1. Introduction

Responding to the urgent need to address climate change, alternative fuels are being proposed. Among these alternatives, ammonia has emerged as a promising candidate due to its carbon-free combustion properties, high energy density, and scalability for large-scale applications [

1]. However, ammonia’s potential as a carbon-free fuel is contingent on being produced from renewable sources, such as green ammonia derived from electrolysis powered by renewable energy. Additionally, ammonia serves as an efficient hydrogen carrier, facilitating the storage and transport of hydrogen, which is crucial for various clean energy applications [

2]. To ensure the long-term success and sustainability of such initiatives, a science-based, systematic, and holistic approach is needed.

Achieving International Maritime Organization (IMO) targets for maritime industry [

3] necessitates a transformative shift in maritime energy systems, with retrofitting existing vessels to accommodate alternative fuels emerging as a critical pathway. The novel application of ammonia as a marine fuel, apart from the benefits, poses significant technical, economic, and social challenges that need to be addressed, including onboard storage and handling. Through the systematic life cycle analysis (LCA) of all stages—from raw material extraction to end-of-life disposal—businesses can make more sustainable choices that benefit both the environment and their bottom line. While traditional LCA focuses on environmental impacts, life cycle cost analysis (LCCA) is a tool for assessing economic costs over a product’s or service’s life cycle.

To ensure the long-term success and sustainability of such initiatives, a robust LCCA methodology is essential. This approach is critical for evaluating the economic viability of ammonia storage systems, addressing unique challenges, and enabling informed decision making. To facilitate the large-scale deployment of ammonia in marine applications, there is a critical need to develop a robust methodology for assessing the life cycle costs of ammonia storage systems on vessels. With an LCCA methodology, the maritime industry can better evaluate the feasibility of ammonia storage systems, paving the way for their large-scale adoption and supporting global efforts to reduce carbon emissions.

While general guidelines for LCCA, such as ISO 15686-5 [

4], provide a foundation, they do not account for the specific requirements and risks associated with onboard ammonia fuel storage. Moreover, the diverse operational profiles and vessel configurations in the shipping industry necessitate a flexible and customizable LCCA methodology that can adapt to varying technological alternatives and uncertainties.

This paper addresses the gap in the existing literature by presenting a customizable LCCA methodology specifically tailored for the onboard storage of liquid ammonia fuel on vessels or similar cases (

Figure 1). The proposed framework incorporates probabilistic modeling to address uncertainties, modularity to adapt to different vessel configurations, and a life cycle approach to quantify costs from design to decommissioning. The findings contribute to bridging the knowledge gap and facilitating the adoption of ammonia as a sustainable marine fuel.

To achieve this study’s aim, an extensive review of the existing literature and publications on LCCA was conducted to identify the common steps and principals involved in performing LCCA. This review informed the development of a robust, tailored methodology specifically for evaluating ammonia fuel storage systems onboard vessels. The proposed methodology incorporates general best practices while addressing the unique technical and economic challenges associated with onboard ammonia fuel storage. It was subsequently applied to a detailed case study involving a multipurpose vessel, enabling practical insights into the methodology’s effectiveness. This case study facilitated an in-depth evaluation of cost components and the consideration of non-quantifiable factors, culminating in actionable conclusions about the utility of the proposed framework for guiding sustainable storage.

The remainder of this article is organized as follows:

Section 2 provides a comprehensive literature review, exploring ammonia as a marine fuel, relevant regulatory frameworks, and the principles of LCCA, along with its benefits, challenges, and general procedural steps.

Section 3 introduces a robust LCCA methodology tailored specifically for onboard ammonia fuel storage systems, detailing its step-by-step implementation.

Section 4 applies the proposed methodology to a case study, illustrating its practical utility in evaluating alternatives for ammonia storage tank systems.

Section 5 discusses the results as well as their implications for the maritime industry and provides recommendations for stakeholders, alongside future research opportunities. Finally,

Section 6 concludes this study by summarizing the findings and emphasizing the significance of adopting a systematic LCCA approach for sustainable and cost-effective marine fuel solutions.

2. Literature Review

2.1. Ammonia as a Marine Fuel

Ammonia’s zero-carbon emissions during combustion and its potential to contribute to decarbonizing the shipping industry have been extensively discussed in recent studies [

5,

6,

7,

8]. However, ammonia’s potential as a carbon-free fuel is contingent on being produced from renewable sources, such as green ammonia derived from electrolysis powered by renewable energy. Unlike conventional marine fuels, ammonia does not produce direct CO₂ emissions when burned [

9], and methane slipping either pre- or post-combustion makes it a viable solution to meet the IMO GHG reduction targets for 2050. Ammonia is extensively utilized across various industries, including agriculture, chemicals, and refrigeration, leading to a well-established global infrastructure for its production, storage, and transportation. Many seaports are equipped with facilities to store and handle ammonia, primarily due to its significant role in these sectors [

10]. However, ammonia poses several challenges, including its toxicity, corrosiveness, and high flammability, which necessitate specialized storage and handling systems onboard ships [

9]. Despite these challenges, its potential to act as an efficient hydrogen carrier has been recognized, which enhances its appeal for broader clean energy applications [

2,

11,

12].

2.2. Regulations

Using ammonia as a marine fuel introduces unique challenges due to its chemical properties, requiring adherence to strict regulations and standards to ensure safety and environmental protection. These are governed by international, national, and industry-specific guidelines, and classification societies play a pivotal role in developing and enforcing these standards. The IMO, through conventions and guidelines, establishes the primary regulatory framework for the safe use of alternative marine fuels, including ammonia [

13,

14], while flag authorities also play a crucial role in setting and enforcing safety and operational requirements for the vessels under their jurisdiction.

