The Properties of Diesel Blends with Tire Pyrolysis Oil and Their Wear-Related Parameters

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Sulfur Content in the Fuels Under Study

3.2. Water Content in the Fuels Under Study

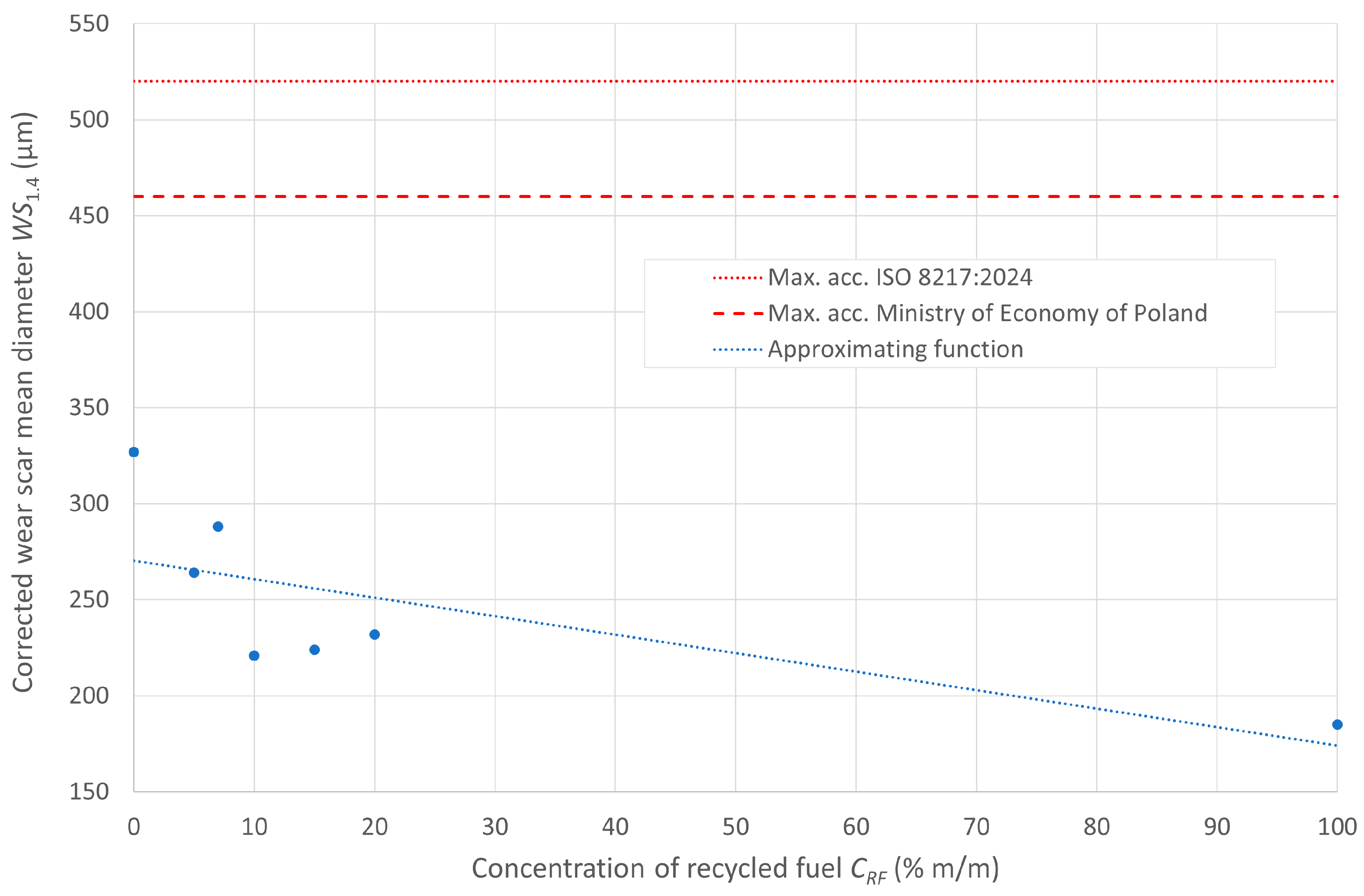

3.3. Lubricity of the Fuels Under Study

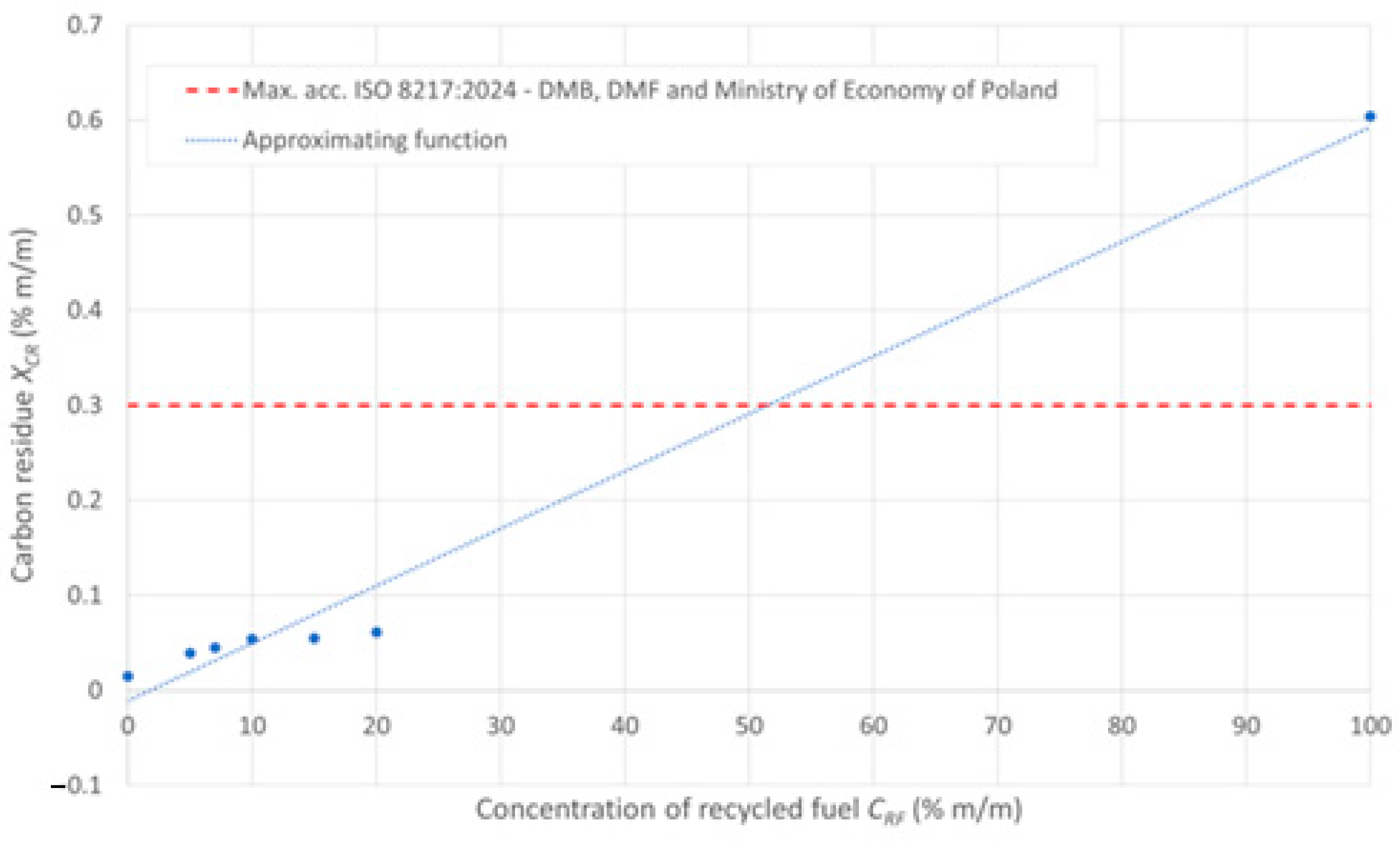

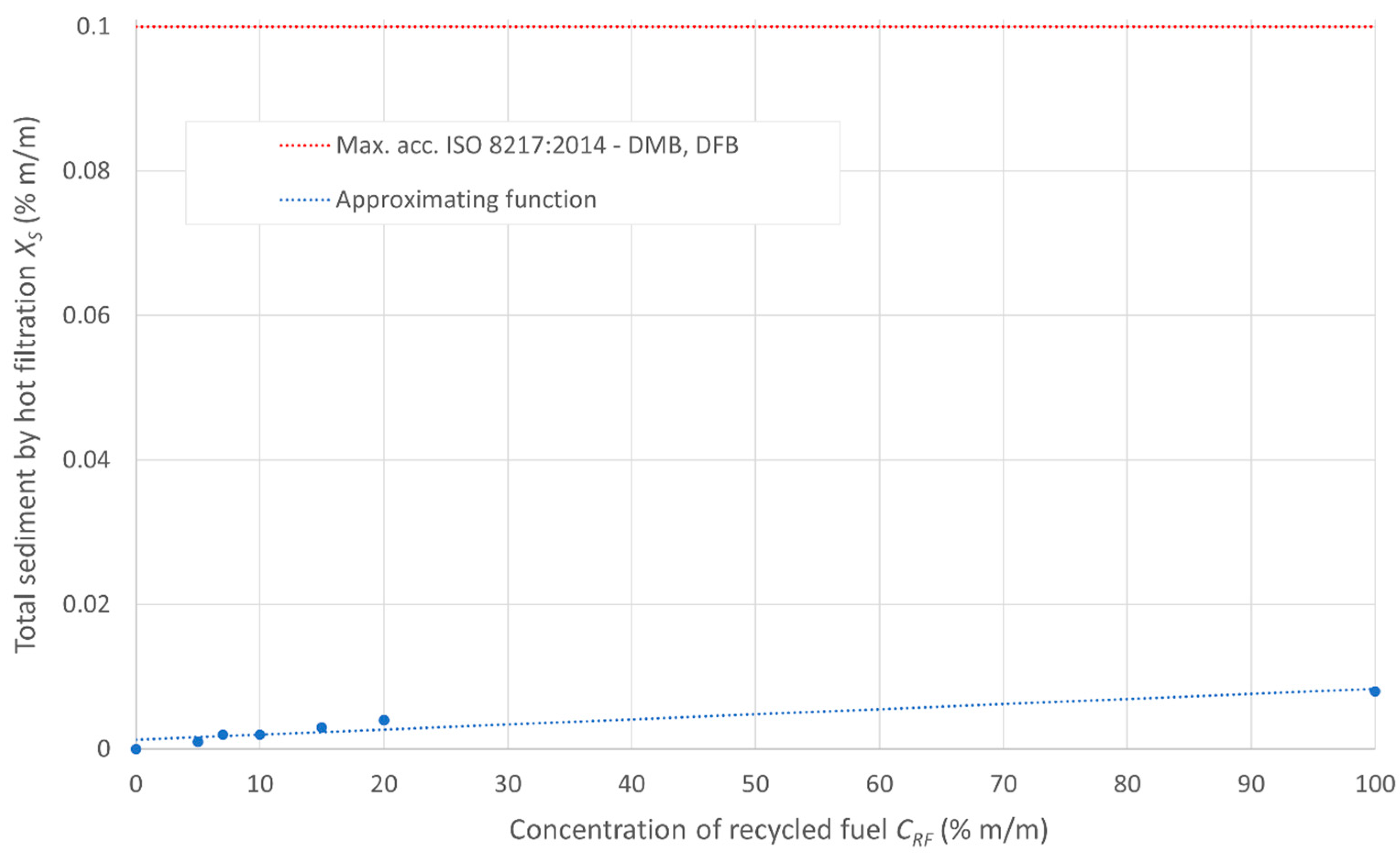

3.4. Impurities in the Fuels Under Study

3.5. Summary of the Obtained Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CS | sulfur content in the fuels under study |

| CRF | mass percentage of recycled oil in the diesel blend |

| Cw | water content in the fuels under study |

| D100 | pure diesel oil without FAME additives |

| deSOx | flue gas desulfurization system |

| DFA, DFB, DFZ, DMA, DMB, DMZ, DMX | categories of distillation fuels indicated in the standard [38] marked as ISO-F-… |

| EU | European Union |

| FAME | fatty acid methyl esters |

