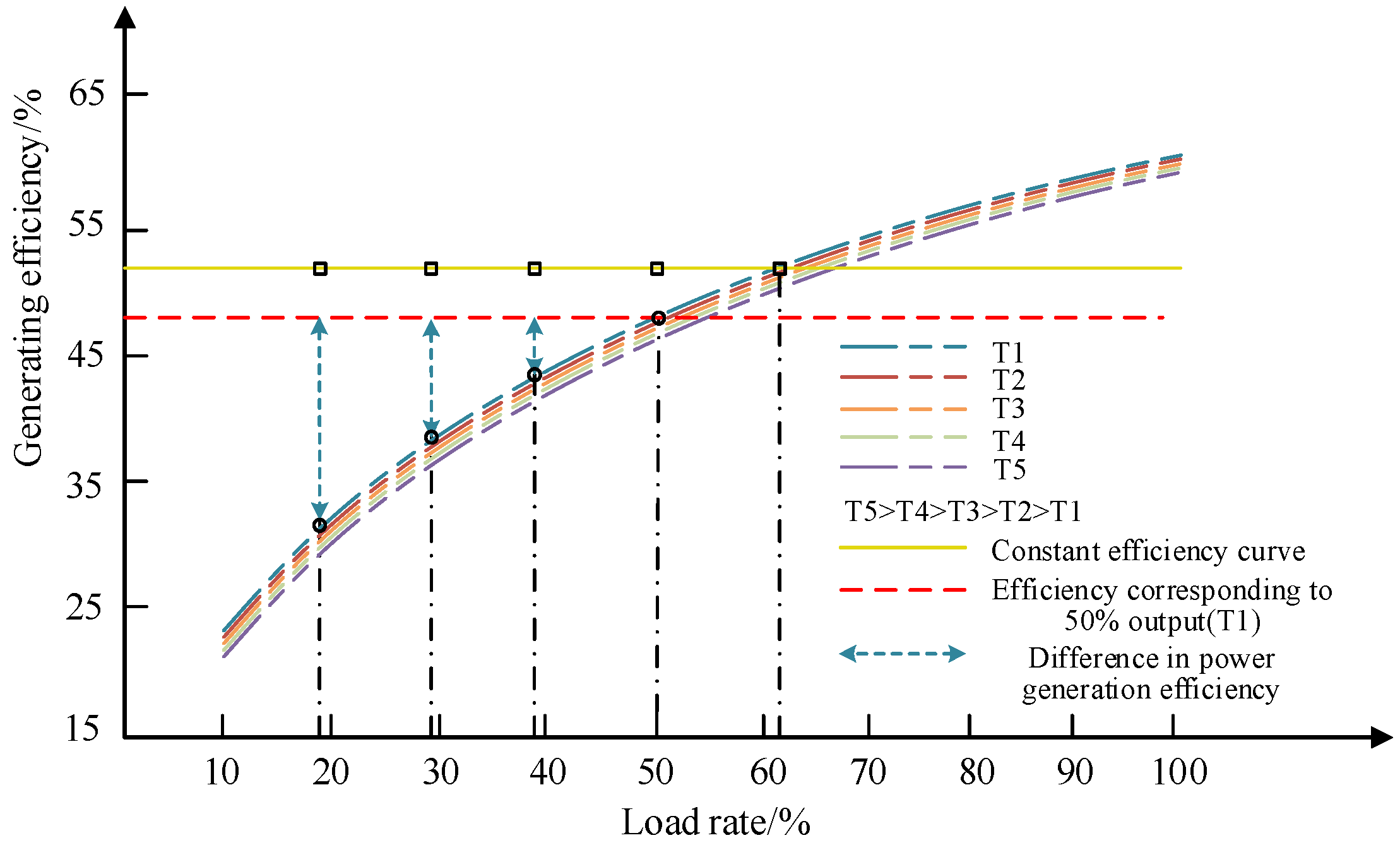

4.1. Load-Efficiency Characteristics of Gas Turbines at Variable Temperatures

4.2. Deep Peaking Cost Analysis

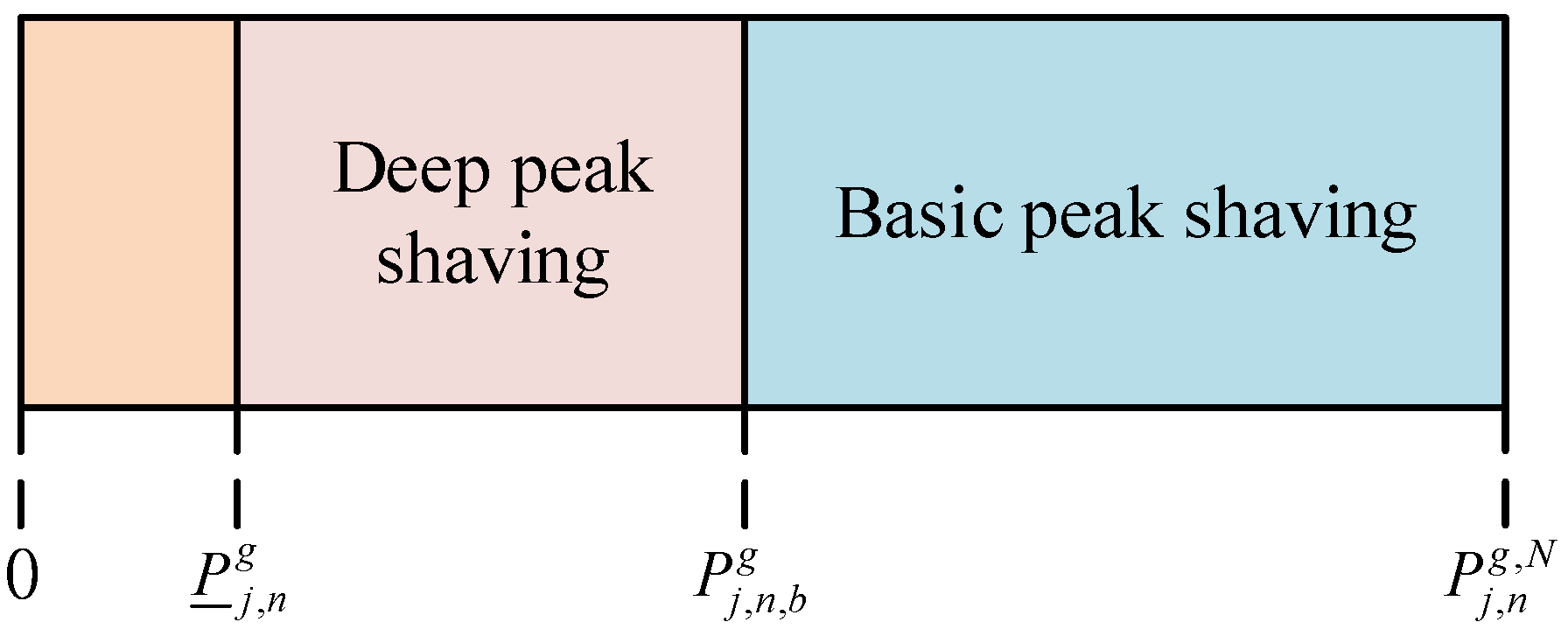

4.2.1. Cost of Lost Energy for Deep Peak Shaving of Units

4.2.2. Unit Life Wear and Tear Cost

5. Gas–Hydro Coordinated Peaking Model Considering Source-Load Uncertainty and Deep Peaking

5.1. Model Building

5.1.1. Hydroelectric Power Output Modeling

5.1.2. Gas-Fired Power Generation Output Modeling

5.1.3. Objective Function

- (1)

- Operational benefits of coordinated gas–hydro power generation

- (2)

- Operating costs of gas–hydro coordinated power generation

- (3)

- Deep peaking losses for gas turbines

- (4)

- System Standby Costs

- (5)

- Cost of Load Shedding and Abandonment Risks