The key considerations in ammonia storage regulations are material compatibility, safety measures, and environmental compliance. Storage tanks must withstand ammonia’s corrosive nature, requiring materials like nickel alloys, stainless steel, or advanced composites [

15]. Redundant safety systems, including pressure relief valves, temperature monitoring, and ventilation, are mandatory. There are specific requirements for tank inerting, venting, and emergency shutdown procedures. These systems must be designed to prevent ammonia leaks and minimize the environmental impacts in case of accidents. The International Convention for the Prevention of Pollution from Ships (MARPOL) regulations ensure the proper handling of ammonia residues and emissions. Additionally, the International Convention for the Safety of Life at Sea (SOLAS) provides essential safety requirements for ammonia as a marine fuel, particularly regarding its storage and fire protection measures. Recent developments at the IMO, including ongoing discussions on regulatory frameworks for alternative fuels, emphasize the need for specific design, ventilation, and leakage detection requirements for ammonia storage. Expanding on these evolving SOLAS provisions will be critical in ensuring safe ammonia adoption in maritime applications.

2.3. Life Cycle Cost Analysis

Sustainability is driven by the urgent need for a science-based, systematic, and holistic approach to address the environmental, economic, and social challenges of modern life. By providing insights into the full life cycle of products and services, the stakeholders are empowered to make informed decisions that advance sustainability goals while minimizing unintended consequences.

The transition to alternative fuels in the maritime sector to meet decarbonization goals is a complex challenge requiring not only technical innovation but also economic feasibility. Accurate cost estimation is crucial for successful project management. It ensures that projects stay within budget, prevents unexpected expenses, and helps allocate resources effectively. LCCA is a comprehensive approach used to evaluate the total cost of owning, operating, maintaining, and eventually disposing of a project or asset over its entire life span. It is widely applied in infrastructure, energy, building, and manufacturing projects to compare alternatives and make cost-effective decisions. The focus of LCCA is not only on initial capital expenditures but also on the long-term costs and benefits associated with a project, incorporating financial metrics such as net present value (NPV), to provide a comprehensive economic evaluation.

2.4. Life Cycle Cost Analysis Guides

Several publications provide guidance on conducting LCCA. Most industry LCC guides provide a framework for practitioners to move beyond initial cost considerations and embrace a more holistic, life cycle perspective on building projects [

16,

17,

18,

19,

20,

21]. The European Commission has developed a series of sector-specific LCC calculation tools that aim to facilitate the use of LCC amongst public procurers [

22]. While acknowledging a historical lack of standardization in LCC application, guides point to the development of standards like ISO 15686-5 [

4].

ISO 15686-5 provides a structured approach to LCC, emphasizing the importance of defining the system boundary, identifying cost categories, and conducting a comprehensive analysis over the product’s or system’s life cycle.

LCCA offers numerous benefits, including enabling informed decision making by providing a comprehensive assessment of the total cost of ownership over a project’s lifespan. This approach considers all relevant costs, including acquisition, operation, maintenance, and disposal, enabling more informed decisions regarding design, construction, and maintenance. LCCA facilitates cost optimization by identifying cost drivers and trade-offs throughout a project’s life cycle. This allows for the selection of more cost-effective designs, materials, and maintenance strategies. LCCA allows for the direct comparison of different design alternatives, enabling the selection of the most cost-efficient option. This is particularly useful when evaluating options that have different initial investment costs but offer potential savings in operating or maintenance costs. LCCA promotes transparency by documenting the analysis process and assumptions used. This can enhance investor confidence and demonstrate the responsible use of public funds. LCCA assists in risk management by incorporating uncertainty analysis to assess the potential impact of variable costs, such as energy prices and equipment lifespans. This allows for better-informed decisions under uncertain conditions. LCCA highlights future expenses that need to be considered in infrastructure budgets, such as those for rehabilitation, repair, and replacement. This can improve long-term financial planning and resource allocation. The sources emphasize that LCCA should be performed early in the design process while there is still flexibility to refine the design and reduce life cycle costs. It is also crucial to use reasonable, consistent, and well-documented assumptions when estimating costs. While LCCA is a valuable tool for evaluating the cost-effectiveness of projects, it should not be the sole decision-making factor. Other considerations, such as sustainability, user preferences, and non-quantifiable benefits, should also be taken into account.

Obtaining reliable and relevant cost data, especially for future costs, is a significant challenge in LCCA. Historical data may be incomplete, outdated, or not applicable to new projects. The wide range of cost components and levels of detail needed can make data collection difficult [

21,

23]. Projecting future costs involves inherent uncertainty, as factors such as energy prices, inflation rates, and equipment lifespans can fluctuate significantly. Properly accounting for this uncertainty in LCCA can be challenging [

18,

19,

23]. LCCA can be complex and time-consuming, requiring specialized knowledge and skills. Calculations involving discounting, inflation adjustments, and uncertainty analysis can be intricate, and gathering comprehensive cost data for multiple alternatives can take time [

21]. Although standards and guidelines for LCCA exist, there is no single universally accepted methodology. Variations in approaches and interpretations can make it difficult to compare bids or analyze projects consistently [

21]. Estimating costs and selecting discount rates can involve subjective judgments. Different analysts may make different assumptions, leading to variations in LCCA results [

19,

21]. The lack of client demand for LCCA can be a barrier to its wider adoption. Clients may not be willing to pay for the additional time and expertise required for a comprehensive LCCA [

21]. Addressing these challenges requires careful planning, data collection, and analysis. Using standardized methodologies, clearly documenting assumptions, and conducting sensitivity analysis can help improve the reliability and usefulness of LCCA results.