| HC | hydrocarbons with general designation |

| HFRR | high-frequency reciprocating rig |

| ISO | International Organization for Standardization |

| MARPOL | International Convention for the Prevention of Pollution from Ships |

| NOx | generic determination of NO and NO2 nitrogen oxides |

| RF | index for the parameters measured or calculated for recycled fuel TPO |

| RMG | Regulation of the Ministry of Economy of Poland on the properties of fuels |

| SECA | Sulfur Emission Control Areas |

| SOx | general designation for sulfur oxides SO2 and SO3 |

| tCFPP | cold filter plugging point temperature |

| tFP | flash point temperature |

| TPO | tire pyrolysis oil |

| U | uncertainty |

| UR | reproducibility |

| W | lower heat value |

| WS1.4 | average diameter of wear scar during HFRR lubricity test corrected to a reference pressure of 1.4 kPa |

| XA | ash residue |

| XCR | coking residue with 10% distillation residue |

| XS | total sediment by hot filtration |

| ν100 | kinematic viscosity at a reference temperature of 100 °C |

| ν40 | kinematic viscosity at a reference temperature of 40 °C |

| ρ15 | density at a reference temperature of 15 °C |

References

- Baensch-Baltruschat, B.; Kocher, B.; Stock, F.; Reifferscheid, G. Tyre and Road Wear Particles (TRWP)—A Review of Generation, Properties, Emissions, Human Health Risk, Ecotoxicity, and Fate in the Environment. Sci. Total Environ. 2020, 733, 137823. [Google Scholar] [CrossRef] [PubMed]

- Jaworski, A.; Balawender, K.; Kuszewski, H.; Jaremcio, M. The Assessment of PM2.5 and PM10 Immission in Atmospheric Air in a Climate Chamber During Tests of an Electric Car on a Chassis Dynamometer. Atmosphere 2024, 15, 270. [Google Scholar] [CrossRef]

- Available online: https://euric-aisbl.eu/images/Brochures/EuRIC_MTR_mechanical_tyre_recycling_Fact_sheet.pdf (accessed on 19 February 2025).