5.1.4. Restrictive Condition

- (1)

- System power balance constraints

- (2)

- Inter-reservoir hydraulic linkages

- (3)

- Water balance constraints

- (4)

- Reservoir capacity constraints

- (5)

- Reservoir opening and closing capacity constraints

- (6)

- Hydroelectric power plant outflow constraintswhere and are the lower and upper limits of the outflow flow of hydropower station i during time period t, respectively, m3/s.

- (7)

- Power plant unit output constraints

- (8)

- Hydroelectric power plant unit generation flow constraints

- (9)

- Hydroelectric power plant unit climbing rate constraints

- (10)

- Hydroelectric power plant unit start-up and shutdown duration constraints

- (11)

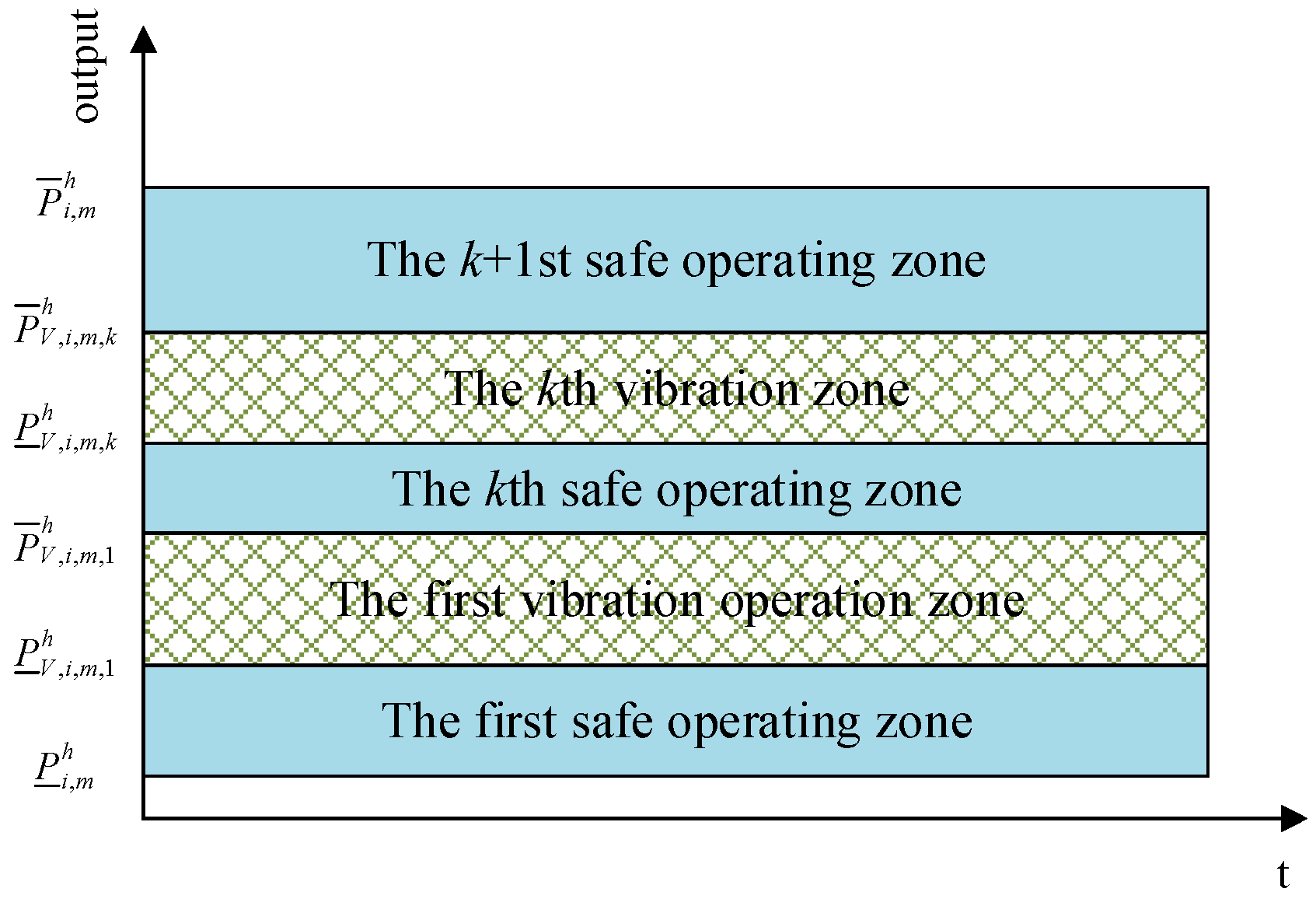

- Hydroelectric power plant unit vibration zone constraints

- (12)