The sources outline a common set of steps for conducting an LCCA, although the specific details and emphasis may vary depending on the context and application. LCCA typically involves defining the problem and objectives, identifying feasible alternatives, establishing common assumptions and parameters, estimating the costs and timing for each alternative, discounting future costs to present value, calculating and comparing life cycle costs, computing supplementary measures, assessing uncertainty, considering non-quantifiable effects, and, finally, documenting and communicating the results. Key steps include defining the study period; selecting a discount rate; estimating initial, operating, maintenance, and replacement costs; and considering factors like inflation and residual value. LCCA involves a comprehensive evaluation of the costs over the project’s lifespan, considering factors like net savings, savings-to-investment ratio, and payback period. While LCCA provides valuable insights, it is crucial to consider it alongside other relevant factors, such as environmental impacts and social considerations, when making final decisions.

2.5. The Need for a Robust LCCA Methodology for Onboard Ammonia Fuel Storage

The novel application of ammonia as a marine fuel presents significant opportunities and challenges, particularly in the context of onboard storage systems. To ensure the long-term success and sustainability of such initiatives, a robust LCCA methodology is essential. This approach is critical for evaluating the economic viability of ammonia storage systems, addressing unique challenges, and enabling informed decision making.

As ammonia emerges as a viable alternative to traditional marine fuels, understanding its economic implications becomes crucial. Studies indicate that while ammonia offers substantial environmental benefits in terms of carbon reduction [

24,

25], it also presents critical safety and environmental challenges, including toxicity and the potential for ammonia slip, which can be harmful to human health and marine ecosystems. As a result, its adoption requires stringent mitigation measures, adherence to Classification Society and Flag Authority regulations, and the integration of risk assessment methodologies such as HAZOP, HAZID, and FMEA. These frameworks ensure that ammonia fuel systems are designed with robust safety measures, minimizing potential hazards while optimizing life cycle costs. A dedicated LCCA methodology provides a comprehensive framework to evaluate these costs over the entire life cycle of ammonia storage systems, facilitating effective financial planning and investment strategies.

Ammonia storage poses unique technical and safety challenges distinct from traditional fuels. A tailored LCCA methodology accounts for ammonia’s specific properties, such as toxicity, corrosiveness, and handling requirements, ensuring compliance with stringent maritime safety regulations [

26]. This ensures that all relevant costs, including those related to safety measures and regulatory compliance, are incorporated into the analysis.

A robust LCCA methodology allows stakeholders to conduct comparative analyses between ammonia storage systems and alternative low-emission fuels, such as liquefied natural gas (LNG) and hydrogen. By evaluating life cycle costs, including environmental and regulatory compliance expenses, decision makers can identify the most financially and environmentally viable technology.

Transparent and comprehensive LCCA results facilitate better communication among stakeholders, including shipowners, fuel suppliers, regulators, and technology providers. This common framework promotes collaboration in advancing ammonia adoption in maritime applications. Additionally, LCCA data can support policymakers in developing market-based measures, such as subsidies or incentives, to offset the cost gap between ammonia and conventional fuels, encouraging investment in ammonia infrastructure.

The modular nature of the proposed LCCA methodology enables adaptation to various vessel types and operational configurations. This flexibility ensures that the analysis remains applicable to diverse maritime scenarios, enhancing its practicality and relevance.

The adoption of ammonia involves uncertainties, including regulatory changes, market fluctuations, and technological advancements. LCCA methodologies that incorporate sensitivity and scenario analyses help proactively identify and manage these risks, ensuring robust financial planning. By forecasting the costs associated with operations, maintenance, and end-of-life recycling or decommissioning, LCCA ensures long-term economic sustainability for ammonia fuel systems.

Ammonia fuel storage systems are technologically complex, requiring components capable of handling corrosive, toxic, and pressurized substances. A robust LCCA evaluates the financial implications of scaling these systems for widespread use, identifying cost-saving opportunities through economies of scale and technological innovations.

3. Proposition of a Robust LCCA Methodology for Onboard Ammonia Fuel Storage

To address the complexities associated with onboard ammonia fuel storage systems, a tailored LCCA methodology is proposed. This methodology builds upon established LCCA principles while integrating considerations specific to ammonia as a marine fuel. The framework aims to ensure a comprehensive, reliable, and actionable evaluation of life cycle costs, supporting informed decision making and sustainable development.

3.1. Step 1: Problem Definition and Objectives

The first step involves clearly defining the objectives of the LCCA for the project of onboard ammonia fuel storage systems. This phase is crucial as it sets the foundation for the entire evaluation process, ensuring that all relevant factors are considered in the decision-making framework.

Key objectives for the studied project could be as follows:

Evaluating economic viability involves determining whether the adoption of ammonia storage systems is financially sustainable over their entire life cycle. This involves accounting for costs such as initial capital expenditure (CAPEX), operating expenses (OPEXs), maintenance, and end-of-life decommissioning. Such assessments provide insight into the total cost of ownership and help with decision-making for investments [

27].

Comparing design alternatives involves identifying and evaluating various design configurations for ammonia storage systems. These comparisons enable stakeholders to weigh the trade-offs between upfront costs and long-term savings, considering factors like material selection, integration complexity, and safety enhancements [

24].

Variations in tank volume and layout can be assessed to accommodate space constraints.

Assessing long-term cost implications involves considering life cycle costs that extend beyond initial investments, such as recurring maintenance and regulatory compliance expenses. Long-term analysis supports the design of systems that minimize hidden costs and enhance operational efficiency over time.

Identifying key cost drivers involves pinpointing critical components and processes that significantly influence life cycle costs. For ammonia systems, this might include costs related to safety infrastructure or compliance with evolving regulations [

25].

3.2. Step 2: Identification of Alternatives

The range of feasible alternatives for ammonia storage systems is identified and compared. These alternatives may include

Tank designs, with options such as pressurized tanks, cryogenic tanks, or combinations thereof.

Materials of construction, with Choices such as stainless steel, composite materials, or other corrosion-resistant materials.

Operational configurations, considering variations in auxiliary systems, including ventilation, monitoring, or refrigeration integration.