- Šimková, Z.; Taušová, M.; Čulková, K.; Tauš, P.; Shyp, D.; Krasniči, D.; Novotná, S. Evaluation of the Landfill Storage Capacity in Slovakia, Compared to the EU Situation. Recycling 2024, 9, 10. [Google Scholar] [CrossRef]

- Conesa, J.A.; Gálvez, A.; Mateos, F.; Martín-Gullón, I.; Font, R. Organic and Inorganic Pollutants from Cement Kiln Stack Feeding Alternative Fuels. J. Hazard. Mater. 2008, 158, 585–592. [Google Scholar] [CrossRef] [PubMed]

- Thomas, V.M.; Spiro, T.G. An Estimation of Dioxin Emissions in the United States. Toxicol. Environ. Chem. 1995, 50, 1–37. [Google Scholar] [CrossRef]

- Wastes—Resource Conservation—Common Wastes & Materials—Scrap Tires. Available online: https://archive.epa.gov/epawaste/conserve/materials/tires/web/html/basic.html (accessed on 13 December 2024).

- Abnisa, F.; Daud, W.M.A.W. Optimization of Fuel Recovery through the Stepwise Co-Pyrolysis of Palm Shell and Scrap Tire. Energy Convers. Manag. 2015, 99, 334–345. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of Waste Tire Rubber as Aggregate in Concrete: Durability-Related Performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Han, W.; Jiang, C.; Wang, J.; Chen, H. Enhancement of Heat Transfer During Rubber Pyrolysis Process. J. Clean. Prod. 2022, 348, 131363. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of Wind Turbine Blades Through Modern Recycling Technologies: A Road to Zero Waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B. Time and Temperature Depended Fuel Gas Generation from Pyrolysis of Real World Municipal Plastic Waste. Fuel 2016, 174, 164–171. [Google Scholar] [CrossRef]

- Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 Amending Directive 98/70/EC as Regards the Specification of Petrol, Diesel and Gas-Oil and Introducing a Mechanism to Monitor and Reduce Greenhouse Gas Emissions and Amending Council Directive 1999/32/EC as Regards the Specification of Fuel Used by Inland Waterway Vessels and Repealing Directive 93/12/EEC (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02009L0030-20160610 (accessed on 10 December 2024).

- Mohan, D.; Pittman, C.U., Jr.; Steele, P.H. Pyrolysis of Wood/Biomass for Bio-Oil: A Critical Review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Han, W.; Han, D.; Chen, H. Pyrolysis of Waste Tires: A Review. Polymers 2023, 15, 1604. [Google Scholar] [CrossRef]

- Tian, X.; Zhuang, Q.; Han, S.; Li, S.; Liu, H.; Li, L.; Zhang, J.; Wang, C.; Bian, H. A Novel Approach of Reapplication of Carbon Black Recovered from Waste Tyre Pyrolysis to Rubber Composites. J. Clean. Prod. 2021, 280, 124460. [Google Scholar] [CrossRef]

- EN 590 Diesel Specifications. Available online: https://www.nationwidefuels.co.uk/fuel-specifications/en-590/ (accessed on 20 December 2024).

- Diesel Fuel Standards. Available online: https://www.epa.gov/diesel-fuel-standards (accessed on 9 January 2025).

- DIRECTIVE 2012/33/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 21 November 2012 Amending Council Directive 1999/32/EC as Regards the Sulphur Content of Marine Fuels. Available online: https://faolex.fao.org/docs/pdf/eur117700.pdf (accessed on 30 November 2024).

- Annex IV of the Marpol 73/78 Convention. Available online: https://static.pmg.org.za/140729annexiv.pdf (accessed on 12 December 2024).

- IMO—The International Maritime Organization. Available online: https://www.imo.org/en (accessed on 28 December 2024).

- Zerin, N.H.; Rasul, M.G.; Jahirul, M.I.; Sayem, A.S.M. End-of-Life Tyre Conversion to Energy: A Review on Pyrolysis and Activated Carbon Production Processes and Their Challenges. Sci. Total Environ. 2023, 905, 166981. [Google Scholar] [CrossRef] [PubMed]

- Maga, D.; Aryan, V.; Blömer, J. A Comparative Life Cycle Assessment of Tyre Recycling Using Pyrolysis Compared to Conventional End-of-Life Pathways. Resour. Conserv. Recycl. 2023, 199, 107255. [Google Scholar] [CrossRef]

- Tamizhdurai, P.; Arthi, P.; Mangesh, V.L.; Krishnan, P.S.; Kumar, N.S.; Saravanan, P.; Subramani, A.; Sasikumar, P.; Alotibi, M.F.; Alreshaidan, S.B.; et al. Clean Energy Technology: Hydro-Processing of Waste Tyre Pyrolysis Oil (WTPO) to Diesel Fuel in a Continuous Reactor Using Co/SBA-15 Catalyst. Appl. Energy Combust. Sci. 2025, 21, 100305. [Google Scholar] [CrossRef]