- GTCC unit output constraints

- (13)

- GTCC unit climbing rate constraints

- (14)

- System standby capacity constraints

- (15)

- Transmission corridor capacity constraints

5.2. Model Solution

5.2.1. CVaR Segment Linearization

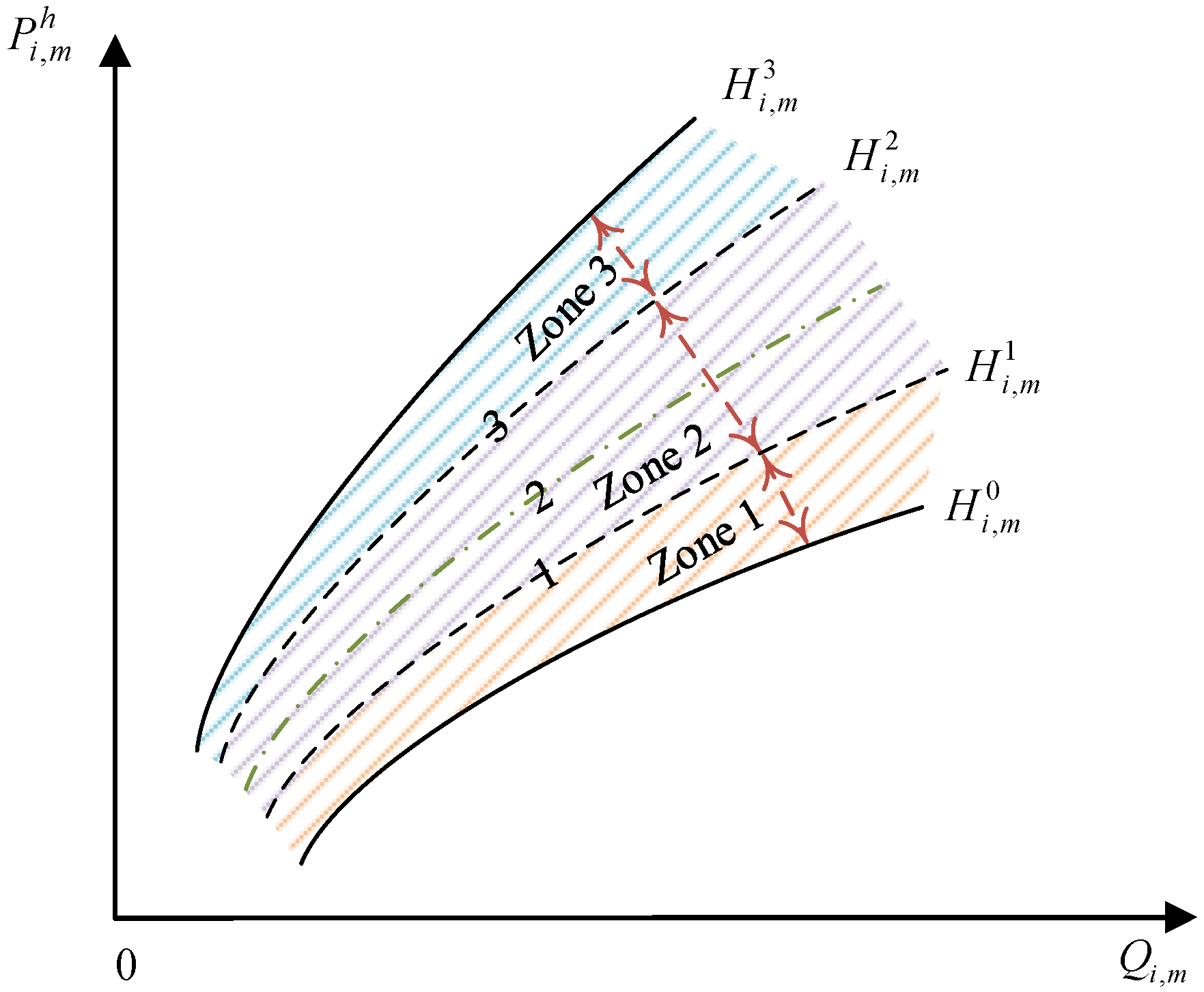

5.2.2. Linearization of Hydroelectric Output Characteristics

- (1)

- Linearization of the head of a daily regulated hydroelectric power station

- (2)