Each alternative represents a distinct approach to achieving the same functional goals, balancing cost, safety, and performance.

3.3. Step 3: Establishment of Assumptions and Parameters

Consistent and well-documented assumptions and parameters, tailored to ammonia’s unique requirements, have been established. These include

Study period: typically aligned with the operational lifespan of a vessel (e.g., 20–30 years).

Base date: corresponding to the current year and economic conditions.

Discount rate: reflecting the financial practices and risk environment of the maritime industry.

Inflation treatment: accounting for anticipated changes in energy prices and material costs.

Regulatory frameworks: incorporating current and projected regulations for ammonia as a marine fuel.

3.4. Step 4: Cost Estimation for Each Alternative

The costs for each alternative are comprehensively evaluated across the system’s life cycle, including

Initial costs: expenses such as tank fabrication, installation, safety systems, and regulatory compliance.

Operational costs: ongoing costs for refrigeration, monitoring systems, and the maintenance of ammonia containment systems.

Maintenance and repair costs: costs associated with ammonia’s corrosive nature, including frequent inspections and repairs.

Replacement costs: costs for components with shorter lifespans than the overall system, such as seals or sensors.

End-of-life costs: costs for decommissioning, disposal, or recycling of system components.

Residual value: salvageable value of materials or reusable components at the end of the study period.

3.5. Step 5: Discounting Future Costs

Discounting ensures the costs of different design alternatives (e.g., metallic vs. composite tanks) are evaluated on an equal financial basis. All relevant costs, including initial capital expenditures (CAPEXs), operational expenditures (OPEXs), maintenance costs, repair and refurbishment costs, and end-of-life costs, should be discounted back to their present values. The discount rate is applied to all future costs, converting them to the present value for consistent comparison. The time value of money is aligned with the financial practices and risk considerations of the maritime sector.

3.6. Step 6: Comparison of Life Cycle Costs

The total life cycle costs for each alternative are aggregated and compared. By aggregating and discounting the costs for each alternative over the life cycle, the comparison reveals the long-term cost implications, helping to identify the more sustainable and economically viable choice. The analysis identifies the most cost-effective option while accounting for trade-offs between initial investment and long-term operational savings.

3.7. Step 7: Sensitivity and Uncertainty Analysis

Sensitivity analysis is conducted to address uncertainties inherent in ammonia storage systems, considering, for example,

Fluctuations in material costs. Commodity prices for materials like stainless steel or composite materials can fluctuate significantly due to global market conditions, supply and demand, and geopolitical events.

Fluctuations in regulatory compliance costs. These costs encompass the expenses associated with meeting the various safety, environmental, and operational regulations imposed by governmental and international bodies.

Technological advancements. New materials or manufacturing processes may emerge, potentially impacting costs and performance.

Understanding how these fluctuations impact LCCA is crucial for stakeholders involved in the design, operation, and economic evaluation of ammonia as a marine fuel.

3.8. Step 8: Consideration of Non-Quantifiable Factors

While the LCCA primarily focuses on quantifiable costs, it is crucial to acknowledge and consider non-quantifiable factors such as the environmental benefits from reduced greenhouse gas emissions and the safety enhancements required for handling toxic and corrosive materials. These factors can significantly influence the overall decision-making process and should be carefully evaluated alongside the economic considerations. Incorporating qualitative assessments allows for a more holistic and informed evaluation of the long-term viability and sustainability of ammonia as a marine fuel as well as increase stakeholder confidence in adopting ammonia as a sustainable marine fuel.

Non-quantifiable factors require monetization to reflect their impact. This involves assigning monetary value to the external costs of GHG emissions, such as crop damage, health care expenses, and property loss from climate impacts. Carbon pricing mechanisms like the EU Emissions Trading System (EU ETS) help internalize these costs. Social life cycle cost assessment methods [

28] are often used for such evaluations.

By acknowledging and addressing these non-quantifiable factors, the LCCA can provide a more comprehensive and balanced assessment of the potential benefits and risks associated with adopting ammonia as a marine fuel.

3.9. Step 9: Documentation and Stakeholder Communication

A comprehensive LCCA report is prepared, detailing

Objectives, scope, and assumptions.

Cost estimations and methodologies.

Analysis of alternatives and recommendations.

Findings are communicated to stakeholders, emphasizing the transparency, rigor, and alignment of the results with broader sustainability and economic goals.

3.10. Step 10: Iterative Refinement

Recognizing the iterative nature of LCCA, the analysis is revised and refined as new data become available, technologies advance, or regulatory environments evolve. This adaptable approach ensures that the methodology remains robust and relevant throughout the system’s life cycle.

This structured methodology addresses the unique challenges posed by onboard ammonia fuel storage systems.

4. Application of the Proposed Methodology for Onboard Ammonia Fuel Storage

The developed LCCA methodology provides a structured framework for evaluating the economic performance of onboard ammonia fuel storage solutions. By addressing all phases of the system’s life cycle, this methodology ensures that cost estimations are comprehensive, consistent, and aligned with the unique characteristics of ammonia as a marine fuel. The application of this methodology enables stakeholders to make informed decisions by quantifying the costs and identifying the cost drivers specific to ammonia storage systems.

4.1. Step 1: Problem Definition and Objectives

The project involves the development of a next-generation onboard ammonia fuel storage system for a 31,000 deadweight ton multipurpose vessel. The proposed system stores liquid ammonia at a pressure of 10 bar (designed pressure is 20 bar) and ambient temperature, using two horizontal Type C tanks, each with a capacity of 300 cubic meters. The material for these tanks may be metallic or composite, depending on the design and operational requirements.

Challenges in this context include ensuring the economic feasibility of the storage system by balancing capital and operational costs with long-term economic returns; designing for safety and sustainability, given the corrosive and toxic nature of ammonia, and complying with stringent maritime safety standards; managing space constraints aboard the vessel while maintaining sufficient storage capacity; and addressing uncertainties in design and cost parameters during early development stages.