- Wu, K.; Ren, T.; Chen, H.; Zhu, Y. Experimental Investigation of Whole Tires and Biomass Mixed Firing in Reverse Burning Fixed-Bed Gasifier. Energy Procedia 2017, 105, 583–589. [Google Scholar] [CrossRef]

- Chybowski, L.; Kowalak, P.; Dąbrowski, P. Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability. Energies 2023, 16, 5056. [Google Scholar] [CrossRef]

- Baczewski, K.; Kałdoński, T. Paliwa Do Silników o Zapłonie Samoczynnym; WKiŁ: Warszawa, Poland, 2018. [Google Scholar]

- Krupowies, J. Badania i Ocena Zmian Właściwości Użytkowych Olejów Urządzeń Okrętowych; Maritime University of Szczecin: Szczecin, Poland, 2009. [Google Scholar]

- ISO 8754:2003; Petroleum Products—Determination of Sulfur Content—Energy-Dispersive X-Ray Fluorescence Spectrometry. ISO: Geneva, Switzerland, 2003.

- ISO 12937:2005; Petroleum Products—Determination of Water—Coulometric Karl Fischer Titration Method. ISO: Geneva, Switzerland, 2005.

- ISO 12156-1:2023; Diesel Fuel—Assessment of Lubricity Using the High-Frequency Reciprocating Rig (HFRR)—Part 1: Test Method. ISO: Geneva, Switzerland, 2023.

- ISO 10370:2014; Petroleum Products—Determination of Carbon Residue—Micro Method. ISO: Geneva, Switzerland, 2014.

- ISO 6245:2008; Petroleum Products—Determination of Ash. ISO: Geneva, Switzerland, 2008.

- ISO 10307-1:2009; Petroleum Products—Total Sediment in Residual Fuel Oils—Part 1: Determination by Hot Filtration. ISO: Geneva, Switzerland, 2009.

- ISO 4405:2022; Hydraulic Fluid Power—Fluid Contamination—Determination of Particulate Contamination by the Gravimetric Method. ISO: Geneva, Switzerland, 2022.

- ISO 12662:2024; Liquid Petroleum Products—Determination of Total. ISO: Geneva, Switzerland, 2024.

- ASTM D6595-17; Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry. ASTM: West Conshohocken, PA, USA, 2022.

- ISO 8217:2024; Petroleum Products—Fuels (Class F)—Specifications of Marine Fuels, 7th ed. ISO: Geneva, Switzerland, 2024.

- MARPOL—International Convention for the Prevention of Pollution from Ships; Consolided Edition; International Maritime Organization: London, UK, 2021; Available online: https://www.imo.org/en/about/Conventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx (accessed on 19 February 2025).

- Minister Gospodarki RP. Rozporządzenie Ministra Gospodarki z Dnia 9 Października 2015 r. w Sprawie Wymagań Jakościowych Dla Paliw Ciekłych; Ministerstwo Gospodarki RP: Warszawa, Poland, 2015.

- Sautermeister, F.A.; Priest, M.; Lee, P.M.; Fox, M.F. Impact of Sulphuric Acid on Cylinder Lubrication for Large 2-Stroke Marine Diesel Engines: Contact Angle, Interfacial Tension and Chemical Interaction. Tribol. Int. 2013, 59, 47–56. [Google Scholar] [CrossRef]

- Danish EPA Development of a Bunker Norm for Ships. Sulphur. Available online: https://www2.mst.dk/udgiv/publications/1998/87-7909-173-3/html/indhold_eng.htm (accessed on 2 January 2025).

- Wain, K.S.; Perez, J.M.; Chapman, E.; Boehman, A.L. Alternative and Low Sulfur Fuel Options: Boundary Lubrication Performance and Potential Problems. Tribol. Int. 2005, 38, 313–319. [Google Scholar] [CrossRef]

- Bejger, A.; Chybowski, L.; Gawdzińska, K. Utilising Elastic Waves of Acoustic Emission to Assess the Condition of Spray Nozzles in a Marine Diesel Engine. J. Mar. Eng. Technol. 2018, 17, 153–159. [Google Scholar] [CrossRef]

- Hou, X.; Wang, Y.; Dai, L.; Yang, Y.; Du, J.; Wang, Y.; Wan, H. Study on the Corrosion and Wear Behaviors of Cylinder Liner in Marine Diesel Engine Burning Low Sulfur Fuel Oil. Eng. Fail. Anal. 2023, 147, 107151. [Google Scholar] [CrossRef]

- Kim, M.-S.; Akpudo, U.E.; Hur, J.-W. A Study on Water-Induced Damage Severity on Diesel Engine Injection System Using Emulsified Diesel Fuels. Electronics 2021, 10, 2285. [Google Scholar] [CrossRef]