- Linearization of unit power characteristic curve

5.2.3. Constrained Linearization of Vibration Zones in Hydroelectric Units

5.2.4. Linearization of the Objective Function

6. Case Study

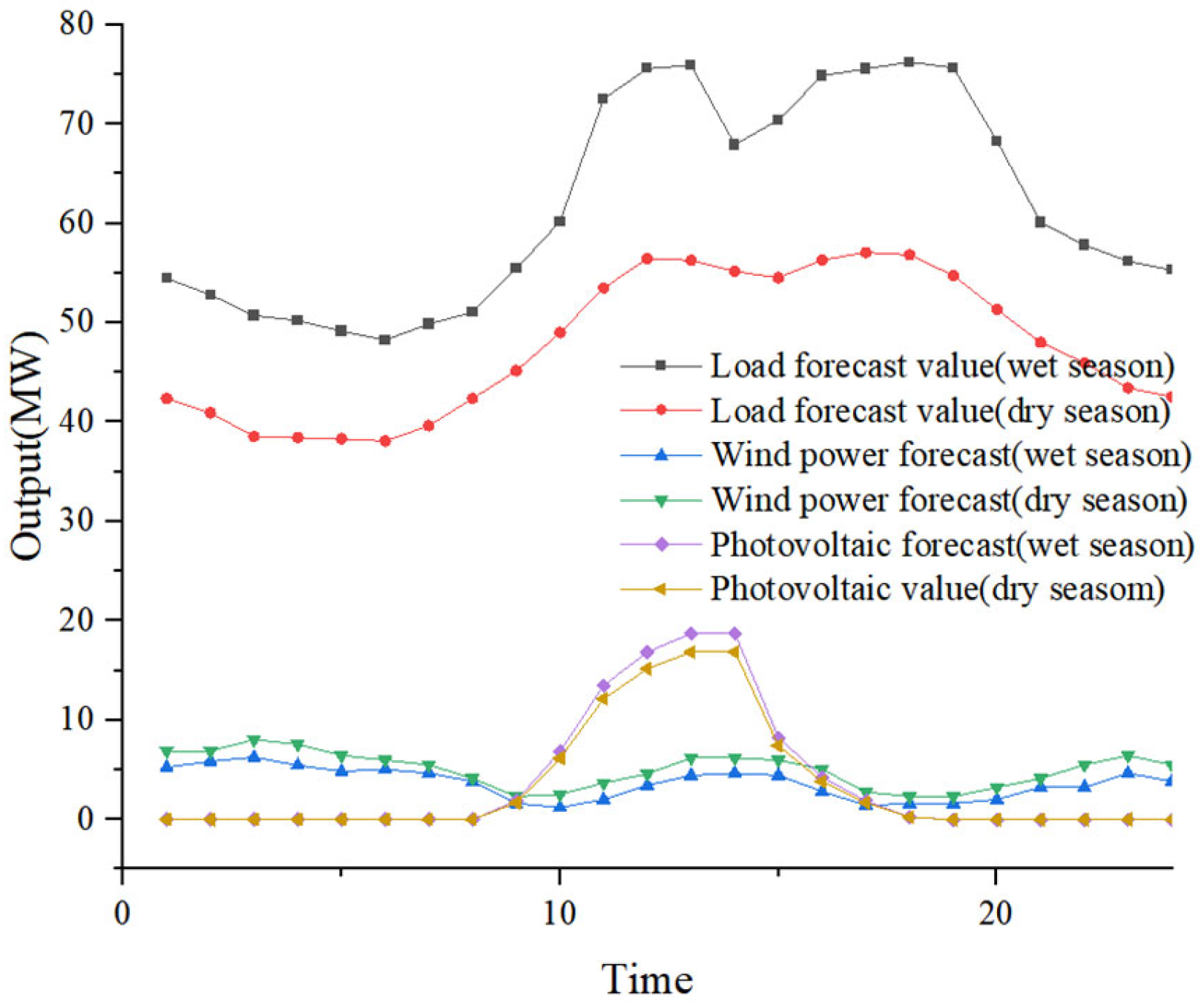

6.1. Basic Parameters

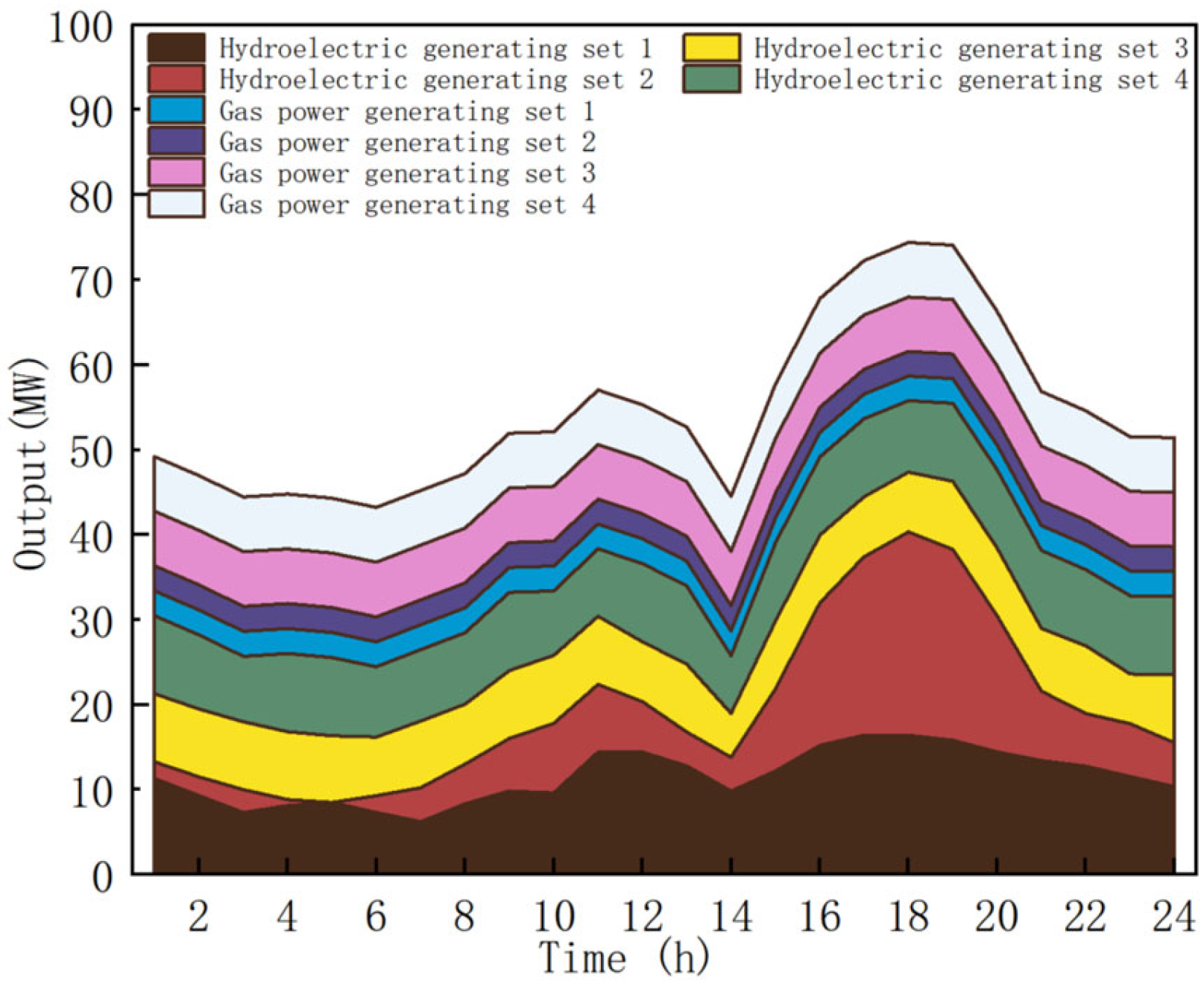

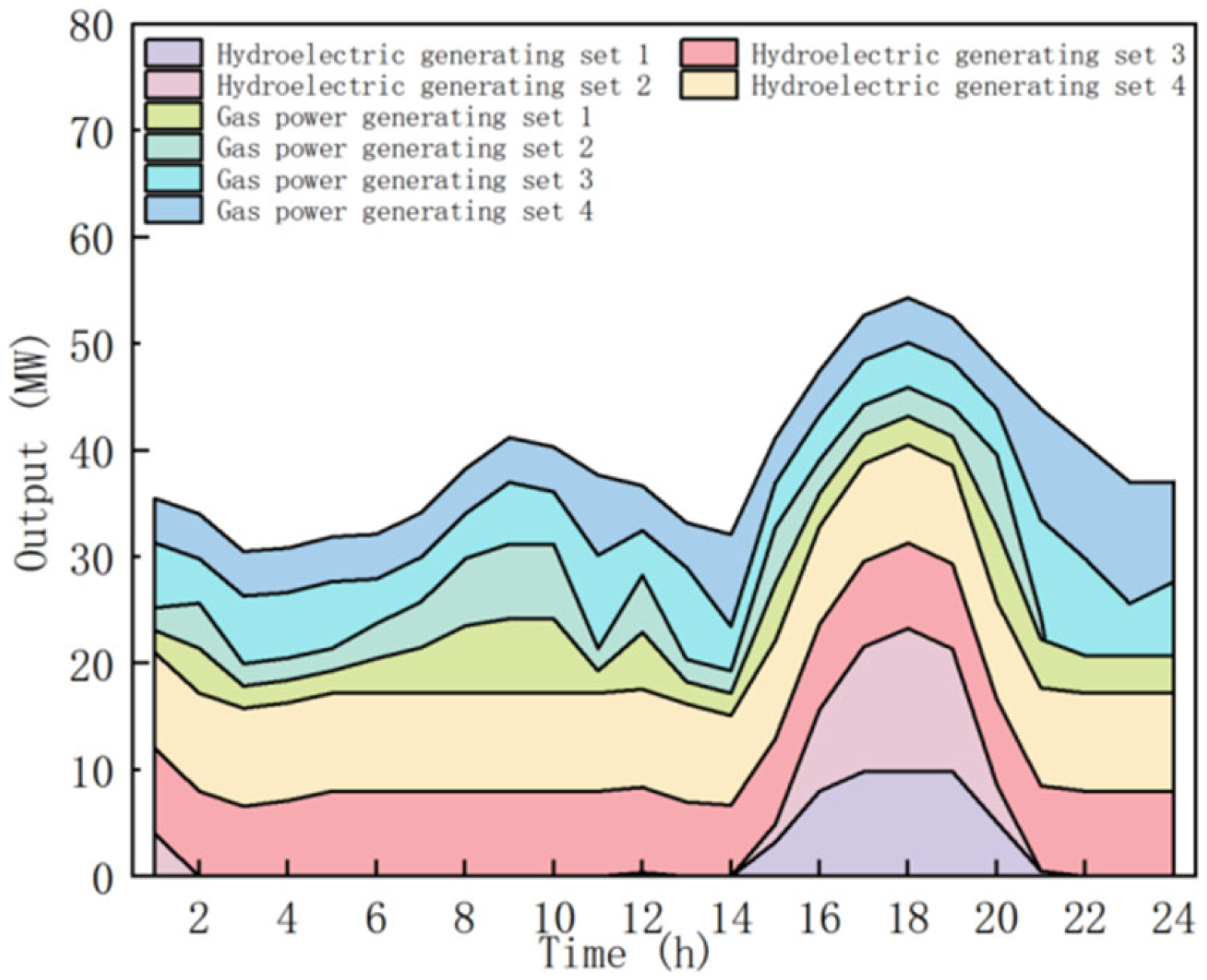

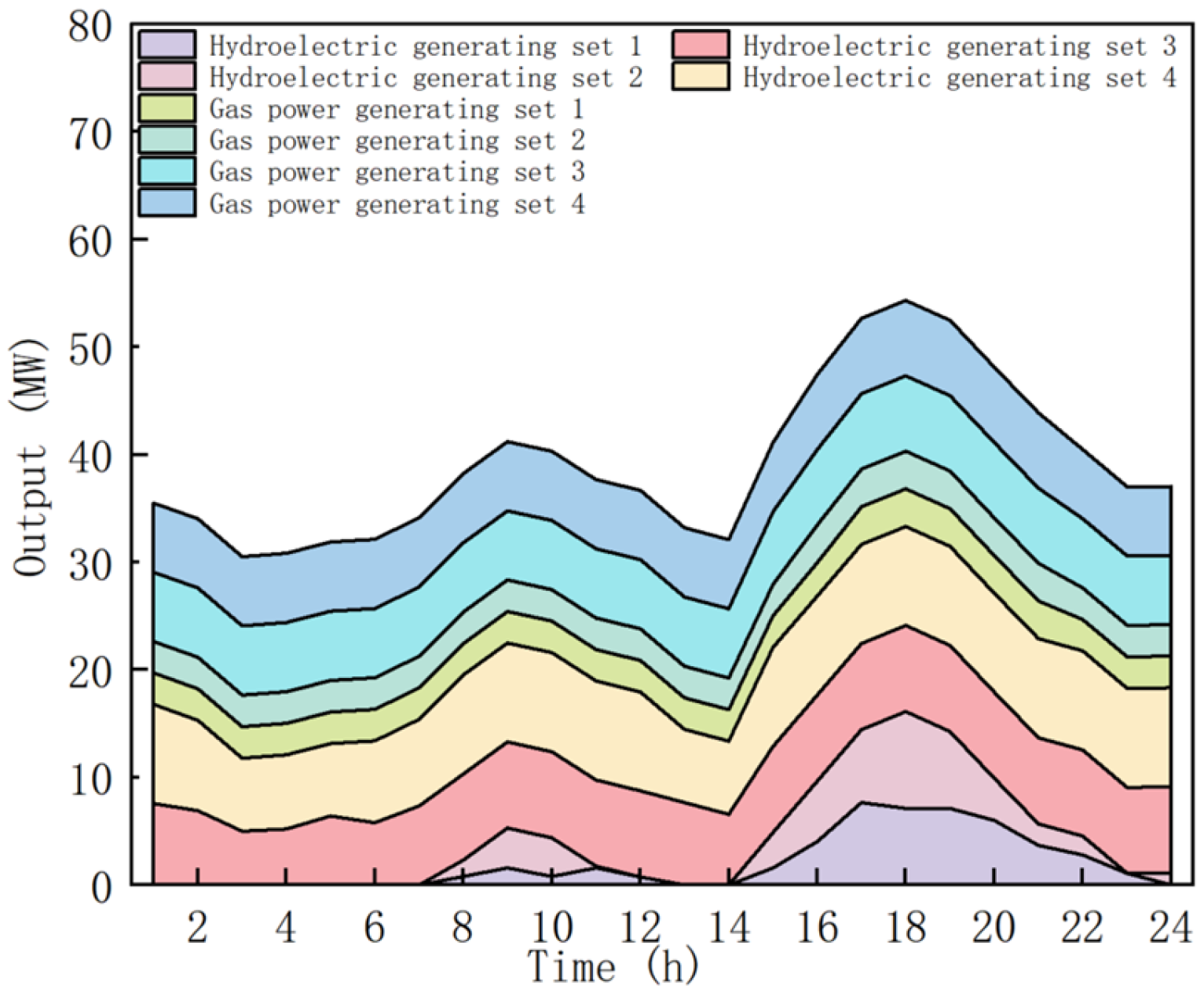

6.2. Analysis of Example Simulation Results

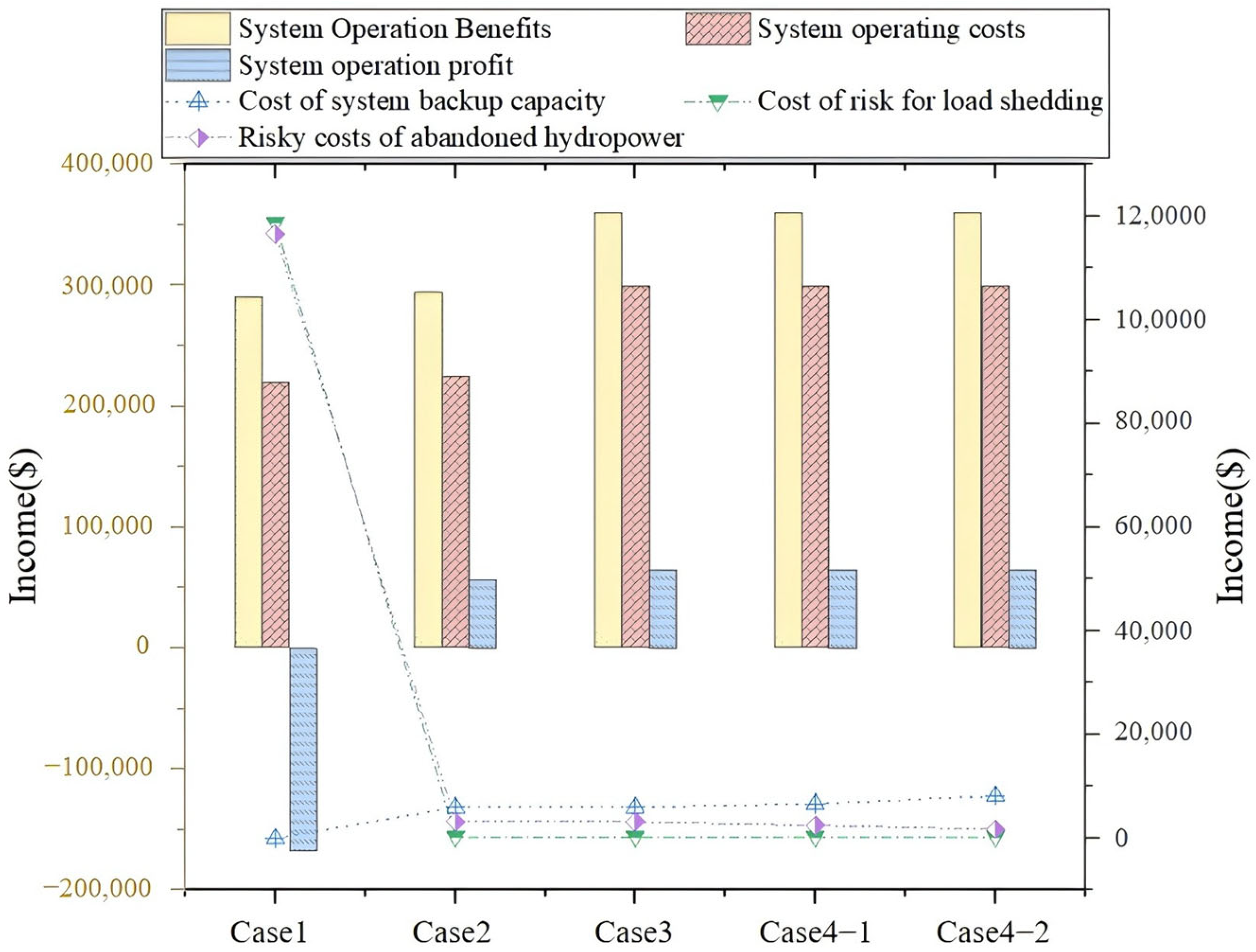

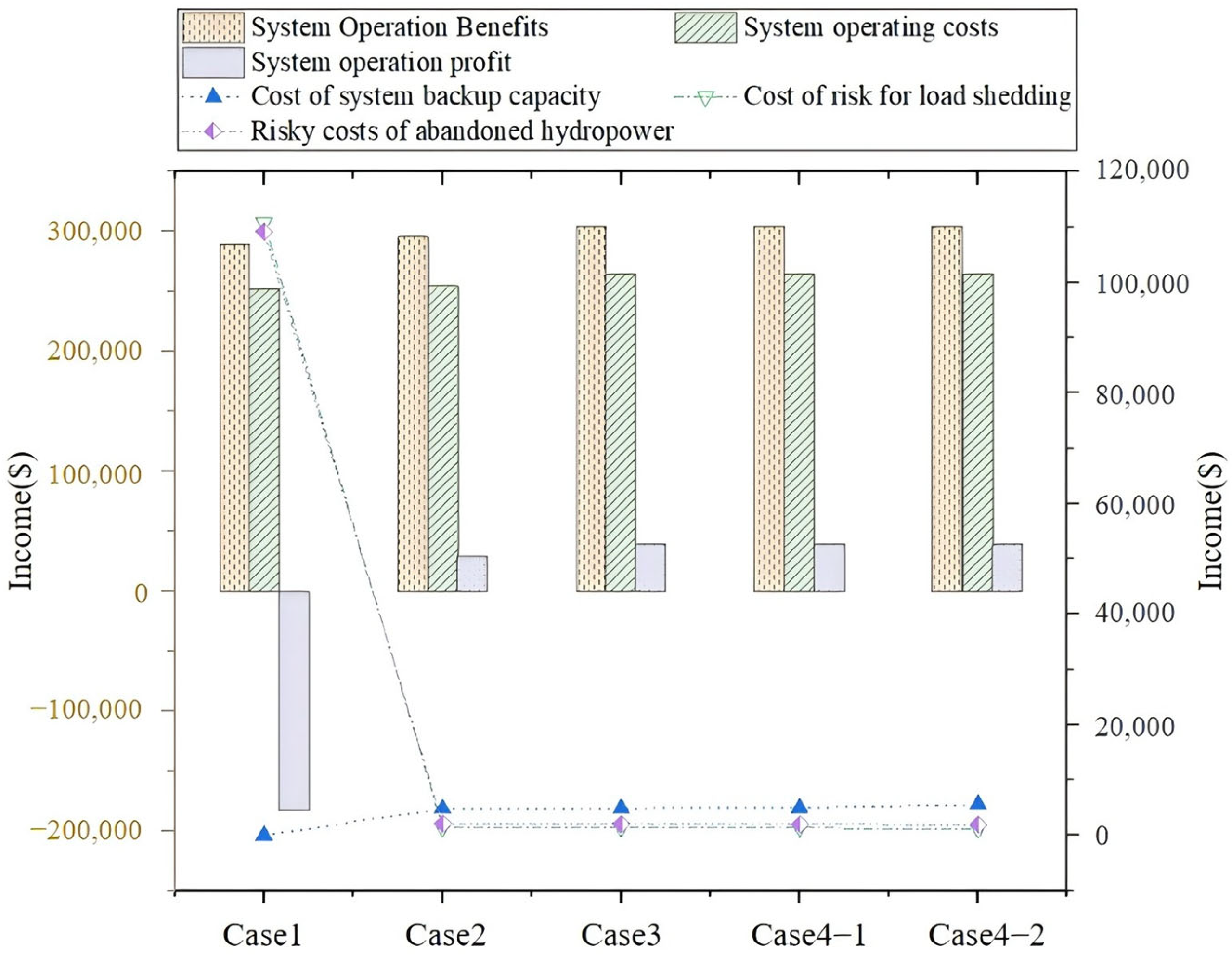

6.3. Analysis of the Results of the Calculation and System Operational Risk

6.4. Analysis of the Results Considering Source-Load Uncertainty and Deep Peaking

- Analysis of the Results for Power Optimization

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pingkuo, L.; Huan, P. What drives the green and low-carbon energy transition in China?: An empirical analysis based on a novel framework. Energy 2021, 239, 122450. [Google Scholar] [CrossRef]