The LCCA for the onboard ammonia fuel storage system aims to evaluate economic viability by quantifying initial, operating, repair, and end-of-life costs; assess long-term cost implications by identifying cost drivers across the system’s life cycle and evaluating different maintenance and replacement strategies; enable early design decision making by developing a cost model with sufficient resolution to guide system developers during early design stages and ensuring the model accounts for uncertainties or low-confidence data inherent to early-stage development; address ammonia-specific challenges by incorporating safety considerations for handling and storing liquid ammonia and ensuring compliance with maritime safety regulations and environmental standards.

By meeting these objectives, the analysis helps with selecting the most feasible and sustainable alternative.

4.2. Step 2: Identification of Alternatives

During the design stage of an ammonia storage system for a marine vessel, multiple alternatives are evaluated to identify the most effective solution. These alternatives are defined based on variations in tank design, construction materials, and operational configurations. Each option represents a distinct approach to achieving the functional goals of cost efficiency, safety, and operational performance.

Pressurized tanks are designed to store ammonia at elevated pressures; the proposed system stores liquid ammonia at 10 bar (design pressure is 20 bar) to maintain it in liquid form at ambient temperatures. These tanks are simpler in design but require robust materials to withstand internal pressure.

Construction materials such as stainless steel offer high durability, corrosion resistance, and compliance with stringent maritime standards. However, stainless steel is heavier and requires more expensive maintenance than the alternatives.

On the other hand, composite materials are lightweight and corrosion-resistant, offering advantages in weight savings and operational flexibility. However, they are relatively new for ammonia storage and may face challenges with regulatory acceptance.

Table 1 provides a weighted decision matrix with actionable criteria for selecting between stainless steel and composite materials, using a scoring system (e.g., 1–5, where 5 is the best). Each score is multiplied by the criterion weight to calculate a weighted score.

Operational configurations such as ventilation systems ensure proper handling of ammonia vapors to meet safety requirements. Monitoring systems include options such as basic instrumentation for pressure and temperature or advanced systems with remote monitoring and predictive maintenance capabilities.

By identifying and comparing these alternatives, the analysis aims to determine the optimal solution that aligns with the project’s objectives of economic feasibility, safety, and operational performance. Each alternative is evaluated using LCCA to quantify its long-term economic and functional viability.

4.3. Step 3: Establishment of Assumptions and Parameters

To ensure consistency and reliability in the LCCA for ammonia-based fuel storage systems, the following key assumptions and parameters were established. These considerations are tailored to address the specific challenges and requirements of ammonia as a marine fuel, balancing economic, technical, and regulatory factors:

Study Period:

The analysis aligns with the operational lifespan of the vessel; for this evaluation, it is set to 25 years. This timeframe ensures the inclusion of all major cost events, such as maintenance, replacement cycles, and end-of-life considerations.

Base Date:

The economic evaluation uses the current year as the base date to establish present-value cost estimates. This accounts for the prevailing economic conditions, including market prices for materials, labor, and fuel.

Discount Rate:

A discount rate reflecting the maritime industry’s financial practices and associated risks is applied. For this evaluation, it is taken as 5%, since the risk is relatively low, and, as an environmental protection project, it receives favorable treatment in terms of lending.

Regulatory Frameworks:

The parameters consider compliance with current and anticipated international regulations, including IMO guidelines, the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code), the International Convention for the Prevention of Pollution from Ships (MARPOL), and the International Convention for the Safety of Life at Sea (SOLAS). The IGC Code outlines specific design and operational requirements for the safe storage and handling of ammonia as a marine fuel, while MARPOL regulates emissions and discharge standards to minimize environmental impact. SOLAS, in particular, imposes safety requirements for fire protection, ventilation, and crew protection when handling hazardous fuels such as ammonia. These regulatory provisions are integrated into the cost estimation to ensure compliance and account for potential future regulatory developments that may impact the economic feasibility of ammonia storage solutions.

These assumptions create a standardized framework for evaluating different design alternatives, enabling a robust comparison of costs and long-term feasibility. Adjustments to these parameters are made transparently to reflect variations in operational conditions, vessel type, and economic environments.

4.4. Step 4: Cost Estimation for Each Alternative

An analysis was conducted with the specified parameters for a 25-year study period, 5% discount rate, and inflation treatment.

Table 2 includes the costs categorized per period as initial costs (procurement, instrumentation, certification, insurance), operational costs, maintenance and repair costs, replacement costs, and end-of-life costs, considering metallic and composite tank alternatives:

It should be noted that the cost estimates were compiled from both industry and academic sources. These prices vary from source to source and were subject to some processing before being presented in

Table 2 for information purposes only. Binding offers from suppliers would provide a more accurate cost estimate.