- Malinowska, M.; Zera, D. Analiza Zmian Smarności Oleju Silnikowego Stosowanego w Silniku Cegielski-Sulzer 3AL25/30. Zesz. Nauk. Akad. Morskiej Gdyni 2016, 96, 93–104. [Google Scholar]

- Delgado, J.; Gadea, M.; Esarte, C.; Peláez, A. HFRR and SL-BOCLE Lubricity of Paraffinic Diesel Fuels Considering Different Origins and Final Formulations with Biodiesels and Additives. Energy Fuels 2020, 34, 2654–2664. [Google Scholar] [CrossRef]

- Chybowski, L.; Szczepanek, M.; Sztangierski, R.; Brożek, P. A Quantitative and Qualitative Analysis of the Lubricity of Used Lubricating Oil Diluted with Diesel Oil. Appl. Sci. 2024, 14, 4567. [Google Scholar] [CrossRef]

- Urbański, P. Paliwa i Smary; Fundacja Rozwoju Wyższej Szkoły Morskiej w Gdyni: Gdynia, Poland, 1999. [Google Scholar]

- Górska, K.; Górski, W. Napędy Lotnicze. Materiały Pędne i Smary; WKiŁ: Warszawa, Poland, 1986. [Google Scholar]

- Wang, X.; Zhang, J.; Wang, Z.; Wang, Y.; Vujanović, M.; Li, P.; Tan, H. Experimental and Kinetics Study on SO3 Catalytic Formation by Fe2O3 in Oxy-Combustion. J. Environ. Manag. 2019, 236, 420–427. [Google Scholar] [CrossRef]

- Bogdanowicz, A.; Kniaziewicz, T. Marine Diesel Engine Exhaust Emissions Measured in Ship’s Dynamic Operating Conditions. Sensors 2020, 20, 6589. [Google Scholar] [CrossRef]

- Jakubowski, M.; Jaworski, A.; Kuszewski, H.; Balawender, K. Performance of a Diesel Engine Fueled by Blends of Diesel Fuel and Synthetic Fuel Derived from Waste Car Tires. Sustainability 2024, 16, 6404. [Google Scholar] [CrossRef]

- Emara, K.; Ayoub, H.S.; El-Sherif, A.F.; Ali, M.I.H. Waste Tires Pyrolysis Oil and Its Blend with Diesel Fuel Spectral Flame Analysis, Temperature Contours, and Emissions. Energy Rep. 2022, 8, 1550–1564. [Google Scholar] [CrossRef]

- Zivkovic, S.; Jovanovic-Medojevic, M.; Neskovic, J.; Popovic-Bajic, M. Nickel-Titanium Files in Endodontics: Development, Improvement and Modifications of Nickel-Titanium Alloy. Vojnosanit. Pregl. 2023, 80, 262–269. [Google Scholar] [CrossRef]

- Soysal Özdemir, Ö. Comparison of the Cyclic Fatigue Resistances of Reciproc Blue and Rotate Instruments in Simulated Severe Apical Curvature. Turk. Endod. J. 2021, 6, 71–75. [Google Scholar] [CrossRef]

- ISO 12185:2024; Crude Petroleum, Petroleum Products and Related Products—Determination of Density—Laboratory Density Meter with an Oscillating U-Tube Sensor. ISO: Geneva, Switzerland, 2024.

- ISO 3104:2023; Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. ISO: Geneva, Switzerland, 2023.

- PN-C-04062:2018-05; Przetwory Naftowe—Oznaczanie Ciepła Spalania Paliw Ciekłych w Bombie Kalorymetrycznej i Obliczanie Wartości Opałowej z Zastosowaniem Wzorów Empirycznych. PKN: Warszawa, Poland, 2018.

- ISO 2719:2016; Determination of Flash Point—Pensky-Martens Closed Cup Method. ISO: Geneva, Switzerland, 2016.

- Yang, S.; Cunhao, C.; Haoran, L.; Hairong, R.; Jianghuai, C.; Zhongyue, Z.; Fei, Q. Recent Contributions of Photoionization Mass Spectrometry in the Study of Typical Solid Fuel Pyrolysis. J. Fuel Chem. Technol. 2024, 52, 921–944. [Google Scholar] [CrossRef]

- Chybowski, L.; Szczepanek, M.; Pusty, T.; Brożek, P.; Pełech, R.; Borowski, P. Evaluation of the Ignition Properties of Fuels Based on Oil Diesel Fuel with the Addition of Pyrolytic Oil from Tires. Energies 2025, 18, 860. [Google Scholar] [CrossRef]

- Arya, S.; Sharma, A.; Rawat, M.; Agrawal, A. Tyre Pyrolysis Oil as an Alternative Fuel: A Review. Mater. Today Proc. 2020, 28, 2481–2484. [Google Scholar] [CrossRef]

- Ali, M.H.; Moral, M.N.A. Pyrolytic Fuel Extraction from Tire and Tube: Analysis of Parameters on Product Yield. Case Stud. Chem. Environ. Eng. 2022, 6, 100273. [Google Scholar] [CrossRef]

- AmSpec Blending Linear vs. Non-Linear. Available online: https://www.amspecgroup.com/wp-content/uploads/2014/05/AmSpec-TECHTALK-10-2019-Blending-Linear-vs-Non-Linear.pdf (accessed on 9 January 2025).