- Tian, C.; Huang, G.; Xie, Y. Systematic evaluation for hydropower exploitation rationality in hydro-dominant area: A case study of Sichuan Province, China. Renew. Energy 2020, 168, 1096–1111. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, K.; Zhang, F. Identification of key influencing factors to Chinese coal power enterprises transition in the context of carbon neutrality: A modified fuzzy DEMATEL approach. Energy 2022, 263, 125427. [Google Scholar] [CrossRef]

- Ding, Y.; Hao, J.; Li, A.; Wang, X.; Zhang, X.; Liu, Y. Numerical Simulation of Combustion and Emission Characteristics during Gas Turbine Startup Procedure. Energies 2022, 15, 5444. [Google Scholar] [CrossRef]

- Fan, G.; Lu, X.; Chen, K.; Zhang, Y.; Han, Z.; Yu, H.; Dai, Y. Comparative analysis on design and off-design performance of novel cascade CO2 combined cycles for gas turbine waste heat utilization. Energy 2022, 254, 124222. [Google Scholar] [CrossRef]

- Wang, X.; Duan, L.; Zhu, Z. Peak regulation performance study of GTCC based CHP system with compressor inlet air heating method. Energy 2022, 262, 125366. [Google Scholar] [CrossRef]

- Zheng, Z.; Zuo, Y.; Wen, H.; Zhang, J.; Zhou, G.; Xu, L.; Sun, H.; Yang, M.; Yan, K.; Zeng, J. Natural gas characteristics and gas-source comparisons of the lower triassic Jialingjiang formation, Eastern Sichuan basin. Geoenergy Sci. Eng. 2022, 221, 111165. [Google Scholar] [CrossRef]

- Cheng, Q.; Luo, P.; Liu, P.; Li, X.; Ming, B.; Huang, K.; Xu, W.; Gong, Y. Stochastic short-term scheduling of a wind-solar-hydro complementary system considering both the day-ahead market bidding and bilateral contracts decomposition. Int. J. Electr. Power Energy Syst. 2022, 138, 107904. [Google Scholar] [CrossRef]

- Huang, K.; Liu, P.; Ming, B.; Kim, J.-S.; Gong, Y. Economic operation of a wind-solar-hydro complementary system considering risks of output shortage, power curtailment and spilled water. Appl. Energy 2021, 290, 116805. [Google Scholar] [CrossRef]

- Jin, X.; Liu, B.; Liao, S.; Cheng, C.; Yan, Z. A Wasserstein metric-based distributionally robust optimization approach for reliable-economic equilibrium operation of hydro-wind-solar energy systems. Renew. Energy 2022, 196, 204–219. [Google Scholar] [CrossRef]

- Morillo, J.L.; Zephyr, L.; Pérez, J.F.; Cadena, A.; Anderson, C.L. Distribution-free chance-constrained load balance model for the operation planning of hydrothermal power systems coupled with multiple renewable energy sources. Int. J. Electr. Power Energy Syst. 2022, 142, 108319. [Google Scholar] [CrossRef]