4.5. Step 5: Discounting Future Costs

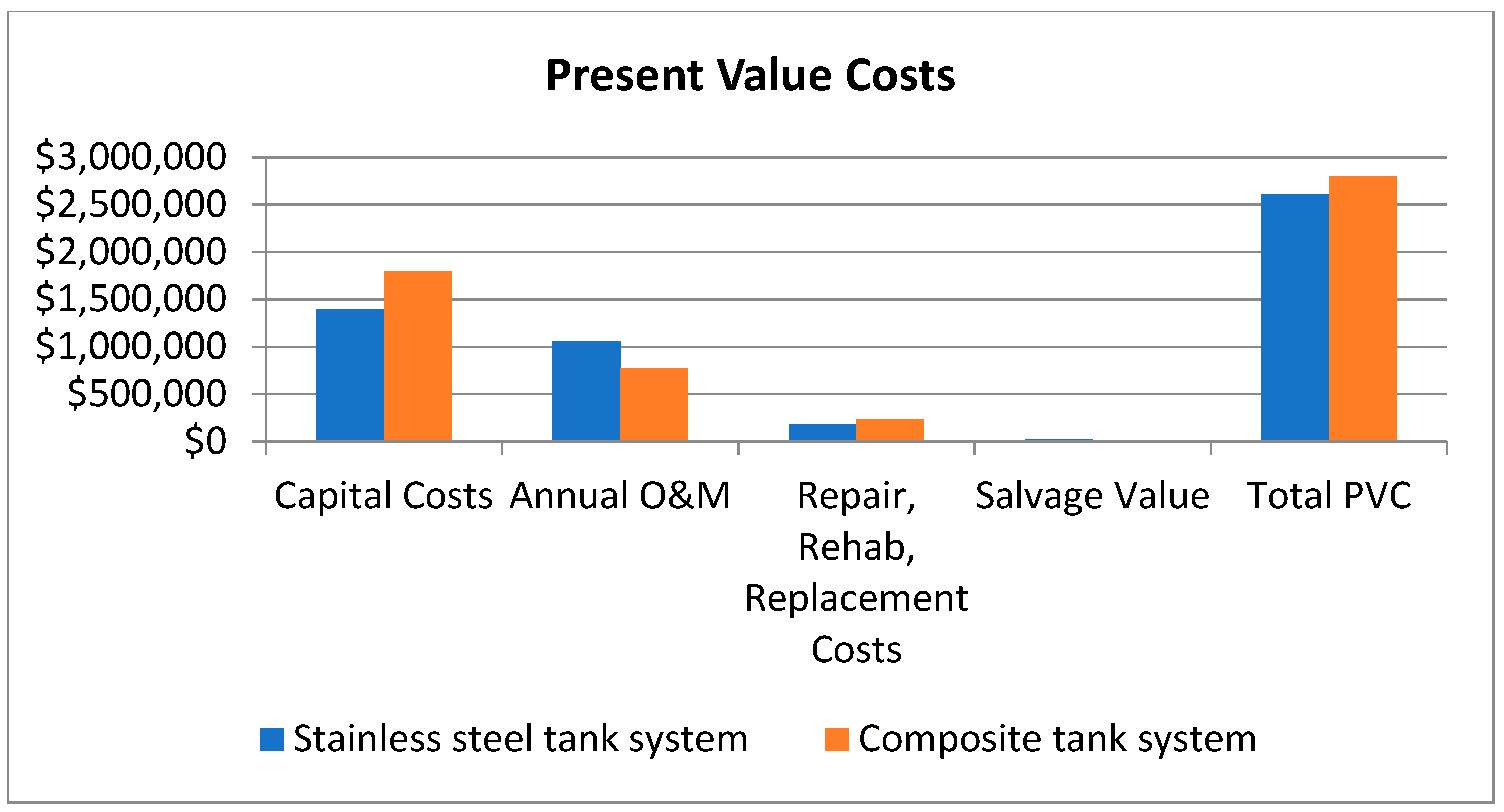

Using a 5% discount rate and 25-year timeframe, the present value (PV) of costs is calculated for each alternative:

Alternative 1 stainless steel tank system: USD 2,613,000;

Alternative 2 composite material tanks: USD 2,803,000.

4.6. Step 6: Comparison of Life Cycle Costs

Stainless steel tanks have higher initial and maintenance costs but better residual value and lower end-of-life costs. On the other hand, composite material tanks have lower initial and maintenance costs but higher end-of-life costs and minimal residual value.