- Kässi, J. Modeling of Base Oil Blends. Bachelor’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2011. [Google Scholar]

| Indicator | Designation | Unit of Measurement | Associated Processes Characterized Directly or Indirectly Before the Indicator | Degradation Processes of Engine Components | |||||

|---|---|---|---|---|---|---|---|---|---|

| Sludge and Carbon Formation | Low-Temperature Corrosion | High-Temperature Corrosion | Abrasive Wear | Erosion Wear | Contamination and Biological Corrosion | ||||

| Sulfur content of fuel | CS | % m/m | Formation of toxic sulfur oxides, sulfuric acids, and sulfate | ++ | ++ | + | +/+ * | + | |

| Water content of fuel | Cw | % m/m | Formation of corrosion compounds, creation of an environment for corrosion processes, deterioration of friction conditions, and creation of an environment for the growth of microorganisms | + | ++ | ++ | ++ | ||

| Fuel lubricity | WS1.4 | μm | Fuel’s ability to form a boundary layer at tribological nodes | + | ++ | ||||

| Coke residue (from 10% distillation residue) | XCR | % m/m | Content of heavy hydrocarbons in fuel | ++ | + | ||||

| Ash residue | XA | % m/m | Content of solid mineral particles and metallic soaps in fuel | + | ++ | ++ | + | ||

| Total sediment by hot filtration (% m/m) | XS | % m/m | Content of mechanical impurities contained in fuel | + | + | ++ | ++ | ||

| Content of insoluble impurities | XC | mg/kg | Content of mechanical impurities contained in fuel | + | ++ | ++ | |||

| Parameter Group | Parameter | Designation | Unit of Measurement | Method Used | Apparatus Used |

|---|---|---|---|---|---|

| Indicators describing the composition of blends | Sulfur content | CS | % m/m | EN ISO 8754:2003+Ap1:2014-02P [29] | SLFA-2800 X-ray fluorescence spectrometer (Horiba, Kyoto, Japan) |

| Water content | Cw | % m/m | EN ISO 12937:2005+Ap1:2021-11P [30] | Metrohm coulometer 831 KF (from Metrohm, Herisau, Switzerland) | |

| Indicators describing the effect of blends on the wear processes of engine components | Lubricity (HFRR wear scar diameter) @ 60 °C | WS1.4 | μm | EN ISO 12156-1:2023 [31] | High-Frequency Reciprocating Rig HFRR V1.0.3 (PCS Instruments, London, UK) |

| Coke residue (from 10% distillation residue) | XCR | % m/m | EN ISO 10370:2014-12 [32] | Automatic micro MCRT 160 coke residue determination apparatus (Alcor Inc., Smithfield, RI, USA) | |

| Ash residue | XA | % m/m | EN ISO 6245:2008 [33] | FCF 2.5M muffle furnace (Czylok, Jastrzębie Zdrój, Poland) | |

| Contaminant content/total sediment by hot filtration | XS | % m/m | ISO 10307-1:2009 [34] | Setaclean Total Sediment Tester Apparatus (Stanhope-Seta, Chertsey, UK) | |

| Content of mechanical insoluble impurities | XC | mg/kg | EN 12662:2024-11 [36] | Suction flask under vacuum and drying oven and a scale RADWAG WPs 510/C/2 (RADWAG Wagi Elektroniczne, Radom, Poland) |

| Parameter | Unit | Measurement Standard | Diesel Oil (D100) | Recycled Oil (TPO) | |

|---|---|---|---|---|---|

| Density @ 15 °C ρ15 | kg/m3 | EN ISO 12185:2002 [58] | 836.4 | 931.9 | |

| Kinematic viscosity @ 40 °C ν40 | mm2/s | EN ISO 3104:2021-03 [59] | 2.728 | 5.096 | |

| Kinematic viscosity @ 100 °C ν100 | mm2/s | EN ISO 3104:2021-03 [59] | 1.173 | 1.620 | |