- Jiang, J.; Ming, B.; Liu, P.; Huang, Q.; Guo, Y.; Chang, J.; Zhang, W. Refining long-term operation of large hydro–photovoltaic–wind hybrid systems by nesting response functions. Renew. Energy 2023, 204, 359–371. [Google Scholar] [CrossRef]

- Guo, Y.; Ming, B.; Huang, Q.; Wang, Y.; Zheng, X.; Zhang, W. Risk-averse day-ahead generation scheduling of hydro–wind–photovoltaic complementary systems considering the steady requirement of power delivery. Appl. Energy 2022, 309, 118467. [Google Scholar] [CrossRef]

- Liao, S.; Liu, H.; Liu, B.; Zhao, H.; Wang, M. An information gap decision theory-based decision-making model for complementary operation of hydro-wind-solar system considering wind and solar output uncertainties. J. Clean. Prod. 2022, 348, 131382. [Google Scholar] [CrossRef]

- Jin, X.; Liu, B.; Liao, S.; Cheng, C.; Zhang, Y.; Zhao, Z.; Lu, J. Wasserstein metric-based two-stage distributionally robust optimization model for optimal daily peak shaving dispatch of cascade hydroplants under renewable energy uncertainties. Energy 2022, 260, 125107. [Google Scholar] [CrossRef]

- Behnamfar, M.R.; Barati, H.; Karami, M. Stochastic Multi-Objective Short-term Hydro-thermal Self-scheduling in Joint Energy and Reserve Markets Considering Wind-Photovoltaic Uncertainty and Small Hydro Units. J. Electr. Eng. Technol. 2021, 16, 1327–1347. [Google Scholar] [CrossRef]

- Hong, Z.; Peihua, J.; Wei, P.; Peitong, H. Research on deep peaking costallocation mechanism considering peaking demand subject and thermal powerunit. Energy Rep. 2024, 12, 158–172. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, J.; Wei, X.; Cheng, C.; Cheng, R. Short-Term Hydro-Wind-PV peak shaving scheduling using approximate hydropower output characters. Renew. Energy 2024, 236, 121502. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, A.; Wang, Y.; Chang, J.; Wang, X.; Wang, Z.; Tian, Y.; Jing, Z.; Peng, Z. How to achieve optimal photovoltaic plant capacity in hydro-photovoltaic complementary systems: Fully coupling long-term and short-term operational modes of cascade hydropower plants. Energy 2024, 313, 134161. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, X.; Jin, Y.; Song, D.; Yang, M.; Zeng, Q. Peaking Compensation Mechanism for Thermal Units and Virtual Peaking Plants Union Promoting Curtailed Wind Power Integration. Energies 2019, 12, 3299. [Google Scholar] [CrossRef]

- Nozarian, M.; Seifi, H.; Sheikh-El-Eslami, M.K.; Delkhosh, H. Hydro Thermal Unit Commitment involving Demand Response resources: A MILP formulation. Electr. Eng. 2022, 105, 175–192. [Google Scholar] [CrossRef]

- Code for Design of Combined-Cycle Power Plant. 2020. Available online: https://d.wanfangdata.com.cn/standard/DL/T 5174-2020 (accessed on 23 October 2020).

- Hou, J.; Yu, W.; Xu, Z.; Ge, Q.; Li, Z.; Meng, Y. Multi-time scale optimization scheduling of microgrid considering source and load uncertainty. Electr. Power Syst. Res. 2022, 216, 109037. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, N.; Kang, C.; Xia, Q.; He, D.; Liu, C.; Huang, Y.; Cheng, L.; Bai, J. A Game Theoretical Pricing Mechanism for Multi-Area Spinning Reserve Trading Considering Wind Power Uncertainty. IEEE Trans. Power Syst. 2015, 31, 1084–1095. [Google Scholar] [CrossRef]

- Ye, L.; Dai, B.; Li, Z.; Pei, M.; Zhao, Y.; Lu, P. An ensemble method for short-term wind power prediction considering error correction strategy. Appl. Energy 2022, 322, 119475. [Google Scholar] [CrossRef]

- Rockafellar, R.T.; Uryasev, S. Optimization of conditional value-at-risk. J. Risk 2000, 2, 21–41. [Google Scholar] [CrossRef]

- Zhou, D.; Jia, X.; Hao, J.; Wang, D.; Huang, D.; Wei, T. Study on Intelligent Control of Gas Turbines for Extending Service Life Based on Reinforcement Learning. J. Eng. Gas Turbines Power 2021, 143, 061001. [Google Scholar] [CrossRef]

- Zhang, B. Low Cycle Fatigue and High Temperature Creep Damage of High Pressure Steam Turbine Rotors. J. North China Electr. Power Univ. 1982, 2, 1–14. [Google Scholar]

- Cheng, C.; Wang, J.; Wu, X. Hydro Unit Commitment with a Head-Sensitive Reservoir and Multiple Vibration Zones Using MILP. IEEE Trans. Power Syst. 2016, 31, 4842–4852. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Xu, T.; Yang, S.; Zheng, Y.; Yan, X.; Mao, M.; Jiang, Z.; Li, Q. Gas−Hydro Coordinated Peaking Considering Source-Load Uncertainty and Deep Peaking. Energies 2025, 18, 1234. https://doi.org/10.3390/en18051234

Wu C, Xu T, Yang S, Zheng Y, Yan X, Mao M, Jiang Z, Li Q. Gas−Hydro Coordinated Peaking Considering Source-Load Uncertainty and Deep Peaking. Energies. 2025; 18(5):1234. https://doi.org/10.3390/en18051234

Chicago/Turabian StyleWu, Chong, Tong Xu, Shenhao Yang, Yong Zheng, Xiaobin Yan, Maoyu Mao, Ziyi Jiang, and Qian Li. 2025. "Gas−Hydro Coordinated Peaking Considering Source-Load Uncertainty and Deep Peaking" Energies 18, no. 5: 1234. https://doi.org/10.3390/en18051234

APA StyleWu, C., Xu, T., Yang, S., Zheng, Y., Yan, X., Mao, M., Jiang, Z., & Li, Q. (2025). Gas−Hydro Coordinated Peaking Considering Source-Load Uncertainty and Deep Peaking. Energies, 18(5), 1234. https://doi.org/10.3390/en18051234