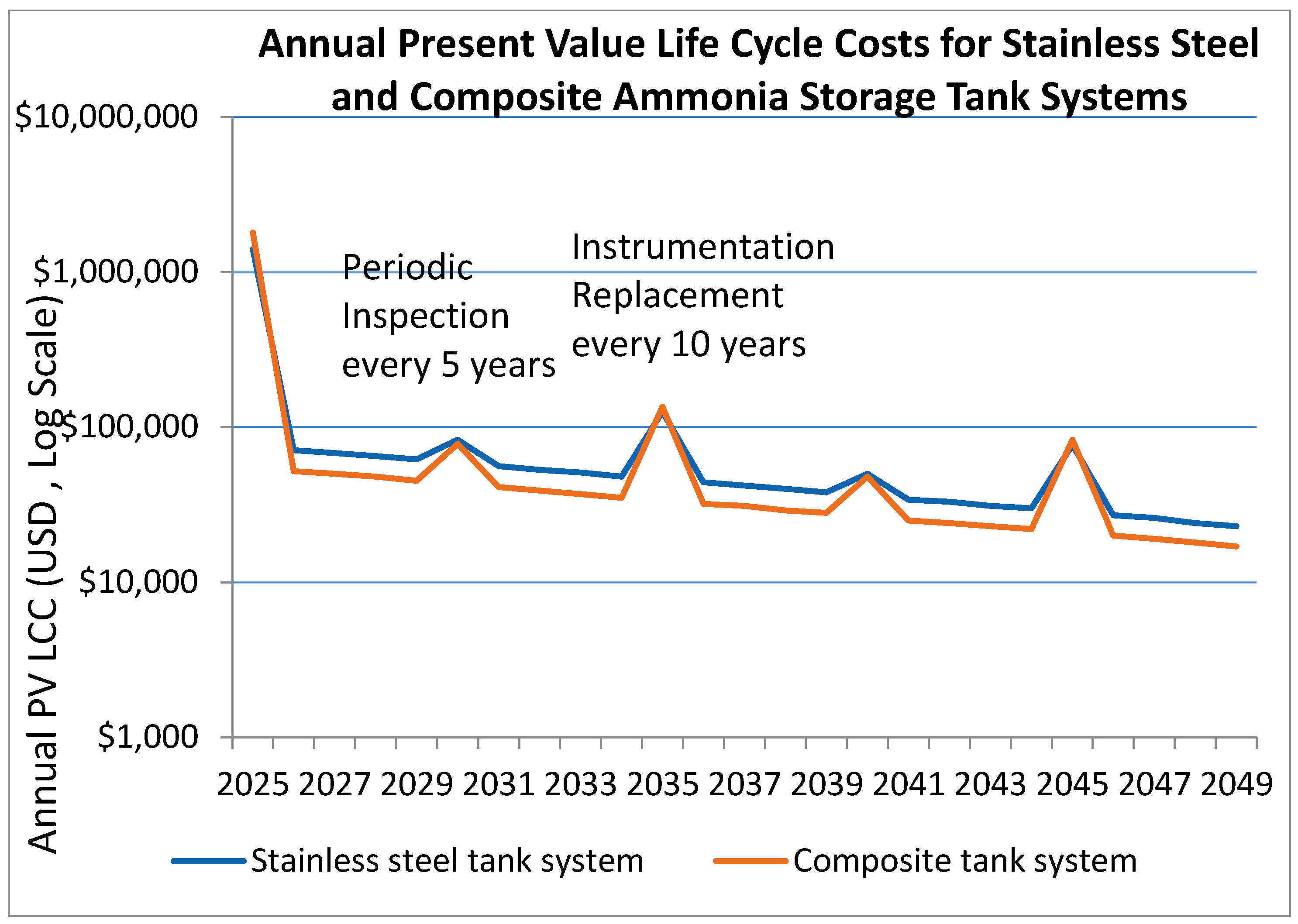

Figure 2 illustrates the annual present value (PV) life cycle costs for the two types of ammonia storage tank systems (stainless steel and composite) over the 25-year study period.

Given the 25-year operational period and 5% discount rate

Figure 3, the stainless steel tank system offers a lower overall NPV, making it the more economical choice for this application, provided it meets all safety and regulatory requirements.

4.7. Step 7: Sensitivity and Uncertainty Analyses

The main uncertainties are centered around material costs, regulatory changes, and technological advancements.

Fluctuations in material costs: As the estimated material cost for two 300 m3 Type C tanks made of 316 L stainless steel is USD 650,000 and considering historical price fluctuations ranging from ±10% to ±30%, the adjusted costs vary accordingly. At a 10% decrease, the cost would be USD 585,000, while at a 10% increase, it would rise to USD 715,000. For ±30%, the variation would be between USD 455,000 and USD 845,000. These variations highlight the impact of material price volatility on total project costs and the need for contingency planning in budget estimations.

Fluctuations in regulatory compliance costs: Potential mandates, for example, an additional vibration monitoring system, may increase CAPEX by 5–10%.

Technological advancements: Technological advancements in composite tank manufacturing introduce uncertainties in cost estimation, as ongoing innovations may lead to increased efficiency. The adoption of advanced materials, improved fabrication techniques, and enhanced safety features could add a premium of 20–30% compared with traditional steel tanks.

4.8. Step 8: Consideration of Non-Quantifiable Factors

Beyond economic considerations, various non-quantifiable effects play a crucial role in shaping decision making for onboard ammonia fuel storage systems. Ammonia fuel adoption reduces greenhouse gas emissions and aligns with global decarbonization goals, enhancing regulatory compliance and supporting climate action efforts. Early adoption improves brand image, market competitiveness, and stakeholder confidence by demonstrating commitment to sustainability and innovation. Investments in advanced safety measures mitigate the risks associated with ammonia’s toxicity and ensure regulatory compliance. Pioneering ammonia storage stimulates innovation, develops supply chains, and positions stakeholders as leaders in green technology. Transitioning to ammonia creates opportunities for workforce upskilling and aligns with global sustainability goals, fostering industry resilience.

4.9. Step 9: Documentation and Stakeholder Communication

Sample Communication of LCCA Results for Ammonia Storage Systems to Stakeholders at a high level.

The key findings include the following:

Total life cycle costs: The LCCA indicates that the total life cycle cost for the metallic (steel) ammonia storage system is approximately USD 2.6 million, while the composite tank system is estimated at USD 2.8 million over a 25-year period. This analysis includes initial capital expenditures, operational and maintenance costs, replacement costs, and end-of-life disposal expenses.

Operational efficiency: The metallic tank system has lower annual operation and maintenance costs, averaging USD 75 thousand per year, compared to USD 55 thousand for the composite system. This suggests that while the initial investment in composite tanks is higher, their operational efficiency may not provide significant long-term savings.

Non-quantifiable factors: Beyond economic considerations, the analysis also highlights the potential for ammonia storage systems to contribute to enhancing regulatory compliance, improves brand image by demonstrating commitment to sustainability, and advances safety measures to mitigate risks. Also, it enhances market competitiveness, strengthens brand image, and leads in sustainable maritime innovation while ensuring long-term industry resilience.

Based on these findings, we recommend considering prioritizing investments in metallic ammonia storage systems due to their lower overall life cycle costs and operational efficiencies. Additionally, further exploration of regulatory incentives for adopting ammonia as a marine fuel could enhance the competitive advantage in the industry.

4.10. Step 10: Iterative Refinement

Recognizing the iterative nature of LCCA, the process of refining and updating the analysis is crucial for maintaining its accuracy and relevance. As new data become available, technologies advance, and regulatory environments evolve, it is essential to revisit and adjust the LCCA to reflect these changes. This adaptable approach ensures that the methodology remains robust and aligned with current industry practices and standards.

For example, if a breakthrough in composite tank technology reduces fabrication costs, the analysis is updated to reflect this improvement, potentially altering the choice of material. The inclusion of stricter ammonia handling guidelines may necessitate additional safety instrumentation, impacting the cost and system design. If a stakeholder expresses concerns about initial certification costs, refinements may focus on exploring cost-reduction strategies or alternative certification processes. A refined report highlights changes in material cost assumptions due to new market data and demonstrates their impact on the net present value (NPV) calculations.