| Lower heat value W | MJ/kg | PN-C-04062:2018-05 [60] | 45.46 | 42.16 | |

| Flash point temperature tFP | °C | EN ISO 2719:2016- [61] | 64 | 38 | |

| Elemental composition | Fe | ppm | ASTM D6595-17 [62] | 0.0 | 0.0 |

| Cr | 1.1 | 0.1 | |||

| Pb | 7.3 | 10.2 | |||

| Cu | 0.0 | 1.2 | |||

| Sn | 7.4 | 10.0 | |||

| Al | 2.5 | 0.6 | |||

| Ni | 7.6 | 13.0 | |||

| Ag | 0.5 | 0.1 | |||

| Si | 27.0 | 1.4 | |||

| B | 1.0 | 1.5 | |||

| Mg | 0.0 | 0.1 | |||

| Ba | 0.0 | 0.0 | |||

| P | 0.0 | 0.0 | |||

| Zn | 9.5 | 1.2 | |||

| Mo | 1.3 | 1.4 | |||

| Ti | 1.7 | 0.9 | |||

| V | 0.0 | 0.0 | |||

| Concentration of Recycled Fuel CRF (% m/m) ± 0.0023% m/m | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameter | Symbol * | Unit | 0 | 5 | 7 | 10 | 15 | 20 | 100 |

| Sulfur content | U(CS) | % m/m | 0.0070 | 0.0089 | 0.0094 | 0.0105 | 0.0118 | 0.0132 | 0.0351 |

| Water content | U(Cw) | % m/m | 0.0023 | 0.0025 | 0.0025 | 0.0025 | 0.0026 | 0.0028 | 0.0050 |

| Lubricity (HFRR wear scar diameter) @ 60 °C | U(WS1.4) | μm | 30.7 | 24.8 | 27.1 | 20.8 | 21.0 | 21.8 | 17.4 |

| Coke residue (from 10% distillation residue) | U(XCR) | % m/m | 0.0405 | 0.0428 | 0.0433 | 0.0442 | 0.0443 | 0.0448 | 0.0959 |

| Ash residue | U(XA) | % m/m | 0.0025 | 0.0030 | 0.0030 | 0.0031 | 0.0032 | 0.0033 | 0.0036 |

| Contaminant content/total sediment by hot filtration | UR (XS) | % m/m | 0.0000 | 0.0055 | 0.0078 | 0.0078 | 0.0095 | 0.0110 | 0.0156 |

| Content of mechanical insoluble impurities | U(XC) | mg/kg | 1.3772 | 10.7171 | 17.4018 | 17.1934 | 8.6236 | 4.8300 | 77.4056 |

| Requirements | TPO Content of the Tested CRF Blende (% m/m) | 0 | 5 | 7 | 10 | 15 | 20 | 100 |

|---|---|---|---|---|---|---|---|---|

| ISO 8217:2024 | Sulfur content, CS | + | + | + | + | + | + | + |

| Water content, Cw | + | + | + | + | + | + | + | |

| Lubricity, WS1.4 | + | + | + | + | + | + | + | |

| Ash, XA | + | − | − | − | − | − | − | |

| Carbon residue, XCR | + | + | + | + | + | + | − | |

| Total sediment by hot filtration, CS | + | + | + | + | + | + | + | |

| Ministry of Economy of Poland | Sulfur content, CS | + | − | − | − | − | − | − |

| Water content, Cw | + | + | + | + | + | + | + | |

| Lubricity, WS1.4 | + | + | + | + | + | + | + | |

| Ash, XA | + | − | − | − | − | − | − | |

| Carbon residue, XCR | + | + | + | + | + | + | + | |

| Mechanical contamination, XC | + | − | − | − | − | − | − | |

| MARPOL, Annex VI | Sulfur content CS (within SECA) | + | + | + | + | − | − | − |

| Sulfur content CS (outside SECA) | + | + | + | + | + | + | − | |

| Sulfur content CS (with deSOx system) | + | + | + | + | + | + | + |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chybowski, L.; Szczepanek, M.; Pusty, T.; Brożek, P.; Pełech, R.; Wieczorek, A. The Properties of Diesel Blends with Tire Pyrolysis Oil and Their Wear-Related Parameters. Energies 2025, 18, 1057. https://doi.org/10.3390/en18051057

Chybowski L, Szczepanek M, Pusty T, Brożek P, Pełech R, Wieczorek A. The Properties of Diesel Blends with Tire Pyrolysis Oil and Their Wear-Related Parameters. Energies. 2025; 18(5):1057. https://doi.org/10.3390/en18051057

Chicago/Turabian StyleChybowski, Leszek, Marcin Szczepanek, Tomasz Pusty, Piotr Brożek, Robert Pełech, and Andrzej Wieczorek. 2025. "The Properties of Diesel Blends with Tire Pyrolysis Oil and Their Wear-Related Parameters" Energies 18, no. 5: 1057. https://doi.org/10.3390/en18051057

APA StyleChybowski, L., Szczepanek, M., Pusty, T., Brożek, P., Pełech, R., & Wieczorek, A. (2025). The Properties of Diesel Blends with Tire Pyrolysis Oil and Their Wear-Related Parameters. Energies, 18(5), 1057. https://doi.org/10.3390/en18051057