By embracing an iterative approach, the LCCA methodology adapts to the complexities and uncertainties inherent in developing and operating an ammonia fuel storage system. This flexibility ensures that the analysis continues to provide accurate, actionable insights, supporting long-term economic and environmental objectives.

5. Discussion

This paper provides a comprehensive LCCA comparing metallic and composite material alternatives for ammonia fuel storage systems on marine vessels. The findings demonstrate differences in cost structure, operational efficiency, and long-term maintenance requirements, offering critical insights for the development of sustainable and economically viable storage technologies.

5.1. Interpretation of Results

The initial costs for composite tanks are higher, primarily due to advanced materials and manufacturing techniques. However, the annual operation and maintenance costs for composite tanks are lower, attributed to their inherent corrosion resistance. This results in a more favorable long-term operational cost profile for composite materials despite their higher upfront investment. The superior resistance of composite materials to ammonia’s corrosive effects contributes to safer and more reliable operation. This advantage is particularly significant given the stringent safety standards for ammonia handling, as dictated by IMO guidelines and the IGC Code. Composite tanks also reduce the risks associated with structural failures, offering an additional incentive for their adoption. Moreover, the end-of-life costs indicate that composite tanks may incur lower expenses related to decommissioning and disposal, as they do not require the same level of hazardous material handling as metallic tanks. The residual value of metallic tanks remains higher due to the established recycling market for stainless steel, which enhances their overall economic attractiveness. The inclusion of residual value further underscores the economic advantages of metallic tanks, whose materials retain higher salvage value despite higher life cycle costs.

Composite tanks are significantly lighter (can be up to 40–60% lighter), which could yield operational savings in fuel consumption and payload optimization. While these potential benefits are not captured in the direct LCCA, they may influence decision making, particularly for vessels operating in weight-sensitive environments. The NPV calculations demonstrate that while both alternatives yield almost similar total costs over a 25-year period, the choice between metallic and composite tanks should consider specific design constrains and operational contexts, including maintenance capabilities, regulatory compliance, and environmental impacts.

The findings resonate with the broader industry trends emphasizing sustainability and cost efficiency in maritime operations. The global transition toward alternative fuels and stricter emissions standards has intensified the need for innovative storage solutions.

5.2. Implications and Recommendations

Operational optimization: The integration of advanced monitoring systems and predictive maintenance technologies can enhance the operational efficiency of both tank types, but particularly of metallic tanks, where maintenance needs are more frequent.

Policy support: Policymakers should consider providing subsidies or incentives for new materials like composites as well as inspection and certification protocols to reduce costs.

Material innovations: Future research should explore hybrid materials that combine the high durability of composites with the salvage value of metals to achieve an optimal cost–performance balance.

5.3. Future Research Directions

Environmental impact assessment: Beyond cost considerations, the environmental footprint of both metallic and composite tanks over their life cycle warrants further investigation, especially in terms of production, operation, and disposal. Conducting an LCCA examining raw material extraction, manufacturing emissions, energy consumption during operation, and end-of-life disposal will help identify key environmental trade-offs between metallic and composite tanks. This approach will enable a more structured evaluation of factors such as carbon footprint, recyclability, and long-term sustainability.

Alternative designs: Explorations of hybrid tank designs and advanced insulation technologies could yield systems that outperform current options in both cost and efficiency.

Scalability: Evaluating the feasibility of scaling composite tank solutions for larger vessels and storage volumes will be critical for broader industry adoption.

Also, integrating price fluctuations and market volatility uncertainties into a stochastic or statistical model would further enhance the robustness of the analysis.

By addressing these dimensions, future studies can refine the design and deployment of ammonia fuel storage systems, supporting the maritime sector’s transition to a greener and more sustainable future.

6. Conclusions

The transition to ammonia as a marine fuel demands comprehensive financial evaluation to ensure its commercial success and sustainability. A robust LCCA methodology provides a structured approach for addressing economic, regulatory, and technological challenges, offering critical insights for stakeholders. By fostering informed decision making, enhancing stakeholder communication, and supporting scalability, LCCA serves as an indispensable tool in advancing onboard ammonia fuel storage systems.

The analysis reveals that while composite tanks entail higher initial costs due to advanced materials and manufacturing techniques, they offer significant advantages in terms of lower annual operation and maintenance expenses. Their inherent corrosion resistance contributes to reduced long-term operational burdens, making them an attractive option for operators prioritizing efficiency and sustainability. Conversely, metallic tanks maintain a competitive edge with their higher residual value, stemming from the well-established recycling market for stainless steel. This characteristic enhances their overall economic attractiveness, particularly for stakeholders focused on initial capital expenditures and material recyclability. These findings underscore the importance of a comprehensive evaluation that considers not only upfront costs but also the long-term implications associated with maintenance, end-of-life expenses, and regulatory compliance. As the maritime industry increasingly turns to ammonia as a sustainable fuel alternative, understanding the financial dynamics of these storage systems becomes paramount. Ultimately, this LCCA serves as a valuable tool for stakeholders in the maritime sector, enabling informed decision making regarding the selection of tank materials for ammonia storage systems. By weighing the economic implications alongside operational requirements and regulatory considerations, operators can align their strategies with both financial objectives and environmental sustainability goals.

This framework may be applied to other alternative fuels and hybrid storage systems or similar retrofitting projects to further refine the decision-making process for a decarbonized shipping industry. Hydrogen, for example, requires cryogenic or high-pressure storage, methanol needs specialized containment and handling, and biofuel use is challenged by feedstock variability and processing costs. Additionally, in hybrid storage systems, integrating multiple fuel types may enhance flexibility and regulatory compliance. Through its flexible and comprehensive approach, this methodology paves the way for more sustainable and economically viable solutions towards decarbonizing the maritime industry.